1. Introduction

Roads, railways, airports, water systems, and electricity networks are typically provided by a nation’s government. This public infrastructure is at the base of all economic activities. However, governments have a tendency to prioritize building new infrastructure, although the neglect of maintenance can lead to deterioration, serious problems, and even disasters [

1]. The media have reported on many serious disasters caused by the neglect of infrastructure maintenance. The collapse of the Morandi bridge in 2018 killed 43 people and left 600 homeless. In 1967 La Stampa newspaper claimed that “the bridge’s concrete structure will not need any maintenance”. The lasting neglect of maintenance is considered the root cause of the tragedy. Inadequate maintenance eventually felled the bridge.

Traditional contracting is often used for infrastructure maintenance: the client organisation sets the specifications and selects the contractor with the lowest price, based on competitive tendering. In a traditional maintenance contract, the contractor is paid per repair or replacement, which constitutes a perverse incentive where the contractor benefits from less reliable systems [

2]. In the last decade, a trend towards performance-based contracting (PBC) can also be observed in infrastructure maintenance. PBC can be conceptualised along three dimensions: performance, incentives and risk [

3]. The essence of PBC is buying performance, instead of buying parts or repair action. PBC is an approach of tying the contractor’s payment to specified performance, rather than merely paying for its activities and tasks [

4]. Financial and non-financial incentives can be used to steer supplier efforts towards the required outputs [

5].

In addition, a central feature of PBC is the transfer of risk to the supplier, i.e., PBC transfers (financial) risks to contractors [

6]. Ideally, risks should be carried by those in the best position to take on these risks because they have the best resources, the best information, or the best expertise. In reality, most participants try to transfer risks to others, resulting in disputes [

7].

Despite the popularity of PBC, literature about the topic is fragmented [

3]. The complexity and uncertainty of performance-based contract incentives require studying the dynamic aspects of risk sharing between customers, OEM and suppliers [

8]. The leading journal

Industrial Marketing Management dedicated a special issue to performance-based contracting in business markets (volume 59, 2016). The guest editors reflected on extant research and identified research gaps [

9]. These research gaps were linked to contracting process stages (i.e., initiation, execution, and finalization). While PBC has been used for several years for contracting infrastructure maintenance, the role of risk remains unclear. There is extant literature on supplier risk in PBC, but the client/buyer/customer side seems underexposed [

6]. Linking payment to performance is considered an effective and efficient sourcing strategy [

8], although important questions arise concerning the identification and management of risks for the buying organisations. Buying organisations are faced with specific risks under PBC [

10]. It remains unclear how customers perceive and handle these PBC induced risks. This study is aimed at providing insights into our understanding of risks under PBC, specifically: what are PBC-induced risks within the context of road maintenance and how do buying organisations handle those risks?

The remainder of this paper is as follows. The literature review summarizes the current understanding of performance-based contracting as used in the context of infrastructure maintenance. The methodology section introduces the in-depth case study at Rijkswaterstaat (RWS), the Dutch public agency responsible for roads and waterways in the Netherlands. The results section reports on the PBC induced risks to RWS, the client organisation. The client encountered risks on the translation of specifications, the division of responsibilities, the ineffectiveness of incentives, and soft contract management. The many issues and problems, leading to poor contractor performance PBC, are linked together in the conclusions. The paper is completed with recommendations, formulated as propositions.

2. Literature Review

2.1. Infrastructure Maintenance

A well-functioning infrastructure is key in poverty eradication and the economic sustainability of nations. Critical issues include controlling the cost of infrastructure maintenance work, as well as maintaining the efficiency of the infrastructure system. Engineering maintenance is not just cosmetic in nature. Maintenance is directed to preserving the value of the assets by preserving the durability of the roads and bridges. Without maintenance the value of these assets can rapidly deteriorate. A single rehabilitation project is estimated to cost three to four times the amount that should have been spent on routine and periodic maintenance of infrastructure [

11]. Still, politicians and policy makers usually take more interest in building new infrastructure rather than preserving the current one [

1].

Civil infrastructure like bridges and other structures are designed for lifetimes of 50–100 years. Today’s maintenance of bridges is governed to a large extent by yesterday’s decisions on investments, choice of materials, design procedures, and construction methods. As Gibson et al. (p. 1) put it: “Delaying maintenance drives up future maintenance costs or leads to even greater expenses for rehabilitation or replacement” [

12]. In other words, today’s maintenance practice will determine tomorrow’s problems. The time lag between the decision taken and its effects is often substantial, many years or even decades [

13]). Contracting out the maintenance of infrastructure creates different challenges. In large-scale procurements such as railroads, highways or airport terminals, the service lifecycle of the infrastructure far exceeds the life of individual parts, components and assemblies of which the infrastructure is composed. This mismatch between the lifecycle of the components and lifecycle of the system creates fundamentally different procurement challenges to typical product centric supply chains [

14].

Political pressure in developed countries has urged public agencies to rethink their mission and core activities. Influenced by neo-liberal programmes like New Public Management (NPM) many public sector organisations have tried to implement enterprise-like principles, such as focussing on core competences, efficiency, lean production, and outsourcing [

15]. The outsourcing of road maintenance to private contractors has become common practice across many public agencies [

16]. Different sorts of maintenance can be outsourced, e.g., routine maintenance (say mowing and pothole repair), periodic maintenance, and urgent maintenance that requires immediate action and intervention [

17]. Outsourcing, as opposed to using in-house resources, fits best in case of specialized work in risky projects where no internal expertise is available [

18].

Maley et al. conclude that outsourcing augments the client’s performance under the condition that outsourcing is properly understood and managed strategically as an intrinsic part of the client’s overall approach [

19]. However, emerging evidence indicates that outsourcing carries disadvantages and risks as well. Consequently, when a firm adopts a strategy of outsourcing its maintenance without regard for its value and inimitability, the resulting outcome will be that the firm’s capabilities are being eroded. Often, managers are disappointed with the outcome of their outsourcing activities [

20].

2.2. PBC and Infrastructure Maintenance

PBC is a contractual approach of tying at least a portion of supplier payment to specific and measurable performance [

3,

21]. PBC is increasingly considered an appropriate strategy for the effective and efficient procurement of goods and services [

8]. Especially for complex service offerings, PBC is considered a promising approach, enabling buying company to adopt use rather than own strategies [

9]. Outcome-based contracts are likely to be useful for procuring maintenance, considering the importance of available and reliable systems and infrastructure [

2,

22]. PBC can be conceptualised along three dimensions: performance, incentives and risk [

3].

In a performance contract, the client specifies the demanded performance (outcomes, output) instead of the efforts needed by the provider (inputs, activities, processes) [

23]. Performance can be measured in terms of availability of systems [

24], reliability of equipment [

25] or product utilization [

26]. The key differences in specifying performance between traditional contracting and PBC are technical specifications versus functional specifications. In traditional contracting the efforts needed to meet the technical specifications are described in detail by the client. In PBC the client specifies the functional performance needed, which must be translated into technical specifications by the contractor. Measurement and (functional) specifications are of critical importance for effective PBC. Lazzarotto et al. emphasize the importance of utilisation of performance indicators for contract management and performance-based compensation [

27].

The client defines the deliverables, such as availability, reliability, maintenance and lifecycle costs. These goals are translated into deliverables for the contractor and guaranteed by means of incentives and penalties. The payment to suppliers is tied to their specified performance [

4]. The incentives can be positive (rewards) or negative (penalties), linked to the specified outputs or outcomes [

3]. The payment system can also partially tie payment to specific outcomes and performance. Such hybrid systems can be preferred if outcomes take a long time or are difficult to achieve [

3]. When it is hard to measure and verify performance, buying organisations tend to tie the payment on hybrid specifications, based on surrogate outputs, processes or even input [

23]. Also, the payment system may include ‘dead zones’, indicating acceptable levels of performance for which suppliers are neither penalised nor extra-rewarded [

28]. The incentive structure is of critical importance to suppliers who are whether or not willing to bear risks and sign a performance-based contract [

29]. In addition, contractors could be tempted to accept irresponsible risks in case of premium payments [

4].

According to Sultana et al., in infrastructure maintenance, PBC is a method under which a contractor must plan, design, and implement maintenance activities in order to achieve short- and long-term asset condition standards for a fixed price, subject to specified risk allocation [

11]. Contractors may need to carry out other services such as collection and management of asset inventory data, call-out and attendance to emergencies, and response to public requests, complaints, and feedback. A contract is awarded to the contractor on the agreement that the contractor/agency takes the responsibility of meeting the minimum standards of performance measures that are set by the government’s highway authority. Most commonly, the willingness of suppliers to bear risks is proportionate to the level of the fees [

23]. However, it should be noted that the transfer of risks is by default restricted for many public organisations. Public agencies are held accountable, even for the operational failures of their suppliers [

28].

2.3. PBC and Moral Hazard

In the principal agency theory, one party (the principal) delegates work to another party (the agent) who performs that work [

30]. Buying organisations are faced with agency problems in governing the relationship with their suppliers [

31]. Agents will not always act in the best interest of the principal [

32]. A key agency problem is known as moral hazard which is a situation where the agent pursues self-interest and is not behaving in line with the goals of the principal [

33].

How can buying companies deal with the key agency problem of moral hazard? They could try to mitigate these problems monitoring systems and establishing appropriate incentives for suppliers [

32]. PBC is believed to reduce the problem of moral hazard and conflicts of interests, since the payment and the incentives are tied to performance [

24]. There is wide agreement that the choice of contract types should be contingent upon various circumstances such as product and/or process uncertainty, desired allocation of risk, owner in-house capability, and market conditions. A proper contract type should encourage the owner and contractor to work rationally together to achieve the best outcomes in accordance to their common objectives and within the expected risk [

34]. The choice between activity-based and performance-based contracts will be influenced by various factors [

30]. More specifically, outcome-based contracts are believed to be attractive for buyers in cases with low outcome uncertainty (due to low cost of transferring risk to suppliers), high outcome measurability [

6], and high goal conflicts [

30]. The effectiveness of PBC also depends on the verifiability of the performance and the quality of the monitoring and reporting system of the buying company [

28].

2.4. Clients’ PBC Risks in the Context of Highway and Road Maintenance

Today’s condition of bridges and highways is governed to a large extent by yesterday’s decisions on investments, choice of materials, design procedures, construction methods and so on. Today’s maintenance practice will determine tomorrow’s needs. Considering the enormous risks long after the duration of a performance contract in case of civil infrastructure maintenance, clients face the difficult tasks of developing appropriate functional specifications. Integrated solutions require a system integrator (‘main contractor’) to bundle and integrate the work and inputs of sub-suppliers (‘subcontractors’) [

24]. The buying company has no direct contact with these subcontractors in the supply chain, which adds to the complexity and risks of PBC. One characteristic of PBC is that the client provides merely functional specifications which are elaborated into technical specifications by the contractor [

23]. Therefore, the client runs the PBC-induced risk that the maintenance contractor may not translate the functional specifications into technical specifications in accordance with client’s intentions and demands.

Another PBC risk for the client concerns the issue of contractors who do not take full responsibility for cost, quality and time schedules in the project. Contractors will be reluctant to accept responsibility when they actually cannot control (undesired variations) in agreed outcomes [

6]. Nullmeijer et al. found that attributability in performance contracts is conducive to supplier performance [

22]. Contractors do not want to be responsible for problems that are not their fault, clients want to avoid discussions and problems concerning the division of responsibilities and tasks. As the end of a project nears, clients might be worried about the performance and might be willing to pay more in order to avoid problems and uncertain outcomes. Contractors might feel encouraged to delay the resolution of ambiguities in the contract [

35]. Although a performance contract intends to shift performance risks to the contractor [

24], clients may have trouble in implementing effective monitoring systems. Clients must face the operational risks that contractors do not deliver the agreed performance [

28].

Client organisations have to take decisions on tying payments fully or partially to specified performance instead of paying per activities and products [

4]. Financial incentives and penalties are linked to specified outputs or outcomes [

3]. The payment structure is intended to positively direct the work and performance of suppliers. However, the incentives could also create unintended and undesirable effects, such as neglecting work for which quality is not included in the contract or even blatant supplier opportunism [

5]. Contractors might reduce their efforts when considering the cost trade-off between extra quality and financial penalties for underperformance [

36]. In the empirical part of our study, we will focus on clients’ PBC risks in the context of road maintenance.

3. Research Method

A qualitative in-depth case study is appropriate, since research on the topic of PBC for road maintenance is still in an exploratory phase. More specifically, this case study is partly based on the contextualised logic of general theory, hence its emphasis is on theory-testing and -elaborating [

37]. This study results in an elaboration of PBC theory by developing propositions in a specific context, i.e., road maintenance.

The case study was carried out at Rijkswaterstaat (RWS), the Dutch public agency responsible for the design, construction, management and maintenance of the main infrastructure facilities. RWS promotes safety, mobility, clean water, and dry feet. The agency has difficulties adequately dealing with increased mobility and constant traffic jams. With a yearly spend of 3 billion euro, RWS is an important client organisation for many contractors and other parties. RWS has developed and promoted a specific Market Vision, with an emphasis on partnerships with market actors. This vision entails the delegation and outsourcing of design, solutions, and operational work to ‘the market’. In line with the ‘Market Vision, PBC is used for selecting and contracting road maintenance contractors. RWS employs integral contracts which means that different categories of tasks are combined within a single contract and are contracted out to a single (relatively large) main contractor.

The unit of analysis for this study is PBC by RWS for the maintenance of highways and roads in the Netherlands. In 2016, the contract was awarded to two service providers: one for the province of Friesland and one for the provinces of Groningen and Drenthe. Purposeful sampling is used for the identification and selection of individuals to interview who are especially knowledgeable about or experienced with PBC-induced risks and influencing factors. We interviewed representatives of the network-management department and the project-management department. The Network-Management department plans and decides about new maintenance and formally initiates a new maintenance project (e.g., PBCs). The Project-Management department is responsible for contract design, purchasing of the required services and contract management of all PBCs and other contracting methods.

The empirical research started with studying internal documents from RWS such as Project Initiation Forms, Contracts (in-use), specifications, model contracts, internal regulations and guides. More specifically, the following documents were analysed:

‘Guidelines for working with performance contracts’. This document was drafted as a guide for every employee within RWS who is in some way concerned with PBC. The document explains PBC and describes how to design and manage a PBC according to RWS. Having the status of a guide, following this document is not compulsory, but it is regarded as best practice.

‘Scope form performance contracts regular maintenance Northern Netherlands 2015–2020’. This document contains the formal internal assignment and corresponding scope from the Network-management department to the Project-management department for the PBC investigated.

‘Matching document KES-PC NN VAST 2016–2019 release demands’. This document is the formal verification and validation document from the Project-management department back to the Network-management department. This document describes how the scope from document 2 is processed in the PBC. This document was created at the final stage of the contract design, but before the contract was awarded to a service provider.

Second, information contained in documents can suggest questions that need to be asked and situations that need to be observed as part of the research. Semi-structured interviews were chosen so that a rich understanding of the influencing factors on risk can be obtained at several levels in the case organisation. To promote openness in the interviews and prevent a possible defensive attitude among the interviewees, as many questions as possible were included related to (personal) experiences with and perceptions of PBC-induced risks.

The interview data about PBC-induced risks were collected in transcripts. The relevant information from these transcripts is categorised by use of the afore mentioned factors. An Excel-file (data matrix.xlsx) was created as a matrix display in the form of a presentable database. All relevant document and interview fragments and subsequent categorisation results are presented in this data matrix for further analysis.

4. Results

4.1. Risk 1: Translation of Functional Specifications

Respondents agreed that not all functional specifications were properly translated by the main contractor into technical specifications. In general, the contractors did not fully perform maintenance in accordance with expectations. The underperformance is partly considered to be due to differences in interpretations. The client had not clearly described the functional requirements. It was found that the contract failed to indicate precisely what the required performance is. Some contract clauses are said to be “too cryptic”, resulting in discussions during the implementation of the maintenance.

“The tricky part with performance contracts are the varying interpretations by the contractor and RWS. An example is the visibility of signs along the roads. There are some guidelines, but there are constant discussions. For instance, someone from RWS drives past a sign and says it is not completely visible, then the contractor drives past it and says that you can still see the sign through those few branches. The performance contract only states that you must be able to see the sign “properly”. But what exactly does that mean? You can disagree about that.”

(asset management director)

“Cryptic texts are included in performance contracts. RWS assumes that the contractor, as good housefather, takes good care of the client’s belongings. RWS has not laid down clearly enough how to deal with the risks. RW and the contractor do not know where they stand. It goes as it goes.”

(technical advisor)

“It is very difficult to translate a functional specification such as "maintaining area" into requirements. How can RWS acknowledge and assess whether all those road surfaces meet or do not meet requirements. It is very complicated. Suppose there are 100 requirements and 1 requirement is not met. How bad is that? How to prove that something does not meet the requirements. How to actually manage functional requirements? That remains complicated, for RWS and for the contractors.”

(contract manager)

The translation of functional specifications can be very difficult for the contractor. Often the asphalt specialist (contractor) gets the contract while having little knowledge of mechanical or electrical engineering. When the contractor has problems with the technical specifications, RWS sometimes helps out and specifies in detail what the contractor should do. However, by helping out, some risk is not transferred to the contractor, because RWS has to approve its own plan. Moreover, this “helping out” is at odds with the principles of PBC.

“We had to replace 5 pieces of deck boarding at the Kruiswater bridge. Sounds simple. However, the functional requirement is actually: make sure that the deck is passable again and that we do not have to maintain it for the next 5 years. Then you notice that they are struggling with that, what they have to do to get that done. Therefore, we put out a helping hand, specifying how thick the boarding should be, what kind of strength class, what type of wood, how long the boarding should be, what kind of busses to put on, what kind of disc springs should be used, how the tightening moment should be. Actually we are making the technical specification for them and put them on a shopping list.”

(technical manager)

Respondents acknowledged that drafting and designing functional specifications are difficult and complex tasks for the client organisation. More specifically, this concerns the factors on which RWS is held responsible, such as availability and reliability (according to the project advisor). Problems arise when functional requirements must be translated in into practical work orders. The abstraction level of functional specifications can be so high that the contractor does not really understand what the client expects and that the measurability and attributability become very problematic or simply impossible. As a result, there is a tendency to just start with the implementation and deal with the problematic interpretations as soon as they come up.

“Now it is often: manage risks when they occur, while it should be: identify risks in advance and see how you deal with them. RWS holds risk adjustment sessions with contractors during the term of contracts. It would be better to get that clear at the start of the process.”

(contract manager)

4.2. Risk 2: Contractor Avoids Full Responsibility

Problematic for RWS is the absence of an appropriate monitoring and controlling system. The lack of sound performance evaluations increased contractors’ tendency to avoid full responsibility.

“It is difficult to hold contractors responsible, if RWS has problems with its own information system. For example, a docking pole was hit, but RWS could not find the required information (how thick that pole was, the steel thickness, the diameter and length). Then RWS sent out a contractor to make some raw estimates.”

(technical manager)

“RWS has a tendency not to record things very strictly. For instance, RWS has informed the contractor what the risks are. But, the risks are not actually transferred to the supplier. A list of risks is not a formal contract document.”

(project advisor)

“More attention needs to be paid to the question, how does RWS ensure that the contractor is checked? It all sounds great and beautiful, but does it function properly? Perhaps RWS has gone too far in testing processes and systems. RWS spends too little time and effort on testing products and performance.”

(department head)

In some cases, it was felt that the responsibilities and risks could not be fully transferred to the main contractor.

“According to the contract, the contractor must assess and inspect all parts that are subject to legal inspection, such as fire extinguishers. The contractor was responsible for the inspection, but at the end of the contract the contractor was unable to provide any information about inspection data. He did not know exactly how and when to inspect. The problem is that RWS runs the risk if anything goes wrong, because it is a legal responsibility. RWS is and remains formally responsible for the inspection of components such as fire extinguishers.”

(asset management director)

More generally, it was reported that the idea of performance contracts contains something contradictory. With a performance contract, risks are transferred to contractors. However, whatever happens, RWS is always responsible for the failures of contractors. RWS has a performance contract to transfer risks, but ultimately RWS bears the risks and is held accountable by the Ministry and by public opinion.

A contractor performed maintenance at the end of the contract at a very minimal level, which increases the risk for the client. RWS then takes action too late to be able to make adjustments. Apparently, the contractor thought the risk was controllable. The risk for the client therefore increased. This problem was illustrated by a project concerning the expansion joints in the national road A28:

“I think this is certainly an example in which the contractor does not benefit at all from putting in any extra effort. He already has the money, so every step he takes in addition are only costs. There is also no recoupment payback model for him within the short contract duration, given the intervention frequencies of, for example, expansion joints. In addition, for every euro spent while there is a calamity, meaning that the risk has occurred, he gets paid. […] we have just experienced this within the PBC. The contract duration is now usually 3 years with 2 times an extension to 5 years. For certain components in the remit, this period gives no incentive to do anything about improving the remit. It is too short, actually and that is a risk.”

(project advisor)

The underlying problem is the availability and the limited number of alternative contractors in this specific market for road maintenance. There are only a few large contractors to whom the client can award performance contracts (according to the technical manager). Contractors are aware of their favourable power position. This dependence position of the client organisation has several negative consequences, for instance: the time that contractors spend on one performance contract is often very limited, contractors are often not prepared to do exactly what the client wants, contractors refuse to accept disadvantageous contracts, and sometimes contractors simply look at the least expensive way to fulfil their contractual obligations. These contractors do not look at added value for the customer, they are focused on efficiency and making money. Since RWS has chosen to work with integral contracts, they unintendedly created dependence on the main contractor and increased the contractor’s power position.

“RWS works with integrated contracts, so we have to deal with one main contractor. However, there are actually only a few major contractors who can do the job. That is because they have to be able to do everything (asphalt, mechanical and technical engineering). The result is that contractors do not want to take on all risks, that they drive a hard bargain and that they are often not willing to do exactly what RWS wants. The contractor therefore has a sort of dominant position vis-à-vis the client.”

(technical manager)

4.3. Risk 3: Incentives Encourage Undesirable Behaviour

Performance can be measured in terms of availability, reliability or product utilization. For RWS, the availability of infrastructure is very important and forms the ultimate goal. However, the performance-based contracts for maintenance do not provide for bonuses or penalties directly linked to preventive maintenance and the availability of infrastructure. There are bonuses and penalties linked to solving and limiting malfunctions and calamities, although these penalties are rarely effected in practice. For instance, small breakdowns of up to € 5000 are a cost incurred by the contractors, while RWS takes responsibility for breakdowns above that amount. The idea behind this is that the contractor will be encouraged to prevent malfunctions as much as possible (unscheduled unavailability), but that the risk of a major malfunction does not become unreasonably large for the contractor. Anticipating and solving malfunctions therefore does not have the highest priority of contractors.

In some cases, the incentive system proved to be rather ineffective. Contractors constantly make trade-offs between costs and returns. For economic reasons, a contractor may decide to just drop the last 10% of the contract. The incentive system contains positive incentives (bonuses), but has a lack of negative incentives (financial penalties). The contract provides for fixed payments for routine and periodic maintenance (prevention) and flexible payments for urgent maintenance (correction). This hybrid system has its flaws.

“Ultimately, many contractors look for the cheapest way to do the work. Especially when contractors do not benefit from making extra efforts during the contract period in case of fixed payment. The contractor has already received the money, so every extra step is just costs. In addition, the contractor gets paid for every calamity that occurs. The contract duration is usually 3 years with 2 times an extension to 5 years. For certain maintenance areas, that period does not give any incentive for preventive maintenance. In addition, it is tempting not to resolve failures directly or at much costs.”

(project advisor)

A contractor exhibited undesirable behaviour because of unintended effects of incentives, which increases the risk for the client. At the end of the contract period, usually after 5 years, RWS cannot always properly determine whether the contractor has done everything well. The next contractor may therefore have to deal with overdue maintenance. In the end, RWS has paid for something, did not receive it, and then had to pay for it a second time.

“For example, the cleaning of sewage systems […] The contractor should have cleaned the gutters, but they are still full of water. Just try to prove that the contractor has not done his job. At a certain moment during a downpour, the entire overtaking lane was full of water, which is very dangerous for aquaplaning. It is a serious risk and it occurs repeatedly.”

(technical advisor)

Another issue concerns the performance-based payment system in the contract. The performance contracts do not always include the right triggers to ensure that contractors work as well as possible for RWS. For instance, a contractor did not carry out sufficient maintenance on a bridge, which caused a 2-hour breakdown with an enormous traffic jam. Apparently, the performance contract did not provide financial penalties for (the consequences of) downtime. The absence of such penalties sent the wrong signal to the contractor.

“RWS could have stated in the contract that a 2-hour outage on a certain route costs the contractor 200,000 euros. That would probably trigger the contractor to ensure that there are no lengthy delays. Performance contracts should tie the performance (in terms of availability of bridges and roads) to financial bonuses and penalties.”

(technical advisor)

“Negative incentives are often not included in the contract. The contractor receives maintenance money for continuous maintenance. Everything he does extra costs him money. In addition, if he does not do his job well, what happens, who checks it? Apparently the contractor can get away with it, because no fines are levied either.”

(department head)

4.4. Risk 4: Soft Contract Management Reduces PBC Effectiveness

Soft or hard is determined by how the client actually deals with the contract. The general feeling is that RWS deals with performance contracts in a rather soft way. The PBC performance is not well enough monitored by the client organisation, which induces the client to deal with the contract in a soft way.

“Contracts are drawn up very strictly, but certainly in the first few years they are managed in a soft way. The idea is that the contractor must get used to the way RWS wants to work. Only in the later years of the contract period, RWS tries to correct and enforce the contract to make adjustments. However, sometimes if RWS wants to play it hard, then contractors point to RWS’s Market Vision where contractors are seen as partners.”

(technical manager)

“It appears that RWS focusses more on relationships than on transactions and contracts. The leading idea is: RWS and contractors build good relationships and that contractors therefor do what RWS wants. That is nice, but the question is whether this actually works that way. RWS is often of two minds about contractual and relational governance.”

(department head)

Some feel that RWS has no other choice than soft contract management, due to the complexity of the contract. Performance-based contracts are so thick and full of referrals and appendices that employees at the contractors do not really understand them or even read them thoroughly (according to the contract manager). The lack of knowledge at the contractor is recognized by the Project-Management department. Soft or hard is determined by how the client deals with the contract.

“The performance contracts are so complex that they are not actually hard. There are so many requirements, demand specifications, guidelines, procedures, etc. Sometimes, RWS itself has no insight into what exactly is in the contracts. The result is that RWS handles contracts in a soft manner. For example, the contract refers to an annex, that annex refers to a directive and that directive states on page 151 what a contractor must also do. It is in the contract, but RWS cannot stick hard to that requirement. Contractors know that.”

(asset management director)

An underlying issue concerns the dominant Market Vision of RWS. According to this vision, a contractor should be regarded as ‘a decent housefather’. However, some feel that this a rather naïve vision. “A contractor will not do a job if it costs money and there are no sanctions” (cf. the technical advisor). At the end, the client organisation is held responsible for the availability and functioning of the public infrastructure. The client organisation is believed to lose money due to a rather soft attitude towards contracts and contractors. Without effective stimuli, contractors are “just doing their best to make as much money as possible”.

“The top management of RWS likes to think in terms of an ideal world where each contractor works as a “good housefather”. He takes his responsibility, is proactive and reliable. The reality is somewhat more unruly. The performance is sometimes not clear and the image of a “good housefather” is incorrect. Contractors simply have to make money.”

(department head)

The main findings are represented in

Table 1.

5. Conclusions and Propositions

5.1. Conclusions

The maintenance of public infrastructure is of critical importance for the preservation of roads, railways, airports, and water systems. Although performance-based contracts have now been used for several years, the literature remains unclear about the role of risks at the client-side. We carried out empirical research in search for answers on the questions: what are PBC-induced risks within the context of road maintenance and how do buying organisations handle those risks? In the case study, we found the following PBC-induced risks for the client company:

Functional specifications are not properly translated into technical specifications by the maintenance contractor;

The maintenance contractor avoids full responsibility for the agreed performance;

The incentives encourage undesirable behaviours of the maintenance contractor;

Soft contract management by the client organisation reduces PBC effectiveness.

We found that functional specifications tend to change repeatedly, and are poorly communicated. Apparently, the performance contract failed to indicate precisely what the required performance is. Translation problems may easily result into discussions and differences in interpretation during the term of the maintenance project. Occasionally, when a contractor is unable to properly translate the functional specifications, the client jumps in and takes over responsibilities, which contradicts PBC principles.

Maintenance contractors are able to avoid full responsibility, since the client organisation has no appropriate controlling and monitoring system. A related issue concerns the limited number of alternative maintenance contractors. Remarkable, by awarding integral contracts, the client company created its own dependence in an oligopolistic market.

Also, in our case study, the contractual incentives seem to encourage undesirable behaviours by contractors, for instance due to the absence of financial penalties for underperformance and downtime of client systems. Performance is not always operationalised and measured in terms of availability. The client organisation employs hybrid payment systems, in which the fixed payments stimulate contractors to perform at a minimum level.

The client company employs a rather soft contract management, which seems to reduce PBC effectiveness. Some feel that the complexity of the contracts prevents full compliance of the maintenance contractor. Another issue is top management’s Market Vision, which promotes partnerships and collaboration with selected contractors. However, this vision may tempt the client organisation to overlook the hard business model of maintenance contractors. Working with performance contracts does not automatically result in partnerships with contractors.

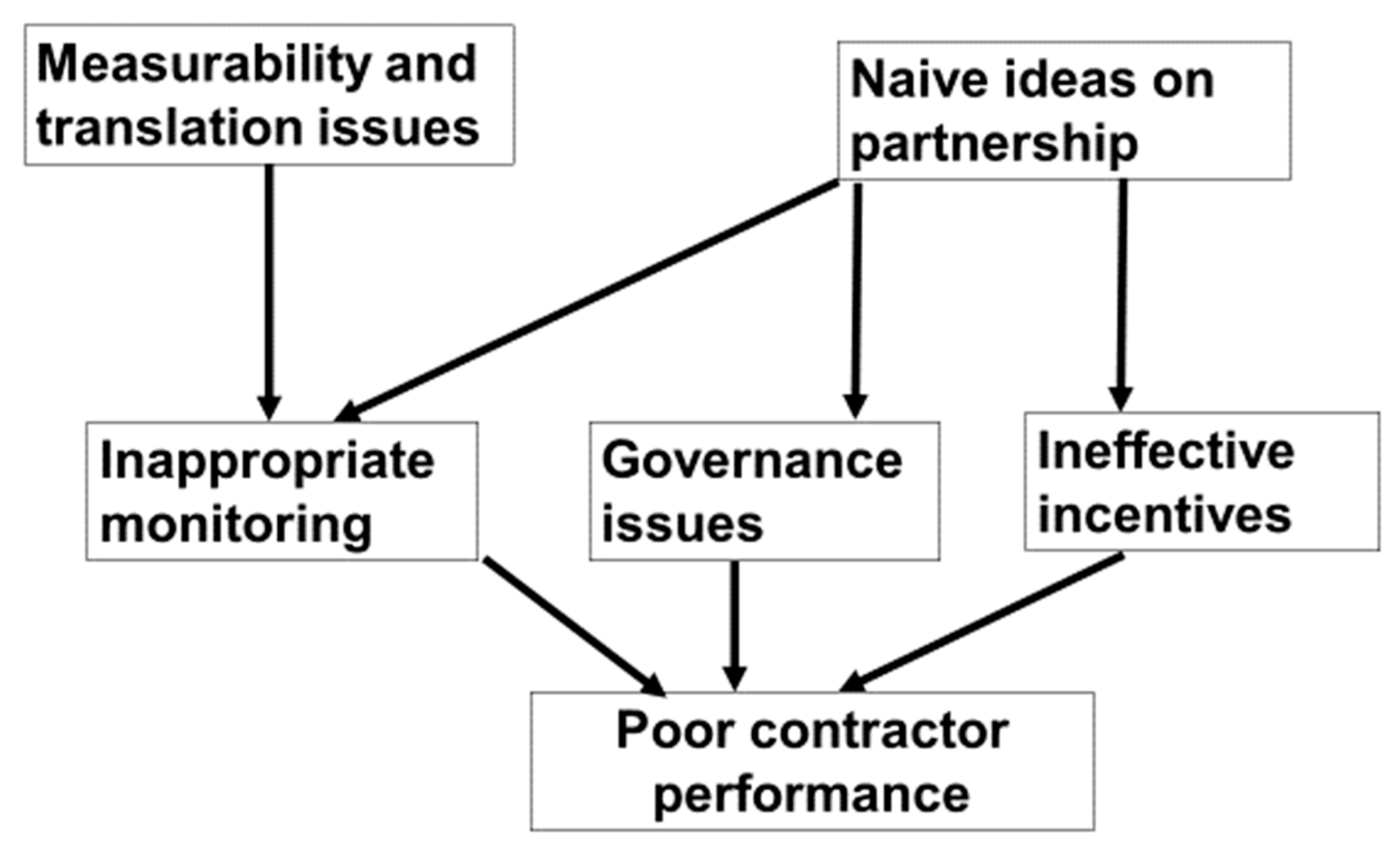

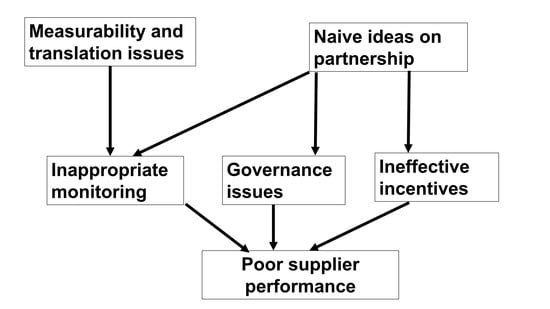

We have tried to capture the main findings of our case study in a coherent representation of PBC-related problems and issues for the client company (see

Figure 1). At the start of every outsourcing project, the buyer is confronted with serious measurement problems and translation issues. These problems prevent the implementation of an appropriate monitoring and controlling systems. The naive ideas on partnership feed the assumption that the organisation does not need a thorough control and monitoring system. These ideas also imply that the client organisation assumes that contractors operate as ‘decent housefather’, due to good relationships and the link between payment and performance. However, the incentives in the performance contracts proved to be rather ineffective. Unrealistic ideas about partnerships are also reflected in governance issues and the rather soft contract management by the client organisation. The end result of this composite of related problems is the poor and disappointing performance of maintenance contractors.

5.2. Development of Propositions

This study is the first to suggest that some of these risks and factors are inherent to PBC specifically and might not easily be transferred from the client to a contractor. Thus, using PBC as means of contracting out maintenance of infrastructure has its downsides and can induce associated risks for the buyer. We have derived and posited a limited number of propositions that may be helpful for clients using PBC for infrastructural maintenance.

Proposition 1. Performance contracts for infrastructural maintenance should include clearly defined metrics to avoid measurement issues and interpretation disputes.

This proposition can be related to Sultana et al., who stated that it is difficult to write all conditions in the contract, and this requires expertise and clear and concise contract language [

11]. More generally, the client must dispose of a high domain knowledge and expertise. The quality of the contracts depends largely on the required competence of the client [

38]. Selviaridis emphasized the importance of clearly defined performance metrics and performance measurement capabilities [

39]. In many working arrangements and projects parties have to deal with ‘hidden fuzzy information’. Not all information is explicitly included in the contract, but merely implied. Client and contractor wrongly believe that they share the same understanding. An assumption that, obviously, is not always true [

40]. We found evidence that client organisations must make much efforts to be crystal clear about the appropriate interpretation of functional specifications.

Proposition 2. The client should be clear about duties and responsibilities, with appropriate monitoring, to assure that the maintenance contractor takes full responsibility in case of cost, quality, and/or time problems at the end of the project.

Positions and roles can change during the execution of performance contracts. A lack of role clarity has been identified as a major cause for less satisfactory results with performance contracts [

41]. An underlying assumption of PBC is that the client can put a contractor in an expert role and shift responsibilities and risks to that contractor [

22]. However, this representation does not do justice to a productive and realistic division of tasks and responsibilities between buyers and suppliers. Clients should assume more roles than merely monitoring and rewarding supplier performance [

22]. Also, the language used in contracts is not always concrete and specific. The client should be attentive to the se of (for example) passive sentences, because the division of work and responsibilities remains unclear [

42]. Subjective language, vague pronouns (‘sufficient’, ‘satisfactory’, etc.) and superlative phrases are indicators of unclear specifications. Especially in case of road maintenance, decisions and projects can have an impact long after the ending of a maintenance performance contract. Contractors may be tempted to take limited responsibilities [

19], especially in the absence of an appropriate monitoring system used by the client.

Proposition 3. Clients should have realistic ideas about the proper relationship with infrastructural maintenance contractors. These ideas must be combined with appropriate governance and effective incentives.

Clients should have sound ideas on partnerships and on the link between PBC use and their purchasing and supply strategies [

9]. Clients may be tempted to consider their preferred contractors as (strategic) partners who act in the best interests of the buyers. Clients should recognize that the actual balance of power is likely to play a role within the relationship. Over time buyers may become very dependent on a supplier, due to supply base reduction and loss of technical skill by the client company [

41]. Also, contractors may focus on finding the least expensive way to fulfil contractual obligations. Incentives do not always contribute to desired behaviour of contractors [

5,

8]. Incentives might induce suppliers to underperform in less emphasized areas or in tasks of which the performance is hard to measure. A related issue concerns the use of a hybrid payment system, including fixed payments for periodic maintenance. Undesirable behaviours can also be encouraged through the absence of financial penalties to motivate contractors to perform according to requirements. In general, it remains unclear how effective incentives actually are. The performance-based payment system may include a mix of bonuses and penalties, linked to minimum, acceptable and maximum standards [

6].

Proposition 4. Within the context of PBC, the agreed-to-performance by maintenance contractors requires appropriate monitoring and appropriate incentives accompanied by a clear governance structure.

This proposition summarises our main finding on PBC for infrastructural maintenance. Many problems and issues can be avoided if the client employs appropriate incentives and appropriate monitoring. Clients should also acknowledge that the success of PBC can only be partially attributed to the contracts. The implementation of the contract should be accompanied by good governance. This point matches with findings of Suprapto et al.: any contract type can deliver success or failure because contract is a second-order concern [

34]. What matters is the ability of both parties to develop relational attitudes and translate this into real team working. Clients should reconcile apparently contradictory management styles. Clients should give the contractor sufficient room for the fulfilment of their expert role, while simultaneously remain engaged and in touch to facilitate and control the work of the contractor [

22]. Contractors may emphasize that they are in business of making money. Such contractors will anticipate the understanding and forgiving attitude of the client organisation and will be tempted to perform at minimum standards.

6. Limitations and Recommendations

Contracting out maintenance of infrastructure creates many challenges. Clients face the complex task of identifying and managing multiple risks induced by PBC. Awareness of the different risks would improve the ability to successfully manage PBCs for public infrastructure maintenance. Functional specifications are typically not always properly elaborated into technical specifications by the contractor in accordance with the buyer’s intentions and wishes. Client organisations may notice that from the moment that specifications are first set, their interpretation changes with every new individual and every new document involved. The effectiveness of the incentive payment structure is also a critical issue in using PBC. When designing incentive programs, clients should consider unintended effects in addition to desired performance [

5]. If availability of infrastructure is the most important outcome of maintenance, bonuses and penalties in the performance contract should be linked to that availability (not to making repairs).

We found that contract management by the client has more impact than the design of the contract itself. For the client it is tempting to manage performance contracts in a soft way, because the complexity and size of a performance contract and all related documents make it very difficult to treat it as a hard contract. A related, underlying problem is the availability and the limited number of alternative contractors in this specific market for road maintenance in the Netherlands. Organisations should recognize and acknowledge the actual balance of power in the relationship with their (main) suppliers. Obviously, dependencies and post-contractual lock-in situations do not benefit or work to the advantage of clients. Maintenance buyers should not be naïve, thinking that a contractor will always act as ‘a decent housefather’ aimed at everyone’s best interest.

Buyers should focus on the clarity and interpretation of functional specifications. Preferably, a mutual understanding on the requirements should be assured in the contracting phase, not in the implementation phase. We do not recommend a sourcing approach that assumes proper translations of functional specifications by the main contractor. Additionally, buyers must employ an appropriate control and monitoring system. Linking payment to performance is not a guarantee for optimal supplier performance. In general, buyers should not shy away from penalties for underperformance.

In addition to the contribution to the literature on PBC induced risks, there are also limitations. We investigated a single case study of a PBC in a specific Dutch context. Findings about the PBC risks and influencing factors are related to that context. Findings are based on interviews held with management and employees of the client organisation, supplemented with internal documents. Future studies could validate and complement our findings by testing our propositions. Multiple case studies over time may give interesting insights in changing contexts. In addition, scholars might be interested in the role and management of subcontractors in PBC, investigating client-contractor triads. We also propose the investigation and testing of the conditions set by the Agency Theory that outcome-based contracting is appropriate in case of high outcome measurability, low outcome uncertainty, high goal incongruence, and risk averse buyers contracting less risk averse suppliers.

Future studies could investigate the appropriateness of PBC in case of dominant suppliers, dominant buyers, and power balanced buyer-supplier relationships. More in general, research could focus on the impact of power and dependence on PBC-effectiveness. The interplay of cooperative and competitive behaviours within PBC-relationships could be an interesting avenue for future research.

Author Contributions

Conceptualization, formal analysis, methodology, validation, visualization, and writing (original draft) by C.J.G., J.S. and S.D.V. Not applicable were funding acquisition, resources and software. Data collection, data curation, investigation, and project administration by S.D.V. Supervision and review & editing by C.J.G.

Funding

This research received no external funding.

Acknowledgments

We thank the Open University of the Netherlands for the opportunity to set up and execute this research project. We thank the respondents for their cooperation in the interviews.

Conflicts of Interest

The authors declare no conflict of interest. There are no funders with a role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Gibson, J.; Rioja, F. Public infrastructure maintenance and the distribution of wealth. Econ. Inq. 2017, 55, 175–186. [Google Scholar] [CrossRef]

- Sandborn, P.; Kashani-Pour, A.; Goudarzi, N.; Lei, X. Outcome-based Contracts—Towards Concurrently Designing Products and Contracts. Procedia CIRP 2017, 59, 8–13. [Google Scholar] [CrossRef]

- Selviaridis, K.; Wynstra, F. Performance-based contracting: A literature review and future research directions. Int. J. Prod. Res. 2015, 53, 3505–3540. [Google Scholar] [CrossRef]

- Kim, S.-H.; Cohen, M.A.; Netessine, S. Performance Contracting in After-Sales Service Supply Chains. Manag. Sci. 2007, 53, 1843–1858. [Google Scholar] [CrossRef]

- McDonald, R.; Roland, M. Pay for performance in primary care in England and California: Comparison of unintended consequences. Ann. Fam. Med. 2009, 7, 121–127. [Google Scholar] [CrossRef] [PubMed]

- Selviaridis, K.; Norrman, A. Performance-based contracting in service supply chains: A service provider risk perspective. Supply Chain Manag. Int. J. 2014, 19, 153–172. [Google Scholar] [CrossRef]

- Mehany, M.S.H.M.; Guggemos, A. Risk Management for Asphalt Road Construction and Maintenance under Performance-Based Contracts. Int. J. Constr. Educ. Res. 2015, 11, 1–24. [Google Scholar]

- Datta, P.P.; Roy, R. Incentive issues in performance-based outsourcing contracts in the UK defence industry: A simulation study. Prod. Plan. Control 2013, 24, 359–374. [Google Scholar] [CrossRef]

- Essig, M.; Glas, A.H.; Selviaridis, K.; Roehrich, J.K. Performance-based contracting in business markets. Ind. Mark. Manag. 2016, 59, 5–11. [Google Scholar] [CrossRef]

- Van Strien, J.; Gelderman, C.J.; Semeijn, J. Performance-based contracting in military supply chains and the willingness to bear risks. J. Def. Anal. Logist. 2018, 3, 83–107. [Google Scholar] [CrossRef]

- Sultana, M.; Rahman, A.; Chowdhury, S. A review of performance based maintenance of road infrastructure by contracting. Int. J. Prod. Perform. Manag. 2013, 62, 276–292. [Google Scholar] [CrossRef]

- Gibson, B.; Albright, N.; Wallace, C.Y.; Van Dyke, C.; Kreis, D. Review of Literature and Maintenance Practices at State Transportation Agencies; University of Kentucky UKnowledge: Lexington, KY, USA, 2018. [Google Scholar]

- Van Der Velde, J.; Klatter, L.; Bakker, J. A holistic approach to asset management in the Netherlands. Struct. Infrastruct. Eng. 2013, 9, 340–348. [Google Scholar] [CrossRef]

- Caldwell, N.; Howard, M. Contracting for complex performance in markets of few buyers and sellers. Int. J. Oper. Prod. Manag. 2014, 34, 270–294. [Google Scholar] [CrossRef]

- Cedergren, A.; Johansson, J.; Hassel, H. Challenges to critical infrastructure resilience in an institutionally fragmented setting. Saf. Sci. 2018, 110, 51–58. [Google Scholar] [CrossRef]

- Hartmann, A.; Aijo, J.; Roehrich, K.; Hess, R.; Altamirano, M.; Bles, T. Procurement of road maintenance: Between knowledge loss and efficiency gains. In Proceedings of the 7th Transport Research Arena (TRA), Vienna, Austria, 16–19 April 2018. [Google Scholar]

- Burningham, S.; Stankevich, N. Why Road Maintenance is Important and How to Get it Done. World Bank Transp. Note 2005, 4, 1–10. [Google Scholar]

- Hegazy, T. Computerized System for Efficient Delivery of Infrastructure Maintenance/Repair Programs. J. Constr. Eng. Manag. 2006, 132, 26–34. [Google Scholar] [CrossRef]

- Maley, J.F.; Kowalkowski, C.; Brege, S.; Biggemann, S. Outsourcing maintenance in complex process industries: Managing firm capabilities in lock-in effect. Asia Pac. J. Mark. Logist. 2015, 27, 801–825. [Google Scholar] [CrossRef]

- König, A.; Spinler, S. The effect of logistics outsourcing on the supply chain vulnerability of shippers. Int. J. Logist. Manag. 2016, 27, 122–141. [Google Scholar] [CrossRef]

- Liinamaa, J.; Viljanen, M.; Humerinta, A.; Ivanova-Gongne, M.; Luotola, H.; Gustafsson, M. Performance-based and functional contracting in value-based solution selling. Ind. Mark. Manag. 2016, 59, 37–49. [Google Scholar] [CrossRef]

- Nullmeier, F.M.; Wynstra, F.; Van Raaij, E.M. Outcome attributability in performance-based contracting: Roles and activities of the buying organization. Ind. Mark. Manag. 2016, 59, 25–36. [Google Scholar] [CrossRef]

- Martin, L.L. Performance-based contracting for human services: Lessons for public procurement? J. Public Procure 2002, 2, 130–151. [Google Scholar]

- Kleemann, F.C.; Essig, M. A providers’ perspective on supplier relationships in performance-based contracting. J. Supply Chain Manag. 2013, 19, 185–198. [Google Scholar] [CrossRef]

- Guajardo, J.A.; Cohen, M.A.; Kim, S.-H.; Netessine, S. Impact of Performance-Based Contracting on Product Reliability: An Empirical Analysis. Manag. Sci. 2012, 58, 961–979. [Google Scholar] [CrossRef]

- Hypko, P.; Tilebein, M.; Gleich, R. Benefits and uncertainties of performance-based contracting in manufacturing industries. J. Serv. Manag. 2010, 21, 460–489. [Google Scholar] [CrossRef]

- Lazzarotto, B.O.; Borchardt, M.; Pereira, G.; Almeida, C. Analysis of management practices in performance-based outsourcing contracts. Bus. Process. Manag. J. 2014, 20, 178–194. [Google Scholar] [CrossRef]

- Ekström, T.; Selviaridis, K. Performance based contracting capabilities–A pre-study of Swedish defence acquisition. In Proceedings of the 31st International Symposium on Military Operating Research, Department of Industrial Management and Logistics, Lund University, London, UK, 29 July–1 August 2014; Volume 1. [Google Scholar]

- Buchanan, N.; Klingner, D.E. Performance-based contracting: Are we following the mandate? J. Public Procure. 2007, 7, 301–332. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Agency theory: An assessment and review. Acad. Manag. Rev. 1989, 14, 57–74. [Google Scholar] [CrossRef]

- McCue, C.; Prier, E. Using agency theory to model cooperative public purchasing. J. Public Procure. 2008, 8, 1–35. [Google Scholar] [CrossRef]

- Jensen, M.; Meckling, H. Theory of the Firm: Managerial Behaviour, Agency Costs and Ownership Structure. J. Financ. Econ. 1976, 3, 305–360. [Google Scholar] [CrossRef]

- Ross, S.A. The economic theory of agency: The principal’s problem. Am. Econ. Rev. 1973, 62, 134–139. [Google Scholar]

- Suprapto, M.; Bakker, H.L.; Mooi, H.G.; Hertogh, M.J. How do contract types and incentives matter to project performance? Int. J. Proj. Manag. 2016, 34, 1071–1087. [Google Scholar] [CrossRef]

- Asadabadi, M.R.; Sharpe, K. The ambiguity dilemma in procurement projects. J. Bus. Ind. Mark. 2019, 34, 792–800. [Google Scholar] [CrossRef]

- Crew, N. Using Market Prices to Regulate the Costs of a Utility’s Inputs. J. Regul. Econ. 1997, 11, 195–216. [Google Scholar] [CrossRef]

- Ketokivi, M.; Choi, T. Renaissance of case research as a scientific method. J. Oper. Manag. 2014, 32, 232–240. [Google Scholar] [CrossRef]

- Femmer, H.; Fernández, D.M.; Wagner, S.; Eder, S. Rapid quality assurance with Requirements Smells. J. Syst. Softw. 2017, 123, 190–213. [Google Scholar] [CrossRef]

- Selviaridis, K. Who’s to blame or praise? Performance attribution challenges in outsourced service provision in supply chains. Supply Chain Manag. Int. J. 2016, 21, 513–533. [Google Scholar] [CrossRef]

- Asadabadi, M.R.; Chang, E.; Zwikael, O.; Saberi, M.; Sharpe, K. Hidden Fuzzy Information: Requirement specification and measurement of project provider performance using the best worst method. Fuzzy Sets Syst. 2019, in press. [Google Scholar] [CrossRef]

- Howard, M.; Wu, Z.; Caldwell, N.; Jia, F.; König, C. Performance-based contracting in the defence industry: Exploring triadic dynamics between government, OEMs and suppliers. Ind. Mark. Manag. 2016, 59, 63–75. [Google Scholar] [CrossRef]

- Femmer, H. Reviewing Natural Language Requirements with Requirements Smells—A Research Proposal. In Proceedings of the IDoESE, Baltimore, MD, USA, 9 October 2013. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).