Simulation of a Radial Pump Fast Startup and Analysis of the Loop Response Using a Transient 1D Mean Stream Line Based Model †

Abstract

:1. Introduction

- To predict reliably the performance of the pump (the detailed features of the flow are not of primary importance as the objective of a system simulation software is to predict the global behaviour and performance of a global system and the interaction and adaptation of the operations of the different components of the system).

- To estimate the performance very quickly: the model has to be integrated in a system simulation software in which the performance of all the components of the system has to be estimated. A too high computational time for a single component would penalise the whole computation.

- To be able to take into account the transient effects affecting the performance of the pump as the systems aimed in the study can encountered very fast transients.

2. Facility and Previous Associated Research

2.1. Description of the Facility

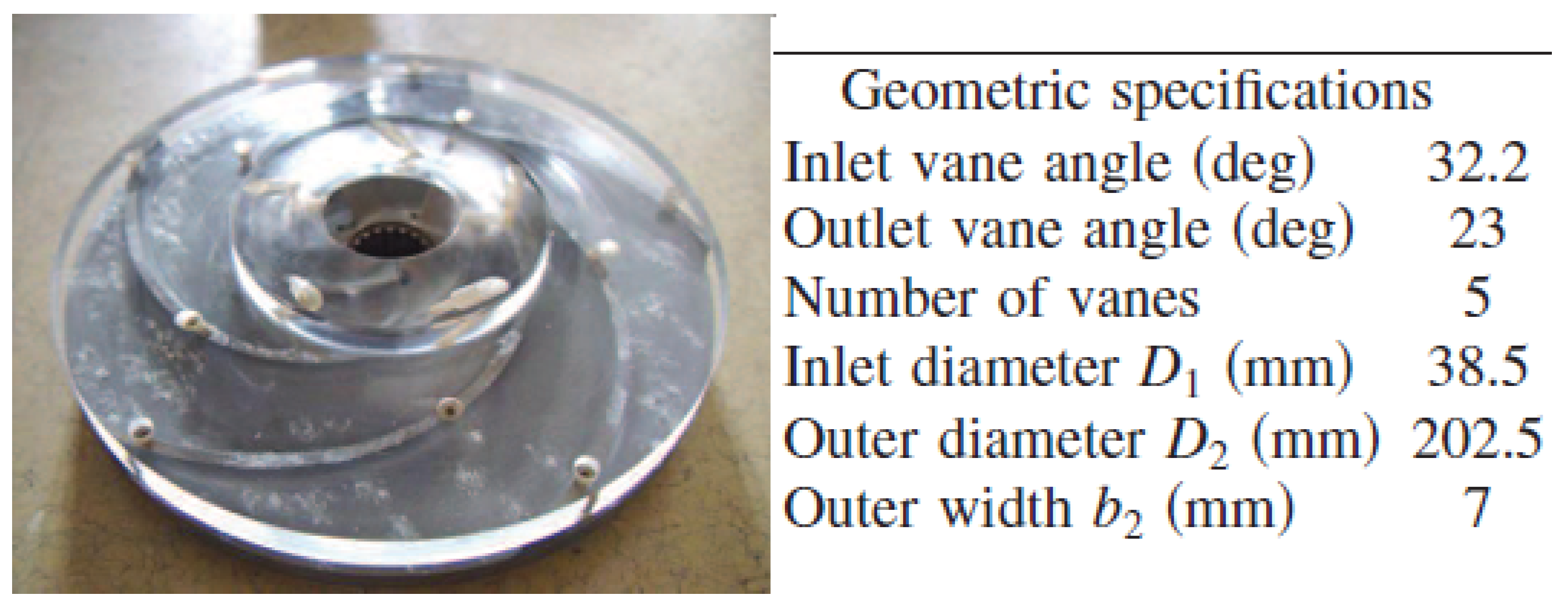

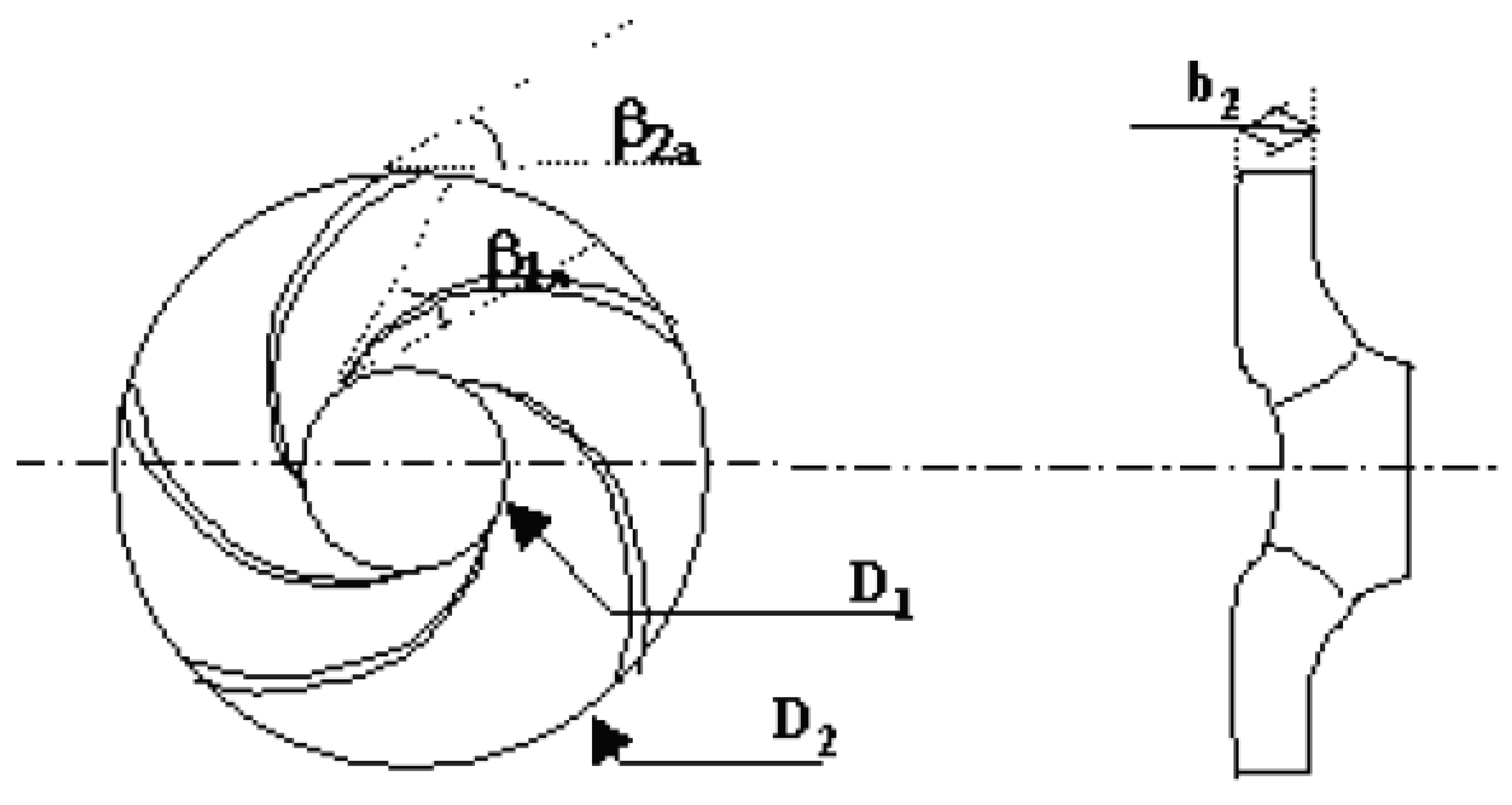

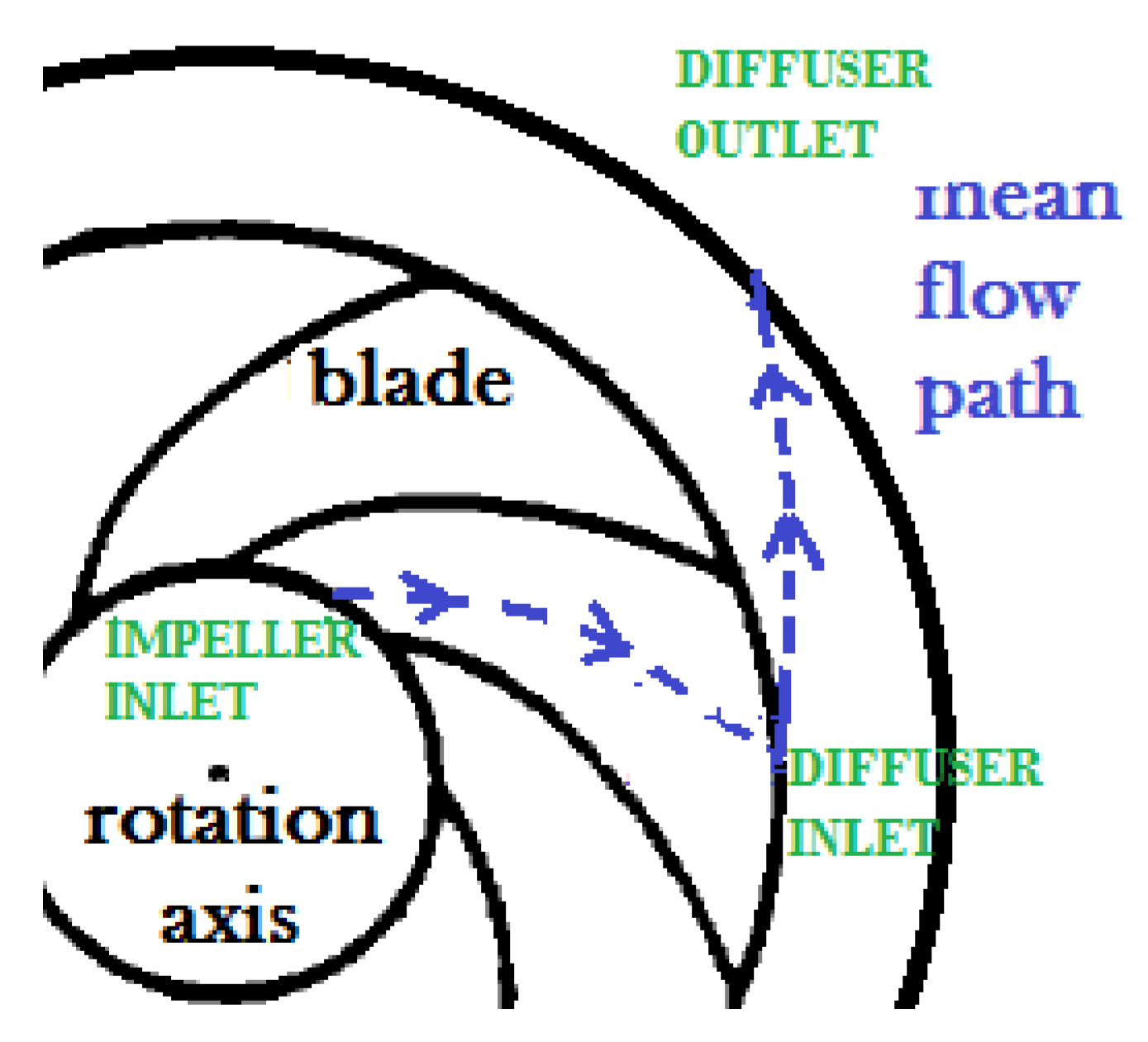

2.2. Description of the Centrifugal Pump of the DERAP Loop

3. Modelling of the Pump and the Complete Circuit

3.1. The CATHARE-3 Code and Its Governing Equations

3.2. The One-Dimensional Pump Model Implemented into the CATHARE-3 Code

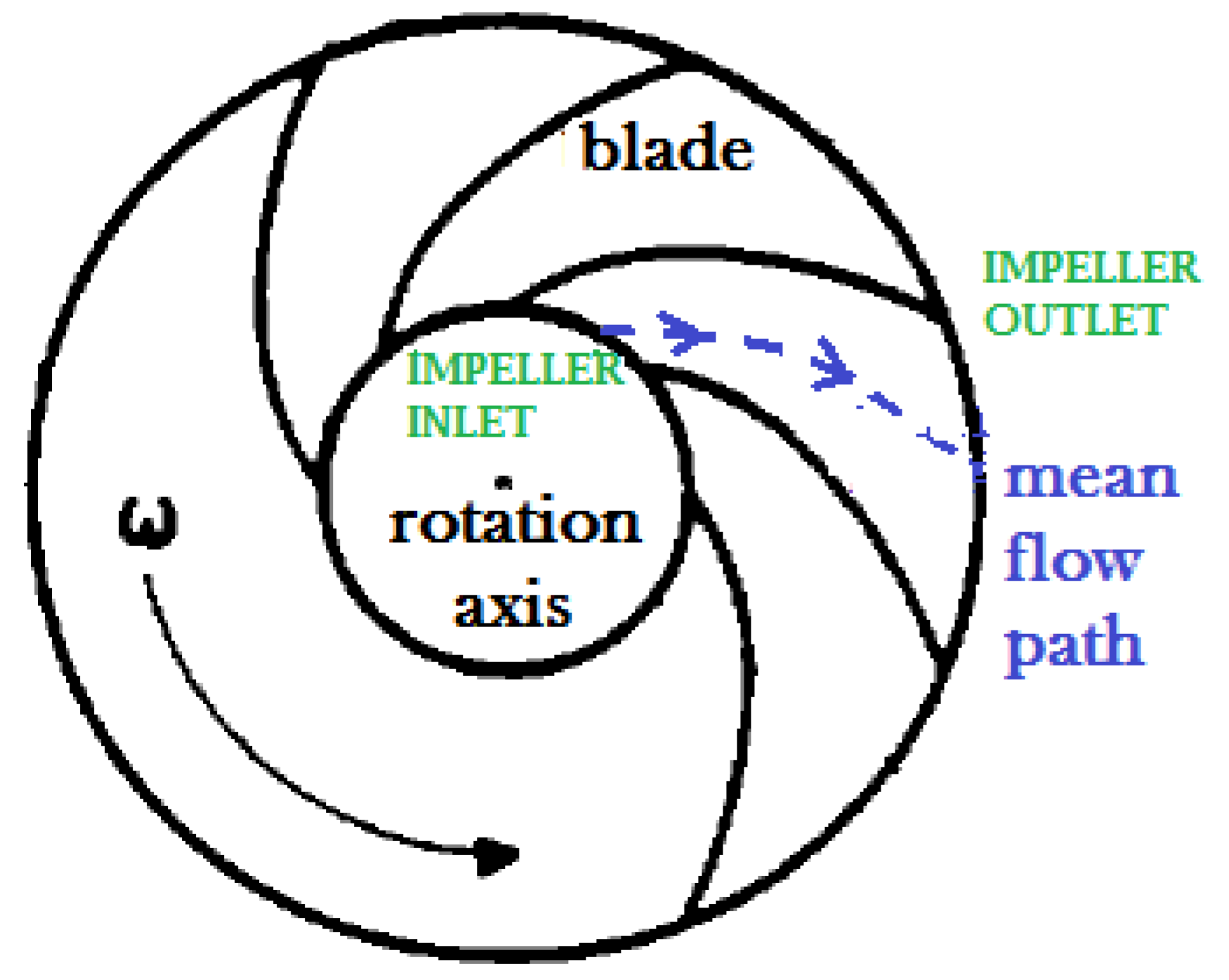

3.2.1. Principle

3.2.2. Source Terms and Implementation

- Inside the impeller, resolution is made with respect to the rotating frame ( relative velocity replaces absolute velocity in each balance equation).

- A centrifugal acceleration term has been added to the right side of momentum balance equation of the impeller part. Its expression is the following:It has also been introduced on the right side of energy balance equation as follows:

- Changes of frame are made at impeller and diffuser inlets using velocity triangles according to a mean velocity of the two-phase mixture. In the case of single-phase computations, this means velocity is simply the phase velocity.

- Flow section is modified inside impeller, diffuser and volute parts in order to solve equations with the appropriate velocity (relative or absolute two-component velocity) and ensure mass flow rate conservation. Taking the example of the impeller part, the face number 1 is shared between suction and impeller. This correspond to the last point calculated in the absolute frame, as a face is the interface between two cells of the mesh. I is the face number, S the modified flow section and A the meridian flow section.The change of frame is made on face number 2, owned only by the impeller part. The relative velocity at the impeller inlet is estimated according to the inlet velocity triangle, which allows calculating a modified section, which replaces the initial meridian flow section in the balance equations.The same procedure is conducted for the change of frame from the relative to the absolute one. Thus, the flow section of the first face of the vaneless diffuser is the one of the impeller outlet.The change of frame is made on face number 2, owned only by the diffuser-volute element part (see Figure 7 for the representation of this element). The two-component absolute velocity at the diffuser inlet is estimated according to the outlet velocity triangle, which allows calculating a modified flow section as follows:

- Flow direction in the vaneless diffuser is modelled considering a constant absolute angle along the diffuser mesh. This corresponds to a logarithmic spiral path.

- Direction of the fluid along the volute is given by the evolution of the absolute angle . The flow is straightened in this component, which is essential to return to a one-component velocity in the downstream elements of the circuit (the discharge pipe in particular). The following relation defines the local absolute angle for each cell of the mesh:

- Conservation of the static pressure and static enthalpies is ensured at frame interfaces. This allows working with the relative total pressure and enthalpies in the rotating frame.

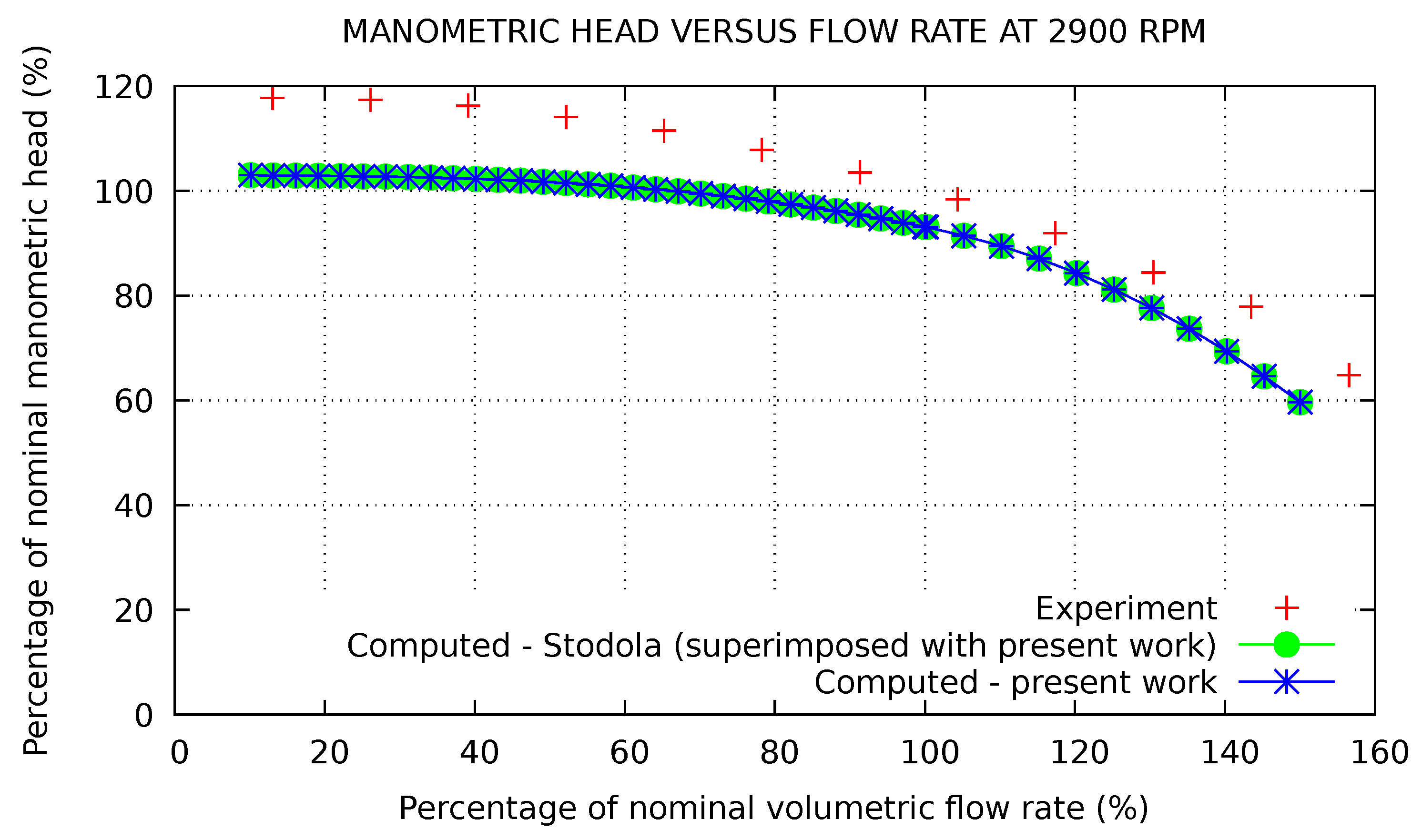

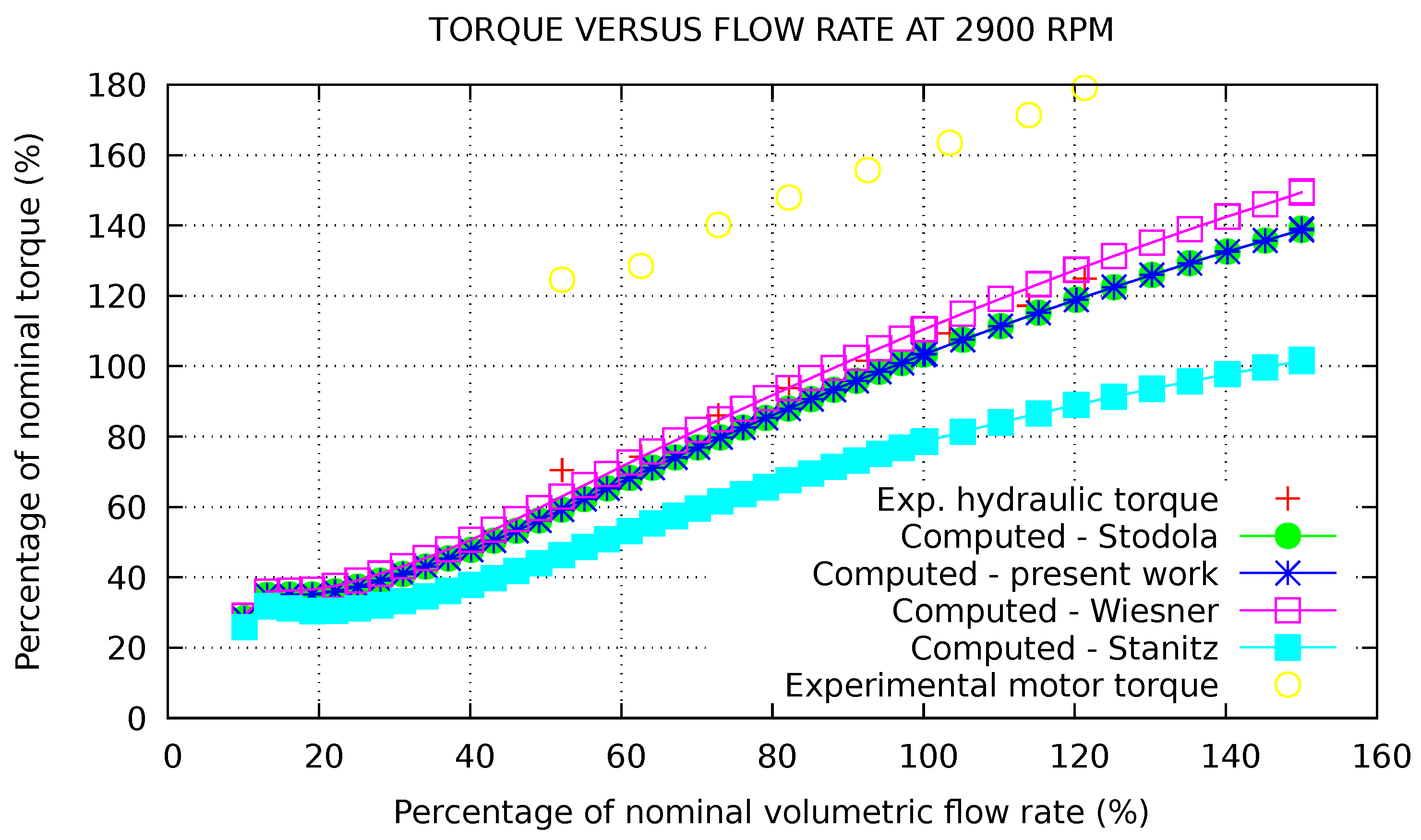

- Fluid deviation at impeller outlet is taken into account by a slip factor model. It represents Coriolis acceleration effects in particular. Several correlations have been implemented, including those of Stodola [32], Stanitz [33], Wiesner [34] and Qiu [35] as well as the one developed in the frame of this project (Matteo et al [13]) activated by default and used for qualification of the pump model. These correlations are presented in the next section. After making the choice of the slip factor model (i.e., a correlation for ), the deviated angle is calculated as follows:with

- A desadaptation (shock) head loss source term has been added to the right side of momentum equations. It is concentrated at the impeller inlet using the repartition function .

- A diffusion head loss source term has been added to the right side of momentum equations of the volute part. It is spread all along the volute mesh using the repartition function .

- Power dissipation in the fluid due to low flow rate recirculations has been introduced into energy balance equations. It is spread all along the impeller mesh using the repartition function .

3.2.3. Deviation and Loss Models

3.2.4. Required Input Data

General Data

Geometric Data

Hydraulic Data

3.3. Graphic Representation of the Modelling

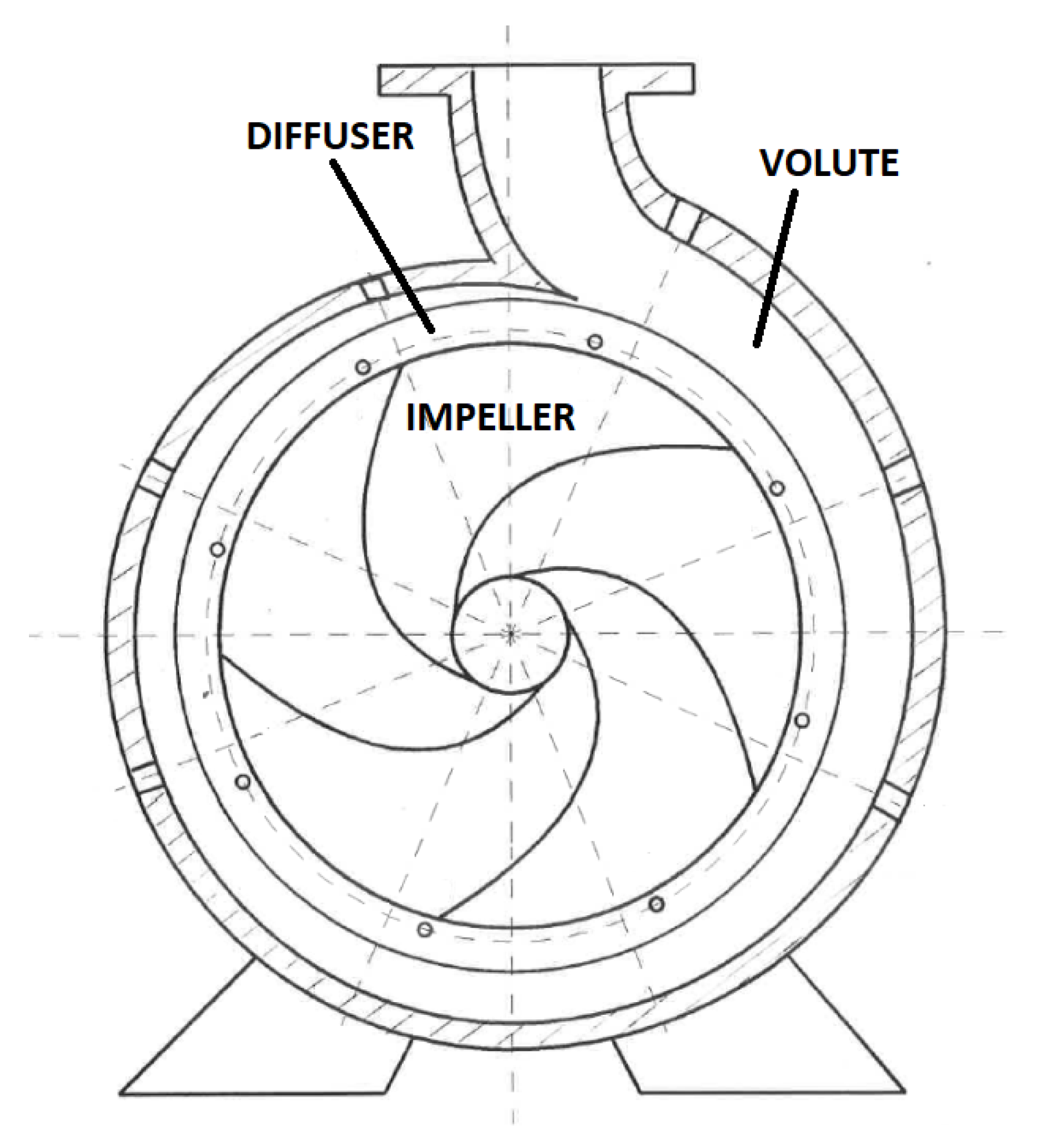

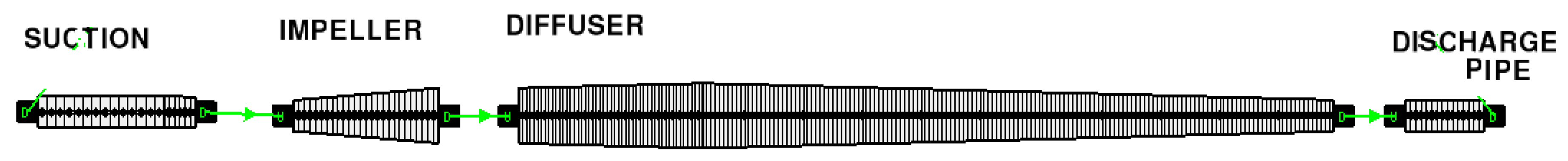

3.3.1. Centrifugal Pump

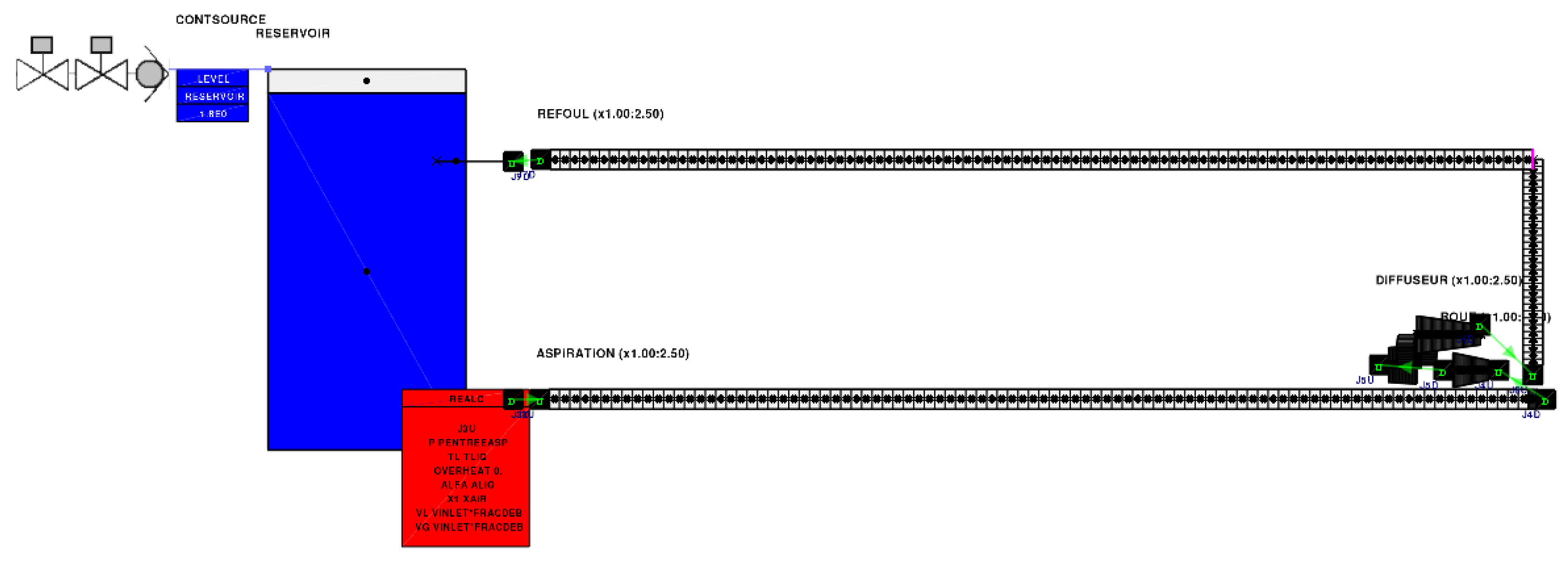

3.3.2. Whole Facility

4. Results

4.1. Prediction of DERAP Steady Performance Curves (Pump Only)

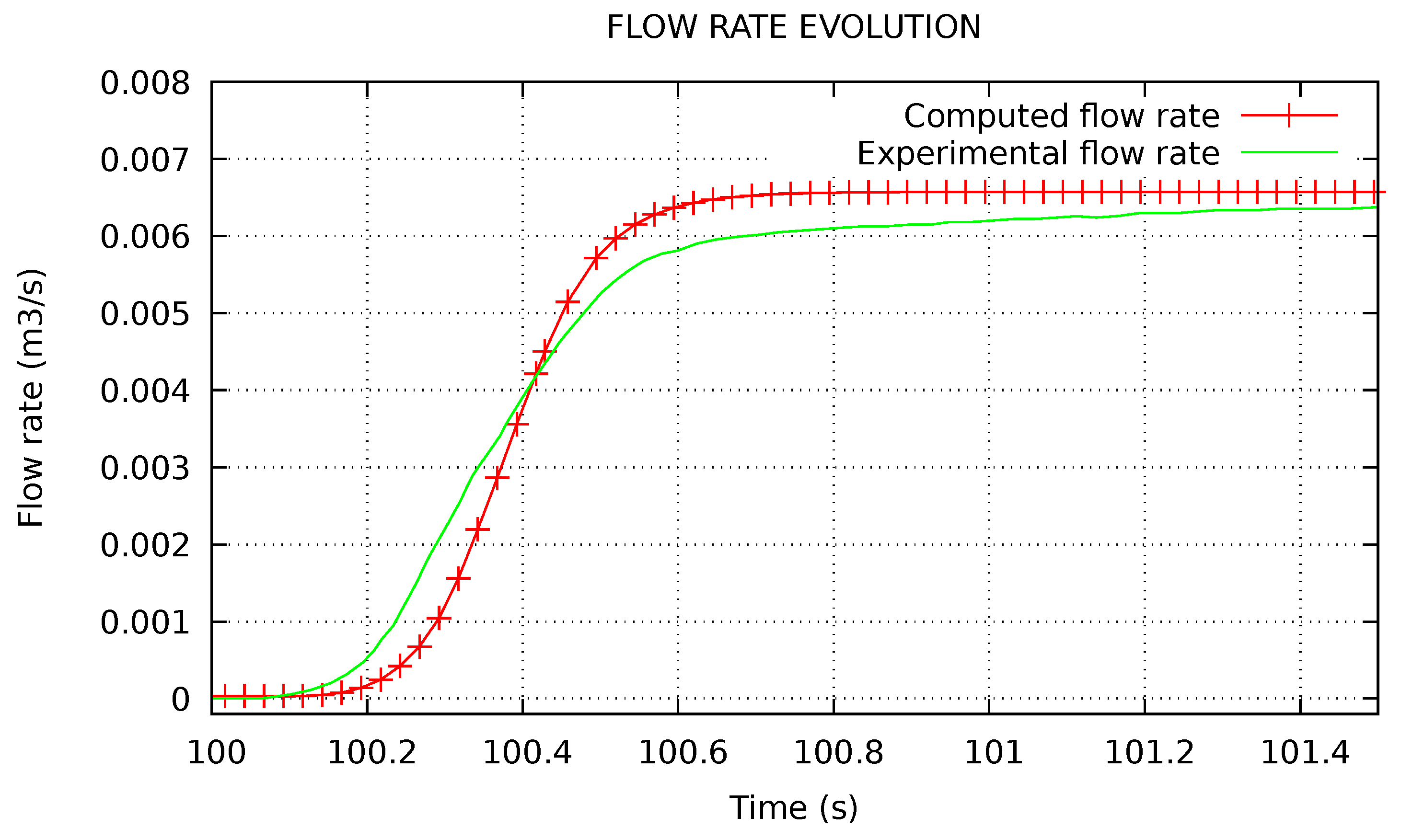

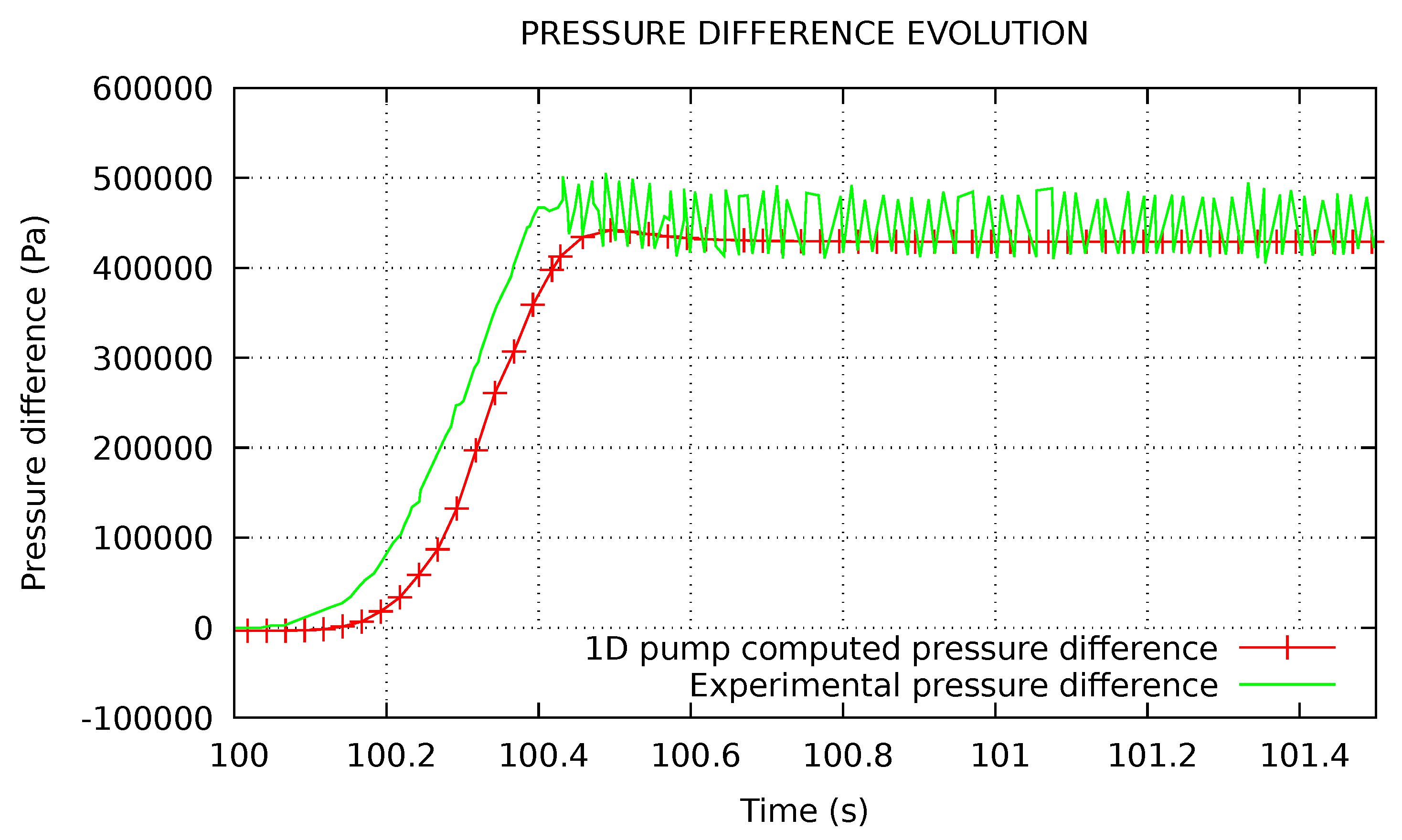

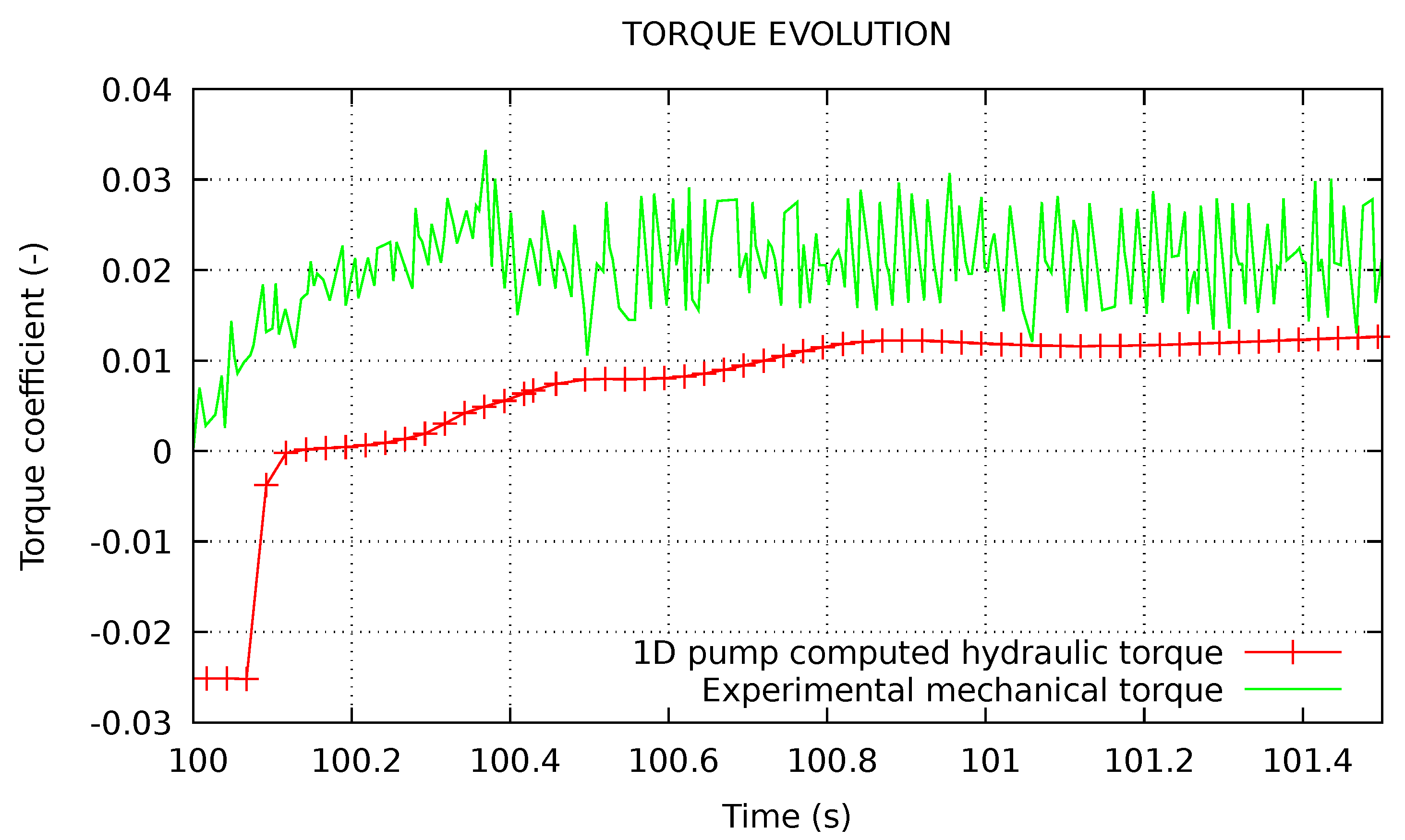

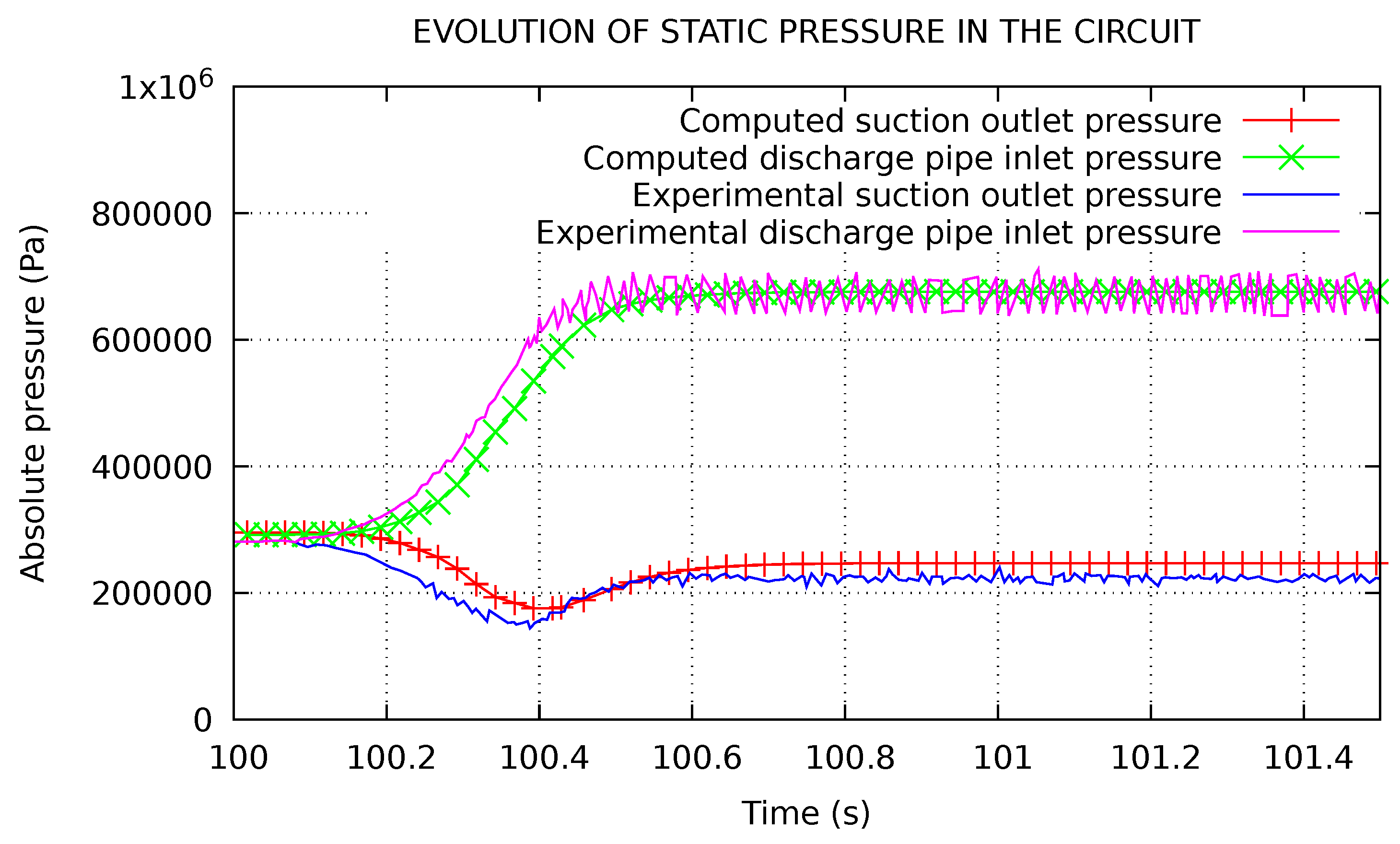

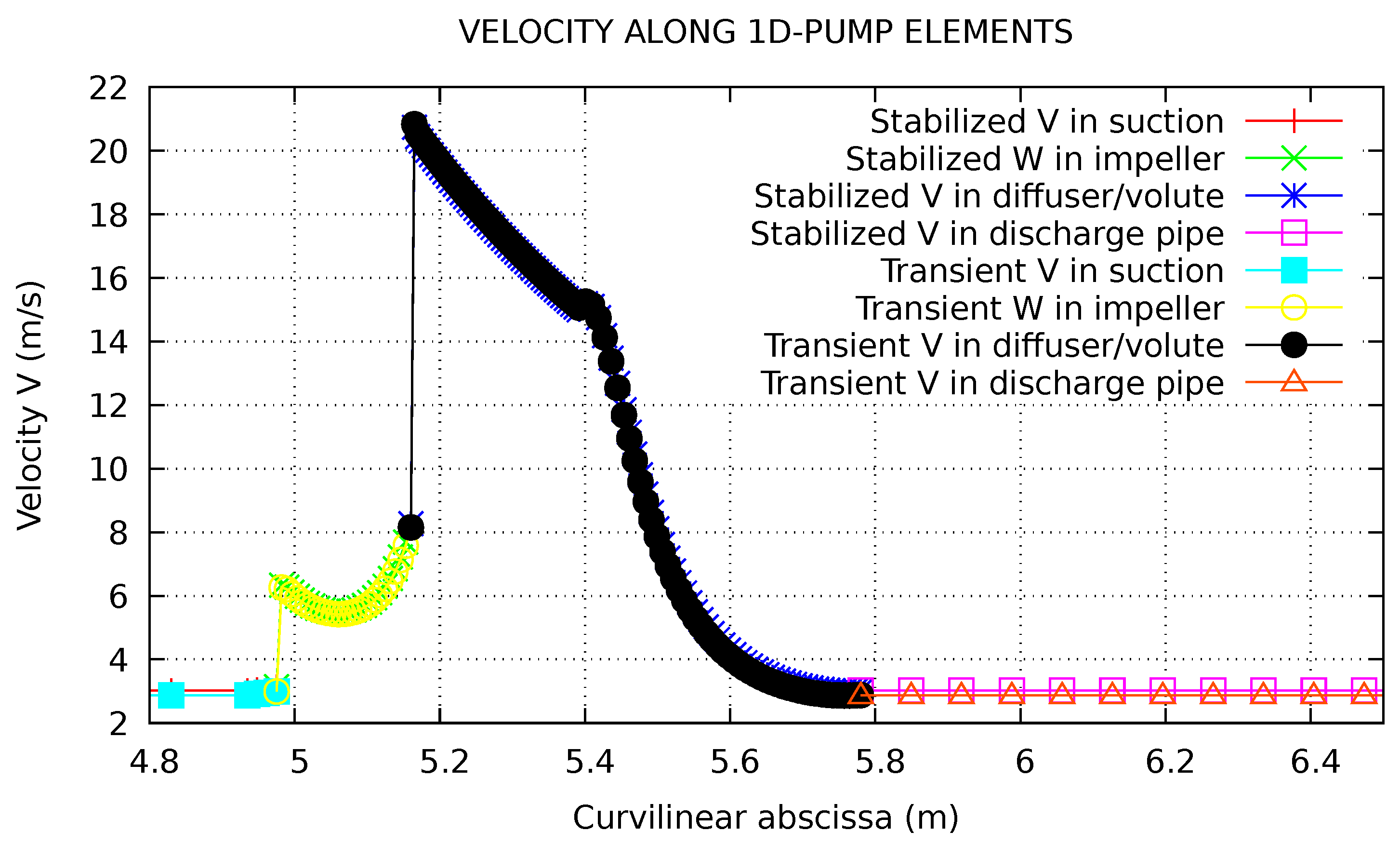

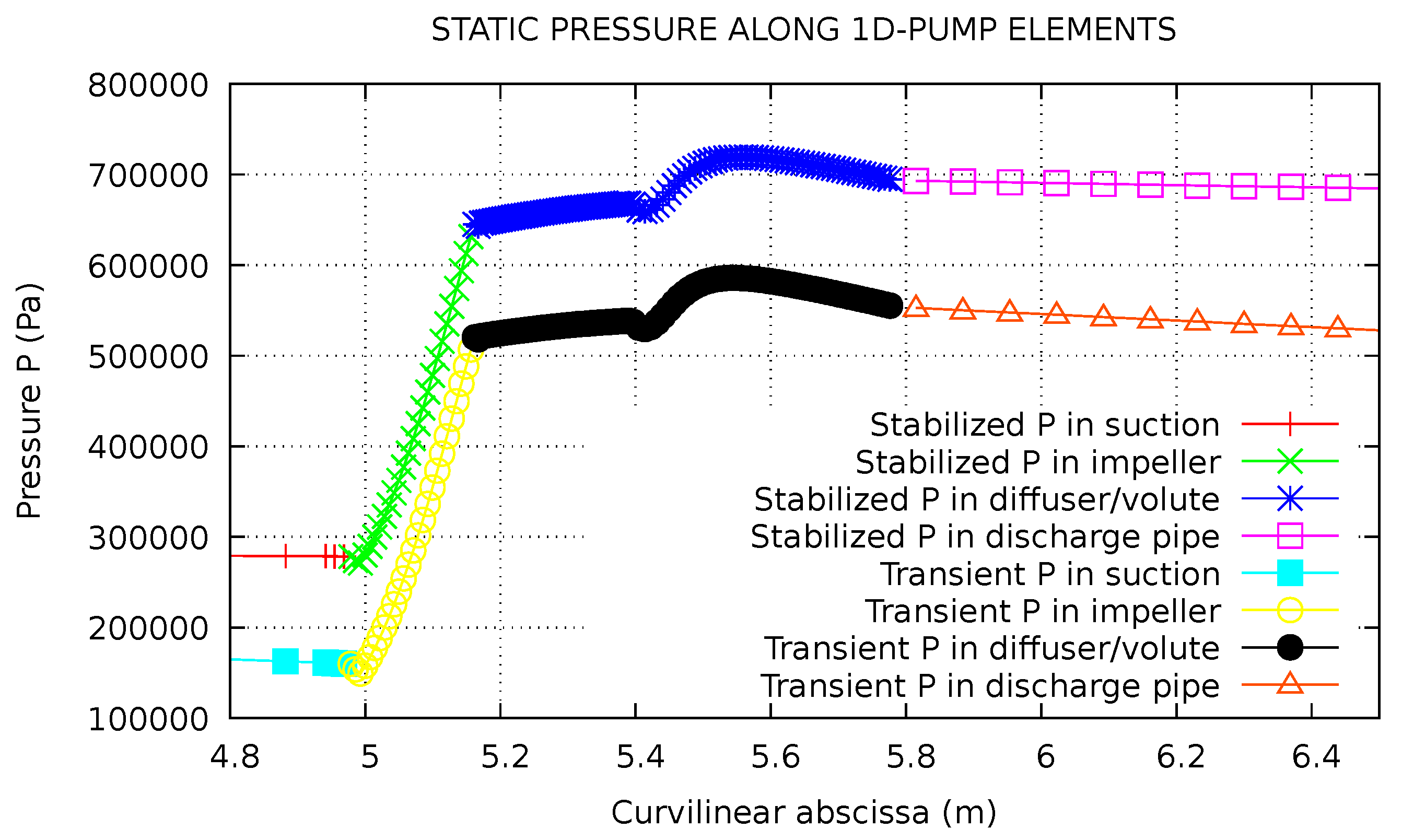

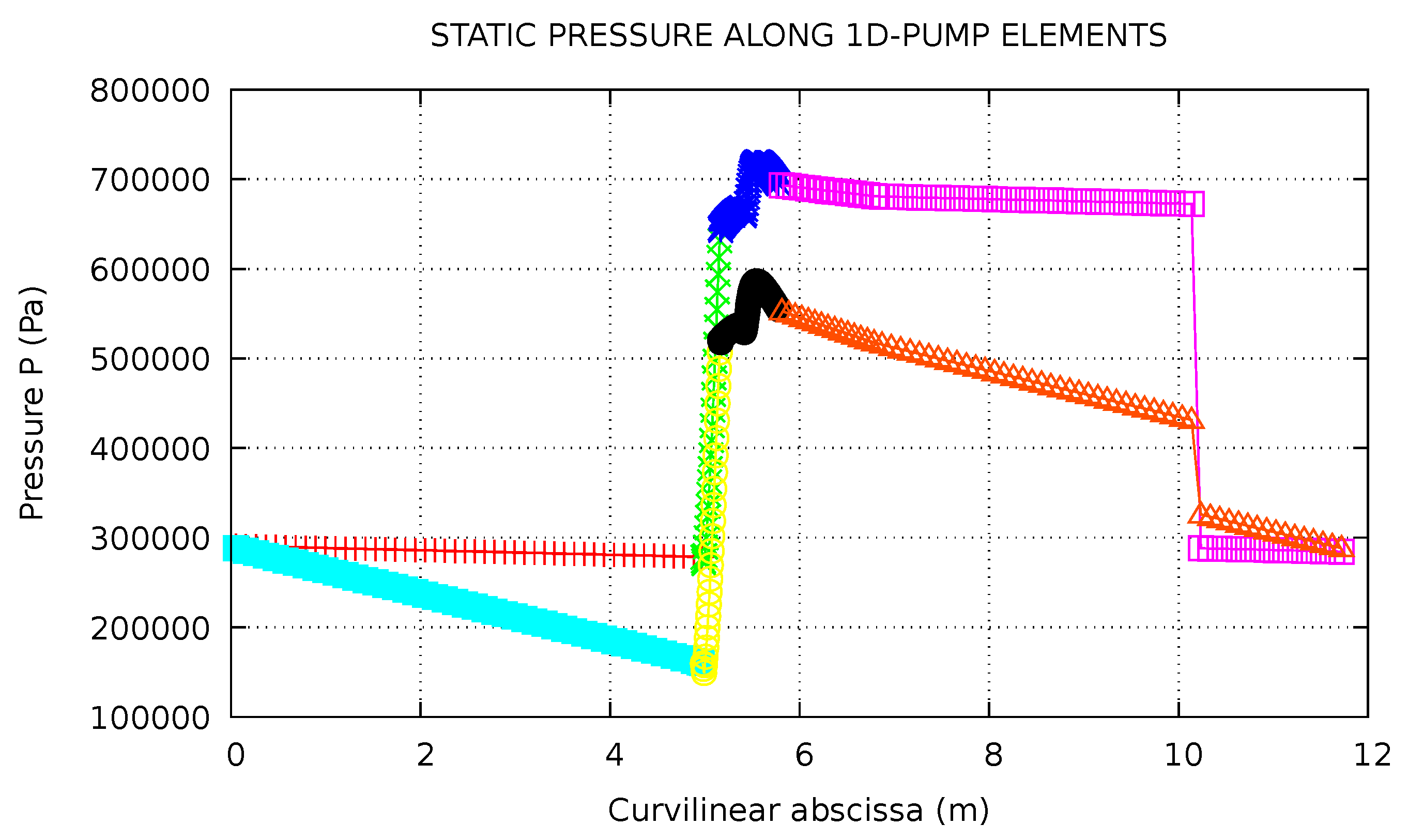

4.2. Fast Startup Transient (Whole Circuit)

4.2.1. Description of the Transient

- The pump was started slowly to reach its nominal speed and then the flow control valve was adjusted to obtain the desired final flow rate.

- The pump was stopped and, after stabilisation of the circuit, the fast startup was launched.

4.2.2. Evolution of Main Quantities During the Fast Startup

4.2.3. Pressure and Velocity Profiles Inside the Pump in Steady and Transient Conditions

5. Discussion

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CATHARE | Code for Analysis of THermalhydraulics during an Accident of Reactor and safety Evaluation |

| CPU | Central Processing Unit |

Nomenclature

| Reduced rotational speed or void fraction or absolute angle | |

| Reduced torque or added mass coefficient or relative angle | |

| Streamline orientation angle | |

| Mass transfer | |

| Variation of a quantity | |

| =1 for the gas and −1 for the liquid | |

| Reduced flow rate | |

| Density | |

| Interfacial friction | |

| Wall friction | |

| Heating perimeter | |

| Friction perimeter | |

| Rotational speed | |

| 1, 2 | Impeller inlet and outlet |

| 3, 4 | Diffuser inlet and outlet |

| 5, 6 | Volute inlet and outlet |

| A | Flow section |

| b | Width |

| D | Diameter or Desadaptation coefficient |

| g | Gravitational acceleration |

| h | Reduced head or mass enthalpy |

| H | Head |

| K | Loss coefficient |

| k | Phase index. k = L for liquid and k = G for gas |

| N | Rotational speed |

| Specific speed (European definition) | |

| P | Mean pressure |

| Interfacial pressure | |

| Q | Flow rate |

| Wall heat flux | |

| Interfacial heat flux | |

| R | Stratification rate or mean radius |

| Repartition function | |

| Mass, Energy and Momentum source terms | |

| t | Time |

| T | Torque |

| U | Blade velocity |

| V | Absolute fluid velocity |

| W | Relative fluid velocity |

| Interfacial velocity | |

| z | Curvilinear abscissa |

| Z | Blade number |

References

- Chenaud, M.; Li, S.; Anderhuber, M.; Matteo, L.; Gerschenfeld, A. Computational thermal hydraulic schemes for SFR transient studies. In Proceedings of the NURETH-16, Chicago, IL, USA, 30 August–4 September 2015. [Google Scholar]

- Bouchard, J. GenIV International Forum 2007; Annual Report; OECD Nuclear Energy Agency: Paris, France, 2007. [Google Scholar]

- Varaine, F.; Marsault, P.; Chenaud, M.S.; Bernardin, B.; Conti, A.; Sciora, P.; Venard, C.; Fontaine, B.; Devictor, N.; Martin, L.; et al. Pre-conceptual design of ASTRID core. In Proceedings of the 2012 International Congress on Advances in Nuclear Power Plants-ICAPP’12, Chicago, IL, USA, 24–28 June 2012. [Google Scholar]

- Tenchine, D.; Pialla, D.; Gauthé, P.; Vasile, A. Natural convection test in Phenix reactor and associated CATHARE calculation. Nucl. Eng. Des. 2012, 253, 23–31. [Google Scholar] [CrossRef]

- Miettinen, J. Nuclear power plant simulators: Goals and evolution. In Proceedings of the Seminar on Transfer of Competence, Knowledge and Experience Gained through CSNI Activities in the Field of Thermal-Hydraulics (THICKET), Pisa, Italy, 5–9 May 2008. [Google Scholar]

- Mauger, G.; Bentivoglio, F.; Tauveron, N. Description of an improved turbomachinery model to be developed in the CATHARE-3 code for ASTRID power conversion system application. In Proceedings of the 16th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-16), Chicago, IL, USA, 30 August–4 September 2015. [Google Scholar]

- Mauger, G.; Tauveron, N.; Bentivoglio, F.; Ruby, A. On the dynamic modeling of Brayton cycle power conversion systems with the CATHARE-3 code. Energy 2019, 168, 1002–1016. [Google Scholar] [CrossRef]

- Matteo, L.; Dazin, A.; Tauveron, N. Development and validation of a one-dimensional transient rotodynamic pump model at component scale. In Proceedings of the 29th IAHR Symposium on Hydraulic Machinery and Systems, Kyoto, Japan, 17–21 September 2018. [Google Scholar]

- Matteo, L.; Dazin, A.; Tauveron, N. Modelling of a centrifugal pump using the CATHARE-3 one-dimensional transient rotodynamic pump model. Int. J. Fluid Mach. Syst. 2019, 12, 147–158. [Google Scholar] [CrossRef]

- Matteo, L.; Moral, R.; Dazin, A.; Tauveron, N. Modelling of a radial pump fast startup with the CATHARE-3 code and analyse of the loop response. In Proceedings of the 13th European Conference on Turbomachinery Fluid dynamics & Thermodynamics, Lausanne, Switzerland, 8–12 April 2019. [Google Scholar]

- Matteo, L.; Dazin, A.; Tauveron, N. Qualification of the CATHARE-3 one-dimensional transient rotodynamic pump model on DERAP two-phase cavitating tests. In Proceedings of the ICAPP 2019—International Congress on Advances in Nuclear Power Plants, Juan-les-Pins, France, 12–15 May 2019. [Google Scholar]

- Matteo, L.; Cerru, F.; Dazin, A.; Tauveron, N. Investigation of the pump, dissipation and inverse turbine operating modes using the CATHARE-3 one-dimensional rotodynamic pump model. In Proceedings of the AJKFLUIDS, San Francisco, CA, USA, 28 July–1 August 2019. [Google Scholar]

- Matteo, L.; Gyomlai, P.; Dazin, A.; Tauveron, N. A rotodynamic pump seizure transient simulated using the CATHARE-3 one-dimensional pump model. In Proceedings of the NURETH-18, Portland, OR, USA, 18–22 August 2019. [Google Scholar]

- Kara-Omar, A.; Khaldi, A.; Ladouani, A. Prediction of centrifugal pump performance using energy loss analysis. Aust. J. Mech. Eng. 2017, 15, 210–221. [Google Scholar] [CrossRef]

- Duplaa, S.; Coutier-Delgosha, O.; Dazin, A.; Roussette, O.; Bois, G.; Caignaert, G. Experimental Study of a Cavitating Centrifugal Pump During Fast Startups. J. Fluids Eng. 2010, 132, 021301. [Google Scholar] [CrossRef]

- Barrand, J.P.; Ghelici, N.; Caignaert, G. Unsteady flow during fast start up of a centrifugal pump. ASME FED Pump. Mach. 1993, 154, 143–150. [Google Scholar]

- Ghelici, N. Etude du régime Transitoire de Démarrage Rapide D’une Pompe Centrifuge. Ph.D. Thesis, Université des Sciences et Technologies de Lille, Lille, France, 1993. [Google Scholar]

- Picavet, A. Etude de Phénomenes Hydrauliques Transitoires Lors du Démarrage Rapide D’une Pompe Centrifuge. Ph.D. Thesis, Ecole Nationale Supérieure d’Arts et Métiers, Paris, France, 1996. [Google Scholar]

- Picavet, A.; Barrand, J.P. Fast start up of a centrifugal pump-experimental study. In Proceedings of the Pump Congress, Karlsruhe, Germany, 30 September–2 October 1996; pp. 3–11. [Google Scholar]

- Barrand, J.P.; Picavet, A. Qualitative flow visualizations during fast start up of centrifugal pumps. In Proceedings of the XVIII IAHR Symposium on Hydraulic Machinery and Cavitation, Valencia, Spain, 16–19 September 1996; Volume 2, pp. 671–675. [Google Scholar]

- Bolpaire, S.; Barrand, J.P. Experimental study of the flow in the suction pipe of a centrifugal pump at partial flow rates in unsteady conditions. ASME J. Press. Vessel Technol. 1999, 121, 291–295. [Google Scholar] [CrossRef]

- Bolpaire, S. Etude des Écoulements Instationnaires Dans une Pompe en Régime de Démarrage ou Régime établi. Ph.D. Thesis, Ecole Nationale Supérieure d’Arts et Métiers, Paris, France, 2000. [Google Scholar]

- Bolpaire, S.; Barrand, J.P.; Caignaert, G. Experimental study of the flow in the suction pipe of a centrifugal impeller: Steady conditions compared with fast start-up. Int. J. Rotating Mach. 2002, 8, 215–222. [Google Scholar] [CrossRef]

- Duplaa, S. Etude expérimentale du fonctionnement cavitant d’une pompe lors de séquences de démarrage rapide. Ph.D. Thesis, Arts et Métiers ParisTech, Paris, France, 2008. [Google Scholar]

- Duplaa, S.; Coutier-Delgosha, O.; Dazin, A.; Bois, G. X-ray Measurements in a Cavitating Centrifugal Pump During Fast Start-Ups. J. Fluids Eng. 2013, 135, 041204. [Google Scholar] [CrossRef]

- Gulich, J.F. Centrifugal Pumps; Springer: Cham, Switzerland, 2014. [Google Scholar]

- Barre, F.; Bernard, M. The CATHARE code strategy and assessment. Nucl. Eng. Des. 1990, 124, 257–284. [Google Scholar] [CrossRef]

- Faydide, B.; Rousseau, J. Two-phase flow modeling with thermal and mechanical non equilibrium. In Proceedings of the European Two Phase Flow Group Meeting, Glasgow, UK, 3–6 June 1980. [Google Scholar]

- Bestion, D. The physical closure laws in the CATHARE code. Nucl. Eng. Des. 1990, 124, 229–245. [Google Scholar] [CrossRef]

- Dou, H. A Method of Predicting the Energy Losses in Vaneless Diffusers of Centrifugal Compressors. In Gas Turbine and Aeroengine Congress and Exposition; American Society of Mechanical Engineers Digital Collection: Toronto, ON, Canada, 1989. [Google Scholar]

- Stanitz, J.D. One-Dimensional Compressible Flow in Vaneless Diffusers of Radial- and Mixed-Flow Centrifugal Compressors, Including Effects of Friction, Heat Transfer and Area Change; National Advisory Committee for Aeronautics: Washington, DC, USA, 1952. [Google Scholar]

- Stodola, A. Steam and Gas Turbines; McGraw-Hill New York: New York, NY, USA, 1927. [Google Scholar]

- Stanitz, J.D. Some theoretical aerodynamic investigations of impellers in radial and mixed-flow centrifugal compressors. Trans. ASME 1952, 74, 473–497. [Google Scholar]

- Wiesner, F.J. A Review of Slip Factors for Centrifugal Impellers. J. Eng. Power 1967, 89, 558–572. [Google Scholar] [CrossRef]

- Qiu, X.; Japikse, D.; Zhao, J.; Anderson, M.R. Analysis and Validation of a Unified Slip Factor Model for Impellers at Design and Off-design Conditions. J. Turbomach. 2011, 133, 1–10. [Google Scholar] [CrossRef]

- Zigrang, D.; Sylvester, N. Explicit approximations to the solution of Colebrook’s friction factor equation. AIChE J. 1982, 28, 514–515. [Google Scholar] [CrossRef]

- Pfleiderer, C. Die Kreiselpumpen; Springer: Berlin/Heidelberg, Germany, 1961. [Google Scholar]

- Eck, B. Ventilatoren; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 1972. [Google Scholar]

- Paeng, K.; Chung, M. A new slip factor for centrifugal impellers. Proc. Inst. Mech. Eng. Part A 2001, 215, 645–649. [Google Scholar] [CrossRef]

- Dixon, S.L.; Hall, C.A. Fluid Mechanics and Thermodynamics of Turbomachinery; BH Elsevier: Oxford, UK, 2014. [Google Scholar]

- Saez, M.; Tauveron, N.; Chataing, T.; Geffraye, G.; Briottet, L.; Alborghetti, N. Analysis of the turbine deblading in a HTGR with the CATHARE code. Nuclear Eng. Des. 2006, 236, 574–586. [Google Scholar] [CrossRef]

- Baviere, R.; Tauveron, N.; Perdu, F.; Garré, E.; Li, S. A first system/CFD coupled simulation of a complete nuclear reactor transient using CATHARE2 and TRIO U. Preliminary validation on the Phénix Reactor Natural Circulation Test. Nucl. Eng. Des. 2014, 277, 124–137. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Matteo, L.; Mauger, G.; Dazin, A.; Tauveron, N. Simulation of a Radial Pump Fast Startup and Analysis of the Loop Response Using a Transient 1D Mean Stream Line Based Model. Int. J. Turbomach. Propuls. Power 2019, 4, 38. https://doi.org/10.3390/ijtpp4040038

Matteo L, Mauger G, Dazin A, Tauveron N. Simulation of a Radial Pump Fast Startup and Analysis of the Loop Response Using a Transient 1D Mean Stream Line Based Model. International Journal of Turbomachinery, Propulsion and Power. 2019; 4(4):38. https://doi.org/10.3390/ijtpp4040038

Chicago/Turabian StyleMatteo, Laura, Gédéon Mauger, Antoine Dazin, and Nicolas Tauveron. 2019. "Simulation of a Radial Pump Fast Startup and Analysis of the Loop Response Using a Transient 1D Mean Stream Line Based Model" International Journal of Turbomachinery, Propulsion and Power 4, no. 4: 38. https://doi.org/10.3390/ijtpp4040038

APA StyleMatteo, L., Mauger, G., Dazin, A., & Tauveron, N. (2019). Simulation of a Radial Pump Fast Startup and Analysis of the Loop Response Using a Transient 1D Mean Stream Line Based Model. International Journal of Turbomachinery, Propulsion and Power, 4(4), 38. https://doi.org/10.3390/ijtpp4040038