1. Introduction

Worldwide material consumption has increased over the last few decades, creating income and jobs in many countries and urban cities [

1,

2]. Meanwhile, with the growth of the economy, increased consumption also puts additional strain on the environment, such as via an increased amount of waste. For example, the latest available statistics showed that the annual increase in the municipal waste (MSW) amount is about 3% in Finland [

3]. One example of municipal produced waste object is textiles, whose share in MSW grew to 5.8% in Finland in 2016 [

4]. This value is consistent with global statistics: for instance, in the USA, textiles’ share of total MSW generation was reported to be at the same level in 2018 [

5]. The presented values indicate that textile amounts are high globally, and the effect of textile waste will be especially significant in the future because clothing production increased by 100% between 2000 and 2014 [

6]. The amount of textile waste materials available for reuse will increase in Europe in the future due to, inter alia, policy control. The European Commission’s (EC) aim is to achieve separate collection for textile waste by 2025, and special targets for reuse and recycling should be considered before that [

7].

The increased waste amount also has a global influence on the end-of-life options for textiles’, which are landfill, energy recovery, and material recovery. At the moment, about 87% of global textile waste ends up in landfill or incineration, while over 90% of that could be reused or recycled [

8]. This fact demonstrates that options for recycling must be available in the initial stages, and there need to be studies and actions to promote material recycling. In particular, from the viewpoint of sustainability, material recovery is recommended for the treatment of textile waste compared to other methods, due to environmental pressures such as air and soil pollution and the reduced energy requirement. It is concluded that the reuse of polyester and cotton clothing has an energy need of 1.8–2.6% of that of the corresponding virgin materials, including various actions such as collection, sorting, baling, selling, and distribution [

9].

Despite today’s improved textile materials, it is a fact that textile products will end up as waste eventually, and due to the increasing amounts of textile waste expected in the future, the recycling options must be considered carefully. Based on the principles of circular economy, one option is recycling textile waste into new textiles. First, the textiles must be processed into a yarn mode, in order for a new textile product to be manufactured. The processing can be done with recently introduced chemical recycling methods, such as the study of Haslinger et al. [

10] introduced. This process is an effective way to regenerate textile waste, but might be also quite energy intensive due to the several processing steps and the use of resources such as water and acidic chemicals. The environmental impacts are also more significant in these cases, and so it is recommended to construct the production close to another factory where integration advantages could be achieved [

11]. In particular, water consumption should be considered carefully because about one-fifth of global wastewater is caused by the “fast fashion” textile industry [

6]. Therefore, other ways for dealing with textile waste must also be considered, such as reutilization in a second production cycle, in which case the scale of production could be lower. The reutilization of textile waste as a raw material in novel composite applications might be a more sustainable treatment method requiring minor investment. Advanced material features were achieved with this solution in recent publications [

12,

13], indicating that it can be a promising way to cope with increased textile waste amounts in future.

The successful utilization of textile waste as a raw material in composites is influenced strongly by the compatibilization of textile fibers with matrix and other compounds. The aim of this study is to investigate the structural properties of recycled PET and rayon textile fibers in the structure of HDPE composites. The quality of textile waste is analyzed, and the mechanical and moisture properties are assessed with tests of tensile and impact strength as well as water absorption and swelling measurements. The knowledge produced is an important contribution to the existing literature on textile waste.

2. Materials and Methods

2.1. Materials

High-density polyethylene (HDPE), RecyPE HDPE 8 mc (L&T Muoviportti, Merikarvia, Finland), with density 0.960 g/m3 and melt mass flow rate 8 g/10 min (190 °C/2.16 kg), was used as the material matrix in the experiments. The coupling agent was anhydride modified polyethylene Fusabond E226 (DuPont, Geneva, Switzerland), and Struktol TPW 113 (Struktol, Stow, OH, USA) was used as the lubricant. The matrix polymer, coupling agent, and lubricant used in the study were commercially available. The filler of the material was either polyethylene terephthalate (PET) or rayon fibers from recycled secondary textile waste material. The recycled secondary textile material was supplied by Partex-paja, which is a non-profit organization in Imatra, Finland, that is focused on the improvement of employment and the circular economy. The textile material was identified by near-infrared (NIR) technology, using a handheld NIR tool (Thermo Scientific microPHAZIR PC, Thermo Fisher Scientific, Waltham, MA, USA) that identifies material in less than 3 s in the spectral range of 1600–2400 nm without special sample preparation. The share per component in the textile material was determined based on the weight. The size of the textile waste material was reduced by using an Untha RS30 shredder (Untha Shredding Technology GmbH, Kuchl, Austria) equipped with a 10 mm sieve.

2.2. Processing of the Composite Materials

The identified components (polymer, textile, coupling agent, and lubricant) were treated by processing technologies of agglomeration and compression molding, in which the component amounts were as follows: HDPE 74%, coupling agent 3%, lubricant 3%, and 20% PET or rayon secondary textile fibers. The reference samples were produced congruently, but textile fibers were replaced by polyethylene (PE) polymer. The components were mixed prior to molding with an agglomeration process in an apparatus that consisted of a PLASMEC TRL 100/FV/W turbomixer (Lonate Pozzolo, Italy) and a PLASMEC RFV-200 cooler (Lonate Pozzolo, Italy). The materials were treated in the turbomixer until the temperature reached 200 °C. The granule materials were generated due to the combination of temperature and friction, following cooling treatment for 10 min in a cooler apparatus. After agglomeration, the components were processed by a compression molding method, utilizing a hydraulic C-frame press made (Stenhøj A/S) that was coupled with a CA-1000 connector accessory with VI Logger version 2.01 (National Instruments, Austin, TX, USA). Before compression, the composite agglomerate was heated in an oven at the temperature of 180 °C for 25–30 min. The heated material was manually transferred to a square (110 × 110 mm) compression molding tool, where it was compressed until 10 mm thickness of material was achieved without extra heating or cooling. The pressure of compression molding varied between 5 and 9 MPa for 60 s, until the sample thickness of 10 mm was applied in the mold tool.

2.3. Analysis of the Properties of the Composite Materials

The processed materials were analyzed with 15 samples of each material composition, based on the feasible standards, and the results were presented as an average value. The test samples were conditioned at 23 °C and 50% relative humidity before testing. The mechanical properties of the processed materials were determined by tensile and impact strength tests. The tensile properties (strength and modulus) of compression-molded materials were analyzed with a Zwick Z020 (Zwick Roell group, Ulm, Germany) testing apparatus, in accordance with standard EN ISO 527-2. The impact strength properties for the processed materials were measured with a Zwick 5102 model impact tester, according to the EN ISO 179-1 standard. In addition to the mechanical properties, the physical features of processed textile materials were assessed with moisture properties tests, by determining the water absorption (WA) and thickness swelling (TS) of materials, based on the procedure of standard EN 317. The moisture analyses were performed with square samples whose side length was 50 mm, with a nominal thickness of material (10 mm). The moisture properties were analyzed from the composite materials, which were processed with recycled PET and rayon fibers. Due to the different nature of the reference material, it was not included in the moisture properties testing. Additionally, the cross-sectional structure of tensile strength materials was examined with a scanning electron microscope (SEM) Hitachi SU3500 (Chiyoda, Tokyo, Japan), indicating, inter alia, fiber composition and their orientation in the HDPE matrix.

4. Discussion

The share of unidentified material can be explained by the material color, because NIR is an unfeasible technology for dark materials, especially black wool, polyamide, and old textile materials [

14]. Additionally, the sensitivity to humidity and the spectral similarity limited the identification capacity of NIR [

15], but those effects were assumed to be minor in this study. The next-level identification method could be hyperspectral NIR, but this still includes still a few-percentage prediction error [

16]. The effects of treatment methods on the material properties must also be considered because the options, such as shredding, influence the quality of the recycled materials. Overall, it is known that recycled fibers have lower properties compared to virgin ones [

17].

The impact strength of the PET composite was more than doubled while the rayon composite had an impact strength similar to that of the reference (PE) composite. Considering the standard error, the lowest impact strength of the PET composite (9.44 kJ/m

2) was still nearly doubled compared to the average properties of the rayon and reference composites. It can be concluded that textile-reinforced composites can absorb more energy under a momentary load. Using PET or rayon as a filler in the structure of the composite gives marginally better tensile features compared to the reference material. Considering the standard deviation of the results, there were no significant differences between material categories, and the tensile properties can be said to be equal between the studied materials. Both fillers can withstand a similar amount of tensile stress and stiffness. The densities of processed materials were also measured and differences between materials were not found, indicating that explanations for the material properties would be found from the materials themselves. Francisczak et al. [

18] studied PET and rayon with polypropylene composites and found that those can be substituted for standard glass fibers in lightweight applications. By reviewing the results of this study, we agree with them because the textile fiber within the structure of HDPE composites did not impair the studied mechanical properties.

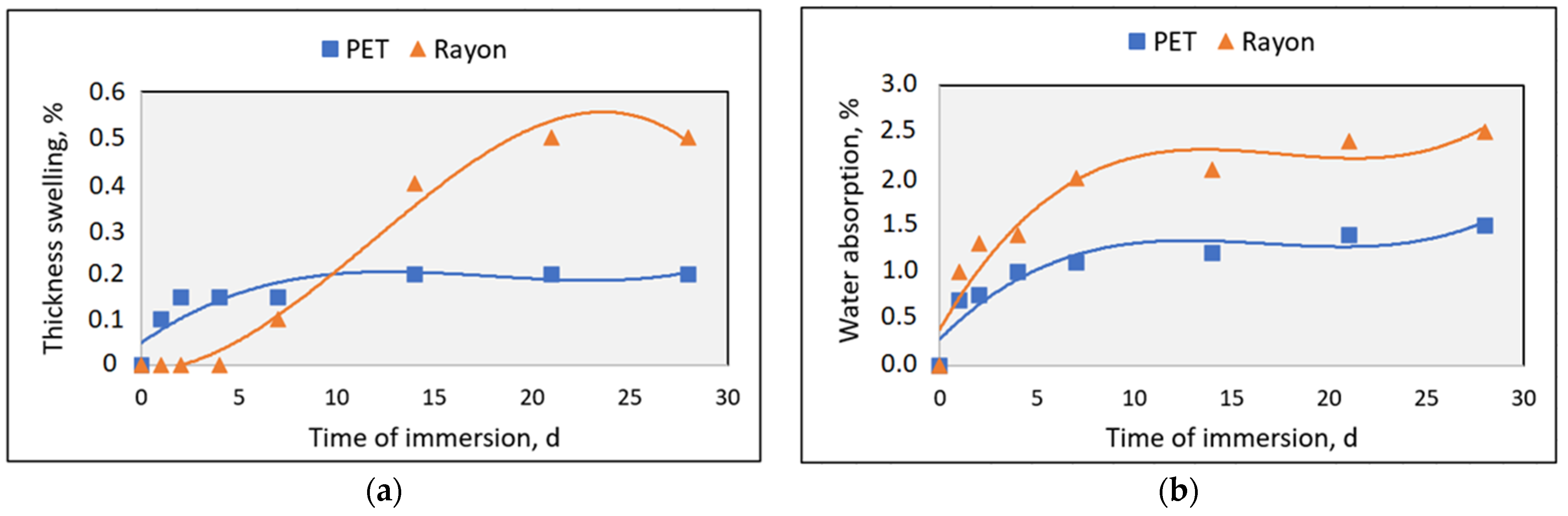

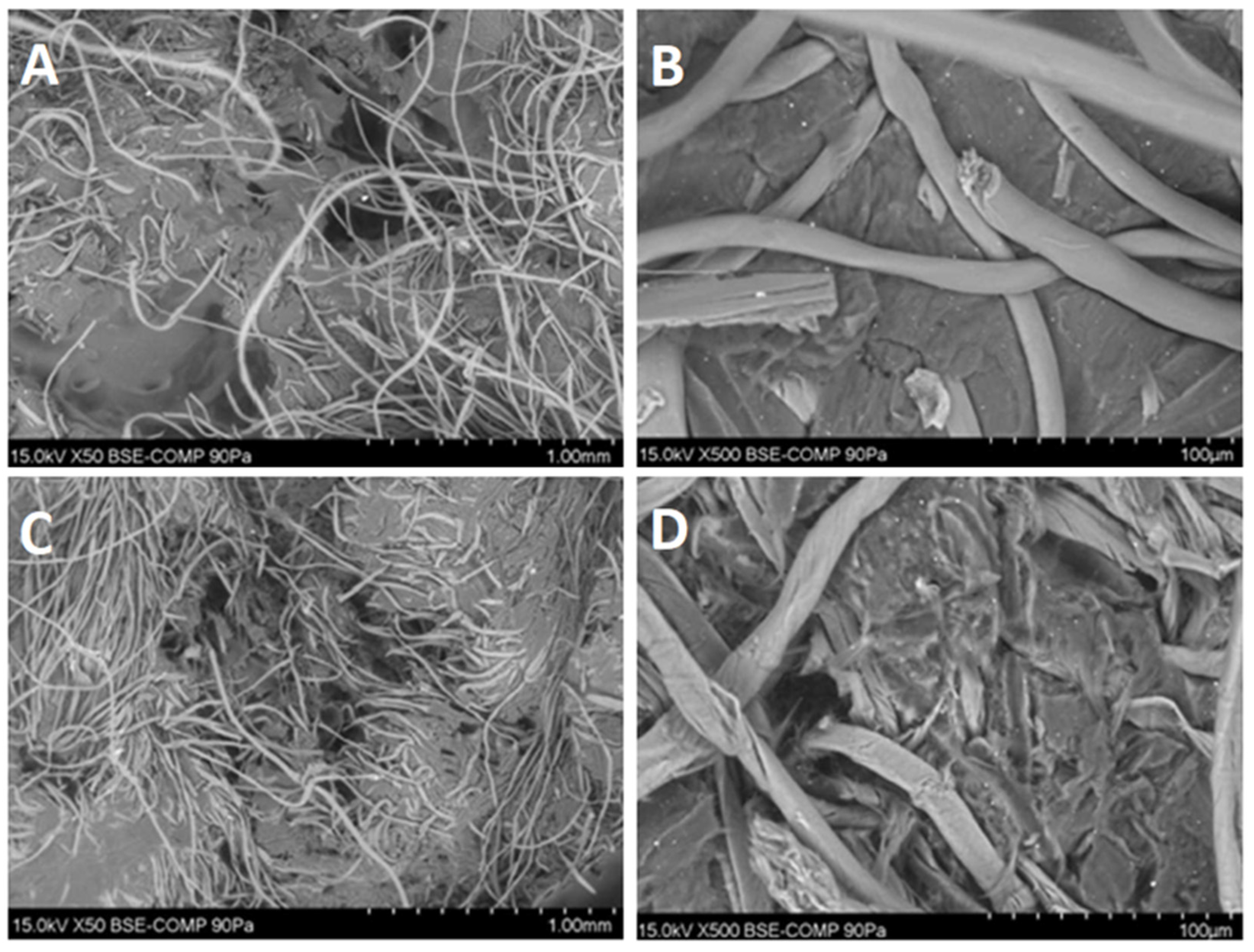

Both materials absorbed water similarly, but swelling was not detectable with rayon fibers during the first few days of immersion. The better moisture behavior of the PET fibers might be due to their synthetic nature, making them easy to manipulate. Rayon fibers are closer to each other in the structure of material, which might influence the impact strength. The more spread-out nature of PET fibers can help them to bear impact better because they can share the load across a wider area, compared to a higher number of rayon fibers located closer to one another. It has been observed previously that gaps between the matrix and fibers help to absorb shock energy [

19]. The rayon fibers being closer together means they cannot share the impact load and must carry it singly. In addition, the higher number of rayon fibers could explain the previously presented moisture properties in that water molecules have more options to bind. Overall, the differences between PET and rayon samples are minor in the analysis of SEM images, indicating quite similar material properties.

Several material properties were assessed in this study, such as impact strength and swelling features during long-term immersion. The separate collection of textile waste might be a key driver for the utilization of textile waste, and all options for reutilization must be studied. Obviously, the properties of materials can be developed by variations in component amounts and treatment parameters, but some pretreatments might also influence the properties of material. For example, Souza et al. [

20] found that pretreatment of textile fiber has a significant effect on the bonding between the fiber filler and the matrix. Strong bonding between the fibers and the matrix is one of the key requirements for any composite material to offer good mechanical properties such as tensile and impact strength. Rayon, also known as viscose, has weaker properties in terms of the structure of composites. It could be reasonable to reuse it again as a textile because its production has a higher climate change impact compared to the production of cotton, though it varies between areas [

4].

The cost of recycled textile raw material was estimated to be reasonable at EUR 1.0–1.3 per kg, depending on the mechanical and chemical recycling [

21]. The raw material stream needed might be huge for the known mechanical and chemical recycling options, so a smaller scale unit for textile recycling must be considered without the need for global logistics. Utilizing textile raw materials directly in the structure of a composite could be an economical treatment method that reduces the environmental stress because its treatment does not include any complicated treatment processes, which could be quite energy intensive. However, this attribute must be evaluated with more accuracy in future studies, as interest in textile recycling is also rising from business and consumer segments. Clothing represents the biggest share of all textile amounts, so the most remarkable and favorable results will be achieved with textile waste if we put more emphasis on the collection, sorting, and reuse of textile waste from every citizen in the future.

5. Conclusions

Global trends indicate that the textile waste amount will increase in the future, and post-treatment must be considered as a part of sustainable development. In this study, HDPE composites containing recycled clothes fibers were manufactured by compression molding, and their mechanical and moisture properties were studied, as the structure of the material was also assessed by a microscope.

The mechanical tests indicated that the addition of recycled clothes fiber can enable the tensile features to be at the same level as the reference material. The impact strength was observed to increase with the addition of recycled PET fibers, while the influence of the addition of recycled rayon fibers on the impact property was minor. Thickness welling and water absorption were stronger after the addition of recycled rayon fibers, compared to the addition of recycled PET fibers as a filler in the structure of the composite. These findings from the mechanical properties demonstrated that the studied textile fibers can be recycled and re-utilized as a comparable raw material in the structure of composite, acting as a substitute for a virgin raw material.

It might be that the awareness of reutilization options for textile waste materials is partly insufficient, so all information and increased awareness of these opportunities will increase textile material recycling and reduce the amount of waste. For example, sorting methods for materials are the key to producing high-quality recycled objects. This kind of actions contribute to the EC’s aim to achieve separate collection for textile waste by 2025, and already two years earlier in Finland. The studied properties showed that, technically, recycled clothes fibers are a feasible material for use within the structure of a composite. One application for fiber composites from recycled clothes could be, for example, in products with insulating properties, such as the insulation components in the automotive industry, e.g., cladding of door panel. Recycled textile materials in the structure of composites could help to save on energy consumption in the form of heating and further reduce CO2 emissions. Combining recycled clothes fibers with biobased materials is an environmental win-win. The significance of textile recycling will continue to grow due to the increased amount of material available from consumers’ purchases and the reduced lifetime of products.