Micro-Grippers with Femtosecond-Laser Machined In-Plane Agonist-Antagonist SMA Actuators Integrated on Wafer-Level by Galvanic Riveting †

Abstract

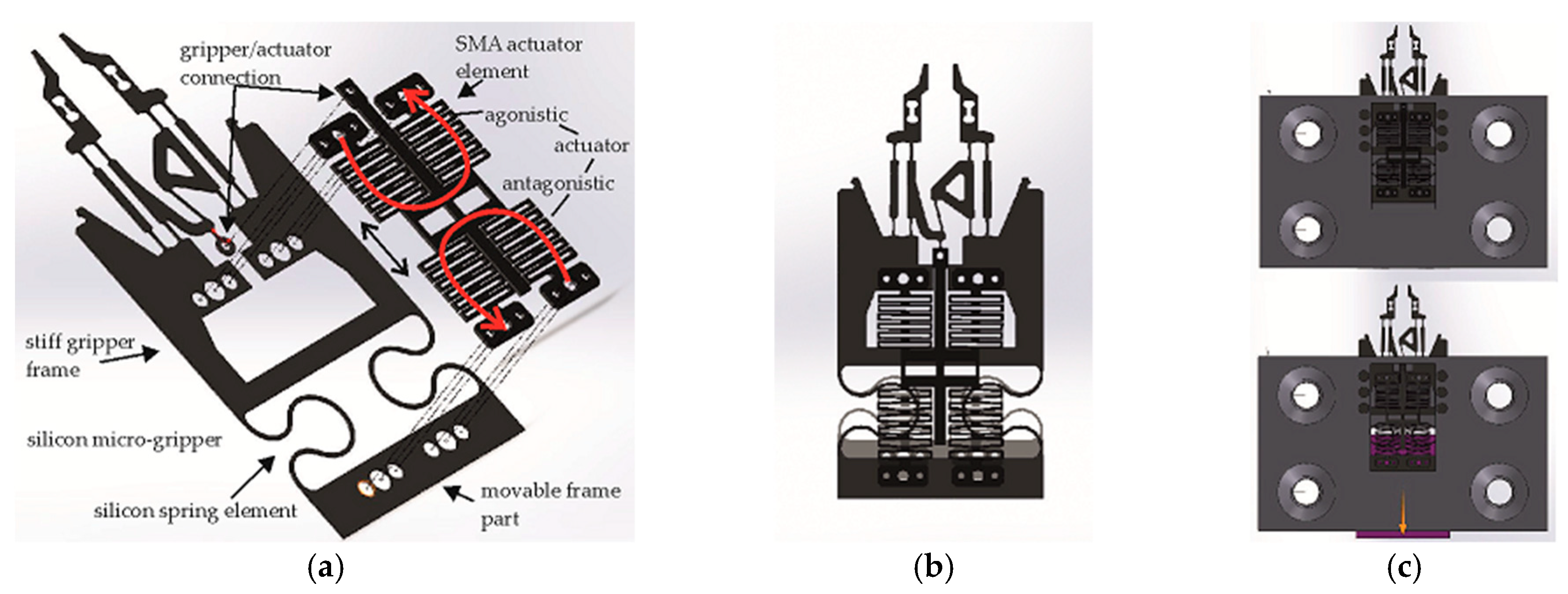

:1. Introduction

2. Materials and Methods

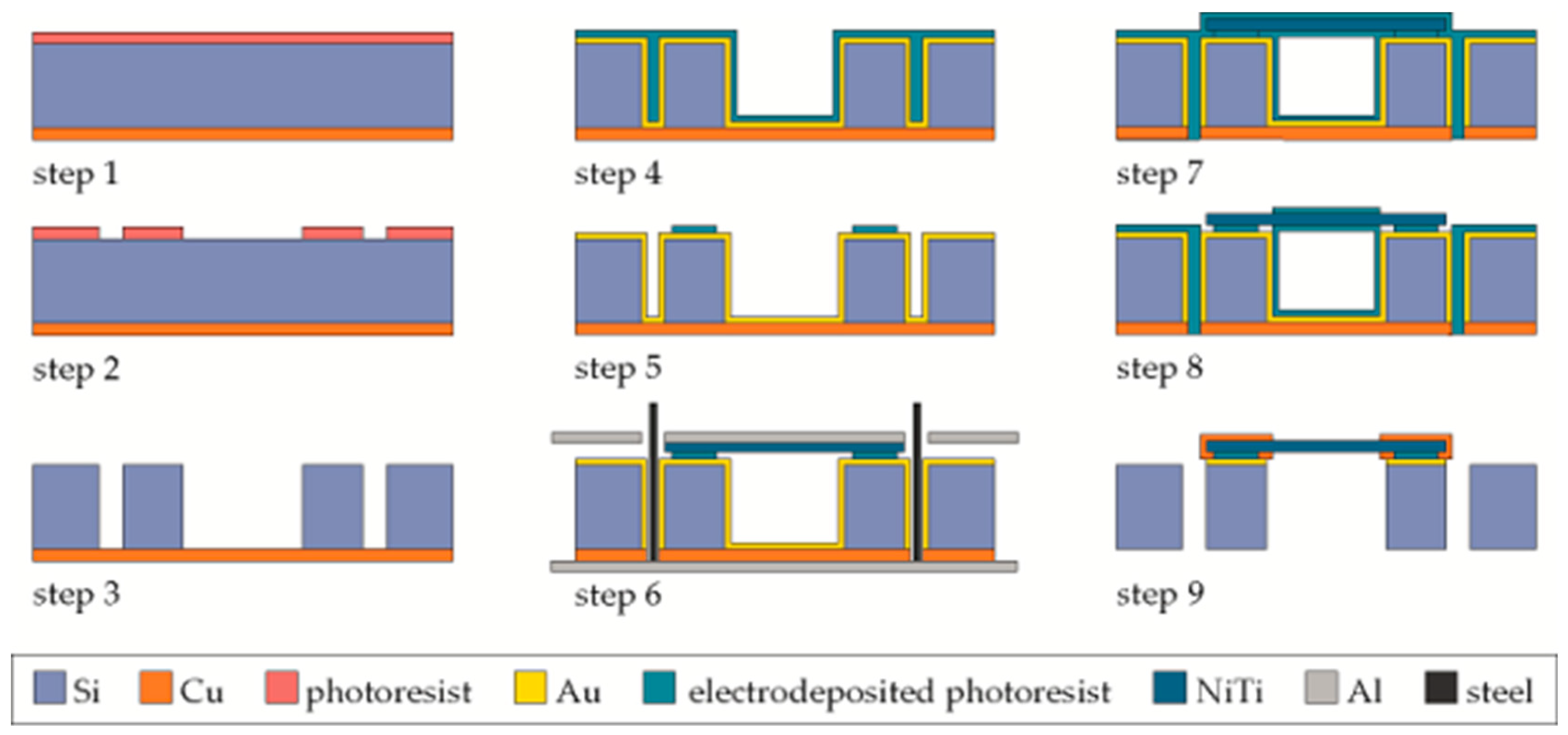

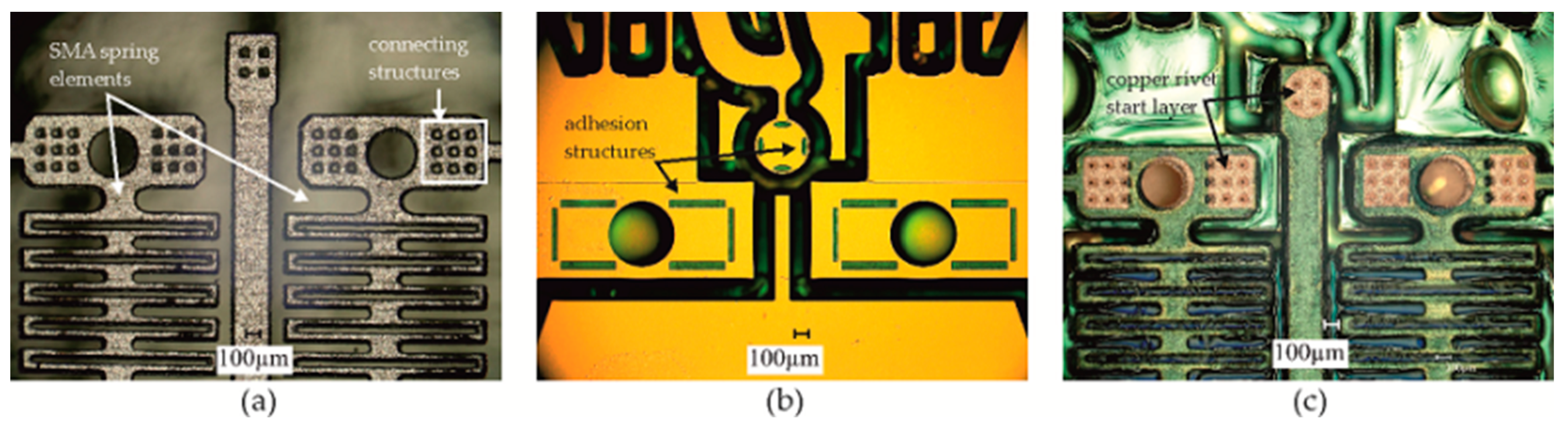

3. Laser-Cutting of SMA Actuators

4. Fabrication of Silicon Micro-Grippers and Wafer-Level Assembly of Grippers and Actuators

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Winzek, B.; Schmitz, S.; Rumpf, H.; Sterzl, T.; Hassdorf, R.; Thienhaus, S.; Feydt, J.; Moske, M.; Quandt, E. Recent developments in shape memory thin film technology. Mater. Sci. Eng. A 2004, 378, 40–46. [Google Scholar] [CrossRef]

- Bütefisch, S.; Seidemann, V.; Büttgenbach, S. Novel micro-pneumatic actuator for MEMS. Sens. Actuators A Phys. 2002, 97–98, 638–645. [Google Scholar] [CrossRef]

- Hoxhold, B. Mikrogreifer und Aktive Mikromontagehilfsmittel mit Integrierten Antrieben. Dissertation; Technische Universität Braunschweig: Braunschweig, Germany, 2010. [Google Scholar]

- Uppal, N.; Shiakolas, P.S. Micromachining Characteristics of NiTi Based Shape Memory Alloy Using Femtosecond Laser. J. Manuf. Sci. Eng. 2008, 130, 31117. [Google Scholar] [CrossRef]

- Hoxhold, B.; Kirchhoff, M.; Bütefisch, S.; Büttgenbach, S. SMA driven micro gripers combining piezo-resistive gripping force sensors with epon SU-8 mechanics. In Proceedings of the XX Eurosensors, 20th Anniversary, Göteborg, Sweden, 17–20 September 2006. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcés-Schröder, M.; Hecht, L.; Vierheller, A.; Leester-Schädel, M.; Böl, M.; Dietzel, A. Micro-Grippers with Femtosecond-Laser Machined In-Plane Agonist-Antagonist SMA Actuators Integrated on Wafer-Level by Galvanic Riveting. Proceedings 2017, 1, 385. https://doi.org/10.3390/proceedings1040385

Garcés-Schröder M, Hecht L, Vierheller A, Leester-Schädel M, Böl M, Dietzel A. Micro-Grippers with Femtosecond-Laser Machined In-Plane Agonist-Antagonist SMA Actuators Integrated on Wafer-Level by Galvanic Riveting. Proceedings. 2017; 1(4):385. https://doi.org/10.3390/proceedings1040385

Chicago/Turabian StyleGarcés-Schröder, Mayra, Lars Hecht, Anke Vierheller, Monika Leester-Schädel, Markus Böl, and Andreas Dietzel. 2017. "Micro-Grippers with Femtosecond-Laser Machined In-Plane Agonist-Antagonist SMA Actuators Integrated on Wafer-Level by Galvanic Riveting" Proceedings 1, no. 4: 385. https://doi.org/10.3390/proceedings1040385

APA StyleGarcés-Schröder, M., Hecht, L., Vierheller, A., Leester-Schädel, M., Böl, M., & Dietzel, A. (2017). Micro-Grippers with Femtosecond-Laser Machined In-Plane Agonist-Antagonist SMA Actuators Integrated on Wafer-Level by Galvanic Riveting. Proceedings, 1(4), 385. https://doi.org/10.3390/proceedings1040385