Numerical Steady and Transient Evaluation of a Confined Swirl Stabilized Burner

Abstract

:1. Introduction

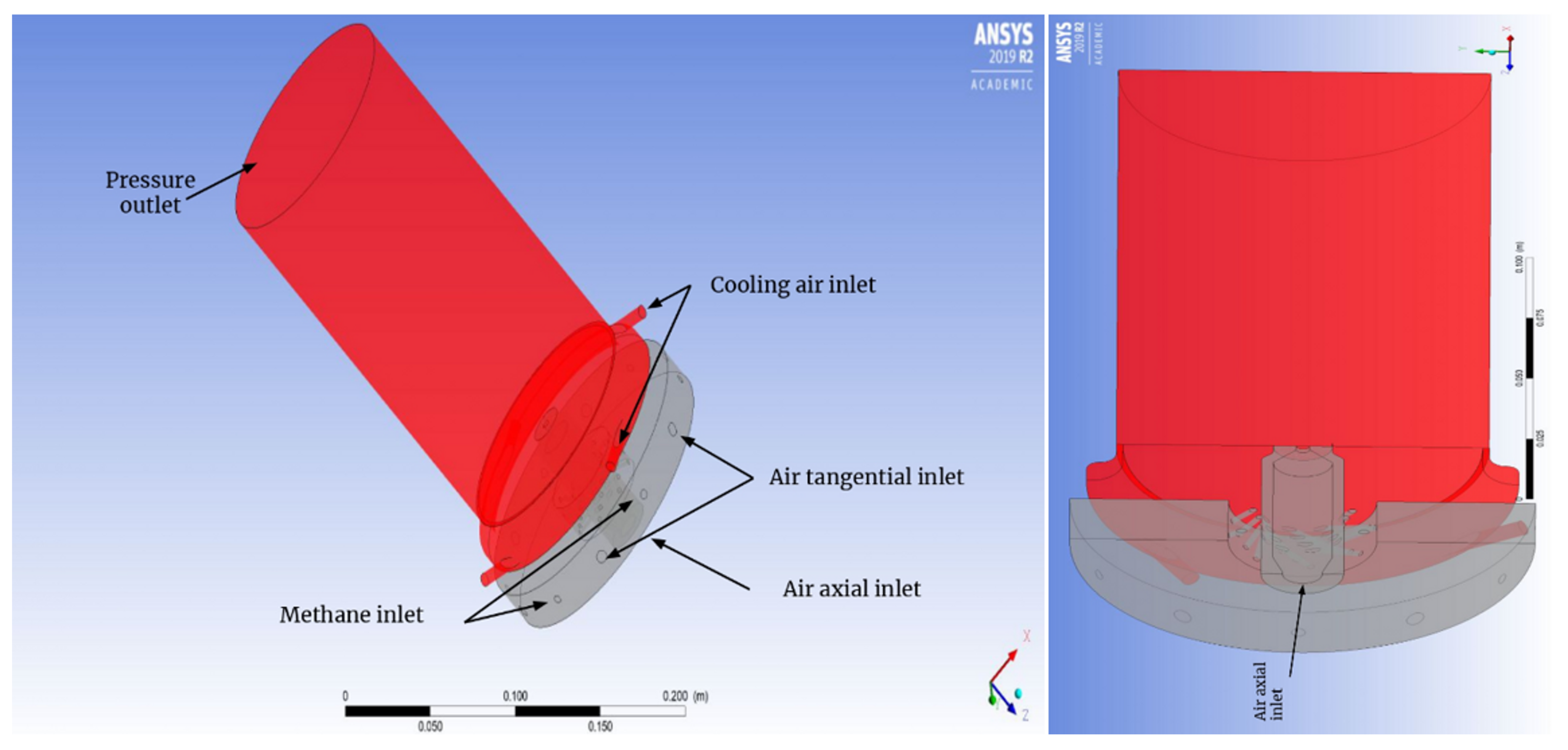

2. Combustor Domain Investigated

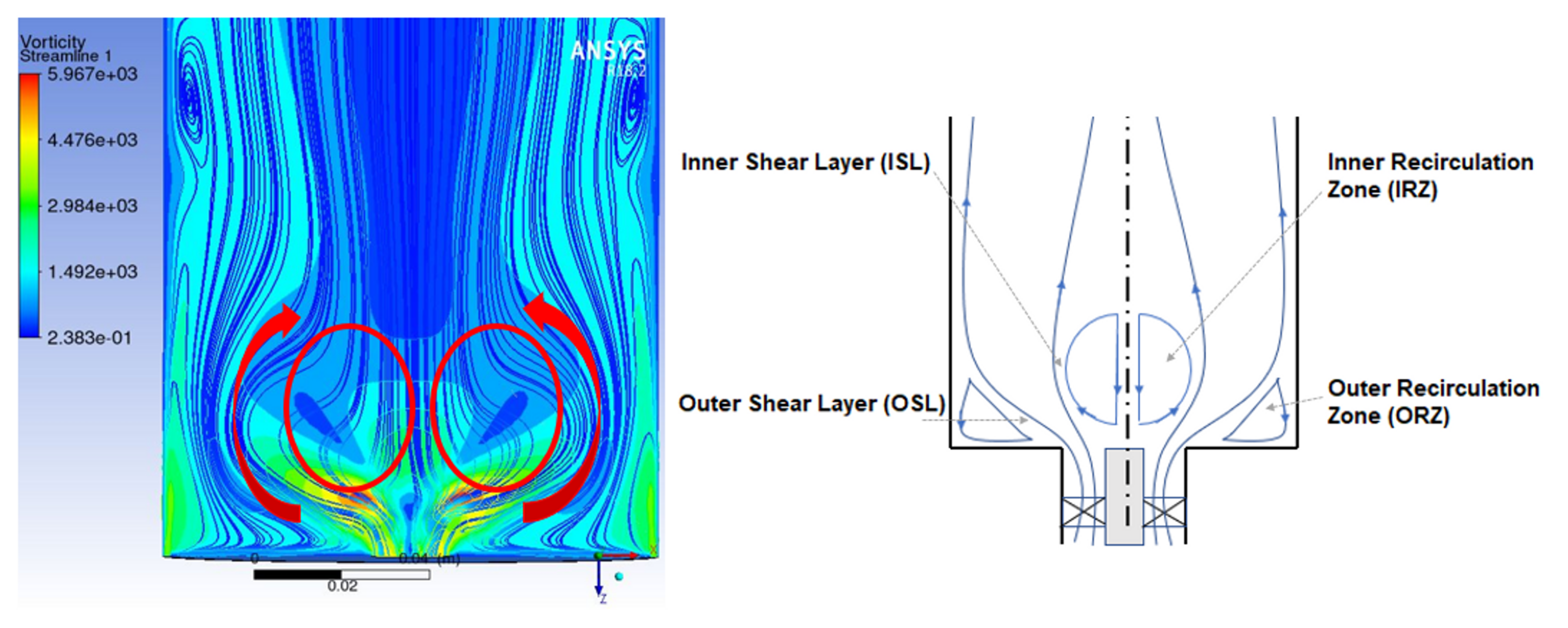

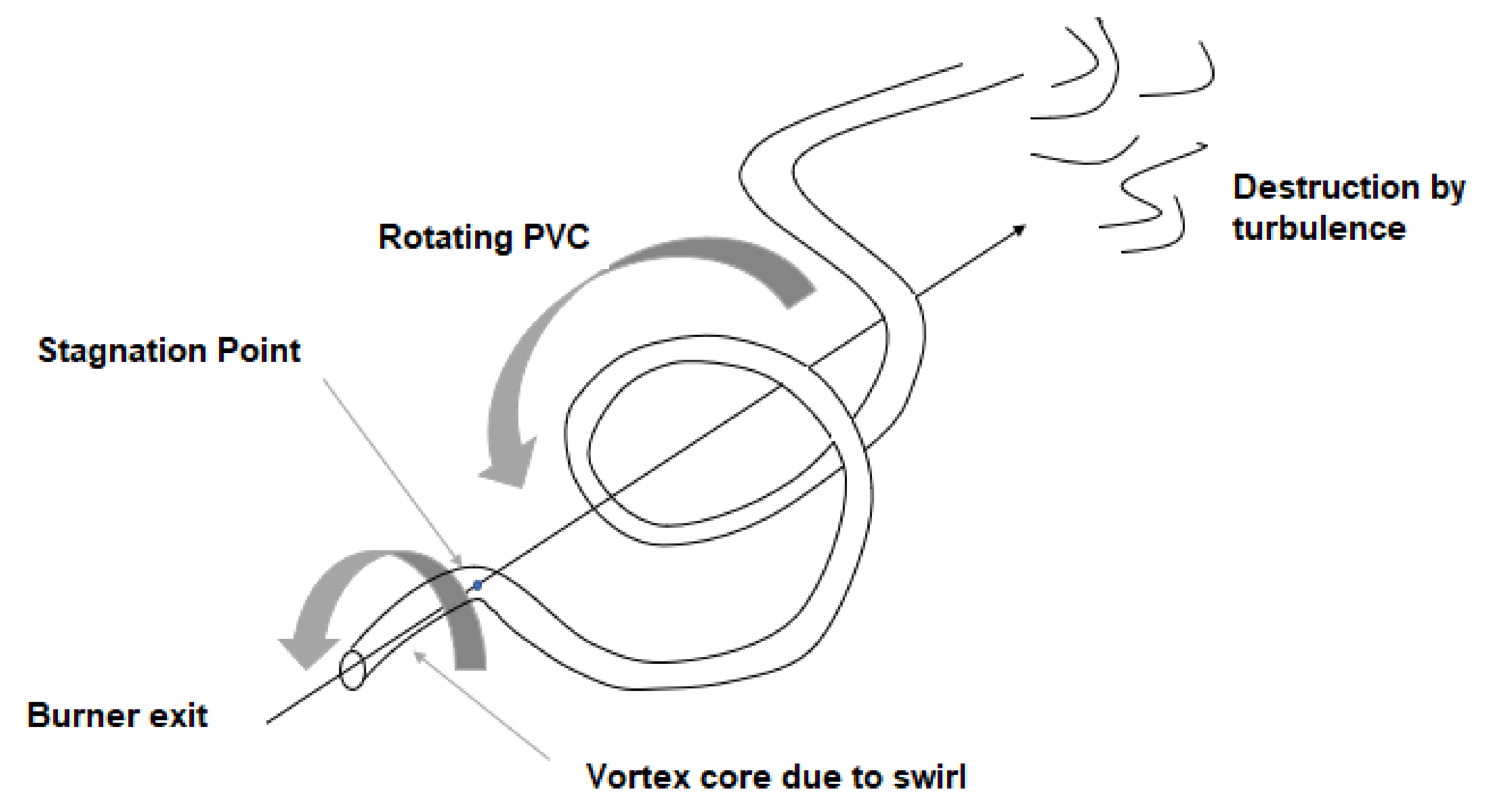

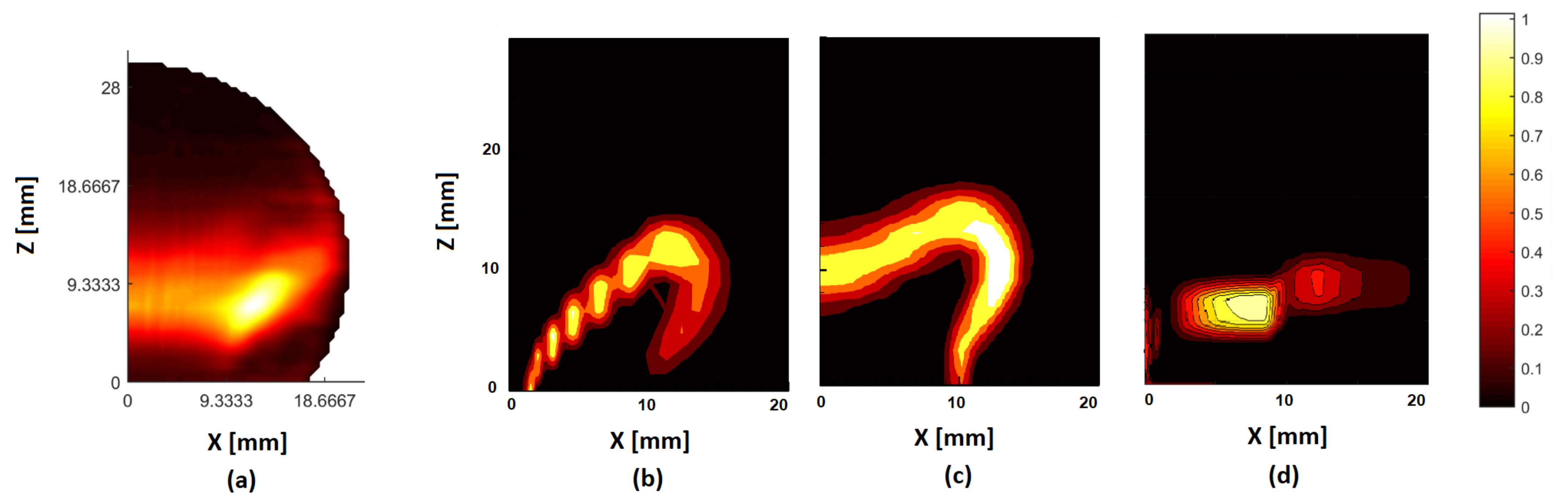

Swirl Flow Structure

3. Experimental Setup

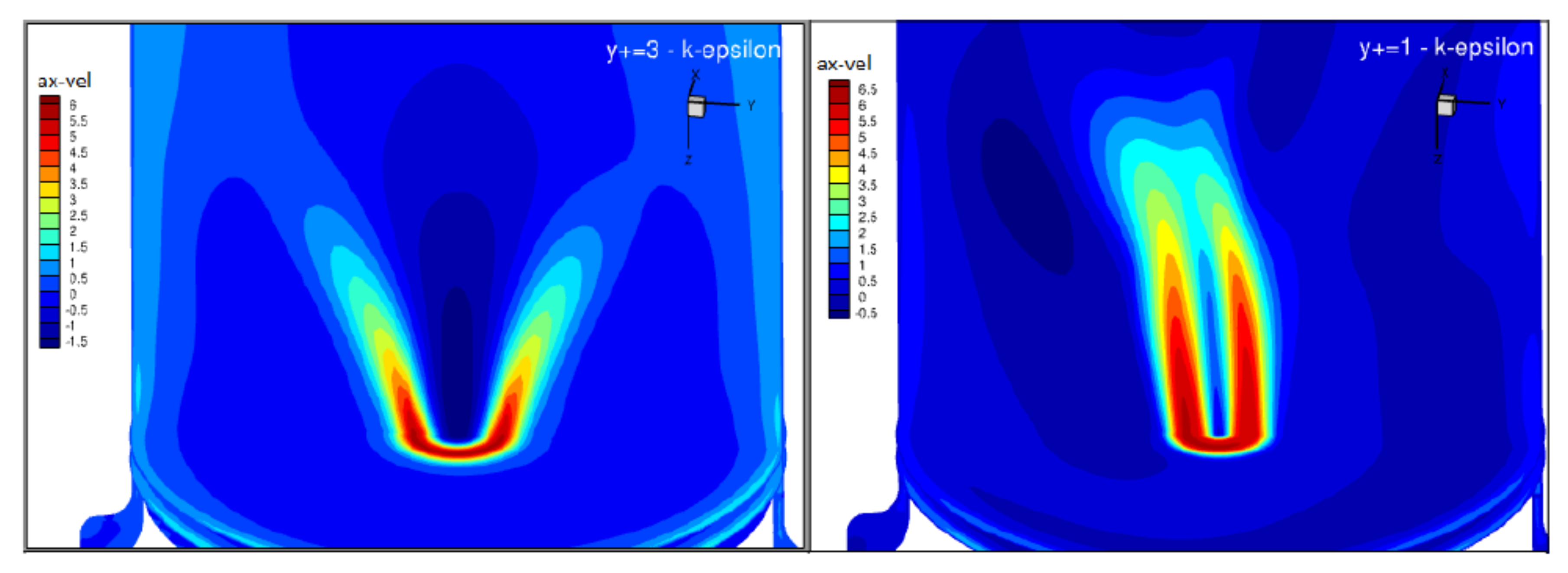

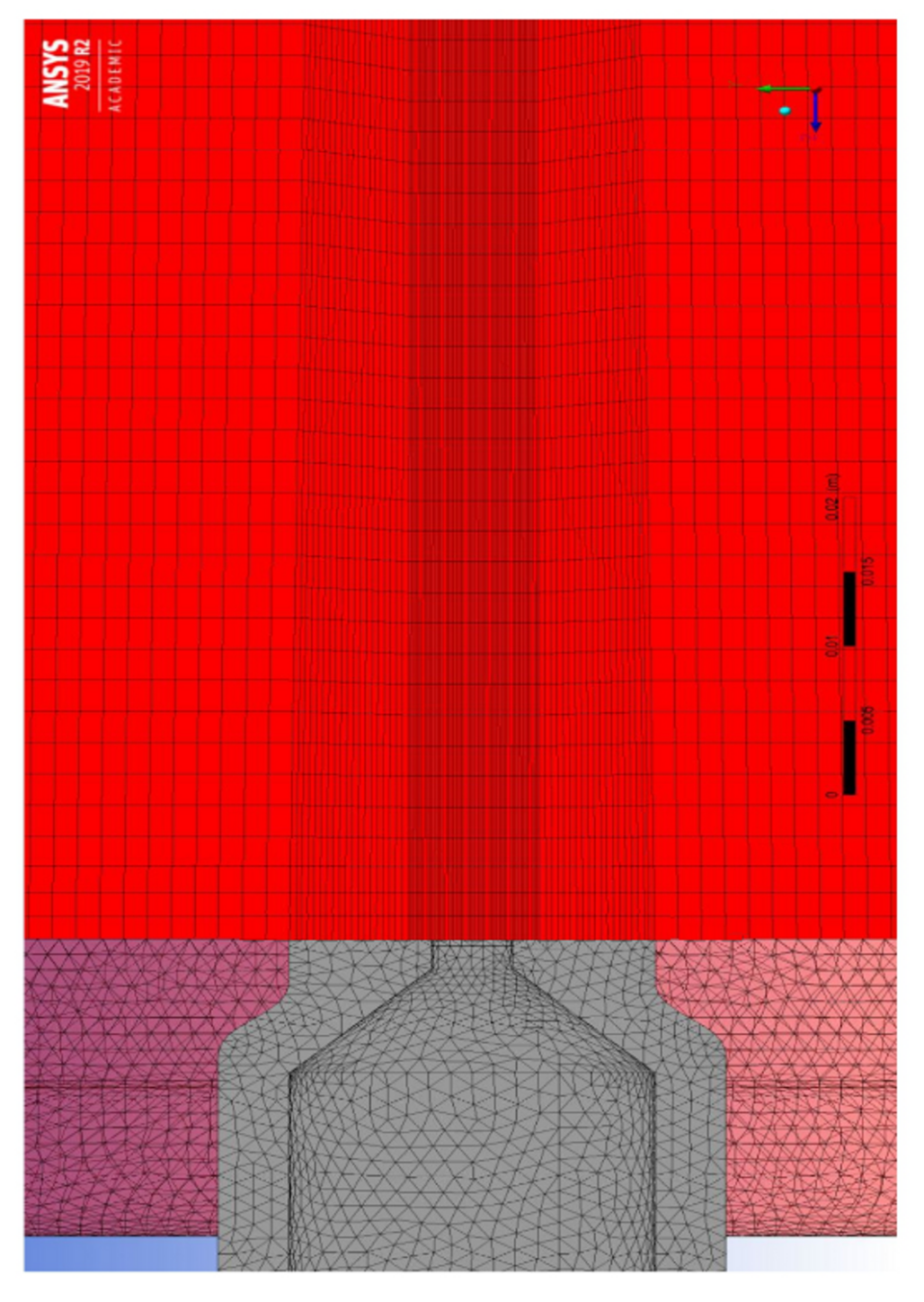

4. Mesh Generation

5. Numerical Approach

5.1. Boundary Conditions Applied

5.2. Turbulence-Chemistry Models

6. Results

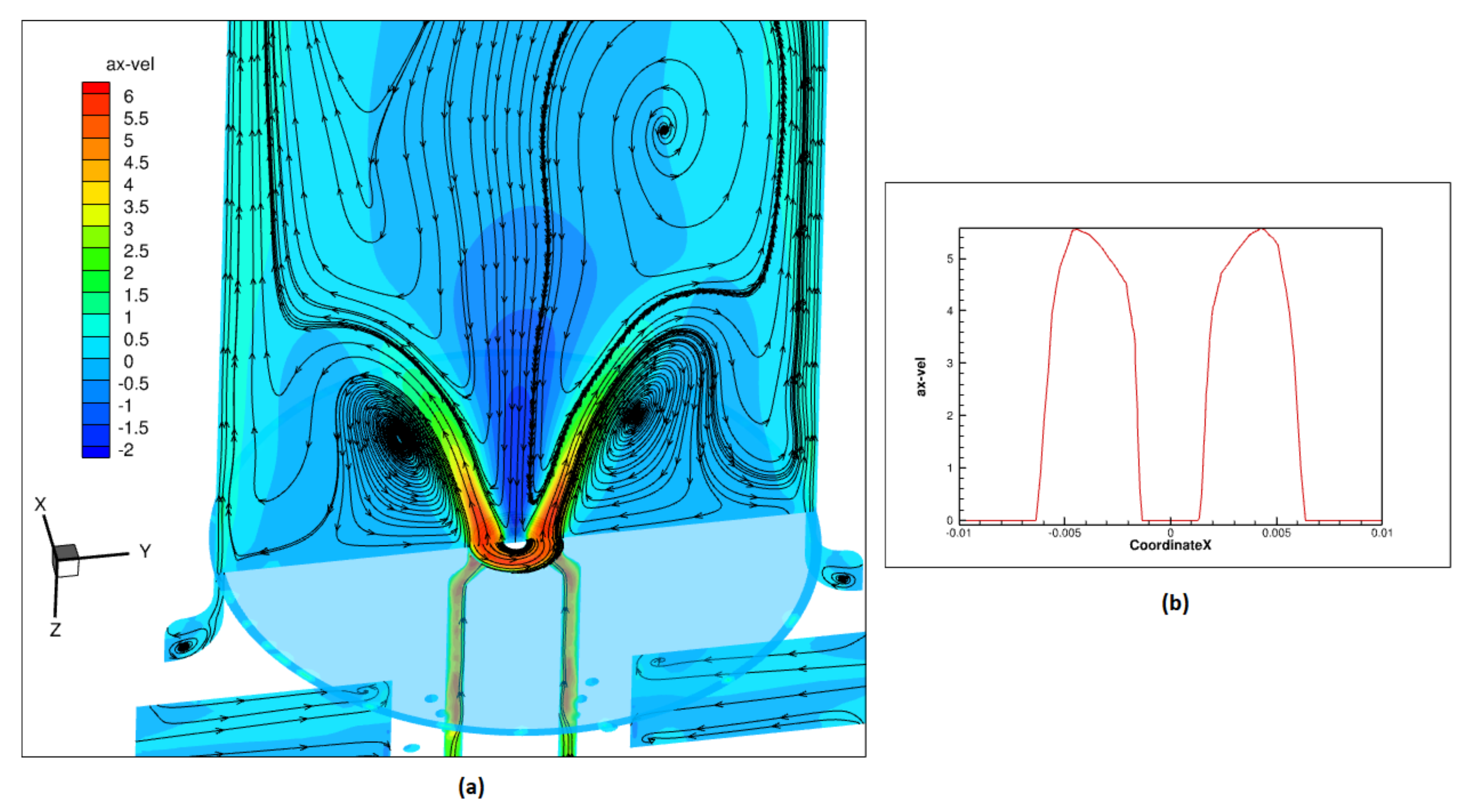

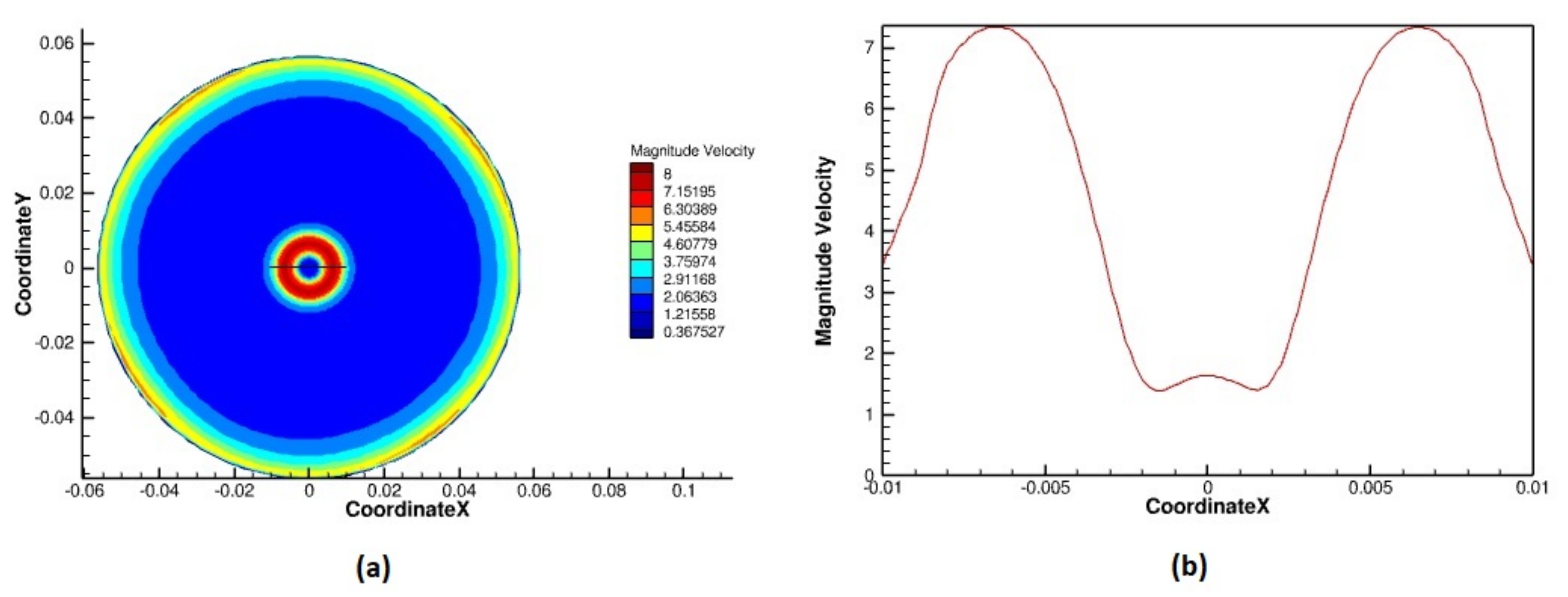

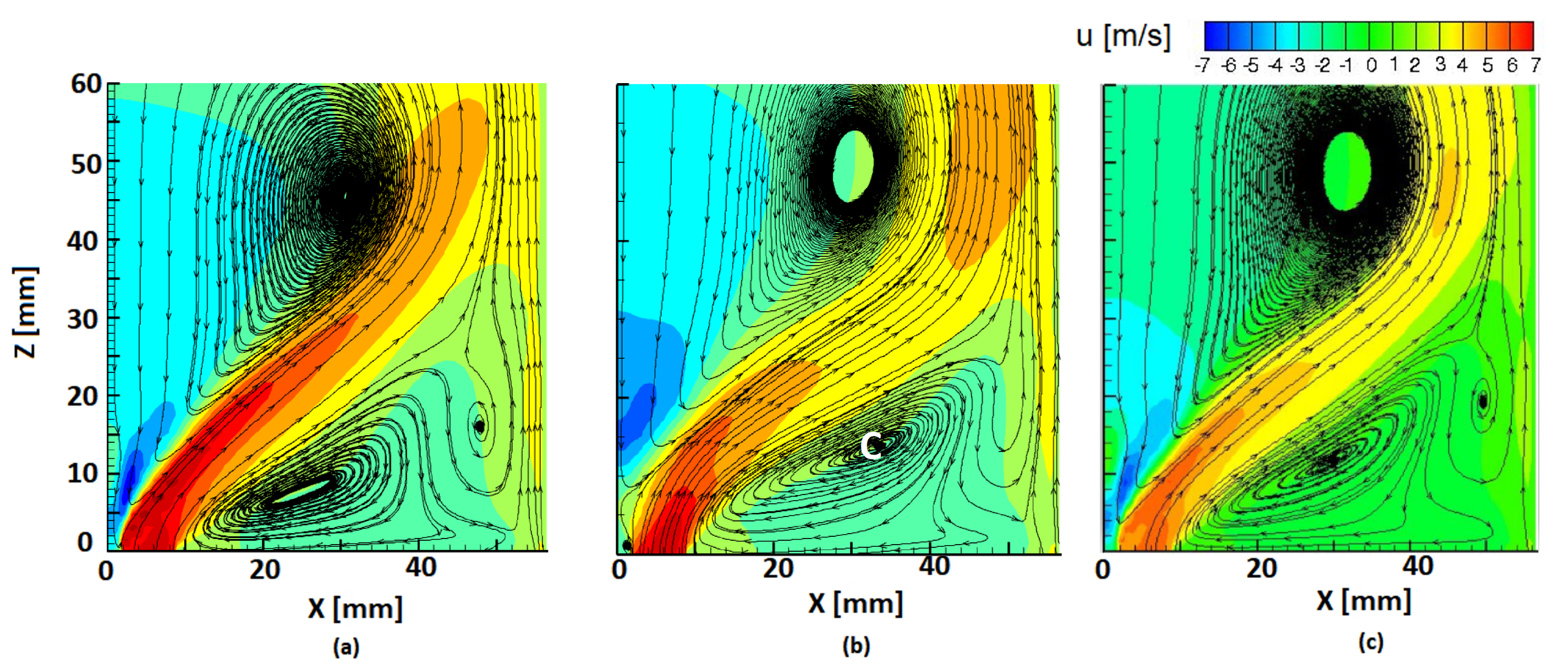

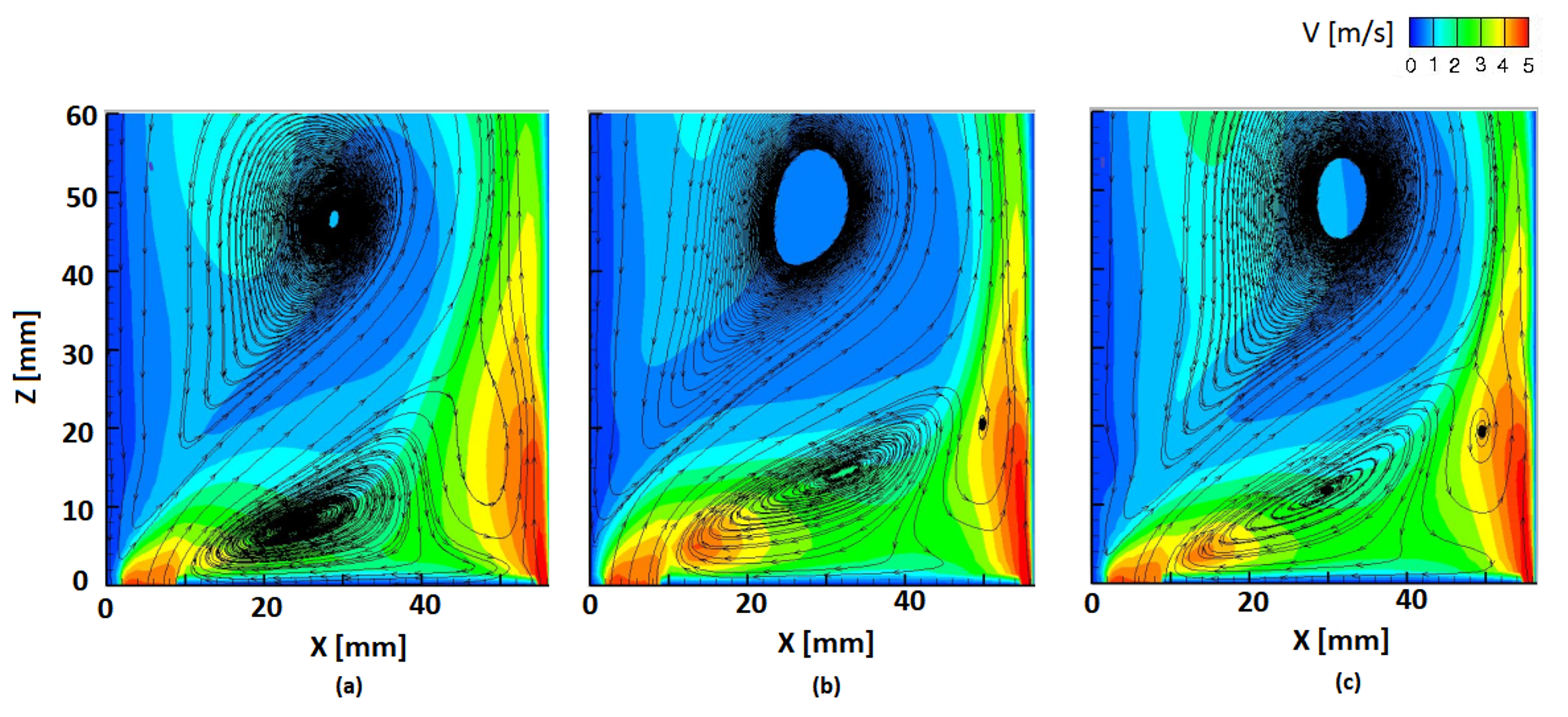

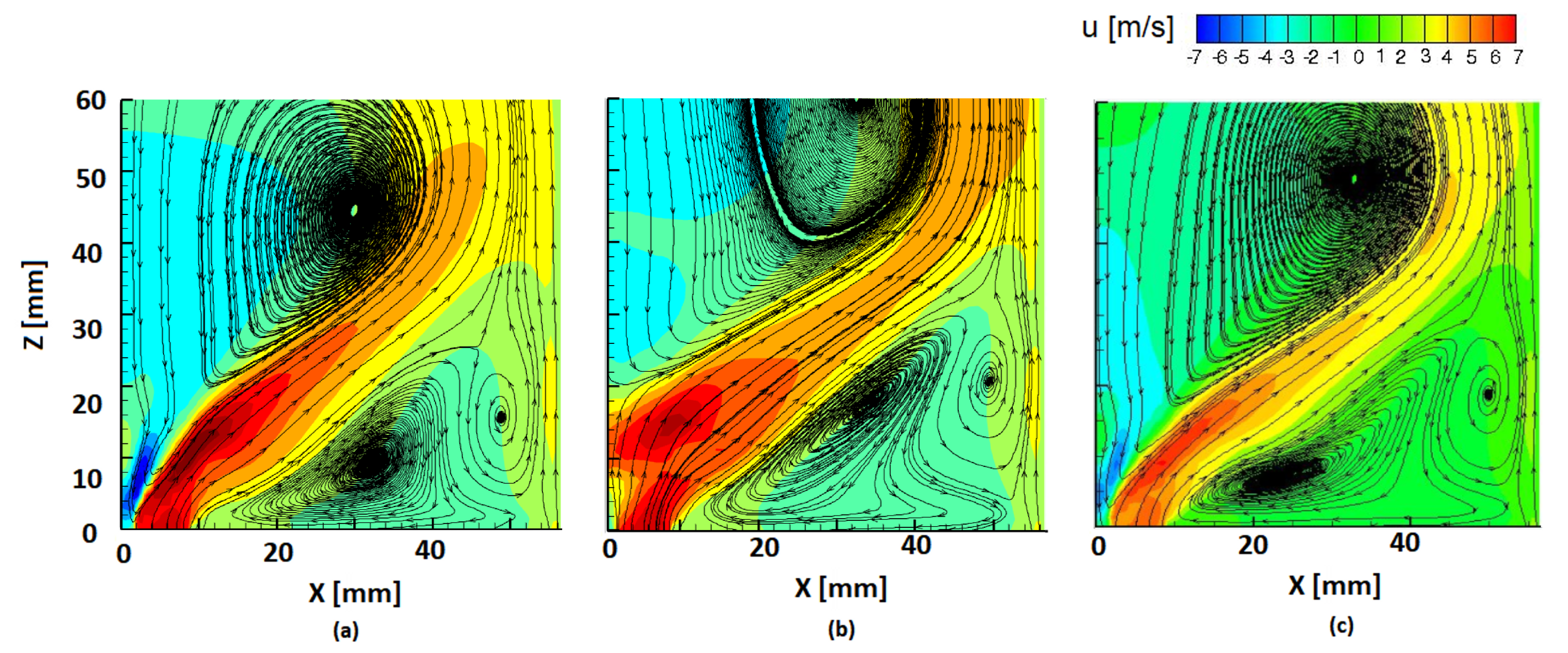

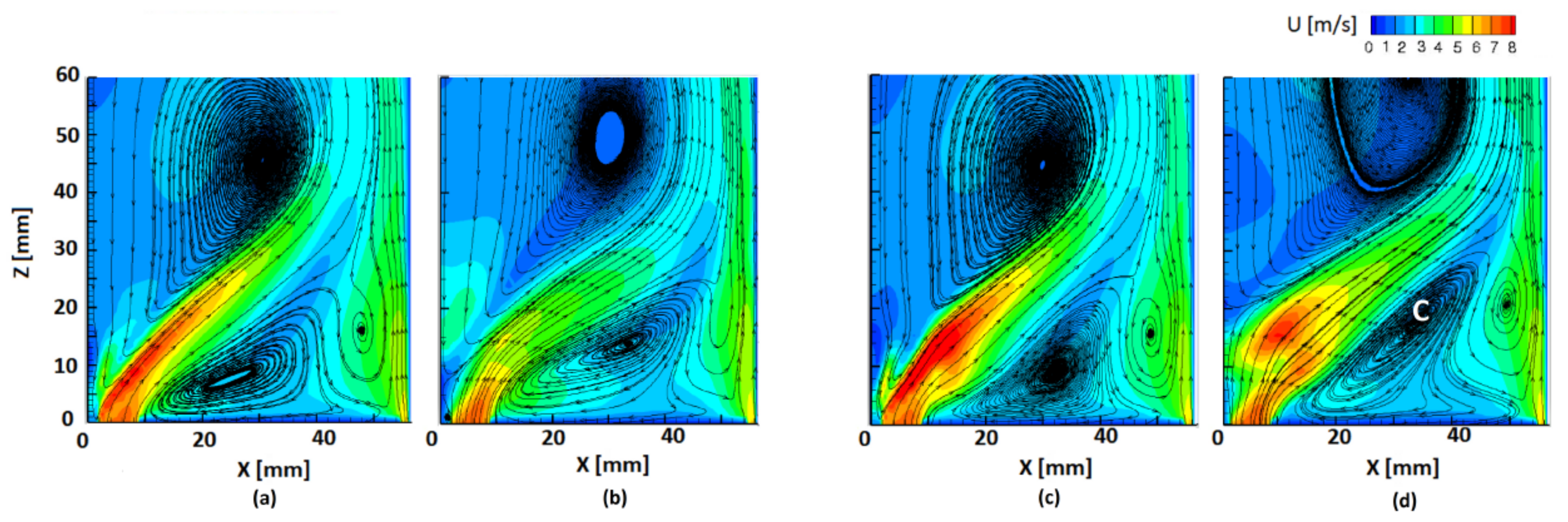

6.1. Cold Flow

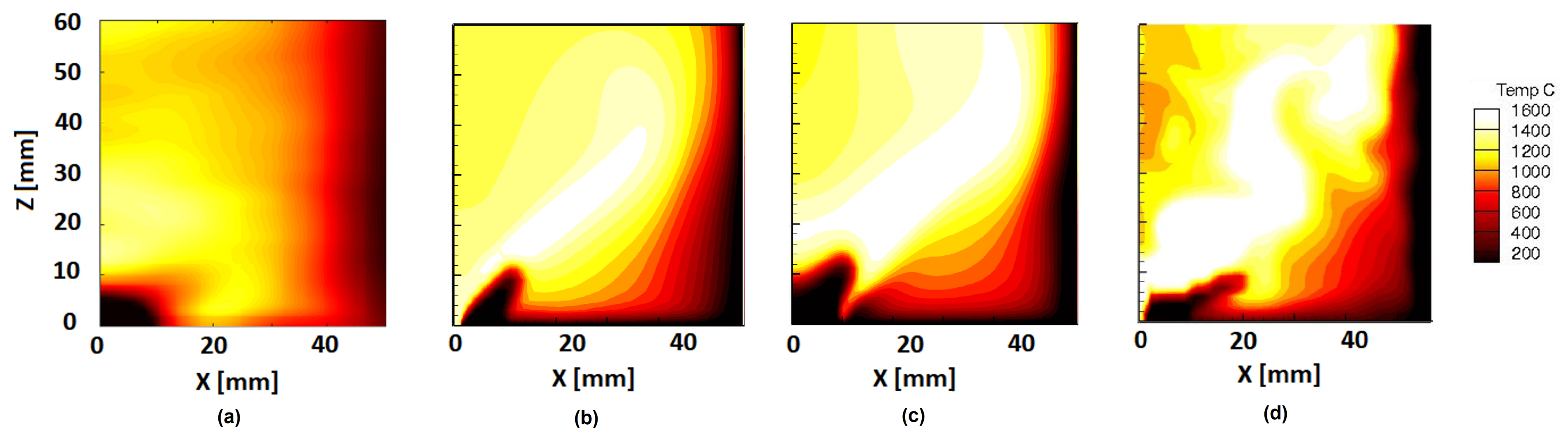

6.2. Hot Flow Using Combustion Models

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| d | Flame length above burner exit (mm) |

| D | Burner exit diameter (mm) |

| Frequency shift of laser light (Hz) | |

| U | Velocity magnitude (m/s) |

| u | Axial velocity component (m/s) |

| V | Tangential velocity component (m/s) |

| Air/fuel ratio (-) | |

| Equivalence ratio (-) | |

| CFD | Computational Fluid Dynamics |

| DES | Detached Eddy Simulation |

| DLE | Dry-Low Emission |

| DO | Discrete Ordinates |

| ED | Eddy Dissipation |

| FGM | Flamelet Generated Manifold |

| FM-DGV | Frequency Modulated Doppler Global Velocimetry |

| IRZ | Inner Recirculation Zone |

| LES | Large Eddy Simulation |

| LIV | Laser Interferometric Vibrometry |

| ORZ | Outer Recirculation Zone |

| Probability Density Function | |

| PIV | Particle Image Velocimetry |

| QUICK | Quadratic Upstream Interpolation for Convective Kinematics; |

| RANS | Reynolds-averaged Navier–Stoke |

| SAS | Scale Adaptive Simulation |

| SLF | Steady Laminar Flamelet |

References

- Lucca-Negro, O.; O’Doherty, T. Vortex breakdown: A review. Prog. Energy Combust. Sci. 2001, 27, 431–481. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, V. Dynamics and stability of lean-premixed swirl-stabilized combustion. Prog. Energy Combust. Sci. 2009, 35, 293–364. [Google Scholar] [CrossRef]

- Schuermans, B.B.; Guethel, H.F.; Pennell, D.; Guyot, D.; Paschereit, D.O. Thermoacoustic modeling of a gas turbine using transfer functions measured under full engine pressure. J. Eng. Gas Turbines Power 2010, 132, 111503. [Google Scholar] [CrossRef]

- Peterleithner, J.; Marn, A.; Woisetschläger, J. Interferometric investigation of the thermoacoustics in a swirl stabilized methane flame. In Turbo Expo: Power for Land, Sea, and Air; GT2015-42743; ASME Turbo Expo: Montreal, QC, Canada, 15–19 June 2015. [Google Scholar]

- Sattelmayer, T.; Polifke, W. Assessment of methods for the computation of the linear stability of combustors. Combust. Sci. Technol. 2003, 175, 453–476. [Google Scholar] [CrossRef]

- Lauer, M.R.W. Determination of the Heat Release Distribution in Turbulent Flames by Chemiluminescence Imaging. Ph.D. Thesis, University of Technology Munich, Munich, Germany, 2011. [Google Scholar]

- Peterleithner, J.; Stadlmair, N.V.; Woisetschläger, J.; Sattelmayer, T. Analysis of measured flame transfer functions with locally resolved density fluctuation and OH-Chemiluminescence Data. J. Eng. Gas Turbines Power 2016, 138, 031504. [Google Scholar] [CrossRef]

- Peterleithner, J.; Basso, R.; Heitmeir, F.; Woisetschläger, J.; Schlüssler, R.; Czarske, J.; Fischer, A. Comparison of flame transfer functions acquired by chemiluminescence and density fluctuation. In Turbo Expo: Power for Land, Sea, and Air; GT2016-57485; ASME Turbo Expo: Seoul, Korea, 13–17 June 2016. [Google Scholar]

- Balachandran, R.; Ayoola, B.O.; Kaminski, C.; Dowling, A.P.; Mastorakos, E. Experimental investigation of the nonlinear response of turbulent premixed flames to imposed inlet velocity fluctuations. Combust. Flame 2005, 143, 37–55. [Google Scholar] [CrossRef]

- Greiffenhagen, F.; Peterleithner, J.; Woisetschläger, J.; Fischer, A.; Gürtler, J.; Czarske, J. Discussion of laser interferometric vibrometry for the determination of heat release fluctuations in an unconfined swirl-stabilized flame. Combust. Flame 2018, 201, 315–327. [Google Scholar] [CrossRef]

- Greiffenhagen, F.; Woisetschläger, J.; Gürtler, J.; Kuschmierz, R.; Czarske, J. Camera based full-field laser interferometric vibrometry for combustion diagnostics. In Proceedings of the 19th International Symposium on the Application of Laser and Imaging Techniques to Fluid Mechanics, Lisbon, Portugal, 16–19 July 2018. [Google Scholar]

- Farisco, F.; Notsch, P.; Prieler, R.; Greiffenhagen, F.; Woisetschlaeger, J.; Heitmeir, F.; Hochenauer, C. Numerical investigation of a swirl stabilized methane fired burner and validation with experimental data. In Turbo Expo: Power for Land, Sea, and Air; GT2019-90452; ASME Turbo Expo: Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar]

- Abou-Taouk, A.; Whiddon, R.; Sigfrid, I.R.; Eriksson, L.E. CFD Investigation of Swirl-Stabilized Flexi-Fuel Burner using Methane-Air Mixture for Gas Turbines. In Proceedings of the Conference ISABE, Gothenburg, Sweden, 12–16 September 2011; pp. 2011–2122. [Google Scholar]

- Hatziapostolou, A.; Orfanoudakis, N.G.; Koukou, M.K.; Raptis, G. CFD modeling of the swirl-stabilised flame produced by a laboratory-scale combustor. selection of the turbulence model. In Proceedings of the 4th WSEAS International Conference on Heat Transfer, Thermal Engineering and Environment, Elounda, Greece, 21–23 August 2006; pp. 83–88. [Google Scholar]

- Van Oijen, J.A.; Donini, A.; Bastiaans, R.J.M.; ten Thije Boonkkamp, J.H.M.; de Goey, L.P.H. State-of-the-art in premixed combustion modeling using flamelet generated manifolds. Prog. Energy Combust. Sci. 2016, 57, 30–74. [Google Scholar] [CrossRef] [Green Version]

- Puggelli, S.; Bertini, D.; Mazzei, L.; Andreini, A. Scale Adaptive Simulations of a swirl stabilized spray flame using Flamelet Generated Manifold. Energy Procedia 2016, 101, 1143–1150. [Google Scholar] [CrossRef]

- Magnussen, B.F.; Hjertager, B.H. On Mathematical Modelling of Turbulent Combustion with Special Enphasis on Soot Formation and Combustion. In Symposium (International) on Combustion; Elsevier: Amsterdam, The Netherlands, 1977; Volume 16, pp. 719–729. [Google Scholar]

- Peters, N. Laminar diffusion flamelet models in non-premixed turbulent combustion. Prog. Energy Combust. Sci. 1984, 10, 319–339. [Google Scholar] [CrossRef]

- Greiffenhagen, J.; Woisetschläger, A.; Gürtler, J.; Czarske, J. Quantitative measurement of density fluctuations with a full-field laser interferometric vibrometer. Exp. Fluids 2020, 61, 1–15. [Google Scholar]

- Candel, S.; Durox, D.; Schuller, T.; Bourgouin, J.; Moeck, J.P. Dynamics of swirling flames. Annu. Rev. Fluid Mech. 2014, 46, 147–173. [Google Scholar] [CrossRef]

- Yiheng, T. Experimental and Numerical Investigations of Flames Stabilized by Swirl Flow and Bluff-Body: Flame Structures and Flame Instabilities. Ph.D. Thesis, Lund University, Lund, Sweden, October 2017. [Google Scholar]

- Bompelly, R.K. Lean Blowout and Its Robust Sensing. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, May 2013. [Google Scholar]

- ANSYS. Quick Guide to Setting Up LES-Type Simulations; ANSYS FLUENT Version 1.4; Prepared and Compiled by Aleksey Gerasimov; ANSYS Sweden AB: Stockholm, Sweden, 2016. [Google Scholar]

- ANSYS. ANSYS FLUENT Theory Guide; ANSYS FLUENT Release 14.5; ANSYS: Canonsburg, PA, USA, 2012. [Google Scholar]

- Tanneberger, T.; Reichel, T.G.; Krüger, O.; Terhaar, S.; Paschereit, C.O. Numerical investigation of the flow field and mixing in a swirl-stabilized burner with a non-swirling axial jet. In ASME Turbo Expo: Power for Land, Sea, and Air; GT2015-43382; ASME Turbo Expo: Montreal, QC, Canada, 15–19 June 2015. [Google Scholar]

- WestBrook, C.K.; Dryer, F.L. Simplified reaction mechanism for the oxidation of hydrocarbon fuels in flames. Combust. Sci. Technol. 1981, 27, 31–43. [Google Scholar] [CrossRef]

- Smith, G.P.; Golden, D.M.; Frenklach, M.; Moriarty, N.W.; Eiteneer, B.; Goldenberg, M.C.; Bowman, T.; Hanson, R.K.; Song, S.; Gardiner, W.C.; et al. GRI-Mech. Available online: http://www.me.berkeley.edu/grimech/ (accessed on 20 January 2021).

- Hardalupas, Y.; Orain, M. Local measurements of the time-dependent heat release rate and equivalence ratio using chemiluminescent emission from a flame. Combust. Flame 2004, 139, 188–207. [Google Scholar] [CrossRef]

| k- | k- | |

|---|---|---|

| 0.5684 | 0.4548 | |

| 0.53625 | 0.54065 |

| k- | k- | |

|---|---|---|

| 0.48035 | 0.4278 | |

| 0.43935 | 0.40995 |

| Eddy Dissipation | k- | k- | SST |

| S | 0.38505 | 0.605785 | 0.3929925 |

| Steady Flamelet | k- | k- | SST |

| S | 0.36569 | 0.27741 | 0.36799 |

| FGM Premixed Flamelet | k- | k- | SST |

| S | 0.378645 | 0.5313975 | 0.3744125 |

| FGM Diffusion Flamelet | k- | k- | SST |

| S | 0.3799175 | 0.523415 | 0.374775 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Farisco, F.; Castellanos, L.; Woisetschläger, J.; Sanz, W. Numerical Steady and Transient Evaluation of a Confined Swirl Stabilized Burner. Int. J. Turbomach. Propuls. Power 2021, 6, 46. https://doi.org/10.3390/ijtpp6040046

Farisco F, Castellanos L, Woisetschläger J, Sanz W. Numerical Steady and Transient Evaluation of a Confined Swirl Stabilized Burner. International Journal of Turbomachinery, Propulsion and Power. 2021; 6(4):46. https://doi.org/10.3390/ijtpp6040046

Chicago/Turabian StyleFarisco, Federica, Luisa Castellanos, Jakob Woisetschläger, and Wolfgang Sanz. 2021. "Numerical Steady and Transient Evaluation of a Confined Swirl Stabilized Burner" International Journal of Turbomachinery, Propulsion and Power 6, no. 4: 46. https://doi.org/10.3390/ijtpp6040046

APA StyleFarisco, F., Castellanos, L., Woisetschläger, J., & Sanz, W. (2021). Numerical Steady and Transient Evaluation of a Confined Swirl Stabilized Burner. International Journal of Turbomachinery, Propulsion and Power, 6(4), 46. https://doi.org/10.3390/ijtpp6040046