Warm-Mix Asphalt Containing Reclaimed Asphalt Pavement: A Case Study in Switzerland

Abstract

1. Introduction

- (I)

- Conducting laboratory and in situ investigations to assess the efficiency of a bio- based chemical additive for high RAP-content WMA (warm-mix asphalt) in alignment with Swiss asphalt standards and best practices.

- (II)

- Evaluating the performance and functionality of chemical additives with relatively small dosages after asphalt mixture production and reheating.

- (III)

- Comparing the visible fumes and emissions during the HMA and WMA asphalt production and laying.

- (IV)

- Investigating the practical challenges that may occur during the production and laying of WMA with relatively high reclaimed asphalt content.

2. Materials

3. Methodology

3.1. Research Project Plan

3.2. Testing Methods

- Penetration, softening point, and viscosity measurement tests according to EN standards EN 1426, EN 1427, and EN 13302, respectively.

- PG grading was conducted according to EN 14770.

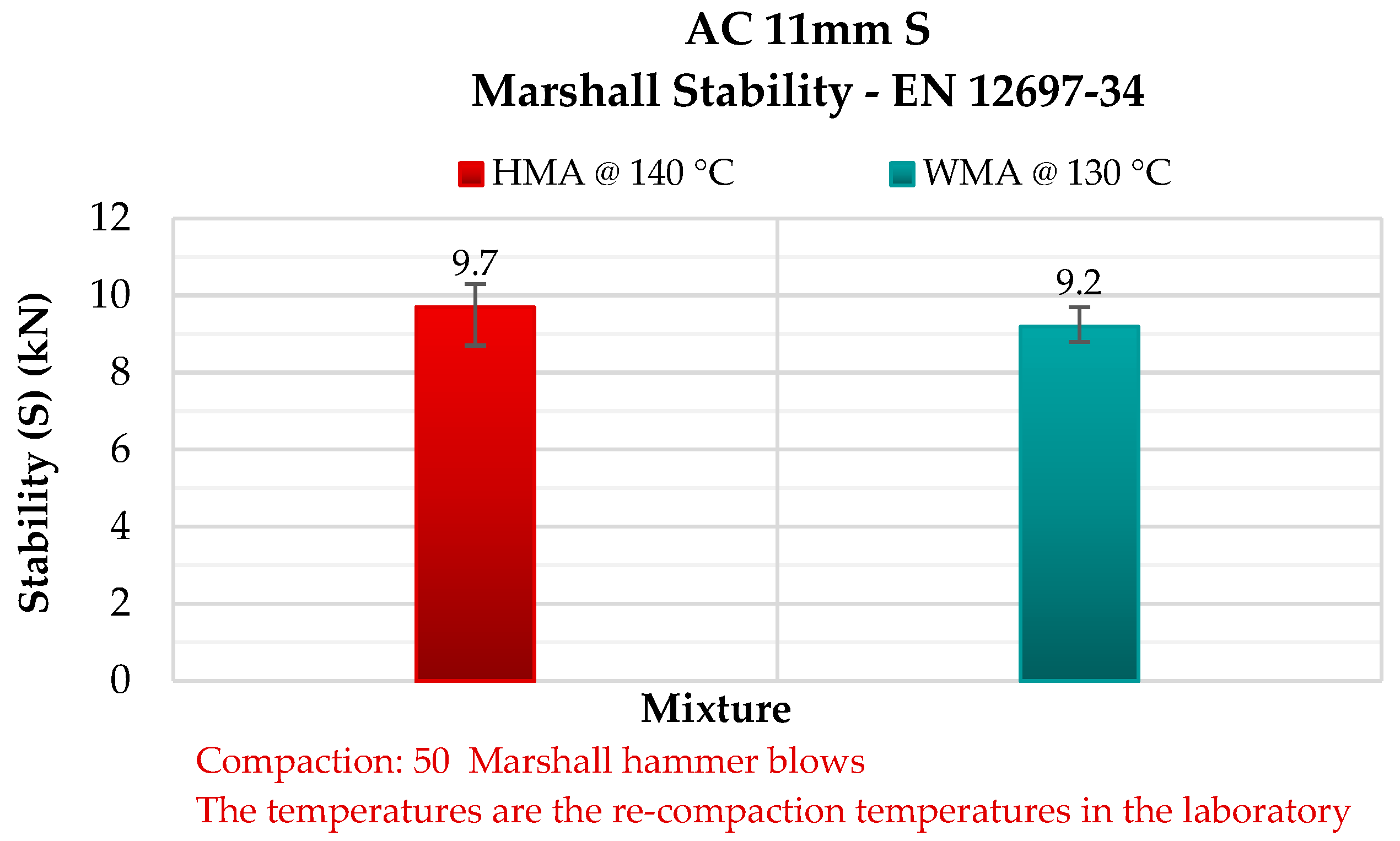

- Marshall stability and flow were conducted based on the European standard EN 12697-34.

- Indirect tensile strength (ITS) and Indirect Tensile Strength Ratio (ITSR) were carried out on 50 blows Marshall compacted specimens according to European standards EN 12697-23 and EN 12697-12, respectively.

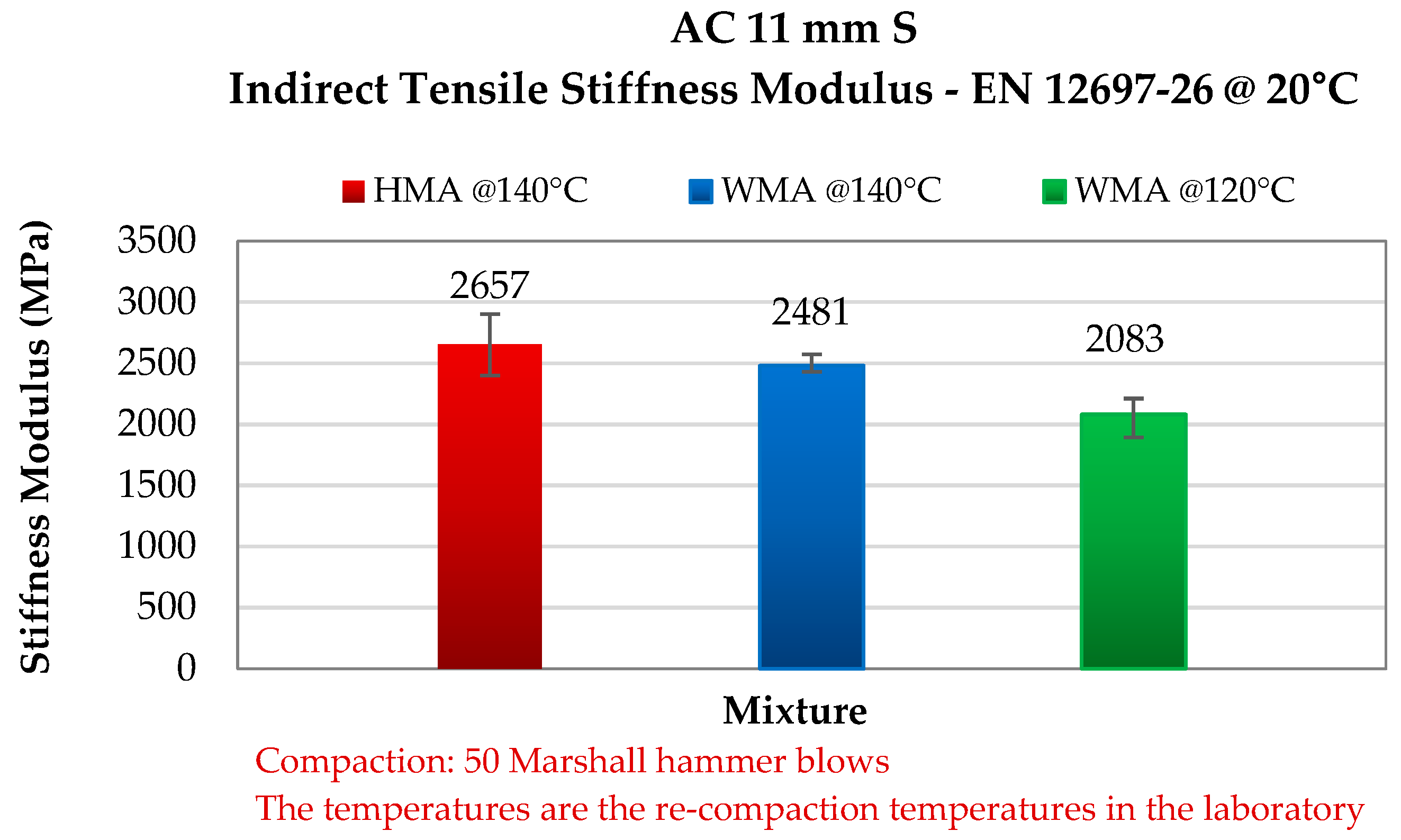

- Indirect Tensile Stiffness Modulus (ITSM) was conducted based on the European standard EN 12697-26 IT CY at 20 °C. According to the standard and based on the diameter of the specimens, 7.5 µm was the maximum horizontal deformation.

- Ideal CT, according to ASTM D 8225 [18], was conducted to investigate the mixtures’ resistance to cracking. The test is elaborated in the NCHRP report No. 195 [19]. For this study, the test was realized at 25 °C. The cracking tolerance (CT) index was calculated using Equation (1):where Gf = failure energy in (J/m2); |m75| = the absolute value of the post-peak slope at 75% of the peak load; l75 = displacement at 75% of peak load after peak; t = specimen thickness in mm; and D = diameter in mm.

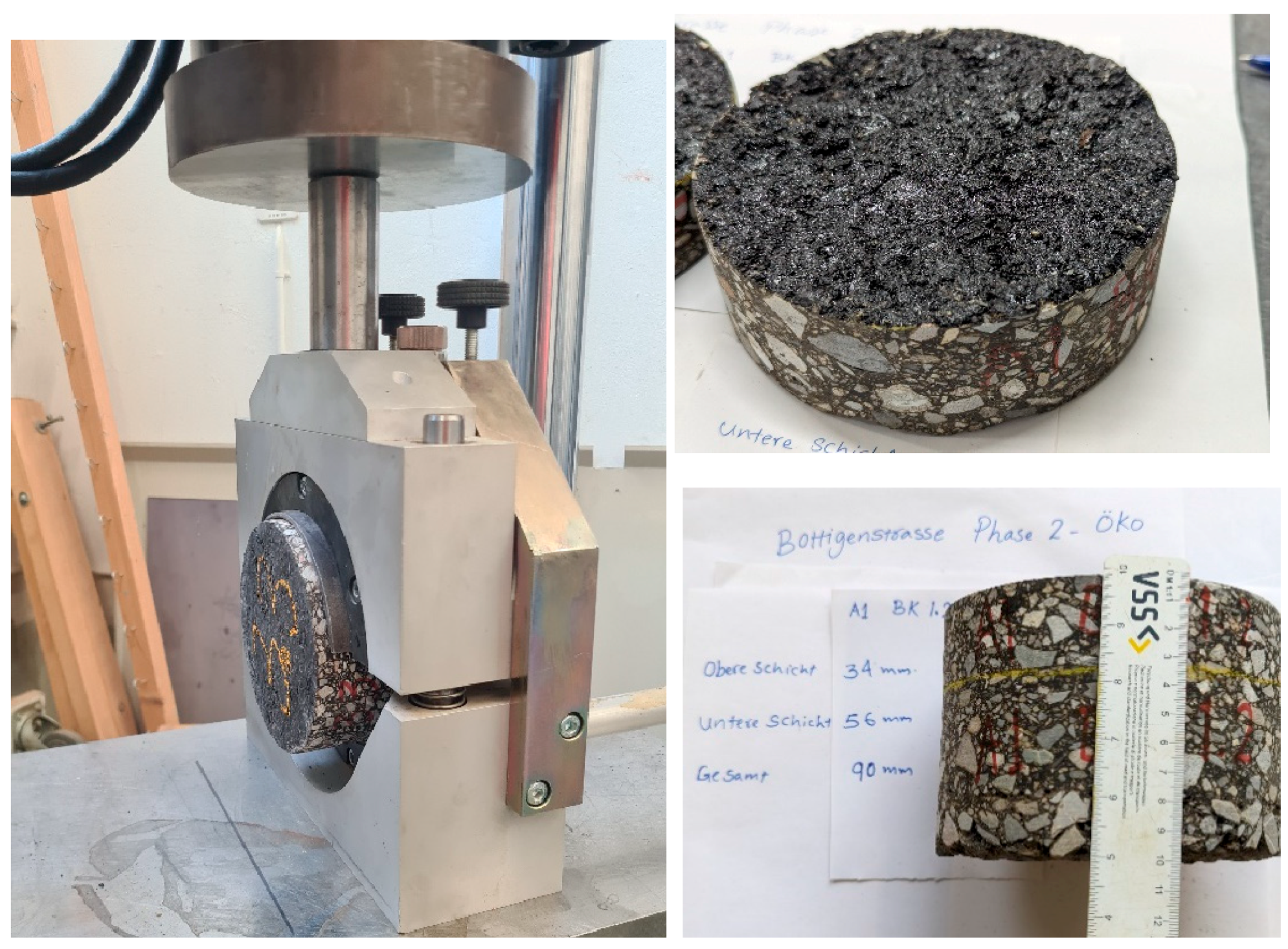

- A shear bond test (Leutner) was conducted to determine the interlaminar bonding strength between the layers of the asphalt core samples according to SN EN 12697-48 at 20 °C.

4. Test Section Profile

5. Results and Analysis

5.1. Aggregates’ Blend Grading Curve Control

5.2. Binder Analysis

- The combination of the added bitumen with the aged bitumen of the RAP perfectly resulted in a typical 50/70 bitumen. In addition, the results of the tests also complied with a typical PEN 70/100 bitumen range, as required by the local specifications.

- Either in a virgin or aged (extracted) state, as expected, the presence of the chemical additive changed the original properties.

- The extracted binder showed small changes compared to the HMA, which is technically attributed to the aging phenomenon during production. However, it should be noted that compared with the typical 50/70 bitumen, due to the short transportation distance, the short-term aging was not significant.

5.3. Mixture-Scale Tests

5.3.1. Marshall Stability and Flow

5.3.2. Indirect Tensile Strength

5.3.3. Indirect Tensile Strength Ratio

5.3.4. Indirect Tensile Stiffness Modulus (ITSM)

5.3.5. Ideal CT

5.3.6. Core Analysis

6. Conclusions

- Due to the nature of the WMA chemical additives as a surfactant and the very small dosage generally applied (150–350 g/ton of asphalt), the additives did not change the rheological properties of the bitumen and consequently the mechanical performance of the final mixture. In fact, it should be noted that the chemical additives do not act similarly to the first production and compaction during the reheating, mixing, and recompacting. Technically, this is a desired characteristic of the WMA chemical additives.

- Overall, no significant difference was observed between the mechanical and performance properties in terms of Marshall stability, water sensitivity, Indirect Tensile Modulus (ITSM) and Strength (ITS) of the HMA mixture and WMA mixture reheated and recompacted specimens, particularly when the WMA specimens were reheated at 30 °C and 140 °C.

- Attested by the Ideal CT test, the HMA mixture showed a higher susceptibility to cracking than WMA mixtures. According to the results, two short-term aging times (during the production and transportation of the mixture and reheating) significantly decreased the mixtures’ flexibility.

- According to the shear bond stress test results of this investigation, it can be deduced that applying the right temperature and paving terms could guarantee the bond properties between the pavement layers.

- As the most representative parameter, the volumetric properties of the laid WMA and HMA mixtures were examined by testing the cores drilled from the job site. Independent of reheating and the function of chemical additives during reheating and compaction for the laboratory manufacturing specimens, similar values were obtained for both WMA and HMA testing mixtures for the cores from the field. In addition to the efficiency of the used additive, this inspires greater confidence in the realistic conditions and properties of the laid and studied pavements.

- As anticipated, no fumes were observed either during the production and discharge of the mass into the truck or at the job site during the laying and compaction of the warm-mix asphalt (WMA) mixture.

7. Future Works

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manolis, S.; Decoo, T.; Lum, P.; Greco, M. Cold weather paving using warm mix asphalt technology. In Proceedings of the Annual Conference of the Transportation Association of Canada, Toronto, ON, Canada, 21–24 September 2008. [Google Scholar]

- Yu, S.; Shen, S.; Steger, R.; Wang, X. Effect of warm mix asphalt additive on the workability of asphalt mixture: From particle perspective. Constr. Build. Mater. 2022, 360, 129548. [Google Scholar] [CrossRef]

- Milad, A.; Babalghaith, A.M.; Al-Sabaeei, A.M.; Dulaimi, A.; Ali, A.; Reddy, S.S.; Bilema, M.; Yusoff, N.I.M. A Comparative Review of Hot and Warm Mix Asphalt Technologies from Environmental and Economic Perspectives: Towards a Sustainable Asphalt Pavement. Int. J. Environ. Res. Public Health 2022, 19, 14863. [Google Scholar] [CrossRef] [PubMed]

- Mohammad, L.; Raghavendra, A.; Medeiros, M.; Hassan, M.; King, W. Evaluation of Warm Mix Asphalt Technology in Flexible Pavements; FHWA/LA.15/553; Louisiana Transportation Research Center: Baton Rouge, LA, USA, 2018. [Google Scholar]

- Qin, Y.C.; Wang, S.Y.; Zeng, W.; Shi, X.P.; Xu, J.; Huang, S.C. The effect of asphalt binder aging on fatigue performance of evotherm WMA. Adv. Mater. Res. 2012, 535–537, 1686–1692. [Google Scholar] [CrossRef]

- Diab, A.; Sangiorgi, C.; Ghabchi, R.; Zaman, M.; Wahaballa, A. Warm Mix Asphalt (WMA) technologies: Benefits and drawbacks—A literature review. In Proceedings of the 4th Chinese European Workshop on Functional Pavement Design, Delft, The Netherlands, 29 June–1 July 2016. [Google Scholar] [CrossRef]

- Federal Highway Administration. Warm Mix Asphalt Technologies and Research. Available online: https://www.fhwa.dot.gov/pavement/asphalt/wma.cfm (accessed on 13 March 2024).

- Tutu, K.; Tuffour, Y. Warm Mix Asphalt and Pavement Sustainability: A Review. J. Civ. Eng. 2016, 6, 84–93. [Google Scholar] [CrossRef]

- Andersen, E. WAM Foam® an Environmental Friendly Alternative to Hot Mix Asphalt; Presentation to WMA Scan Team; Norwegian Public Roads Administration: Oslo, Norway, 2007. [Google Scholar]

- Li, X.; Wang, H.; Zhang, C.; Diab, A.; You, Z. Characteristics of a surfactant produced warm mix asphalt binder and workability of the mixture. J. Test. Eval. 2015, 44, 2219–2230. [Google Scholar] [CrossRef]

- Zaumanis, M.; Smirnovs, J. Analysis of possibilities for use of warm mix asphalt in Latvia. In Proceedings of the 3rd International Conference on Civil Engineering, Jelgava, Latvia, 12–13 May 2011. [Google Scholar]

- European Asphalt Pavement Association. The Use of Warm Mix Asphalt. Available online: https://eapa.org/warm-mix-asphalt/ (accessed on 15 March 2023).

- Olsen, R.; Graff, P.; Daae, H.L.; Bryngelsson, L.; Molander, P.; Ellingsen, D.G. Occupational exposure during asphalt paving-comparison of hot and warm mix asphalt in field experiments. Ann. Work. Expo. Health 2021, 65, 446–457. [Google Scholar] [CrossRef] [PubMed]

- Brown, D.C.; Warm Mix Asphalt: Proving Its Benefits. Asphalt, the Magazine of Asphalt Institute. Available online: http://asphaltmagazine.com/warm-mix-asphalt-proving-its-benefits/ (accessed on 27 October 2023).

- Warming up to New Ideas: The Pros and Cons of Warm Mix Asphalt. Texas A&M Transportation Institute. Available online: https://tti.tamu.edu/researcher/warming-up-to-new-ideas-the-pros-and-cons-of-warm-mix-asphalt/ (accessed on 27 October 2023).

- Botella, R.; Lo Presti, D.; Vasconcelos, K.; Specht, L.; Arámbula Mercado, E.; Menegusso Pires, G.; Pasquini, E.; Ogbo, C.; Preti, F.; Pasetto, M.; et al. Assessment of the Degree of binder Activity of Reclaimed Asphalt Pavement using Support Vector Regression and Clustering. In Proceedings of the 1st International Data Science for Pavements Symposium, McLean, VA, USA, 20–24 March 2022. [Google Scholar]

- Bonaquist, R. Draft Appendix to AASHTO R35: Special Mixture Design Considerations and Methods for Warm Mix Asphalt (WMA); NCHRP Report 691; Transportation Research Board: Washington, DC, USA, 2011; Available online: https://www.co-asphalt.com/assets/docs/nchrp_rpt_691.pdf (accessed on 15 March 2024).

- ASTM D 8225; Standard Test Method for Determination of Cracking Tolerance Index of Asphalt Mixture Using the Indirect Tensile Cracking Test at Intermediate Temperature. ASTM International: West Conshohocken, PA, USA, 2019.

- Development of an IDEAL Cracking Test for Asphalt Mix Design, Quality Control and Quality Assurance; Final Report for NCHRP IDEA Project 195; Transportation Research Board: Washington, DC, USA, 2019.

- Bituminous Mixtures. SN EN 13108-1; Bituminous Mixtures. Materials Specifications—Part 1; Asphalt Concrete. National Appendix. European Committee for Standardization: Brussels, Belgium, 2022.

- Behl, A.; Kumara, G.; Sharmaa, G.; Jaina, P.K. Evaluation of field performance of warm-mix asphalt pavements in India. In Proceedings of the 2nd Conference of Transportation Research Group of India, Agra, India, 12–15 December 2013. [Google Scholar]

- Eskandarsefat, S.; Hofko, B.; Sangiorgi, C. A comparison study on low-temperature properties of stone mastic asphalts modified with PmBs or modified fibres. Int. J. Pavement Eng. 2020, 21, 1541–1549. [Google Scholar] [CrossRef]

- Russo, F.; Eskandarsefat, S.; Venturini, L.; Viscione, N. A complete study on an asphalt mixture modified with graphene and recycled hard-plastic: A case study. Case Stud. Constr. Mater. 2022, 17, e01437. [Google Scholar] [CrossRef]

- Zieliński, P. Indirect tensile test as a simple method for rut resistance evaluation of asphalt mixtures—Polish experience. Road Mater. Pavement Des. 2022, 23, 112–128. [Google Scholar] [CrossRef]

- Eskandarsefat, S.; Dondi, G.; Sangiorgi, C. Recycled and Rubberized SMA Modified Mixtures: A comparison between polymer modified bitumen and modified fibres. Constr. Build. Mater. 2019, 202, 681–691. [Google Scholar] [CrossRef]

- Abo-Shanab, Z.L.; Ragab, A.A.; Naguib Hamdy, M. Improved dynamic mechanical properties of sustainable bio-modified asphalt using agriculture waste. Int. J. Pavement Eng. 2021, 22, 905–911. [Google Scholar] [CrossRef]

- Sangiorgi, C.; Collop, A.C.; Thom, N.H. Laboratory assessment of bond condition using the Leutner shear test. In Proceedings of the 3rd International Conference Bituminous Mixtures and Pavements, Thessaloniki, Greece, 21–22 November 2002. [Google Scholar] [CrossRef]

| Property | Unit | Value |

|---|---|---|

| NMS | mm | 11 |

| Bulk density | kg/m3 | 2512 |

| Binder content | % | 4.6 |

| Aged bitumen penetration | dmm | 29 |

| Aged bitumen softening point | °C | 61 |

| Property | Unit | Value |

|---|---|---|

| Aspect | – | Liquid |

| Colour | – | Light Brown |

| Density @ 25 °C | g/cm3 | 0.85–0.95 |

| Viscosity @ 25 °C | cP | 15–60 |

| Flash point | °C | ˃155 |

| Pour point | °C | ≥0 |

| Material | Measured Time | Temperature * (°C) | |

|---|---|---|---|

| WMA | HMA | ||

| Hot aggregates | In the batch | 200 | 230 |

| RAP | In the parallel drum | 110 | 110 |

| Bitumen | In the silo | 150 | 150 |

| Recovered Filler | In the silo | 50 | 50 |

| Added Filler | In the silo | 20 | 20 |

| Asphalt mixture | In the truck (plant) | 140 | 165 |

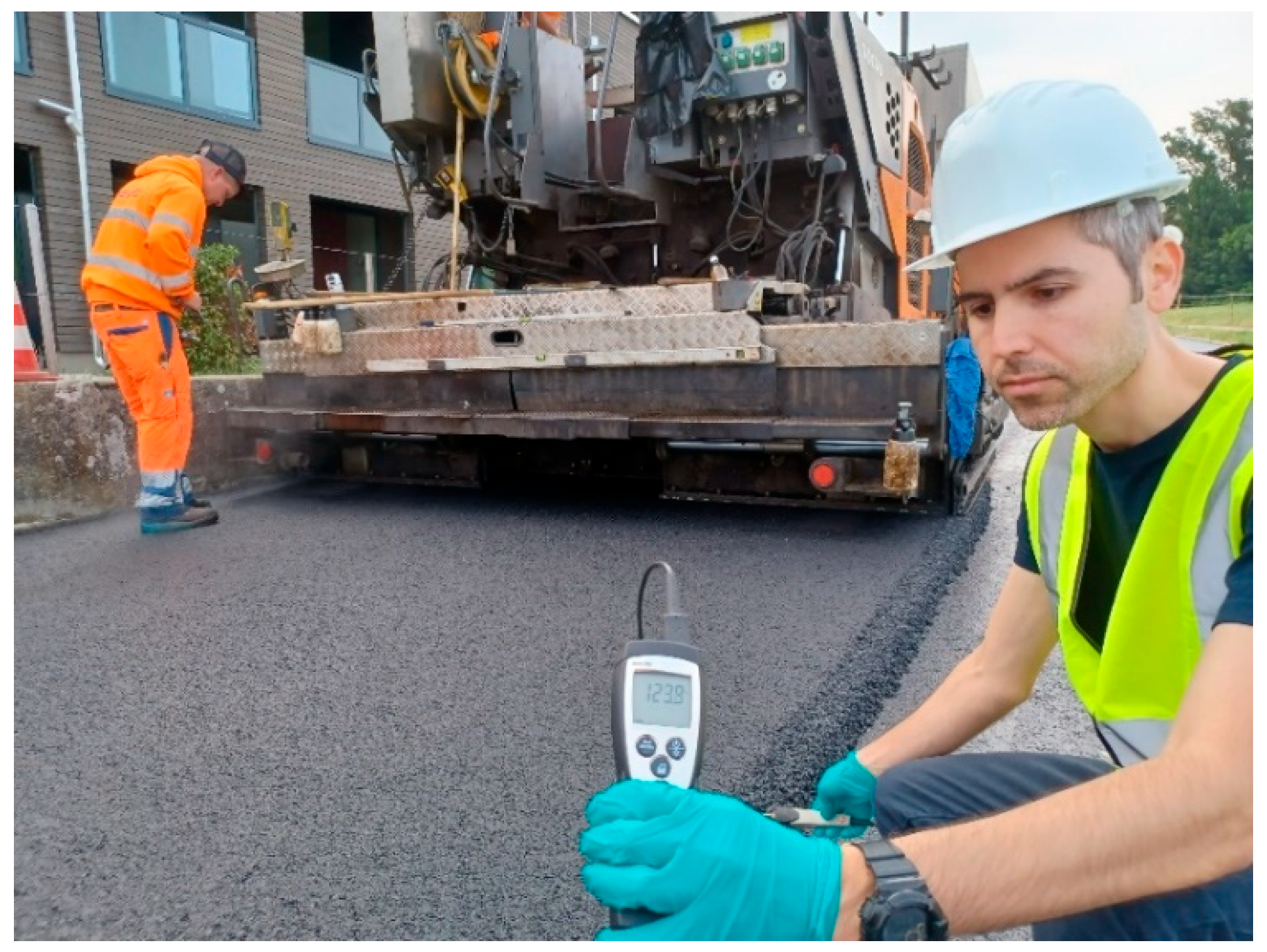

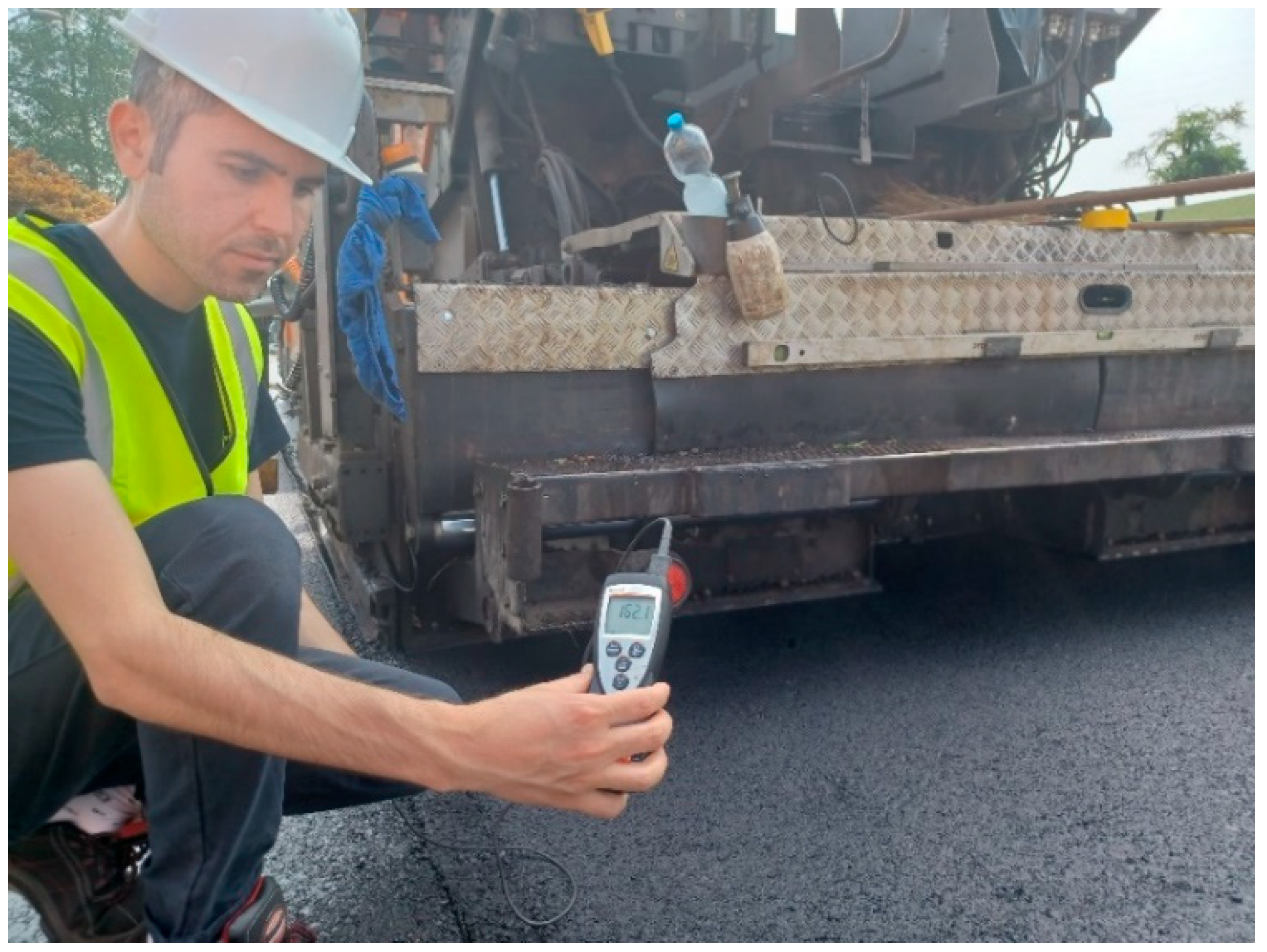

| Behind the finisher | 130 | 155 | |

| Compaction | On the site | 120 | 145 |

| Ambient temperature | During the compaction | 15 | 25 |

| Test | Unit | Standard Testing Method | Virgin Added Bitumen | Extracted Bitumen | Typical PEN 50/70 Bitumen | Typical PEN 70/100 Bitumen | |||

|---|---|---|---|---|---|---|---|---|---|

| Without WMA Additive | With WMA Additive | HMA Mix | WMA * Mix | Virgin State | RTFO State | Virgin State | |||

| Penetration @ 25 °C | dmm | EN 1426:2015 | 204 | 197 | 53 | 57 | 55 | 35 | 40–75 |

| Softening point | °C | EN 427:2015 | 39.4 | 39.0 | 55.4 | 53.6 | 51.0 | 57.8 | 45–62 |

| Dynamic viscosity @ 135 °C | Pa s | EN 13302: 2018 | 0.269 | 0.264 | 0.685 | 0.630 | 0.630 | 0.990 | – |

| Exact Upper PG | °C | EN 14770: 2012 | 56.8 | 55.8 | 74.5 | 72.4 | 71.5 | 77.9 | – |

| Test Item | Unit | WMA | HMA | Specification (VSS 40 430) | ||||

|---|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C1 | C2 | C3 | |||

| GmB | kg/m3 | 2399 | 2372 | 2385 | 2421 | 2386 | 2397 | – |

| Mean GmB | 2385 | 2402 | ||||||

| Gmm | kg/m3 | 2465 | 2475 | – | ||||

| Reference Density | kg/m3 | 2400 | 2422 | – | ||||

| Degree of compaction | % | 99.4 | 99.2 | ≥97 | ||||

| Air void content | % | 2.7 | 3.8 | 3.2 | 1.8 | 3.2 | 2.7 | 2.5–6.0 |

| Mean Air void content | 3.2 | 2.6 | ||||||

| Shear stress | kN | 21.8 | 21.7 | ≥15 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bueche, N.; Probst, S.; Eskandarsefat, S. Warm-Mix Asphalt Containing Reclaimed Asphalt Pavement: A Case Study in Switzerland. Infrastructures 2024, 9, 79. https://doi.org/10.3390/infrastructures9050079

Bueche N, Probst S, Eskandarsefat S. Warm-Mix Asphalt Containing Reclaimed Asphalt Pavement: A Case Study in Switzerland. Infrastructures. 2024; 9(5):79. https://doi.org/10.3390/infrastructures9050079

Chicago/Turabian StyleBueche, Nicolas, Samuel Probst, and Shahin Eskandarsefat. 2024. "Warm-Mix Asphalt Containing Reclaimed Asphalt Pavement: A Case Study in Switzerland" Infrastructures 9, no. 5: 79. https://doi.org/10.3390/infrastructures9050079

APA StyleBueche, N., Probst, S., & Eskandarsefat, S. (2024). Warm-Mix Asphalt Containing Reclaimed Asphalt Pavement: A Case Study in Switzerland. Infrastructures, 9(5), 79. https://doi.org/10.3390/infrastructures9050079