Highly Stable PEDOT:PSS Coating on Gold Microelectrodes with Improved Charge Injection Capacity for Chronic Neural Stimulation †

Abstract

:1. Introduction

2. Materials and Methods

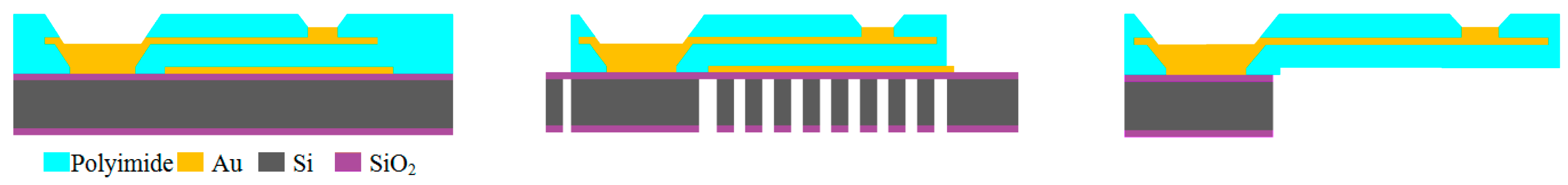

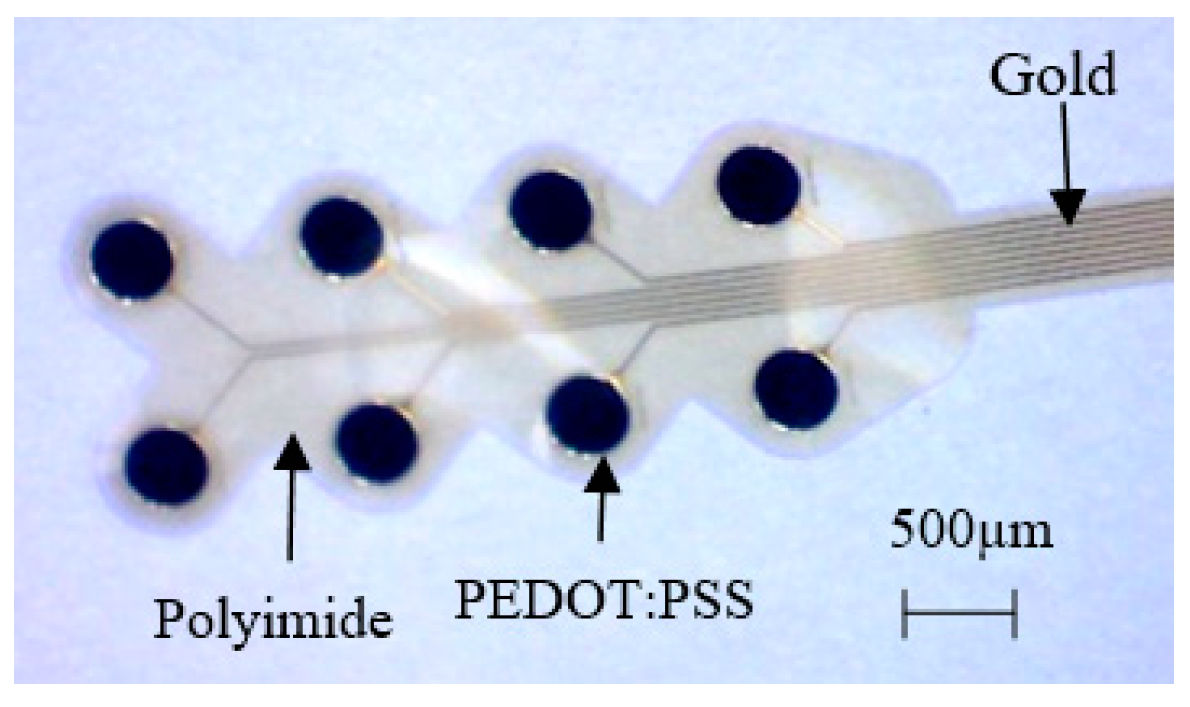

2.1. Fabrication of Flexible Electrode Arrays

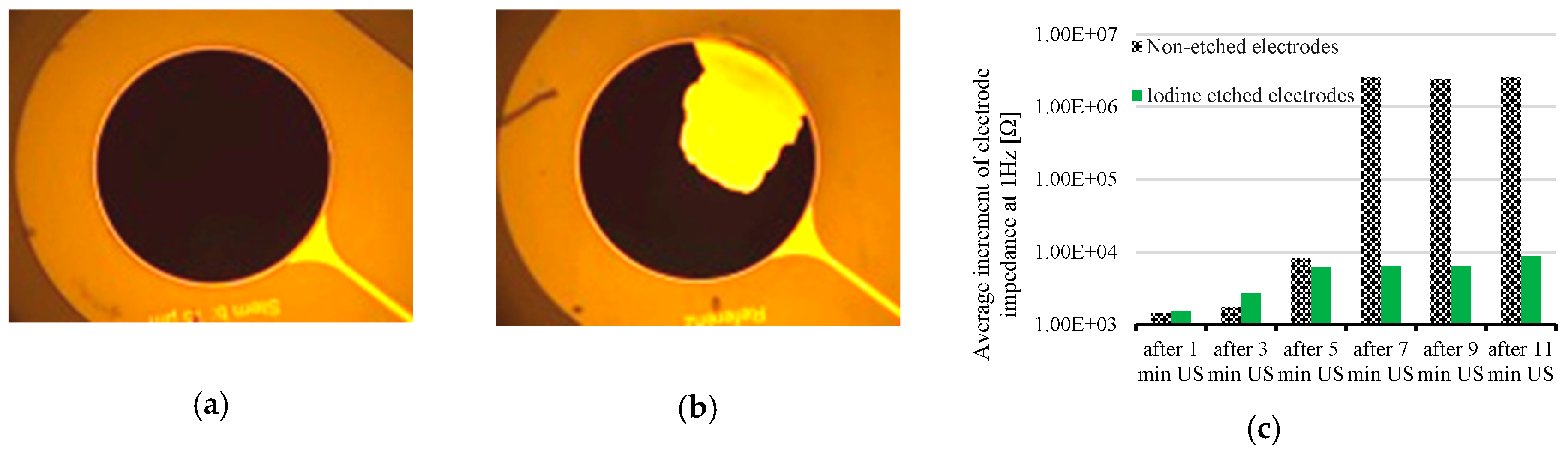

2.2. Gold Etching in Iodine Solution

2.3. PEDOT:PSS Coating Formation

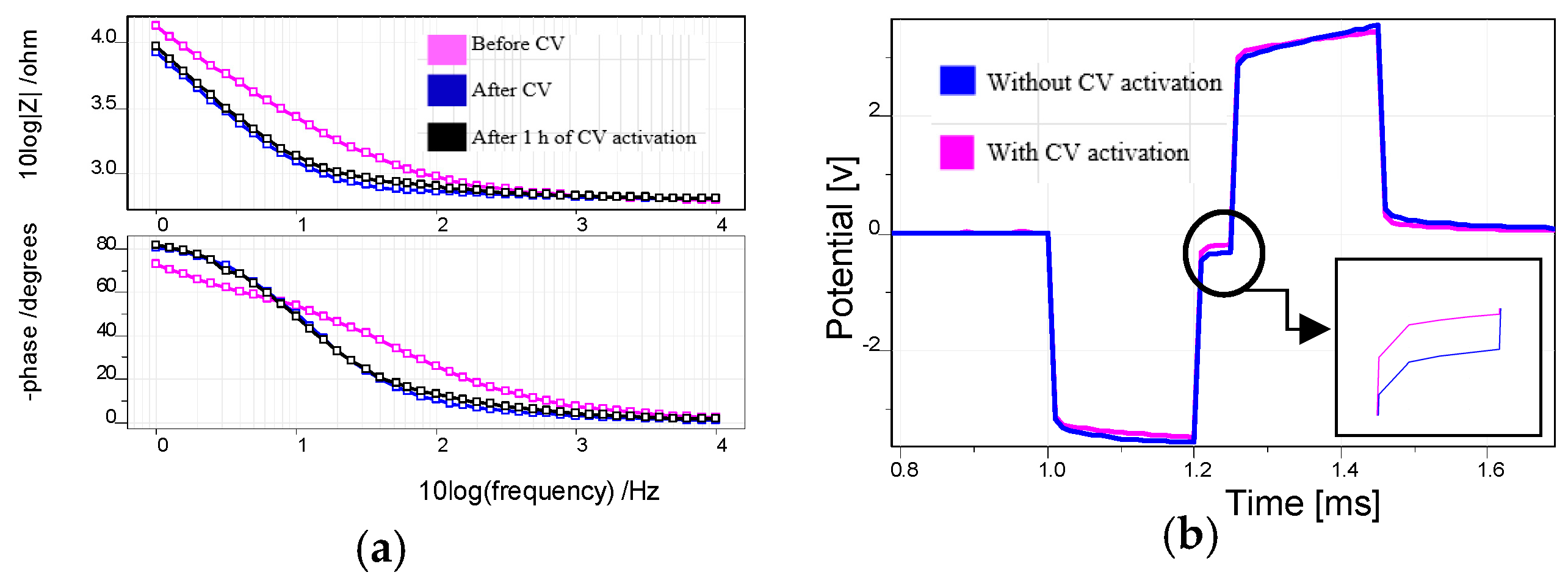

2.4. Electrochemical Modification of PEDOT:PSS Coating

3. Result

3.1. Stability Improvement of PEDOT:PSS Coating

3.2. Electrochemical Modification of PEDOT:PSS Surface

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Venkatraman, S.; Hendricks, J.; King, Z.A.; Sereno, A.J.; Richardson-Burns, S.; Martin, D.; Carmena, J.M. In Vitro and In Vivo Evaluation of PEDOT Microelectrodes for Neural Stimulation and Recording. IEEE Trans. Neural Syst. Rehabil. Eng. 2011, 19, 307–316. [Google Scholar] [CrossRef] [PubMed]

- Mandal, H.S.; Kastee, J.S.; McHail, D.G.; Rubinson, J.F.; Pancrazio, J.J.; Dumas, T.C. Improved Poly(3,4-Ethylenedioxythiophene) (PEDOT) for Neural Stimulation. Neuromodulation 2015, 18, 657–663. [Google Scholar] [CrossRef] [PubMed]

- Schander, A.; Stemmann, H.; Tolstosheeva, E.; Roese, R.; Biefeld, V.; Kempen, L.; Kreiter, A.K.; Lang, W. Design and fabrication of novel multi-channel floating neural probes for intracortical chronic recording. Sens. Actuators A Phys. 2016, 247, 125–135. [Google Scholar] [CrossRef]

- Schander, A.; Teßmann, T.; Strokov, S.; Stemmann, H.; Kreiter, A.K.; Lang, W. In Vitro evaluation of the long-term stability of PEDOT:PSS coated microelectrodes for chronic recording and electrical stimulation of neurons. In Proceedings of the 38th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Orlando, FL, USA, 16–20 August 2016. [Google Scholar]

- Cogan, S.F. Neural stimulation and recording electrodes. Annu. Rev. Biomed. Eng. 2008, 10, 275–309. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pranti, A.S.; Schander, A.; Bödecker, A.; Lang, W. Highly Stable PEDOT:PSS Coating on Gold Microelectrodes with Improved Charge Injection Capacity for Chronic Neural Stimulation. Proceedings 2017, 1, 492. https://doi.org/10.3390/proceedings1040492

Pranti AS, Schander A, Bödecker A, Lang W. Highly Stable PEDOT:PSS Coating on Gold Microelectrodes with Improved Charge Injection Capacity for Chronic Neural Stimulation. Proceedings. 2017; 1(4):492. https://doi.org/10.3390/proceedings1040492

Chicago/Turabian StylePranti, Anmona S., Andreas Schander, André Bödecker, and Walter Lang. 2017. "Highly Stable PEDOT:PSS Coating on Gold Microelectrodes with Improved Charge Injection Capacity for Chronic Neural Stimulation" Proceedings 1, no. 4: 492. https://doi.org/10.3390/proceedings1040492

APA StylePranti, A. S., Schander, A., Bödecker, A., & Lang, W. (2017). Highly Stable PEDOT:PSS Coating on Gold Microelectrodes with Improved Charge Injection Capacity for Chronic Neural Stimulation. Proceedings, 1(4), 492. https://doi.org/10.3390/proceedings1040492