Study on the Ablation of Slide Plate by Pantograph–Catenary Arc Based on Pantograph Slide Material

Abstract

1. Introduction

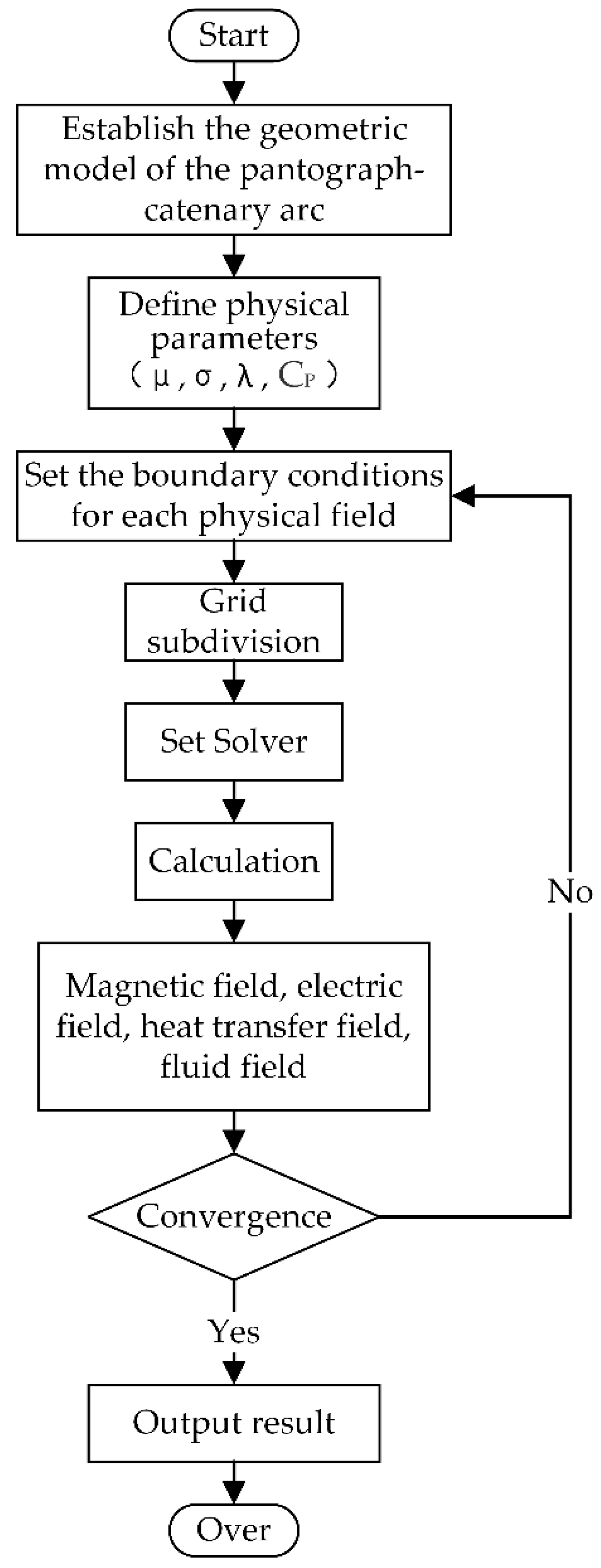

2. Pantograph–Catenary Model Development

2.1. Assumed Properties

- (1)

- The initiation of the arc was not included in the simulation. A stable arc was assumed to be present at the start of the analysis.

- (2)

- The arc plasma was assumed to satisfy local thermal equilibrium.

- (3)

- The arc plasma was assumed to be electrically neutral, and its physical properties were assumed to vary with temperature.

- (4)

- Space charge near the electrodes was neglected, and the electrode sheath was assumed to have no influence on arc formation.

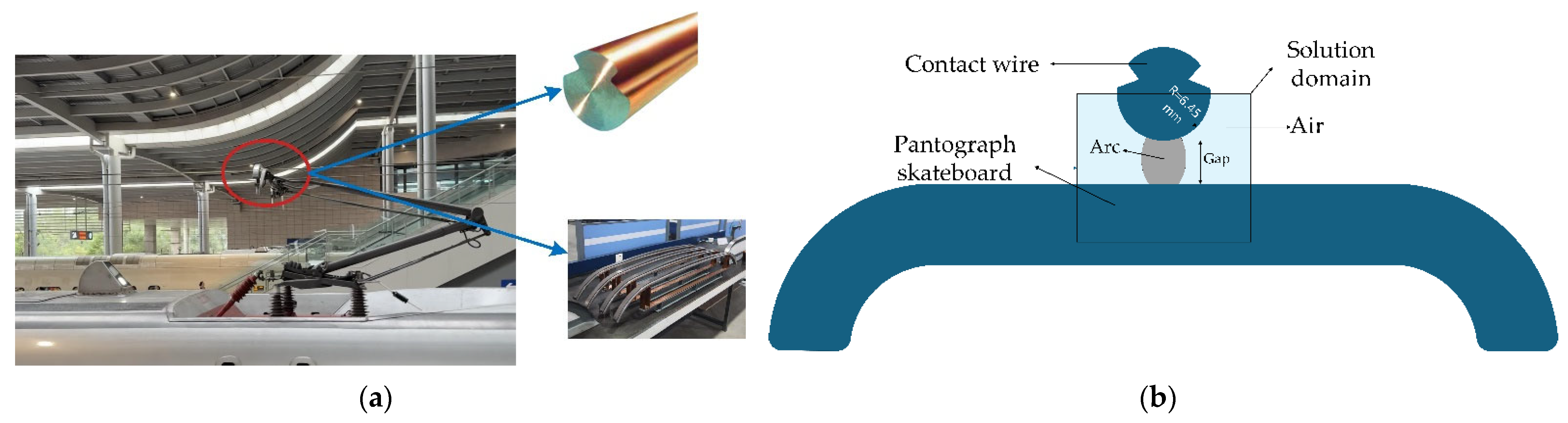

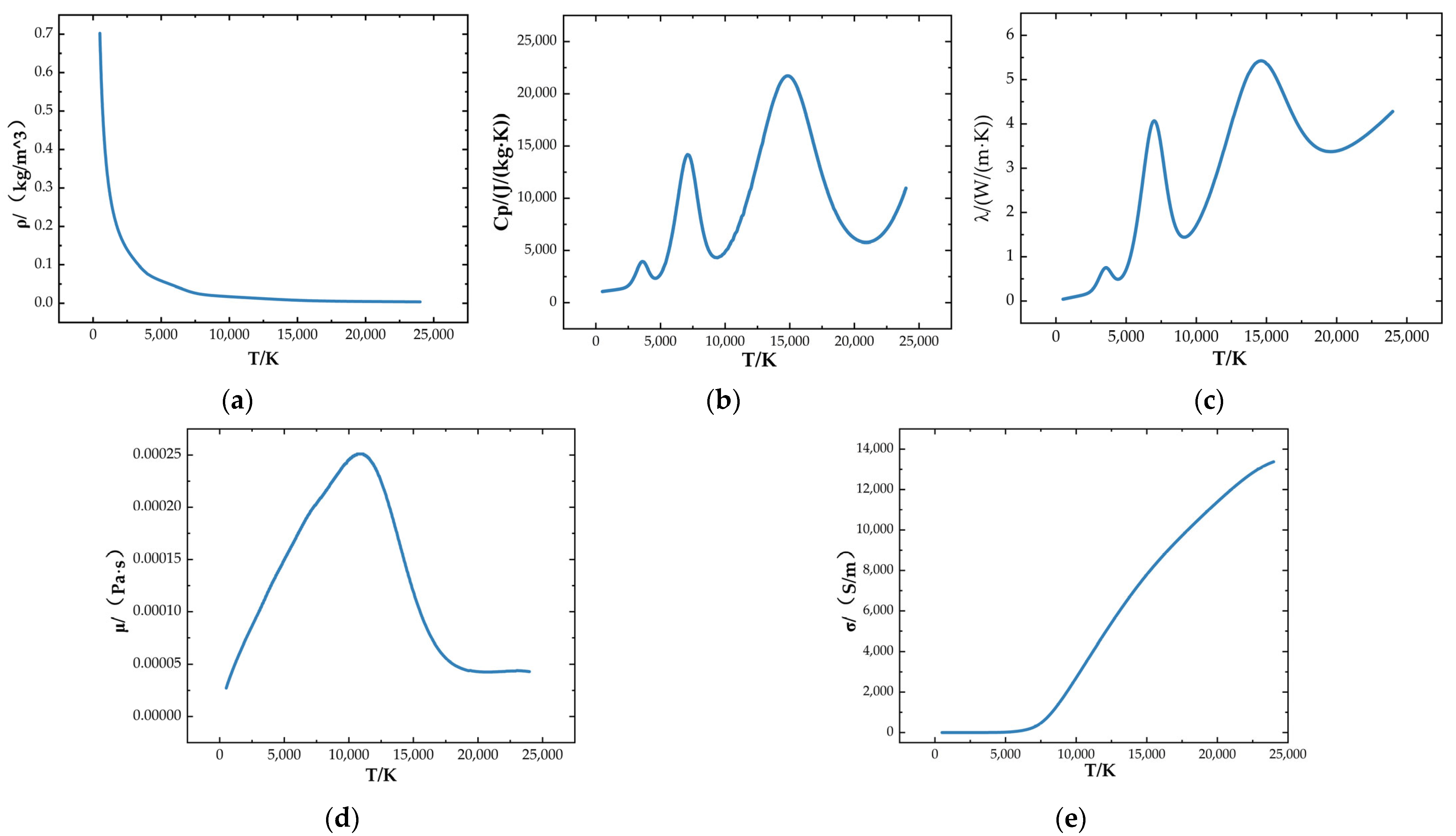

2.2. Pantograph–Catenary Arc Model

2.3. Establishment of the Pantograph–Catenary Geometric Model

3. Governing Equations

3.1. MHD Model

3.2. Surface Ablation Model

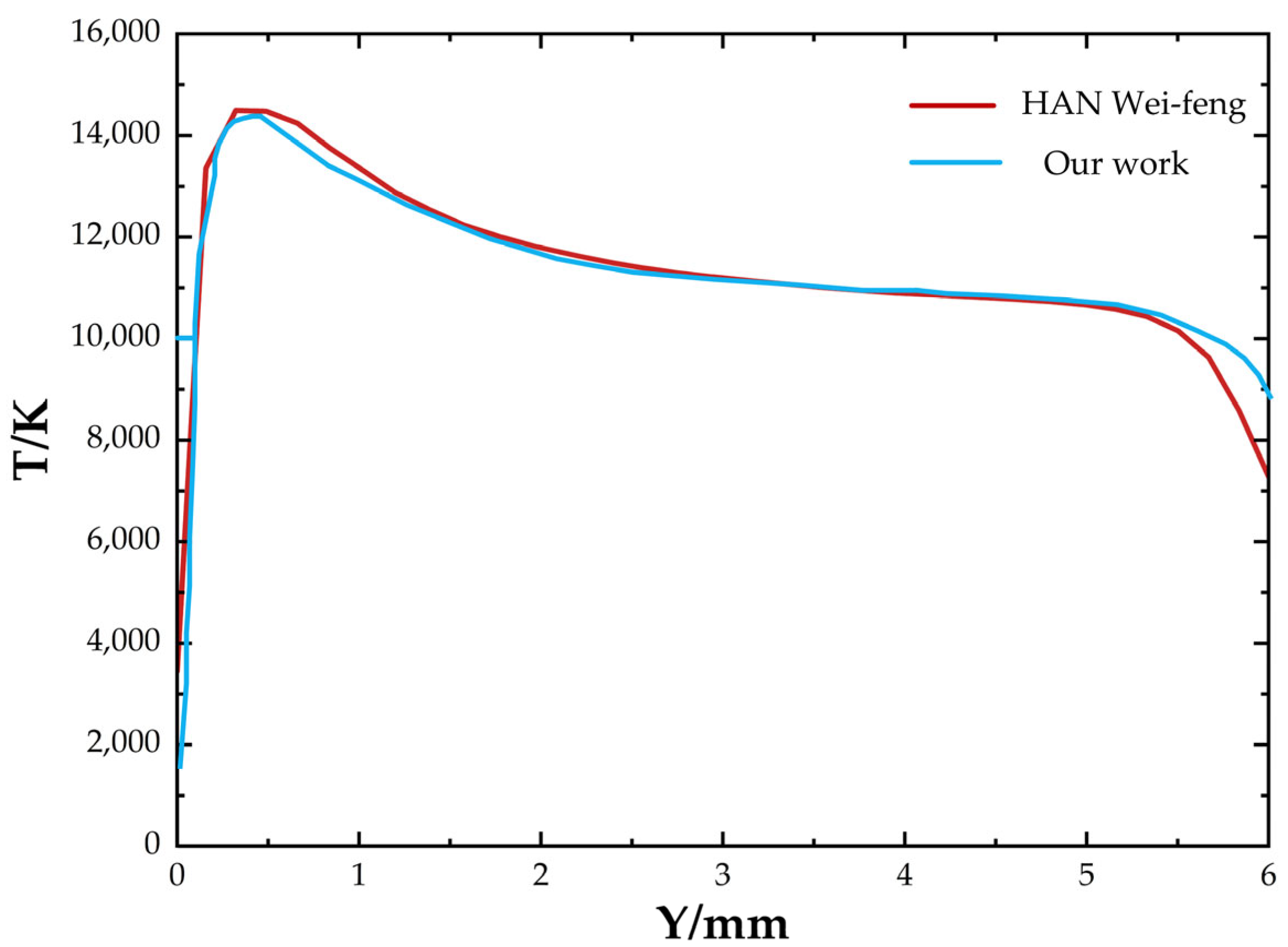

4. Model Validity Verification

5. Simulation and Results Analysis

5.1. Boundary Condition Settings

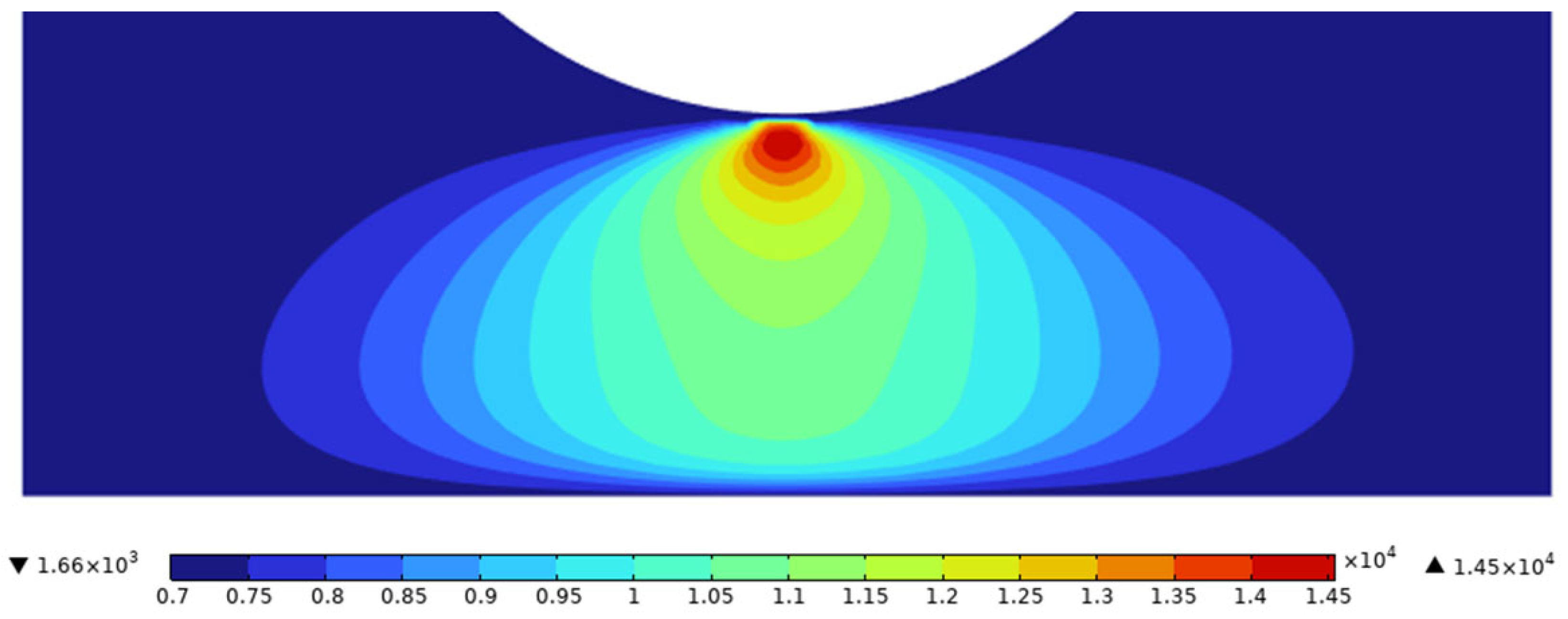

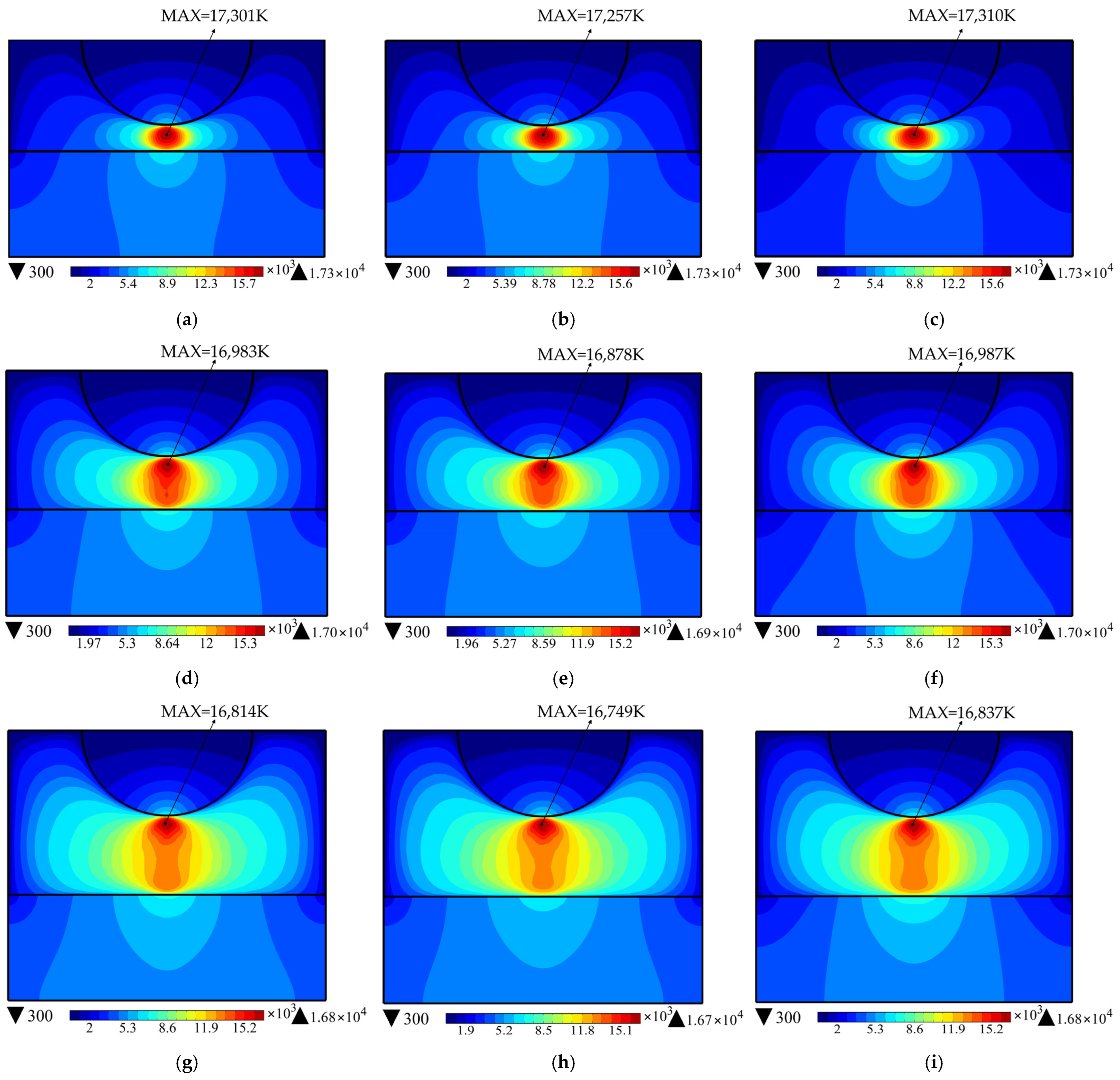

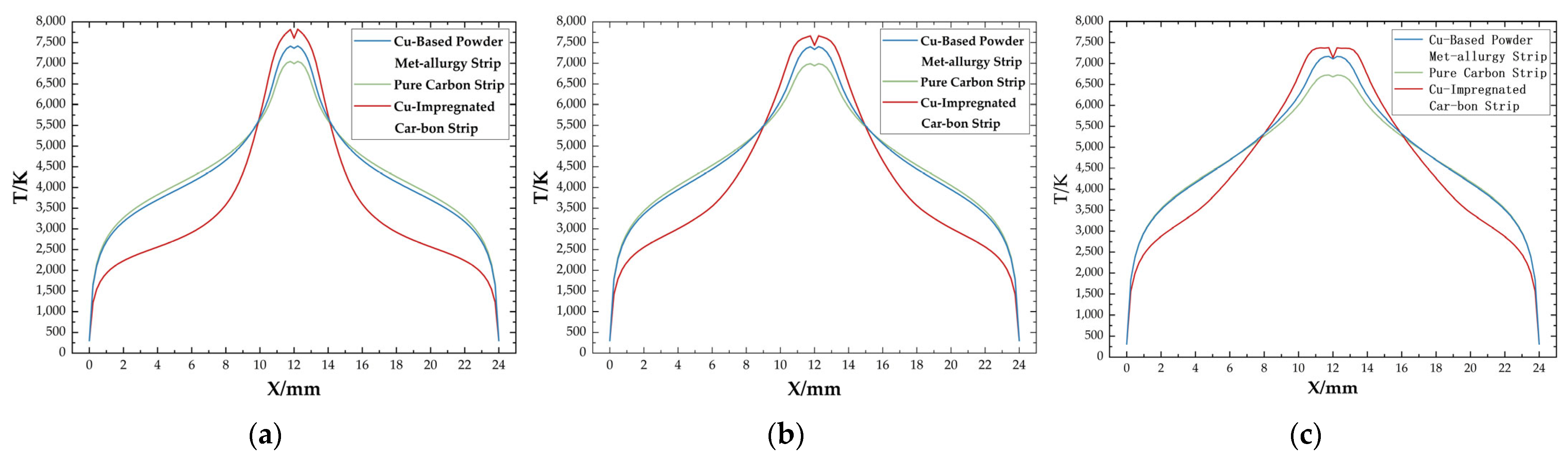

5.2. Effects of Pantograph–Catenary Distance and Collector Strip Material on Arc Temperature Distribution

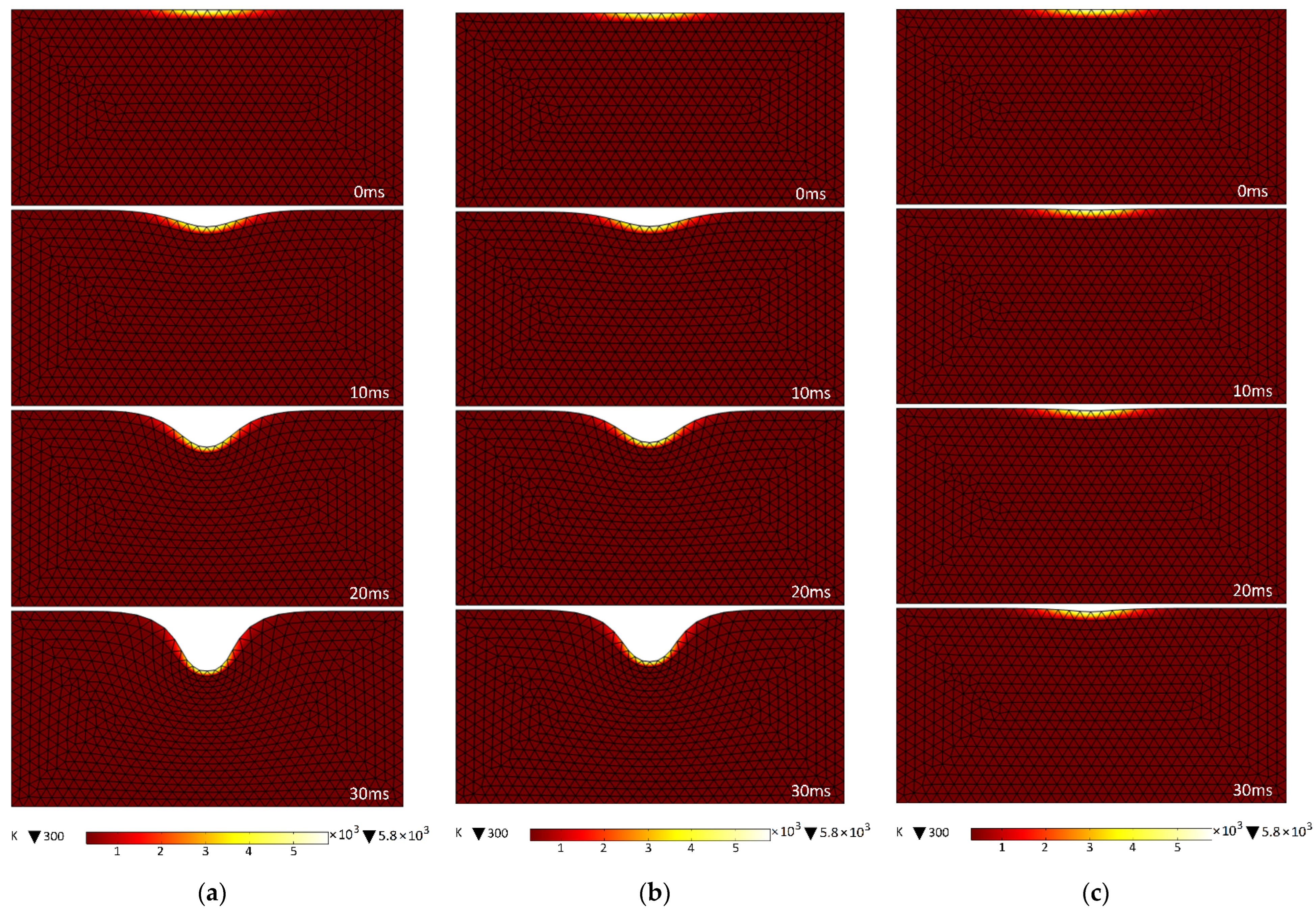

5.3. Effect of Different Slider Materials on Slider Ablation

5.4. Effect of Latent Heat of Sublimation on Slider Ablation

6. Conclusions

- (1)

- The simulation revealed the symmetric distribution characteristic of the pantograph–catenary arc temperature, with the highest arc column temperature reaching 16,800 K, peaking near the catenary. The maximum slider surface temperature was 7170 K, and the high temperature caused material loss and changes in the surface morphology. These findings demonstrated that the high temperatures of the arc had a significant ablation effect on the material, providing key insights for material optimization design.

- (2)

- As the pantograph–catenary gap increased, the shape of the arc transformed from an elliptical to a spindle shape, and the highest temperatures at both the arc center and the slider surface decreased. The slider material had a significant impact on the arc and slider surface temperatures. The copper-impregnated carbon slider exhibited the highest temperature, followed by the copper-based powder metallurgy slider, and the pure carbon slider showed the lowest temperature. This was due to the lower thermal conductivity of the copper-impregnated carbon slider, which caused heat to accumulate on the surface and hinder its diffusion, resulting in a concentration of high-temperature areas. It also caused the arc column near the slider to contract.

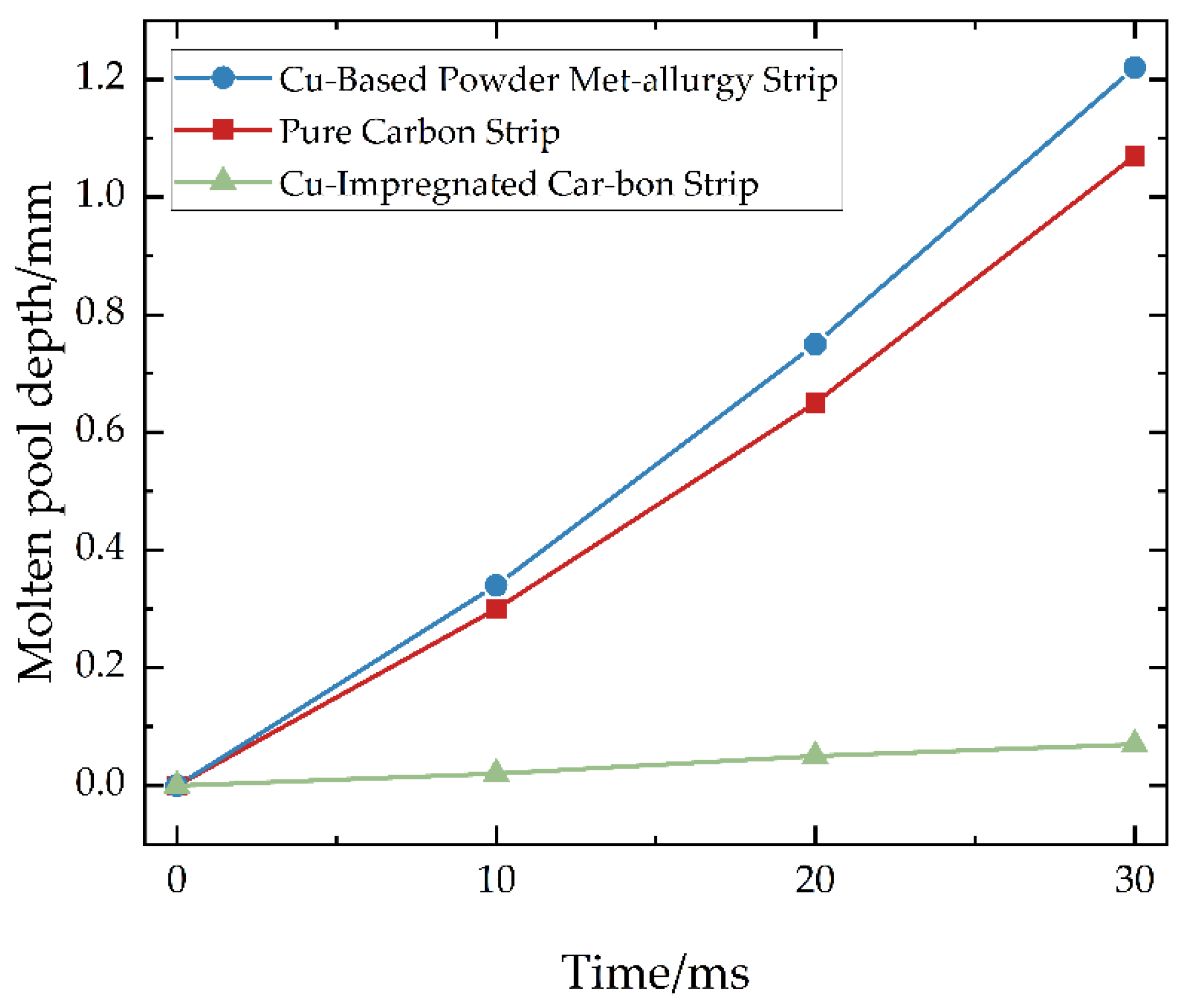

- (3)

- The ablation resistance of different slider materials under arc ablation showed significant differences. The copper-impregnated carbon slider had the best ablation resistance, with a molten pool depth of only 0.07 mm at an arc duration of 30 ms. The pure carbon slider showed a molten pool depth of 1.07 mm, while the copper-based powder metallurgy slider exhibited the poorest ablation resistance, with a molten pool depth of 1.22 mm. Therefore, the latent heat of sublimation was found to be a determining factor in ablation resistance.

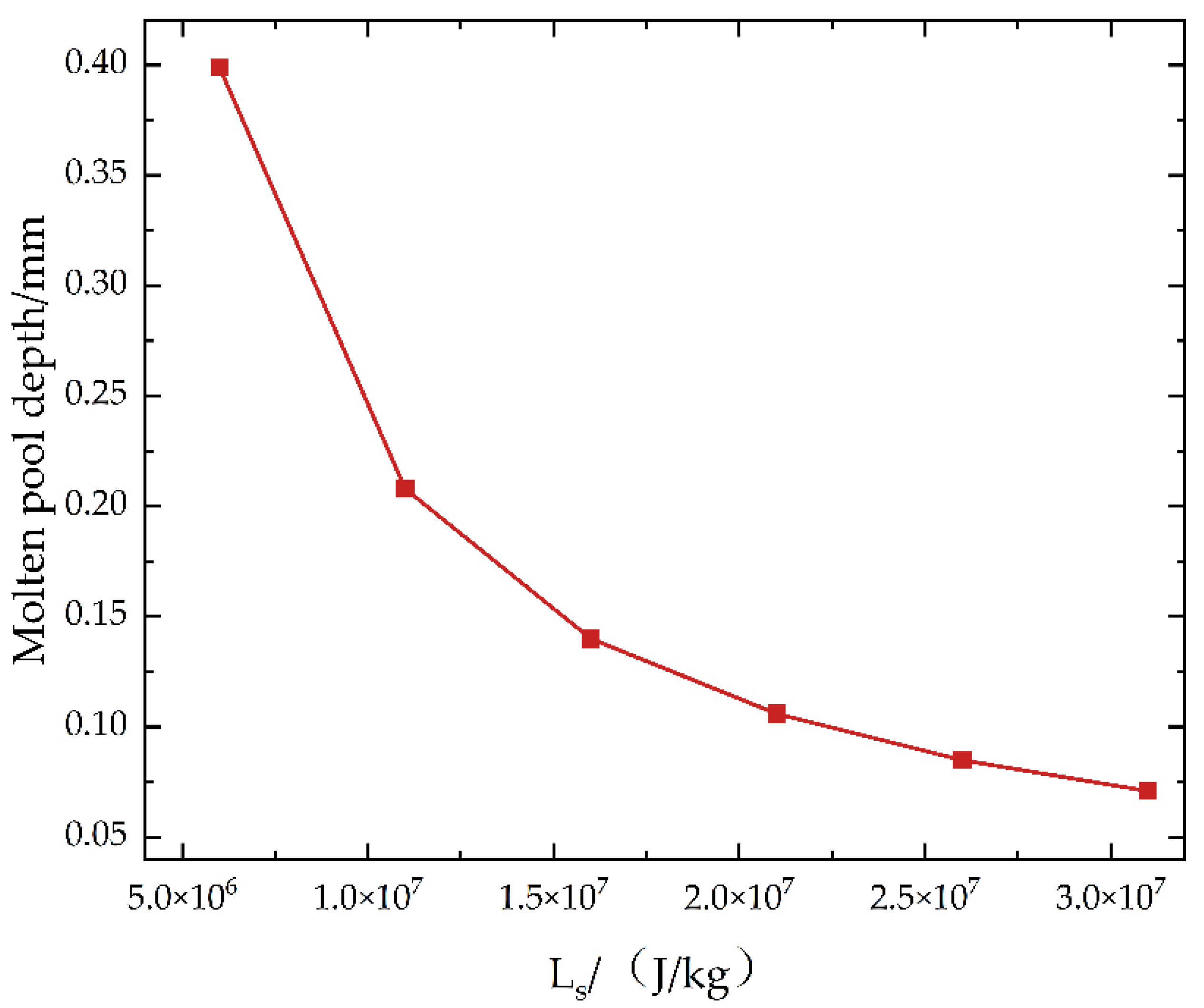

- (4)

- As the latent heat of sublimation of the material increased from 6 × 106 J/kg to 31 × 106 J/kg, the molten pool depth on the slider surface was reduced to a quarter of its original value. By adjusting the chemical composition, purity, environmental conditions, and processing techniques, the latent heat of sublimation could be effectively increased, thereby reducing the degree of ablation on the slider surface and significantly improving the material’s ablation resistance.

7. Discussion and Prospect

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, Z.B.; Wu, G.N.; Lu, W. Research review of arc phenomenon between pantograph and catenary in high-speed electrified railway. High Volt. Appar. 2009, 47, 104–108. [Google Scholar]

- Guo, J.F.; Ke, Z.T.; Liu, J.Z. Identification of railway pantograph-catenary contact force based on data modeling. China Railw. Sci. 2021, 42, 147–174. [Google Scholar]

- Gao, S.B.; Liu, Z.G.; Yang, J. Research prospect for overhead contact system of 400 km/h high-speed railway. High Speed Railw. Technol. 2021, 12, 11–16. [Google Scholar]

- Huang, M.; Yang, B.; Liao, Z.; Lü, P.; Xiao, S.; Yang, G.; Zhu, T. Research on wear of pantograph slide plate: A review. J. Mech. Eng. 2025, 61, 193–213. [Google Scholar]

- Liu, Y.N.; Li, X.Q.; Wang, Q.F. Pantograph catenary off-line overvoltage characteristics of emu. Insul. Surge Arresters 2023, 2, 55–61. [Google Scholar]

- Huang, M.; Yang, B.; Xiao, S.N. Microscopic investigation on current-carrying wear on surface of pantograph carbon slide surface of metro train. Electr. Drive Locomot. 2022, 4, 133–139. [Google Scholar]

- Zhou, H.; Duan, F.; Liu, Z. Study on electric spark discharge between pantograph and catenary in electrified railway. IET Electr. Syst. Transp. 2022, 12, 128–142. [Google Scholar] [CrossRef]

- Tang, Y.T. Research on Model Characteristics and Emi of Pantograph-Catenary Arc of the High Speed Train. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2021. [Google Scholar]

- Xiao, S.; Cao, Y.; Wu, G.N. Influence mechanism and suppression methodologies of the overvoltage of high-speed railway on the vehicle-mounted traction power supply system: Systematic review. Proc. CSEE 2024, 44, 4682–4702. [Google Scholar]

- Gao, G.Q.; Hao, J.; Wei, W.F. Dynamics of pantograph-catenary arc during the pantograph lowering process. IEEE Trans. Plasma Sci. 2016, 44, 2717–2723. [Google Scholar] [CrossRef]

- Ma, H.; Tian, E.; Yan, T. Study on the influence of different magnetic fields on vacuum arc based on COMSOL. J. Phys. Conf. Ser. 2019, 1486, 062038. [Google Scholar] [CrossRef]

- Yu, X.Y.; Song, M.J.; Wang, Z. Simulation and verification of effect of arc duration on arc temperature based on COMSOL. Machines 2023, 11, 2–13. [Google Scholar] [CrossRef]

- Ma, Q.; Rong, M.Z.; Anthony, B.M. Simulation and experimental research on air arc movement characteristics in low-voltage circuit breaker considering electrodes erosion. Proc. CSEE 2009, 29, 117–120. [Google Scholar]

- Shi, Y.D.; Zhou, Y.; Gao, G.Q. Interaction mechanism between copper-impregnated carbon materials and arc. Proc. CSEE 2018, 44, 3872–3979. [Google Scholar]

- Gleizes, A.; Gonzalez, J.J.; Freton, P. Thermal plasma modelling. J. Phys. D Appl. Phys. 2007, 38, R153. [Google Scholar] [CrossRef]

- Zhu, G.; Wu, G.; Han, W.; Gao, G.; Liu, X. Simulation and analysis on steady state characteristics of pantograph arc during static lifting and lifting of high-speed train. China Railw. Soc. 2016, 38, 42–47.22. [Google Scholar]

- Xu, Z.; Gao, G.; Wei, W. Characteristics of pantograph-catenary arc under low air pressure and strong airflow. High Volt. 2022, 7, 369–381. [Google Scholar] [CrossRef]

- Zhu, G.Y.; Gao, G.Q.; Wu, G.N. Modeling pantograph-catenary arcing. Proceedings of the Institution of Mechanical Engineers, Part F. J. Rail Rapid Transit 2016, 230, 1687–1697. [Google Scholar] [CrossRef]

- Hsu, K.C.; Etemadi, K.; Pfender, E. Study of the free-burning high-intensity argon arc. J. Appl. Phys. 1983, 74, 1293–1301. [Google Scholar] [CrossRef]

- Karetta, F.; Lindmayer, M. Simulation of the gas dynamic and electromagnetic processes in low voltage switching arcs. IEEE Trans. Compon. Packag. Manuf. Technol. Part A 1998, 21, 96–103. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, H.; Huang, K.; Song, Y.; Zheng, Z.; Cheng, Y. Extended black-box model of pantograph-catenary detachment arc considering pantograph-catenary dynamics in electrified railway. IEEE Trans. Ind. Appl. 2018, 55, 776–785. [Google Scholar] [CrossRef]

- Wang, W.G.; Wu, G.N.; Gao, G.Q. The pantograph-catenary arc test system for high-speed railways. Tiedao Xuebao/J. China Railw. Soc. 2012, 34, 22–27. [Google Scholar]

- Han, W.F.; Gao, G.Q.; Liu, X.R. MHD model of pantograph-catenary arc. J. China Railw. Soc. 2015, 5, 21–26. [Google Scholar]

- Xing, L.C.; Zhang, X.D.; Liu, B. Spectroscopy method used in temperature and electron density of pantograph-catenary arc. Spectrosc. Spectr. Anal. 2018, 38, 890–894. [Google Scholar]

- Shi, P.A. Effects of latent heat of phase change on dynamic behavior of fluid flow and heat transfer in laser weld pool of beryllium. Hot Work. Technol. 2009, 38, 1–5. [Google Scholar]

| Physical Parameters | Cu–Sn Alloy Conductor | Cu-Based Powder Metallurgy Strip | Pure Carbon Strip | Cu-Impregnated Carbon Strip |

|---|---|---|---|---|

| Density/(kg·m−3) | 9020 | 8100 | 2400 | 2320 |

| Specific Heat Capacity/(J·kg−1·K−1) | 384 | 376 | 710 | 478 |

| Thermal Conductivity/(W·m−1·K−1) | 398 | 80 | 151 | 6 |

| Electrical Resistivity/(μΩ·m) | 0.024 | 0.35 | 3.8 | 10 |

| Sublimation Latent Heat/(J·kg−1) | - | 4.71 × 106 | 3.26 × 107 | 3.1 × 107 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, R.; Wang, S.-J.; Lu, M.; Li, J. Study on the Ablation of Slide Plate by Pantograph–Catenary Arc Based on Pantograph Slide Material. Infrastructures 2025, 10, 276. https://doi.org/10.3390/infrastructures10100276

Tian R, Wang S-J, Lu M, Li J. Study on the Ablation of Slide Plate by Pantograph–Catenary Arc Based on Pantograph Slide Material. Infrastructures. 2025; 10(10):276. https://doi.org/10.3390/infrastructures10100276

Chicago/Turabian StyleTian, Rui, Shao-Jie Wang, Mai Lu, and Jie Li. 2025. "Study on the Ablation of Slide Plate by Pantograph–Catenary Arc Based on Pantograph Slide Material" Infrastructures 10, no. 10: 276. https://doi.org/10.3390/infrastructures10100276

APA StyleTian, R., Wang, S.-J., Lu, M., & Li, J. (2025). Study on the Ablation of Slide Plate by Pantograph–Catenary Arc Based on Pantograph Slide Material. Infrastructures, 10(10), 276. https://doi.org/10.3390/infrastructures10100276