4. Numerical Methods

An in-house code developed at the Faculty of Mechanical Engineering, Czech Technical University, Prague, was used for calculation of transonic and supersonic flow fields. The code is based on the solution of the Favre averaged Navier–Stokes equations and k–ω SST turbulence model by implicit finite volume method with AUSMPW+ scheme in high-resolution formulation. The detailed description of the numerical method can be found in [

2]. Simulations were done also with the correlation based

γ-Re

θ transition and turbulence model by [

6]; for details see [

7].

Ansys Fluent software package (v18, Ansys Inc., Canonsburg, PA, USA) was used as representative commercial code for calculation of the same geometries at similar thermodynamic boundary conditions. The set of density averaged Navier–Stokes equations closed with the k–ω SST turbulence model.

Although both codes are based on similar models and similar numerical methods, they differ in some details including the implementation of boundary conditions and the solution procedure. Our experience show that the ANSYS Fluent has, despite very good overall performance, some difficulties with regimes with M1 ~ 1. Therefore, the in-house code was used for these problematic regimes.

For all calculations 2D single profile geometry with the periodicity boundary condition on the channel boundaries was used. The position of the inlet and outlet plane is far from the cascade compared to the axial chord. In case of the tip section simulations with in-house code, inlet and outlet were positioned in the distance of two chords upstream of the cascade and one chord downstream of the cascade, respectively. In the simulations with Ansys Fluent for both tip sections and root sections, inlet and outlet were positioned in the distance of one chord from the blade cascade. A non-reflecting boundary condition was applied at outlet plane.

5. Results and Discussion

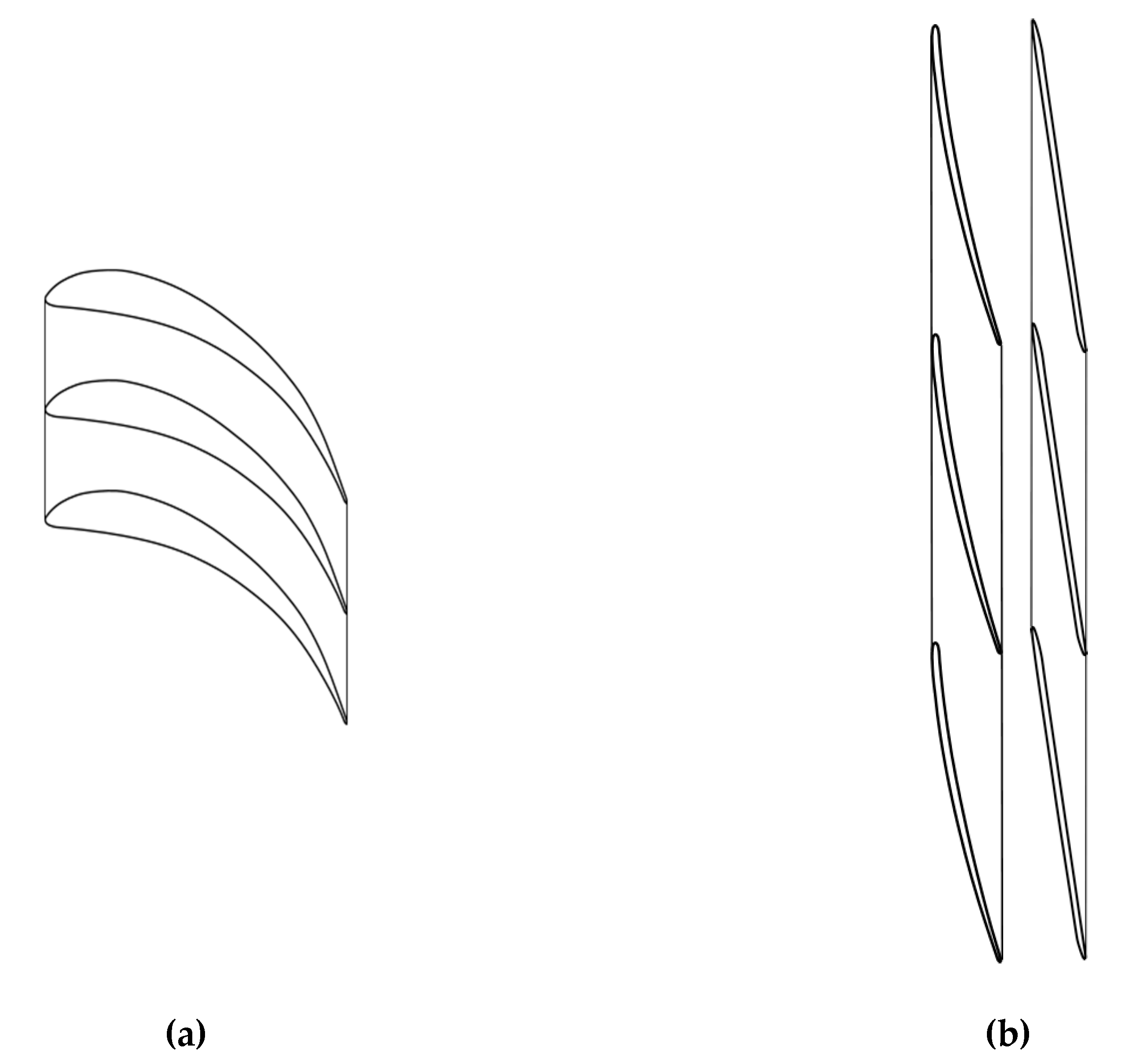

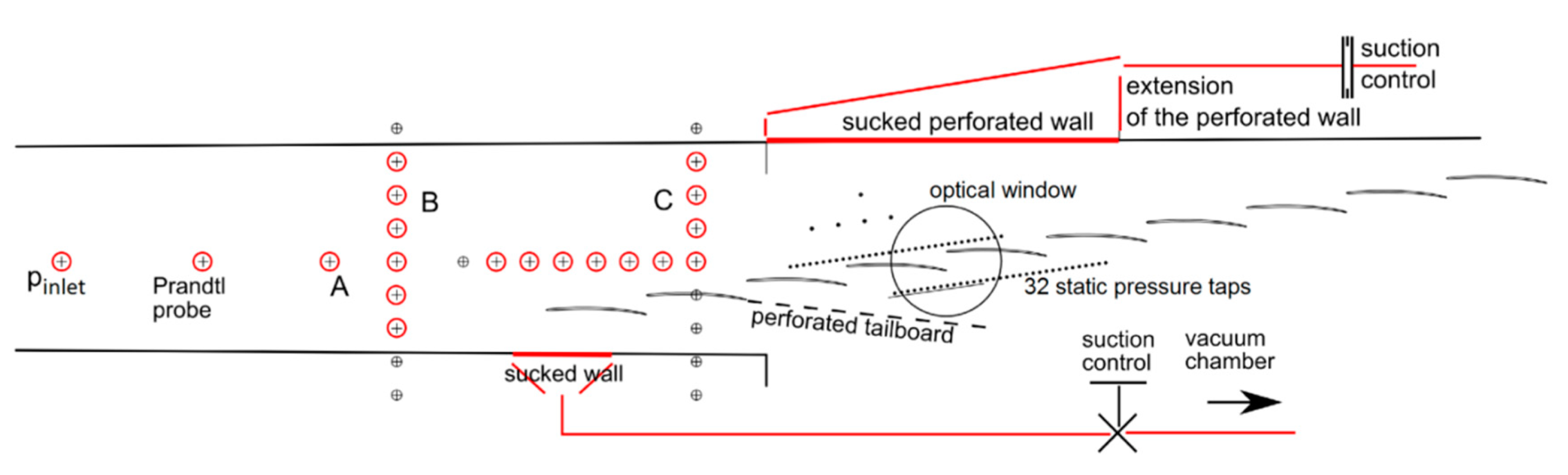

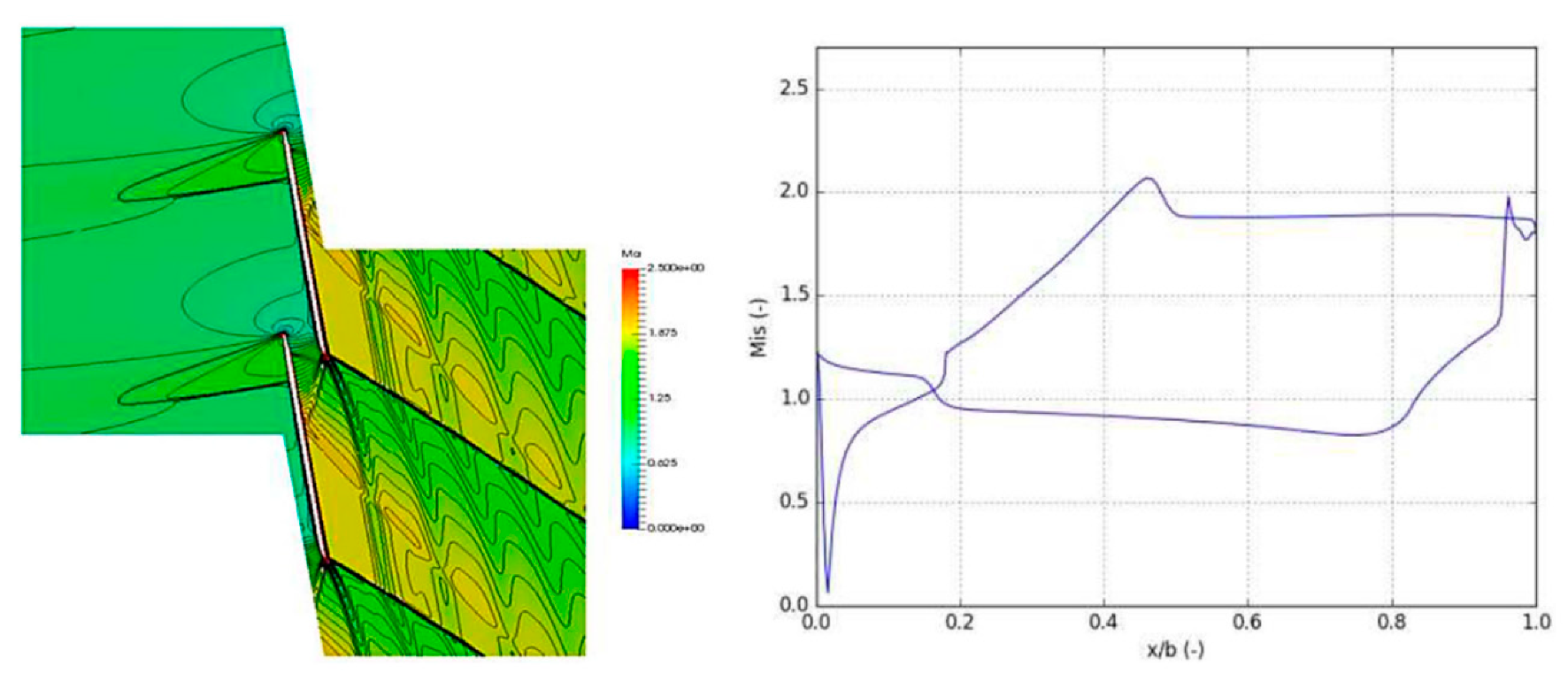

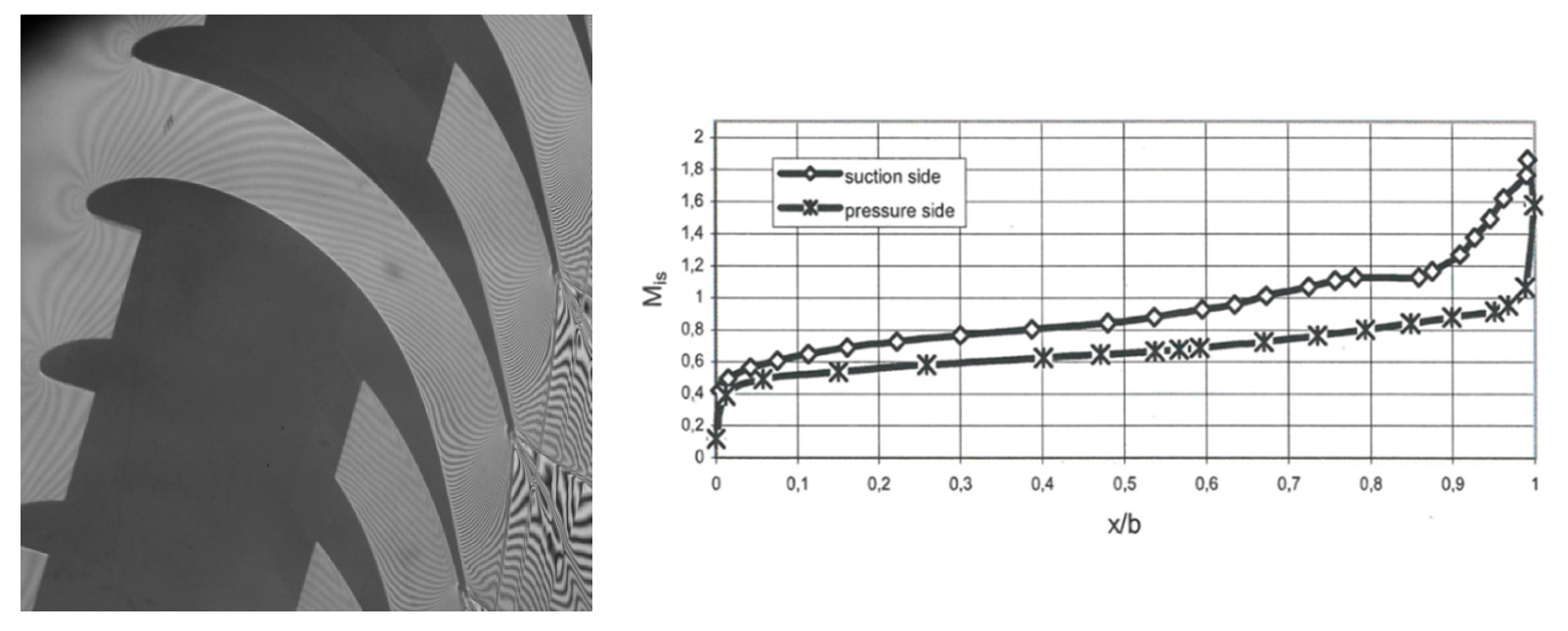

Two very high values of aerodynamic loading representing two operation points of the innovative tip cascade of ultra-long last stage blade can be seen in

Figure 3 and

Figure 4. In both supersonic regimes the tip cascade exhibits impressive aerodynamic performance with only very small area where the aerodynamic force acts in the opposite direction, decreasing the overall torque of the last stage blade.

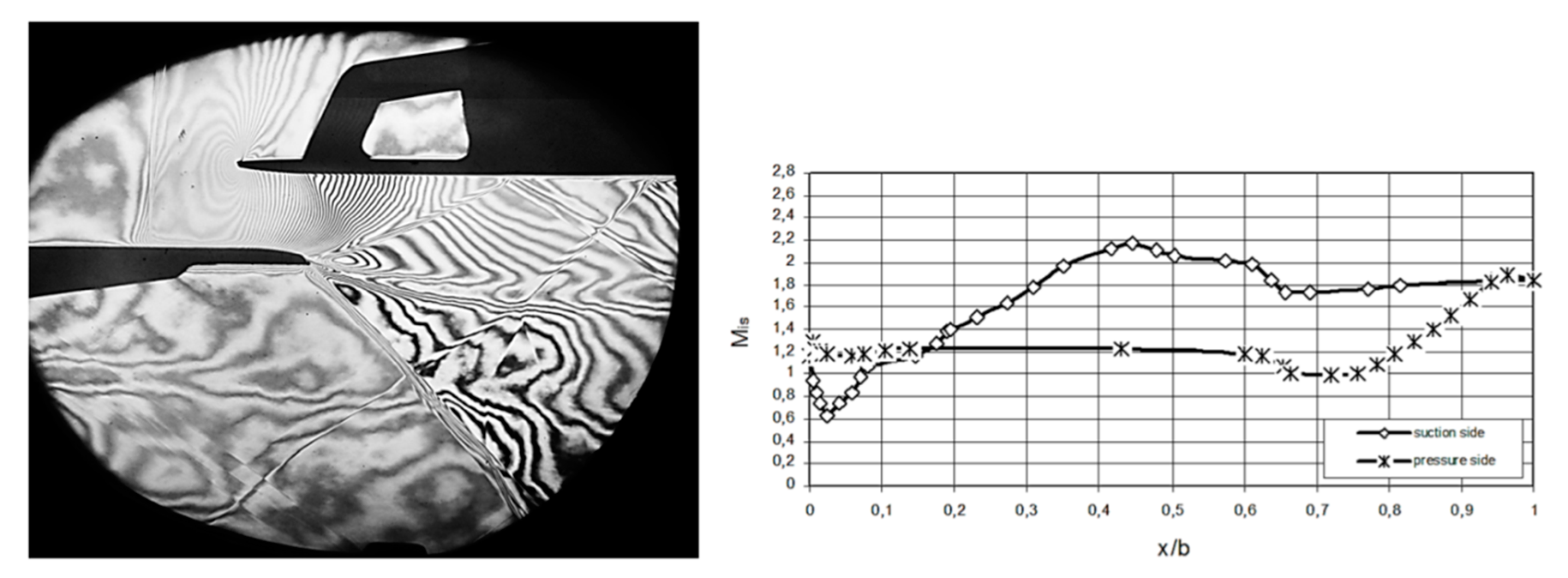

In

Figure 3 the perpendicular inlet shock wave can be seen as a result of supersonic inlet Mach number. The inlet shock wave interacts with the pressure side of the neighboring profile which leads to a decrease of M

is near the 70% of axial chord as can be seen from Mach number distribution in

Figure 3. The complicated flow structure can be seen at cascade exit including the inner and outer branch of the exit shock wave together with wake. Furthermore, the parasitic shock wave reflected into measured area from the exit flow boundary is present resulting in artificial decrease of M

is in the vicinity of the suction side of profile at 60% of axial chord.

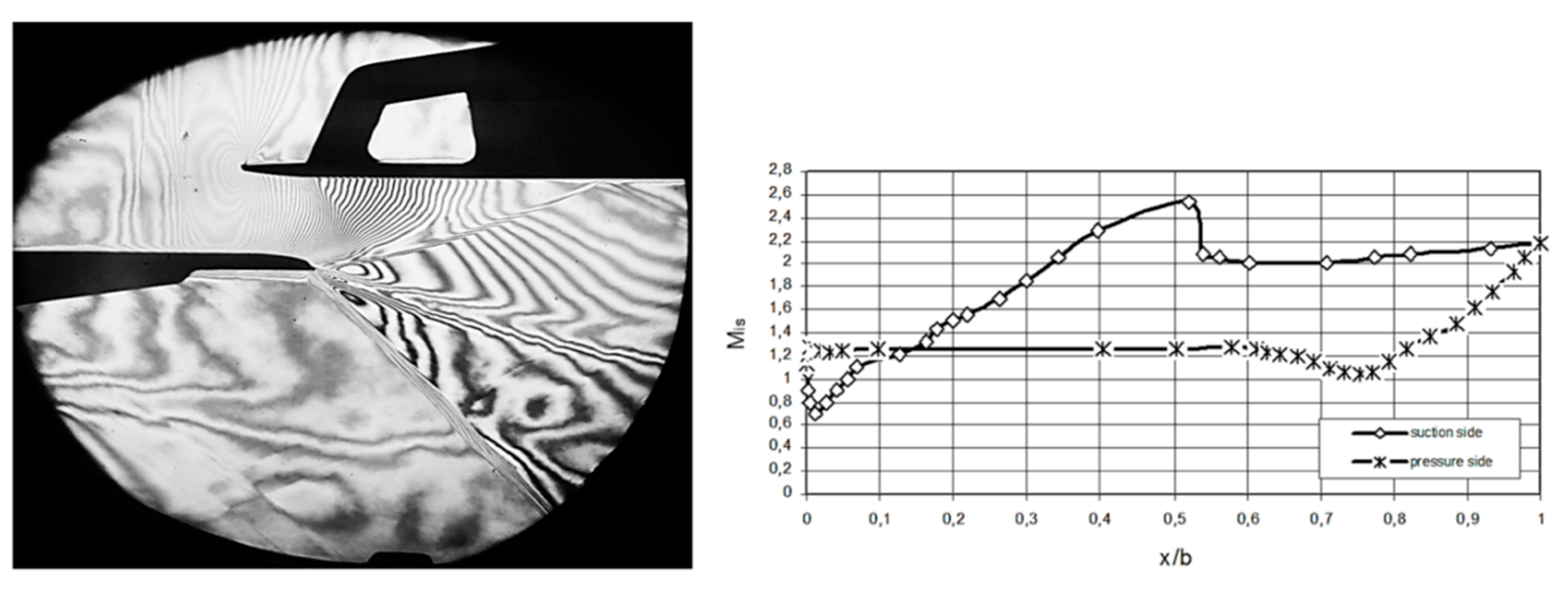

In

Figure 4 the similar behavior of the perpendicular inlet shock wave together with interaction at pressure side of the corresponding profile can be seen. However, the differences appear behind the trailing edge of the profile with variation in angles of the inner and outer branch of the exit shock wave and wake indicating higher outlet velocity. Moreover, the parasitic shock wave is not present which results in a less complicated flow field better reflecting the real cascade performance.

In numerical methods there are serious complications for supersonic inlet due to the unique incidence rule (see [

4]) which states that the value of the incidence angle corresponding to a particular inlet Mach number is dependent on the cascade geometry only. The inlet conditions and the overall flow field vary extensively with each 0.1° change of inlet incidence angle.

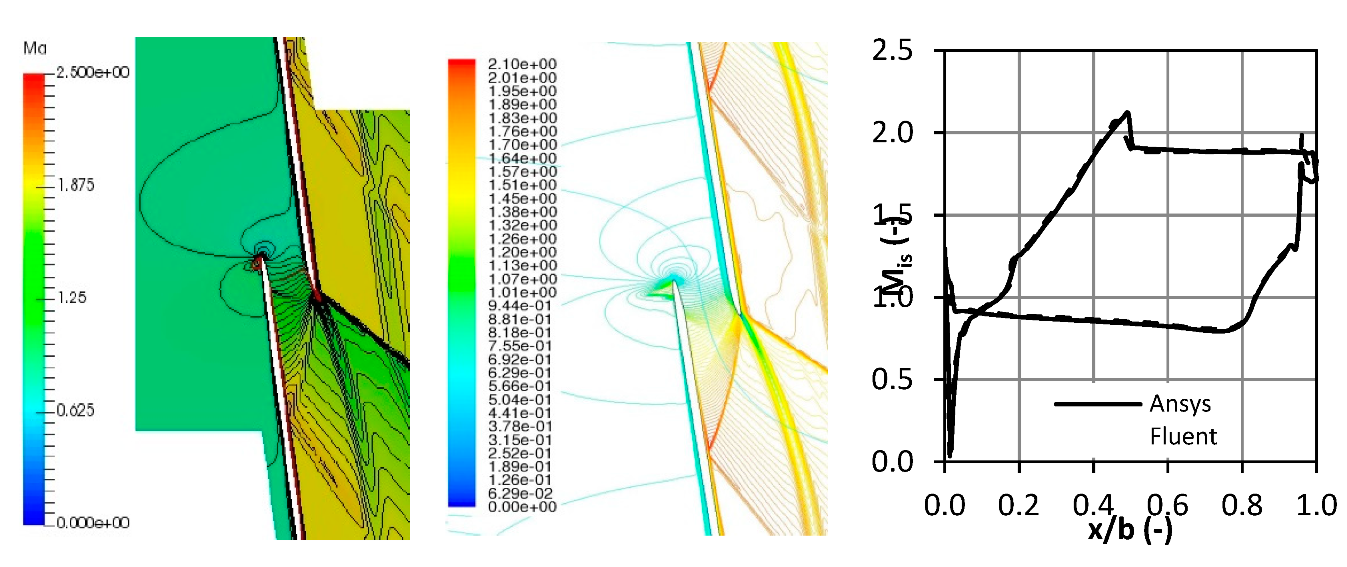

The regime closest to the measured ones was computed using in-house code with

γ-Re

θ transition and turbulence model and the result is shown in

Figure 5. Inlet Mach number is relatively close to 1.2 and the isentropic exit Mach number is just between that of interferograms in

Figure 3 and

Figure 4. The flow structure is well predicted with the normal shock standing in front of the leading edge. Interaction of the inner branch of exit shock wave with the suction side boundary layer resulting in the local flow separation is in agreement with the experiments. The distribution of M

is along profiles also corresponds well to the experimental results. The difference in the level of M

is on the suction side behind x/b ~ 0.55 can be partially attributed to difficulties with evaluation of interferograms and presence of aperiodic flow phenomena.

Operation point with the slightly supersonic inlet Mach number M

1 = 1.03 was calculated by in-house code as can be seen in

Figure 6. There is no normal inlet shock wave in front of the leading edge of profile. Instead, the supersonic area ending by shock wave at 20% of axial chord is present near the leading edge at the pressure side of the profile. M

is distribution is in the vicinity of suction side with a drop between 40% and 50% which is in good agreement with experimental results. This regime corresponds to M

is between the two measured aerodynamic loadings.

The results of commercial code calculation are shown in

Figure 7 together with results of the in-house code. In this case inlet Mach number is even smaller, M

1 = 0.88, since for higher inlet Mach numbers, commercial code predicted non-physical phenomena at inlet of the blade cascade. Agreement between the two codes in this regime is good. Both predicted a very small supersonic region terminated by a normal shock wave on the pressure side at the leading edge. The calculated exit flow field corresponds well to the results of experiments and calculations with in-house codes presented above.

A useful criterion for comparison of aerodynamic behavior of two different profiles of a rotating blade at the same thermodynamic boundary conditions (such as space and time distributions of pressure, enthalpy and velocity vector of working fluid) is the ratio of tangential and axial component of force affecting each profile. As the principle of the turbine is conversion of fluid thermodynamic free energy to torque of the rotor, the tangential component of the force can be seen as beneficial (contributing to torque), contrary to the axial component related with energy leaving the cascade without doing work. This means that profile with higher force ratio at the same thermodynamic conditions is more efficient in the energy to torque conversion.

The comparison of force ratio for original and innovative tip profile depending on flow inlet angle at two different aerodynamic loadings is shown in

Figure 8. The original profile was described in detail by [

4]. The innovative tip profile exhibits a similar evolution of the force ratio for both aerodynamic loadings while the original tip profile shows significantly worse force ratio for low aerodynamic loading.

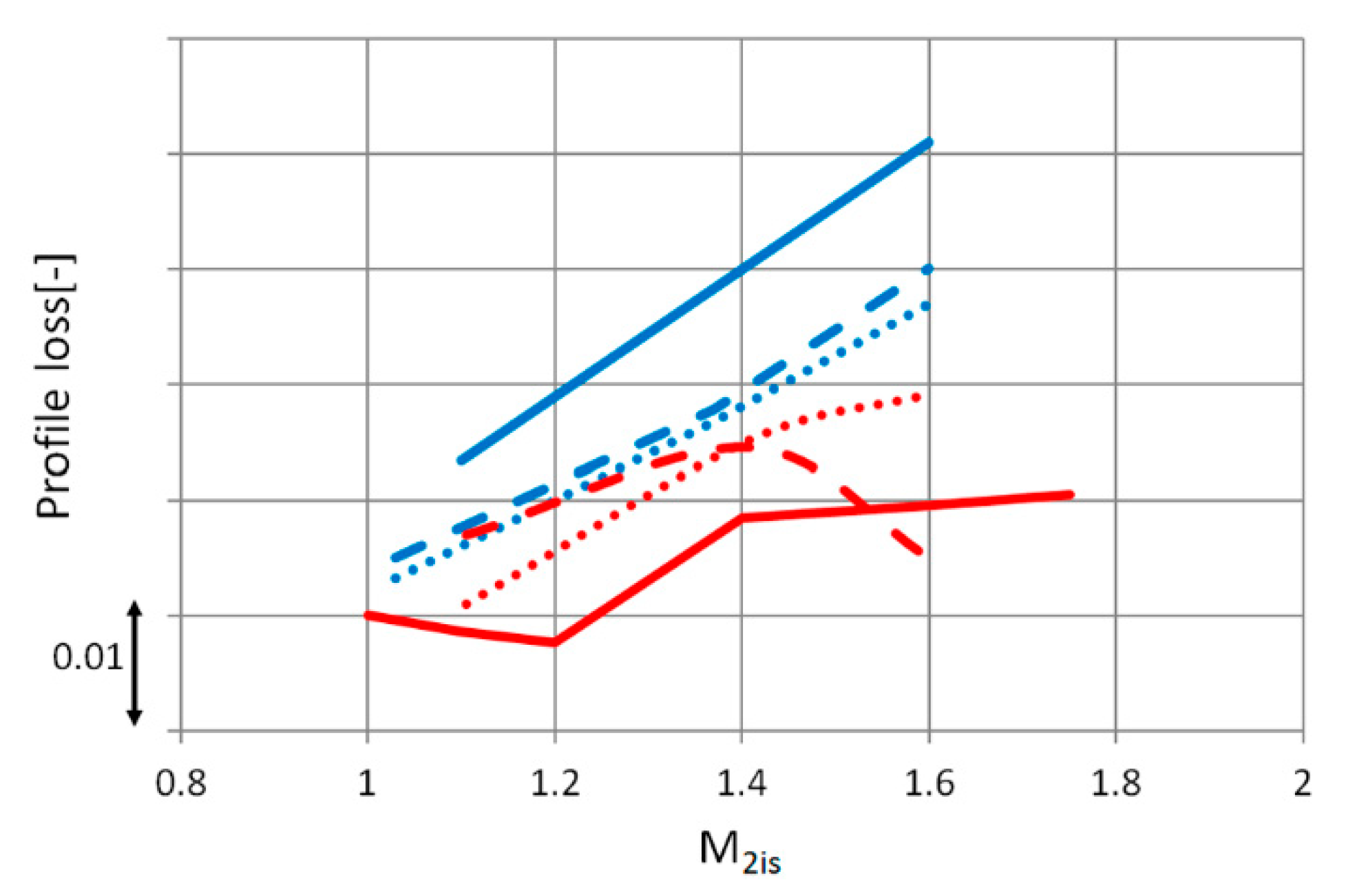

The full potential of innovative tip profile has been demonstrated by measurement in a high-speed tunnel. Comparison of measured profile loss for original and innovative tip profile for two values 1.0 and 1.2 of inlet Mach number is shown in

Figure 9. There can be seen a similar low value of profile losses in a wide range of outlet Mach number for both values 1.0 and 1.2 of inlet Mach number for innovative design. Conversely, the profile losses of original tip profile rise significantly both for higher inlet Mach number and lower outlet Mach number. From these results is apparent that the innovative tip cascade provides strong benefits in a large operating range.

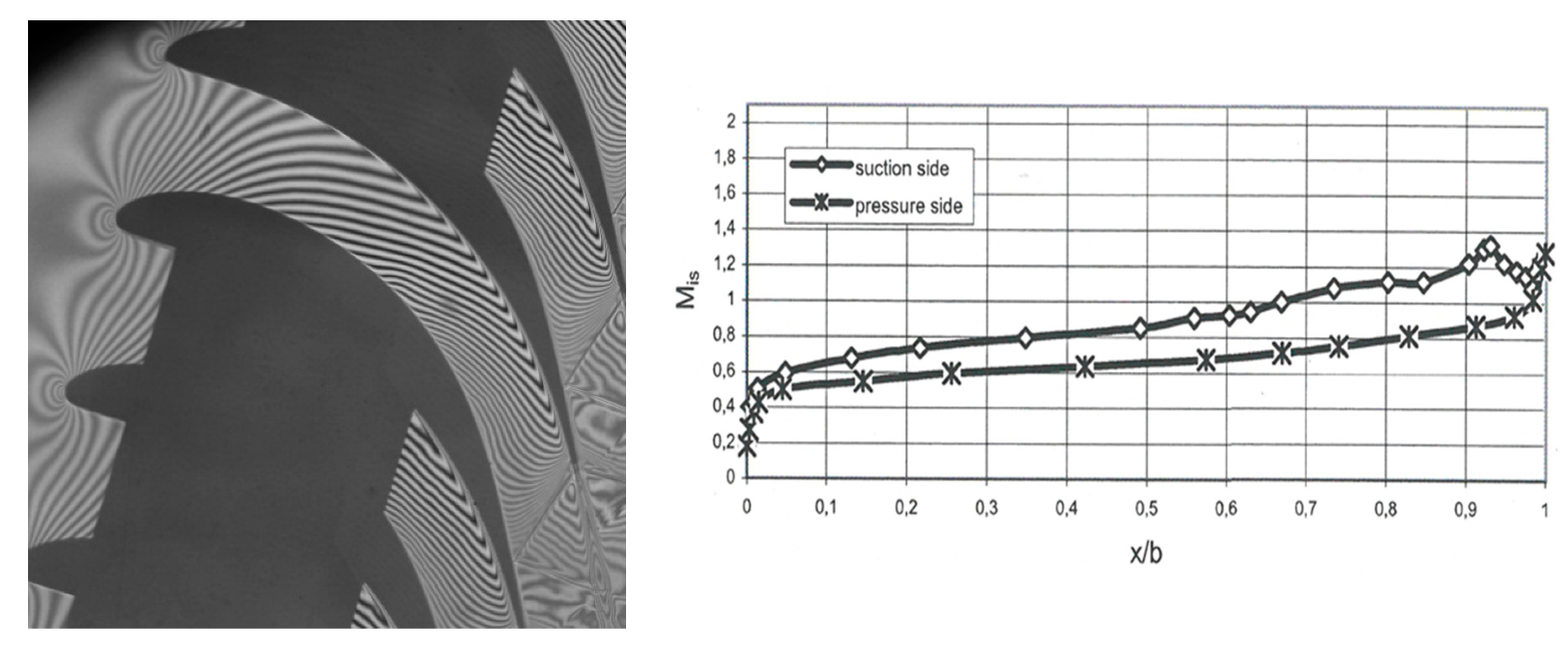

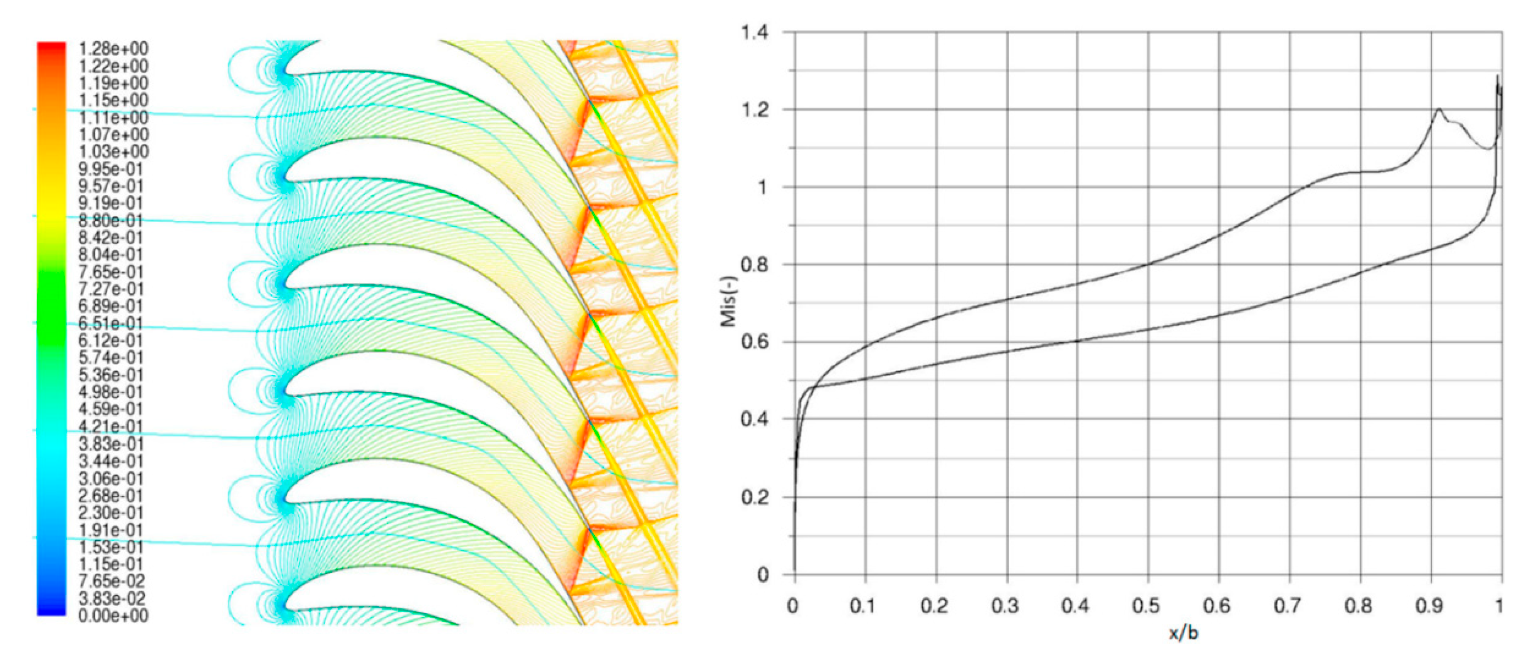

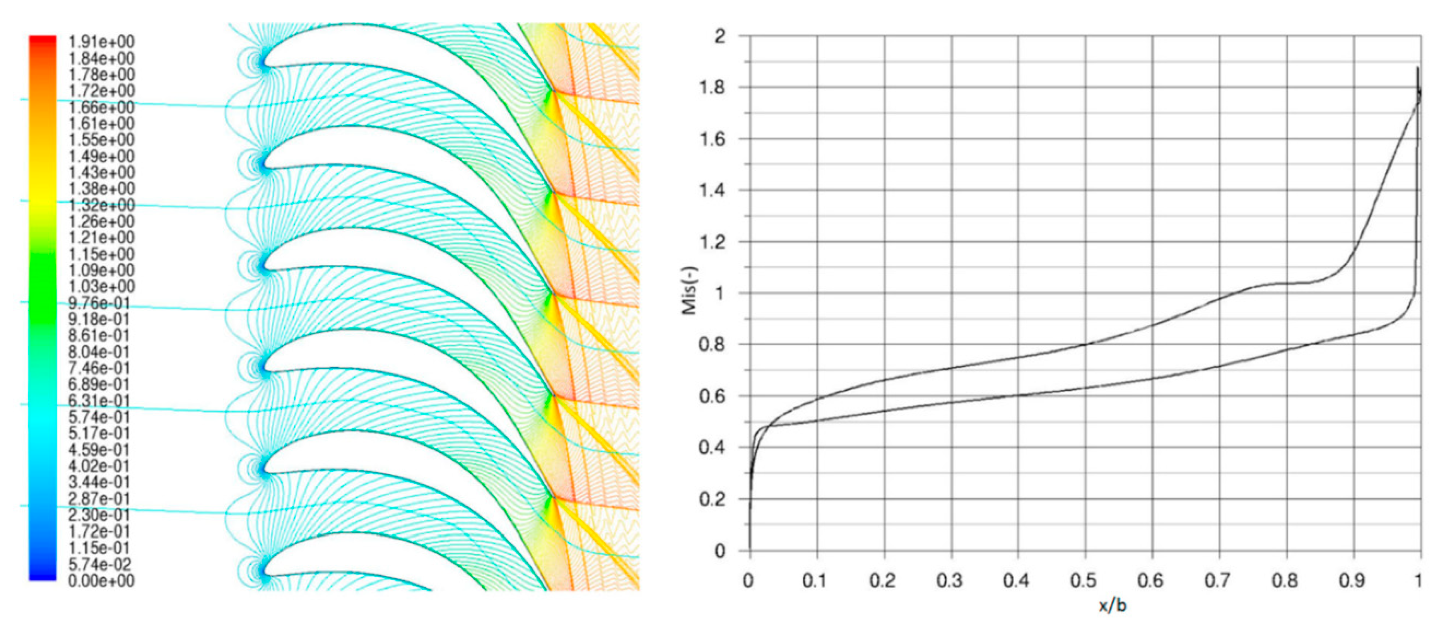

The flow field in the vicinity of the hub profile differs significantly from the tip cascade flow fields discussed above. The dense channel with low convergence results in slow steady acceleration of the flow as can be seen in

Figure 10 and

Figure 11. The inner branch of the exit shock wave together with wake and outer branch of the shock wave are visible both in the interferogram and in the computed Mach number isolines. The inner branch of the shock wave hits the suction side of neighboring profile near 90% of axial chord and results in a decrease of the Mach number in the vicinity of suction side trailing edge.

In

Figure 12 and

Figure 13 the different operating point with significantly higher aerodynamic loading and thus with higher M

2is is present. The flow acceleration is slow and steady in the main portion of the channel in agreement with the previous case. The main difference is near the last 15% of axial chord where the rapid acceleration takes place with peak value up to M

is = 1.8. The sharper angle of inner and outer branch of the shock wave also confirms the higher outlet Mach number. The inner branch of the exit shock misses the suction side of neighbor profile indicating the operation beyond the limit load condition.

There can be seen high conformity in experimental and calculated results for both operating regimes of hub cascade in terms of flow field pattern and isentropic Mach number distribution. On the other hand, significant discrepancy can be seen for integral profile loss evaluation.

The profile loss function on aerodynamic loading represented by M

is can be seen in

Figure 14. For the original hub profile (presented in [

3]) the calculated values are almost the same for both in-house and commercial code. Furthermore, the trend of increasing of profile loss with higher aerodynamic loading of the hub cascade can be seen in experimental results as well, although the absolute value of the profile losses is approximately 1% higher.

On the other hand, for the presented innovative hub profile the profile loss evolution is more complicated. The calculated results for in-house and commercial code agree with each other up to Mis = 1.4. For higher aerodynamic loading the in-house code predicts the decrease in the profile losses. The non-linear dependency is confirmed with experimental data as well. The difference in profile losses is again around 1% but with lower profile losses for the experimental data.

The significantly higher experimental profile losses by 3% can be associated with more complicated structure of flow field for original hub cascade leading to higher energy dissipation as is described in more detail by [

3]. This important information confirms the necessity of experimental verification of calculated results especially for complicated transonic and supersonic flow fields in the vicinity last stage blade cascades.

6. Conclusions

Advanced hub and tip profiles of ultra-long last stage blade were analyzed by both experimental and numerical methods. The optical measurements of transonic and supersonic flow fields were performed in high-speed wind tunnel in the Aerodynamic Laboratory of the Institute of Thermomechanics of the Czech Academy of Sciences. Commercial and in-house software of CTU Prague were used for calculating the corresponding flow fields.

For the tip cascade, the perpendicular inlet shock wave was observed as a result of supersonic inlet Mach number. This phenomenon could not be reproduced by tested numerical codes. The flow structure at cascade exit includes the inner and outer branch of the exit shock wave together with wake. These structures were well reproduced by numerical calculations including position of interaction of the inner branch of the exit shock with suction side of neighboring profile.

The dense hub channel with low convergence results in slow steady acceleration of the flow. The high conformity in experimental and calculated results in terms of flow field pattern and isentropic Mach number distribution was in contrast with significant discrepancy of integral profile loss evaluation.

Both hub and tip cascades were compared with the similar profiles presented in the past. The overall aerodynamic performance was significantly improved in both cases.

The comparison of experimental and numerical results shows limits of both methods. In particular, in the experiment, the parasitic shock wave reflected into measured area from the test section wall resulting in artificial decrease of isentropic Mach number near the suction side of the profile. On the other hand, the numerical methods had issues with supersonic inlet and integral profile loss evaluation. The in-house code exhibits lower overall discrepancy of loss evaluation for the innovative hub cascade.