Biotransforming of Poultry and Swine Slaughterhouse Waste as an Alternative Protein Source for Ruminant Feeding

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Site

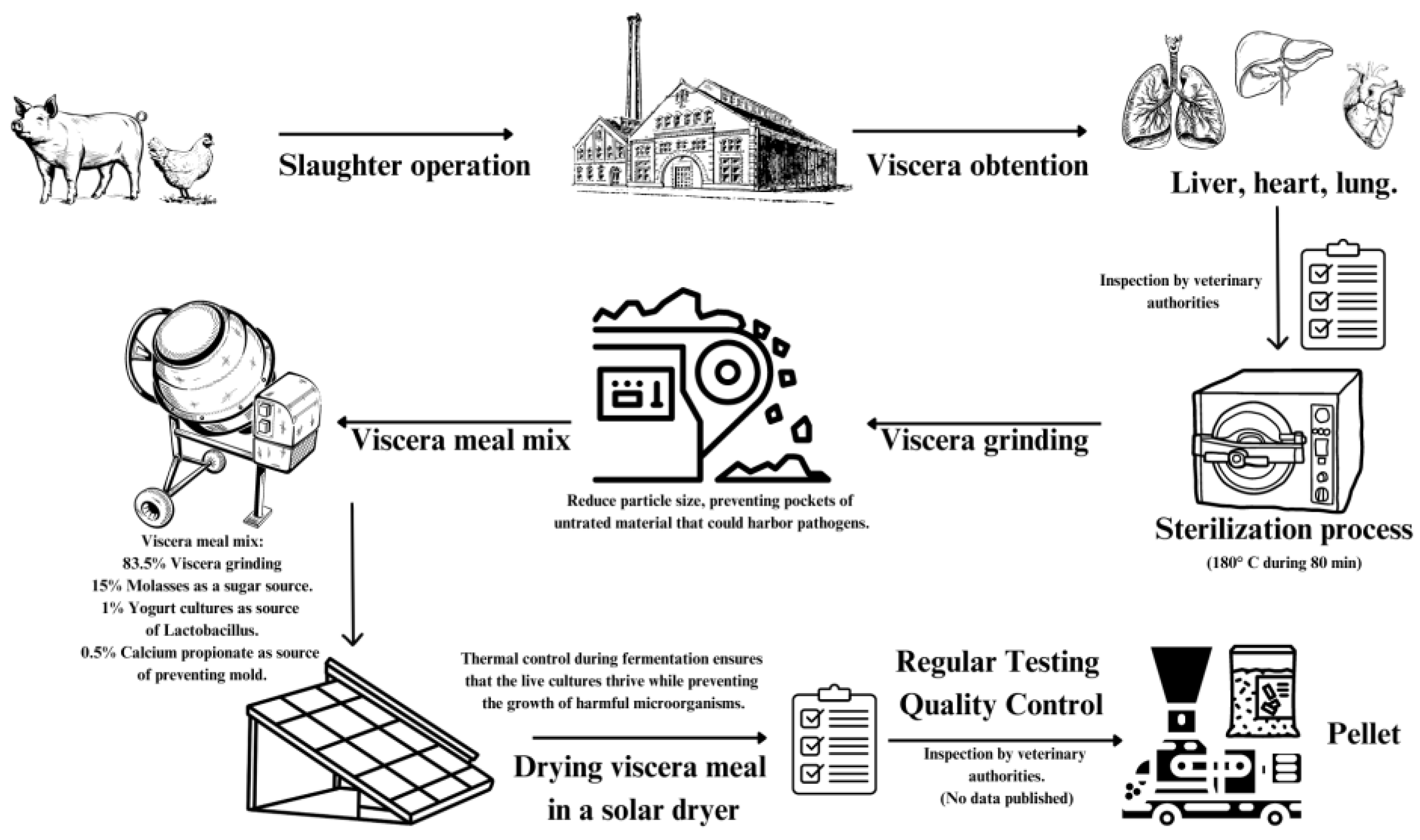

2.2. Slaughterhouse Waste Meal Preparation

2.3. Animal Feeding and Management

2.4. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adhikari, B.B.; Chae, M.; Bressler, D.C. Utilization of slaughterhouse waste in value-added applications: Recent advances in the development of wood adhesives. Polymers 2018, 10, 176. [Google Scholar] [CrossRef]

- Limeneh, D.Y.; Tesfaye, T.; Ayele, M.; Husien, N.M.; Ferede, E.; Haile, A.; Mengie, W.; Abuhay, A.; Gelebo, G.G.; Gibril, M.; et al. A comprehensive review on utilization of slaughterhouse by-product: Current status and prospect. Sustainability 2022, 14, 64–69. [Google Scholar] [CrossRef]

- Malenica, D.; Kass, M.; Bhat, R. Sustainable Management and Valorization of Agri-Food Industrial Wastes and By-products as Animal Feed: For Ruminants, Non-Ruminants, and Poultry Feed. Sustainability 2022, 15, 117. [Google Scholar] [CrossRef]

- Shirazi, J.; Ghoorchi, T.; Toghdory, A.; Almousavi, S.M.M. Investigating the Effect of Replacing Soybean Meal with Poultry Slaughterhouse Waste Mixed with Rice Bran and Urea on Performance, Blood and Rumen Parameters of Fattening Lambs. Res. Anim. Prod. 2023, 13, 110–117. [Google Scholar] [CrossRef]

- Kazemi-Bonchenari, M.; Alizadeh, A.; Javadi, L.; Zohrevand, M.; Odongo, N.E.; Salem, A.Z. Use of poultry pre-cooked slaughterhouse waste as ruminant feed to prevent environmental pollution. J. Clean. Prod. 2017, 145, 151–156. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations, FAO. Agricultural Outlook 2023-32 Maps Key Output, Consumption, and Trade Trends. Available online: https://www.fao.org/documents/card/en/c/cc6361en (accessed on 13 April 2024).

- Colley, A.; Morten, B.; Olsen, I.; Hauschild, M.Z. Using a gate-to-gate LCA to apply circular economy principles to a food processing SME. J. Clean. Prod. 2020, 251, 119566. [Google Scholar] [CrossRef]

- Jayathilakan, K.; Sultana, K.; Radhakrishna, K.; Bawa, A.S. Utilization of byproducts and waste materials from meat, poultry, and fish processing industries: A review. J. Food Sci. Technol. 2012, 49, 278–293. [Google Scholar] [CrossRef] [PubMed]

- Izydorczyk, G.; Mikula, K.; Skrzypczak, D.; Witek-Krowiak, A.; Mironiuk, M.; Furman, K.; Gramza, M.; Moustakas, K.; Chojnacka, K. Valorization of poultry slaughterhouse waste for fertilizer purposes as an alternative for thermal utilization methods. J. Hazard. Mater. 2022, 424, 127328. [Google Scholar] [CrossRef] [PubMed]

- Rivera-Castellanos, J.; Marín-Peña, O.; Juarez Reyes, Z.M.; Sandoval-Herazo, M.; Nani, G.; Gonzalez-Moreno, H.R.; Sandoval-Herazo, L.C. Wastewater management from municipal slaughterhouses in Mexico: Quantities produced, existing legislation, treatment processes applied and future challenges. Renew. Energy Biomass Sustain. 2023, 5, 12–23. [Google Scholar] [CrossRef]

- Ragasri, S.; Sabumon, P.C. A critical review on slaughterhouse waste management and framing sustainable practices in managing slaughterhouse waste in India. J. Environ. Manag. 2023, 327, 116823. [Google Scholar]

- Arora, N.K.; Mishra, I. United Nations Sustainable Development Goals 2030, and environmental sustainability: Race against time. Environ. Sustain. 2019, 2, 339–342. [Google Scholar] [CrossRef]

- Iskakov, R.; Sugirbay, A. Technologies for the Rational Use of Animal Waste: A Review. Sustainability 2023, 15, 2278. [Google Scholar] [CrossRef]

- Franke-Whittle, I.H.; Insam, H. Treatment alternatives of slaughterhouse wastes, and their effect on the inactivation of different pathogens: A review. Crit. Rev. Microbiol. 2013, 39, 139–151. [Google Scholar] [CrossRef] [PubMed]

- Knaus, W.F.; Beermann, D.H.; Robinson, T.F.; Fox, D.G.; Finnerty, K.D. Effects of a dietary mixture of meat and bone meal, feather meal, blood meal, and fish meal on nitrogen utilization in finishing Holstein steers. J. Anim. Sci. 1998, 76, 1481–1487. [Google Scholar] [CrossRef] [PubMed]

- Klemesrud, M.J.; Klopfenstein, T.J.; Lewis, A.J. Complementary responses between feather meal and poultry by-product meal with or without ruminally protected methionine and lysine in growing calves. J. Anim. Sci. 1998, 76, 1970–1975. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Muia, J.M.K.; Tamminga, S.; Mbugua, P.N.; Kariuki, J.N. Effect of supplementing napier grass (Pennisetum purpureum) with poultry litter and sunflower meal based concentrates on feed intake and rumen fermentation in Friesian steers. Anim. Feed Sci. Technol. 2001, 92, 113–126. [Google Scholar] [CrossRef]

- Ayangbile, O.A.; Tallam, S.K.; Surtan, M.S. Processing of slaughterhouse blood and poultry litter and the effects on nutrient digestibility by steers. Anim. Feed Sci. Technol. 1993, 40, 153–164. [Google Scholar] [CrossRef]

- Ashayerizadeh, O.; Dastar, B.; Samadi, F.; Khomeiri, M.; Yamchi, A.; Zerehdaran, S. Study on the chemical and microbial composition and probiotic characteristics of dominant lactic acid bacteria in fermented poultry slaughterhouse waste. Waste Manag. 2017, 65, 178–185. [Google Scholar] [CrossRef] [PubMed]

- Lallo, C.H.O.; Garcia, G.W. Poultry by-product meal as a substitute for soybean meal in the diets of growing hair sheep lambs fed whole chopped sugarcane. Small Rumin. Res. 1994, 14, 107–114. [Google Scholar] [CrossRef]

- Lebzien, P.; Riemeir, A.; Flachowsky, G. Investigations on the effect of the ruminal N-balance on rumen metabolism, urea content in blood serum and milk as well as some liver parameters of lactating cows. Arch. Anim. Nutr. 2006, 60, 99–109. [Google Scholar] [CrossRef]

- Huhtanen, P.; Hristov, A.N. A meta-analysis of the effects of dietary protein concentration and degradability on milk protein yield and milk N efficiency in dairy cows. J. Dairy Sci. 2009, 92, 3222–3232. [Google Scholar] [CrossRef] [PubMed]

- Hristov, A.N.; Hanigan, M.; Cole, A.; Todd, R.; McAllister, T.A.; Ndegwa, P.M.; Rotz, A. Ammonia emissions from dairy farms and beef feedlots: A review. Can. J. Anim. Sci. 2011, 91, 1–35. [Google Scholar] [CrossRef]

- Leiber, F. Resigning protein concentrates in dairy cattle nutrition: A problem or a chance? Org. Agric. 2014, 4, 269–273. [Google Scholar] [CrossRef]

- Külling, D.R.; Menzi, H.; Kröber, T.F.; Neftel, A.; Sutter, F.; Lischer, P.; Kreuzer, M. Emissions of ammonia, nitrous oxide and methane from different types of dairy manure during storage as affected by dietary protein content. J. Agric. Sci. 2001, 137, 235–250. [Google Scholar] [CrossRef]

- Cameron, K.C.; Di, H.J.; Moir, J.L. Nitrogen losses from the soil/plant system: A review. Ann. Appl. Biol. 2013, 162, 145–173. [Google Scholar] [CrossRef]

- Dijkstra, J.; Bannink, A.; Bosma, P.M.; Lantinga, E.A.; Reijs, J.W. Modelling the effect of nutritional strategies for dairy cows on the composition of excreta nitrogen. Front. Sustain. Food Syst. 2018, 2, 63. [Google Scholar] [CrossRef]

- Bergen, W.G. Contribution of research with farm animals to protein metabolism concepts: A historical perspective. J. Nutr. 2007, 137, 706–710. [Google Scholar] [CrossRef] [PubMed]

- Schwab, C.G.; Broderick, G.A. A 100-Year Review: Protein and amino acid nutrition in dairy cows. J. Dairy Sci. 2017, 100, 10094–10112. [Google Scholar] [CrossRef] [PubMed]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis, 15th ed.; Association of Official Analytic Chemist: Washington, DC, USA, 2016. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral detergent fiber, and nonostarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Hristov, A.N.; Bannink, A.; Crompton, L.A. Invited review: Nitrogen in ruminant nutrition: A review of measurement techniques. J. Dairy Sci. 2019, 102, 5811–5852. [Google Scholar] [CrossRef]

- Burroughs, W.; Nelson, D.K.; Mertens, D.R. Protein physiology and its application in the lactating cow: The metabolizable protein feeding standard. J. Anim. Sci. 1975, 41, 933–944. [Google Scholar] [CrossRef] [PubMed]

- Freeman, S.R. Utilization of Poultry Byproducts as Protein Sources in Ruminant Diets. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2008. [Google Scholar]

- Lu, C.D.; Potchoiba, M.J.; Sahlu, T.; Fernandez, J.M. Performance of dairy goats fed isonitrogenous diets containing soybean meal or hydrolyzed feather meal during early lactation. Small Rumin. Res. 1990, 3, 425–434. [Google Scholar] [CrossRef]

- Andrighetto, I.; Bailoni, L. Effect of different animal protein sources on digestive and metabolic parameters and milk production in dairy goats. Small Rumin. Res. 1994, 13, 127–132. [Google Scholar] [CrossRef]

- Bohnert, D.W.; Larson, B.T.; Lewis, S.J.; Richards, C.J.; Swanson, K.C.; Harmon, D.L.; Mitchell Jr, G.E. Net nutrient flux in visceral tissues of lambs fed diets differing in supplemental nitrogen source. J. Anim. Sci. 1999, 77, 2545–2553. [Google Scholar] [CrossRef]

- Lewis, S.J.; Larson, B.T.; Ely, D.G. Effect of Poultry By Product Meal on Growth, Carcass Traits and Muscle Accretion of Finishing Lambs. J. Anim. Sci. 2000, 81, 31. [Google Scholar]

- Bohnert, D.W.; Larson, B.T.; Bauer, M.L.; Branco, A.F.; McLeod, K.R.; Harmon, D.L.; Mitchell Jr, G.E. Nutritional evaluation of poultry by-product meal as a protein source for ruminants: Effects on performance and nutrient flow and disappearance in steers. J. Anim. Sci. 1998, 76, 2474–2484. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Tovilla-Esponoza, C.; Lee-Rangel, H.A.; Hernandez-García, P.A.; Rosales-Nieto, C.; Roque-Jiménez, J.A.; Ponce, J.L. Thermoprocessed whole or ground soybean (Glycine max) on in vitro digestibility, nitrogen balance and performance in ewes lambs. Ecosistemas Recur. Agropecu. 2019, 6, 587–593. [Google Scholar]

- Kamalak, A.D.E.M.; Canbolat, O.; Gurbuz, Y.A.V.U.Z.; Ozay, O. In situ ruminal dry matter and crude protein degradability of plant- and animal-derived protein sources in Southern Turkey. Small Rumin. Res. 2005, 58, 135–141. [Google Scholar] [CrossRef]

- Schwab, C.G.; Huhtanen, P.; Hunt, C.W.; Hvelplund, T. Nitrogen requirements of cattle. In Nitrogen and Phosphorus Nutrition of Cattle: Reducing the Environmental Impact of Cattle Operations; CABI Publishing: Wallingford, UK, 2005; pp. 13–70. [Google Scholar]

- El-Sabban, F.F.; Bratzler, J.W.; Long, T.A.; Frear, D.E.H.; Gentry, R.F. Value of processed poultry waste as a ruminant feed. J. Anim. Sci. 1970, 31, 107–111. [Google Scholar] [CrossRef]

- Sharifi, A.; Chaji, M. Effects of processed recycled poultry bedding with tannins extracted from pomegranate peel on lambs’ nutrient digestibility and growth performance. S. Afr. J. Anim. Sci. 2019, 49, 290–300. [Google Scholar] [CrossRef]

- Skene, K.R. Circles, spirals, pyramids and cubes: Why the circular economy cannot work. Sustain. Sci. 2018, 13, 479–492. [Google Scholar] [CrossRef]

- Velenturf, A.; Purnell, P. Principles for sustainable circular economy. Sustain. Prod. Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

| Ingredients | Diets 1 | ||

|---|---|---|---|

| CTRL | SSW | PSW | |

| Sorghum stubble, % | 29.0 | 25.0 | 24.0 |

| Ground corn, % | 12.0 | 10.7 | 11.0 |

| Rolled corn, % | 12.0 | 10.7 | 11.0 |

| Ground sorghum, % | 20.0 | 22.0 | 22.0 |

| Soybean paste, % | 12.0 | 0.00 | 0.00 |

| PSW 1, % | 0.00 | 0.00 | 15.0 |

| SSW 2, % | 0.00 | 15.5 | 0.00 |

| Ground peanut, % | 7.00 | 6.00 | 8.00 |

| Molasses, % | 8.00 | 8.00 | 8.00 |

| Mineral salt, % | 1.00 | 1.00 | 1.00 |

| Chemical composition (% DM) | |||

| Dry material (%) | 69.8 | 69.5 | 73.3 |

| Crude protein (%) | 12.6 | 12.6 | 13.3 |

| Neutral detergent fiber (%) | 52.2 | 61.9 | 53.8 |

| Ethereal extract (%) | 7.81 | 9.80 | 11.9 |

| Ash (%) | 10.2 | 10.8 | 8.55 |

| Variables 2 | Diets 3 | SEM 4 | ||

|---|---|---|---|---|

| CTRL | PSW | SSW | ||

| IBW, kg | 25.33 | 25.45 | 25.43 | 1.22 |

| FBW, kg | 30.66 | 32.14 | 32.13 | 1.84 |

| DMI, kg animal−1 day−1 | 1.66 | 1.71 | 1.64 | 0.87 |

| ADG, g animal−1 day−1 | 191.14 b | 238.4 a | 240.3 a | 15.97 |

| FCR | 8.6 a | 7.17 b | 6.82 b | 0.23 |

| Variables 2 | Diets 3 | SEM 4 | ||

|---|---|---|---|---|

| CTRL | PSW | SSW | ||

| N intake, g/d | 33.35 | 34.19 | 33.44 | 7.41 |

| N Fecal, g/d | 5.40 b | 5.75 b | 6.04 a | 0.86 |

| N Urine, g/d | 1.63 c | 1.91 b | 2.22 a | 0.04 |

| N Retained, g/d | 26.32 a | 26.53 a | 25.18 b | 1.58 |

| N Excreted, g/d | 7.03 b | 7.66 ab | 8.26 a | 0.9 |

| Variables 2 | Diets 3 | SEM 4 | ||

|---|---|---|---|---|

| CTRL | PSW | SSW | ||

| CP, % | 12.6 | 13.3 | 12.6 | 1.28 |

| OM digestibility, % | 76.4 | 75.6 | 75.9 | 3.86 |

| CP digestibility, % | 82.2 | 81.4 | 79.6 | 1.85 |

| SPMe, g/kg | 79.8 | 78.9 | 79.3 | 0.67 |

| SPMp, g/kg | 103.6 | 108.3 | 100.2 | 2.70 |

| PMp, g/kg | 91.1 | 96.9 | 91.4 | 4.53 |

| PMe, g/kg | 71.9 | 73.4 | 74.6 | 0.99 |

| PMp g/d | 151.1 | 165.6 | 149.8 | 4.81 |

| PMe g/d | 119.5 | 125.5 | 122.3 | 3.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perez-Bautista, J.d.J.; Alvarez-Fuentes, G.; Garcia-Lopez, J.C.; Martinez-Martinez, R.; Roque-Jimenez, J.A.; Ghavipanje, N.; Vargas-Bello-Pérez, E.; Lee-Rangel, H.A. Biotransforming of Poultry and Swine Slaughterhouse Waste as an Alternative Protein Source for Ruminant Feeding. Nitrogen 2024, 5, 518-528. https://doi.org/10.3390/nitrogen5020034

Perez-Bautista JdJ, Alvarez-Fuentes G, Garcia-Lopez JC, Martinez-Martinez R, Roque-Jimenez JA, Ghavipanje N, Vargas-Bello-Pérez E, Lee-Rangel HA. Biotransforming of Poultry and Swine Slaughterhouse Waste as an Alternative Protein Source for Ruminant Feeding. Nitrogen. 2024; 5(2):518-528. https://doi.org/10.3390/nitrogen5020034

Chicago/Turabian StylePerez-Bautista, José de Jesús, Gregorio Alvarez-Fuentes, Juan Carlos Garcia-Lopez, Ricardo Martinez-Martinez, José Alejandro Roque-Jimenez, Navid Ghavipanje, Einar Vargas-Bello-Pérez, and Héctor A. Lee-Rangel. 2024. "Biotransforming of Poultry and Swine Slaughterhouse Waste as an Alternative Protein Source for Ruminant Feeding" Nitrogen 5, no. 2: 518-528. https://doi.org/10.3390/nitrogen5020034

APA StylePerez-Bautista, J. d. J., Alvarez-Fuentes, G., Garcia-Lopez, J. C., Martinez-Martinez, R., Roque-Jimenez, J. A., Ghavipanje, N., Vargas-Bello-Pérez, E., & Lee-Rangel, H. A. (2024). Biotransforming of Poultry and Swine Slaughterhouse Waste as an Alternative Protein Source for Ruminant Feeding. Nitrogen, 5(2), 518-528. https://doi.org/10.3390/nitrogen5020034