Increasing Firm Performance through Industry 4.0—A Method to Define and Reach Meaningful Goals

Abstract

1. Introduction

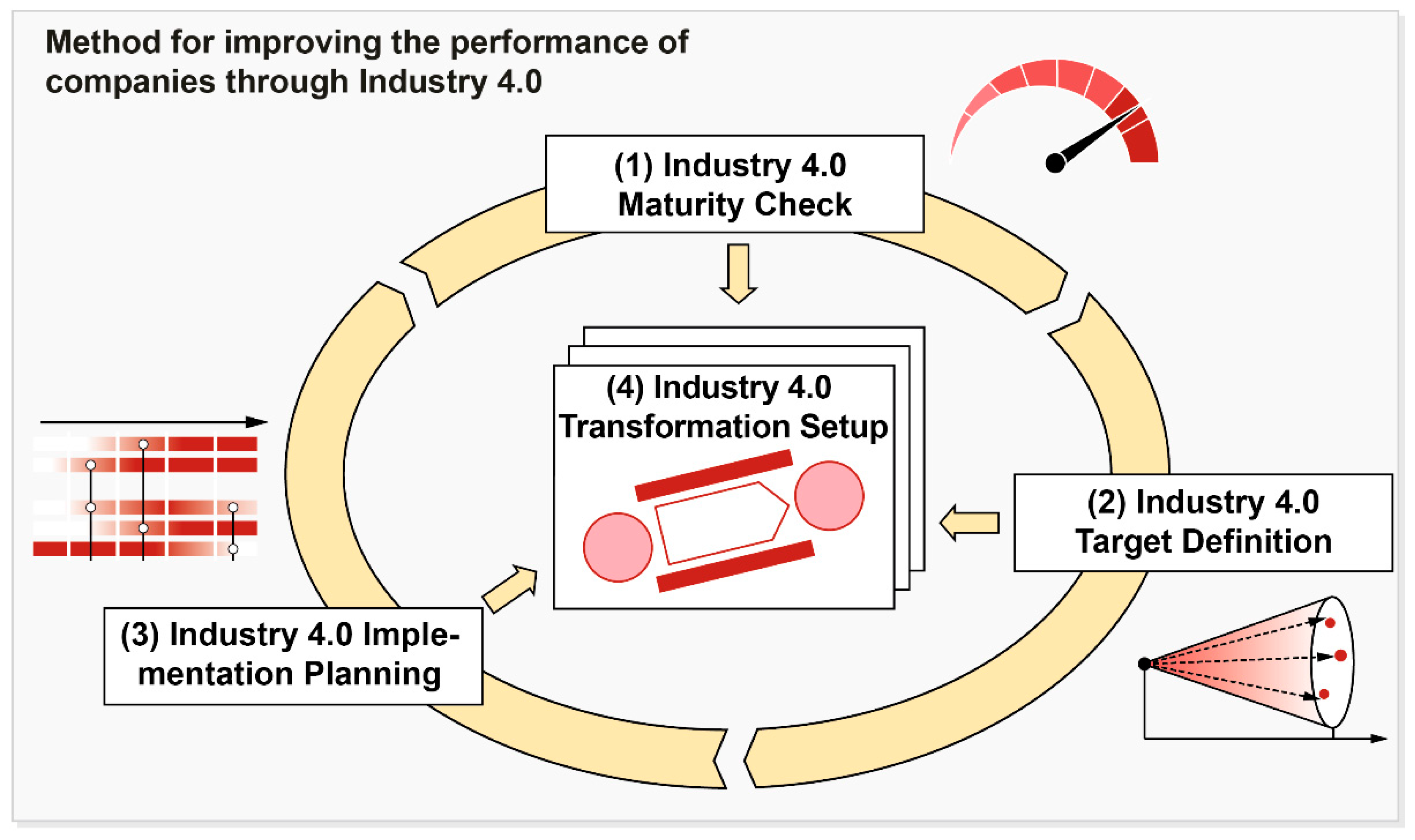

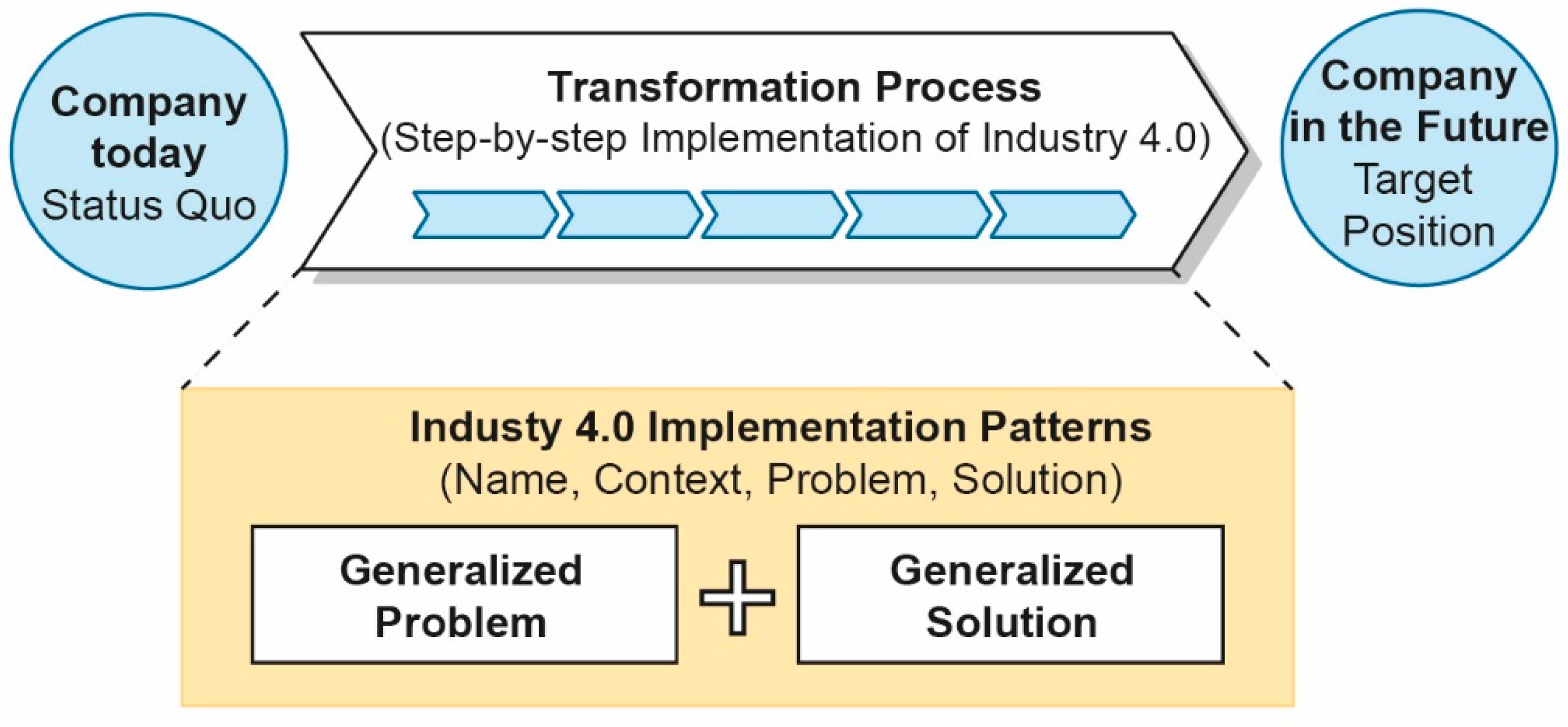

- Maturity Check: To evaluate the performance of the considered company, Industry 4.0 has to be depicted in detail as a socio-technical system in the areas of technology, business, and people. An objective evaluation scheme, i.e., a maturity model, is required to make the company’s initial position measurable.

- Target definition: Based on the individual initial situation, an appropriate target maturity level is to be determined for the company, taking into account the actual and future contingencies of the market, technology, and environment.

- Implementation planning: To select suitable solutions to reach the target position, it is promising to draw on the experience of Industry 4.0 pioneers. The target is to enable companies to participate in the dynamic development of Industry 4.0 with relatively little effort. For that, implementation patterns need to be identified. They allow to tackle typical Industry 4.0 tasks. The selection and combination of implementation patterns must be supported, taking into account the effects on people, technology, and business.

- Transformation setup: For the concrete implementation of Industry 4.0 the status quo, target position, and implementation solutions must be integrated into a coherent view, which can be communicated to the employees. Measures must be defined that translate the plan into action.

2. Literature Review

2.1. Maturity Check for Industry 4.0

2.2. Defining Target Maturity Levels for Industry 4.0

2.3. Solution Pattern as a Means to Close the Gap between Maturity Levels

2.4. Transformation Setup

2.5. Summary

3. Materials and Methods

3.1. Research Process

3.2. Data Collection

3.3. Method Engineering

4. Results

4.1. Method Rationale

4.2. Method Overview

4.3. Method Phases

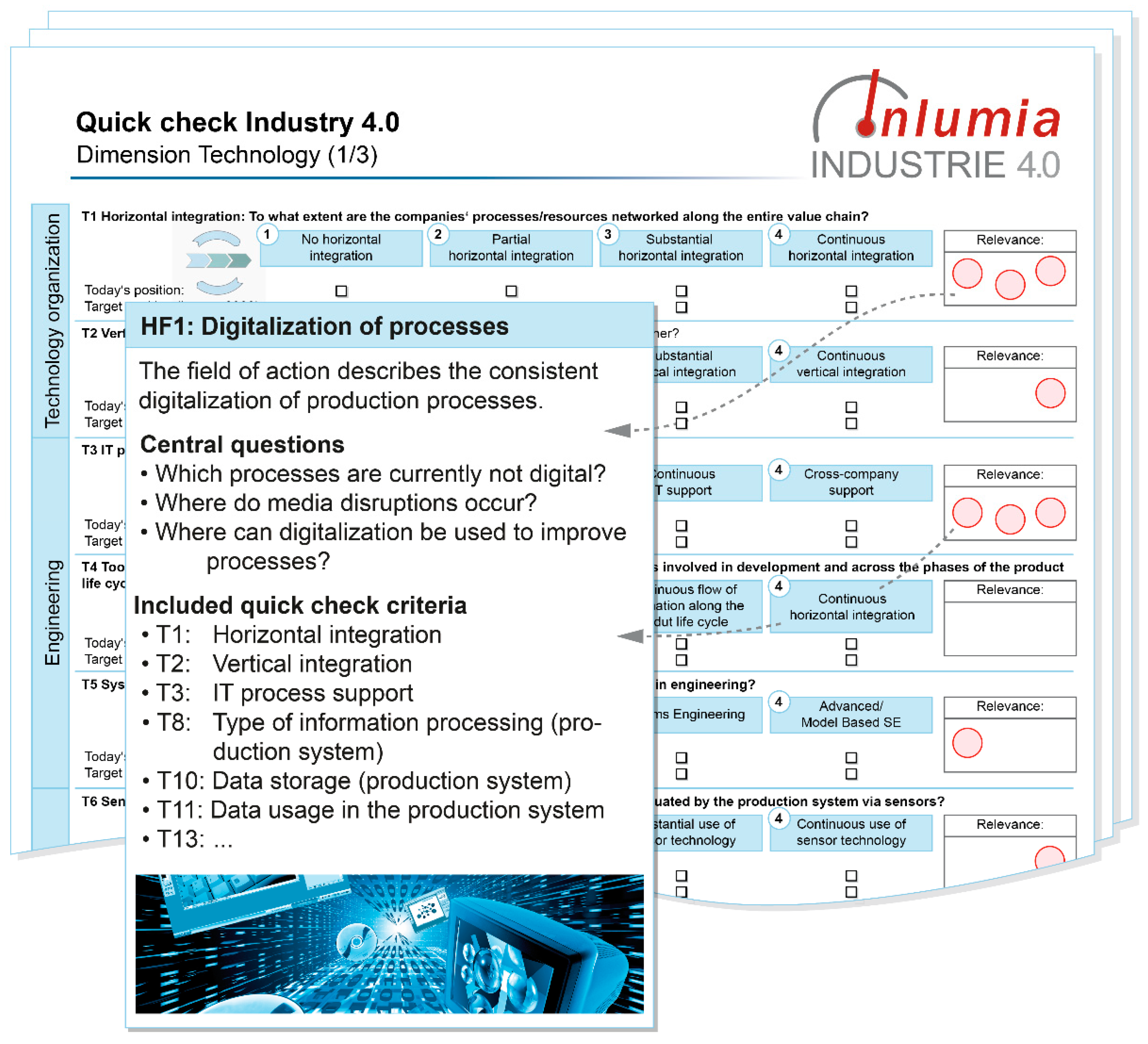

4.3.1. Phase 1: Industry 4.0 Maturity Check

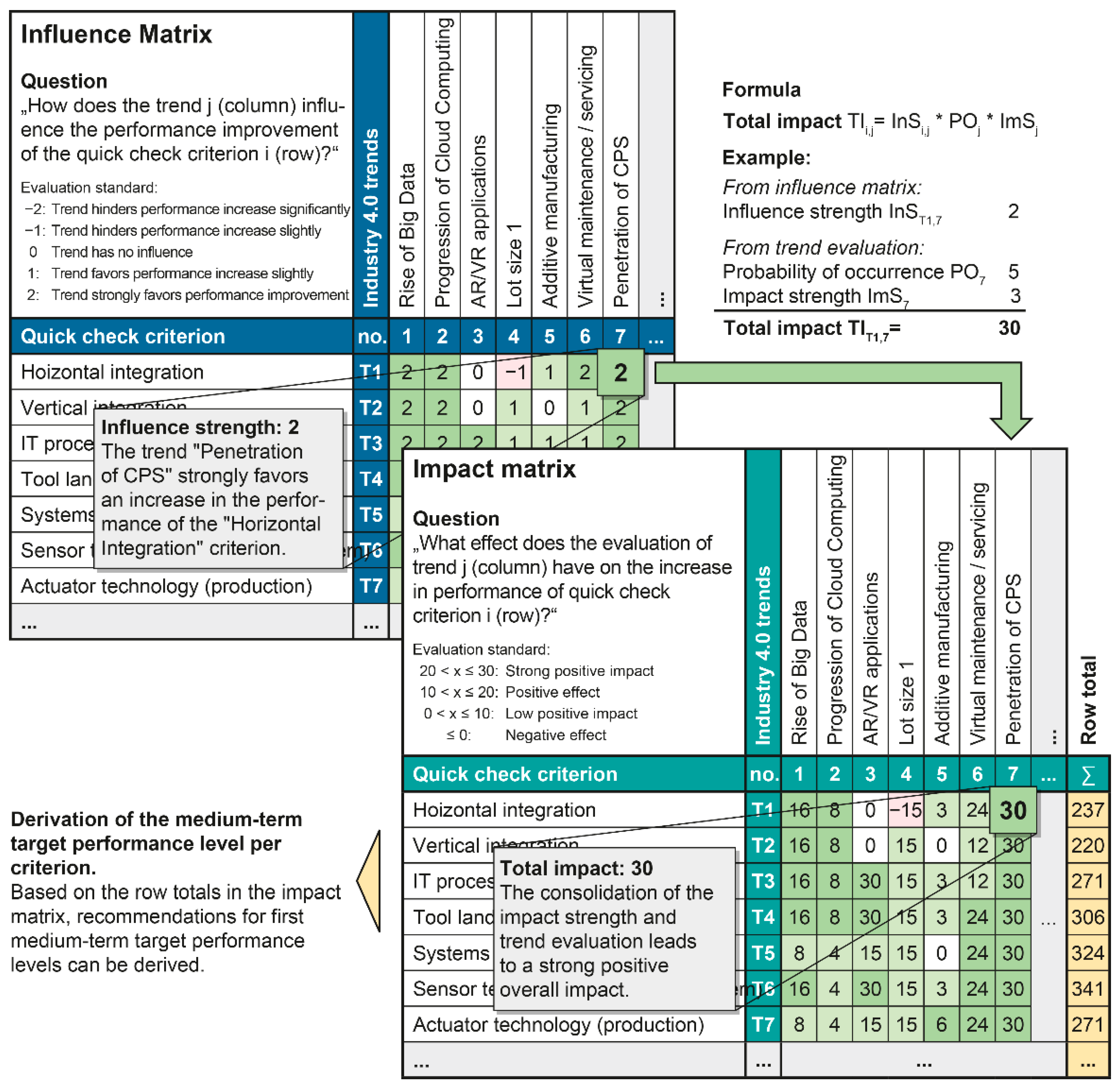

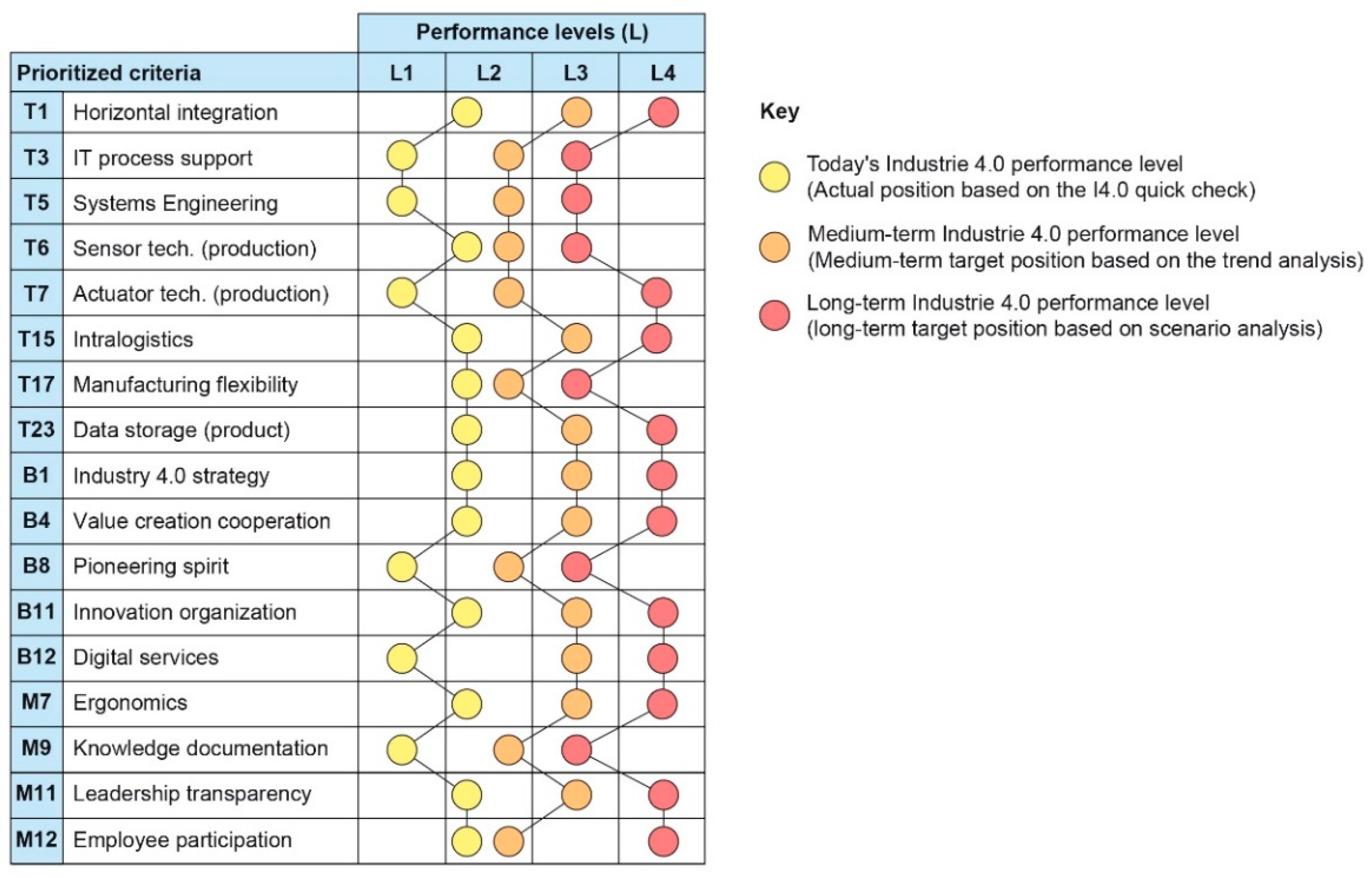

4.3.2. Phase 2: Industry 4.0 Target Position

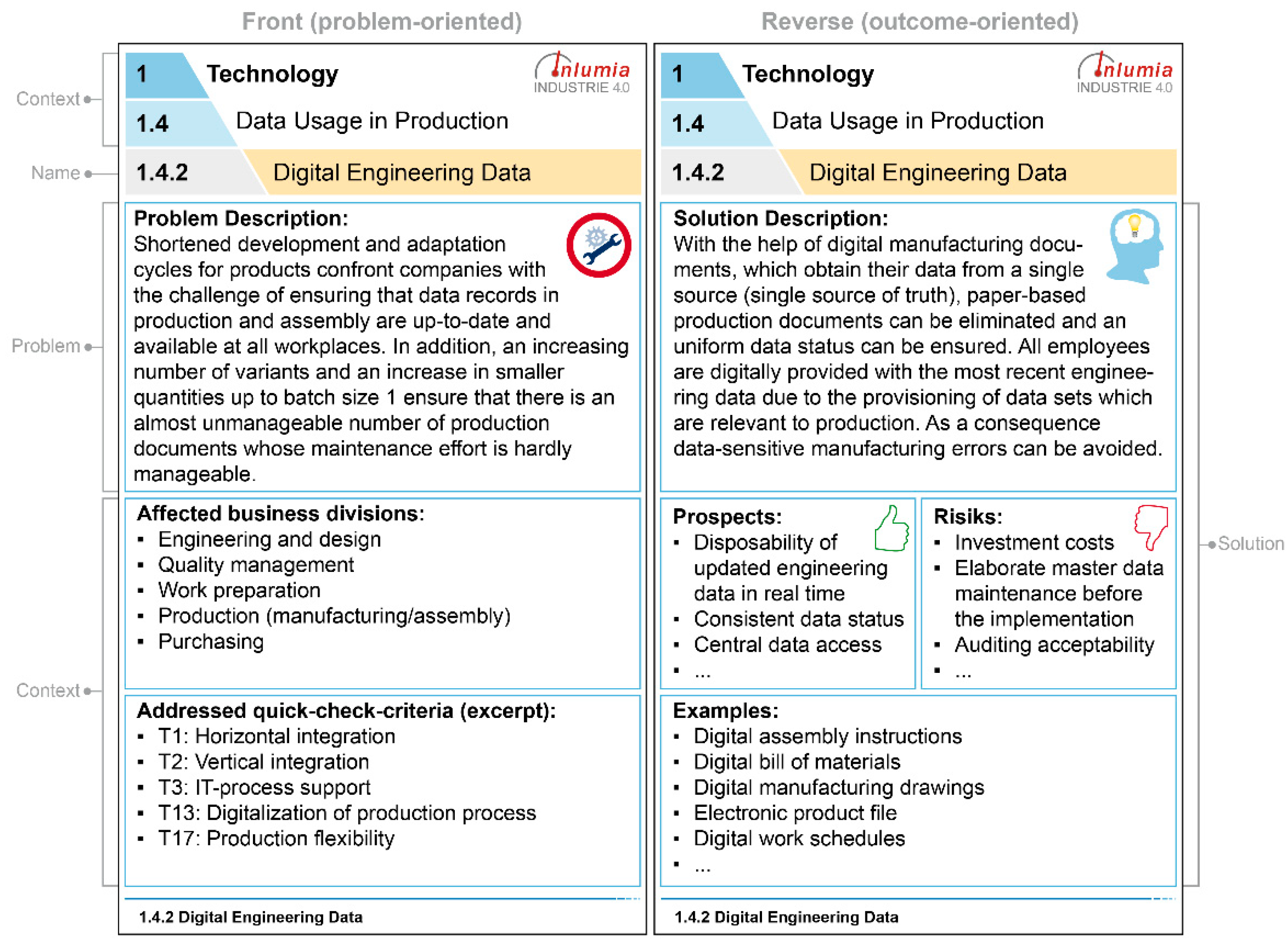

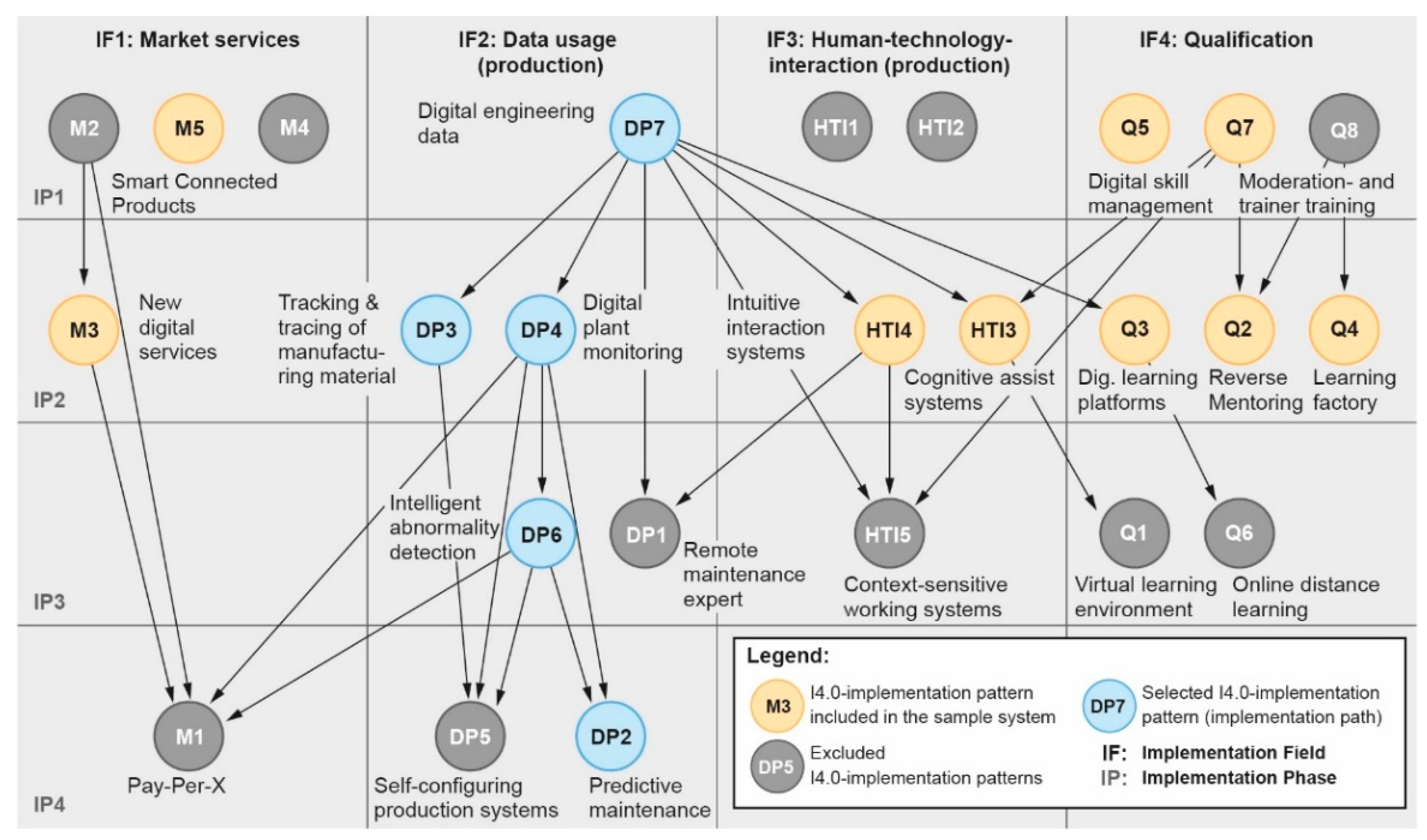

4.3.3. Phase 3: Industry 4.0 Implementation Planning

- Practical project examples: In the context of this study, best practices represent Industry 4.0 projects that have been successfully implemented by pioneers—mostly large companies. This allows identifying both, problems and associated solutions. A comprehensive list of projects is for example provided by the Industry 4.0 platform initiated by the German Federal Ministry of Education and Research as well as by acatech (www.plattform-i40.de (accessed on 14 July 2020)).

- Studies: Publications that deal with challenges and successfully implemented solutions or with future developments provide direct or indirect indications of potential implementation patterns. An example of this is the accompanying research for AUTONOMIK, an Industry 4.0 technology program carried out by the German Federal Ministry for Economic Affairs and Energy [19].

- It’s OWL transfer projects: Within the cluster of excellence it’s OWL 171 so-called transfer projects were successfully carried out. Solutions for Industry 4.0 problems were developed in 8-to-10-month project collaborations between research institutes and SMEs on various cross-sectional topics such as self-optimization or systems engineering. Both the problems as well as the associated solutions represent a valuable source of knowledge [55].

- Industry 4.0 demonstrators: Representations of prototypical solutions in smart factories (e.g., SmartFactoryOWL) internal, and external exhibition demonstrators also represent suitable sources for implementation patterns.

4.3.4. Industry 4.0 Transformation Setup

5. Discussion

5.1. Main Results

5.2. Peculiarities Compared to Literature

5.3. Insights from Application

5.4. Limitations

5.5. Future Research

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Da Xu, L.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Kagermann, H. Change Through Digitization—Value Creation in the Age of Industry 4.0. In Management of Permanent Change; Albach, H., Meffert, H., Pinkwart, A., Reichwald, R., Eds.; Springer Gabler: Wiesbaden, Germany, 2015; pp. 23–45. ISBN 978-3-658-05013-9. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Final Report of the Industrie 4.0 Working Group; Acatech—Deutsche Akademie der Technikwissenschaften e.V.: Berlin, Germany, 2013. [Google Scholar]

- Gausemeier, J.; Klocke, F.; Dülme, C.; Eckelt, D.; Kabasci, P.; Kohlhuber, M.; Schön, N.; Schröder, S.; Wellensiek, M. Industrie 4.0: International Benchmark, Future Options and Recommendations for Action in Production Research; Heinz Nixdorf Institut, Universität Paderborn, Werkzeugmaschinenlabor WZL der Rheinisch-Westfälischen Technischen Hochschule Aachen: Paderborn, Aachen, 2016. [Google Scholar]

- Müller, J.M.; Buliga, O.; Voigt, K.-I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Davies, R.; Coole, T.; Smith, A. Review of Socio-technical Considerations to Ensure Successful Implementation of Industry 4.0. Procedia Manuf. 2017, 11, 1288–1295. [Google Scholar] [CrossRef]

- Walker, G.H.; Stanton, N.A.; Salmon, P.M.; Jenkins, D.P. A review of sociotechnical systems theory: A classic concept for new command and control paradigms. Theor. Issues Ergon. Sci. 2008, 9, 479–499. [Google Scholar] [CrossRef]

- Rousseau, D.M. Technological differences in job characteristics, employee satisfaction, and motivation: A synthesis of job design research and sociotechnical systems theory. Organ. Behav. Hum. Perform. 1977, 19, 18–42. [Google Scholar] [CrossRef]

- Ulich, E. Arbeitssysteme als Soziotechnische Systeme—Eine Erinnerung [Work systems as sociotechnical systems—A memory]. J. Psychol. Des Alltagshandelns 2013, 6, 4–12. [Google Scholar]

- Pierenkemper, C.; Drewel, M.; Gausemeier, J. Zukunftsorientierte Leistungssteigerung von Unternehmen durch Industrie 4.0 [Future-oriented performance enhancement of companies through Industry 4.0]. In Tagungsband AALE 2018, Proceedings of the AALE 2018, Cologne, Germany, 1–2 March 2018; Smajic, H., Ed.; VDE Verlag: Berlin, Germany, 2018; pp. 19–27. [Google Scholar]

- Bajic, B.; Rikalovic, A.; Suzic, N.; Piuri, V. Industry 4.0 Implementation Challenges and Opportunities: A Managerial Perspective. IEEE Syst. J. 2021, 15, 546–559. [Google Scholar] [CrossRef]

- Masood, T.; Sonntag, P. Industry 4.0: Adoption challenges and benefits for SMEs. Comput. Ind. 2020, 121, 103261. [Google Scholar] [CrossRef]

- Schuh, G.; Anderl, R.; Dumitrescu, R.; Krüger, A.; Hompel, M.t. Industrie 4.0 Maturity Index: Managing the Digital Transformation of Companies—UPDATE 2020; Acatech STUDY: Munich, Germany, 2020; Available online: https://www.acatech.de/publikation/industrie-4-0-maturity-index-update-2020/ (accessed on 2 July 2022).

- Ennemann, M.; Linden, S. Survival of the Smartest 2016: Studie zur Digitalen Transformation [Study Regarding Digital Transformation]; KPMG: Amstelveen, The Netherlands, 2016. [Google Scholar]

- Pierenkemper, C.; Gausemeier, J. Developing Strategies for Digital Transformation in SMEs with Maturity Models. In Digitalization: Approaches, Case Studies, and Tools for Strategy, Transformation and Implementation; Schallmo, D., Tidd, J., Eds.; Springer: Cham, Switzerland, 2021; pp. 103–124. ISBN 978-3-030-69379-4. [Google Scholar]

- Büst, R.; Hille, M.; Schestakow, J. Digital Business Readiness; Crisp Research: Kassel, Germany, 2015. [Google Scholar]

- Schmitz, C.; Tschiesner, A.; Jansen, C.; Hallerstede, S.; Garms, F. Industry 4.0: Capturing Value at Scale in Discrete Manufacturing; McKinsey & Company: Chicago, IL, USA, 2019. [Google Scholar]

- Federal Ministry for Economic Affairs and Energy. Studie Industrie 4.0—Volkswirtschaftliche Faktoren für den Standort Deutschland [Study Industry 4.0—Economic Factors for Germany as a Business Location]; Federal Ministry for Economic Affairs and Energy: Berlin, Germany, 2015.

- Dumitrescu, R.; Maier, G.; Pierenkemper, C.; Reinhold, J.; Hobscheidt, D.; Lipsmeier, A.; Gundlach, T.; Schlicher, K.; Heppner, H.; Seifert, L. Soziotechnische Leistungssteigerung von Unternehmen durch Industrie 4.0 [Socio-Technical Performance Enhancement of Companies through Industry 4.0]; Heinz Nixdorf Institute: Paderborn, Germany, 2022; in press. [Google Scholar]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the definition of Industry 4.0: Analysis and open questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- de Bruin, T.; Freeze, R.; Kulkarni, U.; Rosemann, M. Understanding the Main Phases of Developing a Maturity Assessment Model. In Proceedings of the 16th Australasian Conference on Information Systems, Sydney, Australia, 29 November–2 December 2005. [Google Scholar]

- Becker, J.; Knackstedt, R.; Pöppelbuß, J. Developing Maturity Models for IT Management. Bus. Inf. Syst. Eng. 2009, 1, 213–222. [Google Scholar] [CrossRef]

- IT Governance Institute. COBIT 4.1: Framework, Control Objectives, Management Guidelines, Maturity Models; IT Governance Institute: Rolling Meadows, IL, USA, 2007; ISBN 1-933284-72-2.

- Wagire, A.A.; Joshi, R.; Rathore, A.P.S.; Jain, R. Development of maturity model for assessing the implementation of Industry 4.0: Learning from theory and practice. Prod. Plan. Control. 2021, 32, 603–622. [Google Scholar] [CrossRef]

- Gökalp, E.; Martinez, V. Digital transformation capability maturity model enabling the assessment of industrial manufacturers. Comput. Ind. 2021, 132, 103522. [Google Scholar] [CrossRef]

- Chandler, A.D. Strategy and Structure: Chapters in the History of the Industrial Enterprise; M.I.T. Press: Cambridge, MA, USA, 1962; ISBN 9780262530095. [Google Scholar]

- Oleff, A.; Malessa, N. Strategischer Ansatz zur Industrie 4.0-Transformation [Strategic Approach for Industry 4.0 Transformation]. ZWF 2018, 113, 173–177. [Google Scholar] [CrossRef]

- Tüllmann, C.; Sagner, D.; Prasse, C.; Piastowski, H. Vernetzt denken—Vernetzt handeln [Networked Thinking—Networked Acting]. In Disruption und Transformation Management: Digital Leadership—Digitales Mindset—Digitale Strategie [Disruption and Transformation Management: Digital Leadership—Digital Mindset—Digital Strategy]; Keuper, F., Schomann, M., Sikora, L.I., Wassef, R., Eds.; Springer Gabler: Wiesbaden/Heidelberg, Germany, 2018; pp. 165–186. ISBN 978-3-658-19130-6. [Google Scholar]

- Schumacher, A.; Nemeth, T.; Sihn, W. Roadmapping towards industrial digitalization based on an Industry 4.0 maturity model for manufacturing enterprises. In Procedia CIRP, Proceedings of the 12th CIRP Conference on Intelligent Computation in Manufacturing Engineering, Gulf of Naples, Italy, 18–20 July 2018; Teti, R., D’Adonna, D.M., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2018; pp. 409–414. [Google Scholar]

- Pessl, E.; Sorko, S.R.; Mayer, B. Roadmap Industry 4.0—Implementation Guideline for Enterprises. Int. J. Sci. Technol. Soc. 2017, 5, 193–202. [Google Scholar] [CrossRef]

- Morlock, F.; Wienbruch, T.; Leineweber, S.; Kreimeier, D.; Kuhlenkötter, B. Industrie 4.0-Transformation für produzierende Unternehmen [Industrie 4.0-transformation of manufacturing companies]. ZWF 2016, 111, 306–309. [Google Scholar] [CrossRef]

- Jodlbauer, H.; Schagerl, M. Reifegradmodell Industrie 4.0—Ein Vorgehensmodell zur Identifikation von Industrie 4.0 Potentialen [Industrie 4.0 maturity model—A process model for identifying Industrie 4.0 potentials]. In Informatik 2016; Mayr, H.C., Pinzger, M., Eds.; Gesellschaft für Informatik: Bonn, Germany, 2016; ISBN 9783885796534. [Google Scholar]

- Alexander, C.; Ishikawa, S.; Silverstein, M.; Jacobson, M.; Fiksdahl-King, I.; Angel, S. A Pattern Language: Towns Buildings Construction; Oxford University Press: New York, NY, USA, 1977; ISBN 13 978-0-19-501919-3. [Google Scholar]

- Alexander, C. The Timeless Way of Building; Oxford University Press: New York, NY, USA, 1979; ISBN 0195022483. [Google Scholar]

- Anacker, H.; Dumitrescu, R.; Kharatyan, A.; Lipsmeier, A. Pattern Based Systems Engineering—Application of Solution Patterns in the Design of Intelligent Technical Systems. Proc. Des. Soc. Des. Conf. 2020, 1, 1195–1204. [Google Scholar] [CrossRef]

- Echterfeld, J.; Gausemeier, J. Digitising Product Portfolios. Int. J. Innov. Mgt. 2018, 22, 1840003. [Google Scholar] [CrossRef]

- Weking, J.; Stöcker, M.; Kowalkiewicz, M.; Böhm, M.; Krcmar, H. Leveraging industry 4.0—A business model pattern framework. Int. J. Prod. Econ. 2020, 225, 107588. [Google Scholar] [CrossRef]

- Gausemeier, J.; Wieseke, J.; Echterhoff, B.; Koldewey, C.; Mittag, T.; Schneider, M.; Isenberg, L. Mit Industrie 4.0 zum Unternehmenserfolg [With Industry 4.0 to Business Success]: Integrative Planung von Geschäftsmodellen und Wertschöpfungssystemen [Integrative Planning of Business Models and Value Creation Systems]; Heinz Nixdorf Institute: Paderborn, Germany, 2017. [Google Scholar]

- Dumitrescu, R.; Anacker, H.; Gausemeier, J. Design framework for the integration of cognitive functions into intelligent technical systems. Prod. Eng. Res. Devel. 2013, 7, 111–121. [Google Scholar] [CrossRef]

- Balogun, J.; Hope Hailey, V.; Gustafsson, S. Exploring Strategic Change, 4th ed.; Pearson Education Limited: Harlow, UK, 2016; ISBN 978-0-273-77891-2. [Google Scholar]

- Merz, S.L. Industrie 4.0—Vorgehensmodell für die Einführung [Industry 4.0—Procedure model for the implementation]. In Einführung und Umsetzung von Industrie 4.0 [Introduction and Implementation of Industry 4.0]; Roth, A., Ed.; Springer: Berlin, Heidelberg, 2016; pp. 83–132. ISBN 978-3-662-48504-0. [Google Scholar]

- Hennegriff, S.; Terstegen, S.; Stowasser, S.; Dander, H.; Adler, P. Vorgehensmodell für die Industrie 4.0: Strukturierte Einführung und Umsetzung von Digitalisierungsmaßnahmen in der produzierenden Industrie [Procedure model for Industry 4.0: Structured introduction and implementation of digitization measures in the manufacturing industry]. Ind. 4.0 Manag. 2019, 3, 47–50. [Google Scholar]

- Menzefricke, J.S.; Wiederkehr, I.; Koldewey, C.; Dumitrescu, R. Socio-technical risk management in the age of digital transformation-identification and analysis of existing approaches. Procedia CIRP 2021, 100, 708–713. [Google Scholar] [CrossRef]

- Otto, B.; Bärenfänger, R.; Steinbuß, S. Digital Business Engineering: Methodological Foundations and First Experiences from the Field. In BLED 2015, Proceedings of the 28th Bled eConference “#eWellbeing”, Bled, Slovenia, 7–10 June 2015; University of Maribor, University Press: Maribor, Slovenia, 2015; pp. 58–76. [Google Scholar]

- March, S.T.; Smith, G.F. Design and natural science research on information technology. Decis. Support Syst. 1995, 15, 251–266. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research and Applications: Design and Methods, 6th ed.; Sage: Los Angeles, CA, USA, 2018; ISBN 9781544308388. [Google Scholar]

- Österle, H.; Otto, B. Consortium Research. Bus. Inf. Syst. Eng. 2010, 2, 283–293. [Google Scholar] [CrossRef]

- Brinkkemper, S. Method engineering: Engineering of information systems development methods and tools. Inf. Softw. Technol. 1996, 38, 275–280. [Google Scholar] [CrossRef]

- Kumar, K.; Welke, R.J. Methodology Engineering: A Proposal for situation-specific methodology construction. In Challenges and Strategies for Research in Systems Development; Cotterman, W.W., Senn, J.A., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 1992; pp. 257–269. [Google Scholar]

- Harmsen, F.; Brinkkemper, S.; Oei, H. Situational method engineering for information system project approaches. In Methods and Associated Tools for the Information Systems Life Cycle, Proceedings of the IFIP WG 8.1 Working Conference on Methods and Associated Tools for the Information Systems Life Cycle, Maastricht, The Netherlands, 26–28 September 1994; Verrijn-Stuart, A.A., Ed.; Elsevier: Amsterdam, The Netherlands, 1994; ISBN 0-444-82074-4. [Google Scholar]

- Gutzwiller, T.A. Das CC RIM-Referenzmodell für den Entwurf von Betrieblichen, Transaktionsorientierten Informationssystemen [The CC RIM Reference Model for the Design of Operational, Transaction-Oriented Information Systems]; Physica-Verlag HD: Heidelberg, Germany, 1994; ISBN 978-3-642-52406-6. [Google Scholar]

- Goldkuhl, G.; Karlsson, F. Method Engineering as Design Science. JAIS 2020, 21, 1237–1278. [Google Scholar] [CrossRef]

- Deflorin, P.; Scherrer, M.; Eberhardt, N. Digitale Intensität und Management der Transformation [Digital Intensity and Transformation Management]. In Digitale Transformation von Geschäftsmodellen [Digital Transformation of Business Models]; Schallmo, D., Rusnjak, A., Anzengruber, J., Werani, T., Jünger, M., Eds.; Springer Fachmedien: Wiesbaden, Germany, 2017; pp. 265–282. ISBN 978-3-658-12387-1. [Google Scholar]

- Dumitrescu, R.; Ebbesmeyer, P.; Fechtelpeter, C.; Gausemeier, J.; Hobscheidt, D.; Kühn, A. On the Road to Industry 4.0—Technology Transfer in the SME Sector; It’s OWL Clustermanagement GmbH: Paderborn, Germany, 2017. [Google Scholar]

- Westermann, T. Systematik zur Reifegradmodell-Basierten Planung von Cyber-Physical Systems des Maschinen-und Anlagenbaus [Systematic for Maturity Model-Based Planning of Cyber-Physical Systems in Mechanical and Plant Engineering]; Paderborn University: Paderborn, Germany, 2017. [Google Scholar]

- Rauter, R. Interorganisationaler Wissenstransfer [Interorganizational Knowledge Transfer]: Zusammenarbeit Zwischen Forschungseinrichtungen und KMU [Cooperation between Research Institutions and SMEs]. Ph.D. Dissertation, Graz University, Wiesbaden, Germany, 2013. [Google Scholar]

- Gausemeier, J.; Plass, C. Zukunftsorientierte Unternehmensgestaltung [Future-Oriented Company Design]: Strategien, Geschäftsprozesse und IT-Systeme für die Produktion von Morgen [Strategies, Business Processes and IT Systems for Tomorrow‘s Production], 2nd ed.; Carl Hanser Verlag: Munich, Germany, 2014; ISBN 978-3446436312. [Google Scholar]

- Müller-Stewens, G.; Lechner, C. Strategisches Management [Strategic Management]: Wie Strategische Initiativen zum Wandel Führen: Der Strategic Management Navigator [How Strategic Initiatives Lead to Change: The Strategic Management Navigator], 5th ed.; Schäffer-Poeschel Verlag: Stuttgart, Germany, 2016; ISBN 978-3-7910-3439-3. [Google Scholar]

- Kerth, N.L.; Cunningham, W. Using patterns to improve our architectural vision. IEEE Softw. 1997, 14, 53–59. [Google Scholar] [CrossRef][Green Version]

- Cloutier, R.J.; Dinesh, V. Applying the concept of patterns to systems architecture. Syst. Eng. 2007, 10, 138–154. [Google Scholar] [CrossRef]

- Deigendesch, T. Kreativität in der Produktentwicklung und Muster als methodisches Hilfsmittel [Creativity in Product Development and Patterns as a Methodological Tool]. Ph.D. Dissertation, Karlsruhe Institute for Technology, Karlsruhe, Germany, 2009. [Google Scholar]

- Schumacher, M. Security Engineering with Patterns: Origins, Theoretical Model, and New Applications; Springer: Berlin/Heidelberg, Germany, 2003; ISBN 978-3-540-45180-8. [Google Scholar]

- Zimmermann, B. Pattern-basierte Prozessbeschreibung und unterstützung—Ein Werkzeug zur Unterstützung von Prozessen zur Anpassung von E-Learning Materialien [Pattern-Based Process Description and Support—A Tool to Support Processes for Adapting E-Learning Materials]. Ph.D. Dissertation, Technical University of Darmstadt, Darmstadt, Germany, 2008. [Google Scholar]

- Hirsch-Kreinsen, H.; Hompel, M.t.; Ittermann, P.; Niehaus, J.; Dregger, J.; Mättig, B.; Kirks, T. Digitalisierung von Industriearbeit: Forschungsstand und Entwicklungsperspektiven—Ein Leitbild der Technologischen, Organisatorischen und Sozialen Herausforderungen der Industrie 4.0 [Digitization of Industrial Work: State of Research and Development Prospects—A Guide to the Technological, Organizational and Social Challenges of Industry 4.0]; Technical University of Dortmund: Dortmund, Germany, 2015. [Google Scholar]

- Kollmann, T.; Schmidt, H. Deutschland 4.0 [Germany 4.0]: Wie die Digitale Transformation Gelingt [How the Digital Transformation Can Succeed]; Springer Gabler: Wiesbaden, Germany, 2016; ISBN 978-3-658-13145-6. [Google Scholar]

- Fujitsu. Walking the Digital Tightrope; Fujitsu: Munich, Germany, 2016; Available online: https://www.fujitsu.com/global/imagesgig5/br-fujitsu-digital-tightrope-report-em-en.pdf (accessed on 2 June 2022).

- Cole, T. Digitale Transformation [Digital Transformation]: Warum die Deutsche Wirtschaft Gerade Die Digitale Zukunft Verschläft und Was Jetzt Getan Werden Muss! [Why the German Economy is Currently Sleeping through the Digital Future and What Needs to Be Done Now!], 2nd ed.; Verlag Franz Vahlen: Munich, Germany, 2017; ISBN 9783800653997. [Google Scholar]

- Gausemeier, J.; Lewandowski, A.; Siebe, A.; Soetebeer, M. OMEGA: Object-Oriented Method Strategic Redesign of Business Processes. In Changing the Ways We Work, Proceedings of the Shaping the ICT-Solutions for the Next Century, Conference on Integration in Manufacturing, Göteborg, Sweden, 6–8 October 1998; Mårtensson, N., Mackay, R., Björgvinsson, S., Eds.; IOS Press: Amsterdam, The Netherlands, 1998; pp. 381–391. ISBN 4274902528. [Google Scholar]

- Porter, M.E. What is strategy? Harv. Bus. Rev. 1996, 74, 61–78. [Google Scholar]

- Drazin, R.; de van Ven, A.H. Alternative Forms of Fit in Contingency Theory. Adm. Sci. Q. 1985, 30, 514–539. [Google Scholar] [CrossRef]

- Pierenkemper, C.; Reinhold, J.; Dumitrescu, R.; Gausemeier, J. Erfolg versprechende Industrie 4.0-Zielposition [Promising Industry 4.0 target position]. I40M 2019, 2019, 30–34. [Google Scholar] [CrossRef]

- Hobscheidt, D.; Kühn, A.; Dumitrescu, R. Development of risk-optimized implementation paths for Industry 4.0 based on socio-technical pattern. Procedia CIRP 2020, 91, 832–837. [Google Scholar] [CrossRef]

- Anderl, R.; Fleischer, J. Guideline Industrie 4.0: Guiding Principles for the Implementation of Industrie 4.0 in Small and Medium Sized Businesses; VDMA Verlag: Frankfurt am Main, Germany, 2015; ISBN 978-3-8163-0677-1. [Google Scholar]

- Berghaus, S.; Back, A. Gestaltungsbereiche der Digitalen Transformation von Unternehmen: Entwicklung eines Reifegradmodells [Design areas of the digital transformation of companies: Development of a maturity model]. Die Unternehm. 2016, 70, 98–123. [Google Scholar] [CrossRef]

- Schneider, M.; Hellweg, T.; Menzefricke, J.S. Identification of Human and Organizational Key Design Factors for Digital Maturity—A Fuzzy-Set Qualitative Comparative Analysis. Proc. Des. Soc. Des. Conf. 2022, 2, 791–800. [Google Scholar] [CrossRef]

- Horovitz, J. New Perspectives on Strategic Management. J. Bus. Strategy 1984, 4, 19–33. [Google Scholar] [CrossRef]

- Gabriel, S.; Grauthoff, T.; Joppen, R.; Kühn, A.; Dumitrescu, R. Analyzing socio-technical risks in implementation of Industry 4.0-use cases. Procedia CIRP 2021, 100, 241–246. [Google Scholar] [CrossRef]

| Consortium Research Phase | Activities and Methods |

|---|---|

| Analysis | Literature review Interviews and consortium workshops Best practice analysis (e.g., platform Industry 4.0, it’s owl) |

| Design | Rigor: Review of Industry 4.0 and Business Transformation (in Manufacturing) literature Relevance: Interviews and workshops with consortium partners Method Engineering as design paradigm for the development of the method Action research to solve real-world problems within the consortium, check the relevance, and iterate toward the solution |

| Evaluation | Case studies Pilot application Review via workshops |

| Diffusion | Knowledge transfer workshops Homepage, Online-Tool Research papers |

| Case | Industry | Size (Empl.) | Collection Period and Setting | Key Experts | Type of Case Study |

|---|---|---|---|---|---|

| A | White Goods | 800 | July 2016– June 2019, 12 workshops | Industrial engineers, strategic planning, and project management | Explorative, participatory, application company |

| B | Electronics and intelligent technical systems | 40 | July 2016– June 2019, 10 workshops | Business management | Explorative, participatory, application company |

| C | Engineering for printing machines | 60 | July 2016– June 2019, 6 workshops | Technical director, technical engineering team | Explorative, participatory, application company |

| D | Engineering for HVAC | 130 | July 2016– June 2019, 9 workshops | Research and development team | Explorative, participatory, application company |

| E | Engineering for security and access solutions | 7.000 | July 2016– June 2017, 6 workshops | Senior manager strategic innovation | Explorative, participatory, application company |

| X | Cross-case Workshops | - | July 2016– June 2019, 4 workshops | Project leads from the consortium | Explorative, interviews |

| Z | Individual third-party transfer | - | July 2016– June 2019, 3 workshops | Diverse | Explorative, participatory, partial application |

| Date | Topic | Method | Participants |

|---|---|---|---|

| 22 June 2017, 13:00–17:15 | Change of the company as a socio-technical system (technology, business, people) | World Café | 28 experts from industry and research |

| 26 June 2018, 13:00–17:00 | Increasing firm performance: prototypes of Industry 4.0, patterns for Industry 4.0, use cases with the firm | World Café | 34 experts from industry and research |

| 27 June 2019, 14:00–18:00 | Industry 4.0 Expert Group: From digitalization strategy to implementation | Presentation and Workshop | 85 experts from industry and research |

| Cat. | Req. | Description | Supporting Literature |

|---|---|---|---|

| Maturity Check | R1 | Consideration of the relevant aspects of Industry 4.0 | [54,55] |

| R2 | Objective evaluation criteria for Industry 4.0 | [56] | |

| R3 | Benchmarking with similar companies | [15,57] | |

| Target defini-tion | R4 | Integration of foresight into target definition | [58] |

| R5 | Internal and external consistency of the target | [59] | |

| Implemen-tation planning | R6 | Inductive development of Industry 4.0 implementation patterns | [35,60] |

| R7 | Interdisciplinary notation scheme | [61,62] | |

| R8 | Identification of consistent pattern paths | [63,64] | |

| Transfor-mation setup | R9 | Socio-technical view on transformation | [10,65] |

| R10 | Transparent and holistic transformation set-up | [66,67,68] |

| Phase | Method Components | Goal |

|---|---|---|

| Maturity Check | Quick check Industry 4.0 | Determine the current maturity level |

| Relevance ranking | Find the most important maturity criteria | |

| Derivation of fields of action | Find fields of action for further investigation | |

| In-depth analysis | Identify concrete potentials for improvement within fields of action and rank them | |

| Target definition | Anticipation of the future | Gain an idea of the future environmental conditions |

| Impact analysis | Find out how the future environment influences the different maturity criteria and levels | |

| Target position definition | Define medium- and long-term target maturity levels | |

| Implementation planning | Implementation patterns for Industry 4.0 | Provide generic solutions for recurring problems/potentials within Industry 4.0, that can be concretized for the specific company |

| Identification of relevant implementation fields | Narrow down the solution space according to the concrete transformation needs | |

| Assessment of implementation patterns | Find established solutions that contribute to reaching the target position | |

| Combination analysis | Build a set of solutions that support each other and sort them in a meaningful way | |

| Transformation setup | Definition of measures | Break down general solutions into concrete work packages |

| Risk assessment | Identify risks associated with the implementation and measures to mitigate them | |

| Masterplan of action | Condense the previous results into a document, that can be used for communication | |

| Transformation controlling | Continuously check if the assumptions are still correct and if the transformation is going according to plan |

| Technology | Business | People |

|---|---|---|

| T1 Horizontal Integration | B1 Industry 4.0 Strategy | P1 Scope of activity and autonomy |

| T2 Vertical Integration | B2 Strategy Controlling | P2 Variety of requirements |

| T3 IT Process Support | B3 IT Security Concept | P3 Flexibility of Working Hours |

| T4 Tool Landscape | B4 Value-creation Cooperation | P4 Co-dependency |

| T5 Systems Engineering | B5 Access to capital | P5 Performance Feedback |

| T6 Sensor Technology (production) | B6 Approach to New Product Development | P6 Collaboration and Social Interaction |

| T7 Actuator Technology (production) | B7 Customer Integration | P7 Ergonomics |

| T8 Information Processing (production) | B8 Pioneering Spirit | P8 Continuing Education |

| T9 Human Machine Interface (production) | B9 Technology Transfer | P9 Documentation of Experiential Knowledge |

| T10 Data Storage (production) | B10 Participation in Innovation Networks | P10 Availability of Support |

| T11 Data Usage (production) | B11 Innovation Organization | P11 Leadership Transparency |

| T12 External Data Integration (production) | B12 Approach to Business Model Development | P12 Employee Participation |

| T13 Digitalization of production processes | B13 Product-Service-Systems | P13 Strategy for Change |

| T14 Connectivity (production) | B14 Penetration of Digital Services | P14 Software Usability |

| T15 Intralogistics | B15 Data Collection and Analysis | P15 Assistance Systems |

| T16 Organization of Production Planning and Steering | B16 Data Exploitation | P16 Human-technology Dependency |

| T17 Production Flexibility | B17 Digital Customer Channels | |

| T18 Assistance Systems in Assembly | ||

| T19 Sensor Technology (product) | ||

| T20 Actuator Technology (product) | ||

| T21 Information Processing (product) | ||

| T22 Human Machine Interface (product) | ||

| T23 Data Storage (product) | ||

| T24 Data Usage (product) | ||

| T25 External Data Integration (product) | ||

| T26 Connectivity (product) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koldewey, C.; Hobscheidt, D.; Pierenkemper, C.; Kühn, A.; Dumitrescu, R. Increasing Firm Performance through Industry 4.0—A Method to Define and Reach Meaningful Goals. Sci 2022, 4, 39. https://doi.org/10.3390/sci4040039

Koldewey C, Hobscheidt D, Pierenkemper C, Kühn A, Dumitrescu R. Increasing Firm Performance through Industry 4.0—A Method to Define and Reach Meaningful Goals. Sci. 2022; 4(4):39. https://doi.org/10.3390/sci4040039

Chicago/Turabian StyleKoldewey, Christian, Daniela Hobscheidt, Christoph Pierenkemper, Arno Kühn, and Roman Dumitrescu. 2022. "Increasing Firm Performance through Industry 4.0—A Method to Define and Reach Meaningful Goals" Sci 4, no. 4: 39. https://doi.org/10.3390/sci4040039

APA StyleKoldewey, C., Hobscheidt, D., Pierenkemper, C., Kühn, A., & Dumitrescu, R. (2022). Increasing Firm Performance through Industry 4.0—A Method to Define and Reach Meaningful Goals. Sci, 4(4), 39. https://doi.org/10.3390/sci4040039