Silicon Sacrificial Layer Technology for the Production of 3D MEMS (EPyC Process) †

Abstract

:1. Introduction

2. Silicon Dry Etching

2.1. Chemical Etching Process with XeF2

2.2. The Plasma Process with SF6

3. Sample Preparation

4. Results

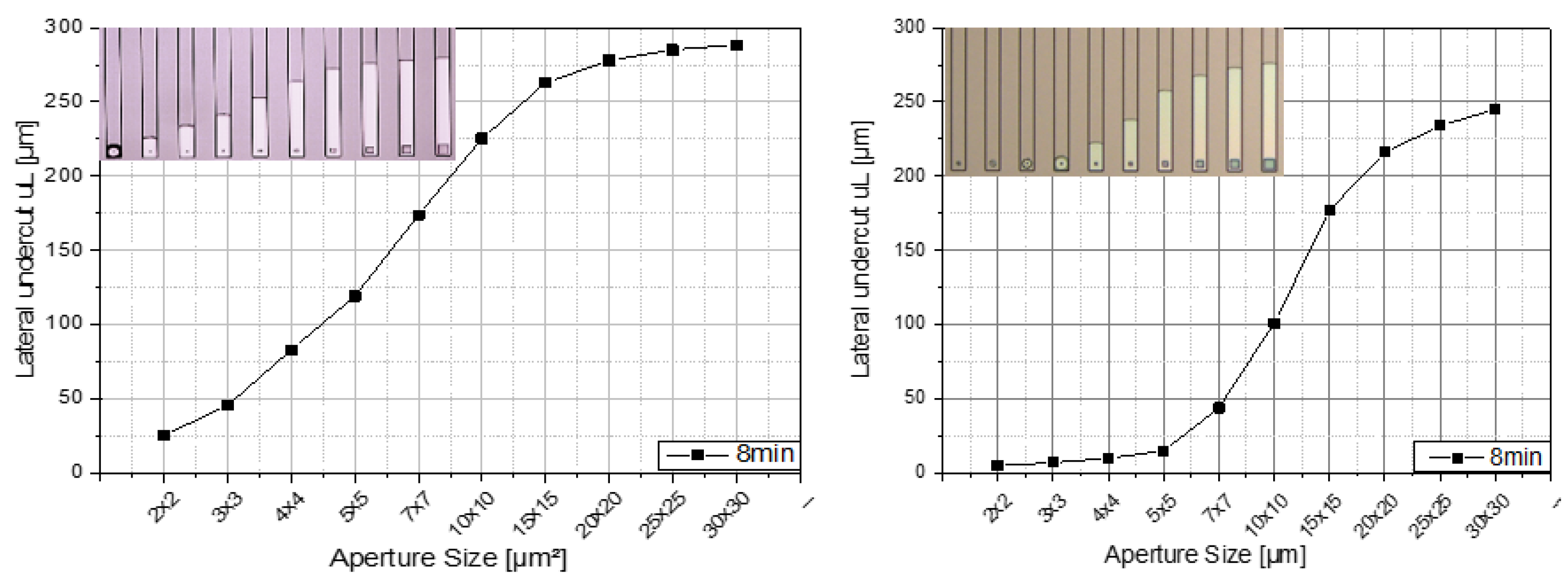

4.1. Aperture Size Effect

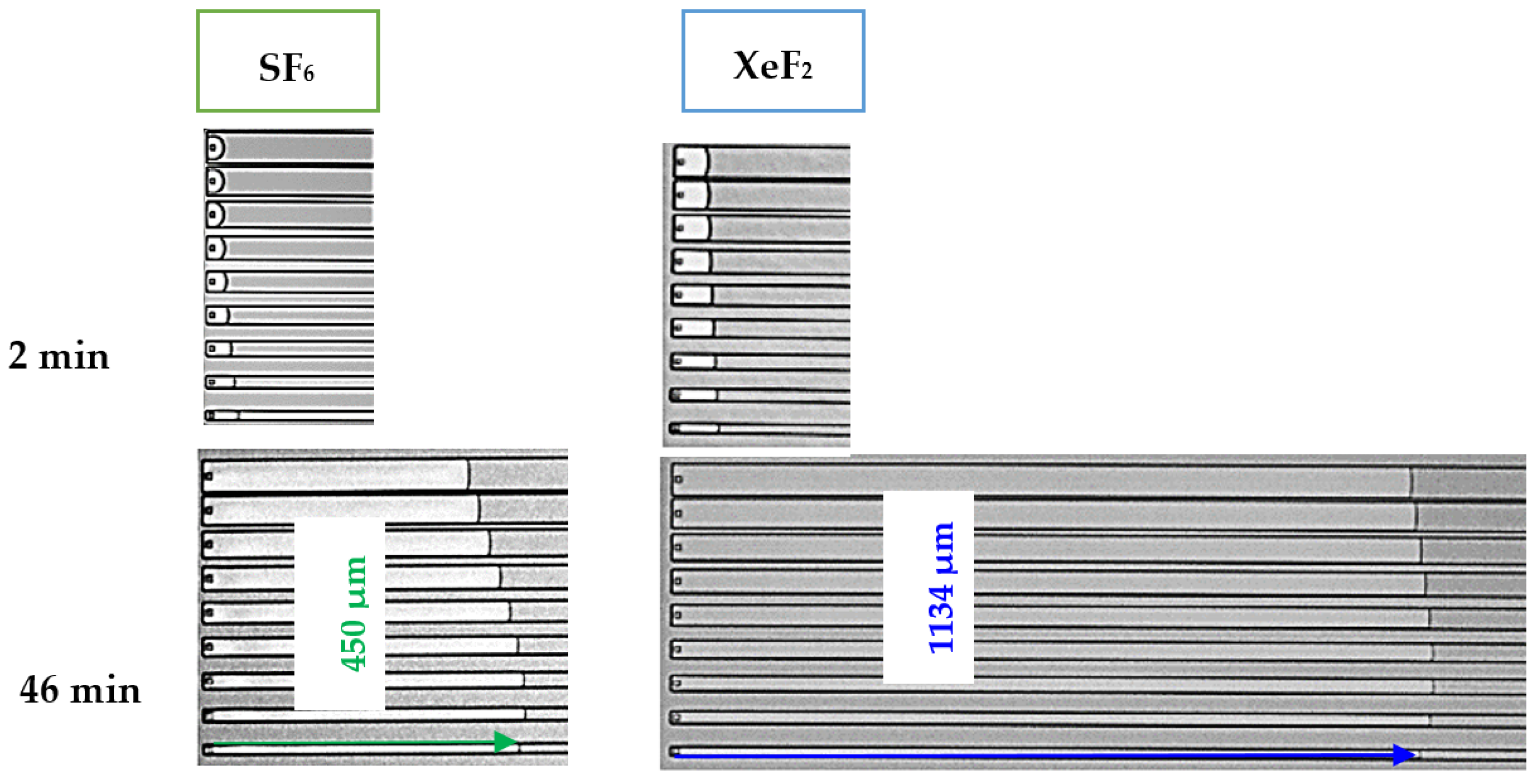

4.2. Channel Size Effect

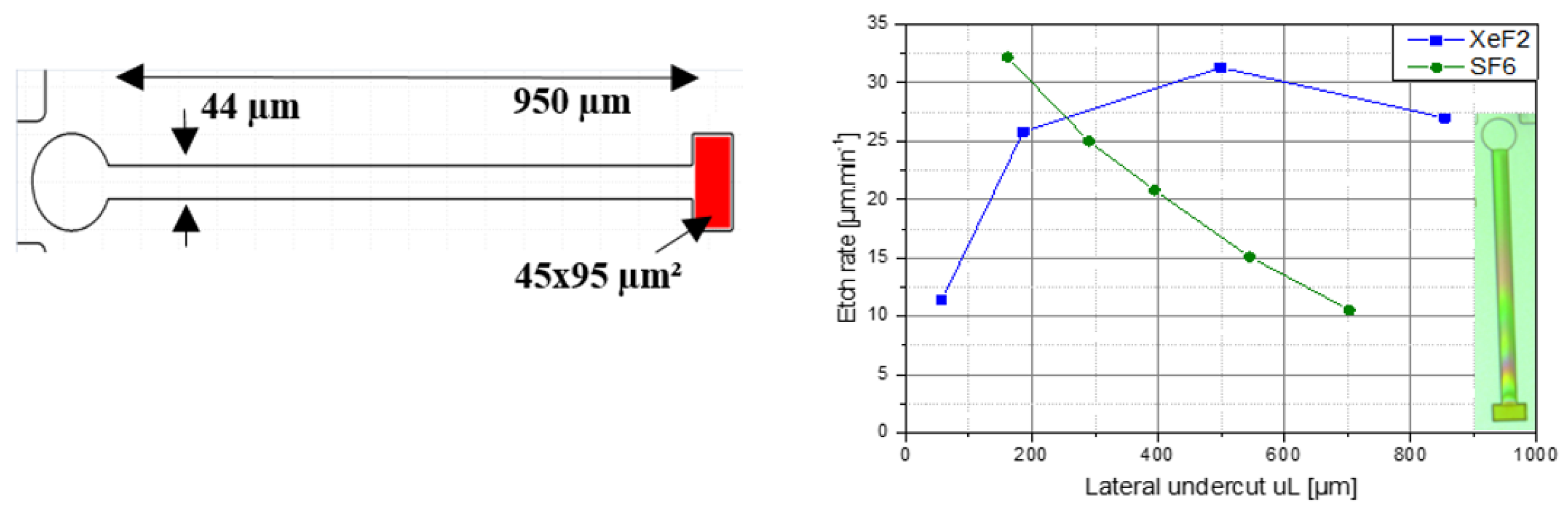

4.3. Optimization of the Etching Process by Combining SF6 and XeF2

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Breitschaedel, O.; Kaelberer, A.; Zielke, C.; Staffeld, P.B.; Artmann, H. Method for Manufacturing Microelectromechanical Structures in A Layer Sequence and a Corresponding Electronic Component Having a Microelectromechanical Structure. US Patent Application 15/097,331, 20 October 2016. [Google Scholar]

- Metzger, L.; Fischer, F.; Mokwa, W. Polysilicon Sacrificial Layer Etching Using XeF2 for Silicon Acceleration Sensors with High Aspect Ratio. In Proceedings of the European Conference on Solid-State Transducers, Eurosensors XVI, Prague, Czech Republic, 15–18 September 2002. [Google Scholar]

- Chang, F.I.; Yeh, R.; Lin, G.; Chu, P.B.; Hoffman, E.; Kruglick, E.J.J.; Pister, K.S.J. Gas-phase silicon micromachining with xenon difluoride. SPIE 1995, 2641, 117–128. [Google Scholar]

- Dagata, J.A.; Squire, D.W.; Dulcey, C.S.; Hsu, D.S.Y.; Lin, M.C. Chemical processes involved in the etching of silicon by xenon difluoride. J. Vac. Sci. Technol. B 1987, 5, 1495–1500. [Google Scholar] [CrossRef]

- Anderson, H.M.; Merson, J.A.; Light, R.W. A kinetic model for plasma etching silicon in a SF6/02 RF discharge. IEEE Trans. Plasma Sci. 1986, 14, 156–164. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Louriki, L.; Staffeld, P.; Kaelberer, A.; Otto, T. Silicon Sacrificial Layer Technology for the Production of 3D MEMS (EPyC Process). Proceedings 2017, 1, 295. https://doi.org/10.3390/proceedings1040295

Louriki L, Staffeld P, Kaelberer A, Otto T. Silicon Sacrificial Layer Technology for the Production of 3D MEMS (EPyC Process). Proceedings. 2017; 1(4):295. https://doi.org/10.3390/proceedings1040295

Chicago/Turabian StyleLouriki, Latifa, Peter Staffeld, Arnd Kaelberer, and Thomas Otto. 2017. "Silicon Sacrificial Layer Technology for the Production of 3D MEMS (EPyC Process)" Proceedings 1, no. 4: 295. https://doi.org/10.3390/proceedings1040295

APA StyleLouriki, L., Staffeld, P., Kaelberer, A., & Otto, T. (2017). Silicon Sacrificial Layer Technology for the Production of 3D MEMS (EPyC Process). Proceedings, 1(4), 295. https://doi.org/10.3390/proceedings1040295