A Data-Driven Machine Learning Approach for Corrosion Risk Assessment—A Comparative Study

Abstract

1. Introduction

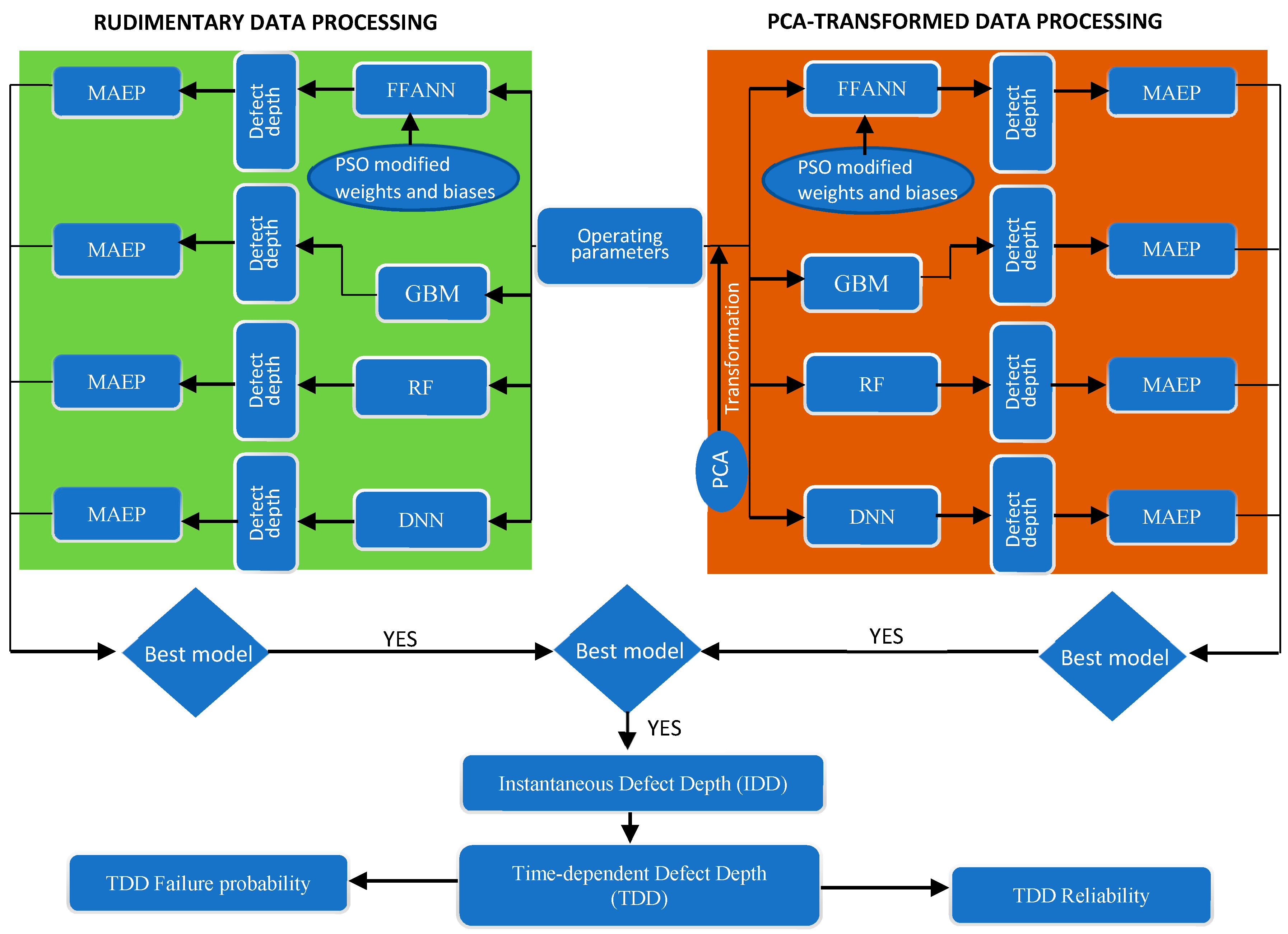

- Implementing a data-driven Principal Component Analysis, Particle Swarm Optimization and Feed-Forward Artificial Neural Network (PCA-PSO-FFANN) model and comparing the results with Principal Component Analysis and Gradient Boosting Machine (PCA-GBM), Principal Component Analysis and Random Forest (PCA-RF) and Principal Component Analysis and Deep Neural Network (PCA-DNN) models to establish a robust algorithm for corrosion defect depth estimation.

- Developing a technique for using the robust PCA transformed machine learning algorithm to determine the failure probability and reliability of the pipeline using the hazard function of the pipe-wall thickness loss.

2. Research Methodology

2.1. Development of the Corrosion Risk Assessment (CRA) Model

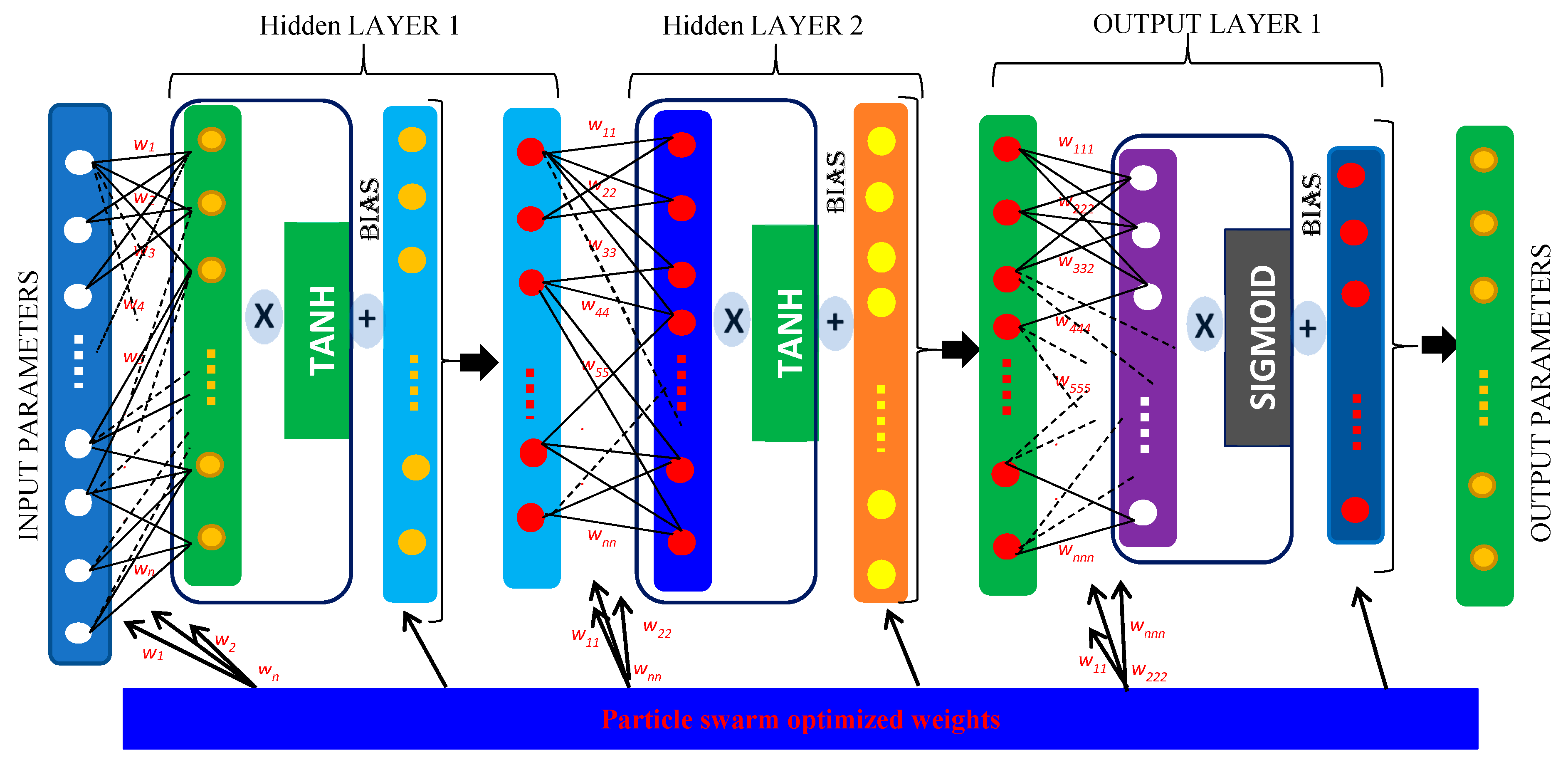

2.2. PCA-PSO-FFANN Modelling Algorithm

2.2.1. Principal Component Analysis (PCA) Transformation

2.2.2. Feed-Forward Artificial Neural Network (FFANN) Modelling

2.3. PCA-Gradient Boosting Machine (GBM) Algorithm

2.4. PCA-Random Forest (RF) Algorithm

2.5. PCA-Deep Neural Network (DNN) Algorithm

3. Time-Dependent Reliability Modelling

4. Industrial Experiment and Application

- Randomly generate 20,000 uniform distribution of the operating parameters to sufficiently represent different data combinations of the operating parameters and corrosion defect depth growth.

- Compute the corrosion defect depths growth rate based on Equation (25).

- Randomly select 5000 samples of the corrosion defect depth and the operating parameters ensuring that the values are not more than ±25% of the original values. This variability is to give room for noises that are characteristics of field data operating in varying conditions. Since small changes in some of the operating parameters of the pipelines can result in corrosion defect growth changes [47,48,49], it is important to account for possible variation of the data beyond the original boundaries. This is vital for improving the quality of the model to cope with unexpected changes in the operating parameters characteristics and the attendant impact on the corrosion defect growth.

- The dataset is used for training and validation in a 5-fold cross-ensemble validation training model having 20% of the original dataset for validation.

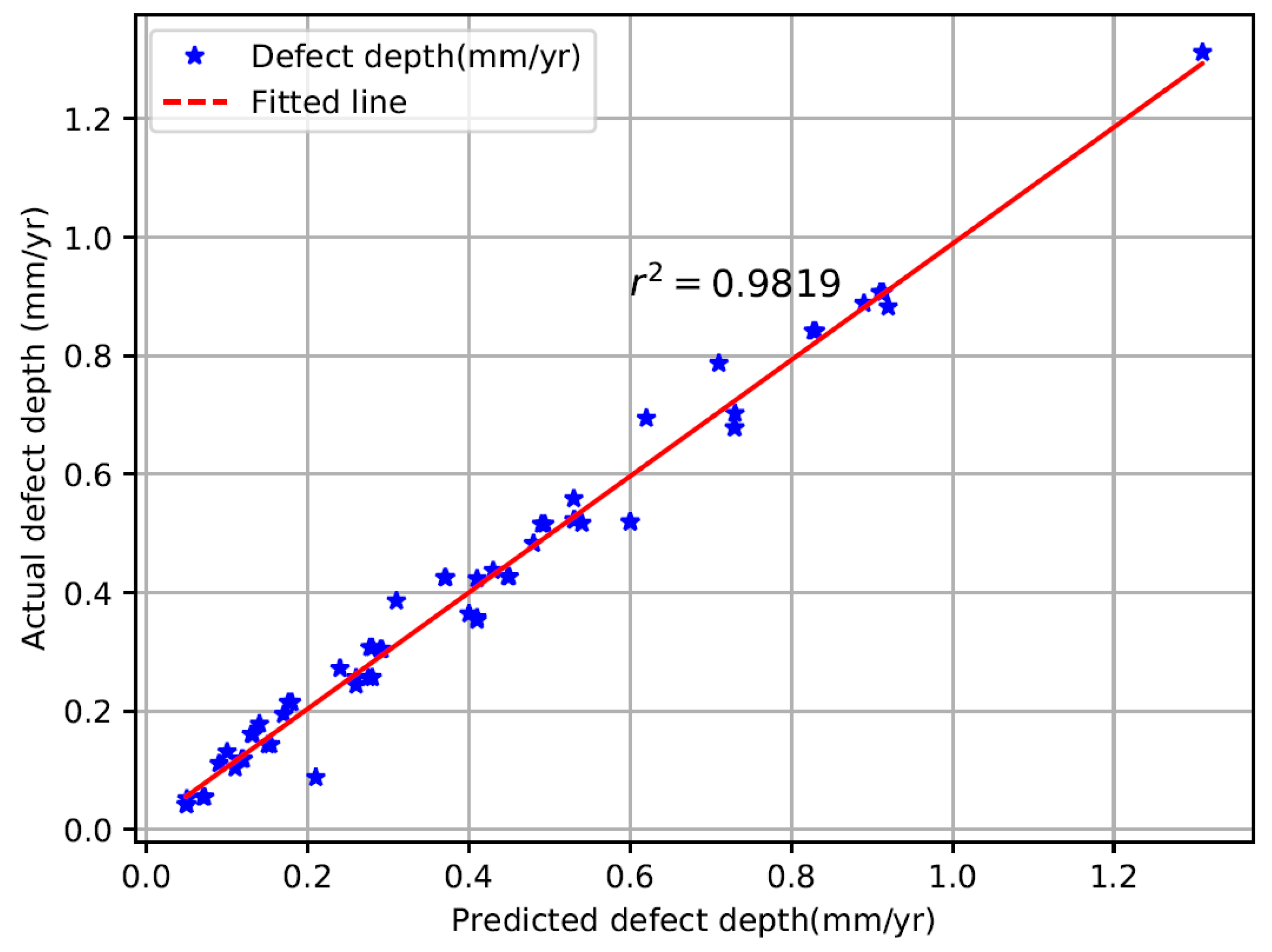

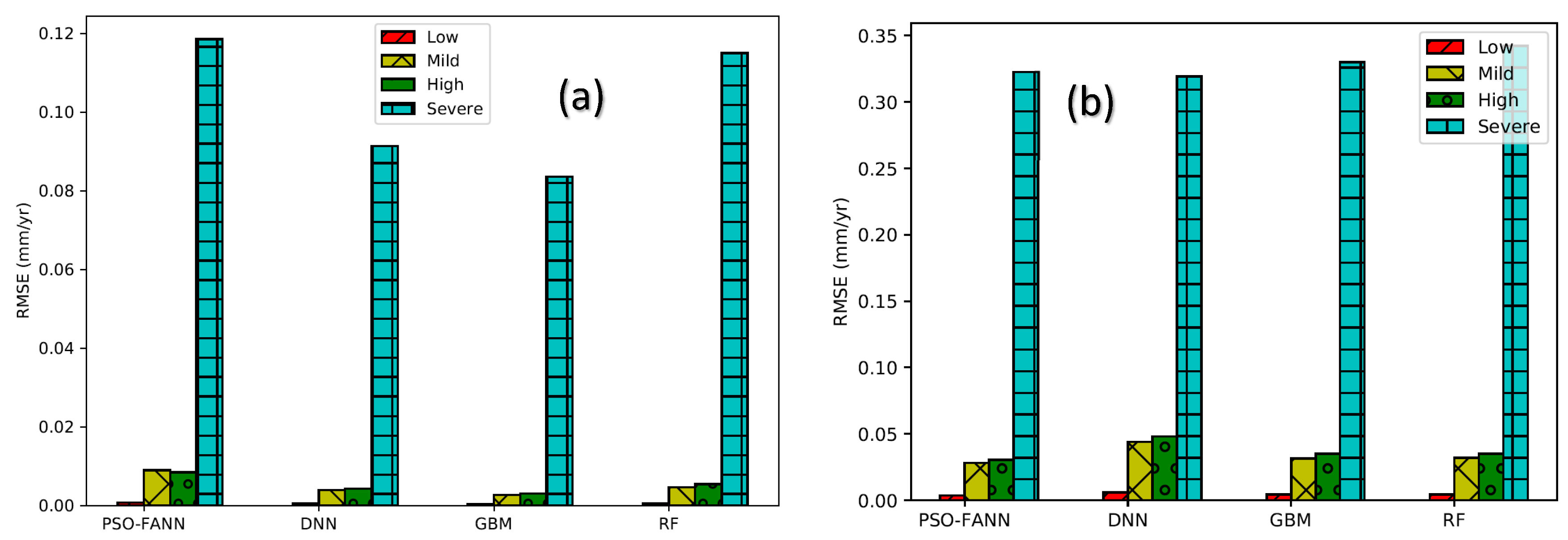

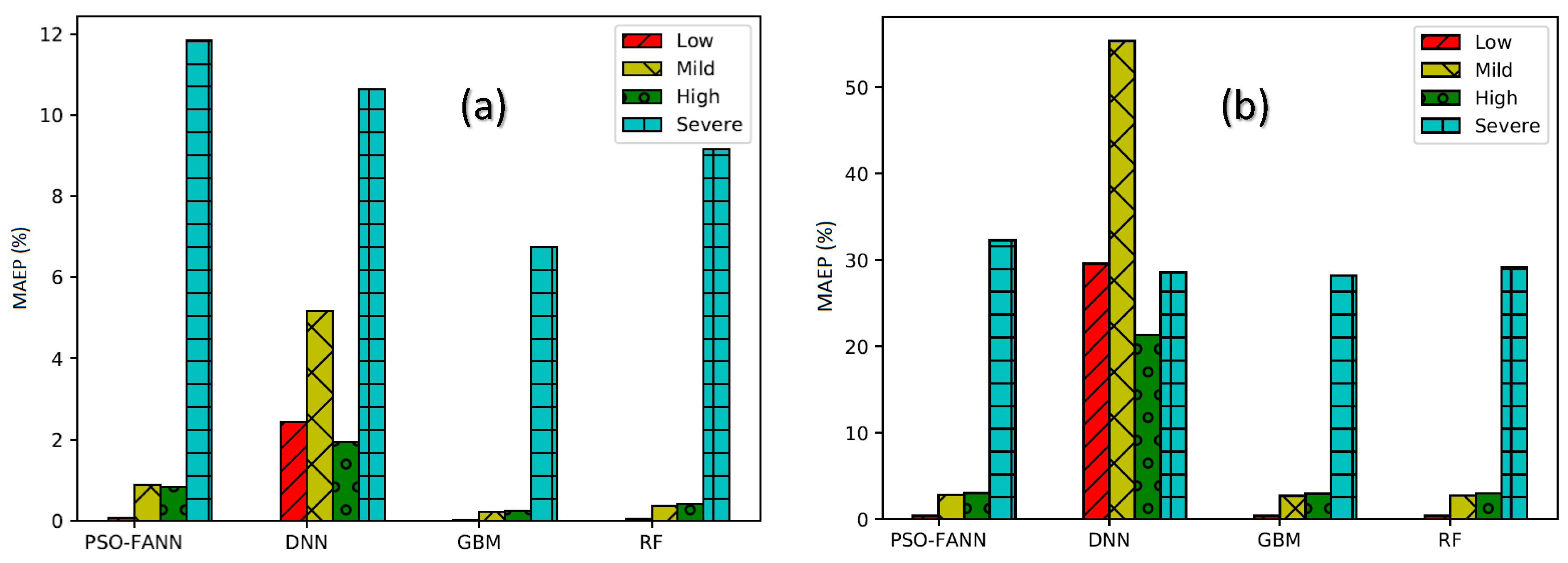

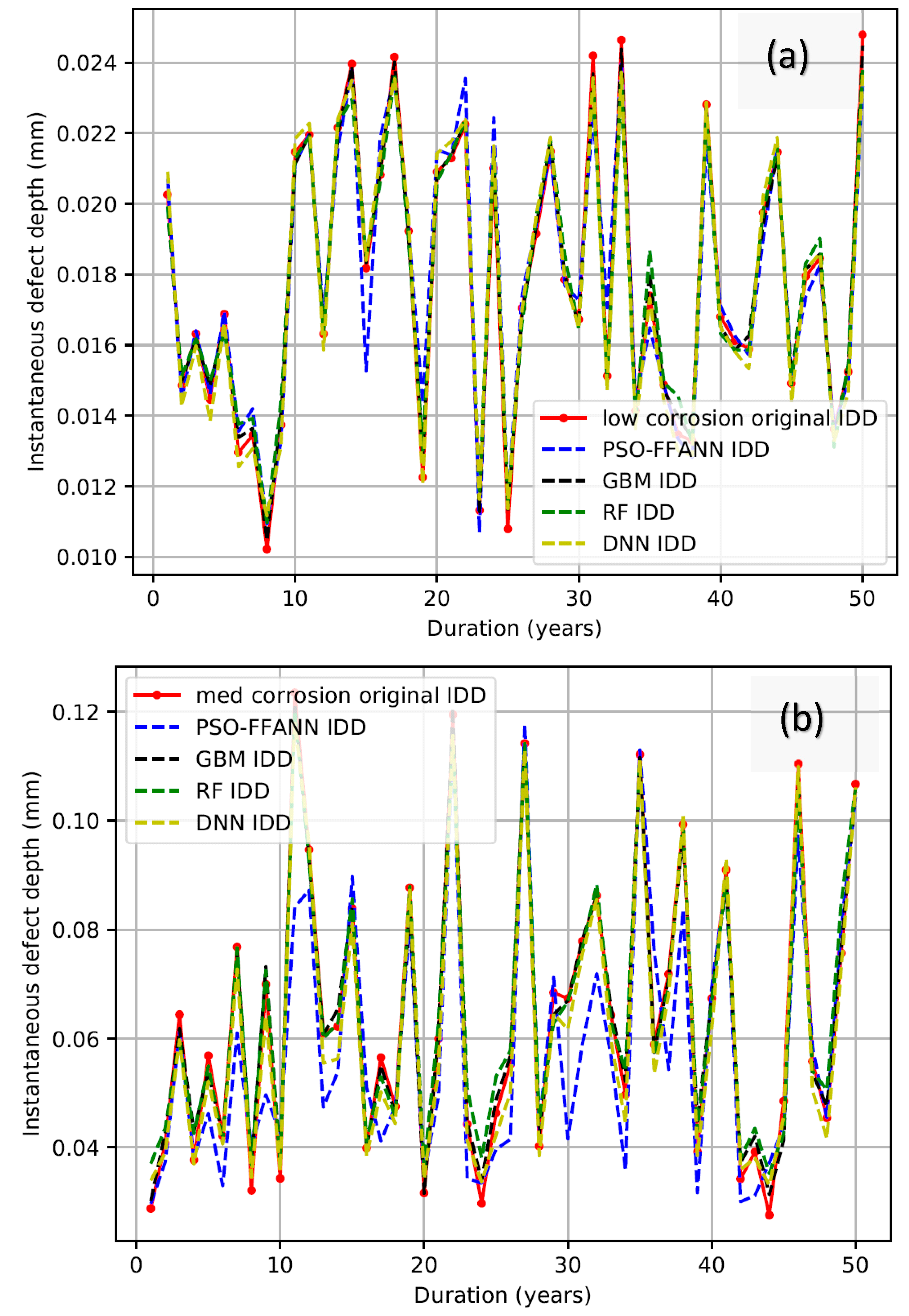

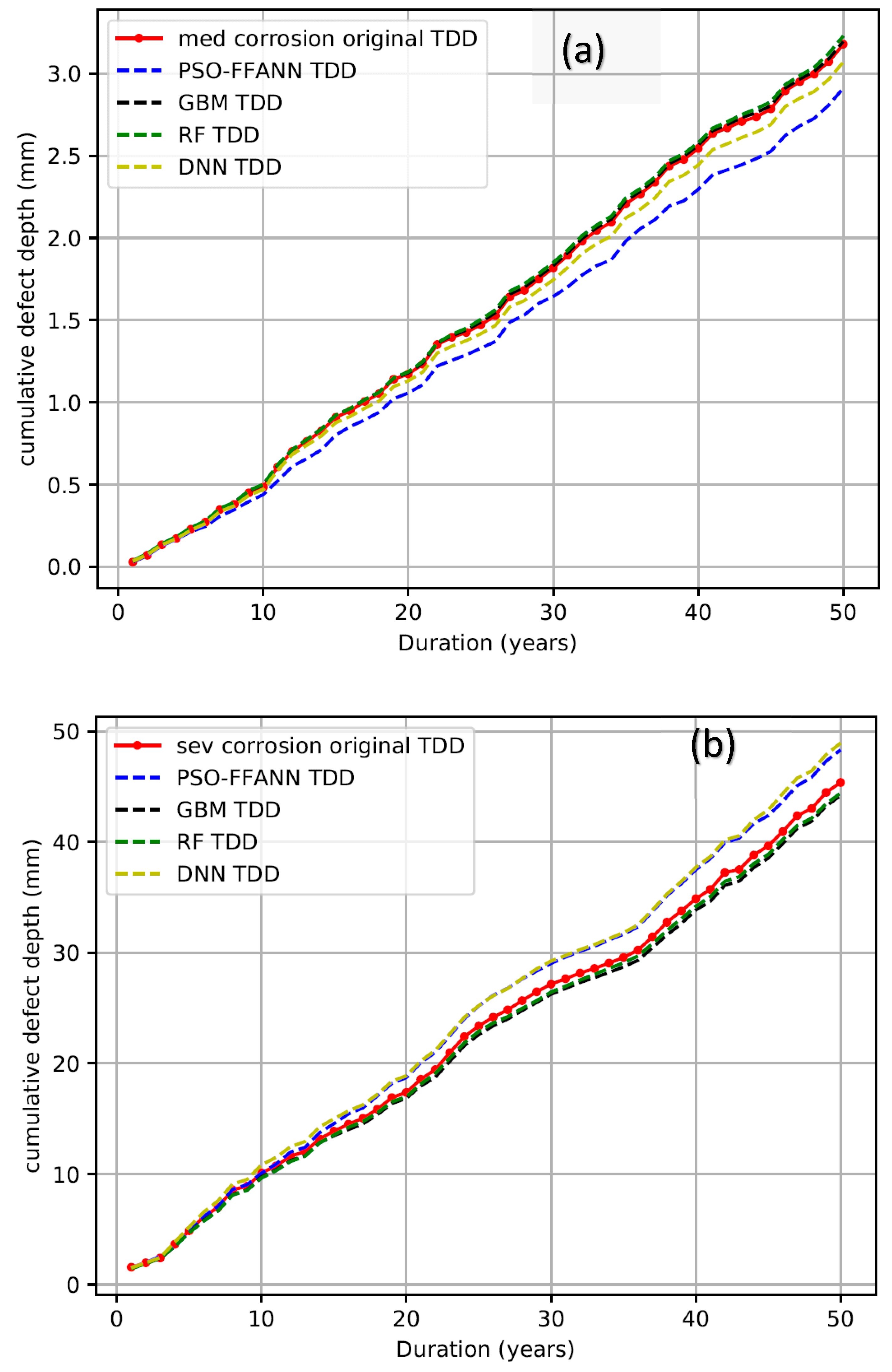

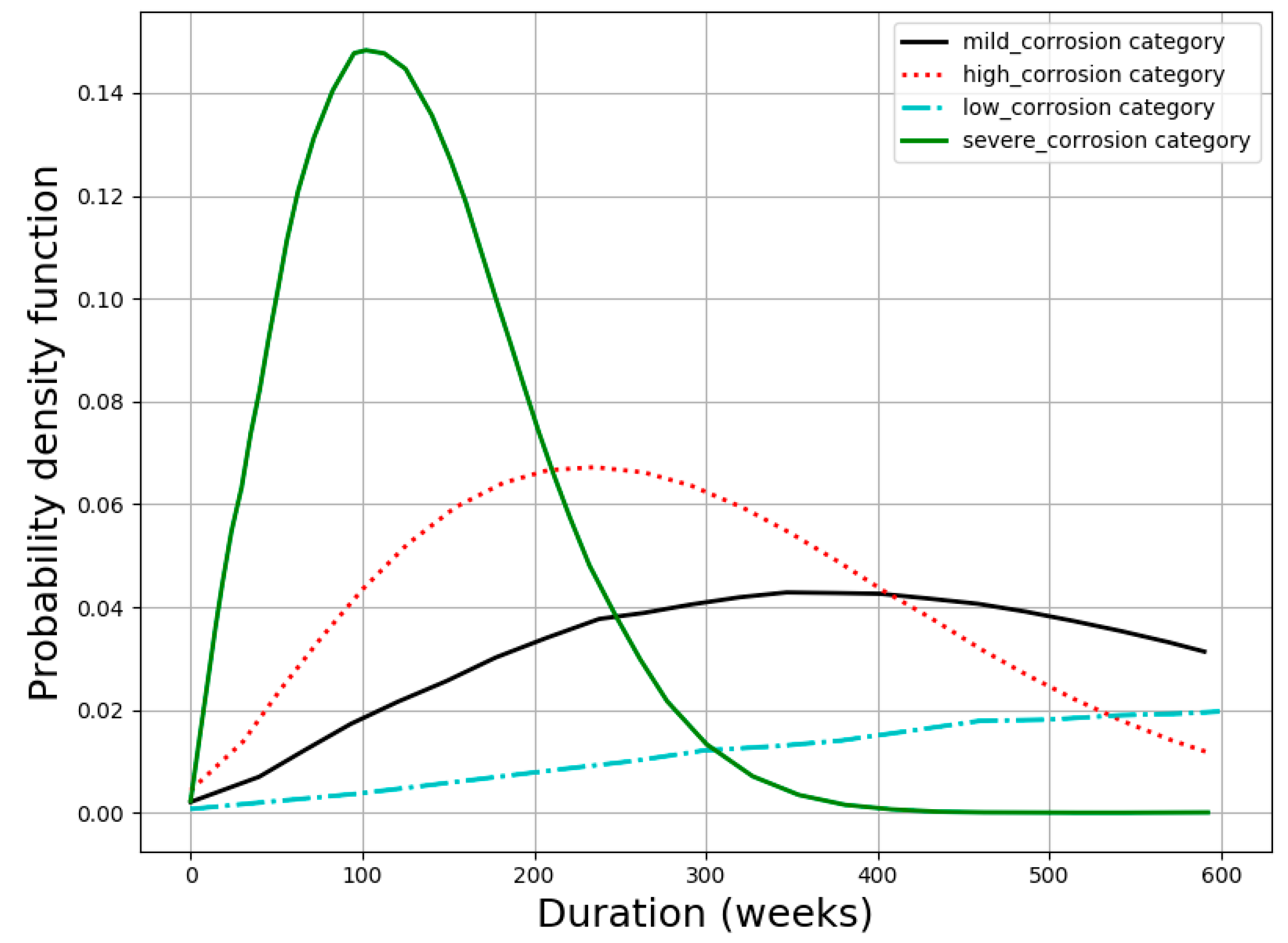

5. Results and Discussion

5.1. Estimation of the Instantaneous Defect Depth (IDD) and Time-Dependent Defect Depth (TDD) Growth

5.2. Time-Dependent Reliability Estimation

6. Conclusions

- Understand the expected time-dependent changes in the corrosion defect depth growth trajectory using the variabilities in the historical operating parameters and the corrosion defect depths growth rates.

- Provide a handy tool for planning the pipeline integrity management by providing a guide to experts on the expected pipe wall thickness loss over a given time interval.

- Give baseline information for effective management of the quality of the operating parameters, thereby maintaining a low cost of production in a safe operating environment.

- Implement a microscale corrosion defect depth estimation since corrosion degradation in the pipeline is a continuous process, thereby opening a new frontier for quick and effective decisions on pipeline integrity management.

Funding

Conflicts of Interest

Data Availability

References

- Ossai, C.I.; Boswell, B.; Davies, I.J. Pipeline failures in corrosive environments–A conceptual analysis of trends and effects. Eng. Fail. Anal. 2015, 53, 36–58. [Google Scholar] [CrossRef]

- Papavinasam, S.; Doiron, A.; Revie, R.W. Effect of surface layers on the initiation of internal pitting corrosion in oil and gas pipelines. Corrosion 2009, 65, 663–673. [Google Scholar] [CrossRef]

- Nordsveen, M.; Nešic, S.; Nyborg, R.; Stangeland, A. A mechanistic model for carbon dioxide corrosion of mild steel in the presence of protective iron carbonate films-Part 1: Theory and verification. Corrosion 2003, 59, 443–456. [Google Scholar] [CrossRef]

- Nešić, S. Key issues related to modelling of internal corrosion of oil and gas pipelines–A review. Corros. Sci. 2007, 49, 4308–4338. [Google Scholar] [CrossRef]

- Bazan, F.A.V.; Beck, A.T. Stochastic process corrosion growth models for pipeline reliability. Corros. Sci. 2013, 74, 50–58. [Google Scholar] [CrossRef]

- Melchers, R.E. Estimating uncertainty in maximum pit depth from limited observational data. Corros. Eng. Sci. Technol. 2010, 45, 240–248. [Google Scholar] [CrossRef]

- Melchers, R.E.; Jeffrey, R. Early corrosion of mild steel in seawater. Corros. Sci. 2005, 47, 1678–1693. [Google Scholar] [CrossRef]

- Nesic, S.; Postlethwaite, J. Relationship between the structure of disturbed flow and erosion-corrosion. Corrosion 1990, 46, 874–880. [Google Scholar] [CrossRef]

- Hu, X.; Neville, A. CO2 erosion–corrosion of pipeline steel (API X65) in oil and gas conditions—A systematic approach. Wear 2009, 267, 2027–2032. [Google Scholar] [CrossRef]

- Sheikh, A.K.; Boah, J.K.; Hansen, D.A. Statistical modeling of pitting corrosion and pipeline reliability. Corrosion 1990, 46, 190–197. [Google Scholar] [CrossRef]

- Caleyo, F.; Velázquez, J.C.; Valor, A.; Hallen, J.M. Markov chain modelling of pitting corrosion in underground pipelines. Corros. Sci. 2009, 51, 2197–2207. [Google Scholar] [CrossRef]

- Ossai, C.I.; Boswell, B.; Davies, I. Markov chain modelling for time evolution of internal pitting corrosion distribution of oil and gas pipelines. Eng. Fail. Anal. 2016, 60, 209–228. [Google Scholar] [CrossRef]

- Cai, J.; Cottis, R.A.; Lyon, S.B. Phenomenological modelling of atmospheric corrosion using an artificial neural network. Corros. Sci. 1999, 41, 2001–2030. [Google Scholar] [CrossRef]

- Abbas, M.H.; Norman, R.; Charles, A. Neural network modelling of high-pressure CO2 corrosion in pipeline steels. Process Saf. Environ. Prot. 2018, 119, 36–45. [Google Scholar] [CrossRef]

- Arzaghi, E.; Abbassi, R.; Garaniya, V.; Binns, J.; Chin, C.; Khakzad, N.; Reniers, G. Developing a dynamic model for pitting and corrosion-fatigue damage of subsea pipelines. Ocean Eng. 2018, 150, 391–396. [Google Scholar] [CrossRef]

- De Masi, G.; Vichi, R.; Gentile, M.; Bruschi, R.; Gabetta, G. A Neural Network Predictive Model of Pipeline Internal Corrosion Profile. In Proceedings of the IEEE SIMS, Washington, DC, USA, 29 April–1 May 2014. [Google Scholar]

- Askari, M.; Aliofkhazraei, M.; Ghaffari, S.; Hajizadeh, A. Film former corrosion inhibitors for oil and gas pipelines—A technical review. J. Nat. Gas Sci. Eng. 2018, 58, 92–114. [Google Scholar] [CrossRef]

- Cheng, A.; Chen, N.-Z. Corrosion fatigue crack growth modelling for subsea pipeline steels. Ocean Eng. 2017, 142, 10–19. [Google Scholar] [CrossRef]

- Dann, M.R.; Maes, M.A. Stochastic corrosion growth modeling for pipelines using mass inspection data. Reliab. Eng. Syst. Saf. 2018, 180, 245–254. [Google Scholar] [CrossRef]

- Velázquez, J.C.; Cruz-Ramirez, J.C.; Valor, A.; Venegas, V.; Caleyo, F.; Hallen, J.M. Modeling localized corrosion of pipeline steels in oilfield produced water environments. Eng. Fail. Anal. 2017, 79, 216–231. [Google Scholar] [CrossRef]

- Jančíková, Z.; Zimný, O.; Koštial, P. Prediction of metal corrosion by neural networks. Metalurgija 2013, 52, 379–381. [Google Scholar]

- Kenny, E.D.; Paredes, R.S.; de Lacerda, L.A.; Sica, Y.C.; de Souza, G.P.; Lázaris, J. Artificial neural network corrosion modeling for metals in an equatorial climate. Corros. Sci. 2009, 51, 2266–2278. [Google Scholar] [CrossRef]

- Cheng, Y.; Huang, W.L.; Zhou, C.Y. Artificial neural network technology for the data processing of on-line corrosion fatigue crack growth monitoring. Int. J. Press. Vessel. Pip. 1999, 76, 113–116. [Google Scholar] [CrossRef]

- Singer, M. Top-of-the-line corrosion. In Trends in Oil and Gas Corrosion Research and Technologies; Woodhead Publishing: Cambridge, Sawston, UK, 2017; pp. 385–408. [Google Scholar]

- Boyun, G.; Xinghui, L.; Xuehao, T. Chapter 22—Pipeline Pigging. Petroleum Production Engineering, 2nd ed.; Boyun, G., Xinghui, L., Xuehao, T., Eds.; Gulf Professional Publishing: Oxford, UK, 2017; pp. 701–720. ISBN 9780128093740. [Google Scholar] [CrossRef]

- Nianzhong, L.; Kaiming, C.; Jianhua, F. Intelligent Pigging Technology and Application for Gas Pipelines. Nat. Gas Ind. 2005, 25, 116. [Google Scholar]

- Yu, B.; Li, D.Y.; Grondin, A. Effects of the dissolved oxygen and slurry velocity on erosion–corrosion of carbon steel in aqueous slurries with carbon dioxide and silica sand. Wear 2013, 302, 1609–1614. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Lubeck, J.; Kilbane, J.J. Characterization of microbial communities in gas industry pipelines. Appl. Environ. Microbiol. 2003, 69, 5354–5363. [Google Scholar] [CrossRef]

- Abdi, H.; Williams, L.J. Principal component analysis. Wiley interdisciplinary reviews: Comput. Stat. 2010, 2, 433–459. [Google Scholar] [CrossRef]

- Coulibaly, P.; Baldwin, C.K. Nonstationary Hydrological Time Series Forecasting Using Nonlinear Dynamic Methods. J. Hydrol. 2005, 307, 174–307. [Google Scholar] [CrossRef]

- Shi, Y.; Eberhart, R.C. A Modified Particle Swarm Optimizer. In Proceedings of the IEEE International Conference on Evolutionary Computation, Anchorage, AK, USA, 4–9 May 1988; pp. 69–73. [Google Scholar]

- Wall, M.E.; Rechtsteiner, A.; Rocha, L.M. Singular value decomposition and principal component analysis. In A Practical Approach to Microarray Data Analysis; Springer: Boston, MA, USA, 2003; pp. 91–109. [Google Scholar]

- Lagerlund, T.D.; Sharbrough, F.W.; Busacker, N.E. Spatial filtering of multichannel electroencephalographic recordings through principal component analysis by singular value decomposition. J. Clin. Neurophysiol. 1997, 14, 73–82. [Google Scholar] [CrossRef]

- Natekin, A.; Alois, K. Gradient Boosting Machines, a Tutorial. Front. Neurorobotics 2013, 7, 21. [Google Scholar] [CrossRef]

- Friedman, J.H. Greedy Function Approximation: A Gradient Boosting Machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Ridgeway, G. Generalized Boosted Models: A Guide to the gbm Package. Update 1.1. 2007. Available online: http://btr0x2.rz.uni-bayreuth.de/math/statlib/R/CRAN/doc/vignettes/gbm/gbm.pdf (accessed on 15 December 2019).

- Chen, L.; Cheng, X. Classification of High-resolution Remotely Sensed Images Based on Random Forests. J. Softw. Eng. 2016, 10, 318–327. [Google Scholar] [CrossRef]

- Breiman, L. Bagging predictors. Mach. Learn. 1996, 24, 123–140. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Segal, M.R. Machine Learning Benchmarks and Random Forest Regression; Center for Bioinformatics and Molecular Biostatistics: UC San Francisco, CA, USA, 2004; Available online: https://escholarship.org/uc/item/35x3v9t4 (accessed on 12 January 2019).

- Brillante, L.; Gaiotti, F.; Lovat, L.; Vincenzi, S.; Giacosa, S.; Torchio, F.; Segade, S.R.; Rolle, L.; Tomasi, D. Investigating the use of gradient boosting machine, random forest and their ensemble to predict skin flavonoid content from berry physical–mechanical characteristics in wine grapes. Comput. Electron. Agric. 2015, 117, 186–193. [Google Scholar] [CrossRef]

- Ahammed, M. Probabilistic estimation of remaining life of a pipeline in the presence of active corrosion defects. Int. J. Press. Vessel. Pip. 1998, 75, 321–329. [Google Scholar] [CrossRef]

- Caleyo, F.; Gonzalez, J.L.; Hallen, J.M. A study on the reliability assessment methodology for pipelines with active corrosion defects. Int. J. Press. Vessel. Pip. 2002, 79, 77–86. [Google Scholar] [CrossRef]

- Rausand, M.; Høyland, A. System Reliability Theory: Models, Statistical Methods, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2004; Volume 396. [Google Scholar]

- Akpan, U.O.; Koko, T.S.; Ayyub, B.; Dunbar, T.E. Risk assessment of aging ship hull structures in the presence of corrosion and fatigue. Mar. Struct. 2002, 15, 211–231. [Google Scholar] [CrossRef]

- Ossai, C.I.; Boswell, B.; Davies, I.J. Predictive modelling of internal pitting corrosion of aged non-piggable pipelines. J. Electrochem. Soc. 2015, 162, C251–C259. [Google Scholar] [CrossRef]

- Nesic, S.; Lee, K.L.J.; Ruzic, V. A Mechanistic Model of Iron Carbonate Film Growth and the Effect on Co2 Corrosion of Mild Steel; CORROSION/2002, paper; 02237; NACE International: Houston, TX, USA, 2002. [Google Scholar]

- Mora-Mendoza, J.L.; Turgoose, S. Fe3C influence on the corrosion rate of mild steel in aqueous CO2 systems under turbulent flow conditions. Corros. Sci. 2002, 44, 1223–1246. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, G.; Wu, W.; Qiao, Q.; Li, Y.; Li, X. Effect of pH and chloride on the micro-mechanism of pitting corrosion for high strength pipeline steel in aerated NaCl solutions. Appl. Surf. Sci. 2015, 349, 746–756. [Google Scholar] [CrossRef]

- NACE Standard RP0775, Preparation, Installation, Analysis and Interpretation of Corrosion Coupons in Oilfield Operations; NACE International: Houston, TX USA, 2005.

| Input Variable | Description | Unit | Remark |

|---|---|---|---|

| TM | Temperature | °C | Water chemistry |

| PCO2 | CO2 Partial Pressure | MPa | |

| pH | pH | ||

| SO4 | sulphate ion concentration | g/ml | |

| CL | chloride ion concentration | g/ml | |

| FE | iron content | g/ml | |

| HCO3 | Total Alkalinity as HCO−3 | g/ml | |

| PS | Operating pressure | psi | |

| CA | Calcium concentration | g/ml | |

| BSW | Basic sediment and water | % | Flow characteristics |

| MMCFD | Million Cubic Feet per day of gas | mmcfd | |

| BOPD | Barrel of Oil production per day | bbl/day | |

| BWPD | Barrel of Water production per day | bbl/day |

| Variable | Description | Unit | Mean | st. dev | Min | Max |

|---|---|---|---|---|---|---|

| TM | Temperature | °C | 45.98 | 17.29 | 21 | 74 |

| PCO2 | CO2 Partial Pressure | MPa | 0.13 | 0.1 | 0.01 | 0.61 |

| pH | pH | 7.6 | 0.64 | 6.21 | 8.57 | |

| SO | sulphate ion concentration | g/mL | 34.31 | 20.37 | 2 | 70 |

| CL | chloride ion concentration | g/mL | 3168.79 | 2382.86 | 66 | 7571.14 |

| BSW | Basic sediment and water | % | 0.42 | 0.34 | 0.01 | 0.9 |

| MMCFD | Million Cubic Feet per day of gas | mmcfd | 8.54 | 5.17 | 0.2 | 17.54 |

| BOPD | Barrel of Oil production per day | bbl/day | 684.48 | 337.45 | 125 | 1565.97 |

| BWPD | Barrel of Water production per day | bbl/day | 1269.38 | 1965.96 | 1 | 9328 |

| FE | iron content | g/mL | 1.17 | 0.97 | 0.04 | 2.79 |

| HCO3 | Total Alkalinity as HCO−3 | g/mL | 2404.93 | 1161.44 | 152.5 | 4209 |

| PS | operating pressure | psi | 880.93 | 569.82 | 65 | 2050 |

| CA | Calcium concentration | g/mL | 1.11 | 0.79 | 0.02 | 2.56 |

| Dd | Max defect depth rate | mm/yr. | 0.4 | 0.28 | 0.05 | 1.31 |

| Algorithm | Original Data without Transformation | PCA Transformed | ||||||

|---|---|---|---|---|---|---|---|---|

| RMSE | MAEP | RMSE | MAEP | |||||

| Mean | std | Mean | std | Mean | std | Mean | std | |

| PSO-FFANN | 0.4117 | 0.0146 | 34.1329 | 1.3774 | 0.09601 | 0.0118 | 7.8588 | 1.1361 |

| GBM | 0.377 | 0.0054 | 31.9266 | 0.7906 | 0.0765 | 0.003 | 6.0082 | 0.13334 |

| RF | 0.3851 | 0.01 | 32.4267 | 0.9919 | 0.0973 | 0.0021 | 7.7421 | 0.099 |

| DNN | 0.2963 | 0.0343 | 23.647 | 2.427 | 0.0788 | 0.0277 | 6.6813 | 2.4862 |

| Corrosion Category | Mean | Std | Min | Max |

|---|---|---|---|---|

| low | 0.018 | 0.004 | 0.01 | 0.025 |

| Mild | 0.077 | 0.031 | 0.025 | 0.13 |

| High | 0.189 | 0.034 | 0.13 | 0.25 |

| Severe | 0.88 | 0.378 | 0.251 | 1.57 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ossai, C.I. A Data-Driven Machine Learning Approach for Corrosion Risk Assessment—A Comparative Study. Big Data Cogn. Comput. 2019, 3, 28. https://doi.org/10.3390/bdcc3020028

Ossai CI. A Data-Driven Machine Learning Approach for Corrosion Risk Assessment—A Comparative Study. Big Data and Cognitive Computing. 2019; 3(2):28. https://doi.org/10.3390/bdcc3020028

Chicago/Turabian StyleOssai, Chinedu I. 2019. "A Data-Driven Machine Learning Approach for Corrosion Risk Assessment—A Comparative Study" Big Data and Cognitive Computing 3, no. 2: 28. https://doi.org/10.3390/bdcc3020028

APA StyleOssai, C. I. (2019). A Data-Driven Machine Learning Approach for Corrosion Risk Assessment—A Comparative Study. Big Data and Cognitive Computing, 3(2), 28. https://doi.org/10.3390/bdcc3020028