Abstract

This study examines the reduction in energy consumption in residential and commercial buildings by utilizing eco-efficient ceramic bricks, converted into building blocks for the construction industry, in light of their significant energy usage and the challenges associated with solid waste management. A ceramic brick composed of zeolite and sugarcane bagasse ash (ZS brick) was selected and simulated as a building block. Such building blocks were used in building design models, and annual building energy simulation was performed by applying different approaches and modes. The results in four different climatic regions in Iran proved that the use of ZS bricks in building envelopes without a thermal insulation layer could lead to a reduction in building energy consumption from 5 to 12.5% compared with conventional fired clay bricks. Also, the use of ZS brick in the layering of the building walls with a thermal insulation layer, compared with conventional fired clay bricks, resulted in an energy consumption reduction from 2.3 to 7.5%.

1. Introduction

The importance and urgency of reducing energy consumption were highlighted by the energy crisis of the early 1970s, which was caused by a significant rise in petroleum prices. This crisis, coupled with the escalating energy consumption resulting from industrial development and population growth, prompted serious consideration of the issue. The buildings and construction sector, known for its high energy usage, accounts for approximately 40% of overall energy consumption and contributes to 36% of total carbon dioxide emissions [1,2,3]. Also, as per the report by the United States Department of Energy (DOE) [4], the residential and commercial building sector has a substantial impact on energy consumption. This sector alone accounts for 76% of total electricity consumption and 40% of greenhouse gas (GHG) emissions in the United States, as stated in the DOE report [4]. It is imperative to make well-informed and comprehensive decisions to attain energy efficiency in buildings, thereby effectively minimizing energy wastage. The implementation of energy efficiency measures not only leads to a reduction in pollutant and greenhouse gas emissions but also plays a significant role in combating climate change and improving global public health [5]. Walls provide a major portion of thermal insulation in modern buildings. An evaluation of the thermal properties of wall materials can be achieved by establishing a relationship between indoor and outdoor environmental temperatures. Understanding the specific heat capacity and thermal conductivity of construction materials is crucial to accurately assessing their thermal characteristics [6,7].

Moreover, the exponential growth of the population, urbanization, industrialization, and various human activities significantly contribute to the release of waste and the demand for construction materials [8,9]. Globally, an approximate annual generation of two billion tons of solid waste has been observed [10]. Therefore, to prevent damage to the environment, waste management must be considered. Meanwhile, lignocellulosic biomass, including sugarcane bagasse (SCB), corn stover, cereal straw, and forest woody residue (such as birch, spruce, and eucalyptus), possess a significant amount of energy that can potentially alleviate the imminent energy crisis [11,12,13]. The substances in question are derived from organic matter which originates from biological sources, with plant biomass being the most significant and abundant repository of sustainable materials worldwide [12,13]. The residue known as SCB is a material that is found in abundance and possesses the capability to tackle the worldwide energy crisis and environmental issues [14]. Global sugarcane production yields an estimated 1.6 billion tons annually, leading to the creation of around 279 million metric tons of sugarcane bagasse (SCB) [15]. Bagasse is used as cogeneration fuel in sugar mills. In the end, SCBA is produced by burning bagasse in a cogeneration boiler [16,17]. Although bagasse is a useful biofuel for cogeneration boilers, there are significant environmental problems when the residual ash is disposed of. Due to the lightweight, fibrous, unburned elements and the material’s striking black color, bagasse ash disposal seriously contaminates neighboring land and water [17]. Using bagasse ash as a partial replacement for cement and bagasse sand as a partial replacement for fine aggregates can help reduce the environmental effects of rock mining and sand extraction in rivers and reservoirs [15,17]. Scanning Electron Microscopy (SEM) was used for the microscopic analysis which revealed that raw SCBA had a tubular structure with increased irregularity and porosity. The material’s microstructure, however, retained its rough and uneven pattern but became denser and more angular following grinding [17,18,19]. The specific gravity of raw SCBA ranges from 1.91 to 2.63. The low specific gravity of raw SCBA is caused by the massively porous microstructure of the carbon-rich particles [17].

As a material with special physical and chemical characteristics, natural zeolite is widely used in many different industries. Because of their remarkable structural properties, considerable porosity, and light composition, natural zeolites are considered effective building materials [17]. They can be effectively used in the manufacturing of porous structural materials with improved thermal insulation qualities [17]. The United States Geological Survey reported in 2014 [20] that 2.8 million tons of natural zeolite minerals are produced worldwide each year. Although global reserves are unknown, they are thought to be substantial. For instance, zeolite deposits in the United States may have estimated probable resources of around 10 trillion tons [20].

Sintered ceramic bricks have recently emerged as a promising technical solution for the recycling of solid wastes [21,22,23]. The feasibility of waste reuse is dependent on its technological, environmental, and economic viability [23,24,25,26,27]. Another issue that arises is the swift depletion of natural clay resources, resulting in scarcities and apprehensions regarding the accessibility of raw materials [28,29]. Therefore, composite bricks should be produced with base materials other than clay and waste additives to reduce the demand for conventional construction clay bricks.

Hence, considerable research is performed globally on fired composite ceramic bricks which are cast on clay or zeolite. The additive part of their composition includes materials such as coconut shell waste [30], rice husk waste [31], Cigarette filters [32], agricultural wastes [33], sawdust [34], Polyethylene terephthalate [35], and Paper pulp residues [36]. In most of the mentioned studies, the thermal characteristics of fired ceramic bricks are not converted into building blocks, and the effect of building blocks on building energy consumption is not studied. Khadija Annaba et al.’s [37] study is one of the few studies that turned the produced bricks into building blocks by using TRISCO software and performed annual building energy simulation by using TRNSYS 16 software. In their study, the thermal characteristics of bricks with multi-layer mortar and light pozzolanic concrete have been identified. After production using TRISCO software, the bricks were converted into sandwich samples and the thermal conductivity of the samples was from 0.42 to 0.68 W/mk. Finally, this product was used in the walls of a building designed in Morocco, and building energy simulation was implemented [37].

To analyze a building’s energy performance, one design parameter can be modified at a time while keeping the rest constant using the one-factor-at-a-time (OFAT) technique. This approach is simple and effective in evaluating different building parameters and can provide a comprehensive understanding of the building’s energy behavior [5].

Based on the reasons stated in the production of ceramic composite bricks regarding the importance of using clay substitutes, the present study has chosen composite ceramic brick consisting of zeolite as the base material and sugarcane bagasse ash (SCBA) as the additive (ZS brick) [17]. Then, by applying equations, the thermal characteristics of the ceramic bricks become the thermal characteristics of the building blocks. Also, after converting the ceramic composite brick into a building block, a building model is drawn that uses this block in its walls, and annual building energy simulation is performed for it. Finally, the simulated model is compared with a similar building model whose walls are made of conventional fired clay bricks and for which annual building energy simulation has been performed, and the effect of the produced block on energy efficiency is determined.

Additionally, a new method for converting the thermal and dimensional properties of ceramic bricks to the thermal and dimensional properties of building blocks is described. Accordingly, the developed ceramic composite brick transforms into a building block for the first time. The mentioned block is used for building walls and annual building energy simulation. Two main approaches and a secondary approach are carried out to compare the simulated building models. Considering the high volume of SCBA production, as well as the need for improving energy efficiency and reducing energy consumption, new innovative bricks can be promising choices for the construction industry. It is worth noting that buildings are an important component of a country’s infrastructure and play a significant role in this area. Therefore, from an environmental point of view, producing eco-efficient bricks and applying them in the building sector to boost building energy efficiency might result in the construction of more efficient buildings.

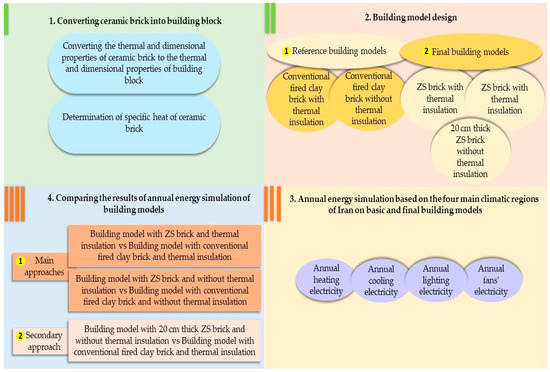

Figure 1 shows the framework of the present study.

Figure 1.

Framework of present study.

2. Materials and Methods

2.1. Converting Ceramic Bricks into Building Blocks

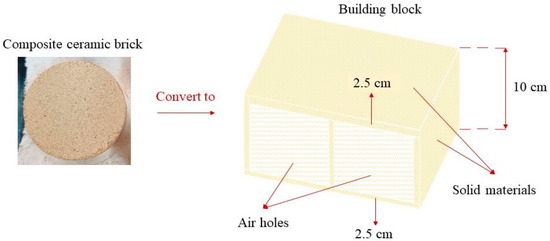

Building blocks are usually hollow. Accordingly, it was intended to change the dimensions and thermal characteristics of ceramic bricks to the dimensions and thermal characteristics of such blocks with holes. The measured thermal conductivity of the ceramic brick does not change with the change in the thickness of the sample. However, the change in thickness causes a change in the thermal resistance [38]. As a result, thermal conductivity is improved by placing the trapped air layer between the two layers of solid brick materials. Figure 2 shows the schematic of converting ceramic brick into a building block. According to ASHRAE HANDBOOK FUNDAMENTALS [39], the thermal resistance of the air layer trapped between two solid layers of the outer shell wall is equal to 0.15 m2k/W. Also, the thermal resistance is equal to the inverse of the thermal conductivity multiplied by the thickness of the sample [40]. The thermal conductivity of the selected ceramic brick that researchers produced in Iran is equal to 0.89 W/mk [17]. Therefore, in this way, the thermal resistance of this selected ceramic brick can be obtained.

Figure 2.

Schematic of converting ceramic brick into building block.

As a result, with the help of Equations (1)–(4), the laboratory sample (sintered ceramic brick) can be converted into the building block used in the building.

2.2. Determination of Specific Heat

One of the properties of brick that is given as an input to the building energy simulation software is specific heat. In the realm of thermodynamics, the calculation of a substance’s specific heat capacity (c) involves dividing the heat capacity of a substance sample by its mass. This quantity is commonly referred to as the specific heat and represents the quantity of heat required to raise the temperature of one unit of mass of the substance by one unit. The standard unit of measurement for specific heat capacity is Joule per Kelvin per kilogram in the International System of Units (SI) [41]. The specific heat capacity examination used employs a combination of techniques. The mixture method is widely adopted by researchers as a convenient, straightforward, and moderately precise approach to determine the specific heat of a solid specimen [41]. This test is carried out with the help of a laboratory calorimeter. After the test, the specific heat capacity of the ceramic brick can be obtained with the help of the law of energy exchange. Also, specific heat capacity is a compact property of a substance, an intrinsic property that does not depend on the size or shape of the quantity in question [42]. As a result, according to the law of conservation of energy, Equations (5) and (6) can be written.

Q1 + Q2 + Q3 = 0

The heat capacity of the calorimeter (C) is equal to 253.53 J/K. As a result, the specific heat capacity (c2) of ceramic brick is obtained by knowing the difference in temperature and weights and with the help of the equations.

2.3. Building Energy Simulation

In this study, the simulation was carried out using EnergyPlus V23.1.0 software developed by the US Department of Energy (DOE) [4]. EnergyPlus is a comprehensive software tool designed for simulating the energy usage of entire buildings. It performs calculations to determine the required heating and cooling loads for maintaining desired thermal control set points within a secondary HVAC system. Additionally, EnergyPlus evaluates the energy consumption of the primary plant equipment involved in the building’s operation [5]. EnergyPlus is an independent simulation program that lacks a user-friendly visual interface. Within EnergyPlus, the process of providing inputs and obtaining outputs is accomplished through the utilization of text files [5].

2.4. The Implementation of the Annual Building Energy Simulation: A Case Study

Building Models

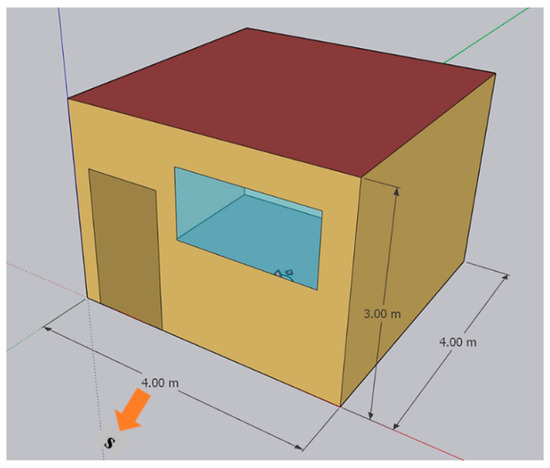

After converting the ceramic brick into a building block, a building model should be designed. For this purpose, a simple model design was drawn in SketchupPro.2021.v21.1.332 software, and due to the lack of a user-friendly visual interface in EnergyPlus software, the Open Studio plugin was used in Sketchup software to define and assign materials to the designed model. Finally, the output model was taken for use in the EnergyPlus software so that the energy simulation process was performed for it. The duration of the building energy simulation is one year. The drawn model is a one-story building with residential use which consists of a thermal zone. Figure 3 shows the drawn architectural model. As seen in Figure 3, four sides of the building are exposed to sunlight (full radiation on the outside and inside of the building) and outside air. The angle of the building with the baseline to the north is 0° and the building is in the north direction.

Figure 3.

Schematic of designed model of building.

The length, width, and height of the designed model are 4, 4, and 3 m, respectively. This model has a transparent double-glazed window that consists of two 6 mm thick transparent glass panes with a 6 mm thick layer of air between them, and the window frame is vinyl frame. Overhang shade and blinds are not considered for this model. Also, the area of the window is 2 m2. Assuming the presence of a packaged terminal heat pump (PTHP) air-conditioning system in the building, with a coefficient of performance of 3 in the heating mode and 2.75 in the cooling mode, the designated heating and cooling set points are 22 °C and 26 °C, respectively. This room is equipped with a 25 W lamp lighting system and its schedule is set to be off from 12:00 p.m. to 7:00 a.m. and then it can be on for 17 h a day. Furthermore, the model includes a daylighting controller sensor that efficiently reduces the intensity of the lighting system when the illuminance reaches a threshold of 500 lux. This functionality guarantees that once the illuminance exceeds 500 lux, which is considered adequate to eliminate the necessity for artificial lighting, the lighting system is promptly deactivated [5]. In this study, to concentrate more on the thermal load caused by the external walls of the designed model, occupants and infiltration loads have not been considered.

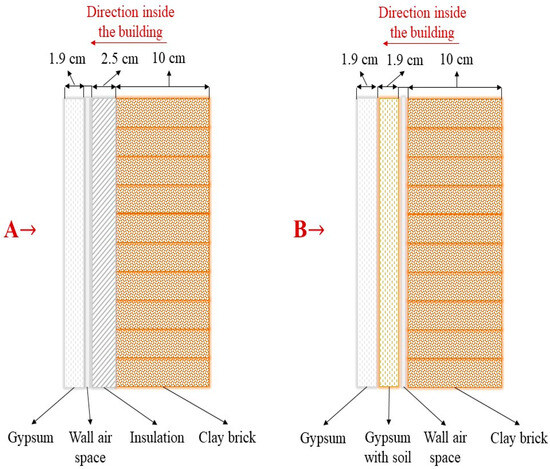

Two reference models are considered in this study; the first is a model designed in which there is thermal insulation in the walls, and the second is a model designed in which there is no thermal insulation in the layering of the walls. All of the characteristics of the energy simulation and the definition and allocation of materials are equal in the two reference models and only the layering of their walls is different. Figure 4A,B show the schematic of the layering of the walls with thermal insulation and the walls without insulation, respectively. Also, Table 1 and Table 2 show, respectively, the properties of the enveloping materials of the model with thermal insulation and the model without thermal insulation.

Figure 4.

Schematic cross-section of wall layering (A) with thermal insulation and (B) without thermal insulation.

Table 1.

Properties of envelope materials of reference model with thermal insulation.

Table 2.

Properties of envelope materials of reference model without thermal insulation.

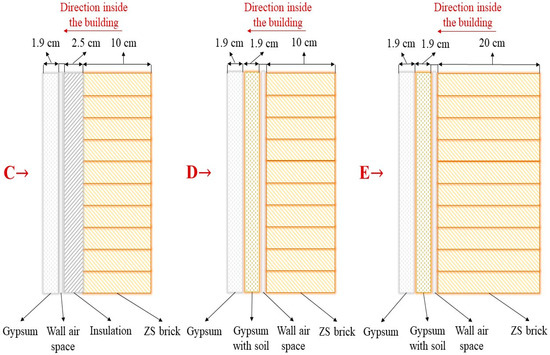

As can be seen in Figure 5, in this study, three final models are included: C—a wall consisting of 10 cm thick ZS brick with thermal insulation, D—a wall consisting of 10 cm thick ZS brick without thermal insulation, and E—a wall consisting of 20 cm thick ZS bricks without thermal insulation. In all three final models, the design and architectural features are similar to the reference models, and their energy simulation inputs are also similar to the reference models. The only difference is in the layering of the walls of the final models compared with the reference models. Also, Table 3, Table 4 and Table 5 show the properties of the enveloping materials of the three final models.

Figure 5.

Schematic cross-section of wall layering consisting of ZS bricks (C) with thermal insulation and (D) without thermal insulation and (E) 20 cm thick ZS bricks without thermal insulation.

Table 3.

Properties of envelope materials of final model with thermal insulation.

Table 4.

Properties of envelope materials of final model without thermal insulation.

Table 5.

Properties of envelope materials of final model (20 cm thick ZS bricks) without thermal insulation.

Three approaches to calculate and compare the annual building energy simulation were used. The first approach was to compare the annual electricity consumption of the final building model C (with a wall consisting of 10 cm thick ZS bricks with thermal insulation) with the reference building model A (with a wall consisting of 10 cm thick clay bricks with thermal insulation). The second approach was to compare the annual electricity consumption of the final building model D (with a wall consisting of 10 cm thick ZS bricks without thermal insulation) with the reference building model B (with a wall consisting of 10 cm thick clay bricks without thermal insulation). The last approach was to compare the annual electricity consumption of the final building model E (with a wall consisting of 20 cm thick ZS bricks without thermal insulation) with the reference building model A (with a wall consisting of 10 cm thick clay bricks with thermal insulation). Also, in each model, the annual building energy simulation of the four below-mentioned cities with different weather climates in Iran has been investigated.

2.5. Main Climates of Iran

Iran, situated in the Middle East, spans approximately 1,648,000 square kilometers and is positioned between latitudes 24° and 40° N and longitudes 44° and 64° E. The weather conditions in Iran can be classified into four primary climate regions, namely cold, mild, warm–dry, and warm–humid [5,43]. The current study has chosen Tabriz, Tehran, Isfahan, and Bandar Abbas as the cities that represent the respective climates. The geographical features of these cities are presented in Table 6 [5]. The weather data files (.epw) utilized in the simulations are sourced from the database of the U.S. Department of Energy Building Technologies Office (BTO) in this study [44].

Table 6.

Characteristics of representative cities [5].

3. Results

3.1. Thermal Conductivity of Building Block

Using the provided equations, the thermal conductivity of ceramic brick after converting it into a building block is equal to 0.48 W/mk.

3.2. Specific Heat of Building Block

According to the mentioned equations, the specific heat of ceramic brick is equal to 2571.8 J/kgk.

3.3. Annual Building Energy Simulation for All Approaches

Table 7 shows the results of the annual building energy simulation for four different climates of Iran and is based on the amount of energy consumed in each sector. Also, the difference between each approach can be seen in Table 7.

Table 7.

Results of annual building energy simulation for four different climates of Iran.

4. Discussion

The annual fans’ electricity is consumed when the air-conditioning system detects that it is directing the outside air into the model for air circulation; the resulting electricity consumption is the annual fans’ electricity. As can be seen in Table 7, in all simulated models in all climates (city), the amount of electricity consumed due to lighting inside the building space is equal.

According to Table 7, the use of new brick (ZS) in all approaches and cities improved the results of electrical energy consumption, which is due to the reduction in energy loss from the walls of the building. The improvement rate of total electricity energy consumption was in the range from 2.3 to 12.5%. Based on the results of Table 7, electricity consumption due to heating production was higher than electricity consumption due to cooling production in all of the simulated models in Tabriz city, which was due to the cold climate of this city. The other side is Bandar Abbas city, where due to the warm–humid climate of this city, electricity consumption from cooling production was much higher than electricity consumption from heating production. As can be seen for the cities of Isfahan and Tehran, electricity consumption due to the production of heating and cooling was almost equal, which is due to the warm–dry and mild climate of these cities, respectively. Also, Isfahan and Tehran had the lowest total electricity consumption in all of the simulated models when compared to the rest of the cities.

According to the results exhibited in Table 7, the comparison approach between models D and B compared to the comparison approach between models C and A had more significant changes in all cities. This is because in the approach comparing models D and B, these models do not use insulation in their wall layering, and the thermal resistance of these walls is lower than of the walls of the approach comparing models C and A. This indicates that in the approach comparing models D and B, the bricks made a greater contribution to the thermal resistance of the walls. Also, the approach comparing models E and A was adopted to compare total electricity consumption between the model consisting of 20 cm thick ZS brick in the wall without thermal insulation and the model consisting of 10 cm thick clay brick in the wall with thermal insulation. The improvement rate of total electricity consumption in this approach was negative and ranged from −3.9 to −16.1%.

According to ASHRAE HANDBOOK FUNDAMENTALS [39], the bulk density and thermal conductivity of conventional fired clay brick are 1920 kg/m3 and 0.895 W/mk, respectively. Therefore, the significant difference in thermal conductivity between ZS bricks and conventional clay bricks accounts for the reduction in electrical energy consumption in the two main approaches to comparing the models. Additionally, ZS brick has a bulk density of 1300 kg/m3 [17]. Because it is less dense than conventional clay brick, it can reduce the dead load of a building, which in turn can reduce the cross-sections of the beams and columns and the amount of steel and concrete used in the building structure.

Other products used in the construction industry include conventional heavy concrete blocks and modern lightweight concrete blocks. According to ASHRAE HANDBOOK FUNDAMENTALS [39], the bulk density and thermal conductivity of conventional heavy concrete blocks are 2210 kg/m3 and 1.13 W/mk, respectively, and the bulk density and thermal conductivity of modern lightweight concrete blocks are 512 kg/m3 and 0.49 W/mk, respectively. Compared to conventional heavy concrete blocks, ZS bricks have significant advantages in all three aspects: bulk density, thermal conductivity, and the use of environmentally friendly and recycled constituent materials. Compared to modern lightweight concrete blocks, ZS bricks have a higher bulk density and the same thermal conductivity, but in return, they benefit from better constituent materials from an environmental perspective.

5. Conclusions

The main goals of this study, which includes the use of new innovative bricks compatible with the environment in a building and reducing the energy loss of the building, have been achieved. The general results of this study include the following:

Considering the high volume of waste types and the high number of creative and eco-friendly ceramic bricks in research, a solution is presented in this study which converts the ceramic brick into a hollow building block that reduces the thermal conductivity of the brick. With this approach and by obtaining the specific heat of ceramic bricks, many building blocks can be prepared for use in building models, and then building energy simulation can be performed for them.

The results show that the use of ZS brick compared to conventional fired clay brick can reduce the consumption of electrical energy in the model of buildings where thermal insulation is used in the layering of the walls. As a result, the cities of Isfahan and Tehran had the best results, at 7.5% and 7.1%, respectively, compared to the other cities.

In Iran, most buildings do not have thermal insulation in their walls. As a result, the second approach in this study was developed for this purpose. As the results of this approach show, the use of ZS bricks has a significant effect on the reduction in electricity consumption compared to conventional fired clay bricks, with the greatest effect on the building models of Isfahan and Tehran, leading to reductions of 12.5% and 12%, respectively.

Based on the findings from the two main approaches, it has been concluded that there is less variation in the reduction in electricity consumption in cold and hot–humid regions when comparing the base building model and the final building model than there is in mild and warm–dry regions. This is because Bandar Abbas is one of the warmest places in the world and Tabriz is one of the coldest. The significant temperature difference between the interior and exterior of the building causes greater heat and cooling loss, which in turn increases the amount of electricity used.

The third approach was to use 20 cm thick ZS brick in the wall without thermal insulation to replace clay brick with thermal insulation, thus eliminating thermal insulation. The results show that this approach can be used in the cities of Bandar Abbas and Tehran, only causing a small increase in electricity consumption, but it is difficult to use this approach in the cities of Isfahan and especially Tabriz.

Author Contributions

M.K.F.: investigation, methodology, validation, formal analysis, and writing—original draft, review, and editing. S.M.: supervision, validation, reviewing, and editing. M.A.: electrical energy advising, validation, reviewing, and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding. The authors are waived from Article Processing fee payment by the journal.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Abbreviations

| R | thermal resistance (m2k/W) |

| K | thermal conductivity (W/mk) |

| L | thickness of material around the holes (m) |

| Q | heat energy (J) |

| U | thermal transmittance coefficient (W/m2k) |

| c | specific heat (J/kg.k) |

| C | heat capacity (J/k) |

| ∆θ | change in temperature (k) |

| R1 | thermal resistance of solid materials |

| R2 | thermal resistance of trapped air |

| Q1 | heat energy of calorimeter |

| Q2 | heat energy of water |

| Q3 | heat energy of ceramic brick |

| c1 | water specific heat capacity |

| c2 | ceramic brick specific heat capacity |

| m1 | weight of water |

| m1 | weight of ceramic brick |

References

- Tian, W.; Song, J.; Li, Z.; de Wilde, P. Bootstrap techniques for sensitivity analysis and model selection in building thermal performance analysis. Appl. Energy 2014, 135, 320–328. [Google Scholar] [CrossRef]

- Sanchez, D.G.; Lacarriere, B.; Musy, M.; Bourges, B. Application of sensitivity analysis in building energy simulations: Combining first-and second-order elementary effects methods. Energy Build. 2014, 68, 741–750. [Google Scholar] [CrossRef]

- Ferrara, M.; Fabrizio, E.; Virgone, J.; Filippi, M. A simulation-based optimization method for cost-optimal analysis of nearly Zero Energy Buildings. Energy Build. 2014, 84, 442–457. [Google Scholar] [CrossRef]

- Doe, U. An Assessment of Energy Technologies and Research Opportunities. Quadrennial Technology Review; United States Department of Energy: Washington, DC, USA, 2015; pp. 12–19.

- Delgarm, N.; Sajadi, B.; Delgarm, S.; Kowsary, F. A novel approach for the simulation-based optimization of the buildings energy consumption using NSGA-II: Case study in Iran. Energy Build. 2016, 127, 552–560. [Google Scholar] [CrossRef]

- Raut, A.N.; Gomez, C.P. Utilization of waste as a constituent ingredient for enhancing thermal performance of bricks—A review paper. Indian J. Sci. Technol. 2016, 9, 1–12. [Google Scholar]

- Vijayan, D.; Mohan, A.; Revathy, J.; Parthiban, D.; Varatharajan, R. Evaluation of the impact of thermal performance on various building bricks and blocks: A review. Environ. Technol. Innov. 2021, 23, 101577. [Google Scholar] [CrossRef]

- Munir, M.J.; Kazmi, S.M.S.; Gencel, O.; Ahmad, M.R.; Chen, B. Synergistic effect of rice husk, glass and marble sludges on the engineering characteristics of eco-friendly bricks. J. Build. Eng. 2021, 42, 102484. [Google Scholar] [CrossRef]

- Goel, G.; Vasić, M.V.; Katiyar, N.K.; Kirthika, S.; Pezo, M.; Dinakar, P. Potential pathway for recycling of the paper mill sludge compost for brick making. Constr. Build. Mater. 2021, 278, 122384. [Google Scholar] [CrossRef]

- Rehman, M.U.; Ahmad, M.; Rashid, K. Influence of fluxing oxides from waste on the production and physico-mechanical properties of fired clay brick: A review. J. Build. Eng. 2020, 27, 100965. [Google Scholar] [CrossRef]

- Yin, C.-Y. Prediction of higher heating values of biomass from proximate and ultimate analyses. Fuel 2011, 90, 1128–1132. [Google Scholar] [CrossRef]

- Ajala, E.O.; Olonade, Y.O.; Ajala, M.A.; Akinpelu, G.S. Lactic acid production from lignocellulose—A review of major challenges and selected solutions. ChemBioEng Rev. 2020, 7, 38–49. [Google Scholar] [CrossRef]

- Ajala, E.; Ighalo, J.; Ajala, M.; Adeniyi, A.; Ayanshola, A. Sugarcane bagasse: A biomass sufficiently applied for improving global energy, environment and economic sustainability. Bioresour. Bioprocess. 2021, 8, 87. [Google Scholar] [CrossRef]

- Scaramucci, J.A.; Perin, C.; Pulino, P.; Bordoni, O.F.; Da Cunha, M.P.; Cortez, L.A. Energy from sugarcane bagasse under electricity rationing in Brazil: A computable general equilibrium model. Energy Policy 2006, 34, 986–992. [Google Scholar] [CrossRef]

- Chandel, A.K.; da Silva, S.S.; Carvalho, W.; Singh, O.V. Sugarcane bagasse and leaves: Foreseeable biomass of biofuel and bio-products. J. Chem. Technol. Biotechnol. 2012, 87, 11–20. [Google Scholar] [CrossRef]

- Katare, V.D.; Madurwar, M.V. Experimental characterization of sugarcane biomass ash—A review. Constr. Build. Mater. 2017, 152, 1–15. [Google Scholar] [CrossRef]

- Kamalabadi Farahani, M.; Mirvalad, S.; Azimizadeh, M. Natural zeolite composite bricks containing sugarcane bagasse ash: An innovative sustainable construction material. J. Mater. Cycles Waste Manag. 2024, 27, 544–557. [Google Scholar] [CrossRef]

- Bubalo, A.; Vouk, D.; Stirmer, N.; Nad, K. Use of Sewage Sludge Ash in the Production of Innovative Bricks—An Example of a Circular Economy. Sustainability 2021, 13, 9330. [Google Scholar] [CrossRef]

- Mohammadi, F.; Abdoli, M.; Amidpour, M.; Vahidi, H.; Gitipour, S. Environmental-economic evaluation of sugar cane bagasse gasification power plants versus combined-cycle gas power plants. Glob. J. Environ. Sci. Manag. 2020, 6, 73–84. [Google Scholar]

- U.S. Geological Survey. Mineral Commodity Summaries 2014; U.S. Geological Survey: Reston, VA, USA, 2014; p. 184. [CrossRef]

- Reinosa, J.; Silva, A.; Rubio-Marcos, F.; Mello-Castanho, S.; Moya, J.; Fernandez, J. High chemical stability of stoneware tiles containing waste metals. J. Eur. Ceram. Soc. 2010, 30, 2997–3004. [Google Scholar] [CrossRef]

- Shakir, A.A.; Mohammed, A.A. Manufacturing of Bricks in the Past, in the Present and in the Future: A state of the Art Review. Int. J. Adv. Appl. Sci. 2013, 2, 145–156. [Google Scholar] [CrossRef]

- Ibrahim, J.E.F.; Kotova, O.B.; Sun, S.; Kurovics, E.; Tihtih, M.; Gömze, L.A. Preparation of innovative eco-efficient composite bricks based on zeolite-poor rock and Hen’s eggshell. J. Build. Eng. 2022, 45, 103491. [Google Scholar] [CrossRef]

- Mymrin, V.; Alekseev, K.; Catai, R.E.; Nagalli, A.; Aibuldinov, Y.K.; Bekturganov, N.S.; Rose, J.L.; Izzo, R.L. Red ceramics from composites of hazardous sludge with foundry sand, glass waste and acid neutralization salts. J. Environ. Chem. Eng. 2016, 4, 753–761. [Google Scholar] [CrossRef]

- Wiemes, L.; Pawlowsky, U.; Mymrin, V. Incorporation of industrial wastes as raw materials in brick’s formulation. J. Clean. Prod. 2017, 142, 69–77. [Google Scholar] [CrossRef]

- Kocserha, I.; Gömze, L.A.; Kristály, F.; Géber, R.; Győrffy, B. Effect of organic additives on friction properties of clay based compounds. Mater. Sci. Forum 2013, 729, 403–408. [Google Scholar] [CrossRef]

- Sutcu, M.; Erdogmus, E.; Gencel, O.; Gholampour, A.; Atan, E.; Ozbakkaloglu, T. Recycling of bottom ash and fly ash wastes in eco-friendly clay brick production. J. Clean. Prod. 2019, 233, 753–764. [Google Scholar] [CrossRef]

- Karayannis, V. Development of extruded and fired bricks with steel industry byproduct towards circular economy. J. Build. Eng. 2016, 7, 382–387. [Google Scholar] [CrossRef]

- Munir, M.J.; Kazmi, S.M.S.; Wu, Y.-F.; Hanif, A.; Khan, M.U.A. Thermally efficient fired clay bricks incorporating waste marble sludge: An industrial-scale study. J. Clean. Prod. 2018, 174, 1122–1135. [Google Scholar] [CrossRef]

- Moujoud, Z.; Harrati, A.; Manni, A.; Naim, A.; El Bouari, A.; Tanane, O. Study of fired clay bricks with coconut shell waste as a renewable pore-forming agent: Technological, mechanical, and thermal properties. J. Build. Eng. 2023, 68, 106107. [Google Scholar] [CrossRef]

- Eliche-Quesada, D.; Felipe-Sesé, M.; López-Pérez, J.; Infantes-Molina, A. Characterization and evaluation of rice husk ash and wood ash in sustainable clay matrix bricks. Ceram. Int. 2017, 43, 463–475. [Google Scholar] [CrossRef]

- Kurmus, H.; Mohajerani, A. Recycling of cigarette butts in fired clay bricks: A new laboratory investigation. Materials 2020, 13, 790. [Google Scholar] [CrossRef]

- Bánhidi, V.; Gömze, L.A. Improvement of insulation properties of conventional brick products. Mater. Sci. Forum 2008, 589, 1–6. [Google Scholar] [CrossRef]

- Ibrahim, J.E.F.; Tihtih, M.; Gömze, L.A. Environmentally-friendly ceramic bricks made from zeolite-poor rock and sawdust. Constr. Build. Mater. 2021, 297, 123715. [Google Scholar] [CrossRef]

- Akinyele, J.; Igba, U.; Adigun, B. Effect of waste PET on the structural properties of burnt bricks. Sci. Afr. 2020, 7, e00301. [Google Scholar] [CrossRef]

- Muñoz, P.; Letelier, V.; Zamora, D.; Morales, M. Feasibility of using paper pulp residues into fired clay bricks. J. Clean. Prod. 2020, 262, 121464. [Google Scholar] [CrossRef]

- Annaba, K.; El Wardi, F.Z.; Ibaaz, K.; Bouyahyaoui, A.; Cherkaoui, M.; Ouaki, B.; Oubenmoh, S. Thermomechanical characterization and thermal simulation of a new multilayer mortar and a light-weight pozzolanic concrete for building energy efficiency. Constr. Build. Mater. 2022, 346, 128479. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Fundamentals, A.H. American Society of Heating; Refrigerating and Air-Conditioning Engineers: Peachtree Corners, GA, USA, 2005. [Google Scholar]

- Mishra, R.; Militky, J.; Venkataraman, M. 7-Nanoporous materials. In Nanotechnology in Textiles; Mishra, R., Militky, J., Eds.; Woodhead Publishing: Sawston, UK, 2019; pp. 311–353. [Google Scholar]

- Halliday, D.; Resnick, R.; Walker, J. Fundamentals of Physics; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Mills, I. Quantities, Units and Symbols in Physical Chemistry; Blackwell Science: Oxford, UK; Boston, MA, USA; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- Bagheri, F.; Mokarizadeh, V.; Jabbar, M. Developing energy performance label for office buildings in Iran. Energy Build. 2013, 61, 116–124. [Google Scholar] [CrossRef]

- U.S. Department of Energy Building Technologies Office. EnergyPlus Weather Data Sources. Available online: https://energyplus.net/weather/sources (accessed on 1 January 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).