An Experimental Study of Portland Cement and Superfine Cement Slurry Grouting in Loose Sand and Sandy Soil

Abstract

:1. Introduction

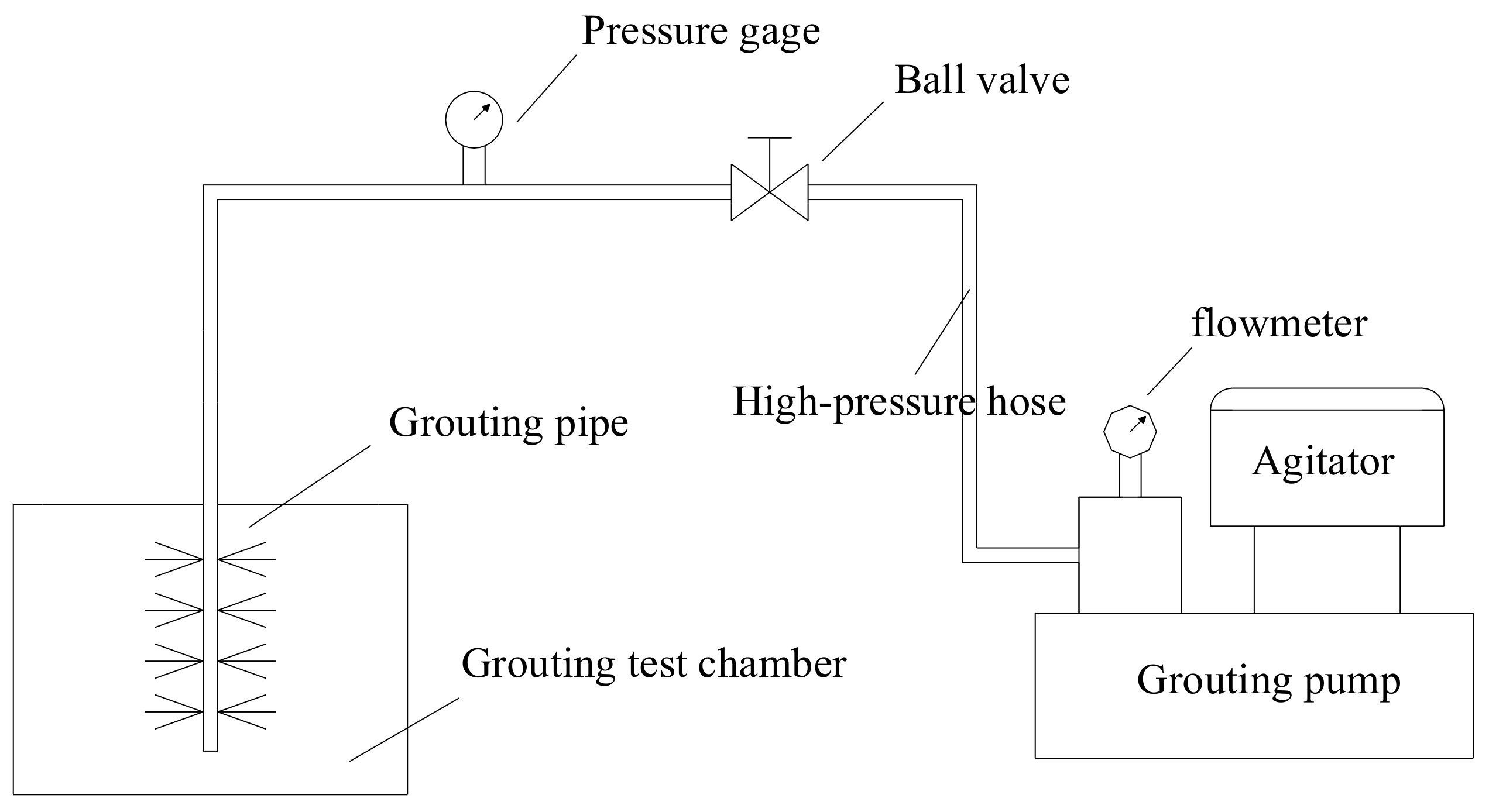

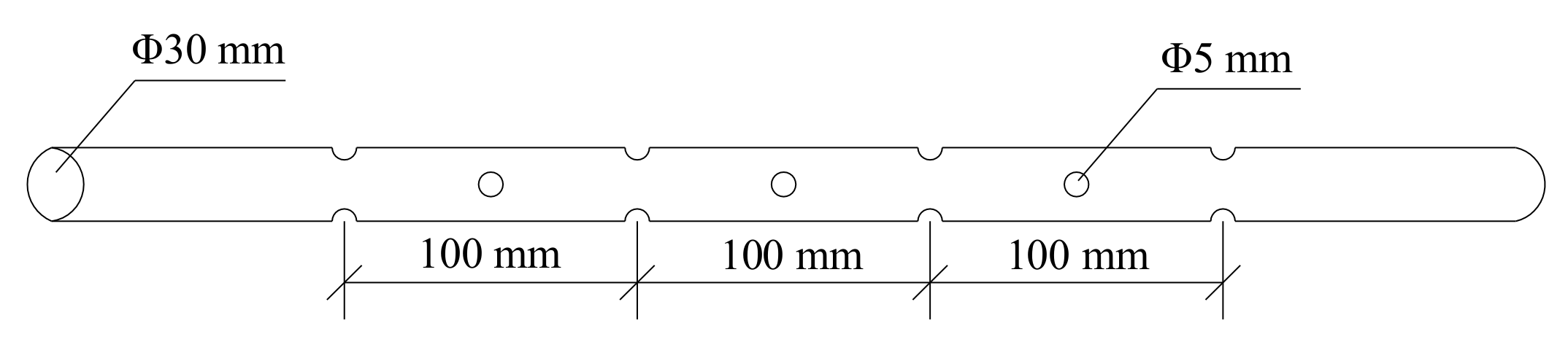

2. Equipment and Materials

2.1. Equipment

2.2. Materials

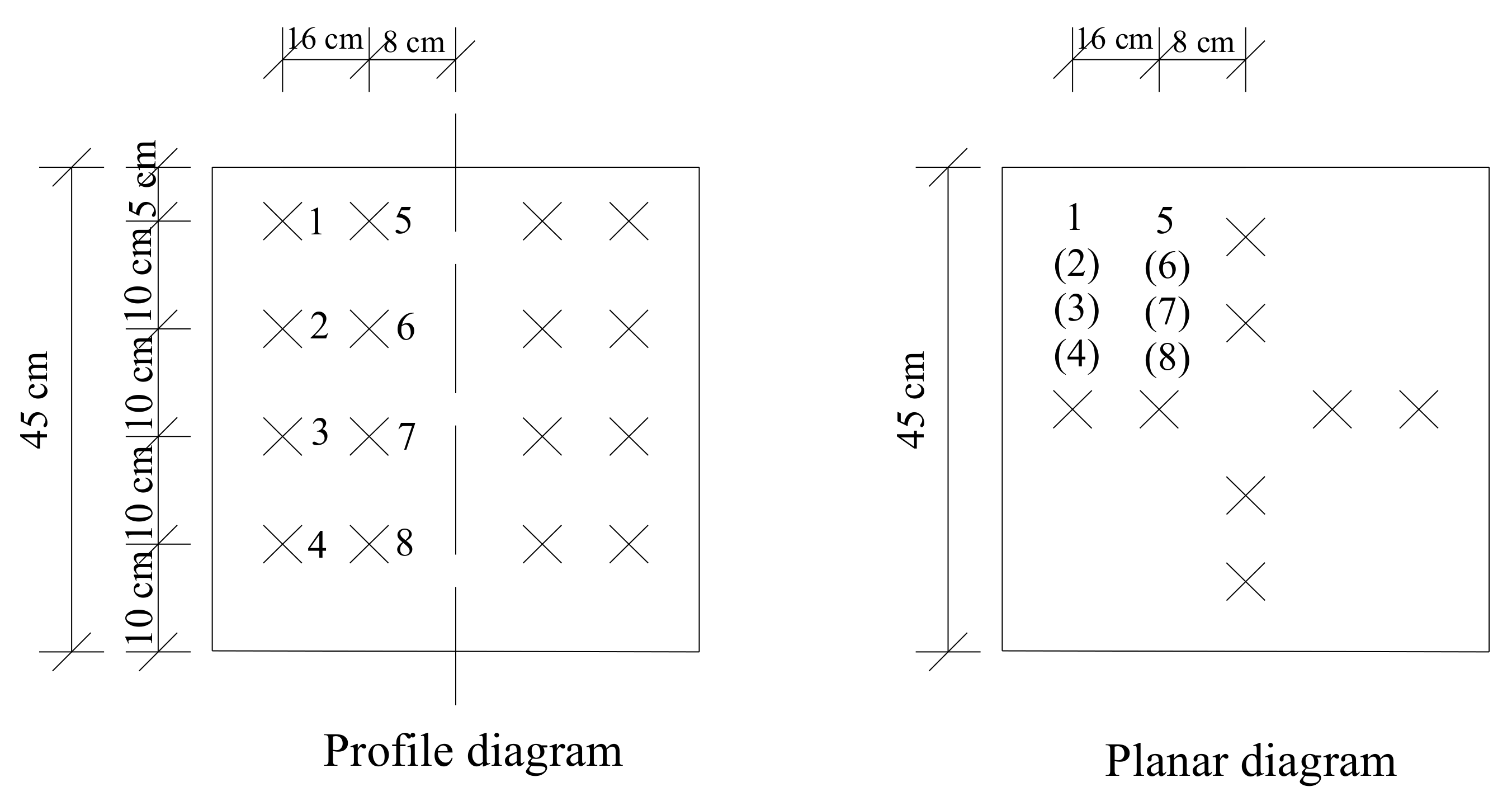

3. Methods

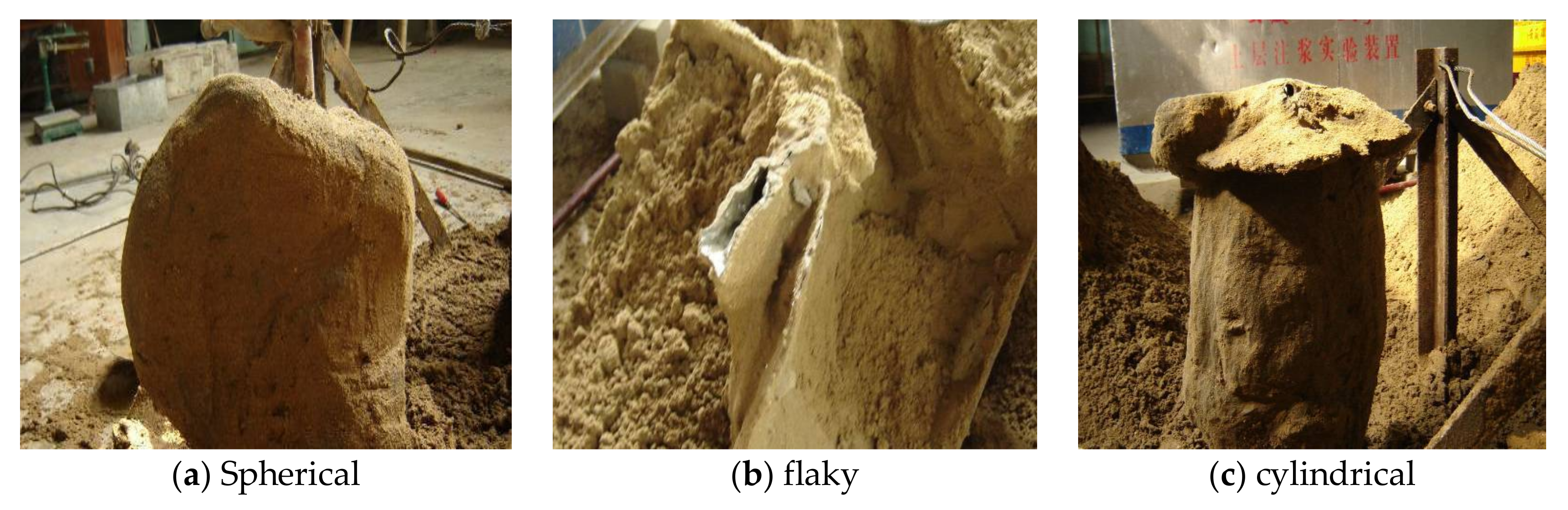

4. Results and Analysis

4.1. Analysis

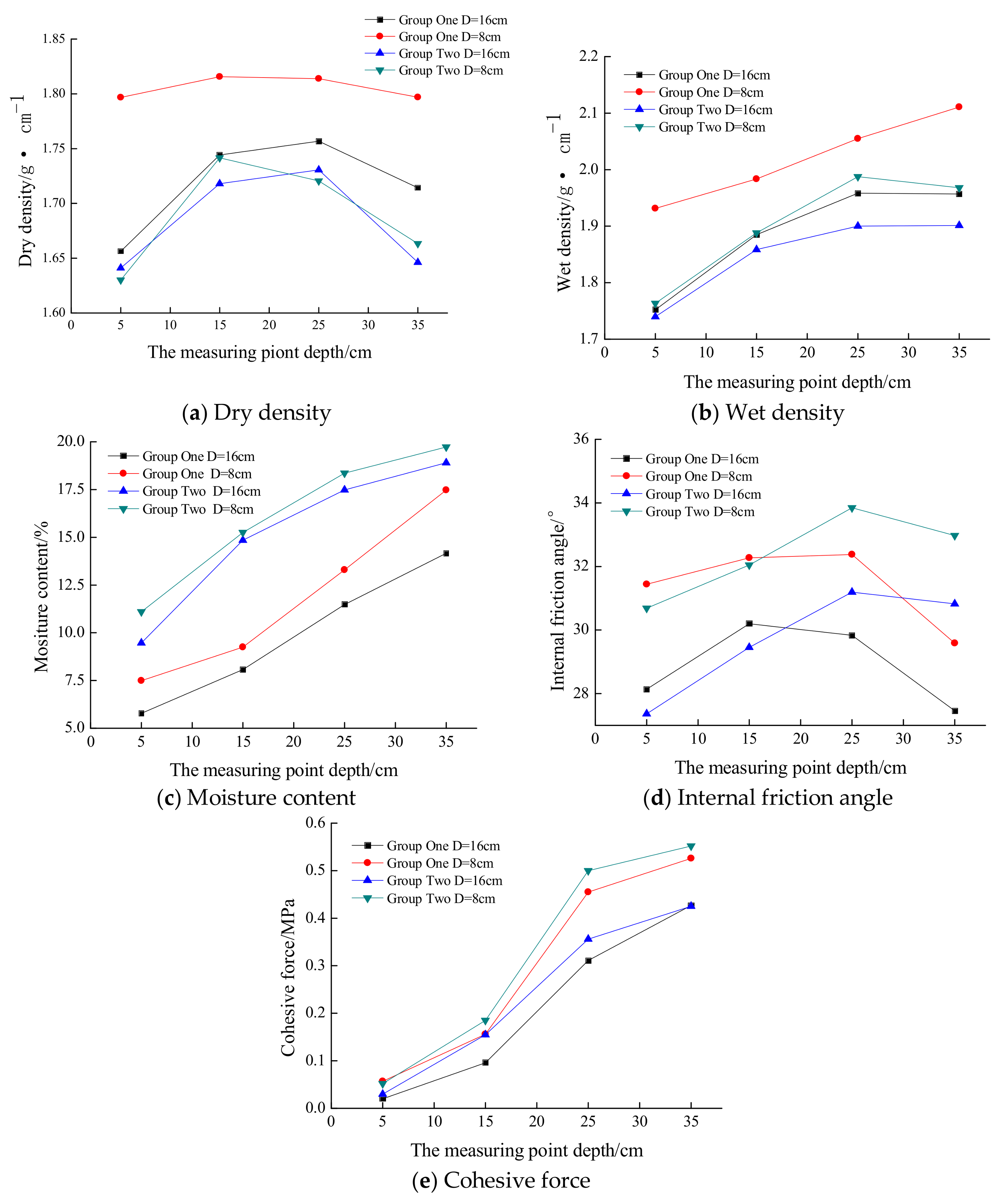

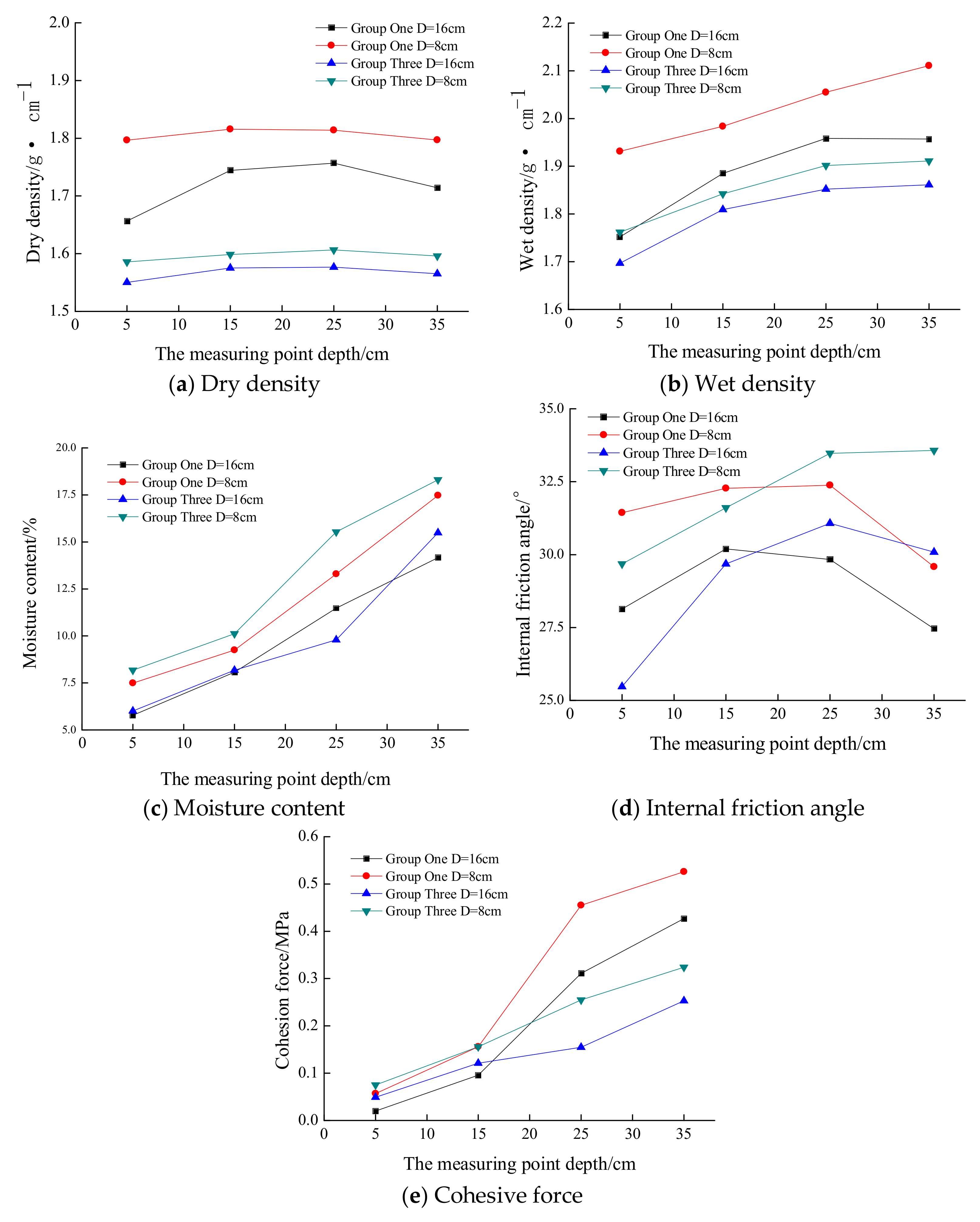

4.2. Mechanics Performance Analysis of Grouting Soil

5. Conclusions

- (1)

- In view of the status of the superfine cement treatment of loose sand and sandy soil, a laboratory test was conducted to compare the injection effects of Portland cement and superfine cement on sandy soil. The results show that the superfine cement slurry consolidation effect of sandy soil is better and the strength is improved because the superfine cement particles diffuse in the form of infiltration, extrusion, and splitting. However, the Portland cement can hardly be injected and diffused into the sandy soil. This indicates that superfine cement slurry is effective for reinforcing the sandy soil.

- (2)

- Three groups of experiments were designed to study the effect of superfine cement slurry injection. The results show that the superfine cement slurry grouted into sand or sandy soil can significantly improve the physical and mechanical properties of the injected medium. When the water–cement ratio of superfine cement slurry is less than 2:1 grouting into loose sand, the dry and wet density decrease with the increase in the water–cement ratio while the moisture content and cohesive force increase gradually. Compared with the same water–cement ratio of 1:1, the grouting effect of slurry injection sand and sandy soil, the dry density, wet density, and cohesive force of sand are significantly larger than for sandy soil.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gullu, H. A new prediction method for the rheological behavior of grout with bottom ash for jet grouting columns. Soils Found. J. 2017, 57, 384–396. [Google Scholar] [CrossRef]

- Kogler, K. Grouting technology in tunnelling. Geomech. Tunnelbau J. 2013, 6, 261–273. [Google Scholar] [CrossRef]

- Bellendir, E.N.; Aleksandrov, A.V.; Zertsalov, M.G.; Simutin, A.N. Building and structure protection and leveling using compensation grouting technology. Power Technol. Eng. J. 2016, 50, 142–146. [Google Scholar] [CrossRef]

- Jiang, Y.S. Application and development of modern grouting technology. Mod. Tunn. Technol. J. 2008, 45, 6–10, (In Chinese with English Abstract). [Google Scholar]

- Yang, M.J.; Chen, M.X.; He, Y.N. Current research state of grouting technology and its development direction in future. Chin. J. Rock Mech. Eng. J. 2001, 20, 839–841, (In Chinese with English Abstract). [Google Scholar]

- Chen, X.; Zhang, F.X. Construct and Effect Inspect of Grouting in Engineering; Tongji University Press: Shanghai, China, 1998. (In Chinese) [Google Scholar]

- Zhang, M.Q.; Zhang, W.Q.; Sun, G.Q. Evaluation technique of grouting effect and its application to engineering. Chin. J. Rock Mech. Eng. J. 2006, 25, 3909–3918, (In Chinese with English Abstract). [Google Scholar]

- Wang, Z.S.; Zhang, D.J. Key technology on shallow embedded tunnel constructed beneath existing subway tunnel. Chin. J. Rock Mech. Eng. J. 2007, 26, 4208–4214, (In Chinese with English Abstract). [Google Scholar]

- Feng, Z.Q.; Kang, H.P.; Yang, J.H. Discussion on grouting technology of fractured rock mass. Coal Sci. Technol. J. 2005, 33, 63–66. (In Chinese) [Google Scholar]

- Burke, G.K.; Cacoil, D.M.; Chadwick, K.R. Superjet grouting: New technology for in situ soil improvement. Transp. Res. Rec. J. 2000, 1721, 45–53. [Google Scholar] [CrossRef]

- Ge, J.L.; Lu, S.L. Study on grouting simulation experiment and its application. Chin. J. Geotech. Eng. J. 1997, 19, 28–33, (In Chinese with English Abstract). [Google Scholar]

- Ge, J.L. The Study of Grouting Reinforcement Mechanism and Technology of Soft Rock Roadways; China University of Mining and Technology: Xuzhou, China, 1995. (In Chinese) [Google Scholar]

- Bouchelaghem, F. Multi-scale modelling of the permeability evolution of fine sand during cement suspension grouting with filtration. Comput. Geotech. J. 2009, 36, 1058–1071. [Google Scholar] [CrossRef]

- Kim, J.W.; Chough, S.K. A gravel lobe deposit in the prodelta of the Doumsan Fan Delta (Miocene), SE Korea. Sediment. Geol. J. 2000, 130, 183–203. [Google Scholar] [CrossRef]

- Vincent, P.; Sadah, A. Fabric analyses of some Saudi Arabian pediment gravels. J. Arid Environ. J. 1995, 30, 371–384. [Google Scholar] [CrossRef]

- Avci, E.; Mollamahmutoglu, M. Permeability characteristics of superfine cement-grouted sand. ACI Mater. J. 2017, 114, 21–28. [Google Scholar] [CrossRef]

- Fransson, A. Characterisation of a fractured rock mass for a grouting field test. Tunn. Undergr. Space Technol. J. 2001, 16, 331–339. [Google Scholar] [CrossRef]

- Wu, A.X.; Yu, S.F.; Han, B.; Wang, Y.M.; Huang, M.Q.; Wang, Y. Optimization of mix-proportion and diffusing rule of super-fine cement grouting slurry. J. Min. Saf. Eng. J. 2014, 31, 304–309, (In Chinese with English Abstract). [Google Scholar]

- Xu, S.H.; Xing, L.L.; Wang, G.Q.; Han, Q. Experimental research on grouting of superfine cement slurry in micro-fissured rock body. J. Saf. Sci. Technol. J. 2014, 10, 96–102, (In Chinese with English Abstract). [Google Scholar]

- Yang, P.; Tang, Y.Q.; Peng, Z.B.; Chen, A. Study on grouting simulating experiment in sandy gravels. Chin. J. Geotech. Eng. J. 2006, 28, 2134–2138, (In Chinese with English Abstract). [Google Scholar]

- Zhang, Z.M.; Zou, J.; He, J.Y.; Wang, H.Q. Laboratory tests on compaction grouting and fracture grouting of clay. Chin. J. Geotech. Eng. J. 2009, 31, 1818–1824, (In Chinese with English Abstract). [Google Scholar]

- Zhang, W.J.; Li, S.C.; Wei, J.C.; Zhang, Q.S.; Zhang, X.; Li, Z.P.; Xie, D.L. Development of a 3D grouting model test and its application. Rock Soil Mech. J. 2016, 37, 902–911, (In Chinese with English Abstract). [Google Scholar]

- Research Institute of Highway Ministry of Transport. Test Methods of Soils for Highway Engineering JTG E40-2007; Research Institute of Highway Ministry of Transport: Beijing, China, 2007. (In Chinese) [Google Scholar]

| Materials | Elasticity Modulus/MPa | Poisson Ratio | Void Ratio | Unit Weight/kg·m−3 | Moisture Content/% |

|---|---|---|---|---|---|

| Sand | 18 | 0.3 | 0.39 | 1750 | 10 |

| Sandy soil | 20 | 0.3 | 0.35 | 1750 | 10 |

| Parameters | Volume Mass/kg·L−1 | Water Absorption of 2 h/h | Marsh Funnel Viscosity/Pa·s | Cohesion/N·m−2 | The Slurry Body Strength of 28 d/MPa |

|---|---|---|---|---|---|

| The superfine cement slurry of water–cement ratio 1:1 | 1.53 | <5 | <35 | <4 | >15 |

| The superfine cement slurry of water–cement ratio 2:1 | 1.27 | <6 | <30 | <4 | >12 |

| The Portland cement slurry of water–cement ratio 1:1 | 2.01 | <4 | <40 | <4 | >12 |

| Number of Measuring Points | Dry Density/g·cm−3 | Wet Density/g·cm−3 | Moisture Content/% | Internal Friction Angle/° | Cohesive Force/MPa |

|---|---|---|---|---|---|

| 1 | 1.65638 | 1.75212 | 5.78 | 28.13729 | 0.020 |

| 2 | 1.74422 | 1.88498 | 8.07 | 30.19861 | 0.096 |

| 3 | 1.75676 | 1.95844 | 11.48 | 29.83082 | 0.311 |

| 4 | 1.71426 | 1.95700 | 14.16 | 27.45718 | 0.427 |

| 5 | 1.79678 | 1.93136 | 7.49 | 31.43870 | 0.057 |

| 6 | 1.81562 | 1.98356 | 9.25 | 32.27310 | 0.156 |

| 7 | 1.81380 | 2.05485 | 13.29 | 32.37840 | 0.455 |

| 8 | 1.79696 | 2.11089 | 17.47 | 29.58446 | 0.526 |

| Number of Measuring Points | Dry Density/g·cm−3 | Wet Density/g·cm−3 | Moisture Content/% | Internal Friction Angle/° | Cohesive Force/MPa |

|---|---|---|---|---|---|

| 1 | 1.64114 | 1.73977 | 9.47 | 27.36077 | 0.030 |

| 2 | 1.71798 | 1.85852 | 14.85 | 29.45473 | 0.155 |

| 3 | 1.73059 | 1.90002 | 17.48 | 31.19078 | 0.356 |

| 4 | 1.64623 | 1.90124 | 18.90 | 30.82560 | 0.425 |

| 5 | 1.63017 | 1.76352 | 11.10 | 30.68656 | 0.052 |

| 6 | 1.71464 | 1.88816 | 15.25 | 32.04380 | 0.185 |

| 7 | 1.72052 | 1.98772 | 18.36 | 33.84496 | 0.500 |

| 8 | 1.66338 | 1.96794 | 19.73 | 32.97151 | 0.552 |

| Number of Measuring Points | Dry Density/g·cm−3 | Wet Density/g·cm−3 | Moisture Content/% | Internal Friction Angle/° | Cohesive Force/MPa |

|---|---|---|---|---|---|

| 1 | 1.55026 | 1.69707 | 6.01 | 25.47224 | 0.049 |

| 2 | 1.57527 | 1.80920 | 8.18 | 29.67818 | 0.121 |

| 3 | 1.57653 | 1.85211 | 9.79 | 31.07645 | 0.155 |

| 4 | 1.56531 | 1.86115 | 15.49 | 30.08660 | 0.253 |

| 5 | 1.58581 | 1.76183 | 8.18 | 29.68110 | 0.075 |

| 6 | 1.59846 | 1.84223 | 10.12 | 31.60698 | 0.156 |

| 7 | 1.60663 | 1.90161 | 15.53 | 33.47386 | 0.255 |

| 8 | 1.59604 | 1.91094 | 18.31 | 33.57000 | 0.324 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, W.; Pang, J.; Liu, Y. An Experimental Study of Portland Cement and Superfine Cement Slurry Grouting in Loose Sand and Sandy Soil. Infrastructures 2018, 3, 9. https://doi.org/10.3390/infrastructures3020009

Yao W, Pang J, Liu Y. An Experimental Study of Portland Cement and Superfine Cement Slurry Grouting in Loose Sand and Sandy Soil. Infrastructures. 2018; 3(2):9. https://doi.org/10.3390/infrastructures3020009

Chicago/Turabian StyleYao, Weijing, Jianyong Pang, and Yushan Liu. 2018. "An Experimental Study of Portland Cement and Superfine Cement Slurry Grouting in Loose Sand and Sandy Soil" Infrastructures 3, no. 2: 9. https://doi.org/10.3390/infrastructures3020009

APA StyleYao, W., Pang, J., & Liu, Y. (2018). An Experimental Study of Portland Cement and Superfine Cement Slurry Grouting in Loose Sand and Sandy Soil. Infrastructures, 3(2), 9. https://doi.org/10.3390/infrastructures3020009