The Status of Plasma Induced Acidification and Its Valorising Potential on Slurries and Digestate: A Review

Abstract

1. Introduction

2. Problem Definition and Current Mitigation Landscape

2.1. Ammonia Emission Sources and Current Mitigation Techniques

| Emission Source/Stage | Current Mitigation Technique(s) | Typical Challenges | Opportunities/Effectiveness | References |

|---|---|---|---|---|

| Feed and Animal Housing (Cattle, Pigs, Poultry) |

| High feed cost; infrastructure modification; increased labour and equipment needs; limited retrofitting feasibility | Reduces NH3 emissions by 10–74%; improves feed efficiency, animal welfare, and indoor air quality | [20,26,27,28] |

| Slurry Storage and Handling |

| High capital and maintenance cost; acid safety and corrosion issues; potential foaming; energy demand | Achieves 40–95% NH3 reduction; reduces odours and conserves N; potential for renewable energy recovery | [21,23,26,29,30] |

| Field Application of Slurry/Digestate |

| Requires specialized machinery; limited feasibility on some soils; higher operational cost | Reduces NH3 volatilisation by 22–99%; improves N retention and crop uptake | [21,22,29] |

| Synthetic Fertiliser Use |

| High cost; variable effectiveness under different soils and climates; user training required | 50–90% NH3 reduction; improved nitrogen use efficiency and reduced losses | [24,27] |

| Poultry Litter and Solid Manure |

| Cost of additives; risk of soil acidification if misapplied; potential N loss during composting | Reduces NH3 emissions by 40–73%; odour control and pathogen reduction | [31,32,33] |

2.2. Fundamentals of Slurry and Digestate Management

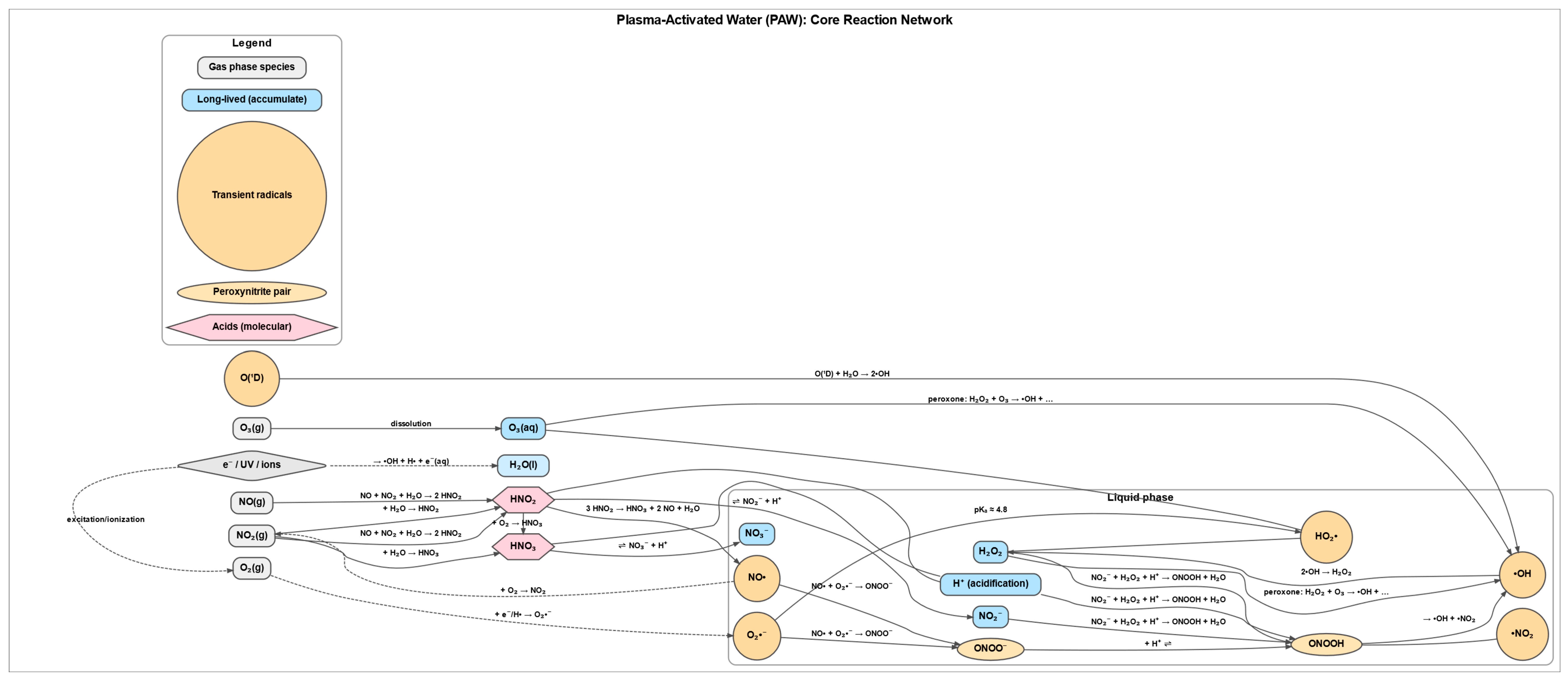

3. Fundamentals and Mechanistic Insights into Plasma Systems for Plasma-Induced Acidification

3.1. Mechanisms and Kinetic Constraints of Plasma-Induced Acidification

3.2. Physico-Chemical Processes and Reactor Configurations

3.3. Plasma-Activated Liquids (PAL): Composition and Function

3.4. Plasma-Induced Acidification as an Intervention in the Nitrogen Cycle

3.5. Environmental & Agronomic Impacts of Plasma-Based Treatments in Agriculture

| Treatment | Agronomic/Environmental Outcome | Operational Notes (Energy & Scalability) | Undesirable/Observed Effects | Ref. |

|---|---|---|---|---|

| Plasma-activated liquid (PAL) for seed treatment | ↑ Germination (15–20%), ↑ root growth (23%), ↓ NH3 volatilisation potential | Operates at 50 W–1.5 kW (≈2–3 kWh m−3 PAL); scalable with DBD reactors and irrigation systems | Over-exposure causes oxidative stress; PAL acidity may injure seedlings | [68] |

| Plasma catalytic systems for N fixation | On-site NH3/NOx production enhancing fertiliser availability | Moderate energy input (~0.2 MJ mol−1 N); modular, decentralised design for farm use | O3 interference; catalyst degradation over time | [10] |

| PAL for crop growth | ↑ Foliar weight (~25%), ↑ chlorophyll (~11%); improved N uptake efficiency | Low-input process noted for energy efficiency; scalable on large farms via irrigation | High reactive species levels may inhibit growth; nitrate accumulation | [69] |

| Plasma catalysis with heated catalyst | Enhanced N conversion yield; improved fertiliser value | 200–250 GJ tN−1 energy use; heated catalyst raises efficiency ~20%; scalable with increased gas flow | Catalyst performance declines at high flow rates | [11] |

| DBD plasma reactor for NOx generation | Produces NO3−-rich solutions for liquid fertilisers | Operates ~300 W (≈1.1 g-NOx kWh−1); continuous mode supports scale-up | pH fluctuation in treated water; diminishing returns at long residence times | [70] |

| Nitrogen fixation plasma system | Generates ~15,500 ppm NOx; precursor for nitrate fertilisers | ~4.2 MJ mol−1 NOx; energy drops 35% at high flow; suited to moderate throughputs | Discharge instability at high O2 levels | [10] |

| PAL for horticulture | ↑ Leaf area (~75%); lower plant NO3− accumulation | Operates at 125 W; low running cost; adaptable to greenhouses | Reduced phenolic content; species-dependent response | [71] |

| Gliding arc discharge (GAD) system | ↑ Seed germination (12–13%) and FGP (~17%) | ≈415 W low-input system; highly scalable | Water acidification possible; crop-specific variation | [72] |

| Cold plasma | Improved germination and crop vigour via ROS/RNS stimulation | Low-energy room-temperature discharge; field applicable | Repeated use may acidify soils | [68] |

| Plasma treatment of digestates | ↓ NH3 and CH4 emissions; enhanced N retention | ≈60 kWh kg−1 NOx; scales with slurry buffer capacity; renewable-compatible | Nitrite toxicity; possible NO3− leaching or nitrification inhibition | [14] |

| Plasma-treated pig slurry | ↓ CH4 (>90%) but ↑ N2O after application | Moderate electric load for air ionisation; farm-scale integration feasible | Higher GHG intensity than mineral fertilisers if N2O uncontrolled | [65] |

| Plasma elimination of CH4 in slurry | 100% CH4 removal; microbial suppression of CH4 & N2O | High-load operation; suited to renewables; avoids S-acid issues | Requires NO3−/NO2− control to limit denitrification | [9] |

| Plasma-treated cattle slurry | 9% ↑ dry matter yield vs. untreated; ↓ CH4 emission | Electrical discharge ionises air; renewable integration possible | Lower N uptake than mineral fertiliser; clover content sensitivity | [73] |

| Decarbonising N fertiliser with NTP | Efficient NO3− + NH4+ generation; ↑ NUE potential | ≈5.3 kWh mol−1-N; modular, renewable-driven design | Risk of N2O emissions; nitrite toxicity; monitor water quality | [66] |

| Plasma-fixated N for turf grass | Biomass ↑ ~60%; enhanced yield at optimal concentration | 450 W reactor; decentralised irrigation integration | Acidification risk; potential run-off toxicity | [74] |

| Plasma for gerbera plants | Biomass gain in peat substrates | 5–25 kV DBD; scalable for controlled environments | Substrate sensitivity; microbial reduction | [67] |

| Plasma agriculture (lab → farm) | ↑ Germination and biochemical health indices | 50–400 W systems; APP adaptable to field irrigation | Over-exposure reduces germination; crop specificity | [62] |

| Plasma agriculture for sustainability | ↑ Seed germination; ↑ root/shoot growth (~2 min exposure) | High-voltage DBD; renewable operation recommended | Over-exposure reduces growth; nutrient (P, K, S) deficiency possible | [75] |

| Plasma-assisted N fixation | Produces 1–5% NH3, 6% NO; ↓ GWP (~19%) for HNO3 synthesis | ~17 g NH3 kWh−1; modular plant design | Low product yield; energy still limiting factor | [76] |

| Plasma-activated water (PAW) in agriculture | ↑ Germination (50%), ↑ dry weight (6.6×), 61% disease control | 6–30 kW power range; easy integration with irrigation | ROS toxicity if overdosed; reactive species short-lived (<48 h) | [28] |

| Plasma-fixed N for lettuce | 250% ↑ marketable yield; high NUE at low rate (8 lb acre−1) | 1.8 kW DBD reactor; farm scale adaptable | Product pH ~1.5 → soil acidification risk; low P content | [64] |

| Plasma dinitrogen pentoxide for plants | Complete N2O5 → NO3− conversion; efficient fertilisation | ~70 MJ mol−1-N; portable renewable devices emerging | High dose phytotoxicity; nodulation reduction in legumes | [77] |

| Plasma agriculture (advancements) | ↑ Yield and growth (spinach, sunflower); pathogen control | Up to 30 kV DBD systems; modular and portable | Over-exposure inhibits seedlings; potential soil acidification | [78] |

| Plasma-activated organic fertiliser (PAOF) | ↓ VOC, CH4, NH3 emissions; ↑ N retention in organic waste | Moderate–high energy use (~€2–3 kg−1 N converted); distributed renewables scalable | ↑ N2O after application; soil acidification risk | [50] |

| Plasma agriculture and ecosystem studies | ↑ Germination and growth at optimal (4–20 min) exposure | Generally, energy-efficient vs. traditional processes; irrigation integration possible | Over-exposure damages seeds; microbiome impacts at high RNS | [79] |

4. Evidence of Efficacy of Plasma-Induced Acidification

Key Parameters Affecting Process Efficiency

5. Economic and Environmental Assessment of Plasma—Induced Acidification

6. Integration of Full Lifecycle Costing in Techno-Economic Analyses of Plasma Acidification Systems

7. Path to Deployment of Plasma Induce Acidification Technology

7.1. Market Outlook and Enabling Conditions for Plasma Acidification

7.2. Existing Pilot and Demonstration Projects for Plasma-Induced Acidification and Nitrate Enrichment

| Project/Partner | Location | Technology Type | Key Findings/Outcomes | Application | Ref. |

|---|---|---|---|---|---|

| NEO—Danish Studies (N2 Applied) | Denmark | Plasma-treated organic fertiliser (N2 Applied NEO system) | Demonstrated substantial reduction in ammonia (NH3) emissions from field application and verified long-term chemical stability of the NEO-treated slurry. | Sustainable agriculture, emissions reduction | [105] |

| Snarum Gartneri Pilot (N2 Applied) | Norway | On-farm plasma manure acidification system | Reduced ammonia losses during storage and application of manure; improved nitrogen utilisation in greenhouse fertigation. | Horticulture, fertigation | [109] |

| Galåvolden Gård (N2 Applied) | Norway | Plasma reactor for manure treatment | Increased nitrogen retention and reduced greenhouse gas emissions in dairy farm trials; improved nutrient recovery. | Dairy farming, circular agriculture | [110] |

| Møre Biogas Collaboration (N2 Applied) | Norway | Biogas-integrated plasma acidification system | Combined plasma technology with anaerobic digestion to enhance nutrient value and reduce odour emissions. | Biogas, renewable energy integration | [111] |

| Van den Borne Aardappelen Pilot (N2 Applied) | The Netherlands | Plasma-treated slurry demonstration | Field trials indicated nitrate-enriched slurry improved potato crop yields and reduced nitrogen losses. | Arable farming, precision agriculture | [112] |

| Nitricity | United States | Non-thermal plasma nitrogen fixation system | Renewable electricity-driven plasma process that converts air and water into nitrate fertilizer, enabling on-site, carbon-free production and reducing dependence on industrial ammonia supply chains. | Sustainable fertilizer production, decentralized agriculture | [106] |

| VitalFluid Plasma System | The Netherlands | Atmospheric plasma reactor | Converts air and water into plasma-activated water for on-site fertiliser generation using renewable electricity. | Horticulture, fertigation, greenhouse systems | [113] |

| Plasma2X | United Kingdom | Plasma and electrocatalytic ammonia synthesis system | Demonstrated renewable, CO2-free ammonia and fertilizer production directly from air and water using low-energy plasma technology. | Sustainable fertilizer production, green chemicals | [114] |

8. Research Gaps

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- WRAP (n.d.). The Global Environmental Action NGO—UK. Available online: https://wrap.org.uk (accessed on 12 September 2025).

- Shen, J.; Treu, R.; Wang, J.; Nicholson, F.; Bhogal, A.; Thorman, R. Modeling nitrous oxide emissions from digestate and slurry applied to three agricultural soils in the United Kingdom: Fluxes and emission factors. Environ. Pollut. 2018, 243, 1952–1965. [Google Scholar] [CrossRef]

- Möller, K.; Müller, T. Effects of anaerobic digestion on digestate nutrient availability and crop growth: A review. Eng. Life Sci. 2012, 12, 242–257. [Google Scholar] [CrossRef]

- Kai, P.; Pedersen, P.; Jensen, J.E.; Hansen, M.N.; Sommer, S.G. A whole-farm assessment of the efficacy of slurry acidification in reducing ammonia emissions. Eur. J. Agron. 2008, 28, 148–154. [Google Scholar] [CrossRef]

- Case, S.D.C.; Oelofse, M.; Hou, Y.; Oenema, O.; Jensen, L.S. Farmer perceptions and use of organic waste products as fertilisers—A survey study of potential benefits and barriers. Agric. Syst. 2017, 151, 84–95. [Google Scholar] [CrossRef]

- Shi, W.; Healy, M.G.; Ashekuzzaman, S.M.; Daly, K.; Fenton, O. Mineral fertiliser equivalent value of dairy processing sludge and derived biochar using ryegrass (Lolium perenne L.) and spring wheat (Triticum aestivum). J. Environ. Manag. 2022, 321, 116012. [Google Scholar] [CrossRef]

- Murnane, J.G. Combined Zeolite and Chemical Amendments Mixed with Agricultural Wastes to Reduce Surface and Leaching Losses of Nutrients and Greenhouse Gas Emissions, and Biofilter Treatment of Dairy Soiled Water. Ph.D. Thesis, National University of Ireland Galway, Galway, Ireland, 2017. Available online: https://www.universityofgalway.ie/media/gene/files/John-Murnane---Thesis-%28final%29.pdf (accessed on 12 August 2025).

- Ingels, R.; Graves, D.B. Improving the efficiency of organic fertilizer and nitrogen use via air plasma and distributed renewable energy. Plasma Med. 2015, 5, 257–270. [Google Scholar] [CrossRef]

- Nyvold, M.; Dörsch, P. Complete elimination of methane formation in stored livestock manure using plasma technology. Front. Sustain. Food Syst. 2024, 8, 1370542. [Google Scholar] [CrossRef]

- Chen, H.; Yuan, D.; Wu, A.; Lin, X.; Li, X. Review of low-temperature plasma nitrogen fixation technology. Waste Dispos. Sustain. Energy 2021, 3, 201–217. [Google Scholar] [CrossRef]

- Pei, X.; Gidon, D.; Yang, Y.-J.; Xiong, Z.; Graves, D.B. Reducing energy cost of NOx production in air plasmas. Chem. Eng. J. 2019, 362, 217–228. [Google Scholar] [CrossRef]

- Rouwenhorst, K.H.; Jardali, F.; Bogaerts, A.; Lefferts, L. From the Birkeland–Eyde process towards energy-efficient plasma-based NOx synthesis: A techno-economic analysis. Energy Environ. Sci. 2021, 14, 2520–2534. [Google Scholar] [CrossRef]

- Rouwenhorst, K.H.; Engelmann, Y.; van ’t Veer, K.; Postma, R.S.; Bogaerts, A.; Lefferts, L. Plasma-driven catalysis: Green ammonia synthesis with intermittent electricity. Green Chem. 2020, 22, 6258–6287. [Google Scholar] [CrossRef]

- Nyang’au, J.O.; Sørensen, P.; Møller, H.B. Effects of plasma treatment of digestates on pH, nitrification and nitrogen turnover during storage and after soil application. Environ. Technol. Innov. 2024, 34, 103578. [Google Scholar] [CrossRef]

- Jiang, B.; Zheng, J.; Qiu, S.; Wu, M.; Zhang, Q.; Yan, Z.; Xue, Q. Review on electrical discharge plasma technology for wastewater remediation. Chem. Eng. J. 2014, 236, 348–368. [Google Scholar] [CrossRef]

- Tripathi, B.M.; Shukla, S.K.; Rathore, P.K.S. A comprehensive review on solar to thermal energy conversion and storage using phase change materials. J. Energy Storage 2023, 72, 108280. [Google Scholar] [CrossRef]

- Akay, G. Green ammonia, nitric acid, advanced fertilizer and electricity production with in situ CO2 capture and utilization by integrated intensified nonthermal plasma catalytic processes: A technology transfer review for distributed biorefineries. Catalysts 2025, 15, 105. [Google Scholar]

- Jacob, S.; Kundu, D.; Chintagunta, A.D.; Samanta, P.; Mahata, C.; Dey, S.; Shibirathna, R.G.; Barathi, A.; Kumar, S.; Wang, Z.; et al. Anaerobic digestion-derived digestate valorization: Green chemistry innovations for resource recovery and reutilization. Green Chem. 2025, 27, 7472–7505. [Google Scholar] [CrossRef]

- Speer, D. Optimization and Implementation of Continuous Liquid–Liquid Extraction and In-Situ Separation Processes for Practical Recovery. Doctoral Dissertation, 2024. University of Michigan. Available online: https://hdl.handle.net/2027.42/194447 (accessed on 21 October 2025).

- Vaneeckhaute, C.; Belia, E.; Meers, E.; Tack, F.M.G.; Vanrolleghem, P.A. Nutrient recovery from digested waste: Towards a generic roadmap for setting up an optimal treatment train. Waste Manag. 2018, 78, 385–392. [Google Scholar] [CrossRef]

- Ndegwa, P.M.; Hristov, A.N.; Arogo, J.; Sheffield, R.E. A review of ammonia emission mitigation techniques for concentrated animal feeding operations. Biosyst. Eng. 2008, 100, 453–469. [Google Scholar] [CrossRef]

- Webb, J.; Menzi, H.; Pain, B.F.; Misselbrook, T.H.; Dämmgen, U.; Hendriks, H.; Döhler, H. Managing ammonia emissions from livestock production in Europe. Environ. Pollut. 2005, 135, 399–406. [Google Scholar] [CrossRef]

- Finzi, A.; Riva, E.; Bicoku, A.; Guido, V.; Shallari, S.; Provolo, G. Comparison of techniques for ammonia emission mitigation during storage of livestock manure and assessment of their effect in the management chain. J. Agric. Eng. 2019, 50, 12–19. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, H.; Wang, S.; Zhang, J.; Zhu, Z.; Li, X.; Dong, H. Sulfuric acid modified expanded vermiculite cover for reducing ammonia emissions from animal slurry storage. J. Hazard. Mater. 2021, 403, 123954. [Google Scholar] [CrossRef]

- Pan, B.; Lam, S.K.; Mosier, A.; Luo, Y.; Chen, D. Ammonia volatilization from synthetic fertilizers and its mitigation strategies: A global synthesis. Agric. Ecosyst. Environ. 2016, 232, 283–289. [Google Scholar] [CrossRef]

- Li, X.; Wen, Q.; Zhang, S.; Li, N.; Yang, J.; Romanyà, J.; Han, X. Long-term changes in organic and inorganic phosphorus compounds as affected by long-term synthetic fertilisers and pig manure in arable soils. Plant Soil 2022, 472, 239–255. [Google Scholar] [CrossRef]

- Philippe, F.X.; Laitat, M.; Wavreille, J.; Bartiaux-Thill, N.; Nicks, B.; Cabaraux, J.F. Ammonia and greenhouse gas emission from group-housed gestating sows depends on floor type. Agric. Ecosyst. Environ. 2011, 140, 498–505. [Google Scholar] [CrossRef]

- Guo, L.; Zhao, B.; Jia, Y.; He, F.; Chen, W. Mitigation strategies of air pollutants for mechanical ventilated livestock and poultry housing—A review. Atmosphere 2022, 13, 452. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, H.; Zhu, Z.; Gerber, P.J.; Xin, H.; Smith, P.; Opio, C.; Steinfeld, H.; Chadwick, D. Mitigating greenhouse gas and ammonia emissions from swine manure management: A system analysis. Environ. Sci. Technol. 2017, 51, 4503–4511. [Google Scholar] [CrossRef]

- Montes, F.; Meinen, R.; Dell, C.; Rotz, A.; Hristov, A.N.; Oh, J.; Waghorn, G.; Gerber, P.J.; Henderson, B.; Makkar, H.P.; et al. SPECIAL TOPICS—Mitigation of methane and nitrous oxide emissions from animal operations: II. A review of manure management mitigation options. J. Anim. Sci. 2013, 91, 5070–5094. [Google Scholar] [CrossRef]

- Smith, D.R. Reducing Phosphorus Runoff Through Diet Modification and Treatment of Manure with Aluminum Amendments; University of Arkansas: Fayetteville, AR, USA, 2002. [Google Scholar]

- Karamanlis, X.; Fortomaris, P.; Arsenos, G.; Dosis, I.; Papaioannou, D.; Batzios, C.; Kamarianos, A. The effect of a natural zeolite (clinoptilolite) on the performance of broiler chickens and the quality of their litter. Asian-Australas. J. Anim. Sci. 2008, 21, 1642–1650. [Google Scholar] [CrossRef]

- Zielińska, M.; Bułkowska, K. Sustainable management and advanced nutrient recovery from biogas energy sector effluents. Energies 2024, 17, 3705. [Google Scholar] [CrossRef]

- Sommer, S.G.; Hutchings, N.J. Ammonia emission from field applied manure and its reduction. Eur. J. Agron. 2001, 15, 1–15. [Google Scholar] [CrossRef]

- Ragazzi, M.; Maniscalco, M.; Torretta, V.; Ferronato, N.; Rada, E.C. Anaerobic digestion as sustainable source of energy: A dynamic approach for improving the recovery of organic waste. Energy Procedia 2017, 119, 602–614. [Google Scholar] [CrossRef]

- Obileke, K.; Nwokolo, N.; Makaka, G.; Mukumba, P.; Onyeaka, H. Anaerobic digestion: Technology for biogas production as a source of renewable energy—A review. Energy Environ. 2021, 32, 191–225. [Google Scholar] [CrossRef]

- Perera, M.K.; Englehardt, J.D.; Dvorak, A.C. Technologies for recovering nutrients from wastewater: A critical review. Environ. Eng. Sci. 2019, 36, 511–529. [Google Scholar] [CrossRef]

- Kumar, R.; Pal, P. Assessing the feasibility of N and P recovery by struvite precipitation from nutrient-rich wastewater: A review. Environ. Sci. Pollut. Res. 2015, 22, 17453–17464. [Google Scholar] [CrossRef]

- Van Grinsven, H.J.; Tiktak, A.; Rougoor, C.W. Evaluation of the Dutch implementation of the nitrates directive, the water framework directive and the national emission ceilings directive. NJAS—Wagening. J. Life Sci. 2016, 78, 69–84. [Google Scholar] [CrossRef]

- Suárez Valdés, M.Á.; Soriano Disla, J.M.; Gambuzzi, E.; Castejón Martínez, G. Innovative circular biowaste valorisation—State of the art and guidance for cities and regions. Sustainability 2024, 16, 8963. [Google Scholar] [CrossRef]

- Long, A.S.M. Multi-Objective Analysis of Nutrient Use and Recycling Under Consideration of Economic Conditions and Regional Structures. Doctoral Dissertation, Technische Universität Wien, Vienna, Austria, 2025. [Google Scholar]

- Terraz, L.; Silva, T.; Morillo-Candas, A.; Guaitella, O.; Tejero-del-Caz, A.; Alves, L.L.; Guerra, V. Influence of N2 on the CO2 vibrational distribution function and dissociation yield in non-equilibrium plasmas. J. Phys. D Appl. Phys. 2019, 53, 094002. [Google Scholar] [CrossRef]

- Vervloessem, E.; Gorbanev, Y.; Nikiforov, A.; De Geyter, N.; Bogaerts, A. Sustainable NO x production from air in pulsed plasma: Elucidating the chemistry behind the low energy consumption. Green Chem. 2022, 24, 916–929. [Google Scholar] [CrossRef]

- Lamichhane, P.; Paneru, R.; Nguyen, L.N.; Lim, J.S.; Bhartiya, P.; Adhikari, B.C.; Mumtaz, S.; Choi, E.H. Plasma-assisted nitrogen fixation in water with various metals. React. Chem. Eng. 2020, 5, 2053–2057. [Google Scholar] [CrossRef]

- van ’t Veer, K.; Engelmann, Y.; Reniers, F.; Bogaerts, A. Plasma-catalytic ammonia synthesis in a DBD plasma: Role of microdischarges and their afterglows. J. Phys. Chem. C 2020, 124, 22871–22883. [Google Scholar] [CrossRef]

- Cai, Y.; Lv, L.; Lu, X. The effects of inner electrode diameter on the performance of dielectric barrier discharge reactor for desulfurization and denitrification. IEEE Trans. Plasma Sci. 2021, 49, 786–793. [Google Scholar] [CrossRef]

- Mizoi, K.; Rodríguez-González, V.; Sasaki, M.; Suzuki, S.; Honda, K.; Ishida, N.; Suzuki, N.; Kuchitsu, K.; Kondo, T.; Yuasa, M.; et al. Interactions between pH, reactive species, and cells in plasma-activated water can remove algae. RSC Adv. 2022, 12, 7626–7634. [Google Scholar] [CrossRef]

- Wong, K.S.; Chew, N.S.; Low, M.; Tan, M.K. Plasma-activated water: Physicochemical properties, generation techniques, and applications. Processes 2023, 11, 2213. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, Y.; Wu, R.A.; Liao, X.; Liu, D.; Cullen, P.J.; Zhou, R.W.; Ding, T. Diagnostic analysis of reactive species in plasma-activated water (PAW): Current advances and outlooks. J. Phys. D Appl. Phys. 2021, 55, 023002. [Google Scholar] [CrossRef]

- Graves, D.B.; Bakken, L.B.; Jensen, M.B.; Ingels, R. Plasma activated organic fertilizer. Plasma Chem. Plasma Process. 2019, 39, 1–19. [Google Scholar] [CrossRef]

- Burström, P.E.C. CFD-Modelling of the SNCR Process in Iron Ore Grate-Kiln Plants; Luleå University of Technology: Luleå, Sweden, 2012; Available online: https://www.diva-portal.org/smash/get/diva2:990041/FULLTEXT01.pdf (accessed on 10 October 2025).

- Babatunde, A.O.; Zhao, Y.Q. Equilibrium and kinetic analysis of phosphorus adsorption from aqueous solution by alum sludge. J. Hazard. Mater. 2010, 184, 746–752. [Google Scholar] [CrossRef]

- Liu, S.; Berns, A.E.; Vereecken, H.; Wu, D.; Brüggemann, N. Interactive effects of MnO2, organic matter and pH on abiotic formation of N2O from hydroxylamine in artificial soil mixtures. Sci. Rep. 2017, 7, 39590. [Google Scholar] [CrossRef]

- Anglada, J.M.; Martins-Costa, M.; Francisco, J.S.; Ruiz-Lopez, M.F. Interconnection of reactive oxygen species chemistry across the interfaces of atmospheric, environmental, and biological processes. Acc. Chem. Res. 2015, 48, 575–583. [Google Scholar] [CrossRef]

- Rumbach, P.; Bartels, D.M.; Go, D.B. The penetration and concentration of solvated electrons and hydroxyl radicals at a plasma-liquid interface. Plasma Sources Sci. Technol. 2018, 27, 115013. [Google Scholar] [CrossRef]

- Vanraes, P.; Nikiforov, A.; Bogaerts, A.; Leys, C. Study of an AC dielectric barrier single micro-discharge filament over a water film. Sci. Rep. 2018, 8, 10919. [Google Scholar] [CrossRef] [PubMed]

- Snoeckx, R.; Bogaerts, A. Plasma technology—A novel solution for CO2 conversion? Chem. Soc. Rev. 2017, 46, 5805–5863. [Google Scholar] [CrossRef]

- Kogelschatz, U. Dielectric-barrier discharges: Their history, discharge physics, and industrial applications. Plasma Chem. Plasma Process. 2003, 23, 1–46. [Google Scholar] [CrossRef]

- Galloway, J.N.; Townsend, A.R.; Erisman, J.W.; Bekunda, M.; Cai, Z.; Freney, J.R.; Martinelli, L.A.; Seitzinger, S.P.; Sutton, M.A. Transformation of the nitrogen cycle: Recent trends, questions, and potential solutions. Science 2008, 320, 889–892. [Google Scholar] [CrossRef]

- Oehmigen, K.; Hähnel, M.; Brandenburg, R.; Wilke, C.; Weltmann, K.D.; Von Woedtke, T. The role of acidification for antimicrobial activity of atmospheric pressure plasma in liquids. Plasma Process. Polym. 2010, 7, 250–257. [Google Scholar] [CrossRef]

- Vaneeckhaute, C. Nutrient Recovery from Bio-Digestion Waste: From Field Experimentation to Model-Based Optimization. Doctoral Dissertation, Université Laval, Québec, QC, Canada, 2015. [Google Scholar]

- Attri, P.; Ishikawa, K.; Okumura, T.; Koga, K.; Shiratani, M. Plasma agriculture from laboratory to farm: A review. Processes 2020, 8, 1002. [Google Scholar] [CrossRef]

- Li, M.; Xiong, Z.; Song, Z.; Wang, W.; Hou, Z.; Dai, Y. Inhibit ammonia volatilization from agriculture and livestock by air plasma-activated water. J. Phys. D Appl. Phys. 2024, 57, 395205. [Google Scholar] [CrossRef]

- Wang, B.; Hu, Q.; Castillo, B.F.; Simley, C.; Yates, A.; Sharbono, B.; Brasier, K.; Cappelli, M.A. Plasma-fixed nitrogen improves lettuce field holding potential. HortTechnology 2024, 34, 187–189. [Google Scholar] [CrossRef]

- Lloyd, I.L.; Grayson, R.P.; Galdos, M.V.; Morrison, R.; Chapman, P.J. Nitrous oxide and methane fluxes from plasma-treated pig slurry applied to winter wheat. Nutr. Cycl. Agroecosyst. 2024, 129, 505–520. [Google Scholar] [CrossRef]

- Ye, X.P. Decarbonizing nitrogen fertilizer for agriculture with nonthermal plasma technology. Engineering 2024, 5, 1823–1837. [Google Scholar] [CrossRef]

- Cannazzaro, S.; Traversari, S.; Cacini, S.; Di Lonardo, S.; Pane, C.; Burchi, G.; Massa, D. Non-thermal plasma treatment influences shoot biomass, flower production and nutrition of gerbera plants depending on substrate composition and fertigation level. Plants 2021, 10, 689. [Google Scholar] [CrossRef]

- Kocira, S.; Pérez-Pizá, M.C.; Bohata, A.; Bartos, P.; Szparaga, A. Cold plasma as a potential activator of plant biostimulants. Sustainability 2022, 14, 495. [Google Scholar] [CrossRef]

- Stoleru, V.; Burlica, R.; Mihalache, G.; Dirlau, D.; Padureanu, S.; Teliban, G.C.; Astanei, D.; Cojocaru, A.; Beniuga, O.; Patras, A. Plant growth promotion effect of plasma activated water on Lactuca sativa L. cultivated in two different volumes of substrate. Sci. Rep. 2020, 10, 20920. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Thapa, B.; Rivera, C.; Yuan, Y. Nitrate and nitrite fertilizer production from air and water by continuous flow liquid-phase plasma discharge. J. Environ. Chem. Eng. 2021, 9, 104761. [Google Scholar] [CrossRef]

- Ruamrungsri, S.; Sawangrat, C.; Panjama, K.; Sojithamporn, P.; Jaipinta, S.; Srisuwan, W.; Intanoo, M.; Inkham, C.; Thanapornpoonpong, S.N. Effects of using plasma-activated water as a nitrate source on the growth and nutritional quality of hydroponically grown green oak lettuces. Horticulturae 2023, 9, 248. [Google Scholar] [CrossRef]

- Sedhai, B.; Guragain, R.P.; Shrestha, B.; Sedhai, S.; Baniya, H.B.; Subedi, D.P. Enhancement of seed germination of Daucus carota sativus L. by non--thermal plasma treatment. Contrib. Plasma Phys. 2023, 63, e202200123. [Google Scholar] [CrossRef]

- Cottis, T.; Mousavi, H.; Solberg, S.Ø. Plasma treated cattle slurry with modest fertilizer effect on grass. Eur. J. Agron. 2025, 168, 127649. [Google Scholar] [CrossRef]

- Sze, C.; Wang, B.; Xu, J.; Rivas-Davila, J.; Cappelli, M.A. Plasma-fixated nitrogen as fertilizer for turf grass. RSC Adv. 2021, 11, 37886–37895. [Google Scholar] [CrossRef]

- Malek, T.; Choudhary, M. Plasma Agriculture: A green technology to attain the sustainable agriculture goal. arXiv 2023, arXiv:2302.02273. [Google Scholar] [CrossRef]

- Anastasopoulou, A.; Keijzer, R.; Butala, S.; Lang, J.; Van Rooij, G.; Hessel, V. Eco-efficiency analysis of plasma-assisted nitrogen fixation. J. Phys. D Appl. Phys. 2020, 53, 234001. [Google Scholar] [CrossRef]

- Takeshi, S.; Takashima, K.; Sasaki, S.; Higashitani, A.; Kaneko, T. Plasma nitrogen fixation for plant cultivation with air-derived dinitrogen pentoxide. Plasma Process. Polym. 2024, 21, e2400096. [Google Scholar] [CrossRef]

- Konchekov, E.M.; Krivtsov, I.V.; O’Connell, D.; Fridman, A. Advancements in Plasma Agriculture: A Review of Recent Studies. Plasma Chem. Plasma Process. 2023, 43, 15093. [Google Scholar] [CrossRef]

- Ranieri, P.; Sponsel, N.; Kizer, J.; Rojas-Pierce, M.; Hernández, R.; Gatiboni, L.; Grunden, A.; Stapelmann, K. Plasma agriculture: Review from the perspective of the plant and its ecosystem. Plasma Process. Polym. 2021, 18, e2000162. [Google Scholar] [CrossRef]

- Thirumdas, R.; Kothakota, A.; Annapure, U.; Siliveru, K.; Blundell, R.; Gatt, R.; Valdramidis, V.P. Plasma-activated water (PAW): Chemistry, physico-chemical properties, applications in food and agriculture. Trends Food Sci. Technol. 2018, 77, 21–33. [Google Scholar] [CrossRef]

- European Parliament and Council of the European Union (2019) Regulation (EU) 2019/1009 of 5 June 2019 Laying down Rules on the Making Available on the Market of EU Fertilising Products and Amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 and Repealing Regulation (EC) No 2003/2003. Official Journal of the European Union, L 170. pp. 1–114. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32019R1009 (accessed on 12 August 2024).

- Zhou, R.; Wang, P.; Xian, Y.; Mai-Prochnow, A.; Lu, X.; Cullen, P.J.; Ostrikov, K.K.; Bazaka, K. Plasma-activated water: Generation, origin of reactive species and biological applications. J. Phys. D Appl. Phys. 2020, 53, 303001. [Google Scholar] [CrossRef]

- Abdelaziz, A.A.; Teramoto, Y.; Nozaki, T.; Kim, H.H. Performance of high-frequency spark discharge for efficient NOx production with tunable selectivity. Chem. Eng. J. 2023, 470, 144182. [Google Scholar] [CrossRef]

- Patil, B.S.; Wang, Q.; Hessel, V.; Lang, J. Plasma N2-fixation: 1900–2014. Catal. Today 2015, 256, 49–66. [Google Scholar] [CrossRef]

- Klimek, A.; Piercey, D.G. Nitrogen fixation via plasma-assisted processes: Energy performance, scale-up challenges and techno-economic perspectives. Processes 2024, 12, 786. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). World Energy Outlook 2024; OECD/IEA: Paris, France, 2024; Available online: https://www.iea.org/reports/world-energy-outlook-2024 (accessed on 12 October 2025).

- Fasihi, M.; Weiss, R.; Savolainen, J.; Breyer, C. Global potential of green ammonia based on hybrid PV-wind power plants. Appl. Energy 2021, 294, 116170. [Google Scholar] [CrossRef]

- Osorio-Tejada, J.L.; Rebrov, E.V.; Hessel, V. Internalisation of environmental costs of decentralised nitrogen-fertiliser production. Int. J. Life Cycle Assess. 2023, 28, 2213–2228. [Google Scholar] [CrossRef] [PubMed]

- Nyvold, S.; Ingels, R. The Industrial Applications and Economic Viability of Plasma-Based Nitrogen Fixation. 2025. Available online: https://www.researchgate.net/publication/387867891_The_industrial_applications_and_economic_viability_of_plasma-based_nitrogen_fixation (accessed on 12 October 2025).

- Pérez-Ramírez, J.; Kapteijn, F.; Schöffel, K.; Moulijn, J.A. Formation and control of N2O in nitric acid production: Where do we stand today? Appl. Catal. B Environ. 2003, 44, 117–151. [Google Scholar] [CrossRef]

- Miller, V.V.; Clark, D.S.; Mesbah, A. Ammonia retention in biowaste via low-temperature-plasma-synthesized nitrogen oxyacids: Toward sustainable upcycling of animal waste. ACS Sustain. Chem. Eng. 2024, 12, 2621–2631. [Google Scholar] [CrossRef]

- Hermann, L.; Hermann, R. Report on Regulations Governing AD and NRR in EU Member States. SYSTEMIC Project. 2018. Available online: https://systemicproject.eu/wp-content/uploads/2018/07/D-2.1_Reg_governing_AD_and_NRR_in_EU_MS_final_report.pdf (accessed on 10 September 2025).

- Anastasopoulou, A. Conceptual Process Design of Plasma-Assisted Nitrogen Fixation Through Energy-Integration Paradigms; Eindhoven University of Technology: Eindhoven, The Netherlands, 2018; Available online: https://research.tue.nl/files/105883898/20180919_CO_Anastasopoulou.pdf (accessed on 9 October 2025).

- Escribà-Gelonch, M.; Osorio-Tejada, J.; Yu, L.; Wanten, B.; Bogaerts, A.; Hessel, V. Techno-economic and life-cycle assessment for syngas production using sustainable plasma-assisted methane reforming technologies. Energy Environ. Sci. 2025, 18, 6043–6062. [Google Scholar] [CrossRef]

- Lamberts-Van Assche, H. A Techno-Economic and Environmental Life Cycle Assessment of Plasma Catalysis for the Conversion of CO2: Towards the Design of a Novel Carbon Capture and Utilization Technology in an Uncertain Future; University of Antwerp: Antwerp, Belgium, 2023. [Google Scholar]

- Tan, W.E.; Liew, P.Y.; Tan, L.S.; Woon, K.S.; Mohammad Rozali, N.E.; Ho, W.S.; NorRuwaida, J. Life cycle assessment and techno-economic analysis for anaerobic digestion as cow manure management system. Energies 2022, 15, 9586. [Google Scholar] [CrossRef]

- Chadwick, D.; Sommer, S.; Thorman, R.; Fangueiro, D.; Cardenas, L.; Amon, B.; Misselbrook, T. Manure management: Implications for greenhouse gas emissions. Anim. Feed Sci. Technol. 2011, 166, 514–531. [Google Scholar] [CrossRef]

- Aghdam, S. Environmental Impact Assessment (LCA) and Techno-Economic Assessment (TEA) of Struvite Recovery in Swine Manure; North Carolina State University: Raleigh, NC, USA, 2022. [Google Scholar]

- Li, B.; Liao, H.; Li, K.; Wang, Y.; Zhang, L.; Guo, Y.; Liu, L.; Li, J.; Jin, J.; Yang, Y.; et al. Unlocking nitrogen management potential via large-scale farming for air quality and substantial co-benefits. Natl. Sci. Rev. 2024, 11, nwae324. [Google Scholar] [CrossRef]

- Adamovich, I.; Agarwal, S.; Ahedo, E.; Alves, L.L.; Baalrud, S.; Babaeva, N.; Bogaerts, A.; Bourdon, A.; Bruggeman, P.J.; Canal, C.; et al. The 2022 Plasma Roadmap: Low temperature plasma science and technology. J. Phys. D Appl. Phys. 2022, 55, 373001. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Ammonia Technology Roadmap: Towards More Sustainable Nitrogen Fertilizer Production; OECD/IEA: Paris, France, 2021; Available online: https://www.iea.org/reports/ammonia-technology-roadmap (accessed on 11 October 2025).

- Ayub, Y.; Zhou, J.; Ren, J.; Wang, Y.; Shen, W.; He, C.; Dong, L.; Toniolo, S. Plasma gasification-based monetization of poultry litter: System optimization and comprehensive 5E analysis. Energy Convers. Manag. 2023, 282, 116878. [Google Scholar] [CrossRef]

- Carmona-Martínez, A.A.; Rontogianni, A.; Zeneli, M.; Grammelis, P.; Birgi, O.; Janssen, R.; Di Costanzo, B.; Vis, M.; Davidis, B.; Reumerman, P.; et al. Charting the course: Navigating decarbonisation pathways in Greece, Germany, The Netherlands, and Spain’s industrial sectors. Sustainability 2024, 16, 6176. [Google Scholar] [CrossRef]

- Tichý, O.; Eckhardt, S.; Balkanski, Y.; Hauglustaine, D.; Evangeliou, N. Decreasing trends of ammonia emissions over Europe seen from remote sensing and inverse modelling. Atmos. Chem. Phys. 2023, 23, 15235–15252. [Google Scholar] [CrossRef]

- N2 Applied. Danish Studies Demonstrate Substantial Reduction in Ammonia Emissions from Field Application and Long-Term Stability of NEO Fertiliser. 2025. Available online: https://n2applied.com/2025/01/16/danish-studies-demonstrate-substantial-reduction-in-ammonia-emissions-from-field-application-and-long-term-chemical-stability-of-neo-n2-applieds-organic-fertiliser/ (accessed on 13 October 2025).

- Nitricity. Non-Equilibrium Plasma for Energy-Efficient Nitrogen Fixation; U.S. Department of Energy: Washington, DC, USA, 2025. Available online: https://arpa-e.energy.gov/programs-and-initiatives/search-all-projects/non-equilibrium-plasma-energy-efficient-nitrogen-fixation (accessed on 13 October 2025).

- Heidner, Performance Report 2020 (N2 Applied Trial Data) 2020. N2 Applied—NEO Performance Data. Available online: https://heidner.no/wp-content/uploads/2021/04/N2-Applied-NEO-Performance-Report-2020-2.pdf (accessed on 12 October 2025).

- N2 Applied. Desktop Study for Performance Potential of N2 Applied Plasma Technology. (Interim Report). 2022. Available online: https://arc-csg.cymru/wp-content/uploads/2022/11/N2-Applied-interim-report-Tywi-Nutrient-Partnership.pdf (accessed on 12 October 2025).

- N2 Applied. Snarum Gartneri. N2 Applied Case Studies. 2024. Available online: https://n2applied.com/2024/12/12/snarum-gartneri/ (accessed on 12 October 2025).

- N2 Applied. Galåvolden Gård. N2 Applied Case Studies. 2021. Available online: https://n2applied.com/2021/11/24/galavolden-gard/ (accessed on 12 October 2025).

- N2 Applied. Møre Biogas. N2 Applied Case Studies. 2021b. Available online: https://n2applied.com/2021/11/24/more-biogas/ (accessed on 13 October 2025).

- N2 Applied. Van den Borne Aardappelen Pilot. N2 Applied Case Studies. 2021c. Available online: https://n2applied.com/2021/11/22/van-den-borne-aardappelen-pilot/ (accessed on 13 October 2025).

- VitalFluid. Harnessing the Power of Lightning into a Controlled, Scalable System. 2025. Available online: https://www.vitalfluid.com/ (accessed on 13 October 2025).

- Plasma2X. Plasma2X—Green Ammonia and Fertiliser Production from Air, Water, and Renewable Energy. 2025. Available online: https://www.plasma2x.com/ (accessed on 12 October 2025).

- Thiermann, I.; Latacz-Lohmann, U. Incentivising ammonia emission abatement through in-house slurry acidification: Evidence from a discrete choice experiment in Germany. J. Clean. Prod. 2022, 345, 131158. [Google Scholar] [CrossRef]

| Technique | Efficiency (NH3 Reduction) | Challenges | Opportunities | References |

|---|---|---|---|---|

| Dietary Manipulation | Up to 74% | High precision in feed formulation; increased costs | No infrastructure changes; improves feed efficiency | [21] |

| Slurry Storage Covers | Up to 95% | Labor-intensive; maintenance of covers | Reduces other pollutants; suitable for large-scale operations | [21,24] |

| Urease Inhibitors | 53.7% | Variable effectiveness depending on conditions | Enhances nitrogen retention | [25] |

| Slurry Acidification | Up to 95% | Safety risks; potential soil acidification | Highly effective; improves nitrogen use efficiency | [23,24] |

| Plasma-Induced Acidification | Over 99% for CH4; | High energy use; increases N2O emissions post-application | Increases nitrogen content; reduces need for synthetic fertilisers; stabilises pH | [9] |

| System Studied | Lifecycle Cost Parameters Considered | Key Findings/Contributions | Identified Shortfalls/Gaps | Reference |

|---|---|---|---|---|

| Plasma-assisted NH3 and HNO3 synthesis | Equipment: Factorial estimation of CAPEX (reactor, gas feed, power supply) Maintenance: Preventive and corrective scheduling costs Electricity: Modelled for grid and renewable supply Monitoring: Included as control and diagnostic subsystem | Integrated TEA–LCA–LCC assessment for plasma nitrogen fixation; electricity consumption dominated (≈70% of total LCC); maintenance and monitoring 10–15%. | Static depreciation and linear maintenance assumptions; no end-of-life or recycling costs; limited regional cost calibration. | [93] |

| High-power plasma reactors for nitrogen fixation | Equipment: CAPEX scaling by geometry and reactor size Maintenance: Reactor degradation model based on electrode wear Electricity: Detailed energy consumption model per reactor design Monitoring: Partial inclusion (diagnostic costs estimated as % of CAPEX) | Developed geometry-dependent cost model showing monitoring and degradation can increase OPEX by 25%; underscored need for durability data. | Empirical maintenance data limited; simplified treatment of monitoring; constant energy cost assumptions. | [76] |

| Decentralised NH3/nitrate plasma fertiliser systems | Equipment: Annualised CAPEX for reactors and storage Maintenance: Included scheduled replacement intervals Electricity: Dynamic renewable vs. grid cost integration Monitoring: Included Via automation and control system costs | Conducted cradle-to-gate TEA–LCA integrating environmental externalities; predicted cost competitiveness for NTP systems under renewable electricity. | Monitoring and degradation data remain low-resolution; regional monetisation uncertainty; end-of-life impacts omitted. | [88] |

| Plasma-catalytic CO2 conversion | Equipment: CAPEX and depreciation Maintenance: Operating and downtime maintenance Electricity: Regional grid-mix based consumption Monitoring: Not explicitly modelled | Combined TEA–LCA for plasma catalysis; identified electricity intensity and maintenance as main economic burdens. | No explicit monitoring inclusion; lacks time-resolved degradation data. | [95] |

| Plasma-assisted syngas production | Equipment: Industrial-scale CAPEX functions Maintenance: Annual repair and replacement costs Electricity: Dynamic time-varying pricing Monitoring: Included as continuous control and diagnostic module | Integrated dynamic TEA–LCA model; found maintenance + monitoring contribute 18% of total OPEX; electricity variability strongly influences LCC. | End-of-life excluded; model limited to energy systems (not fertiliser context). | [94] |

| Electrolyser-Haber–Bosch systems | Equipment: CAPEX Maintenance: Generic fixed O&M factor Electricity: Renewable vs. grid scenario analysis Monitoring: Not included | Showed future cost parity of renewable ammonia under CO2 taxation; benchmark for plasma comparisons. | Oversimplified O&M costs; monitoring and replacement phases not modelled. | [87] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumi, B.; Worrall, S.; Sawtell, D.; Sakrabani, R. The Status of Plasma Induced Acidification and Its Valorising Potential on Slurries and Digestate: A Review. Nitrogen 2025, 6, 97. https://doi.org/10.3390/nitrogen6040097

Kumi B, Worrall S, Sawtell D, Sakrabani R. The Status of Plasma Induced Acidification and Its Valorising Potential on Slurries and Digestate: A Review. Nitrogen. 2025; 6(4):97. https://doi.org/10.3390/nitrogen6040097

Chicago/Turabian StyleKumi, Bridget, Stephen Worrall, David Sawtell, and Ruben Sakrabani. 2025. "The Status of Plasma Induced Acidification and Its Valorising Potential on Slurries and Digestate: A Review" Nitrogen 6, no. 4: 97. https://doi.org/10.3390/nitrogen6040097

APA StyleKumi, B., Worrall, S., Sawtell, D., & Sakrabani, R. (2025). The Status of Plasma Induced Acidification and Its Valorising Potential on Slurries and Digestate: A Review. Nitrogen, 6(4), 97. https://doi.org/10.3390/nitrogen6040097