1. Introduction

Concentrating photovoltaic (CPV) systems offer a promising pathway for clean and efficient solar power generation by focusing sunlight onto high-efficiency multi-junction solar cells using optical elements such as Fresnel lenses. These systems can significantly increase solar-to-electric conversion efficiency while reducing the required photovoltaic material footprint, contributing to both economic and environmental sustainability. However, a high optical concentration also introduces substantial thermal loads, which can reduce electrical performance and shorten a system’s lifespan. Therefore, the design of clean and efficient CPV systems must holistically integrate both optical concentration and thermal management strategies from the earliest development stages [

1].

Recent advances, such as the use of achromatic silicon-on-glass (SOG) Fresnel lenses with 95% transmissivity and four-junction solar cells, have achieved conversion efficiencies of up to 43% [

2]. Fresnel lenses are particularly attractive for their optical efficiency and cost-effectiveness [

3], yet higher concentration ratios often result in elevated cell temperatures, which compromise the electrical output and system reliability. Studies have shown that under ultra-high concentrations, resistive losses and thermal degradation become critical issues. For instance, Fernández et al. [

4] reported a 28.4% efficiency drop in Vertical-Tunnel-Junction (VTJ) solar cells operating at 15,000 suns, while El-Gahouchi et al. [

5] demonstrated that the efficiency decreased from 33% at 3500 suns to 28% at 10,000 suns using duplicated junction architectures.

Effective thermal management, whether passive or active, is essential for ensuring long-term system performance and safety, especially under ultra-high solar flux. Various studies have explored thermal behaviors of CPV receivers and cooling strategies [

6,

7,

8,

9]. For example, thermal modeling of a 3 × 3 mm

2 triple-junction solar cell without a heat sink revealed critical temperature limits [

10], and further investigations examined passive cooling across diverse cell sizes and concentration levels [

10,

11]. Recent efforts have shown that well-designed passive systems can maintain safe cell temperatures even at ≥10,000 suns [

12,

13], while active cooling continues to be viable under extreme thermal loads.

Traditional CPV thermal models often the simplify solar input as a uniform or boundary heat source [

14,

15,

16,

17,

18,

19], which fails to represent the real spatial irradiance distribution on the cell surface. Only in recent years have coupled optical–thermal simulation approaches emerged to address this limitation. For example, bidirectionally coupled ray tracing models have been used to analyze Fresnel optics paired with multi-junction cells and homogenizing stages [

20]. Similar multi-domain approaches have been applied in clean energy technologies such as micro-scale Organic Rankine Cycles (ORCs) [

21] and hybrid adsorption–ORC systems [

22].

The utility of Fresnel lenses has also been confirmed in broader solar–thermal applications, such as solar-driven metal welding and Stirling engines, using multiphysics simulation environments like COMSOL [

23,

24]. These simulations not only reinforce the importance of accurate optical–thermal modeling but also highlight the relevance of scalable clean technologies that are driven by solar concentration.

To support the sustainable development and deployment of ultra-high-concentration photovoltaic (UHCPV) systems, comprehensive system-level modeling must consider all major components optically, thermally, and mechanically. Such integrated analysis helps minimize material waste, optimize cooling solutions, and improve long-term reliability under extreme solar concentrations. Despite notable progress, there remains a gap in early-stage design tools that accurately link optical and thermal subsystems for UHCPV applications, particularly at concentration levels beyond 2000 suns, where design tolerances are tight and solar tracking precision is critical.

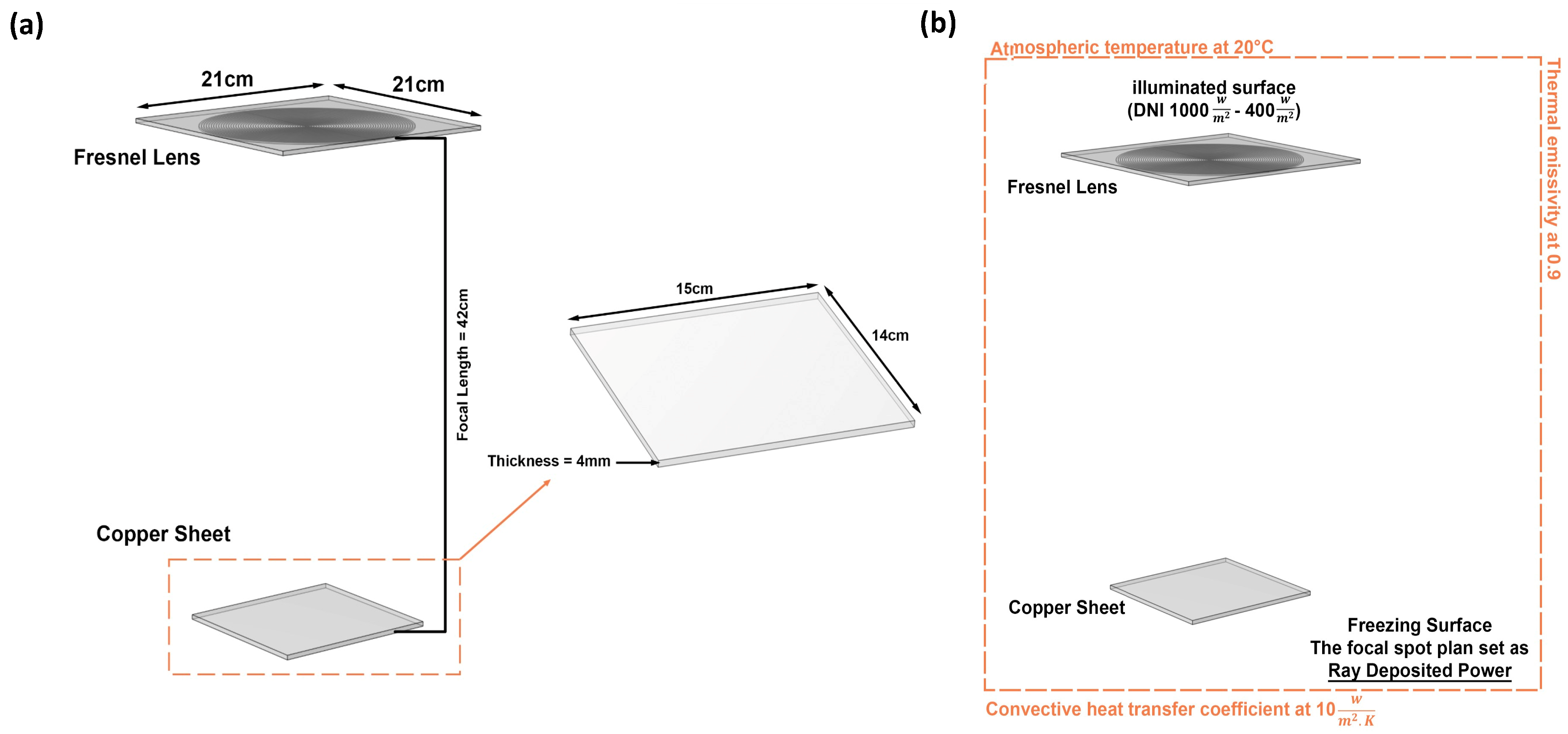

In response to these challenges, this study introduces a high-fidelity, bidirectionally coupled optical–thermal model developed in COMSOL Multiphysics. The model simulates a CPV system featuring a Fresnel lens as its primary optical interface and targets multi-stage concentrations to achieve ultra-high flux ratios. In contrast to traditional thermal models, which assume a uniform heat input, this approach integrates spatial irradiance maps obtained through ray tracing directly into the thermal solver. Direct normal irradiance (DNI) conditions from 400 W/m2 to 1000 W/m2 were explored to assess optical–thermal interactions across realistic operating scenarios. Validation was performed using both theoretical benchmarks and experimental thermal testing under a controlled solar simulator.

By isolating and analyzing the primary optical interface before full system integration, this work provides a scalable and sustainable design framework for next-generation UHCPV technologies. The model enables accurate prediction of key performance parameters such as concentration ratios, receiver temperatures, and thermal load distributions, informing material choices, cooling strategies, and system reliability. This contributes to the broader goal of advancing clean, high-efficiency solar energy systems that are capable of meeting future energy demands with minimal environmental impacts.

The State of the Art vs. This Work

Previously coupled optical–thermal models for CPV systems have often assumed uniform irradiance distributions or treated optical and thermal domains sequentially, limiting their predictive accuracy under ultra-high flux. In contrast, the present work introduces a bidirectional coupling strategy where ray-traced irradiance maps are directly integrated into the thermal solver. This approach improves fidelity in focal regions with steep irradiance gradients and enables accurate prediction of hotspot distributions. Furthermore, unlike prior studies that were validated only against theoretical benchmarks, our framework is validated through both theoretical and experimental testing, achieving <1% optical and <2.2% thermal deviation. This integration and validation advance the current state of the art by providing a scalable, experimentally verified tool for UHCPV system design.

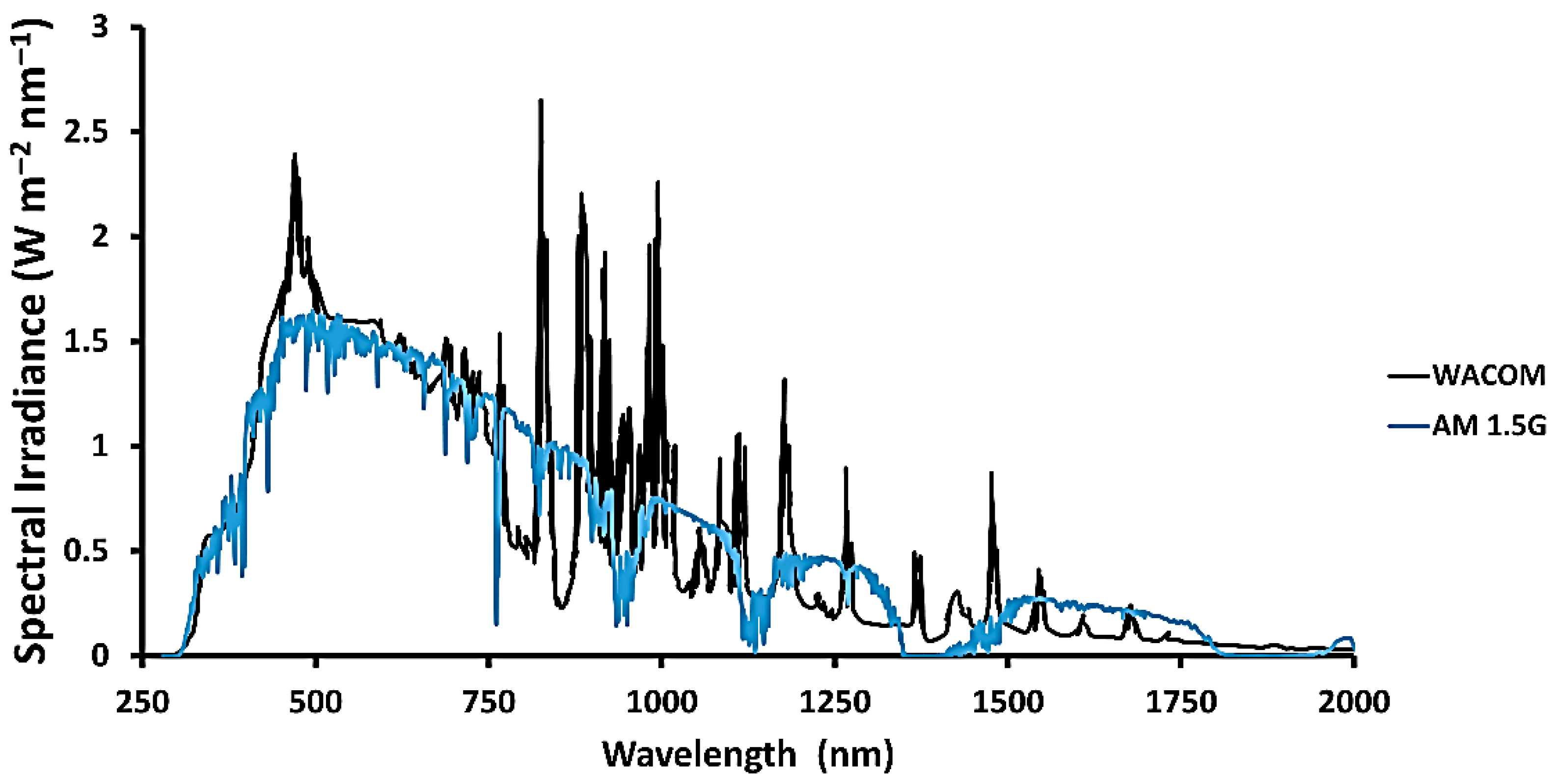

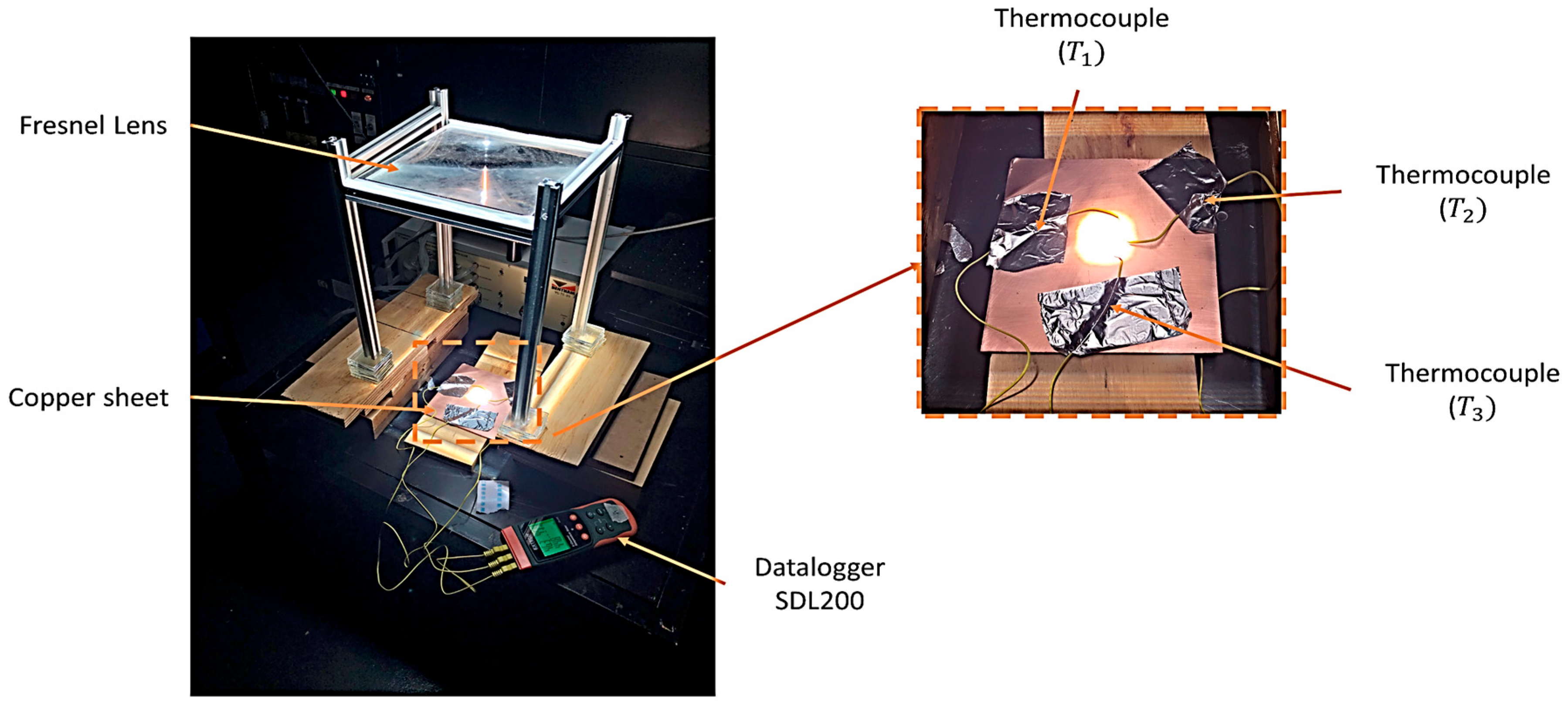

4. Validation of the Optical and Thermal Model

To verify the reliability of the computational model estimating the optical and thermal performance of the Fresnel lens, two approaches were used for validation: one is a combined theoretical/experimental validation of the optical model results, and the other is experimental validation of the thermal model results. An experimental thermal setup was established based on a refractive optic [SOG–Fresnel lens] of 441

aperture area, which was exposed to a constant solar irradiance of 1000

. A WACOM AAA rating and

spatial non-uniformity solar simulator combining both the Xenon short-arc lamp and an optical filter to reproduce a continuous solar irradiance at AM 1.5G were utilized. The solar simulator fabricated by WACOM (Model no. WXS-210S-20 AM1.5 G, made by Wacom Electric Co., Ltd., Fukaya-shi, Japan) to emulate a solar irradiance intensity approximating AM 1.5G through an angular optical filter of

° was used [

28], as shown in

Figure 5.

The refractive optic was vertically adjusted normally to the collimator lens of the solar simulator to achieve the optimum focal length of 42 cm. At this focal length, the optimum focal spot of

in diameter is generated on a

copper surface area, on which the maximum concentration ratio is achieved. The copper plate was adjusted to center the focal spot on its plain. The temperature was measured and acquired utilizing a Datalogger SDL200-EXTECH INSTRUMENTS, manufactured by Extech Instruments (Nashua, NH, USA). The test bench was configured to ensure high reproducibility. The Fresnel lens was mounted on a stable optical frame aligned with the simulator beam axis, and the copper receiver plate was positioned on a three-axis stage to allow for fine adjustments in both the lateral and longitudinal directions. Alignment was performed iteratively until the focal spot diameter matched the predicted ~10 mm distribution, ensuring consistent concentration conditions. The simulator provided a certified AM 1.5G spectrum with <2% non-uniformity, thereby minimizing external sources of optical variation. Three thermocouples were placed in the focal spot domain to gather the maximum measured temperatures and then average them for the measurement certainties, as illustrated in

Figure 6.

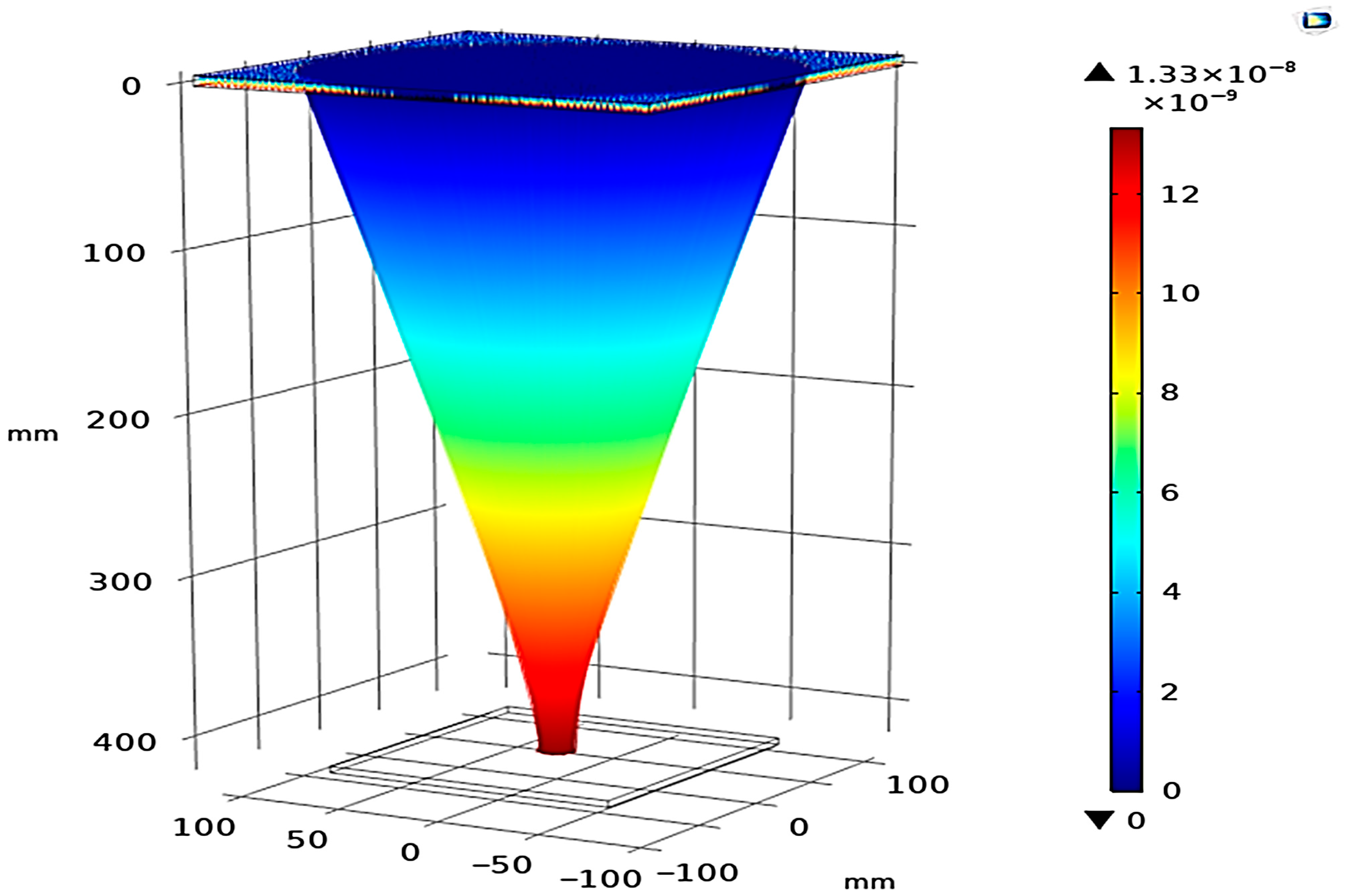

4.1. Optical Validation

To theoretically characterize the performance of a CPV system based on a Fresnel Lens design, we need to solve for the theoretical optical efficiency at different DNI values ranging from 400

–1000

in an interval of 100

To do so, the focal spot diameter obtained from the simulation was used to calculate the geometrical concentration ratio

to find the geometrical concentration ratio (

.

represents the area of the Fresnel lens (

to the area of the focal spot (

. The optical efficiency of the Fresnel lens (transmissivity) (

of

(transmittance spectra measured via spectrophotometry) needs to be accounted for in the calculation [

27]. Therefore, the theoretical optical efficiency (

) is calculated as in Equation (11).

Afterwards, the theoretical optical concentration ratio (

is found using Equation (12).

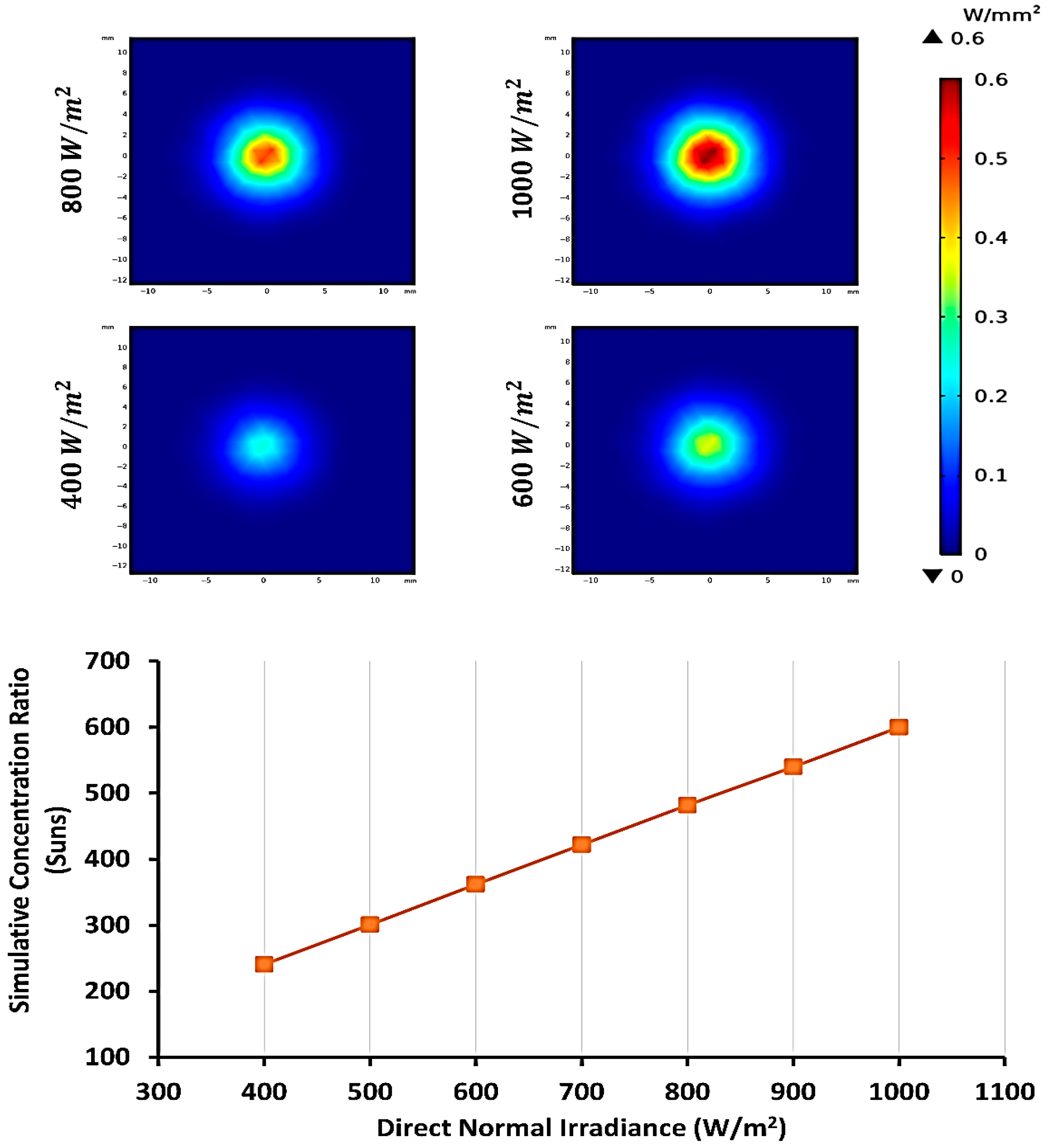

As a result,

is found to be 89.64% where

is found to be 89.08% with a discrepancy of 1%. The

showed results of 604 suns, 543 suns, 483 suns, 423 suns, 362 suns, 301 suns, and 242 suns for DNI values ranging from

to 400

in an interval of 100

. The results of

and

in relation to the input power to the Fresnel lens is shown in

Figure 7 for comparison. The discrepancy of the optical concentration between

and

is only 0.3% on average, reflecting a strong agreement in the results.

As an example, a

multi-junction solar cell with base material of GaInP/GaInAs/Ge on Ge substrates manufactured by Azurspace was unitized to understand the electrical performance optically [

29]. The multi-junction solar cell was placed in the focal spot zone and maintained at a temperature of 25 °C using a cooling mount, similarly to the experimental approach in [

30]. To determine the effective concentration ratio (

) (suns), the impact of the solar intensity on the multi-junction solar cell in terms of the short circuit current (

) to the short circuit current (

) value at the reference intensity of 1 sun equivalent to

of solar irradiance was used, as in Equation (13).

To validate the to the , the simulation results must consider the collimating angle of irradiance for the WACOM solar simulator, which is 1.43°, and then account for the measured cell efficiency under the concentrated sun rays, which is found to be 33.5% on average. The divergence of optical concentration between and is found to be 1.1% on average at a 1.43° convergence angle, indicating a stable matching between the simulation and the experimental measurements. However, we can observe a drop in the optical concentration ratio at a convergence angle of 1.43° in comparison to the one at 0.27°, because the large collimating angle results in a wider focal spot than the solar cell area, where longer sun rays are lost.

4.2. Thermal Validation

To measure the maximum temperature, the solar simulator illuminates the Fresnel lens, which concentrates solar irradiance to produce a focal spot on a copper plate. The focal spot temperature reaches a steady-state plateau within 20 s. The temperature on the copper plate starts fluctuating within a minimized range around its saturation level. After the temperature reaches its saturation level, the temperature measurement is logged for a time interval of 5 min. Then, the logged data is averaged among the thermocouples (

and over the time (t) of 5 min, as in Equation (14):

The simulated maximum temperature using COMSOL and the measured maximum temperature are in good agreement, with an average discrepancy of 2.18%, as shown in

Figure 8.

To ensure the reliability of the thermal validation, three Type K thermocouples were employed, factory-calibrated, and cross-checked against a reference probe, with an accuracy of ±0.5 °C. The sampling rate was set at 1 Hz, and steady-state data were logged over a 5 min interval. Placement tolerance within the focal spot was maintained within ±0.5 mm of the peak flux zone to minimize positional bias. In addition, the WACOM solar simulator used in this study has a certified spatial non-uniformity of <2%. Together, these factors define the measurement uncertainty. Considering both thermocouple positioning and simulator non-uniformity, the overall contribution to the reported ±2% discrepancy is minor, thereby reinforcing the robustness of the agreement between the experimental and simulated results.

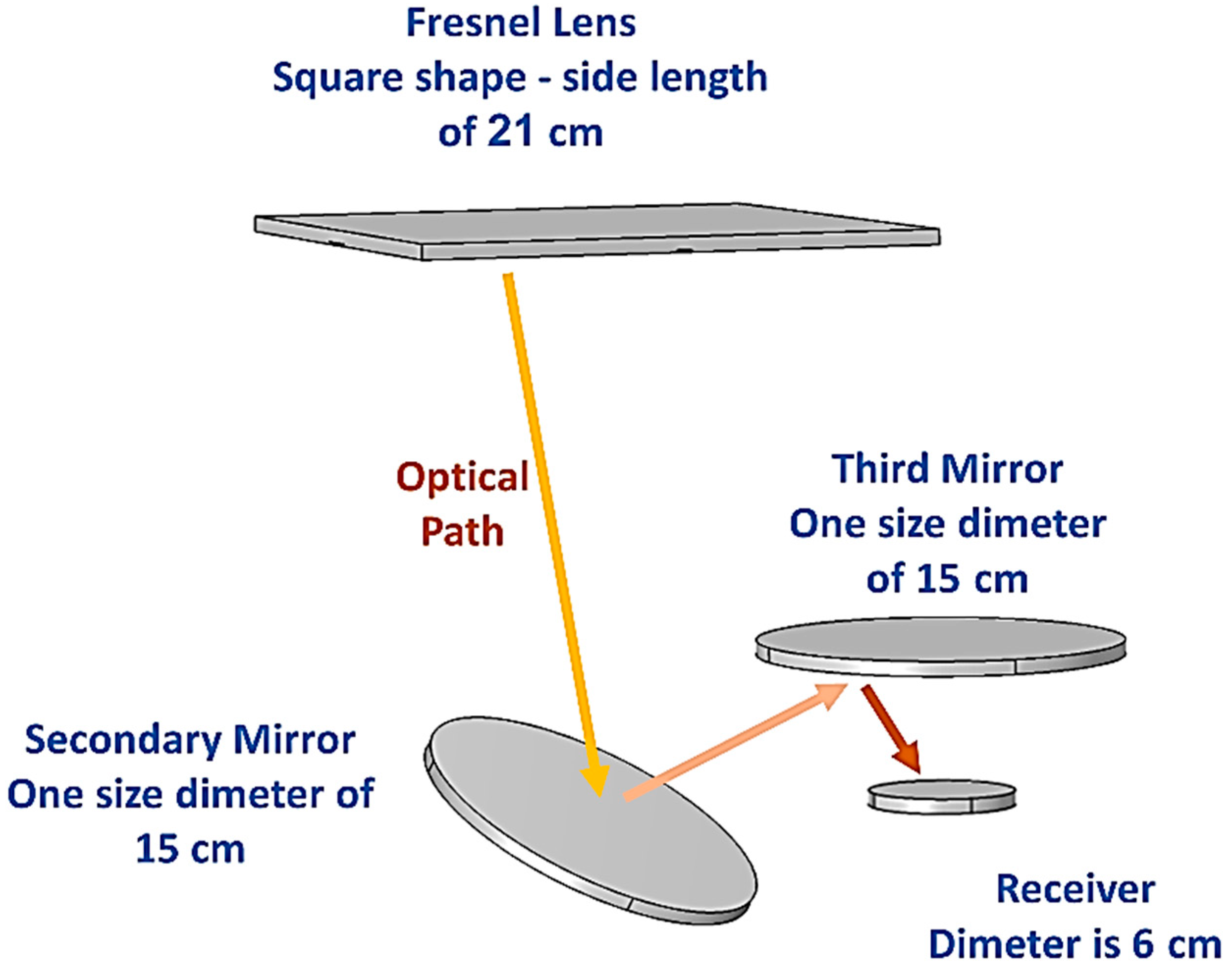

5. The Potential Temperature for ¼ of the UHCPV System

To prepare for the UHCPV system design, the temperature needs to be predicted to plan for the selected optical materials and size/configure the associated cooling mechanism. The accumulation of temperature in the ultra-high-concentration range is harmful and could not only damage the receiver solar cells and their materials, but also any secondary or tertiary optics in between. Thus, the investigated model was extended to include secondary and tertiary reflective optics for a quarter of the UHCPV configuration, which is the receiver, to predict the temperature on the optical stages and then on the final central receiver [

1]. All the consecutive optics to the Fresnel lens have been selected to be aluminum materials, keeping the same boundary condition as before. The geometry description and an illustration of the optics size and position in a 3D domain for ¼ of the UHCPV system are shown in

Figure 9.

This section shows only the preliminary temperature level at ambient temperatures of 50 °C and 20 °C, while keeping the convective heat transfer coefficient at 10

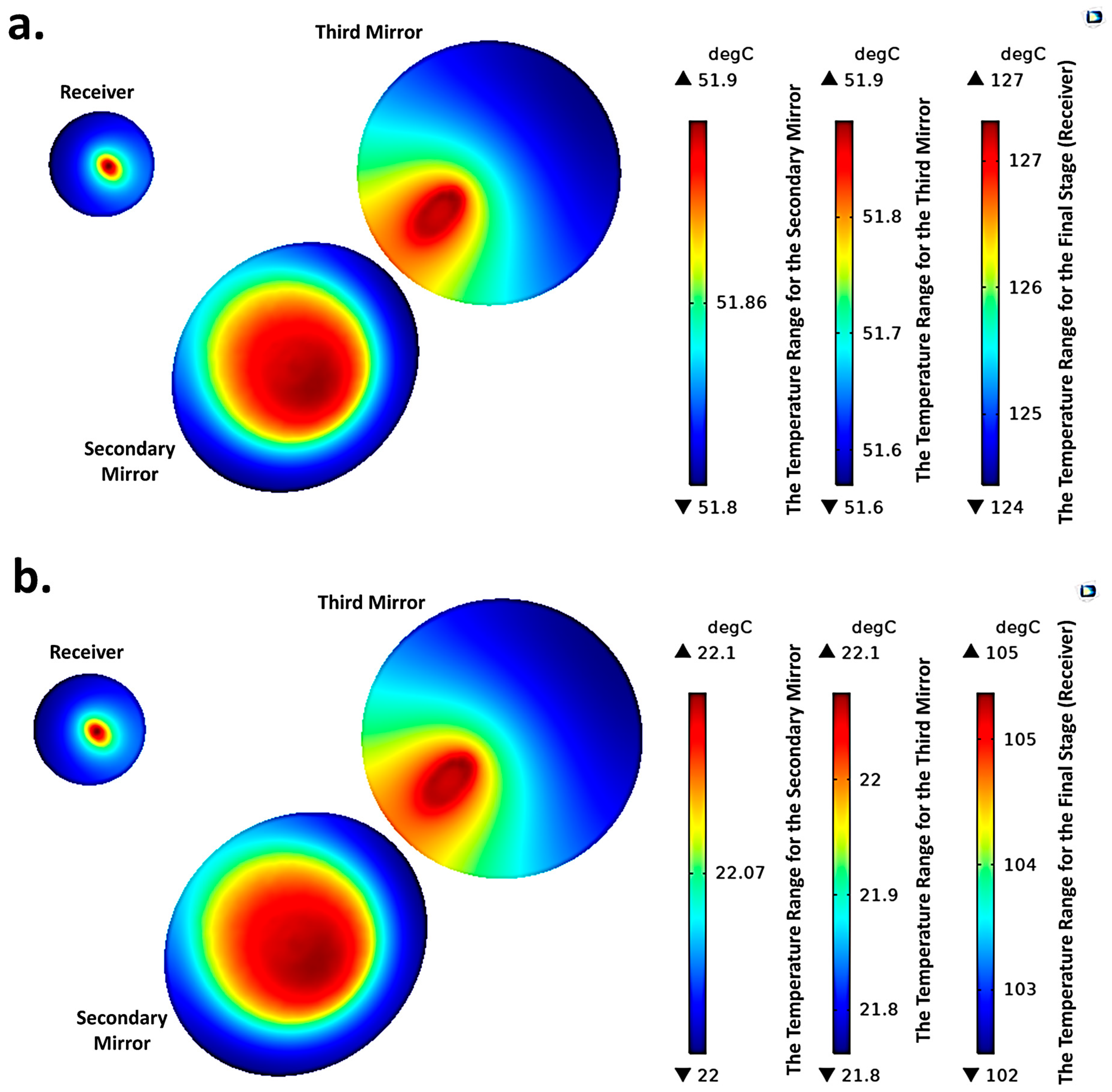

, whereas a detailed numerical investigation of the full UHCPV system will be presented in separate papers.

Figure 10 shows the temperature stratification on the consecutive optical surfaces for a ¼ of the system at ambient temperatures of 50 °C (

Figure 10a) and 20 °C (

Figure 10b). Also, the temperature distribution is influenced by the angular orientation of the secondary optical stage, which can be observed through the focal spot image reflective optics and the final receiver stages.

Figure 10 shows that the maximum estimated temperature conditions for the secondary mirror, third mirror, and receiver are ~52, 52, and 130 °C. Hence, for the experimental setup of the full ultra-high system, the materials chosen for these components should be stable within these temperature ranges. If they are below these temperatures but above those presented in

Figure 10b, ambient temperature control may allow for safe experimental testing if needed. Beyond the passive convective pathways considered here, the presented Fresnel-based UHCPV framework is adaptable to advanced cooling methods. For example, phase change materials (PCMs) could buffer transient thermal spikes, while microchannel heat sinks or pin-fin structures may significantly enhance convective heat removal at the receiver stage. Such techniques can be integrated without altering the primary optical interface and will be addressed in future work.

6. Performance Analogs and Discussion

The common approach to predicting the thermal performance of a solar system numerically, either in a flat PV panel or a CPV system, is through “Heat Transfer in Solids” physics in COMSOL software, version 6.2. In this approach, the heat source term in the heat transfer balance equation is defined as a physical node called “Boundary Heat Source” for a surface area or “heat source” for a volume. The heat source terms need to be interlinked into a domain within the solar assembly, where photogeneration is induced (semiconductor layer). Briefly, all the photon energy within the bandgap energy of the semiconductor materials will be absorbed, and the rest generates thermal energy losses (thermalization intrinsic loss). Researchers rely on the heat source method to model the resultant heat on single cells, as well as dense array models. This approach is widely implemented, in which the temperature variance on the cell (

) translates, both for uniform and non-uniform distributions in the cell, while the distribution is originally Gaussian. However, in this approach, the uniformity distributions reflect a Gaussian distribution with much flattening in the peak (lower

between the center of the solar cell and the solar cell edge), and the non-uniformity distributions still reflect a Gaussian distribution with a sharp peak (larger

between the center of the solar cell and the solar cell edge) [

31,

32,

33,

34]. The boundary heat source is generally calculated in units (

based on Equation (15) [

35].

where

stands for the optical efficiency, and

stands for the electrical efficiency of the solar cell. While this work is tailored for UHCPVs, similar stability challenges are faced by emerging perovskite solar cells under high optical and thermal flux. A recent study [

36] reported degradation pathways in perovskite devices that parallel those in UHCPV receivers. Highlighting this cross-disciplinary relevance strengthens the broader applicability of the proposed framework. Performing a thermal numerical study based on this approach is less complicated and requires less computational time to predict performance. However, this approach assumes a completely uniform irradiance distribution over the cell surface area, which is not the case, especially for the fixed flat PV panel or CPV system for either a point or focal line concentration. To overcome this issue, the ray tracing model is computed in optical-based software (such as Zmax, ASPA, and APEX) and then imported into COMSOL as an interpolation function to be incorporated with Equation (14). In terms of computational resources, each coupled optical–thermal case required approximately 20–25 min on a workstation (Intel Xeon, 64 GB RAM-manufactured by Intel Corporation, California-US) for full 3D focal spot resolution. A mesh refinement study was conducted in the focal region to account for steep irradiance gradients, and further densification of the mesh (40% smaller elements) changed the peak temperature predictions by less than 1.5%. This confirms that the results are numerically stable and not sensitive to further mesh refinement.

This limitation can be overcome by employing COMSOL’s integrated ray optics and heat transfer modules to predict thermal performance. Through the ray optics model, the optical concentration ratio is computed by relying on geometrical optics (system design). The instantaneous ray trajectory computation exhibits a close-to-reality solar irradiance distribution on a receiver surface area, which helps to define the size that is needed of a solar cell. In contrast, the numerical study based only on the heat transfer on the solid model assumed that the area of the focal spot is like the area of the solar cell and that the heat distribution is homogenous (Gaussian) across only the solar cell area. The fidelity of coupled optical–thermal simulations remain sensitive to mesh resolution, especially in focal regions, where the optical result is significantly influenced. Computational time is another challenge, but only when the optical model is coupled with the thermal model to predict performance optically and thermally. Compared to earlier Gaussian-based thermal models, which often assume uniform irradiance distributions, the present framework directly integrates spatially resolved irradiance maps into the thermal solver. This leads to more accurate hotspot prediction and improves thermal estimation, as reflected in the <2.2% validation error. Such fidelity, combined with experimental benchmarking, represents the main original contribution of this work relative to prior studies.

7. Conclusions

This study introduces a validated, high-resolution simulation framework that integrates bidirectional optical modeling with steady-state thermal analysis to support the sustainable design of Fresnel-based concentrating photovoltaic (CPV) systems. Developed in COMSOL Multiphysics, the model captures system-level interactions between optical concentration and thermal distribution across a range of real-world direct normal irradiance (DNI) conditions. It achieves up to 89.08% optical efficiency and concentration ratios from 240 to 600 suns, with corresponding focal spot temperatures between 37.2 °C and 61.7 °C. Experimental comparisons showed excellent agreement, with less than 1% deviation in optical efficiency and under 2.2% in thermal accuracy.

These results offer critical design insights for ensuring reliable operation of CPV systems, such as maintaining mirror and receiver temperatures below 52 °C and 130 °C, respectively. By providing early-stage system validation and guiding material selection and thermal management strategies, the model supports the development of high-performance, environmentally conscious solar energy technologies.

Through its tightly integrated optical–thermal approach, this work contributes a scalable, simulation-driven toolset that is tailored for clean energy innovation. It bridges the gap between component-level characterization and full system implementation, enabling more efficient, cost-effective, and sustainable deployment of ultra-high-concentration photovoltaic (UHCPV) technologies. To extend this framework to practical deployment, large-scale validation on pilot UHCPV modules (e.g., 1 kW installations) would be required. Such validation would not only confirm the thermal predictions but also establish a direct correlation with electrical performance metrics, including I–V characteristics and conversion efficiencies under real DNI fluctuations. In addition to UHCPV systems, the presented framework is adaptable to hybrid architectures, such as CPV/thermal co-generation, where waste heat can be harvested, or to modules incorporating spectral management layers to optimize the usable photon flux. Considering these pathways will further emphasize the scalability and interdisciplinary impact of the proposed model.

Future Avenues: Future work will extend the model to incorporate solar tracking, spectral management, and dynamic thermal behaviors, further aligning with the goals of clean, next-generation energy systems.