Combined Experimental and CFD Investigation of Flat Plate Film Cooling through Fan Shaped Holes

Abstract

:1. Introduction

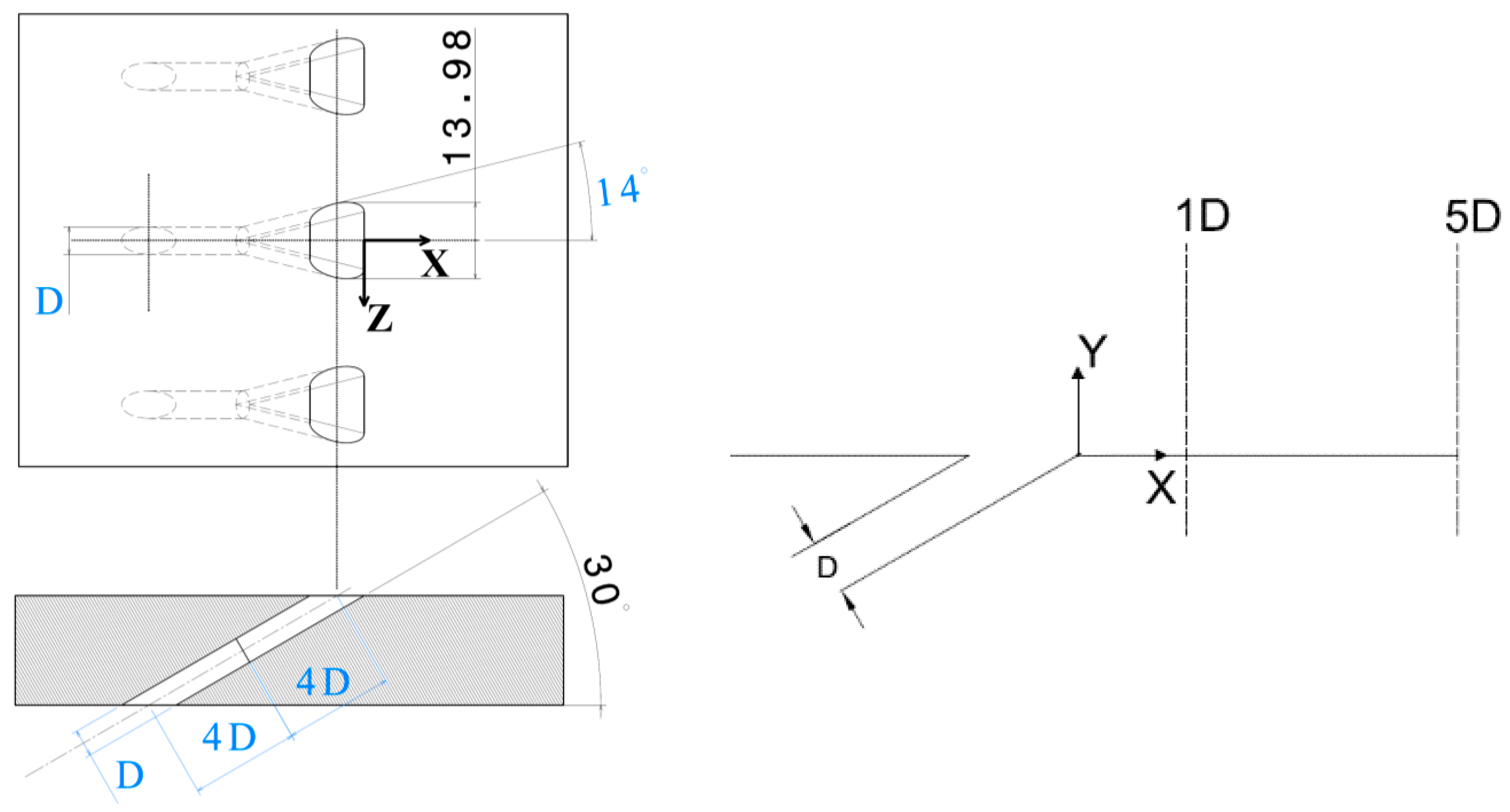

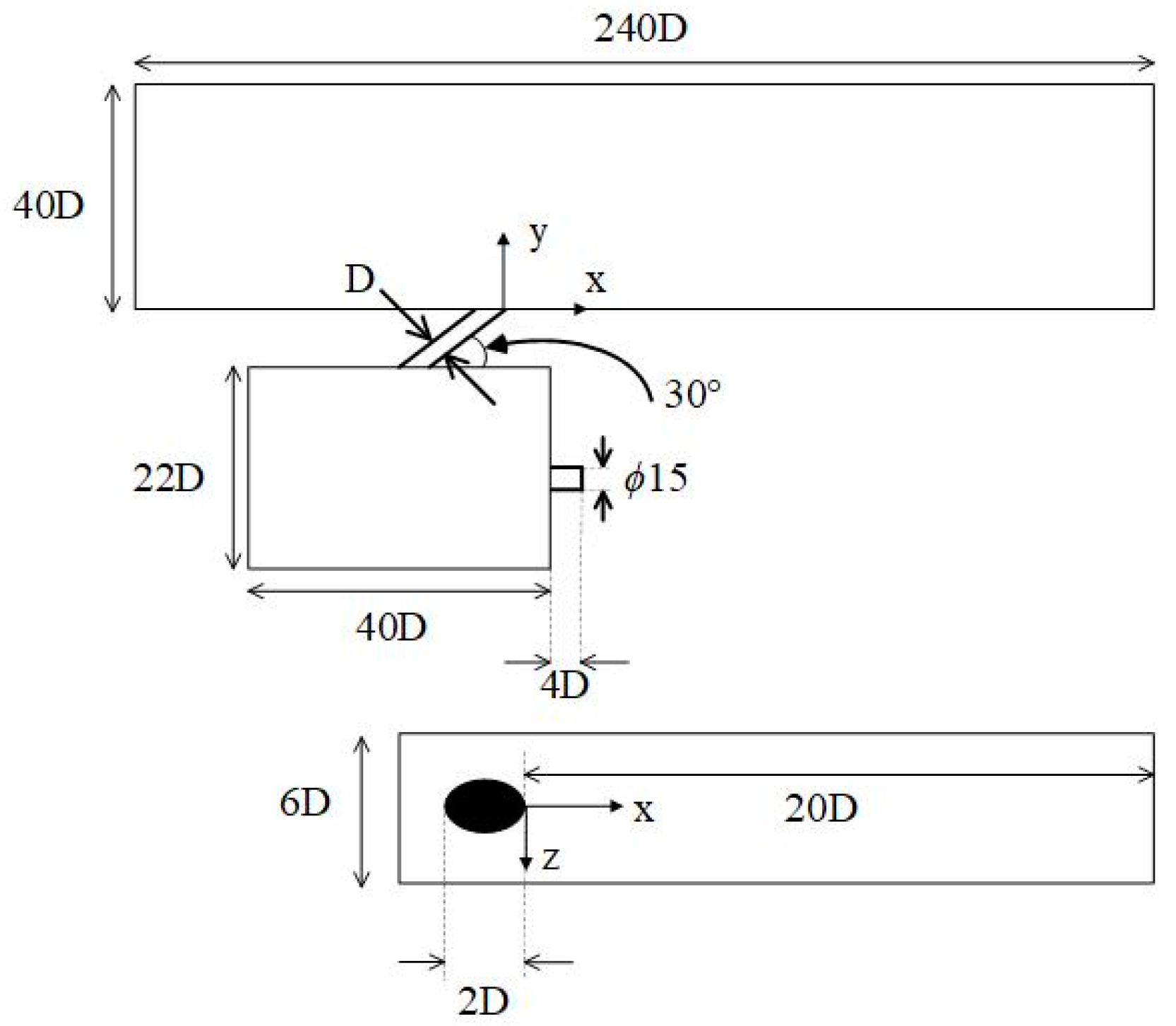

2. Experimental Set-Up

3. Computational Set-Up

3.1. Numerical Method and Boundary Conditions

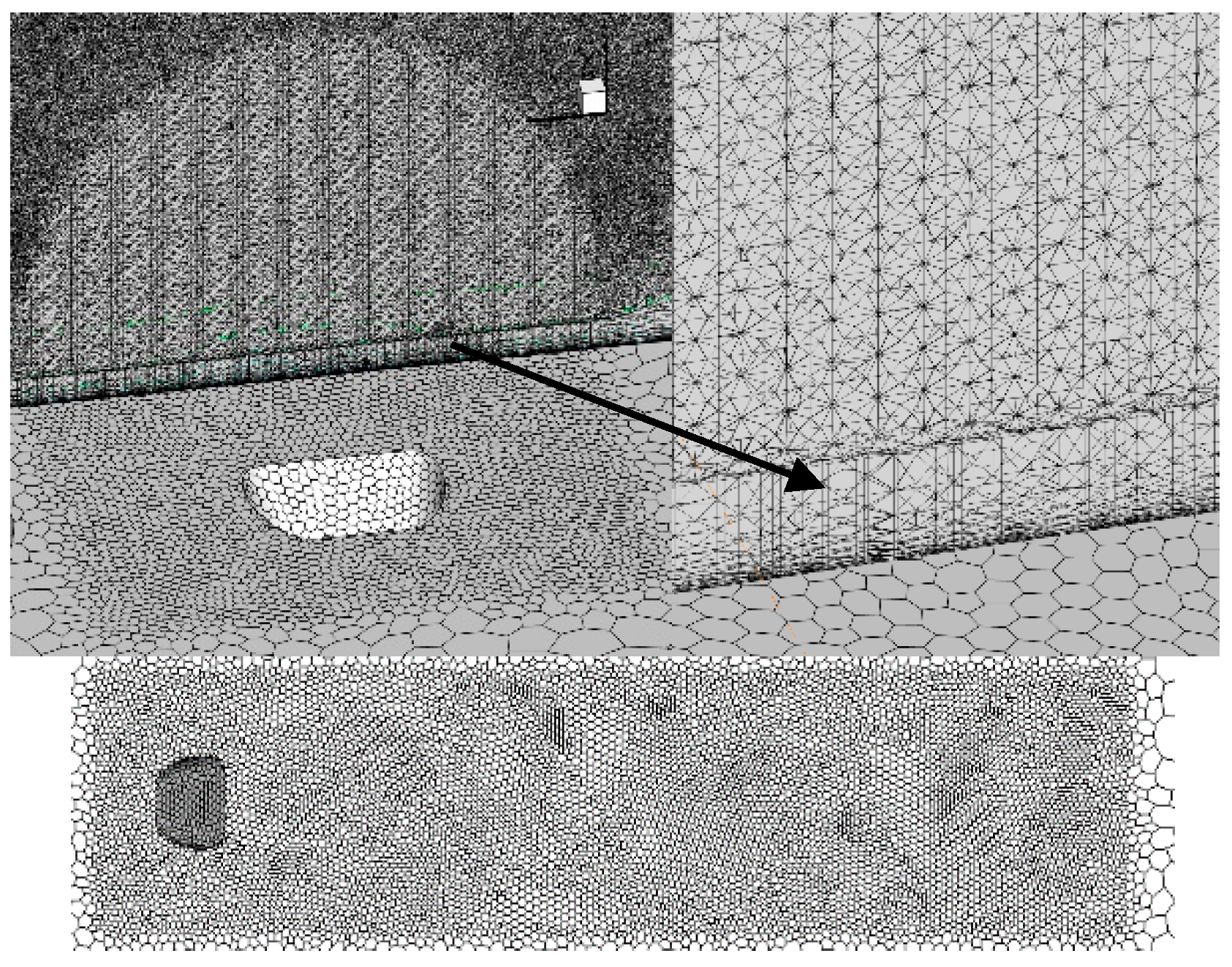

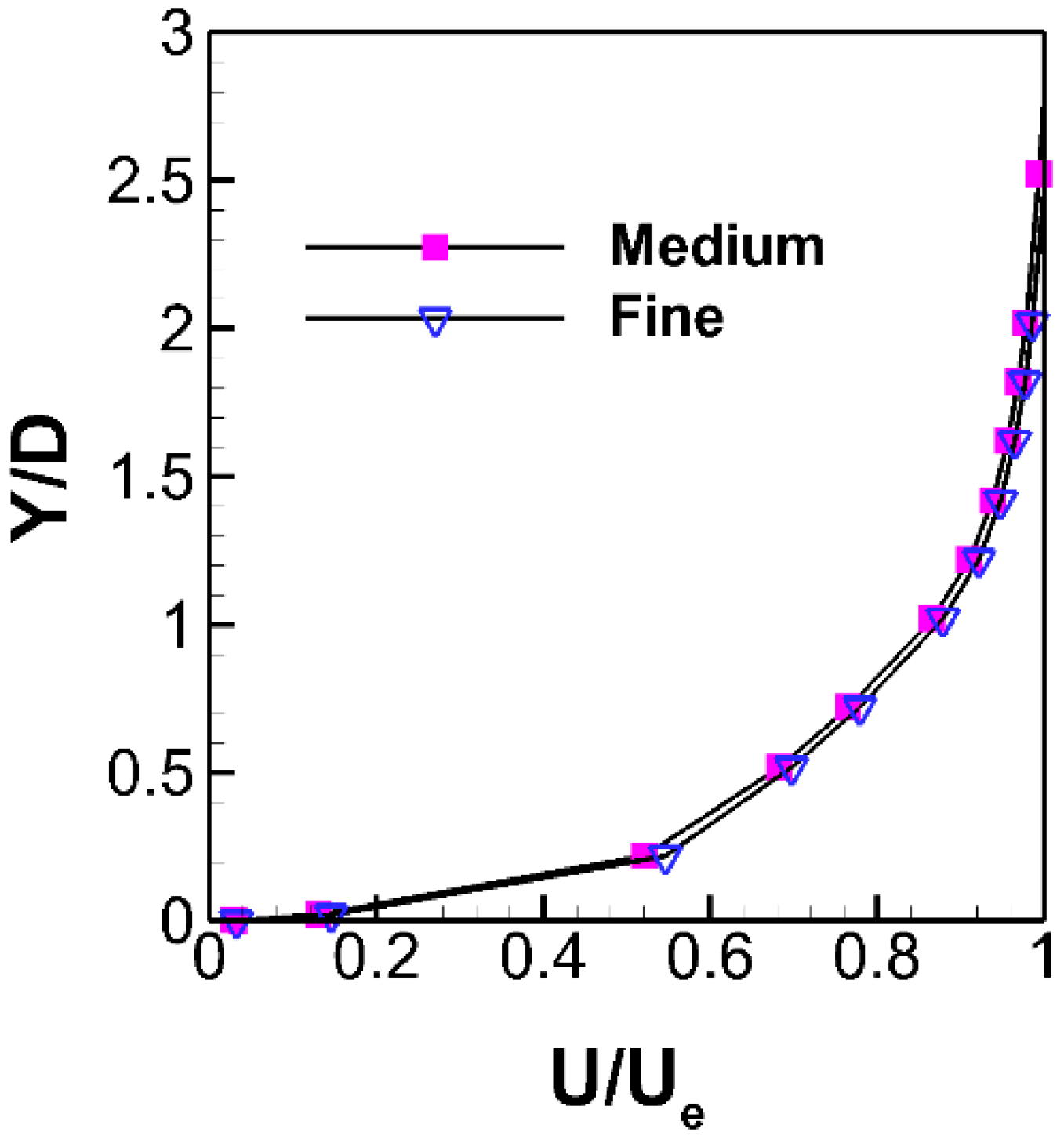

3.2. Computational Grid

4. Experimental Results

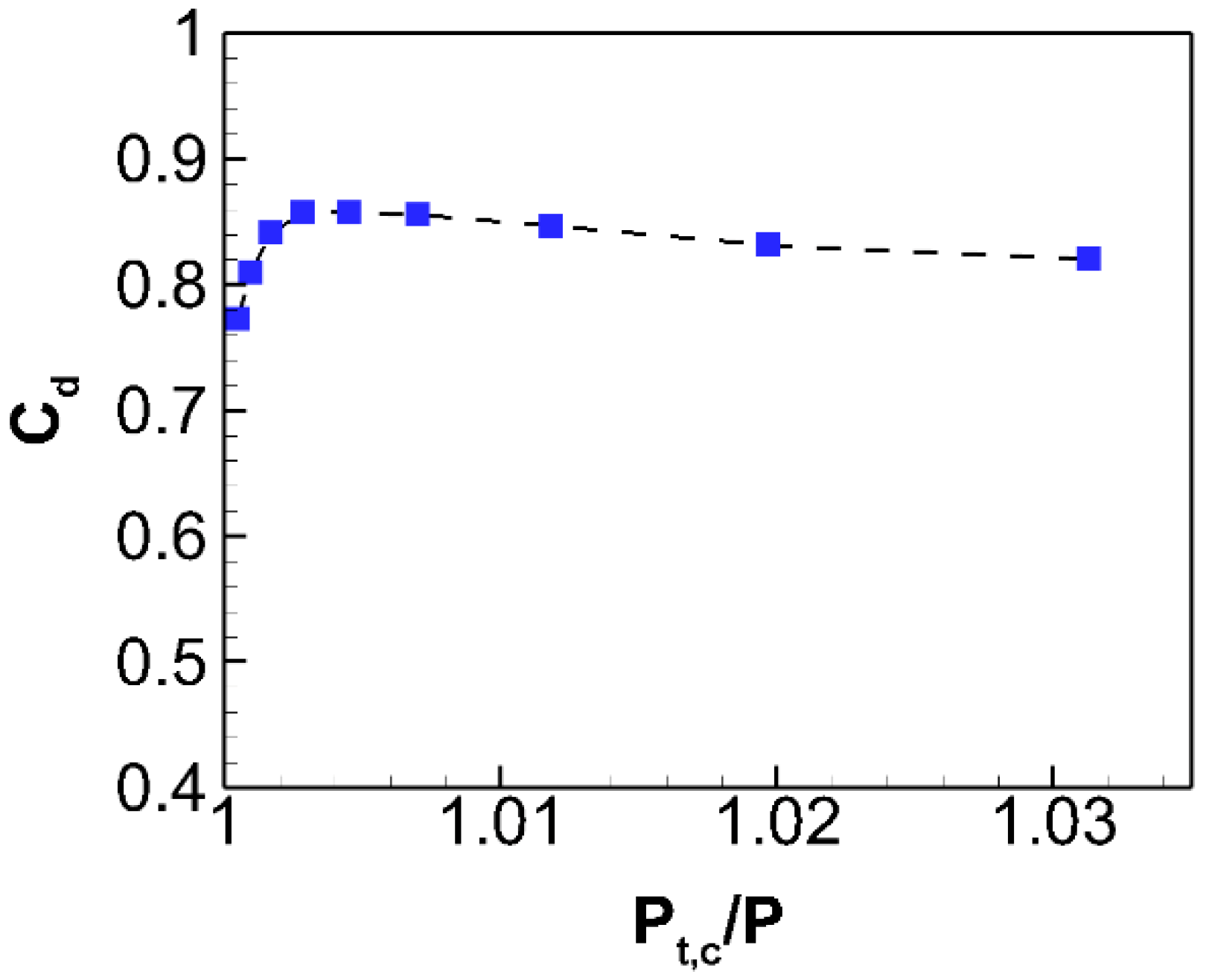

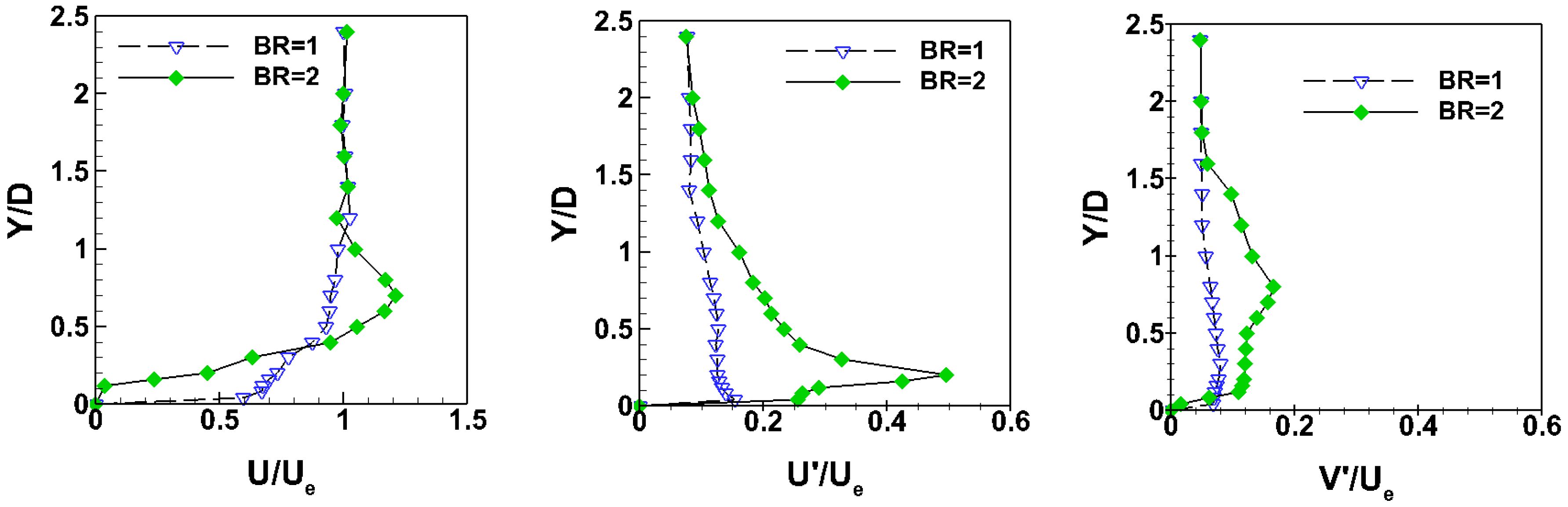

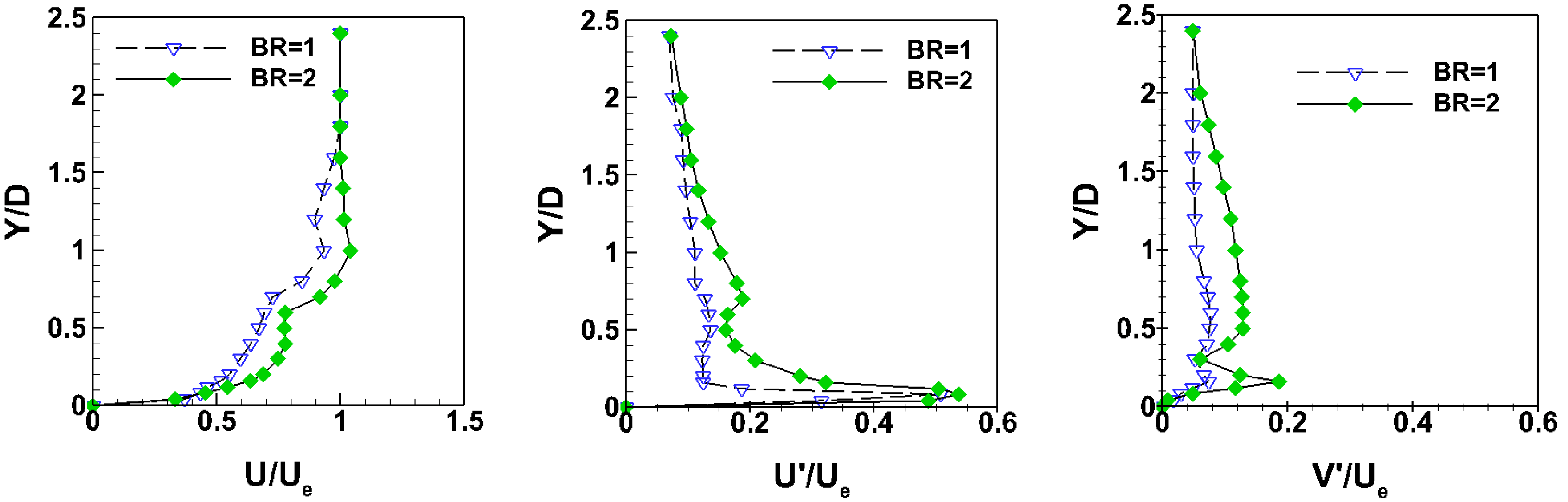

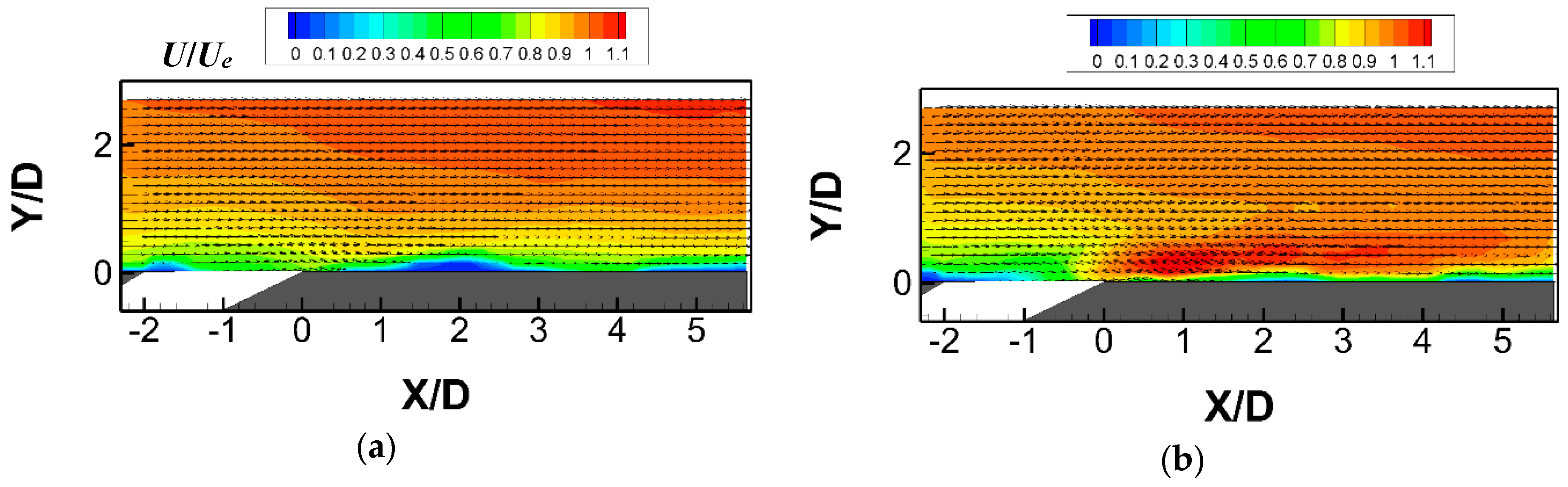

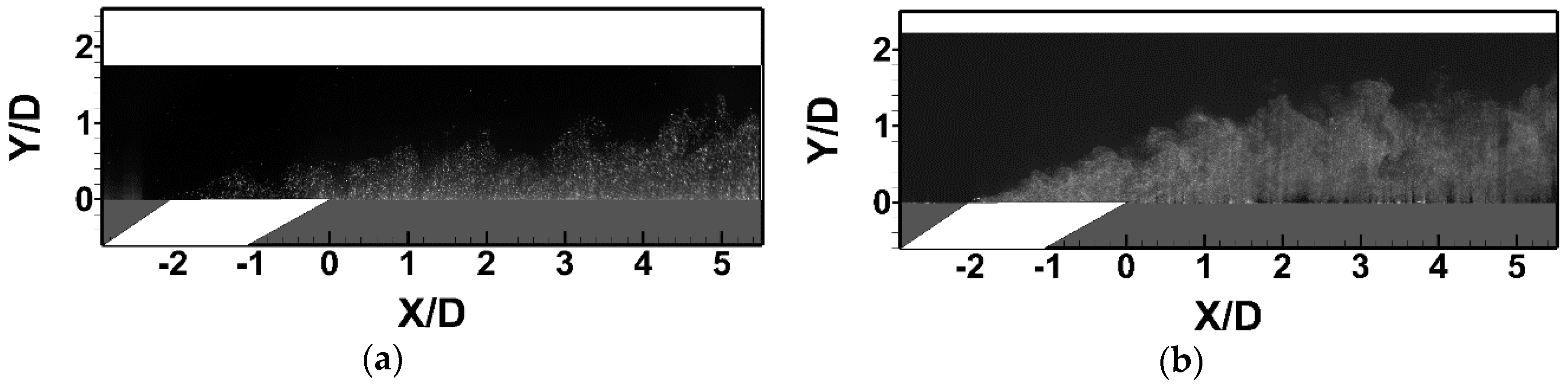

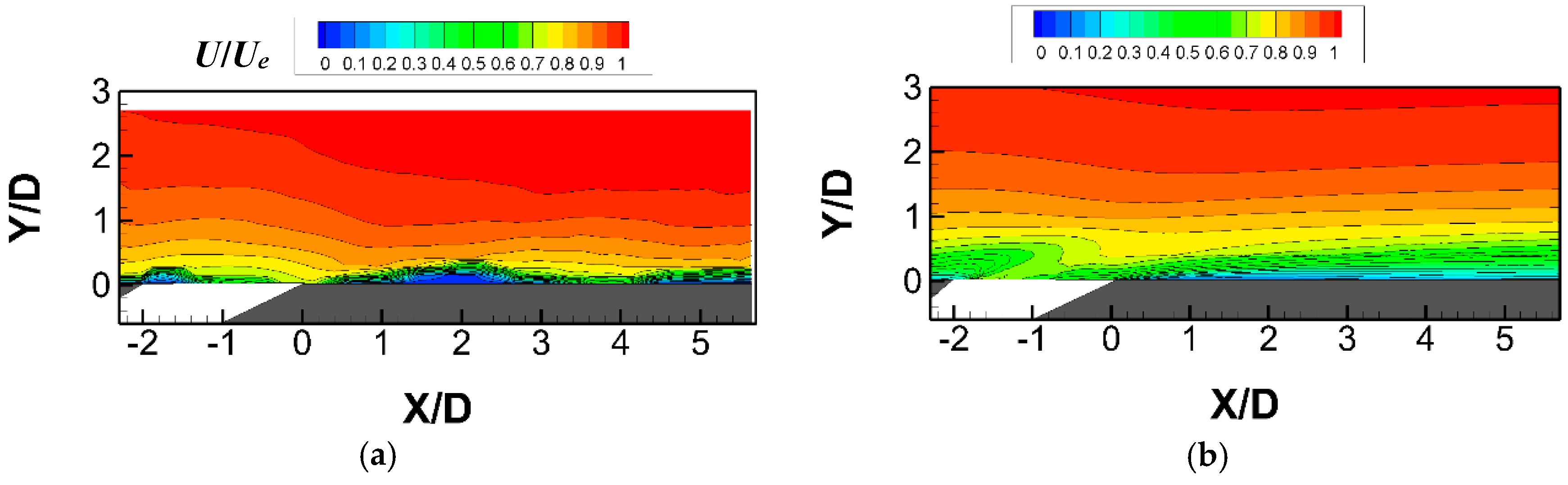

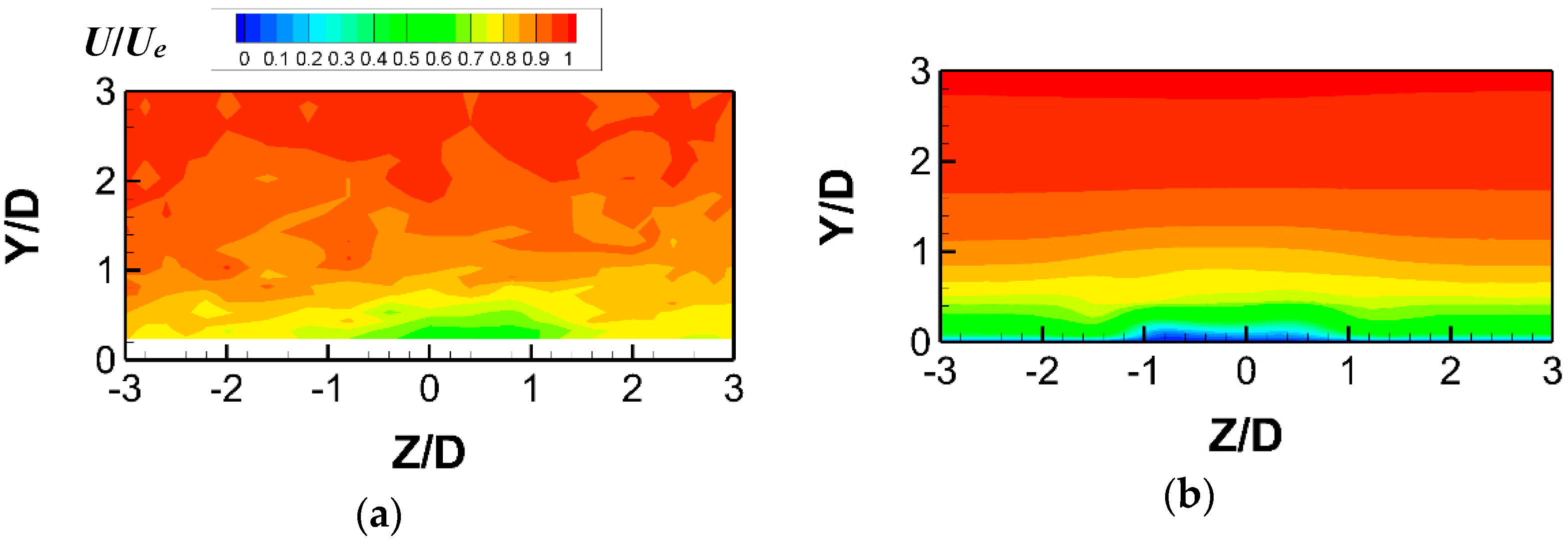

4.1. Aerodynamic Aspects of Film Cooling

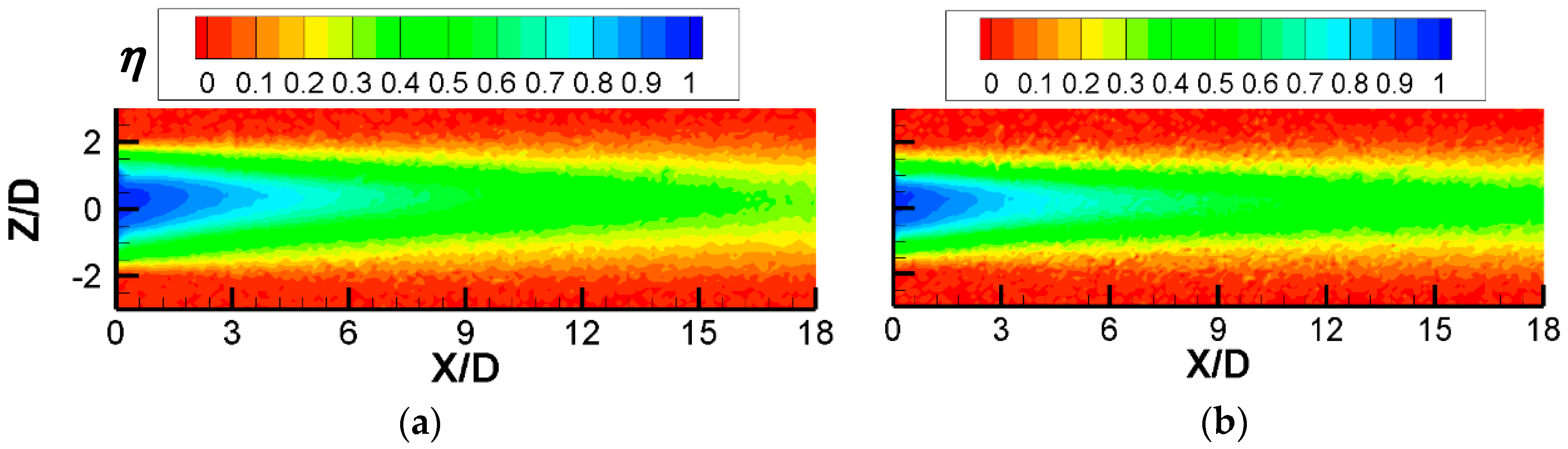

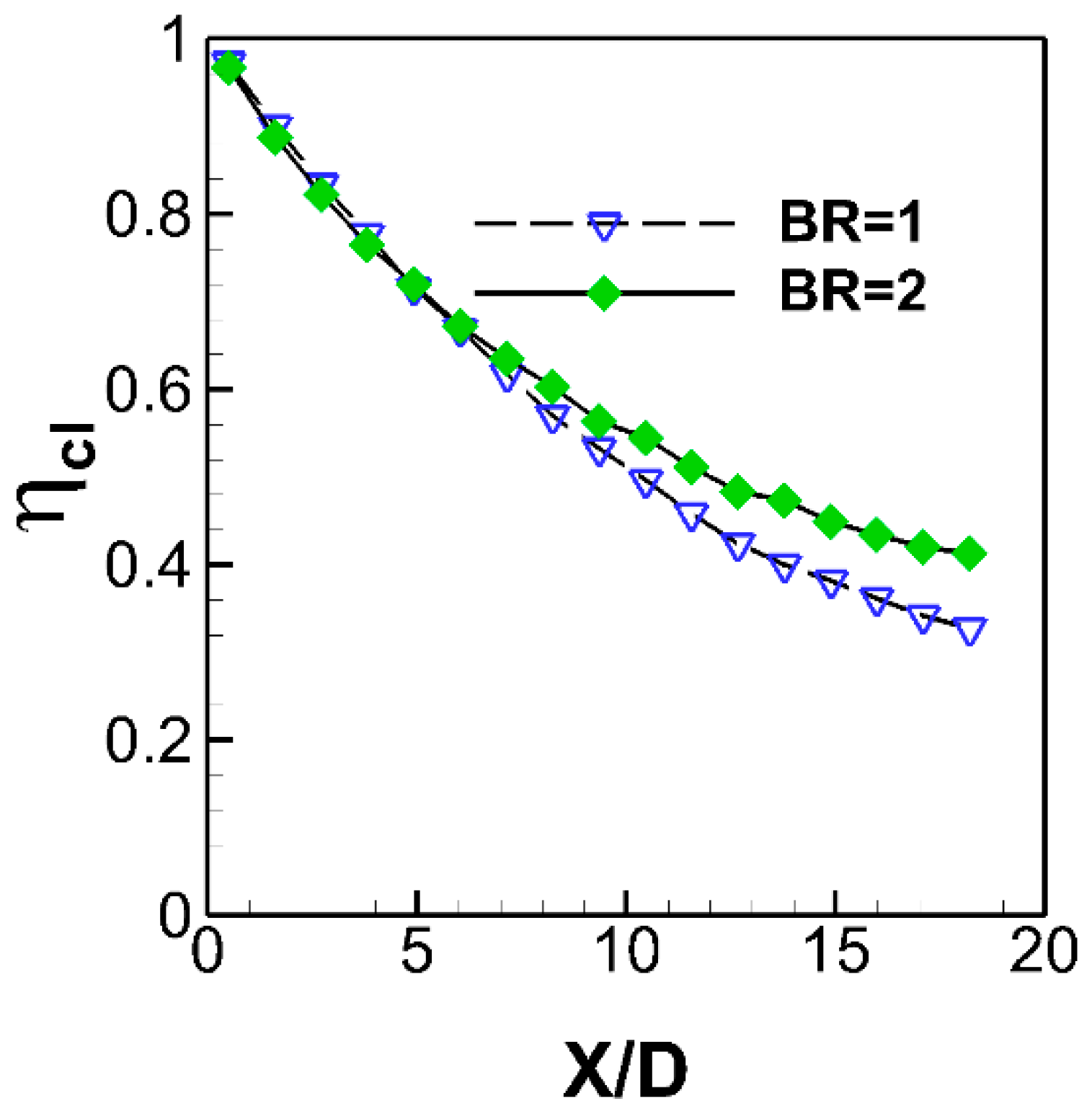

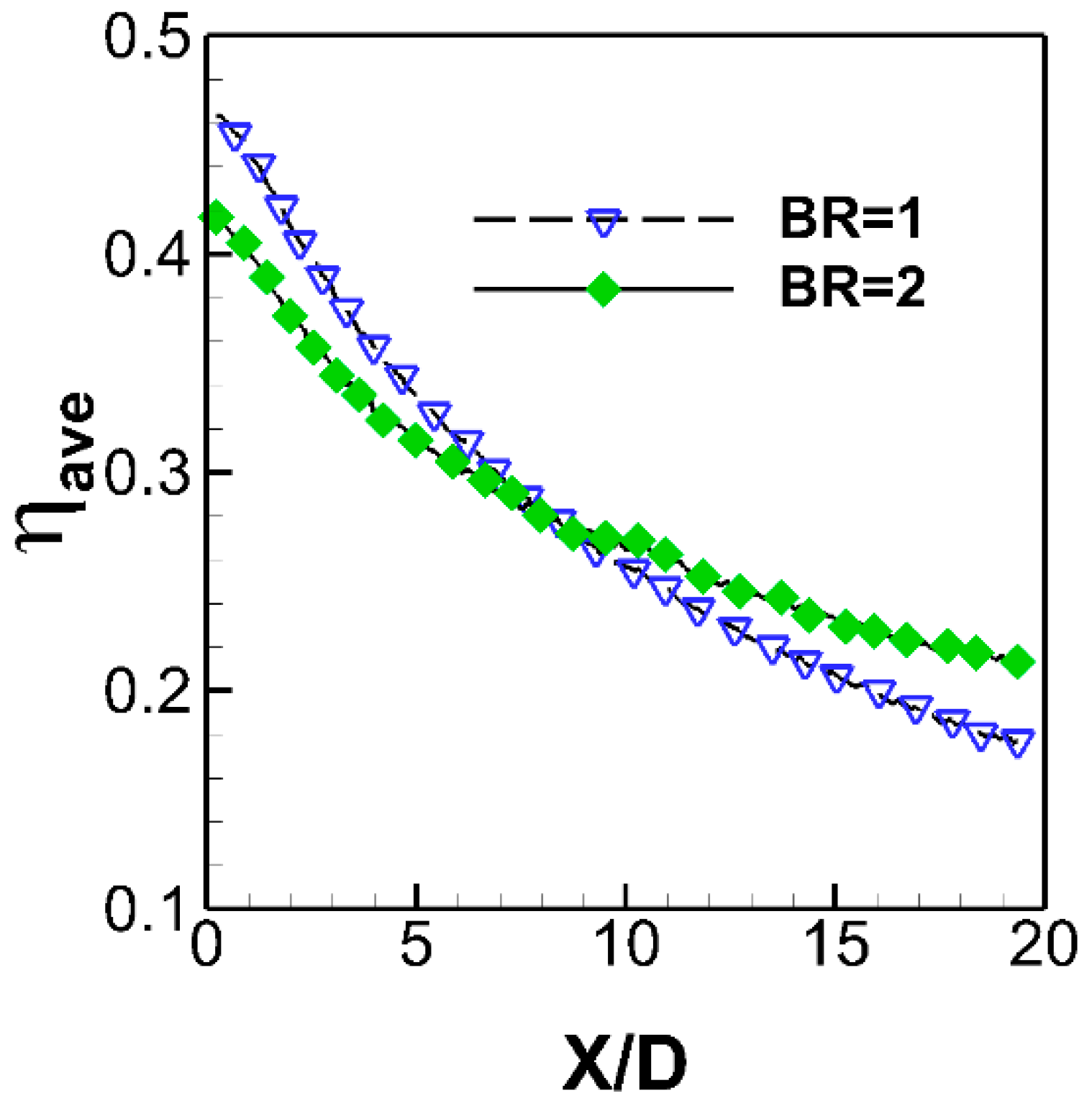

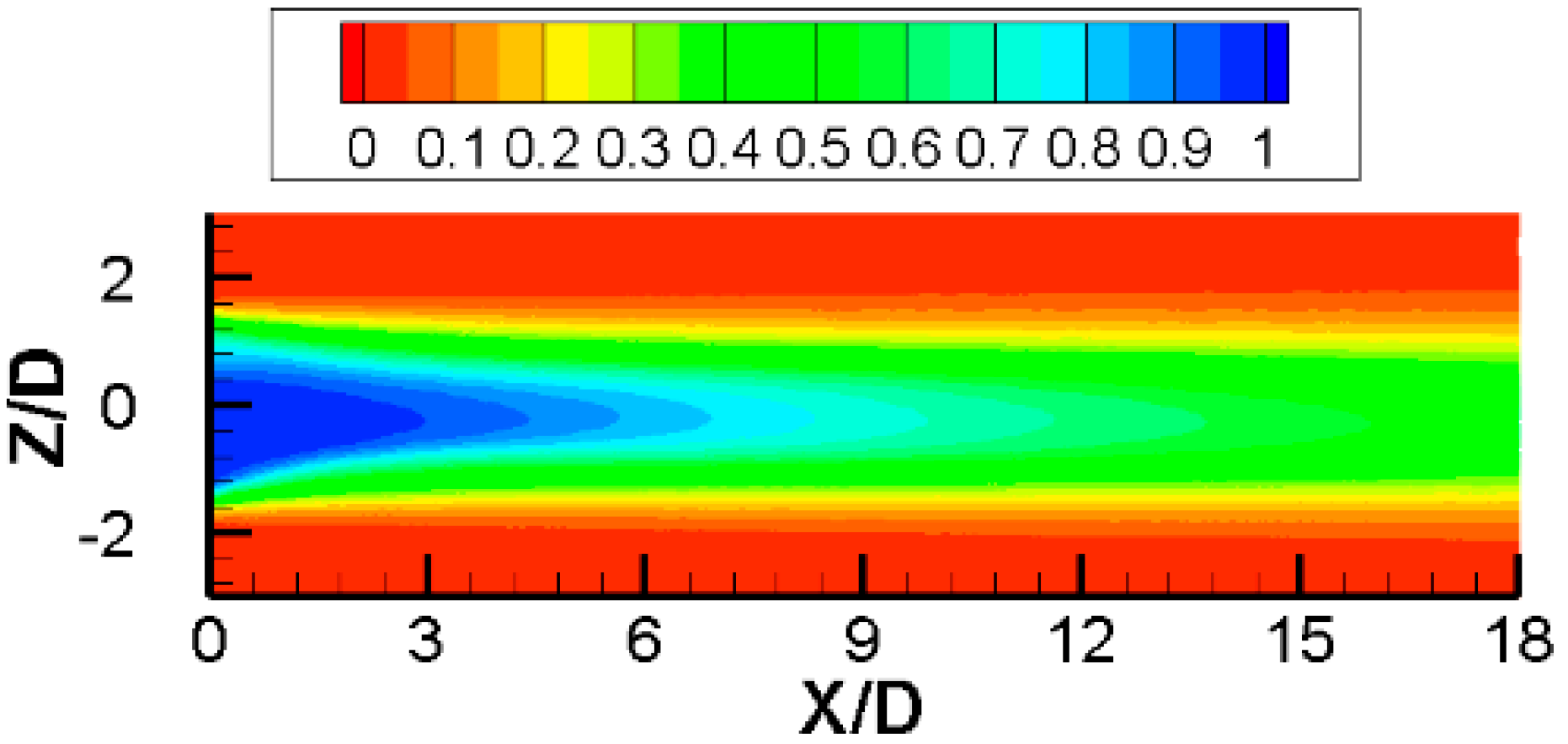

4.2. Thermal Aspects of Film Cooling

5. Numerical Results

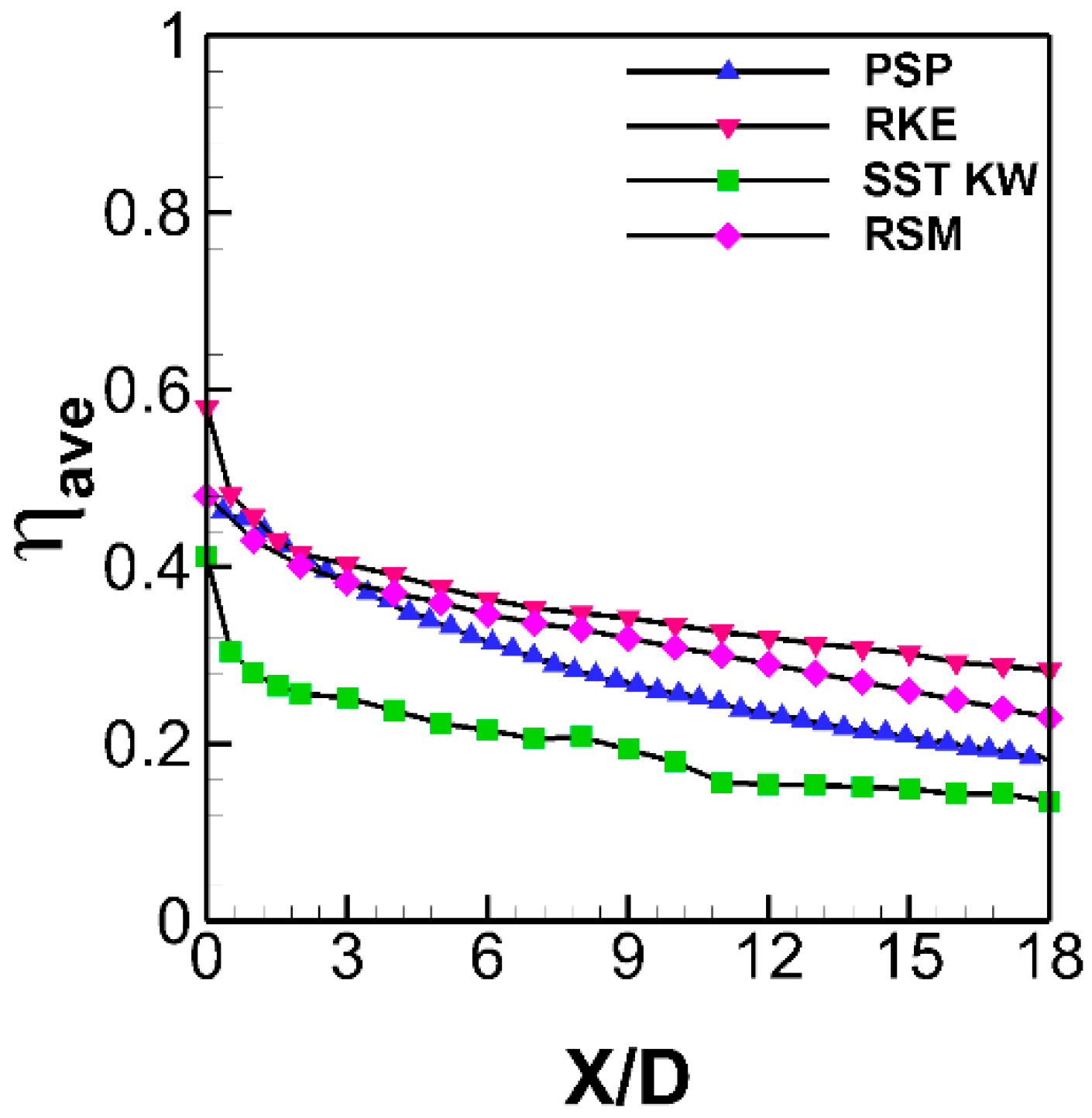

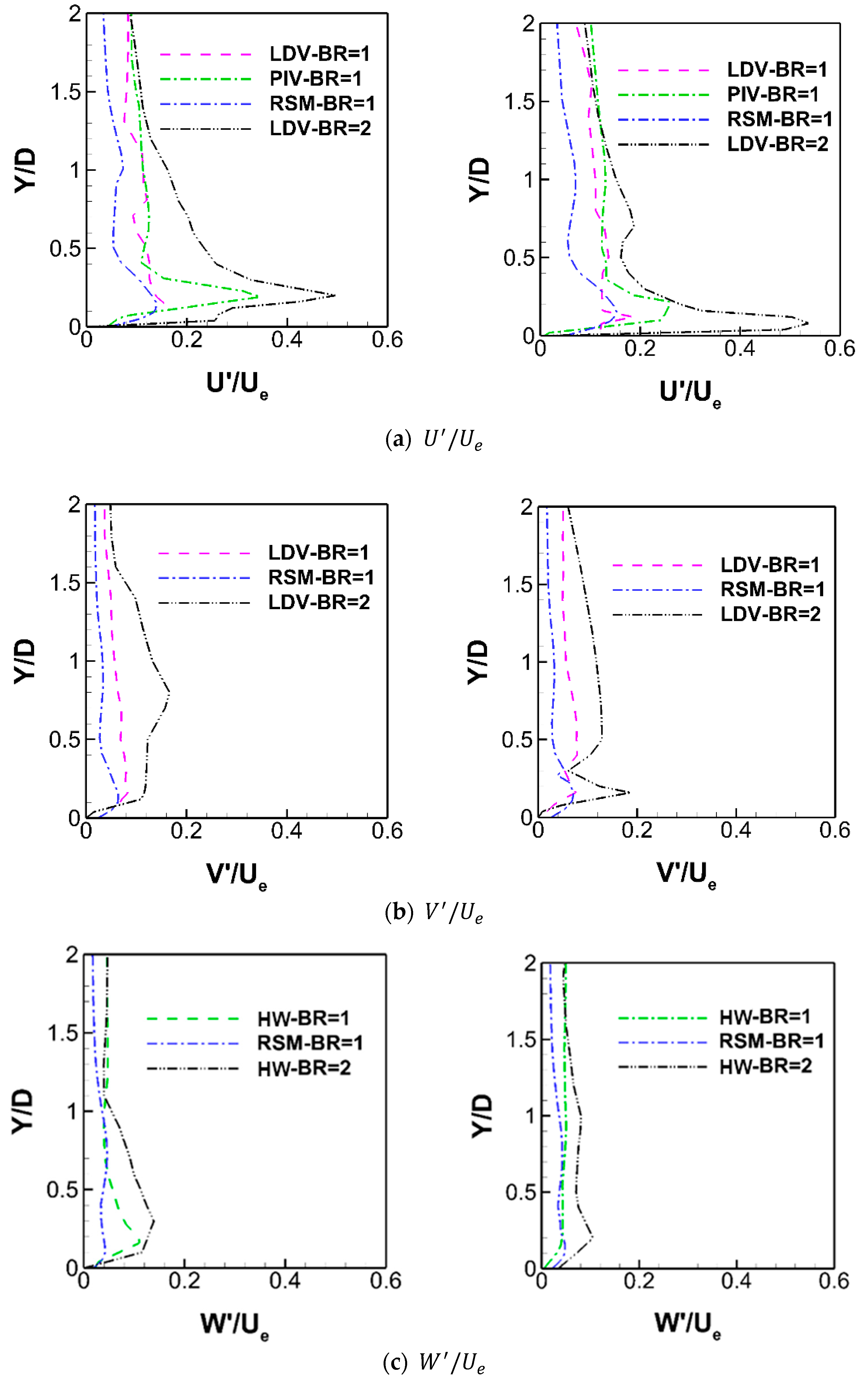

5.1. Turbulence Model Assessment

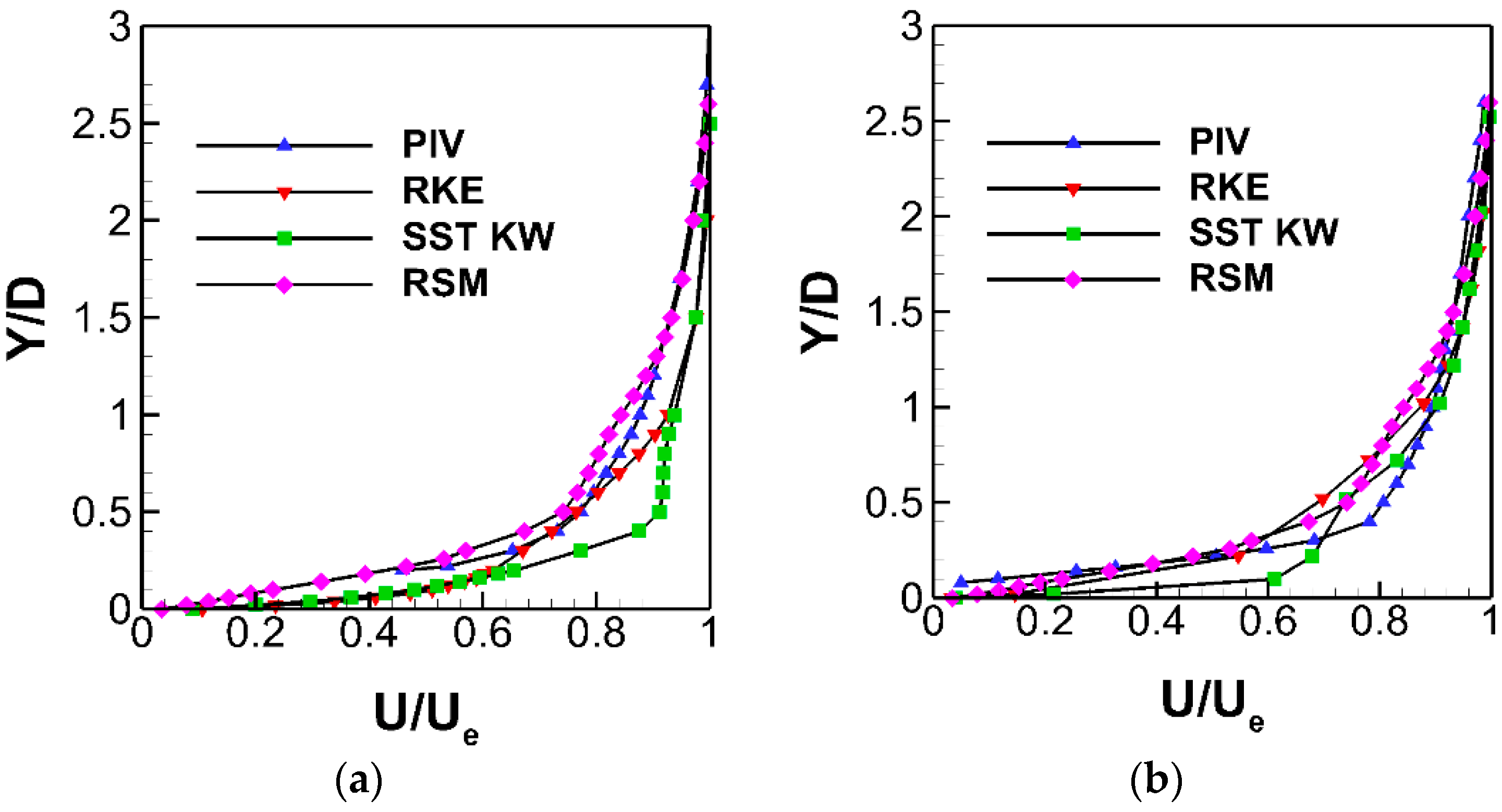

5.2. RSM Validation Against Experimental Data

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| BR | Blowing ratio |

| Cd | Discharge coefficient |

| D | Hole Diameter |

| L | Hole length |

| P | Pitch |

| Pressure | |

| Re | Reynolds Number |

| TU | Turbulence Intensity, % |

| U, V, W | Velocity Components |

| U′, V′, W′ | RMS Velocity Components |

| η | Film Cooling Effectiveness |

| λ | Turbulent Length Scale |

| Subscripts | |

| ave | Laterally averaged |

| c | Coolant |

| cl | Centerline |

| e | Mainstream |

| in | Inlet |

| Abbreviations | |

| CFD | Computational Fluid Dynamic |

| LDV | Laser Doppler Anemometry |

| PIV | Particle Image Velocimetry |

| PSP | Pressure Sensitive Paint |

| RANS | Reynolds-averaged Navier-Stokes |

| RKE | Realizable k-ε model |

| RSM | Reynolds stress model |

| SST KW | Menter SST k-ω |

References

- Goldstein, R.J.; Eckert, E.R.G.; Burggraf, F. Effects of Hole Geometry and Density on Three Dimensional Film Cooling. Int. J. Heat Mass Transf. 1974, 17, 595–607. [Google Scholar] [CrossRef]

- Gritsch, M.; Schulz, A.; Wittig, S. Discharge Coefficient Measurements of Film-cooling Holes with Expanded Exits. J. Turbomach. 1998, 120, 557–563. [Google Scholar] [CrossRef]

- Gritsch, M.; Schulz, A.; Wittig, S. Film-cooling Holes with Expanded Exits: Near-Hole Heat Transfer Coefficients. Int. J. Heat Fluid Flow 2000, 21, 146–155. [Google Scholar] [CrossRef]

- Gritsch, M.; Colban, W.; Schar, H.; Dobbeling, K. Effect of Hole Geometry on the Thermal Performance of Fan-shaped Film Cooling Holes. ASME J. Turbomach. 2005, 127, 718–825. [Google Scholar] [CrossRef]

- Thole, K.; Gritsch, M.; Schulz, A.; Wittig, S. Flowfield Measurements for Film-Cooling Holes with Expanded Exits. ASME J. Turbomach. 1998, 120, 327–336. [Google Scholar] [CrossRef]

- Porter, J.; Sargison, J.; Walker, G.; Henderson, A. A Comparative Investigation of Round and Fan-Shaped Cooling Hole near Flow Fields. ASME J. Turbomach. 2008, 130, 041020. [Google Scholar] [CrossRef]

- Hyams, D.G.; Leylek, J.H. Detailed Analysis of Film Cooling Physics: PartIII-Streamwise Injection with Shaped Holes. ASME J. Turbomach. 2000, 122, 122–132. [Google Scholar] [CrossRef]

- Kohli, A.; Thole, K.A. A CFD investigation on the Effects of Entrance Crossflow Directions to Film Cooling Holes. In Paper Presented at the ASME Heat Transfer Division Meeting; ASME: New York, NY, USA, 1997; pp. 223–232. [Google Scholar]

- Silieti, M.; Kassab, A.J.; Divo, E. Film cooling effectiveness from a single scaled-up fan-shaped hole a CFD simulation of adiabatic and conjugate heat transfer models. In Proceedings of the ASME Turbo Expo 2005Power for Land, Sea, and Air, Reno-Tahoe, NV, USA, 6–9 June 2005. ASME Paper No. GT2005-68431. [Google Scholar] [CrossRef]

- Gustafsson, K.M.B.; Johansson, T.G. Numerical Simulation of Effusion Cooling with Comparison to Experimental Data. Prog. Comput. Fluid Dyn. 2006, 6, 101–109. [Google Scholar] [CrossRef]

- Javadi, A.; Javadi, K.; Taeibi-Rahni, M.; Keimasi, M.R. Reynold’s Stress Turbulence Models for Prediction of Shear Stress terms in Cross Flow Film Cooling Numerical Simulation. In Proceedings of the ASME 2002 Pressure Vessels and Piping Conference, Vancouver, BC, Canada, 5–9 August 2000; Volume 2, pp. 155–167. [Google Scholar]

- Rouina, S.; Miranda, M.; Barigozzi, G. Experimental Investigation of the Unsteady Flow Behavior on a Film Cooling Flat Plate. Energy Procedia 2016, 101, 726–733. [Google Scholar] [CrossRef]

- ANSYS FLUENT 16.0 User’s Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2015.

- Abdeh, H.; Miranda, M.; Rouina, S.; Barigozzi, G. Development of PSP technique for Vane Film Cooling Investigations. Energy Procedia 2017, 126, 802–809. [Google Scholar] [CrossRef]

- Hoda, A.; Acharya, S.; Tyagi, M. Reynolds Stress Transport Model Predictions and Large Eddy Simulation for Film Coolant Jet in Cross Flow. In Proceedings of the ASME TURBOEXPO 2000, Munich, Germany, 8–11 May 2000. ASME Paper No. 2000-GT-0249. [Google Scholar] [CrossRef]

| Measurement Technique | Plane |

|---|---|

| PIV flow visualization | XY |

| PIV measurement | XY |

| Hotwire | YZ |

| PSP | XZ |

| Grid | Base Size (m) | Volumetric Control Grid Size (m) | y+ | Cells Count |

|---|---|---|---|---|

| Coarse | 0.03 | 0.001 | <5 | 5,785,194 |

| Medium | 0.02 | 0.001 | <1 | 6,785,194 |

| Fine | 0.02 | 0.001 | <1 | 10,920,371 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Rouina, S.; Ravelli, S.; Barigozzi, G. Combined Experimental and CFD Investigation of Flat Plate Film Cooling through Fan Shaped Holes. Int. J. Turbomach. Propuls. Power 2019, 4, 7. https://doi.org/10.3390/ijtpp4020007

Rouina S, Ravelli S, Barigozzi G. Combined Experimental and CFD Investigation of Flat Plate Film Cooling through Fan Shaped Holes. International Journal of Turbomachinery, Propulsion and Power. 2019; 4(2):7. https://doi.org/10.3390/ijtpp4020007

Chicago/Turabian StyleRouina, Samaneh, Silvia Ravelli, and Giovanna Barigozzi. 2019. "Combined Experimental and CFD Investigation of Flat Plate Film Cooling through Fan Shaped Holes" International Journal of Turbomachinery, Propulsion and Power 4, no. 2: 7. https://doi.org/10.3390/ijtpp4020007

APA StyleRouina, S., Ravelli, S., & Barigozzi, G. (2019). Combined Experimental and CFD Investigation of Flat Plate Film Cooling through Fan Shaped Holes. International Journal of Turbomachinery, Propulsion and Power, 4(2), 7. https://doi.org/10.3390/ijtpp4020007