Abstract

It is a universal fact that concrete is one of the most employed construction materials and hence its exigency is booming at a rocket pace, which in turn, has resulted in a titanic demand of ordinary Portland cement. Regrettably, the production of this essential binder of concrete is not merely found to consume restricted natural resources but also found to be associated with emission of carbon dioxide—a primary greenhouse gas (GHG) which is directly answerable to earth heating, resulting in the gigantic dilemma of global warming. Nowadays, in order to address all these impasses, researchers are attracted to innovative Geopolymer concrete technology. However, crack development of various sizes within the concrete is inevitable irrespective of its kind, mix design, etc., owing to external and internal factors viz., over-loading, exposure to severe environments, shrinkage, or error in design, etc., which need to be sealed otherwise these openings permits CO2, water, fluids, chemicals, harmful gases, etc., to pass through reducing service life and ultimately causing the failure of concrete structures in the long term. That is why instant repairs of these cracks are essential, but manual mends are time-consuming and costly too. Hence, self-healing of cracks is desirable to ease their maintenances and repairs. Self-healing geopolymer concrete (SHGPC) is a revolutionary product extending the solution to all these predicaments. The present manuscript investigates the self-healing ability of geopolymer paste, geopolymer mortar, and geopolymer concrete—a slag-based fiber-reinforced and a variety of other composites that endow with multifunction have also been compared, keeping the constant ratio of water to the binder. Additionally, the feasibility of bacteria in a metakaolin-based geopolymer concrete for self-healing the cracks employing Bacteria-Sporosarcina pasteurii, producing Microbial Carbonate Precipitations (MCP), was taken into account with leakage and the healing process in a precipitation medium. Several self-healing mechanisms, assistances, applications, and challenges of every strategy are accentuated, compared with their impacts as a practicable solution of autogenously-healing mechanisms while active concretes are subjected to deterioration, corrosion, cracking, and degradation have also been reviewed systematically.

1. Introduction

Authenticity and commercial significance are the root cause for most far-reaching usage of concrete as a building material for constructions and infrastructures worldwide [1]. However, its deterioration through cracks development over a time period is one of the key factors resulting in mitigation of the structure’s quality. Development of cracks in between its service life happen in concrete structures irrespective of its type, mix design, etc., on account of exterior and interior factors viz., over-load, shrinkage, exposure to severe environmental conditions, design error, etc. [2,3]. That means, in field applications, factors responsible for cracks formations are either environmental or mechanical types. This challenge, essentially, necessitated to be addressed or else the openings in the form of cracks facilitates chemicals, waters, fluids, detrimental gases like CO2, etc., to penetrate declining its service life which may result in one day in eventual failure of structures for longevity. For this reason, the enhancement of the quality of structures of concrete becomes an issue of intense magnitude on an urgent basis. Nevertheless, the repair and maintenance cost of projects of old concrete construction is not merely fairly heavy but also time-consuming, along with uneasiness to reach the interior of cracks to mend [4]. Consequently, the concepts of developing a new-fangled construction material which can heal the smash up autogenously to make certain the extension of the service life of concrete structures were investigated by researchers in the past couple of years [4,5]. Fortunately, self-healing concrete is competent enough to repair cracks autogenously by means of hydration of cement, carbonation of hydration products when water is present with CO2 and leaking. This nature of concrete to heal cracks on its own is highly sought-after to operate their repairs and maintenance works effortlessly.

Quite a lot of engineering approaches have been endeavored to encourage autogenously healing of concrete. According to several researchers [6,7,8,9], there are two chief and noteworthy definitions of the self-healing mechanism to heal deterioration of structures of concrete: (1) Autogenously, i.e., the natural mode of hydrates to plug the cracks over a period of time sans any manual interference, and (2) Engineered repair and maintenance, i.e., the artificial means to close up the cracks, essentially, with human intervention. The later one is activated by non-natural healing agents or through deliberate techniques with the manual intervention [10,11]. A lot of researchers have endeavored to enhance concrete quality to gain healthier longevity, sustainability, along with strength and durability properties. These all will have colossal positive impacts on not merely the environments but also on economics. That is how the concept of self-healing finds its way to concrete. Not only does it have that, but the architectural designs might also get better by forcing novel design techniques, and that is why to alter the shape of interior spaces, thus, it extends scores of functions and contributes flexibility. Self-healing is a happening that occurs through a natural course [10]. The understanding of the progress of hydration of the non-hydrated cemented materials, sealing of cracks resulted by solid materials in the water, C-A-S-H swelling in the crack, along with crystallization of CaCO3 [12]. Additionally, concrete is an extraordinary building material having an aptitude to mend the cracks by itself naturally within a time frame required [2], analogous to the phenomenon of healing the wounds of the human body naturally without being influenced by any exterior factors [4], with the target to provide a longer lifespan to concrete structures. Neville [7] discovered that the petite cracks into the concrete could be plugged wholly under an environmental condition with moisture since the hydration of cement, in this case, will be delayed [7,8]. The crystals of CaCO3 are the key healing material inside the crack width, as explained by Edvardsen [9]. A variety of approaches to augment the competence of the self-healing attribute of a concrete structure to heal the cracks include the induction of bacteria, chemical admixtures, and micro-encapsulation [13,14,15,16]. Recently, the Engineered Cementitious Composite (ECC) has been regarded with the growth of various petite cracks as a unique building material which provides significant potential for self-curing competence [13]. At present, it is a significant topic to study the development of advanced methods of upgrading the capability of self-healing in context of ECC. The mechanic restoration and the rate of cure of the ECC with the wet dry cycle were brought to light by Yang et al. [17]. The self-healing mechanism of the ECC blended with a cemented mixture was revealed by Sisomphon et al. [18]. Hung et al. [19] accounted that the effect of the natural method of weathering with intrinsic narrow crack wideness is achievable in ECC self-healing. Qiu et al. [20] brought about a sophisticated technique of enhancing the self-healing competence of a cementitious composite incorporating blast furnace slag along with the condition of alkalinity. They summed up that when the permitted crack wideness was smaller than 50 mm, it attained the healing of cracks [17,18,19,20]. Moreover, cracks up to several hundred microns can be plugged entirely [21], accompanied with evident mechanical recovery [22] through Microbial Carbonate Precipitations (MCP)-based self-healing concrete. However, enclosing this porous or soft materials leads to reduction concerning strength of concrete [17,23]. Most recent investigations signaled that this mechanism is able to heal the cracks up to 150 mm wide, only relying on mixture chemistry [18]. The cracks with a width ranging from 50 to 150 mm exhibited the reduced property of self-healing; but when the wideness of crack was beyond 150 mm, the capability of self-healing was found to disappear on account of the appearance of grave smash up to the structure of the matrix. Micro-fibers were utilized to manage the width of a crack in the concrete [18] whereas extensive chemical agents were introduced into the concrete to permit the development of surfaces of crack and in consequence, diminishing the width of crack [24,25,26]. One more unique approach employed is through induction of the bacteria producing MCP into the concrete which can survive under the alkaline environment having a pH of 12 to13 for crack plugging [8,21,27,28]. The spores of bacteria can be activated in sought-after liquid environmental conditions and generate local alkalinity in its surrounding area. In this case, the wall of the cell is charged negatively, and it exerts a pull-on Ca+2 ions for the nucleation [29]. This particular type of chemical environment efficiently encourages the development of calcium carbonate precipitations. Jonkers et al. [27] studied it for the first time in the context of the feasibility of Bacillus spores of bacteria into the concrete for the self-healing objective. The outcomes demonstrated that practicability of spores dropped radically with escalating age of concrete since cement hydration is an incessant progression that trims down the size of pores in cement paste and also found to crush the spores. To address the referred predicament, numerous researchers recommended immobilization or encapsulation of bacterial spores in a shielding matrix before induced in the concrete mix. An assortment of porous or soft materials like polyurethane foam, SiranTM, porous glass beads, diatomaceous earth, porous expanded particles of clay, silica sol-gels, hydrogel, light-weight aggregates [23,30,31,32,33,34,35,36] have been employed for encapsulation of these micro species, protecting them from a harsh kind of concrete environment. Additionally, the preceding investigations developed innovative and high-performance fiber-reinforced composites through the process of geopolymerization, namely, geopolymer slag-based composites, characterized by higher ductility along with user and eco-friendliness and above all, the complete absence of Ordinary Portland Cement (OPC) [37,38,39]. Although natural and chemical self-healing mechanisms are widely recognized to develop a self-healing concrete, a biological process is still not completely understood and a promising emerging technology. Until date, numerous micro-organisms that are useful for the design of self-healing concrete can be isolated from nature. Bacteria offer various benefits, such as (1) the cultivation of bacteria is easy, (2) bacterial insulation is less complicated, and (3) several techniques of introducing bacteria to concrete have been described. Bacteria, on the other hand, are not sufficiently resistant to tough concrete conditions such as high pH, low water, high temperature, and so on. Therefore, it is highly vital to investigate different types of microbes, in particular fungus. Although there are few articles about the use of fungus to self-heal concrete designs, the mechanism of fungus for the replenishment of crises or an excellent fungal growth condition has not been fully studied.

2. Geopolymeric Materials

Nowadays, geopolymer technology is drawing the attention of researchers and construction engineers more and more owing to its nine-times less carbon footprint and six-times less energy consumption than OPC [40]. What is more, this green technology replaces the OPC completely as a binder. Geopolymers are a class of inorganic materials in the form of geopolymer paste, geopolymer mortar, geopolymer concretes, etc., for the construction and infrastructure industry produced through the process of geopolymerization—the alkaline activation of solid alumina-silicate precursors, either as industrial by-products or materials of geological origin at low temperature in alkaline medium [40,41]. Geopolymeric materials can bring the significant environmental and economic advantages owing to the opening for the incorporation of diverse profuse waste streams sans compromising durability, strength, and the sustainability attributes to an optimum level along with low carbon footprint [41,42,43,44,45,46,47,48,49,50,51,52,53]. The workability, mix design, mechanical characteristics, durability, and micro-structure, etc., of geopolymer composites have recently been studied by researchers [41,42,43,54,55,56,57,58,59]. The exhibition of some more attributes like freeze-thaw, thermal, resistance to chemicals, and corrosion, etc. [40], along with workability in the fresh state [58,60,61], altogether have established them as promising construction materials as a substitute of OPC-composites. Furthermore, on account of adequate mechanical attributes in hardened conditions [55,58,59,62], and brilliant performances in the context of durability [41,42,56,58], geopolymer composites have proved themselves as a possible emerging green replacement of ordinary Portland cement [63,64,65,66,67,68,69,70,71,72,73,74]. The process of geopolymerization includes the use of alkaline solutions to activate minerals of geological origin like metakaolin or industrial by-products such as fly ash that is desirably rich in alumina and silica, producing a three-dimensional (3D) polymeric structures which sustain load-mechanics. Several geopolymer composites display outstanding resistance to fire and thermal attributes [75,76] with immobilization of heavy metals [75] and peculiar freeze–thaw conditions [40]. As geopolymers do not possess non-hydrated cement or dissolved Ca+2 ions to be leaked out, MCP induced bacterial healing is a potential technique to employ self-healing geopolymer composites since there are no cement hydration or carbonation of hydrated yields as in the case of OPC—composites [65]. Quite recently, geopolymer composites have found an extensive range of applications in the infrastructure and construction industries [41,77]. Largest of its kind, application of geopolymer concrete for roughly about 40,000 m3 was successfully performed for an in situ concreting project work at the Brisbane West Wellcamp Airport, Australia [78]. The first structural application of on-site cast of slag-based geopolymer concrete for a corporate office building, in Chongqing, China, is the one of the best illustrations of utilization of this technology for the most important structural frame [79]. One more illustration is from Lipetsk, Russia whereby quite a lot of residential towers as high-rise buildings of more than 20 stories were built using blast furnace slag-based geopolymer concrete, where the stairways, floor slabs, and other structural sections were precast, and the external walls were cast in situ. Some major utilizations of this novel technology were also accounted in countries, like the USA, UK, the Netherlands, and South Africa, too [80,81,82,83,84]. Therefore, it seems that this innovative technology is capable enough of contributing to new-fangled with improved ductility, self-healing, user and eco-friendly building materials. Nevertheless, geopolymer hydration or reaction processes are more difficult than OPC ones. The raw material type, dose of the activator, and curing conditions all have an important effect on the reaction processes and on the micro-structure features of hardened products. No universal strength assessment or design criteria have yet been devised [85,86]. The variance in raw ingredients demonstrated significant variances in performance in geopolymer produced by various researchers. One of the main aspects that influences its practical application is, for example, the set time of the geopolymer. The time frame to mix, transport, and cast the concrete is determined. The setting period of slag geopolymer is, however, often considerably shorter than typical OPC cement [85,86]. Additionally, there are major problems with geopolymer materials, such as their high cost of manufacture, since the main types of activators used are of high financial cost.

3. Mechanism of Self-Healing Composites

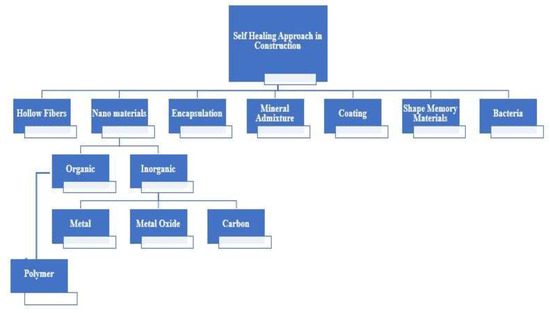

It is a universal fact that when a body of a human being is injured, the skins and tissues get recovered themselves on account of the assimilation of nutrients which creates new-fangled replacements to mend the damaged areas. Analogously, the same kind of self-healing characteristic is possible in the cements-composites when healing agents were incorporated in the mixture at the time of manufacturing the self-healing composites, which act similarly as the nutrients in the human body. These healing agents repair the cracks in the deteriorated concretes on their own. In the recent past, demanding studies were carried out to discover innovative strategies for well-organized self-healing almost without compromising its durability. Figure 1 and Table 1 exemplify approaches of self-healing for construction composites. This means self-healing is the property of a particular material which is competent enough to repair its deteriorations itself by its means to bring it back to the almost original state and those type of building materials are called, “self-healing composites”. The self-healing can be evidenced through many old concrete structures which are standing erect for prolonged periods with merely restricted maintenance. The chief phases of the natural healing capability are hydration of cement pastes and the inflammation; followed by the CaCO3 precipitation, and finally the obstacle of flow pathways on account of the impurities of the water deposition or the concrete movement in some case bits that get separated all through the course of cracking [10]. An extent of damage, temperature, freeze-thaw cycles, the age of the concrete, and the mortar form and many more are the factors influencing the natural pathway of self-healing [87,88,89]. The adhesives preserved either in short fiber or in longer tubes although, more effectual mechanisms were afterwards adopted by others.

Figure 1.

Approaches of self-healing for construction composites.

Table 1.

Self-healing approach in construction sector.

3.1. Key Approaches and Mechanism of Self-Healing

There exist diverse approaches to produce and improve properties of smart concrete while trimming down the cost of overall utilization of the material. Plenty of these approaches were offered to manufacture SHC, out of which, two of the key approaches are found competent, promising, easy to apply, and distinguished.

3.1.1. Hollowed Out Fibers

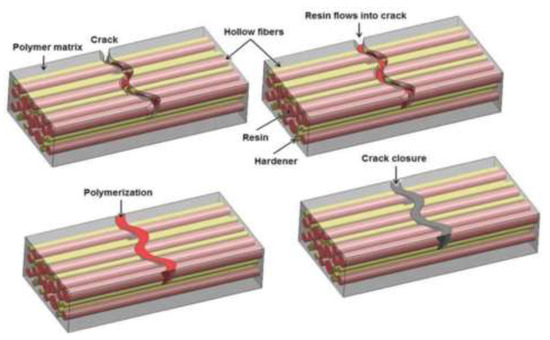

Analogously to arteries in a living system, the courses of self-healing utilize hollow fibers planted with the engineering composites of diverse lengths relying upon the smashed up concrete structures to be mended [90,91], e.g., the bulk polymers employed in polymer-based composites for objectives of self-healing [92,93,94,95]. Figure 2 depicts schematically the hollowed-out fibers making possible the courses of self-healing [101]. The hollow fibers store up a few useful components of materials which play a role as a healing agent within the vacant spaces which develop a composite network matrix [91,131]. On the damaging structure of the concrete, the cracks form under definite exterior pressure or stimuli; the healing agents flood out from the said hollow spaces to mend the cracks instantaneously. The above referred tubular structures or hollow fibers are deeply efficient to discharge the healing agents [132,133]. “Damage visual enhancement” is a technique suggested by Pang and Bond to recognize promptly and effortlessly the interior smashes in structures of the composite [95].

Figure 2.

Self-healing perception with hollow fibersF.

The concept includes functional healing elements packaged in delicate fibrous vessels scattered inside the concrete. The referred brittle fibers are broken on continuous smashes and operating materials are immediately discharged for self-healing purposes. The colorless liquid namely, Methyl Methacrylate (MMA), having a chemical formula, CH2 = C (CH3) COOCH3, is of organic origin and it is a methyl ester from methacrylic acid and a reactive resin entrenched inside hollow fibers of polypropylene and then encapsulated within the concrete [134]. It can discharge the MMA for self-healing function to happen and mitigate the porosity of concrete structures. A few investigations were carried out on crack release of the hollow glass pipettes holding cementitious glue within the concrete shortly following the flexure test. These structures with glue or adhesives have shown that the carrying capacity is approximately 20% higher than that without glue, after the flexural examination.

Copious researchers [135,136,137] have attempted to comprehend the buoyant process entailing the self-healing mechanism. In a cementitious network matrix, the hollow fibers were placed, with one end attached and the other end connected to the self-healing mediator to obtain a fundamental insight into the course of the self-healing process. Here, concrete mixtures were designed [138] and inside the samples, glass tubes were placed with external and inner diameters of 2 and 0.8 mm. Both diluted with 27% and non-diluted silicate of alkali mix and two components united epoxy resin with inferior viscosity were employed for self-healing element. Afterwards, the referred complex solution was loaded till the “Crack Mouth Opening Displacement (CMOD)” attained at 0.03 to 2.0 mm subsequent to the removal of the load. Subsequent to that, the said samples, which possess cracks, were again cured to test the enhancement competence concerning self-healing. Compared to standard samples having an absence of a healing agent which possessed the diluted and non-diluted solution of alkaline silica as the healing component, respectively, demonstrated an average ratio of the recovery of strength as 1.1 and 1.5.

On the contrary, samples with epoxy resin showed a little enhancement in the ratio of strength recovery that was much lower than the value monitored by direct amalgamating of resin and manual insertion into the cracked zones which were displaying roughly threefold improved recovery. The said observation was chiefly attributed to the not enough amalgamation and removal of two components that created the lower healing percentage due to the lower resin hardness. It could also be because of the remaining epoxy remaining inside the tubes on one end due to the sealing. Joseph [136] reported that the testing regime was identical except a few not worth mentioning differences. The plastic tubes, which are bent having respective exterior and the interior diameter of 4 and 3 mm, were utilized as the means of transport of healing mediator, i.e., Ethyl cyanoacrylate. They concluded that making available such healing constituent on the exterior could attain self-healing quite fruitfully. Subsequent to healing the damaged region, the solidity following a crack, the acme load, and the ductility were found improved remarkably. The findings of during and after examinations unearthed that, ethyl cyanoacrylate as an adhesive can infiltrate a larger region of the ruptured surfaces owing to the gravitational and capillary suction impacts.

3.1.2. Micro-Encapsulation

Over time, the artificial materials were produced from natural instances covering from the nano to macro scale for encapsulation. To elaborately understand, the illustration of a seed an egg of birds is the simplest, macroscopically magnitudinal, natural encapsulation, and cell existence within it is an example of the microscope [98,99,100]. The micro-encapsulation development started with the fusion of dyes capsules. The replacement and reproduction of the carbon paper was then done in the paper [13]. Over time, in various areas, several innovative techniques were developed. Micro-encapsulation is not considered to be the unrelated part or product, which is described rather as the increase of the size, separation, and defending of non-needed reactions in an external environment, including micrometer drops, solid granules, or gasses inside the inert shell [102,103]. The executions of micro-encapsulation with products of self-healing were instituted [103,104].

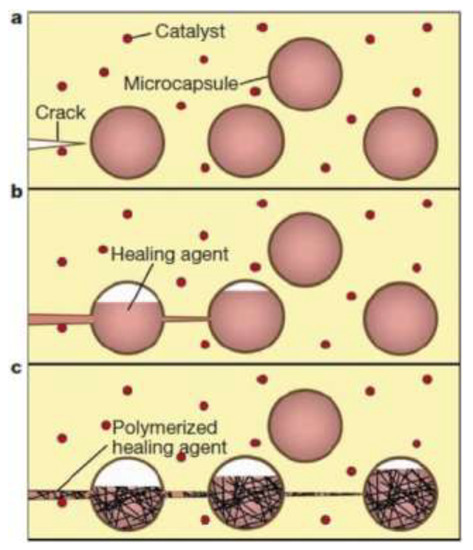

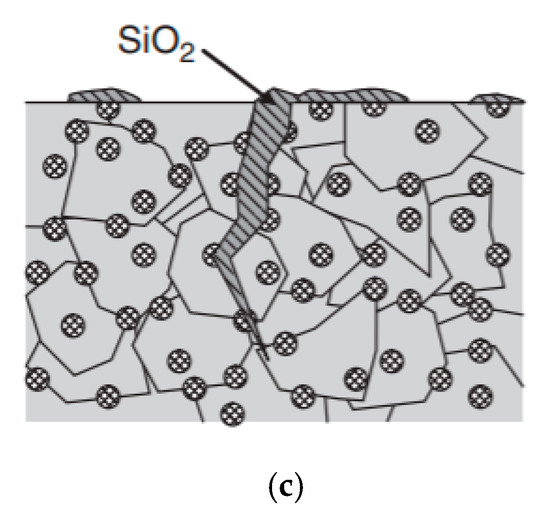

On the one hand, Figure 3 provides an idea for the self-healing [103], whereby the crack breaks the rooted micro-capsules, ensuing the healing agent discharge into crack surfaces using capillary action. Subsequently, the healing agent contacts the fixed catalyst, causing polymerization and therefore the neighboring cracks to plug. The filling of micro-capsules employing healing agent -epoxy resin, whereby the shell of urea–formaldehyde formalin with the size ranging from 20 to 70 μm has been blended by Nishiwaki [105]. The referred micro-capsules and acrylic-resin, which were used as a hardener in the shell form of gelatin with a size varying from 125 to 297 μm were utilized. Nevertheless, the micro-capsules induced with silicate of sodium were efficient for self-healing. During this research work, firstly, concrete was stacked to approximately the breaking point before the load was removed and then healed for 7 days. The upshots unearthed that the concrete having two percent silicate of sodium micro-encapsulation could recover maximum to 26% of its authentic strength in comparison with the reference specimen with merely 10% improvement. The conclusion was made that by escalating the quantity of healing agents, even though upper strength ratio of recovery could be obtained. Du et al. [91] examined the one component micro-capsules which were produced with paraffin as the shell and toluene diisocyanate (TDI) as the healing agent. The findings suggested that the TDI was encapsulated fruitfully in the shell of paraffin, and the mortars incorporating micro-capsules exhibited more encouraging capability of self-healing.

Figure 3.

The concept of autonomous cure micro-capsules. (a) crack breaks the rooted mi-cro-capsules (b) healing agent discharge into crack surfaces (c) causing polymerization and the neighboring cracks to plug.

3.1.3. Mineral Admixtures and Agents

The report regarding the formation of cementitious materials like calcium carbonate, Mono-Al2O3.Fe2O3 (AFm), and Tri-Al2O3.Fe2O3 (AFt) into the concrete which has been cracked along with air voids of Ca(OH)2 crystals has been put forward by Kishi et al. [92]. Such hydration products were intended to leak and crystallize again via fractures in the flowing water. Thus, Kishi et al. [106,139] estimated the performance in the context of self-healing concrete with dissimilar healing agents. In the study of geomaterials, expansive agents, chemical mixes along with their amalgamations were carried out [25,107,139]. The reference sample was compared with the sample possessing 10% of cement substituted by expansive agents consisted of C4A3S, CaO (lime), and CaSO4. It was made known that for the beams, possessing expansive agents might more or less heal initiate crack having a width of 0.22 mm advanced more than 30 days, where the rehydration product in between the cracks was recognized. Even so, these cracks of the conventional concrete structure were partly healed through the identical period.

Consequently, re-crystallization of expansive type agents into air voids of self-healing was additionally competent in comparison with usual concrete [106]. The expansive minerals enhanced the competence of self-healing of concrete mixtures as studied by Qureshi et al. [140]. Additionally, it was displayed that a geologically originated material incorporating SiO2 with 71.3% plus Al2O3 as 15.4%, while introduced to the expansive agent, might produce a geopolymer through the process of geopolymerization of silicate and aluminate complexes independently [25]. After then, dissolved at higher pH, owing to the presence of metals of the alkali group. A systematic study uncovered that the size of particles of geopolymer gel was smaller than 2 μm and ample AFt stages developed during the cracked interfacial phases of the original fractured zone or hydrogarnet. In this manner, expansive agent presence functions as a crucial factor to plug those cracks. Moreover, EDX spectra demonstrated that there is more alteration of the geopolymer gel than the hydrogarnet stage in the denser phase. Advanced investigations on chemical kind of additives [25] pointed towards the incorporation of NaHCO3, Li2CO3, and Na2CO3 to the normal concrete could improve by particles precipitation and cementitious re-crystallization into the concrete. In conclusion, it was accounted that employing appropriate quantities of expansive agents and carbonates, the self-healing properties of composites to heal the cracks on its own could significantly be enhanced.

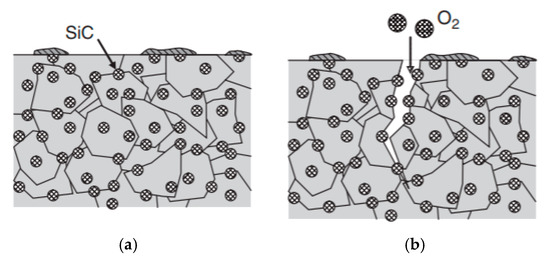

4. Bacterial Bio-Agents of Self-Healing

A novel bacterial or bio-concrete is competent enough to heal cracks autogenously through this natural process with no manual intervention. The core mechanism is obtained by preparing a concrete mix which encloses a precursor viz., calcium lactate having a chemical formula, Ca(C3H5O2)2 and bacterial species planted in micro-capsules or just supplemented to the mix which will germinate afterwards when the water comes into contact with the crack. When germination of bacteria takes place, they produce precipitation of CaCO3 with the help of a particular type of enzyme which seals the cracks of concrete up to certain width. Some of the bacterial species are spore-forming and resistant to alkali, which is the most suitable since they can survive for more than 200 years even in dry conditions [101]. The crack-healing mechanism is shown in Figure 4 [101].

Figure 4.

Crack-healing mechanism. (a) Before cracking; (b) During cracking; (c) After healing.

Consequently, employing particular species of bacteria having sustainable organic attributes with a high rate of survival as healing agents is one of the best mechanisms to manufacture this kind of self-healing bacterial or bio-concrete. Quite recently, the application of the bio-method for mending the cracks was also suggested by several researchers [128,130] through inducing particular species of bacteria within the concrete. Gollapudi et al. [141] carried out investigations in the mid-1990s and proposed for induction of an environment benevolent approach to healing cracks into concrete, whereby urease enzyme producing ureolytic bacteria was induced to pick up the pace for the calcium carbonate precipitation in the micro-cracks into the concrete. Additionally, the microbes have helped for calcium carbonate precipitation which was characterized employing several parameters like the pH of materials, dissolved inorganic carbon amounts, the concentration of calcium ions, and ease of access of sites of nucleation, i.e., localized zones of reaction. The cell walls of bacteria have performed as sites of nucleation and metabolism of bacteria managed some other factors [28]. Tittelboom et al. [28] employed bacterial species into concrete to produce urease enzyme which might catalyze urea [CO(NH2)2] into ions of ammonium (NH4+4) and carbonate (CO3−2). Looking to its chemistry, urea (one mol) has undergone intracellular hydrolyses to one mol of carbamic (Aminoformic) acid and one mol of ammonia (NH3) following Path I. Then, the carbamic (Aminoformic) acid, i.e., carbamate, formed thus was hydrolyzed spontaneously to give rise to carbonic acid (H2CO3) plus one extra mole of ammonia (NH3) as per path II. The said reaction yielded afterwards resulted in 1 mol of bicarbonate ion (HCO3−1) and one mole hydrogen ion in presence of water as per Path III which, in turn, immediately converts to 2 mol of ammonium ion (NH4+1) and two mole of hydroxide (OH−1) ions by reaction of ammonia with water following Path IV. Whereas Path V reaction takes place between bicarbonate ion plus hydrogen ion together with ions of ammonium and hydroxide, resulting in carbonate ion and ammonium ion accompanied with water. Here, Path IV and V are accountable for the augmentation of pH, drifting the equilibrium of bicarbonate (HCO3−1) to result in carbonate (CO3−2) ions.

Further, in Path VI, the bacterial cell could accept cations (Ca+2) in the form of deposition on the surface of walls of cells resulting in Cell-Ca+2 combination from neighboring on account of their negatively charged peculiar cell walls. Ultimately, during follow up of Path VII, the Ca+2 cations on the surface of cell wall i.e., Cell-Ca+2, could react with the negative carbonate (CO3−2) ions giving rise to the final product (Cell-CaCO3) in form of precipitations of calcium carbonate (CaCO3) on the surfaces of cell wall of bacterial species which is competent enough to offer the active nucleation site. The application of this type of approach of localized precipitation of calcium carbonate (CaCO3) through particular species of bacteria is competent to heal the cracked surfaces naturally without manual intervention.

The reactions from Path I to Path VII are represented below:

Path I:

CO(NH2) 2 + H2O (intracellular hydrolyses) → NH2COOH + NH3

Urea + Water (intracellular hydrolyses) → Carbamic (Aminoformic) acid + Ammonia

Path II:

NH2COOH + H2O (spontaneous hydrolyses) → H2CO3 + NH3

Carbamic (Aminoformic) acid + Water (spontaneous hydrolyses) → Carbonic acid + Ammonia

Path III:

H2CO3 + presence of H2O → HCO3−1 + H+1

Carbonic acid + presence of Water → Bicarbonate ion + Hydrogen ion

Path IV:

2NH3 + 2H2O → 2NH4 +1 + 2OH−1

Ammonia + Water → Ammonium ion + Hydroxide ion

Path V:

HCO3−1 + H+1 + 2NH4 +1 + 2OH−1 → CO3−2 + 2NH4 +1 + 2H2O

Bicarbonate + Hydrogen + ammonium + Hydroxide → Carbonate + ammonium + Water

Path VI:

Ca+2 + Cell → Cell-Ca+2

Path VII:

Cell-Ca+2 + CO3−2 → Cell-CaCO3

5. Shape Memory Polymers (SMPs) or Shape Memory Alloys (SMAs)

Several researchers [121,122,123,124] disclosed the efficacy of functional materials amalgamated into cementitious concrete for structures to obtain efficient self-healing property. The original idea behind is that while cracks are developed, then this kind of material could become lower in a controlled situation, with a short memory forms, thereby producing slimming down to optimally play a role as an agent to plug the cracks. These types of self-healing agents are known as Shape Memory Polymers (SMPs) or Shape Memory Alloys (SMAs). These novel smart materials (SMP) are capable enough to return to their original early state by altering back their shape upon employing a stimulus. This mechanism encloses both autonomic and the autogenic principles. It utilizes an artificial system to augment natural autogenic healing and plug the cracks into the concrete. This sort of polymers is semi-crystalline, having a predetermined shape memorized into their structure, which afterwards assists the polymers in returning to their original condition. While a crack develops, the system will be activated, that is why the shape memory polymer inside the crack gets triggered in the course of heating which can be in the form heating directly, or through an electrical current. Immediately after the activation, shrinkage or the shape memory impact occurs, and owing to the controlled nature of the tendon, a tensile force is produced, for this reason, the crack gets sealed on its own. Subsequently, the autogenous healing of cracks initiates to happen. The revocable phase modification in alloy composed of gold plus cadmium (Au-Cd), which is regarded as the earliest remark on the shape memory effect. Over time, many SMAs with wonderful thermo-electric and thermo-mechanical characteristics have been identified [104,108]. For illustration, Nitinol’s super elasticity with the shape memory effect refers to its preset forms when it is thermally treated. In the case study on super-elasticity, it suffers an exceptionally huge rigid deformation and recuperates the shape in next to no time, subsequent to unloading [126,127]. In order to achieve intelligent reinforced concrete (IRC), Song and Mo [126] employed SMA cables. While a SMA is in the shape of “martensite,” the metal can easily be distorted in any form at low temperatures. Nevertheless, the alloys are altered by thermal treatment from “martensite” to “austenite.” The memory metal “remembers” its initial form during the austenite stage, which it had before deformation. Table 2 indicates alloys with a memory effect of shape. The effects of post-tension in IRC were achieved using SMA’s conventional “martensite cables.” The electric resistance modification for the SMA cables was noted in order to transfer the strain distribution to the concrete. The cracks formation, if any, because of earthquakes or explosions or any other plate tectonic movements could be recognized, whereby electrical heat of the SMA cables can show contracture and decrease the cracks, macro-sized cracks can be handled by self-remediation. The structure of concrete was smart and intellectual enough to notice the self-healing justifying its nomenclature. Sakai et al. [123] investigated the self-recovery process within the beam by super-elastic cables made up of SMAs. Their results have shown that the mortar beam that has SMA cables is almost fully recoverable after a large crack was maintained. Analogously, Jefferson et al. [124] created Shape Memory Polymers (SMPs) to mix into cement-based products. While the crack occurs in the cement matrix due to shrinking initial age, thermal effects, and mechanical loading, heat treatment can stimulate the course of shrinkage in SMA tendons included. In turn, the cracks can be mitigated by forming quantifiable compressive stress across the surfaces of the sealed crack. Crack plugging by such a system can naturally improve the course of self-healing and durability of the structural components in the material. Finally, they summarized that post tensioned polymer tendons could work for crack screwing and poor prestressing with lined-up shrunk polymer tendons. The upshots from several screening examinations uncovered that poly-ethylene terephthalate (PET) shrinktite had a capacity of approximately 34 MPa, which could shrink at 90 ℃ and cool off successively in controlled circumstances at room temperature. Together with excess curing, the influence of heating could enhance mortar strength by approximately 25%.

Table 2.

Alloys with a memory effect of shape.

6. Self-Healing Coatings

The developments of technology in the context of materials during recent times have offered advanced functionalities directing to consider these materials as “intelligent material” which are recognized through looked-for response to a few exterior stimuli namely temperature, humidity, light, etc. The innovative types of materials for buildings to serve as coatings have been investigated and developed productively [108,109]. Among the referred materials, the coatings for self-healing concrete having definite durability attributes can be found. These self-healing coatings are utilized with reinforced concrete for self-healing steel bar and decrease the smashed up caused due to the corrosion. They are the latest method of research which can contribute to the battle against the deterioration of contemporary infrastructures. The traditional anti-corrosive coatings impact restrictedly on damaging even a petite segment of the coating [111]. Nevertheless, they can keep on functioning, owing to their capability to heal following a fracture [110]. The referred self-mending is expected to be capable of highly lengthening the life of structures with steel rebar. Early studies on utilization of steel rebar were carried out by Chen et al. [112]. There are so many past studies [113,114,115] to verify the mechanism for protection against minute crack formation of bridges, highways, and other constructions. However, no ultimate conclusion has been obtained in this regard, and hence, it became a key crisis. Cracks are effortless corridors for salt, water employed for de-icing, as well as air to penetrate the concrete. Throughout the winter term, in cold regions, the water freezes into the cracks and this frozen water get bigger in volume, accelerating the deterioration of concrete in the existence of road salt. The micro-container is often mixed into the coatings that can split easily when used. The containers kept the agents of healing and can differ from poly-urethane micro-capsules to micro-filament tubes, in addition often have a slight impact on the mechanical attributes of the coating which afterward plug the crack and extend the coating function. With a view to protect from corrosive agents like salts and water not to enter rebar, the extensive applications of epoxy coatings are found useful. In addition, it has examined the progress of polymer coatings that respond to the pH changes or to heat in order to begin fracture healing [116,117]. On the other hand, healing and encapsulation attributes of drying oils like linseed and tung oils have been significantly investigated [118,119,120]. When the tung oil comes in contact with air, it polymerizes into a glossy, hard waterproof coating. The referred properties have established drying oils worth mentioning constituent in paints, printing inks, and varnishes. Samadzadeh et al. [142] first received the encapsulation of tung oil. These urea-formaldehyde microcapsules have proved high-grade adherence to the epoxy matrix by testing the strength of pull-off micro-capsules in accordance with ASTM D4541-09, comparing with industry norms. Tests were conducted to measure life through immersion into a sodium chloride solution (NaCl). The results were promising as the micro-capsules of tung oil extended their life span to up to nine times as long as epoxy coatings after damage.

7. Engineered Cementitious Composite (ECC)

The distinctive class of composite called ultra-ductile fiber reinforced concrete was initially invented as Engineered Cemetery Composite (ECC) in 1990. [143] which was enhanced gradually and constantly for more the last than 20 years [96,143]. It possesses a higher ductility of 3 to 7%, relatively lower content of fiber of roughly about 2% or less by volume, and tight crack size of approximately 60 μm [144]. The factor analogous to metal is the important mechanical attribute of ECC. It is capable of sustaining elevated loads even subsequent to initial crack during auxiliary distortions. The property of self-healing is ineffectual for ordinary or strengthened fiber concrete or reinforced concrete because the tensile cracks in this material type are difficult to control. Until the tensile load reduces and the available chemical agents responsible for crack sealing and re-healing quickly could multiply local ruptures constantly into the crack width. Consequently, the wider tensile crack, which must be restricted to less than ten micro-scales, requires effective self-healing. Any other method of changing the mechanical characteristics of composites requires large glass-pipes. Some other reports emphasizing the role of the wideness of cracks have supported this argument [97,145,146]. The tightly regulated crack size as one of ECC’s inherent features can be of benefit in using ECC’s self-healing concept.

Afterwards, the feasibility of that idea was examined in two dissimilar experiments [147]. The idea of the first experiment was to determine sensor and control attributes of the ECC. The second experiment was carried out to calculate the flexural power of the ECC and to incorporate the glass fibers for plugging using ethyl cyanacrylic. Both studies were conducted under MTS load frames to ensure the re-healing effectiveness of the plugging mediator after a fracture of the load cycles has occurred. Actuation and sensing courses with FESEM pictures were validated and the revitalization effects confirmed by retrieval of flexural rigidity. Additionally, it was recognized that a number of other crises call for advanced study prior to its possible practical utilizations. Li et al. [133,148,149] also tested the phenomena of cementitious materials in the context of self-healing besides the introduction of the outer chemical in the form of healing glue into the concrete. The matrix of concrete and its contact with the neighboring were studied. The ECC samples were cracked prior to the experiment and subjected to a variety of environments like water penetration and submersion, attack of chloride ions, as well as cycles related to wetting and drying. The findings made known that the transportation and mechanical properties were chiefly recuperated, especially for preloaded ECC with a tensile strain of less than one percent. Other than the smaller cracks, the lower ratio of water: binder and the existence of the colossal amount of fly ash in the mix could assist the course of action of self-recovery by pozzolanic and hydration mechanisms. The ECC materials were developed in the vicinity from either wastes or by-products [150]. Several mixes were designed employing Limestone (LS) and Blast Furnace Slag (BFS) powders along with subsequent analysis through calculating the tensile strain to about 2% to 3% as well rigid cracks having a distinctive size of less than 60 μm. It turned out that [151] the mix design prepared by Zhou et al. [150] was unlike that from Li et al. [133] with regard to basic elements having higher proportion of LS and BFS in place of fly ash and elevated ratio of water:binder which varied from 0.45 to 0.60 against 0.23. The research showed that there was considerably less quantity of non-hydrated cement products healed after 28 days, which was quite less than the one employed by Li et al. [152]. It was disclosed that samples of ECC produced from huge amount of BFS, LS powder, and moderately higher water:binder ratio which could reinstate comparable attributes of self-mending than ECC-materials which have been analyzed by a higher proportion of fly ash and a lower ratio of water:binder. The reference observation was based on the presence of the narrow width of the crack. Accessibility of unhydrated cement and some additional yields together with BFS were determined for ECC self-healing. Consequently, A reduced water to cement ratio and a greater portion of cementitious samples were useful in promoting self-recovery. In terms of continuous hydration, the significance of crack size has been emphasized as it uses very tiny quantities of healing material for sealing the cracks. Moreover, the healing samples had no trouble growing from either side of a mixture of the cracks. The behavior of microcracking and the possibility of cracking ECC, where micro-encapsulated modules exist, has generally been monitored, thereby enhancing the discharge of healing material. Micro-encapsulation thus ensures the effectiveness of actuation and sensing courses. The small size of the crack within the ECC is highly noteworthy because it demands lower amounts of healing performance to seal the cracks and is capable of healing from both façades. Precisely speaking, ECC includes more cementitious components and less water:binding ratio, therefore, is more effective than traditional cements.

8. Smart Functions of Geopolymer Materials

8.1. Self-Healing Property

Self-healing property is related to those materials which are capable enough to repair or mend themselves subsequent to damage, thereby convalescing functionality [153]. The primary potential advantages of materials having self-healing property lend a hand to minimize the cost of maintenance, enhancing the efficiency of the materials and lengthening the service span of structures. They are further categorized as autogenous self-healing and autonomous self-healing materials.

8.1.1. Autogenous Self-Healing

As referred earlier, autogenously self-healing is the natural capability of materials to mend sans exterior supervising or man-made involvement [153]. Some mechanisms are responsible for the auto-healing nature, which mainly examines a widespread hydration of non-hydrated compounds [9]. An irrigation pipeline with a geopolymer concrete based on a slag achieved an initial strength of 25 MPa and then was used for almost 30 years with a long-term strength of over 80 MPa [154]. For that reason, a few researchers argued that these kinds of geopolymeric building materials could heal themselves [155,156,157,158]. Ali et al. [159] studied the healing attribute of beams of geopolymer mortar following the cracking. They loaded the samples to a mouth opening of crack with 0.3 mm width, at the periods of 3, 10, 24, as well as 52 days. The same was subsequently heated for 4 days at 90 °C, and then again loaded to failure. The upshots of the test demonstrated that an augment in strength is found ranging from 42%–166%, relying on the curing age of samples. They made it known that the mechanism of self-healing was assigned to the constant kinetics of geopolymerization. Additionally, the examination unearthed that the durability was increased to a great extent on account of the crack plugging extended from the self-healing nature. Analogous outcomes were also monitored by Liu et al. [150] when self-healing geopolymer hybrid system studies were carried out. In this situation, geopolymer proved its extraordinary self-healing capability, with the material able to withstand increased stress after preloading, while in the Portland cement-based scheme, such action was absent. What is more to add, a micro-structural examination exhibited that the healing composites of geopolymeric origin were structured by the denser phase in comparison with those based on Portland cement, resulting in a healthier self-healing capability into cracks [13]. Of late, Nguyn et al. [160] tested the healing attributes of Slag based geopolymer reinforced concrete incorporating with polyethylene fibers. It has come to notice that manifold cracks with tight crack wideness have developed under tensile loading. Consequently, controlled crack width characteristics facilitated precipitation in products which promoted the healing function of self-healing products. Extensive additives viz., particles, polymers, and hollow fibers show the potential to enhance the self-healing course. Musil et al. [161] researched the effect of adding chamotte particles to the features of geopolymer. Flexural resistance was calculated prior and subsequent to heating, the samples beyond the required temperature for the crystallization of leucite. It was monitored that the composite showed a striking boost in the damage to failure following heating. As a self-healing agent in geopolymer, Kusbiantoro et al. [162] investigated polyethylene vinyl acetate (PVA) by submitting to diverse curing temperatures. PVA 1 percent of fly ash by weight was added to fly ash-based geopolymer concrete and was exposed to heat treatment for 24 h, with a temperature of 60, 70, and 90 °C. The findings unveiled that the supplement of PVA by keeping the temperature of activation at 90 °C could seal the gaps, contributing an improved compressive strength and diminished void content. However, both PVA as well as chamotte possess the probability to be supplemented with formulate self-healing, but still advanced self-healing tests are essential to establish their self-healing behavior. In these modern days, bacteria-based self-healing has attracted researchers more. Andalib et al. [163] accounted that improving the strength and durability of composites could increase the application of bacterial species. In concrete cracks, which form the micro-biological induction in the form of calcification and geopolymerization processes, the material of fillers from the organic origin has been assigned. Presently, Jadhav et al. [164] tested the nature of the crack cures in the geopolymer induced by bacteria, which directly caused bacterial spores without immobilization or encapsulation. Finally, it concluded that geopolymers are able to accommodate bacterial spores and promote the reactivation of spores into feasible cells because of the unwavering geopolymer microstructure. Whereas in the case of the cement paste, other investigations have exhibited that the number of feasible cells of bacteria mitigated significantly on account of the severe decline in the context of the size of the pore with the escalating age [27].

8.1.2. Autonomous Self-Healing

Autonomous self-healing is acknowledged through the incorporation into the host material of self-healing units made up of container and healing agent [153]. Numerous approaches, such as vascular, electro-deposition, micro-capsule, induction energy, and implanting shape memory alloys, have been suggested. One study was conducted on whereby the encapsulation strategy was examined to attain autonomous self-healing. The methodology used has considered the utilized material for capsules as very imperative. It should be strong to survive during the mixing course, and at the same time, it should be brittle enough to crack. Additionally, De Koster et al. [165] studied the geopolymer’s potential as a coating agent bacteria that has granules. Geopolymers with diverse mixes were employed for coating the healing agent particles. Firstly, strength and leaching examinations of the coated particles were made. What is more, particles, which were coated and incorporated with cement paste to establish the viability of utilization of them into the concrete. The outcomes of the tests contributed a hypothetical base for the application of it as a coating agent in favor of the technology of encapsulation in self-healing materials.

9. Self-Healing Geopolymer Concrete

Sustainability of Smart Concrete

Geopolymer composites are known for their low carbon footprint and energy saving. They can be blended together with smart material to make them self-healing geopolymer composites by the use of self-healing technology to improve energy competence and sustainability of structures. The key objective of sustainable development is to preserve world prosperity with full assistance or care in the future so that the ecological balance should not be interrupted [166,167]. The economic security, societal gains, and protection of environments are the three fundamental elements of sustainability. Hence, sustainable progression must safeguard the referred factors to defend the bio-diversity with balanced eco-system. The current era is of industrial revolution in which scientists, policymakers, architects, and engineers are endeavoring to employ the sustainable model ingeniously to mitigate the pessimistic impact on the eco-system. Consequently, in the viewpoint of construction materials, the term “sustainability” is utilized interchangeably within a robust or welcoming and eco-friendly environment [168,169]. Precisely, self-healing materials have drawn escalating attention, owing to their potentially promising and to control the degradation, lengthen the operational service period, and suppress the costs of repairing of materials [27,170]. Nevertheless, the technology of self-healing provides directly to protect the environments and mitigation of the pollution by means of augmenting service life of a concrete and bring a drop in the demand and consumption of OPC and impacting to save energy and enhance the concrete sustainability.

10. Life Cycle Analysis of Self-Healing Concrete

The self-healing attribute has been investigated most during the past decade and has also been introduced as a modern method for auto-repair of cracks of concrete. Numerous groundbreaking strategies for self-healing characteristics of cementitious materials have been suggested and subsequently established by researchers. Presently, ISO 14040–14044 has been standardized for the Life Cycle Assessment (LCA) method. It was therefore used to estimate environmental impacts on all kinds of products and services. The LCA target is to quantify the decrease in the environmental impact by using the proposed self-healing concrete in place of a more standard concrete. A few straight advantages of self-healing property of concrete are the mitigation of in the deterioration rate, a fall in repairing incidences, expansion of service life, and costing over the concrete structure’s life cycle. The referred direct gains may be anticipated to show the way to improved sustainability of environments because smaller number of repairs entail a lower rate of material resource use and mitigation in ingesting of energy and discharge contaminant in transport and production of material along with linked traffic changes in transportation structure during the course of repair and/or renovation incidents [171]. Van Belleghem et al. [172] accounted that the self-healing process of cracks by means of polyurethane precursor encapsulation is found with partly obstruction in opposition to instantaneous doorway for chlorides via the cracks. The utilization of self-healing concrete resulted in a 75% or higher reduction in the chloride content in a cracked area. The service life span of self-healing concrete in marine types of environmental conditions could sum up to 60 to 94 years in comparison with merely seven years for cracked conventional concrete. Nevertheless, the statistics of Life Cycle Assessment (LCA) pointed out significant advantages for environments like 56 to 75% and principally induced by the attainable additional room to service life of the structures.

11. Summary and Conclusions

The review suggests that the self-healing attribute looks to be much more competent than the conventional concrete with benefits like sustainability, saving of energy, and benevolent to environments. Indubitably, it can reshape how engineers think and design in addition to being more sustainable and a smarter development in the construction and infrastructure industries. Looking to the application of diverse approaches to manufacturing SHC, the most promising approach found during the review is the bacteria-based bio-concrete on account of its simple mechanism as compared to other ways of self-healings. However, nanomaterials like diverse nanoparticles, carbon nanofibers, and nanotubes-based self-healing concrete are also drawing the attention of researchers on account of lower pollution, eco-friendliness, excellent durability performance during severe environmental conditions, and of course due to cost-effectiveness. The design of nanomaterials incorporated self-healing concrete through heightened performances and valuable for a number of applications is a new-fangled opportunity in nanotechnology and nanoscience. The review of these materials is supposed to extend the taxonomy to navigate and highlight the progress of research towards nanomaterials blended self-healing concrete. On the other hand, pricing is now one of the main drawbacks for large scale applications. Compared with conventional concrete, it is pricey. Perhaps in the future, the costs of self-healing concrete are going to decrease. It is rather rare now. Not many entrepreneurs know how to use the product. Many engineers have no notion of what to utilize as it is a new product. No code to standardize the self-healing concrete is available.

The innovative technology of geopolymers offers an eye-catching grouping of good-quality mechanical strength, up to the standard durability recital, and low carbon footprint. The multifunctional geopolymer composites are intelligent systems which not merely own basic structural function but also have some other kinds of functional attributes or have the capability to react on exterior stimuli. As regard to smart and mechanical as well as electrical functions concerned with these materials, the attention to their principles, concepts, and existing progress is considered significantly through grouping functional components or tailoring the composition of source materials. Even though numerous kinds of multifunctional geopolymer composites have been developed recently, sufficient data on the characteristics and mechanism of them are not accessible fully. Consequently, more endeavors for experimental and theoretical research are still essential for further development of them for their properties, design, and engineering application and of course, fabrications. The review thrown light on the self-healing characteristics of OPC-based and slag-based fiber reinforced geopolymer composites with higher ductility and controlled wideness of crack. Though, it is a fact that the slag-based geopolymer composites exhibited inferior compressive strength than the OPC-composite, keeping a constant ratio of water:binder, however, the slag-based composite displayed elevated tensile strength and just double tensile strain capability than the OPC-composite. What is more to add, the slag-based composite demonstrated elevated average wideness of crack and amount of cracks than the OPC-composite. Nevertheless, petite width of the crack is found associated with higher self-healing potential in comparison with huge width crack for both types of, i.e., cement and slag-based composites. The threshold width of crack for absolute healing of the slag-based composite was analogous to the cement-composite. Only one of its kind of properties of self-healing geopolymer composites viz., autogenously healing the deterioration, high ductility, user and eco-benevolent nature, etc.; slag-based fiber-reinforced and some other materials incorporating geopolymer composites are promising, innovative, and smart construction materials for the future. Additionally, it seems feasible to induce bacteria in metakaolin-based geopolymer composites for crack healing autogenously because results reviewed displayed that spores of bacteria have not leaked out from the geopolymer matrix and remained inside the matrix. The cracks of the aged geopolymer composite incorporating bacteria were plugged with CaCO3 following conditioning in precipitation medium, suggesting that bacteria stay workable even at a later age. The micro-structure of metakaolin-based geopolymer is controlled by molar ratios of Si:Al, Na:Al, and H2O:Na2O and lesser dependency is shown with respect to age, which permits direct induction of bacteria into thr geopolymer mixture with no immobilization or encapsulation to engage MCP-induced self-healing in geopolymers.

Conclusions are-Some mechanisms are responsible for the auto-healing nature, which mainly examine a widespread hydration of non-hydrated compounds.

SMA physically seal the fissures. However, the hydration of unreacted cemented reagents, polymer reactions or bacterial induced carbonation is also necessary for any true chemical auto-healing.

It is examined that the use of micro-capsules with a greater healing property on the concrete and the micro cracks are totally filled after 56 days of healing time in the concrete.

Toluenedi-Isocyanate is encapsulated fruitfully in the shell of paraffin, and the mortars incorporating micro-capsules exhibited more encouraging capability of self-healing.

The expansive minerals enhanced the competence of self-healing of concrete mixtures.

SMP utilizes an artificial system to augment natural autogenic healing and plug the cracks into the concrete.

Author Contributions

Conceptualization, S.L. and I.L.; methodology, S.L.; validation, F.U.A.S., S.L. and I.L.; formal analysis, I.L.; investigation, S.L., F.U.A.S., I.L.; resources, F.U.A.S.; writing—original draft preparation, S.L., I.L.; writing—review and editing, F.U.A.S.; visualization, I.L.; supervision, F.U.A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Crow, J.M. The concrete conundrum. Chem. World 2008, 5, 62–66. [Google Scholar]

- Zwaag, S. Self-Healing Materials: An Alternative Approach to 20 Centuries of Materials Science. Chem. Int. Newsmag. IUPAC 2008, 30. [Google Scholar] [CrossRef] [Green Version]

- Luhar, S.; Cheng, T.-W.; Nicolaides, D.; Luhar, I.; Panias, D.; Sakkas, K. Valorisation of glass waste for development of Geopolymer composites–Mechanical properties and rheological characteristics: A review. Constr. Build. Mater. 2019, 220, 547–564. [Google Scholar] [CrossRef]

- de Rooij, M.; Tittelboom, K.V.; Belie, N.D.; Schlangen, E. Self-Healing Phenomena in Cement-Based Materials, RILEM State-of-the-Art Reports; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Luhar, S.; Chaudhary, S.; Luhar, I. Development of rubberized geopolymer concrete: Strength and durability studies. Constr. Build. Mater. 2019, 204, 740–753. [Google Scholar] [CrossRef]

- Sinha, A.; Wang, Q.; Wei, J. Feasibility and Compatibility of a Biomass Capsule System in Self-Healing Concrete. Materials 2021, 14, 958. [Google Scholar] [CrossRef] [PubMed]

- Hearn, N. Self-sealing, autogenous healing and continued hydration: What is the difference? Mater. Struct. 1998, 31, 563–567. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman: London, UK, 1995; Volume 4. [Google Scholar]

- Edvardsen, C. Water Permeability and Autogenous Healing of Cracks in Concrete. ACI Mater. J. 1999, 96, 96. [Google Scholar] [CrossRef]

- Luhar, S.; Gourav, S. A review paper on self healing concrete. J. Civ. Eng. Res. 2015, 5, 53–58. [Google Scholar]

- Roig-Flores, M.; Pirritano, F.; Serna, P.; Ferrara, L. Effect of crystalline admixtures on the self-healing capability of early-age concrete studied by means of permeability and crack closing tests. Constr. Build. Mater. 2016, 114, 447–457. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Moscato, S.; Serna, P.; Ferrara, L. Self-healing capability of concrete with crystalline admixtures in different environments. Constr. Build. Mater. 2015, 86, 1–11. [Google Scholar] [CrossRef]

- Wu, M.; Johannesson, B.; Geiker, M. A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Erşan, Y. Çağatay; Hernandez-Sanabria, E.; Boon, N.; de Belie, N. Enhanced crack closure performance of microbial mortar through nitrate reduction. Cem. Concr. Compos. 2016, 70, 159–170. [Google Scholar] [CrossRef]

- Lv, L.; Yang, Z.; Chen, G.; Zhu, G.; Han, N.; Schlangen, E.; Xing, F. Synthesis and characterization of a new polymeric microcapsule and feasibility investigation in self-healing cementitious materials. Constr. Build. Mater. 2016, 105, 487–495. [Google Scholar] [CrossRef]

- Jaroenratanapirom, D.; Sahamitmongkol, R. Self-crack closing ability of mortar with different additives. J. Met. Mater. Miner. 2011, 21, 9–17. [Google Scholar]

- Yang, Y.; Lepech, M.D.; Yang, E.-H.; Li, V.C. Autogenous healing of engineered cementitious composites under wet–dry cycles. Cem. Concr. Res. 2009, 39, 382–390. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E. Effect of exposure conditions on self healing behavior of strain hardening cementitious composites incorporating various cementitious materials. Constr. Build. Mater. 2013, 42, 217–224. [Google Scholar] [CrossRef]

- Hung, C.-C.; Su, Y.-F.; Hung, H.-H. Impact of natural weathering on medium-term self-healing performance of fiber reinforced cementitious composites with intrinsic crack-width control capability. Cem. Concr. Compos. 2017, 80, 200–209. [Google Scholar] [CrossRef]

- Qiu, J.; Tan, H.S.; Yang, E.-H. Coupled effects of crack width, slag content, and conditioning alkalinity on autogenous healing of engineered cementitious composites. Cem. Concr. Compos. 2016, 73, 203–212. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Xu, J.; Yao, W. Multiscale mechanical quantification of self-healing concrete incorporating non-ureolytic bacteria-based healing agent. Cem. Concr. Res. 2014, 64, 1–10. [Google Scholar] [CrossRef]

- Wang, J.; Soens, H.; Verstraete, W.; De Belie, N. Self-healing concrete by use of microencapsulated bacterial spores. Cem. Concr. Res. 2014, 56, 139–152. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E. Self-healing of surface cracks in mortars with expansive additive and crystalline additive. Cem. Concr. Compos. 2012, 34, 566–574. [Google Scholar] [CrossRef]

- Ahn, T.-H.; Kishi, T. Crack Self-healing Behavior of Cementitious Composites Incorporating Various Mineral Admixtures. J. Adv. Concr. Technol. 2010, 8, 171–186. [Google Scholar] [CrossRef] [Green Version]

- Sherir, M.A.; Hossain, K.M.; Lachemi, M. Self-healing and expansion characteristics of cementitious composites with high volume fly ash and MgO-type expansive agent. Constr. Build. Mater. 2016, 127, 80–92. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N.; De Muynck, W.; Verstraete, W. Use of bacteria to repair cracks in concrete. Cem. Concr. Res. 2010, 40, 157–166. [Google Scholar] [CrossRef]

- De Muynck, W.; De Belie, N.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- Tziviloglou, E.; Wiktor, V.; Jonkers, H.; Schlangen, E. Bacteria-based self-healing concrete to increase liquid tightness of cracks. Constr. Build. Mater. 2016, 122, 118–125. [Google Scholar] [CrossRef]

- Bang, S.S.; Lippert, J.J.; Yerra, U.; Mulukutla, S.; Ramakrishnan, V. Microbial calcite, a bio-based smart nanomaterial in concrete remediation. Int. J. Smart Nano Mater. 2010, 1, 28–39. [Google Scholar] [CrossRef]

- Wang, J.; Van Tittelboom, K.; De Belie, N.; Verstraete, W. Use of silica gel or polyurethane immobilized bacteria for self-healing concrete. Constr. Build. Mater. 2012, 26, 532–540. [Google Scholar] [CrossRef]

- Bang, S.S.; Galinat, J.K.; Ramakrishnan, V. Calcite precipitation induced by polyurethane-immobilized Bacillus pasteurii. Enzym. Microb. Technol. 2001, 28, 404–409. [Google Scholar] [CrossRef]

- Wang, J.Y.; De Belie, N.; Verstraete, W. Diatomaceous earth as a protective vehicle for bacteria applied for self-healing concrete. J. Ind. Microbiol. Biotechnol. 2012, 39, 567–577. [Google Scholar] [CrossRef]

- Soltmann, U.; Raff, J.; Selenska-Pobell, S.; Matys, S.; Pompe, W.; Böttcher, H. Biosorp-tion of heavy metals by sol-gel immobilized Bacillus sphaericus cells, spores and S-layers. J. Sol-Gel Sci. Technol. 2003, 26, 1209–1212. [Google Scholar] [CrossRef]

- Wang, J.; Snoeck, D.; Van Vlierberghe, S.; Verstraete, W.; De Belie, N. Application of hydrogel encapsulated carbonate precipitating bacteria for approaching a realistic self-healing in concrete. Constr. Build. Mater. 2014, 68, 110–119. [Google Scholar] [CrossRef]

- Lee, B.Y.; Cho, C.-G.; Lim, H.-J.; Song, J.-K.; Yang, K.-H.; Li, V.C. Strain hardening fiber reinforced alkali-activated mortar–A feasibility study. Constr. Build. Mater. 2012, 37, 15–20. [Google Scholar] [CrossRef]

- Choi, J.-I.; Lee, B.Y.; Ranade, R.; Li, V.C.; Lee, Y. Ultra-high-ductile behavior of a polyethylene fiber-reinforced alkali-activated slag-based composite. Cem. Concr. Compos. 2016, 70, 153–158. [Google Scholar] [CrossRef]

- Lee, Y.; Choi, J.-I.; Kim, H.-K.; Lee, B.Y. Effects of a defoamer on the compressive strength and tensile behavior of alkali-activated slag-based cementless composite reinforced by polyethylene fiber. Compos. Struct. 2017, 172, 166–172. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications; Geopolymer Institute: Saint-Quentin, France, 2008. [Google Scholar]

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Bernal, S.A.; Provis, J.L. Durability of Alkali-Activated Materials: Progress and Perspectives. J. Am. Ceram. Soc. 2014, 97, 997–1008. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.J. Geopolymers-Structures, Processing, Properties and Industrial Applications; Woodhead Publishing: Cambridge, UK, 2009. [Google Scholar]

- Luhar, I.; Luhar, S.; Abdullah, M.M.A.B.; Nabiałek, M.; Sandu, A.V.; Szmidla, J.; Jurczyńska, A.; Razak, R.A.; Aziz, I.H.A.; Jamil, N.H.; et al. Assessment of the Suitability of Ceramic Waste in Geopolymer Composites: An Appraisal. Materials 2021, 14, 3279. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Gupta, R. Durability performance evaluation of green geopolymer concrete. Eur. J. Environ. Civ. Eng. 2020, 1–49. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Nicolaides, D.; Gupta, R. Durability Performance Evaluation of Rubberized Geopolymer Concrete. Sustainability 2021, 13, 5969. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Luhar, S.; Arel, H.Ş.; Luhar, I. Performance evaluation of Ultrahigh performance fibre reinforced concrete–A review. Constr. Build. Mater. 2020, 232, 117152. [Google Scholar] [CrossRef]

- Luhar, S.; Suntharalingam, T.; Navaratnam, S.; Luhar, I.; Thamboo, J.; Poologanathan, K.; Gatheeshgar, P. Sustainable and Renewable Bio-Based Natural Fibres and Its Application for 3D Printed Concrete: A Review. Sustainability 2020, 12, 10485. [Google Scholar] [CrossRef]

- Luhar, S.; Chaudhary, S.; Luhar, I. Thermal resistance of fly ash based rubberized geopolymer concrete. J. Build. Eng. 2018, 19, 420–428. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Nicolaides, D.; Panias, D.; Sakkas, K. The Valorisation of Glass Wastes for the Development of Geopolymer Composites–Durability Properties: A Review. Constr. Build. Mater. 2019, 222, 676–687. [Google Scholar] [CrossRef]

- Luhar, S.; Dave, U.V.; Chaudhary, S.; Khandelwal, U. A brief review on geopolymer concrete. In Proceedings of the 5th Nirma University International Conference on Engineering, Ahmedabad, India, 26–28 November 2015. [Google Scholar]

- Luhar, S.; Chaudhary, P.; Luhar, I. Influence of steel crystal powder on performance of aggregate concrete. IOP Conf. Ser. Mater. Sci. Eng. 2018, 431, 102003. [Google Scholar] [CrossRef]

- Luhar, S.; Nicolaides, D.; Luhar, I. Fire Resistance Behaviour of Geopolymer Concrete: An Overview. Buildings 2021, 11, 82. [Google Scholar] [CrossRef]

- Provis, J.L. Geopolymers and other alkali activated materials: Why, how, and what? Mater. Struct. 2014, 47, 11–25. [Google Scholar] [CrossRef]

- Part, W.; Ramli, M.; Cheah, C. An Overview on the Influence of Various Factors on the Properties of Geopolymer Concrete Derived from Industrial Byproducts. Handb. Low Carbon Concr. 2017, 263–334. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, C.; Zhang, Z.; Ou, Z. Durability of alkali-activated materials in aggressive environments: A review on recent studies. Constr. Build. Mater. 2017, 152, 598–613. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S. Geopolymer concrete: A review of some recent developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Provis, J.L.; Palomo, A.; Shi, C. Advances in understanding alkali-activated materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Shi, C.; Krivenko, P.V.; Roy, D. Alkali-Activated Cements and Concretes; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Alonso, M.; Gismera, S.; Blanco-Varela, M.T.; Lanzón, M.; Puertas, F. Alkali-activated mortars: Workability and rheological behaviour. Constr. Build. Mater. 2017, 145, 576–587. [Google Scholar] [CrossRef]

- Jang, J.; Lee, N.; Lee, H. Fresh and hardened properties of alkali-activated fly ash/slag pastes with superplasticizers. Constr. Build. Mater. 2014, 50, 169–176. [Google Scholar] [CrossRef]

- Ding, Y.; Dai, J.-G.; Shi, C.-J. Mechanical properties of alkali-activated concrete: A state-of-the-art review. Constr. Build. Mater. 2016, 127, 68–79. [Google Scholar] [CrossRef] [Green Version]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E.-H. Micromechanics-based investigation of a sustainable ambient temperature cured one-part strain hardening geopolymer composite. Constr. Build. Mater. 2017, 131, 552–563. [Google Scholar] [CrossRef]

- Lahoti, M.; Narang, P.; Tan, K.H.; Yang, E.-H. Mix design factors and strength prediction of metakaolin-based geopolymer. Ceram. Int. 2017, 43, 11433–11441. [Google Scholar] [CrossRef]

- Duxson PS, W.M.; Mallicoat, S.W.; Lukey, G.C.; Kriven, W.M.; van Deventer, J.S. The effect of alkali and Si/Al ratio on the development of mechanical properties of me-takaolin-based geopolymers. Colloids Surf. A: Physicochem. Eng. Asp. 2007, 292, 8–20. [Google Scholar] [CrossRef]

- Assi, L.; Ghahari, S.; Deaver, E. (Eddie); Leaphart, D.; Ziehl, P. Improvement of the early and final compressive strength of fly ash-based geopolymer concrete at ambient conditions. Constr. Build. Mater. 2016, 123, 806–813. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S. Geopolymer tech-nology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Singh, R.J.; Raut, A.; Murmu, A.L.; Jameel, M. Influence of Glass Powder Incorporated Foamed Geopolymer Blocks on Thermal and Energy Analysis of Building Envelope. J. Build. Eng. 2021, 43, 102520. [Google Scholar] [CrossRef]

- Tchadjié, L.N.; Ekolu, S.O.; Quainoo, H.; Tematio, P. Incorporation of Activated Bauxite to Enhance Engineering Properties and Microstructure of Volcanic Ash Geopolymer Mortar Composites. J. Build. Eng. 2021, 41, 102384. [Google Scholar] [CrossRef]

- Dos Santos GZ, B.; de Oliveira, D.P.; de Almeida Melo Filho, J.; da Silva, N.M. Sustainable geopolymer composite reinforced with sisal fiber: Durability to wetting and drying cycles. J. Build. Eng. 2021, 43, 102568. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Marvila, M.T.; de Oliveira, L.B.; Ferreira, W.M.; Colorado, H.; Teixeira, S.R.; Vieira, C.M.F. Circular economy and durability in geopolymers ceramics pieces obtained from glass polishing waste. Int. J. Appl. Ceram. Technol. 2021. [Google Scholar] [CrossRef]

- Azevedo, A.; Vieira, C.; Ferreira, W.; Faria, K.; Pedroti, L.; Mendes, B. Potential use of ceramic waste as precursor in the geopolymerization reaction for the production of ceramic roof tiles. J. Build. Eng. 2020, 29, 101156. [Google Scholar] [CrossRef]