Abstract

An optical fibre refractometer has been developed by etching and deposition of a thin film of indium tin oxide (ITO) on a single-mode-multimode-single-mode (SMS) fibre structure. The interference between modes in this structure is sensitive to the refractive index changes of the surrounding medium, achieving sensitivities of up to 7000 nm/RIU in the 1.333–1.338 RIU range. A salinity sensor has been implemented as a practical application of this proposed structure. Fast Fourier transform (FFT) analysis and tracking of an interference dip were used to monitor the interference between modes obtaining sensitivities of 0.99 nm/PSU and 0.025 rad/PSU, respectively.

1. Introduction

Oceanography take a decisive role in climate research. Measurement of seawater salinity, with a high accuracy, has become a key issue in thermodynamic ocean control []. One of the most direct methods to achieve reliable and reproducible measurements of seawater salinity is to evaluate the seawater refractive index, which is related to the concentration of dissolved salts.

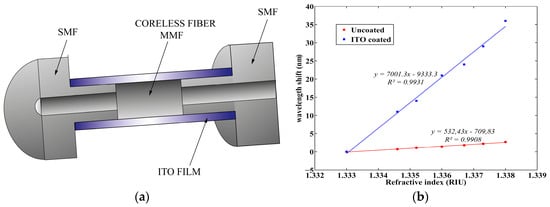

The SMS optical fibre configuration consists of an input and an output single-mode fibres (SMFs) spliced to a section of a multimode coreless fibre (MMF). The operation principle of this refractometer is based on the multimodal interference (MMI). When light propagates along the input SMF and enters the MMF section, several eigenmodes of the MMF are excited and an interference pattern is generated owe to the energy exchange amongst these modes. At the end of the MMF section light is coupled into the output SMF []. When the diameter of the MMF section is reduced, the evanescent field of the light in this waveguide penetrates further into the surrounding medium, thus increasing the interaction with this medium and enhancing the sensitivity [,]. In addition, the deposition of a high refractive index thin film strengthens the interaction with the environment surroundings (see Figure 1a).

Figure 1.

(a) Etched SMS structure with an ITO thin film deposition; (b) Wavelength shift with refractive index uncoated and ITO coated.

This configuration showed to be a suitable choice for applications where high sensitivities and compact structures are required. Additionally, the obtained sensitivities are in the order of magnitude of more complex and expensive structures such as long period fibre gratings (LPFGs). On the other hand, the FFT measurement is an easy method of phase interrogation that can be applicable to systems that require narrow band, multiplexing capability and that have some problems related with high losses and noise. A salinity sensor was implemented with this structure as a practical application of the proposed fibre structure with the FFT interrogation system.

2. Materials and Methods

Coreless MMF segments from POFC Inc. (Taiwan) and standard SMF pigtails from Telnet Redes Inteligentes Inc. (Zaragoza, Spain) were used. The SMS structure consists of a 14-mm segment of coreless MMF spliced on each end to standard SMF pigtails.

This structure was etched by immersing the fibre in a solution of hydrofluoric acid (HF) with a 40% concentration until the diameter of the fibre was reduced to approximately 25 µm. This process took 50 min.

Finally, a thin-film of Indium Tin Oxide (ITO) was deposited by sputtering on the etched region during 80 s in a sputtering device (K675XD, Quorum Technologies, Ltd., Sacramento, CA, USA) using an 150 mA current and an 8 × 10−3 mbar pressure. The ITO film thickness deposited onto the fibre with these parameters is approximately 70 nm.

In order to observe the wavelength shift and calculate the sensitivity to refractive index of the surrounding medium, the sensitive SMS structure was immersed in solutions with various refractive indices [,]. The sensitivity curves were studied by tracking the spectral shift of the nearest attenuation band to a wavelength of 1550 nm.

The sinusoidal spectrum of the SMS sensors after etching exhibits a sharp peak corresponding to the fundamental frequency after applying the fast Fourier transform (FFT) method. Consequently, it is possible to obtain a phase sensitive device by tracking the phase shift of this fundamental frequency as a function of the parameter of interest. In order to probe the feasibility of this method as a salinity concentration sensor, a MATLAB® script was implemented allowing the phase of the fundamental frequency in the optical spectrum response of the sensor to be obtained.

The aqueous saline solutions used were prepared by dissolving sodium chloride (NaCl) in distilled water. One (1) PSU (practical salinity unit) equals one (1) gram of NaCl dissolved in 1000 g of solution.

3. Results

Figure 1b illustrates the wavelength shift as a function of the external refractive index, which allows the sensitivity to be calculated. The wavelength position was taken with the attenuation band closer to 1550 nm. The calculated sentitivity of the ITO coated fibre was 7000 nm/RIU in the 1.333–1.338 RIU range, which enhances in 13 times the sensitivity without the coating.

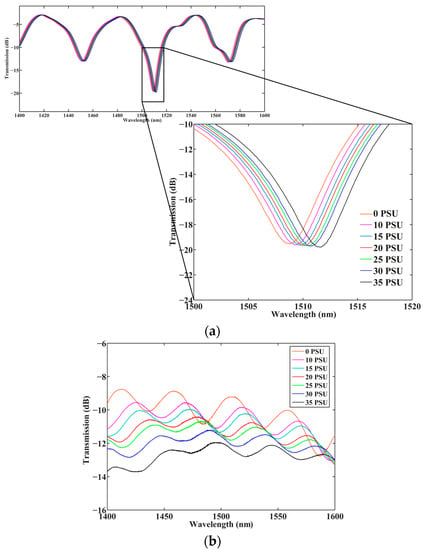

Figure 2a,b depict the transmission as a function of the wavelength for different saline concentrations for the etched SMS and for the etched and ITO-coated SMS; a redshift can be observed in all cases when the RI of the external medium increases. The magnitude of the wavelength shift showed to be more prominent in the coated fiber.

Figure 2.

(a) Transmission for 25 µm diameter SMS structure uncoated structure as a function of wavelength for different saline concentrations; (b) Transmission for 25 µm diameter SMS structure ITO coated structure as a function of wavelength for different saline concentrations.

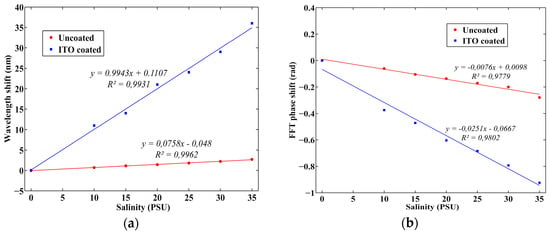

Figure 3a,b shows the behavior of the wavelength shift and the phase shift for different salinity concentrations and the contrast of the behavior without and with ITO film. The calculated sensitivities were 0.076 nm/PSU and −0.007 rad/PSU for the etched SMS, and 0.99 nm/PSU and −0.025 rad/PSU for the etched and ITO-coated SMS.

Figure 3.

(a) Wavelength shift with saline concentration; (b) Phase shift with saline concentration.

4. Discussion and Conclusions

By an adequate design it was possible to track the wavelength shift of the optical spectrum, and by applying a simple FFT measurement technique, the phase shift of the fundamental frequency. The FFT measurement used in the analysis is an easy phase interrogation method that can be applicable to systems that require narrow band, multiplexing capabilities, and that have some problems related with high losses and noise.

The results also showed that the sensitivity obtained for this configuration of SMS was enhanced by reduction of the fiber diameter and by depositing an ITO film, regardless of the attenuation observed in the optical spectrum.

This sensitivity, about 7000 nm/RIU, in the order of magnitude of other structures such as LPFGs, place the developed sensing device as a good option for applications where high sensitivities and compact structures are required. However, it is evident that the configuration proposed here offers a cheaper and easier manufacture procedure.

As an application, a salinity sensor was presented. A sensitivity of 0.99 nm/PSU was obtained by tracking the wavelength shift in a SMS with 25 µm diameter and ITO deposited, whereas for the same device the FFT phase shift analysis showed a −0.025 rad/RIU sensitivity.

After the experimental tests, the sensor exhibited damage in the deposited ITO film, we believe that the NaCl produced an accelerated corrosion of the sensor film. This fact is currently being studied to propose solutions that enhance the lifetime of the sensor with ITO film. The sensor without ITO film, though less sensitive does not present this problem because it is composed just of silica.

Acknowledgments

This work was supported in part by the Agencia Estatal de Investigación (AEI) and Fondo Europeo de Desarrollo Regional (FEDER) (TEC2016-78047-R) and by the Government of Navarre through its projects with references: 2016/PI008, 2016/PC025 and 2016/PC026. As well, it was partially supported by the Colombian Administrative Department of Science, Technology and Innovation - Colciencias, through the Program for national doctorates, calling 617 of 2013.

Conflicts of Interest

The founding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Le Menn, M.; De La Tocnaye, J.D.B.; Grosso, P.; Delauney, L.; Podeur, C.; Brault, P.; Guillerme, O. Advances in measuring ocean salinity with an optical sensor. Meas. Sci. Technol. 2011, 22, 115202. [Google Scholar] [CrossRef]

- Wang, Q.; Farrell, G. All-fiber multimode-interference-based refractometer sensor: Proposal and design. Opt. Lett. 2006, 31, 317–319. [Google Scholar] [CrossRef] [PubMed]

- Lou, J.; Tong, L.; Ye, Z. Modeling of silica nanowires for optical sensing. Opt. Express 2005, 13, 2135–2140. [Google Scholar] [CrossRef] [PubMed]

- Snyder, A.W.; Love, J. Optical Waveguide Theory; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Cooper, P.R. Refractive-index measurements of liquids used in conjunction with optical fibers. Appl. Opt. 1983, 22, 3070–3072. [Google Scholar] [CrossRef] [PubMed]

- Hoyt, L. New table of the refractive index of pure glycerol at 20 C. Ind. Eng. Chem. 1934, 26, 329–332. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).