3D Printed Materials Based Triboelectric Device for Energy Harvesting and Sensing †

Abstract

:1. Introduction

2. Experimental Procedure

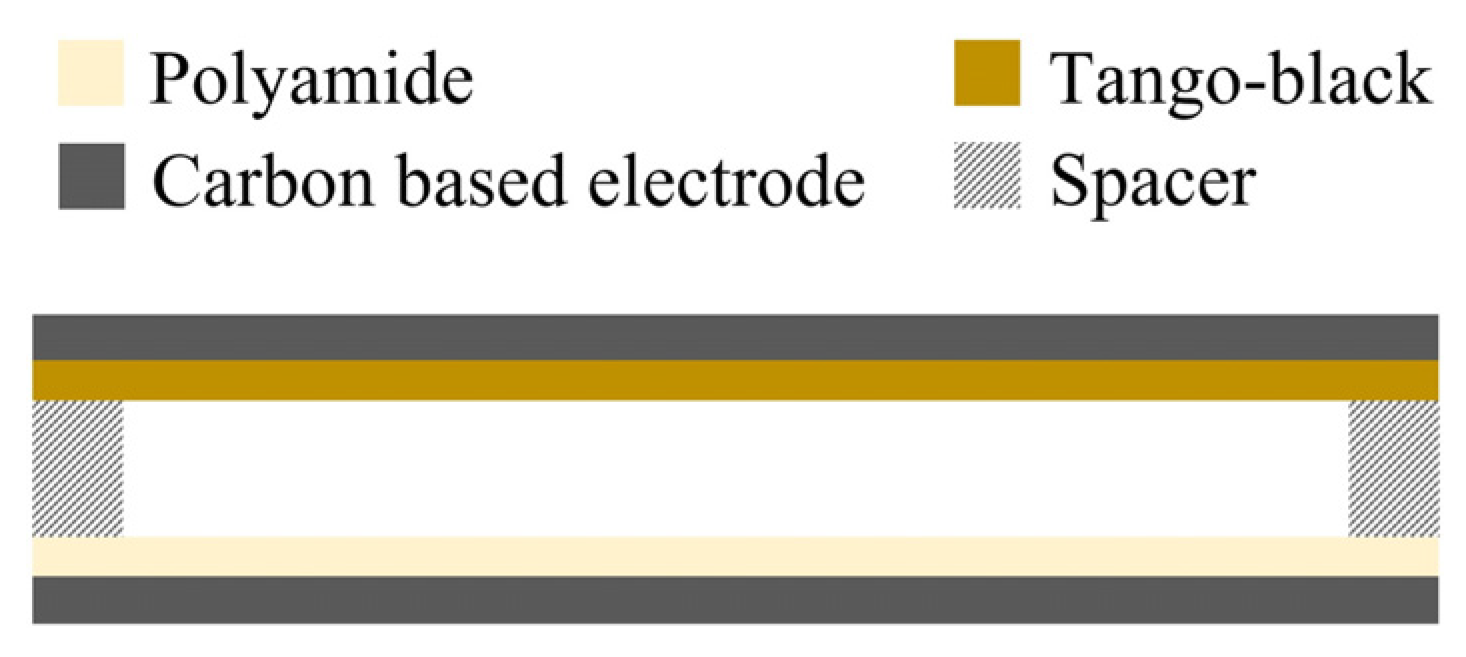

2.1. Design

2.2. Materials

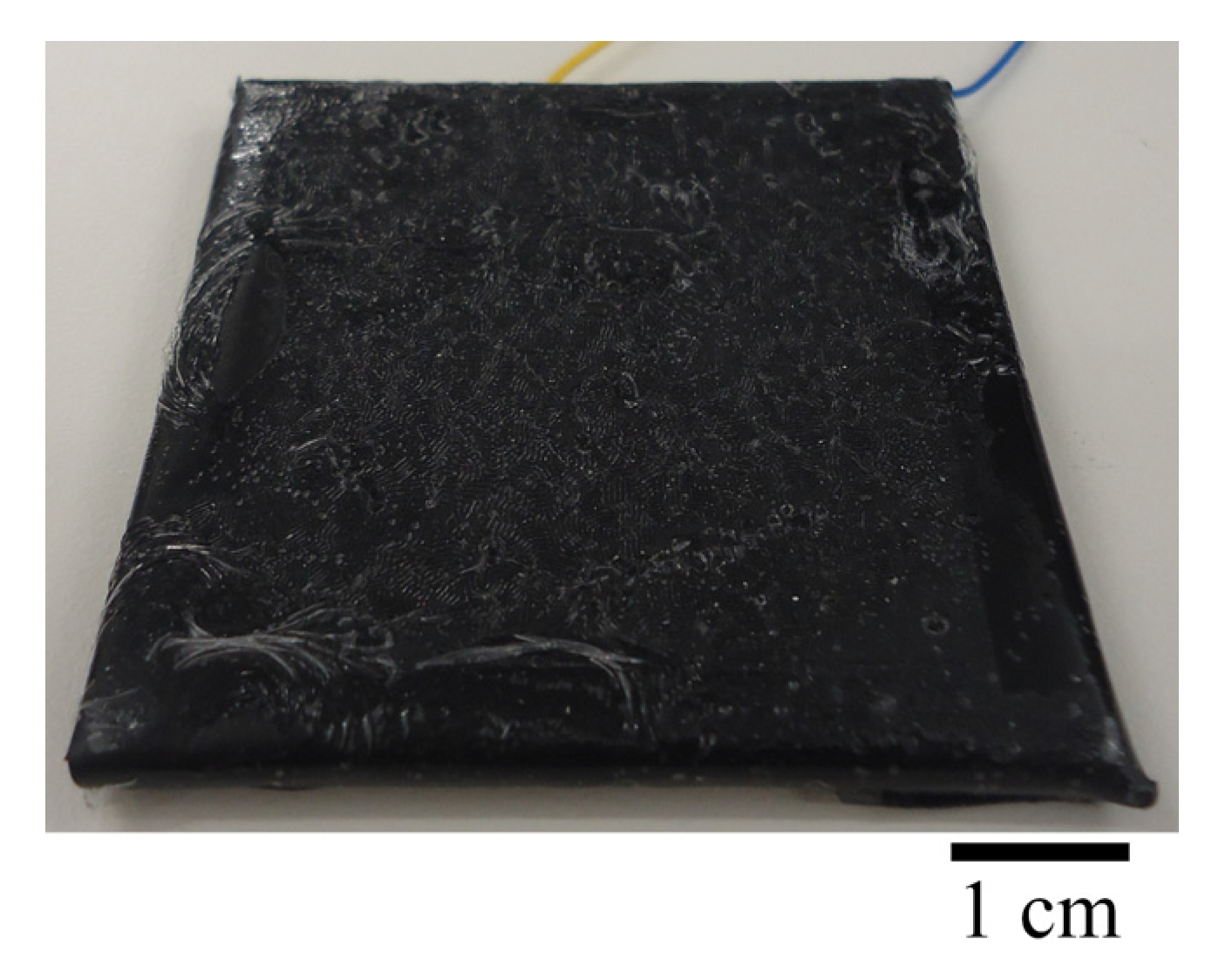

2.3. Process Flow

2.4. Characterizations

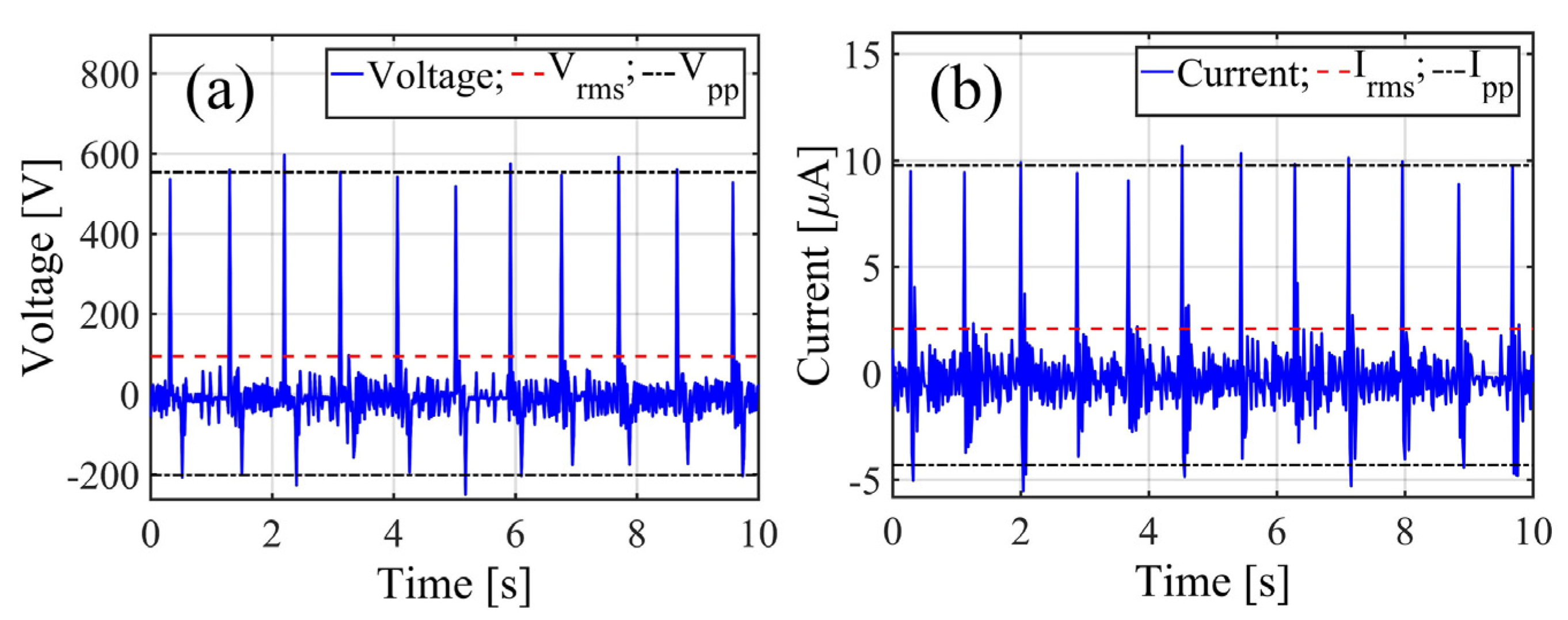

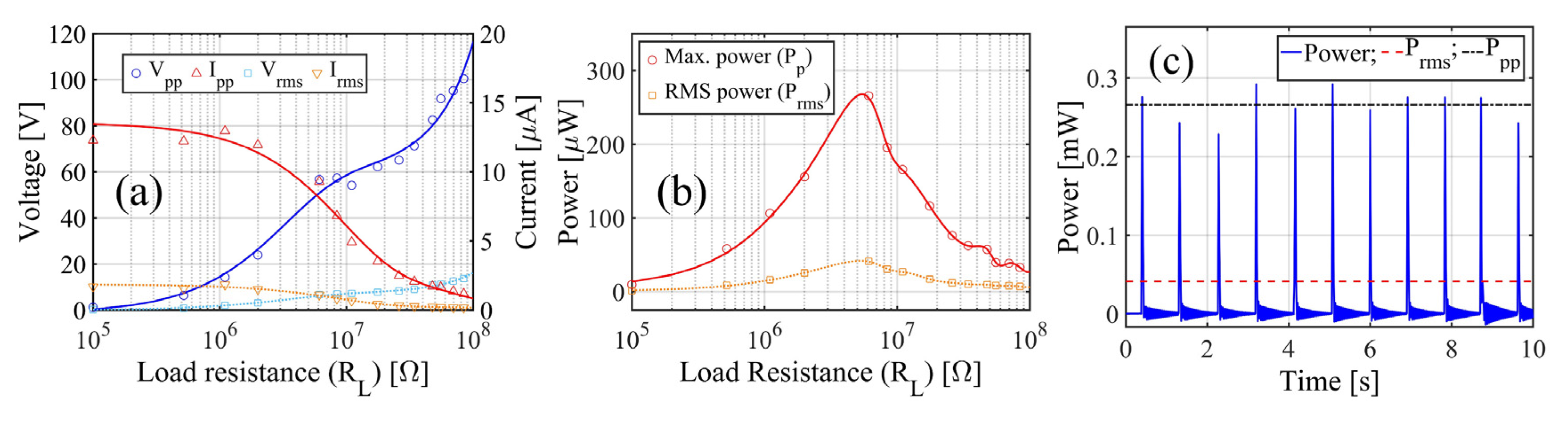

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Wang, Z.L.; Chen, J.; Lin, L. Progress in Triboelectric Nanogenerators as a New Energy Technology and Self-Powered Sensors. Energy Environ. Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Lee, B. The TriboElectric Series. Available online: https://www.trifield.com/content/tribo-electric-series/ (accessed on 21 March 2016).

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible Triboelectric Generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Kanik, M.; Say, M.G.; Daglar, B.; Yavuz, A.F.; Dolas, M.H.; El-Ashry, M.M.; Bayindir, M. A Motion- and Sound-Activated, 3D-Printed, Chalcogenide-Based Triboelectric Nanogenerator. Adv. Mater. 2015, 27, 2367–2376. [Google Scholar] [CrossRef]

- Zhu, G.; Zhou, Y.S.; Bai, P.; Meng, X.S.; Jing, Q.; Chen, J.; Wang, Z.L. A Shape-Adaptive Thin-Film-Based Approach for 50% High-Efficiency Energy Generation through Micro-Grating Sliding Electrification. Adv. Mater. 2014, 26, 3788–3796. [Google Scholar] [CrossRef]

- Haque, R.I.; Farine, P.-A.; Briand, D. Fully casted soft power generating triboelectric shoe insole. J. Phys. Conf. Ser. 2016, 773, 012097. [Google Scholar] [CrossRef]

- Haque, R.I.; Farine, P.-A.; Briand, D. Electrically conductive fabric based stretchable triboelectric energy harvester. J. Phys. Conf. Ser. 2016, 773, 012005. [Google Scholar] [CrossRef]

- Li, X.; Cui, R.; Sun, L.; Aifantis, K.E.; Fan, Y.; Feng, Q.; Cui, F.; Watari, F. 3D-Printed Biopolymers for Tissue Engineering Application. Int. J. Polym. Sci. 2014, 2014, 829145. [Google Scholar] [CrossRef]

- Asa’ad, F.; Pagni, G.; Pilipchuk, S.P.; Giannì, A.B.; Giannobile, W.V.; Rasperini, G. 3D-Printed Scaffolds and Biomaterials: Review of Alveolar Bone Augmentation and Periodontal Regeneration Applications. Int. J. Dent. 2016, 2016, 1239842. [Google Scholar] [CrossRef] [PubMed]

| Physical Parameters | |

|---|---|

| Active area (cm2) | 25 |

| Spacer thickness (mm) | 2.5 |

| Thickness of Tango black layer (μm) | 250 |

| Thickness of PA layer (μm) | 500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haque, R.I.; Farine, P.-A.; Briand, D. 3D Printed Materials Based Triboelectric Device for Energy Harvesting and Sensing. Proceedings 2017, 1, 580. https://doi.org/10.3390/proceedings1040580

Haque RI, Farine P-A, Briand D. 3D Printed Materials Based Triboelectric Device for Energy Harvesting and Sensing. Proceedings. 2017; 1(4):580. https://doi.org/10.3390/proceedings1040580

Chicago/Turabian StyleHaque, Rubaiyet I., Pierre-André Farine, and Danick Briand. 2017. "3D Printed Materials Based Triboelectric Device for Energy Harvesting and Sensing" Proceedings 1, no. 4: 580. https://doi.org/10.3390/proceedings1040580

APA StyleHaque, R. I., Farine, P.-A., & Briand, D. (2017). 3D Printed Materials Based Triboelectric Device for Energy Harvesting and Sensing. Proceedings, 1(4), 580. https://doi.org/10.3390/proceedings1040580