Implementation of Simulation Modeling of Single and High-Volume Machine-Building Productions

Abstract

1. Introduction

2. Materials and Methods

2.1. Structure of the Simulation Model and Description of the Simulation Process

2.2. Description of the Methodology for the Simulation Modeling Process and Development of the Structure of the Simulation Model

- A source that generates applications, and a set of sources create the input flow of applications into the system. As a rule, sources can be of two types, finite and infinite, which differ in the methods of generating requests.

- Buffer memory (storage location of the request queue). As a rule, it is divided into two types: general and zone. The shared memory stores requests from various sources, and the order in which they are recorded is determined only by the buffering discipline. Zone memory is a buffer divided into zones, each of which records requests only from a specific source. Thus, the quantity of zones aligns with the number of sources.

- Devices that service requests and create an output stream of requests after servicing.

- Arrangement manager: sends a request for service or to buffer memory if there are no free devices and organizes the refusal or knocking out of an application from the buffer memory if there are no free places left in the buffer.

- Selection manager: selects the device on which applications will be processed and selects a request from the memory buffer, if it exists there.

- In the model, the sources are represented by technological processes (referred to as TP). TP denotes a precise sequence of tasks, starting from the delivery of raw materials and tools from the warehouse to the machines, and concluding with the storage of finished products of specific types at the warehouse. Moreover, the durations of all tasks are explicitly defined.

- No buffer memory.

- The system operates seamlessly as it cannot bypass any stages of the process.

- The quantity of devices in the system is contingent upon the designated technological equipment required for executing the specified technological processes.

- During the modeling process, applications are generated—a separate stage of the technological process. Simultaneously, the system handles one occurrence of each technological process. Consequently, the quantity of applications within the system does not surpass the overall count of technological processes.

3. Result

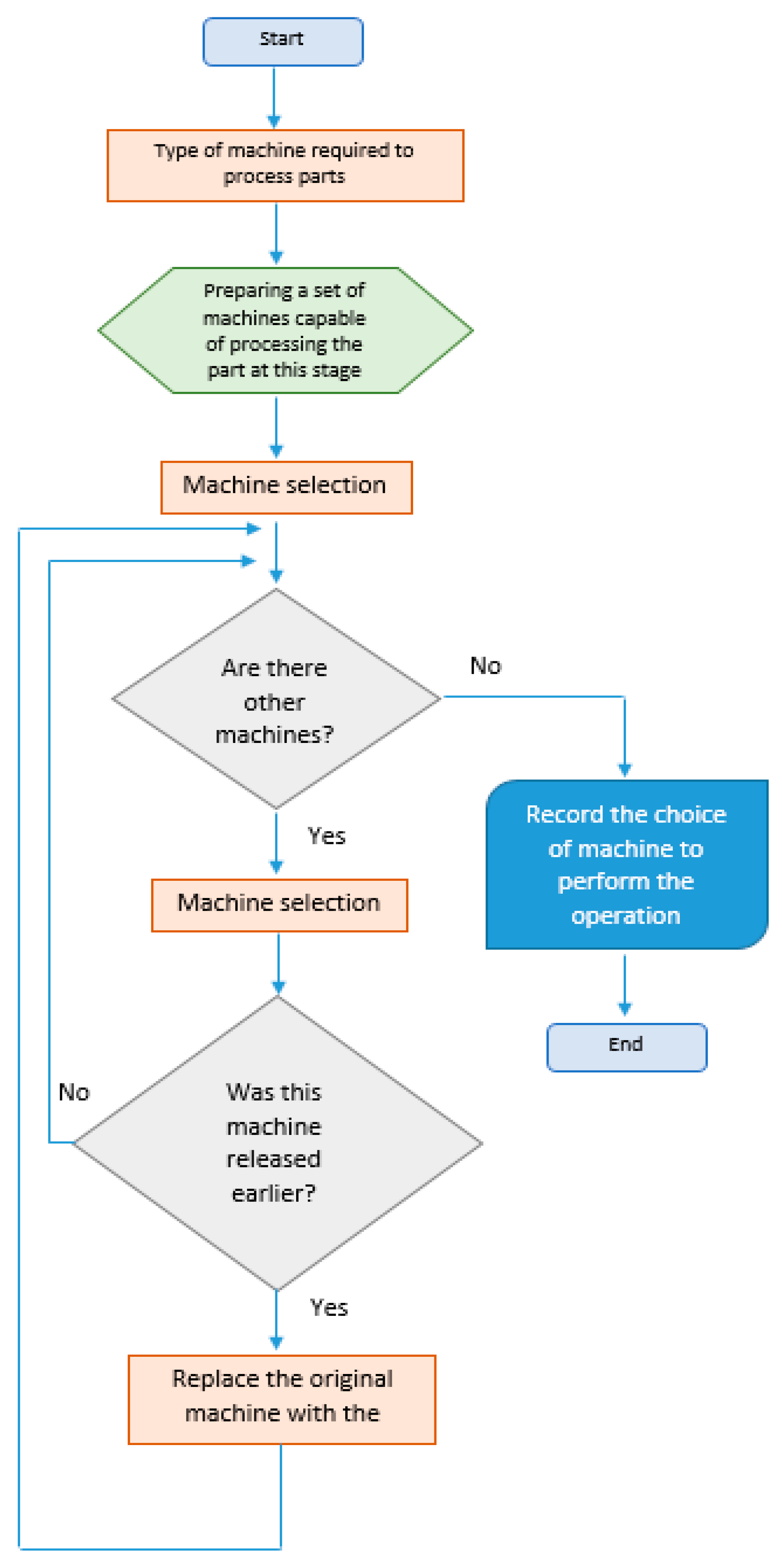

Algorithmization of Simulation Modeling

- A compilation of TPs along with the number of implementations for each, comprising the operation type, time required, and implementation cost.

- A collection of technological equipment—where one unit of a specified piece of equipment corresponds to one or more types of operations conducted.

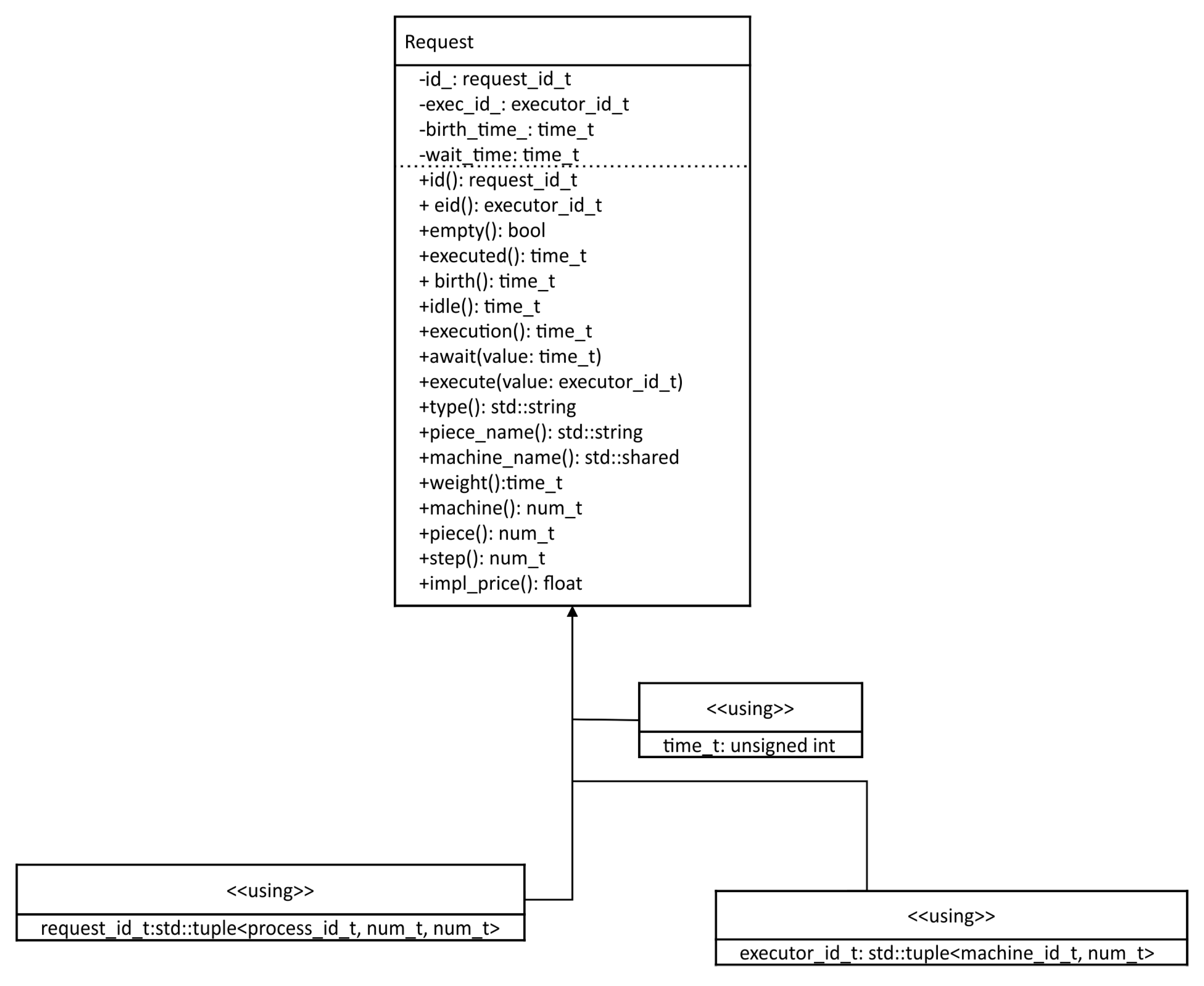

- The TP’s identification number implemented within the system (indicated by the id_ field);

- The sequence number of the operation within this TP (id_);

- The implementation number of the TP (id_);

- The time when the application enters the system (birth_time_).

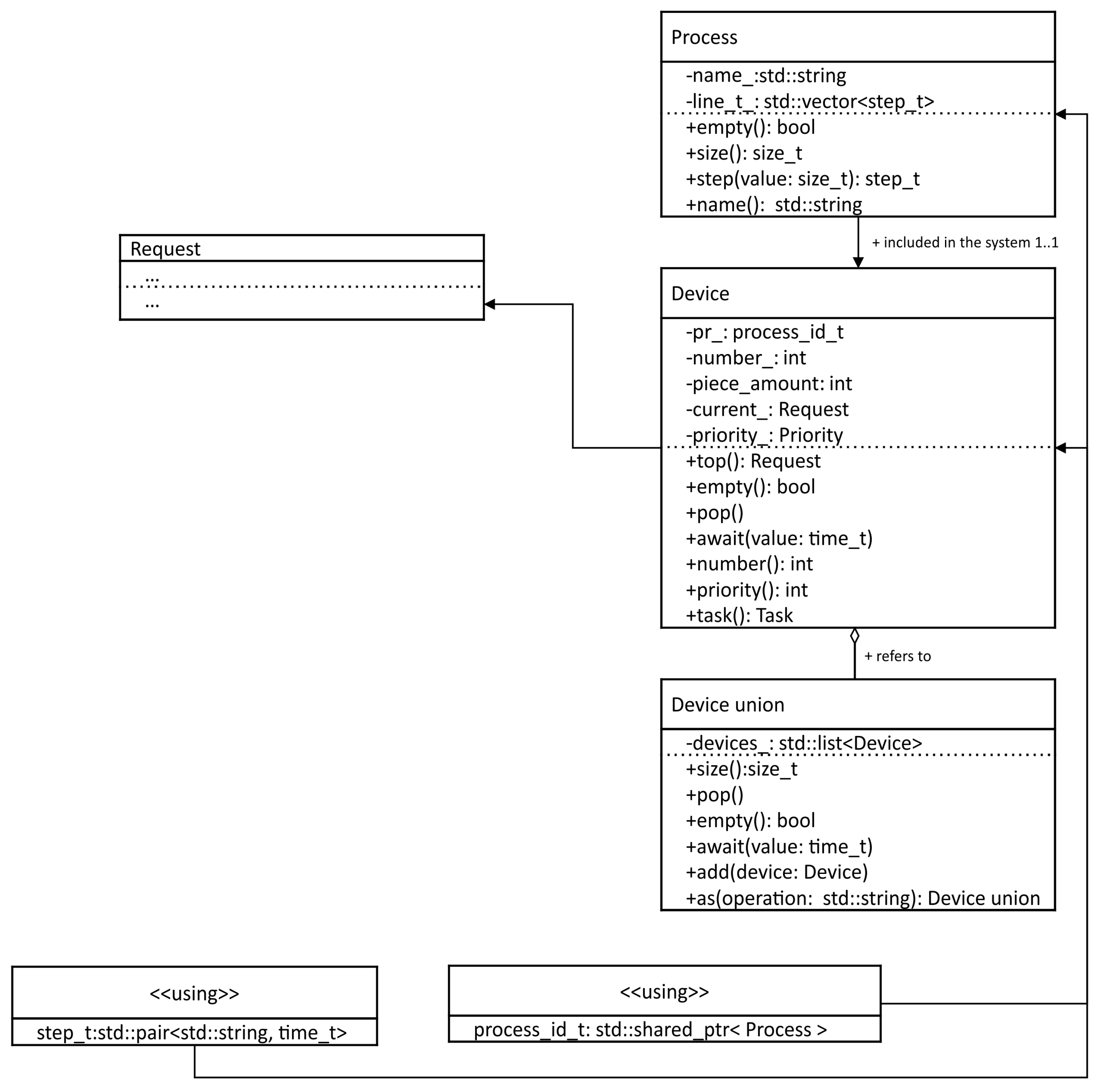

- The designation of the process equipment (captured by the name_attribute);

- The categories of operations it can execute (line_).

4. Discussion

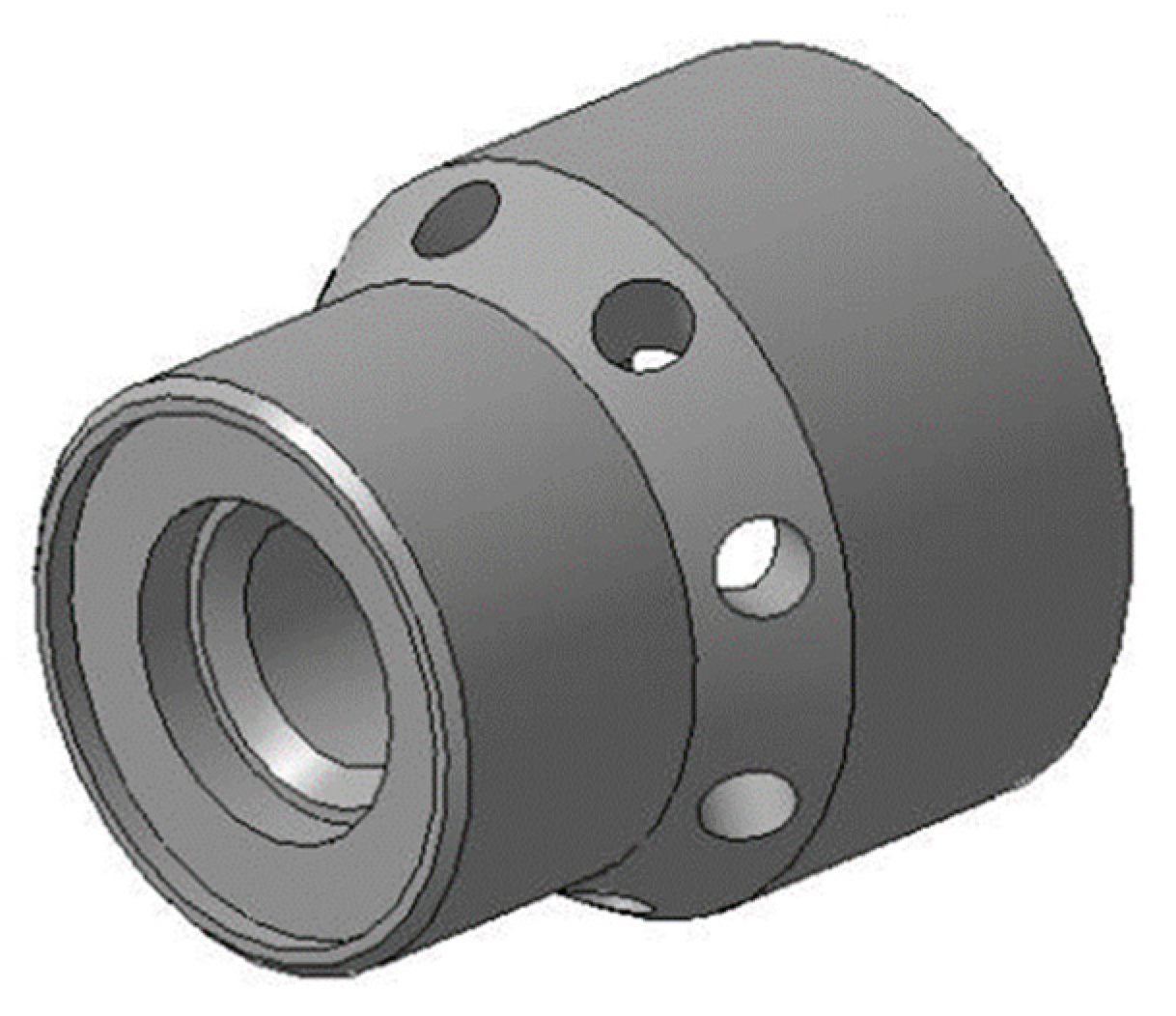

- Dimensions: maximum diameter 24 mm, length 26 mm;

- Exact dimensions:

- -

- outer diameter ϕ 24h6 with roughness Ra 0.8;

- -

- internal diameter ϕ 11H8 with roughness Ra 1.6;

- -

- internal threaded surface M8-7H, roughness Ra 3.2.

- General tolerances for other dimensions: H14, h14, ±IT14/2.

- Thun—universal lathes;

- Tchpu—lathes with numerical control;

- TFNC—turning and milling machines with numerical control;

- KSh—cylindrical grinding machines.

4.1. Equipment

- -

- Consumer ID—unique identifier for the designated equipment;

- -

- Operator—details regarding the designated equipment;

- -

- Machinery—designation of the specified equipment;

- -

- Operation list—roster of operation types feasible on this equipment;

- -

- Factor—cost factor (greater values correspond to higher part processing costs on this equipment).

- MB(1/1): DTE(1H-1)1 → DTE(2H/2-1)2 → DTE(2H/1-1)2 → DTE(2H/2-1)1;

- MB(1/2): DTE(1H-1)2 → DTE(2H/1-4)1;

- MB(2/1): DTE(2B/1-2)1 → DTE(2B/1-1)2 → DTE(2B/2-1)1 → DTE(1B-1)1;

- MB(2/2): DTE(2B/1-2)3 → DTE(2B/1-3)4 → DTE(2B/2-2)2 → DTE(1B-1)2 → DTE(1B-2)3;

- MB(4/1): DTE(4B/1-2)1.

4.2. Technological Process

- -

- Device №—identification number of the specified TP;

- -

- Tsk—information about a given TP;

- -

- Process—name of the specified TP;

- -

- Line—list of operations that make up the given TP:

- (1)

- time—processing time of a given operation;

- (2)

- price—the cost of processing a given operation.

- -

- No.—number of implementations of a given TP.

- id: details concerning the ongoing application;

- name: TP name;

- num: current TP part number;

- step: operation number in progress;

- type: type of ongoing operation;

- birth: timestamp of when the current request entered the system;

- price: cost of the ongoing operation;

- wait: start time of processing the current request;

- executor: details regarding the equipment processing the application:

- name: name of the equipment processing the current request;

- num: equipment number processing the current request;

- execution: completion time of application processing;

- impl_price: cost after the application is processed.

4.3. Part of the Simulation Listing Is Shown Below

5. Conclusions

- The manuscript scrutinized technological production preparation models outlined in both Russian and international literature. In delving into the scientific literature, models focusing on complexity theory, scrutiny of individual design and technological facets, examination of design solution similarities, and scheduling were analyzed.

- 2.

- Methods for estimating the value of inter-operational breaks, based on the method of mathematical statistics, do not allow an accurate assessment of the duration of the production cycle and a highly accurate prediction of the production time of the product.

- 3.

- Approaches relying on the similarity of design solutions during the design of a technological process fail to consider all the design intricacies of the component and its technical specifications. Moreover, they do not facilitate the assessment of numerous processing route options or the determination of production duration with high precision.

- 4.

- A number of the described methods use a production process planning method based on the analysis of identical operations that have already been implemented in the conditions of a particular enterprise. This method does not provide high accuracy in single and small-scale production types due to the wide variety of design and technological solutions.

- 5.

- In the model of technological production preparation, based on the scheduling method, when forming a production schedule, adjustments to the start time of already existing technological operations are not allowed, which significantly limits the number of simulated production scenarios. Consequently, this does not allow for choosing the most rational option for the production process.

- In the model, the sources are represented by technological processes (referred to as TP). TP embodies a strict sequence of operations, encompassing the delivery of raw materials and tools from the warehouse to the machines, culminating in the retrieval of finished products of specified types at the warehouse. Additionally, the durations of all operations are precisely defined.

- There is no provision for buffer memory.

- The system operates flawlessly as it cannot bypass individual stages of the process.

- The quantity of devices within the system is contingent upon the designated technological equipment essential for executing the specified technological processes.

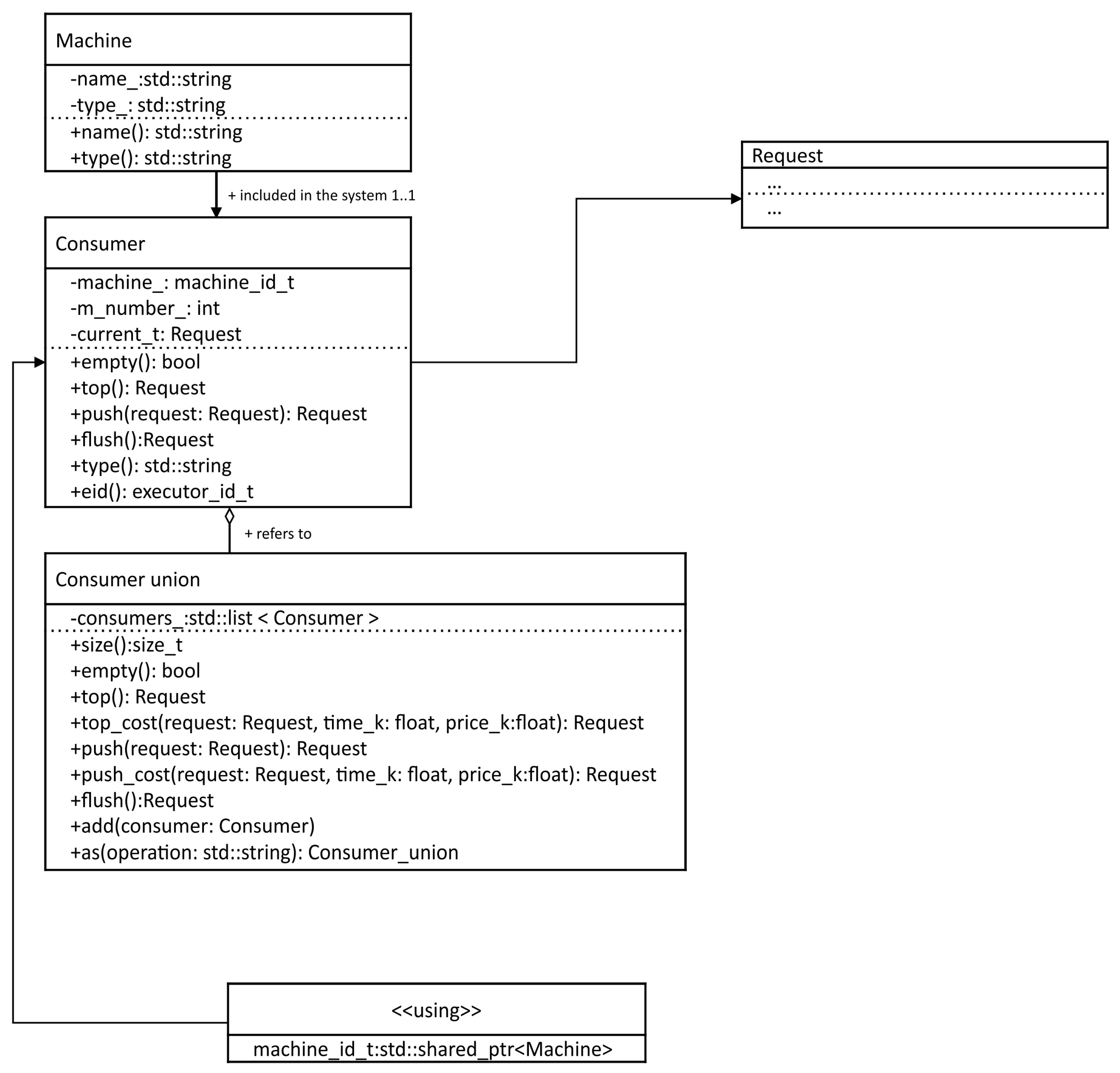

- Throughout the modeling process, applications are generated as a distinct step of the technological process. Concurrently, the system handles a singular instance of each technological process. Consequently, the number of applications within the system does not exceed the overall count of technological processes. Following the analysis, a simulation model algorithm was devised, and UML diagrams were crafted to delineate the system structure, classes, attributes, methods, and object relationships.

- A simulation program was developed in C++ specifically tailored for single and small-scale production, with the objective of automating the technological processing process by automatically generating a plethora of work scenarios and subsequently selecting the optimal scenario for the production site based on two criteria: time and cost.

- Upon simulating the production of the “Pusher” component, the resultant production cycle lasted 471 working hours, with variable costs totaling 175,000 conventional units.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Chernorutsky, I.; Kotlyarov, V.; Shyamasundar, R.; Tolstoles, A.; Voinov, N. Implementation of reliable net-centric management of IoT industrial workshop for small-scale production. IOP Conf. Ser. Mater. Sci. Eng. 2018, 497, 012040. [Google Scholar] [CrossRef]

- Manzei, C.; Schleupner, L.; Heinze, R. Industrie 4.0 im Internationalen Kontext: Kernkonzepte, Ergebnisse, Trends; VDE VERLAG GmbH: Berlin, Germany, 2016; p. 261. [Google Scholar]

- Marcos, M.P.; Pitarch, J.L.; de Prada, C. Integrated Process Re-Design with Operation in the Digital Era: Illustration through an Industrial Case Study. Processes 2021, 9, 1203. [Google Scholar] [CrossRef]

- Bako, B.; Božek, P. Trends in simulation and planning of manufacturing companies. Procedia Eng. 2016, 149, 571–575. [Google Scholar] [CrossRef]

- Chlebus, E.; Krot, K. CAD 3D models decomposition in manufacturing processes. Arch. Civ. Mech. Eng. 2016, 16, 20–29. [Google Scholar] [CrossRef]

- Adam, R.; Kotze, P.; Van der Merwe, A. Acceptance of enterprise resource planning systems by small manufacturing Enterprises. In Proceedings of the 13th International Conference on Enterprise Information Systems, Beijing, China, 8–11 June 2011; Volume 1. [Google Scholar] [CrossRef]

- Browne, J.; O’Kelly, M.E.J.; Davies, B.J. Scheduling in a batch or job shop production environment. Eng. Manag. Int. 1982, 1, 173–184. [Google Scholar] [CrossRef]

- Burdo, G.B. Improving the technological preparations for manufacturing production. Russ. Eng. Res. Vol. 2017, 37, 49–56. [Google Scholar] [CrossRef]

- Siderska, J. Application of tecnomatix plant simulation for modeling production and logistics processes. Bus. Manag. Educ. 2016, 14, 64–73. [Google Scholar] [CrossRef]

- Dong, S.; Medeiros, D.J. Minimising schedule cost via simulation optimization: An application in pipe manufacturing. Int. J. Prod. Res. 2012, 50, 831–841. [Google Scholar] [CrossRef]

- San Cristobal, J.R. Critical Path Definition Using Multicriteria Decision Making: Promethee Method. J. Constr. Eng. Manag. 2013, 29, 158–163. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Castillo-Lopez, E.; Rodriguez-Hernandez, J.; Canteras-Jordana, J. A review of application of multi-criteria decision making methods in construction. Autom. Constr. 2014, 45, 151–162. [Google Scholar] [CrossRef]

- Rosova, A.; Behun, M.; Khouri, S.; Cehlar, M.; Ferencz, V.; Sofranko, M. Case study: The simulation modeling to improve the efficiency and performance of production process. Wirel. Netw. 2022, 28, 863–872. [Google Scholar] [CrossRef]

- Pompeev, K.P.; Timofeeva, O.S.; Yablochnikov, E.I.; Volosatova, E.E. Methods of Parts Digital Models Design for Problems Resolving in Technological Preparation of Production. In Advances in Mechanical Engineering; Lecture Notes in Mechanical Engineering; Evgrafov, A.N., Ed.; Springer: Berlin/Heidelberg, Germany, 2022; pp. 129–139. [Google Scholar] [CrossRef]

- Torres-Jimenez, J.; Rangel-Valdez, N.; De-la-Torre, M.; Avila-George, H. An Approach to Aid Decision-Making by Solving Complex Optimization Problems Using SQL Queries. Appl. Sci. 2022, 12, 4569. [Google Scholar] [CrossRef]

- Sipser, M. Introduction to the Theory of Computation, 2nd ed.; Thomson: Boston, MA, USA, 2006; p. 418. ISBN 0-534-95097-3. [Google Scholar]

- Abramov, S.A. Lectures on the Complexity of Algorithms, 3rd ed.; MTsNMO: Moscow, Russia, 2020; p. 256. ISBN 978-5-443-91464-0. [Google Scholar]

- Kalyakulin, S.Y.; Kuzmin, V.V.; Mitin, E.V.; Suldin, S.P.; Tyurbeeva, T.B. Designing the Structure of Technological Processes Based on Synthesis. Mordovia Univ. Bull. 2018, 28, 77–84. [Google Scholar] [CrossRef]

- Khrustaleva, I.N.; Lyubomudrov, S.A.; Chernykh, L.G.; Stepanov, S.N.; Larionova, T.A. Automating production engineering for custom and small-batch production on the basis of simulation modeling. J. Phys. Conf. Ser. 2021, 1753, 012047. [Google Scholar] [CrossRef]

- Ivanov, V.; Botko, F.; Kolos, V.; Pavlenko, I.; Hatala, M.; Antosz, K.; Trojanowska, J. Locating Chart Choice Based on the Decision-Making Approach. Materials 2022, 15, 3557. [Google Scholar] [CrossRef] [PubMed]

- Trojanowska, J.; Kolinski, A.; Galusik, D.; Rocha Varela, L. A methodology of improvement of manufacturing productivity through increasing operational efficiency of the production process. In Advances in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2018; pp. 23–32. [Google Scholar] [CrossRef]

- Araujo, A.F.; Varela, M.L.; Gomes, M.S.; Barreto, R.C.; Trojanowska, J. Development of an intelligent and automated system for lean industrial production, adding maximum productivity and efficiency in the production process. In Advances in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2018; pp. 131–140. [Google Scholar] [CrossRef]

- Vukelic, D.; Zuperl, U.; Hodolic, J. Complex system for fixture selection, modification, and design. Int. J. Adv. Manuf. Technol. 2009, 45, 731–748. [Google Scholar] [CrossRef]

- Abouel Nasr, E.; Al-Ahmari, A.; Khan, A.A.; Mian, S.H. Integrated system for automation of process, fixture and inspection planning. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 52. [Google Scholar] [CrossRef]

- Liu, M.; Zhou, B.; Li, J.; Li, X.; Bao, J. A Knowledge Graph-Based Approach for Assembly Sequence Recommendations for Wind Turbines. Machines 2023, 11, 930. [Google Scholar] [CrossRef]

- Chen, Z.; Bao, J.; Zheng, X.; Liu, T. Assembly information model based on knowledge graph. J. Shanghai Jiaotong Univ. 2020, 25, 578–588. [Google Scholar] [CrossRef]

- Li, X.; Zhang, S.; Huang, R.; Huang, B.; Xu, C.; Kuang, B. Structured modeling of heterogeneous CAM model based on process knowledge graph. Int. J. Adv. Manuf. Technol. 2018, 96, 4173–4193. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, H.; Li, J.; Zhang, Q.; Tang, Y. CKGAT: Collaborative Knowledge-Aware Graph Attention Network for Top-N Recommendation. Appl. Sci. 2022, 12, 1669. [Google Scholar] [CrossRef]

- Han, Z.; Mo, R.; Hao, L. Clustering and retrieval of mechanical CAD assembly models based on multi-source attributes information. Robot. Comput. Integr. Manuf. 2019, 58, 220–229. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Sabatakakis, K. Data Attributes in Quality Monitoring of Manufacturing Processes: The Welding Case. Appl. Sci. 2023, 13, 10580. [Google Scholar] [CrossRef]

- Wang, X.; Liu, M.; Zhong, P.; Zhang, C.; Zhang, D. A Discrete Cooperative Control Method for Production Scheduling Problem of Assembly Manufacturing System. Sustainability 2023, 15, 13785. [Google Scholar] [CrossRef]

- Xiong, H.; Shi, S.; Ren, D.; Hu, J. A survey of job shop scheduling problem: The types and models. Comput. Oper. Res. 2022, 142, 105731. [Google Scholar] [CrossRef]

- Mokhtari, H.; Hasani, A. An energy-efficient multi-objective optimization for flexible job-shop scheduling problem. Comput. Chem. Eng. 2017, 104, 339–352. [Google Scholar] [CrossRef]

- Ciurana, J.; Garcia-Romeu, M.L.; Ferrer, I.; Casadesus, M. A model for integrating process planning and production planning and control in machining processes. Robot. Comput. Integr. Manuf. 2008, 24, 532–544. [Google Scholar] [CrossRef]

- García-Leon, A.A.; Dauzère-Pérès, S.; Mati, Y. An efficient Pareto approach for solving the multi-objective flexible job-shop scheduling problem with regular criteria. Comput. Oper. Res. 2019, 108, 187–200. [Google Scholar] [CrossRef]

- Knopp, S.; Dauzère-Pérès, S.; Yugma, C. A batch-oblivious approach for Complex Job-Shop scheduling problems. Eur. J. Oper. Res. 2017, 263, 50–61. [Google Scholar] [CrossRef]

- Azzouz, A.; Ennigrou, M.; Ben Said, L. A self-adaptive hybrid algorithm for solving flexible job-shop problem with sequence dependent setup time. Procedia Comput. Sci. 2017, 112, 457–466. [Google Scholar] [CrossRef]

- Xing, L.N.; Chen, Y.W.; Yang, K.W. An efficient search method for multi-objective flexible job shop scheduling problems. J. Intell. Manuf. 2009, 20, 283–293. [Google Scholar] [CrossRef]

- Shen, X.N.; Han, Y.; Fu, J.Z. Robustness measures and robust scheduling for multi-objective stochastic flexible job shop scheduling problems. Soft Comput. 2017, 21, 6531–6554. [Google Scholar] [CrossRef]

- Fernández Pérez, M.A.; Raupp, F.M.P. A Newton-based heuristic algorithm for multi-objective flexible job-shop scheduling problem. J. Intell. Manuf. 2016, 27, 409–416. [Google Scholar] [CrossRef]

- Moslehi, G.; Mahnam, M. A Pareto approach to multi-objective flexible job-shop scheduling problem using particle swarm optimization and local search. Int. J. Prod. Econ. 2011, 129, 14–22. [Google Scholar] [CrossRef]

- Kacem, I.; Hammadi, S.; Borne, P. Pareto-optimality approach for flexible job-shop scheduling problems: Hybridization of evolutionary algorithms and fuzzy logic. Math. Comput. Simul. 2002, 60, 245–276. [Google Scholar] [CrossRef]

- Gunantara, N. A review of multi-objective optimization: Methods and its applications. Cogent Eng. 2018, 5, 1502242. [Google Scholar] [CrossRef]

- Ondov, M.; Rosova, A.; Sofranko, M.; Feher, J.; Cambal, J.; Feckova Skrabulakova, E. Redesigning the Production Process Using Simulation for Sustainable Development of the Enterprise. Sustainability 2022, 14, 1514. [Google Scholar] [CrossRef]

- Iassinovski, S.; Artiba, A.; Fagnart, C. A generic production rules-based system for on-line simulation, decision making and discrete process control. Int. J. Prod. Econ. 2008, 112, 62–76. [Google Scholar] [CrossRef]

- Bernard, A.; Perry, N. Fundamental concepts of product/technology/process informational integration for process modelling and process planning. Int. J. Comput. Integr. Manuf. 2003, 16, 557–565. [Google Scholar] [CrossRef][Green Version]

- Shah, D.; Shin, J. Randomized scheduling algorithm for queueing networks. Ann. Appl. Probab 2012, 22, 128–171. [Google Scholar] [CrossRef]

- Bathaee, M.; Nozari, H.; Szmelter-Jarosz, A. Designing a New Location-Allocation and Routing Model with Simultaneous Pick-Up and Delivery in a Closed-Loop Supply Chain Network under Uncertainty. Logistics 2023, 7, 3. [Google Scholar] [CrossRef]

- Malega, P.; Gazda, V.; Rudy, V. Optimization of production system in plant simulation. Simulation 2022, 98, 295–306. [Google Scholar] [CrossRef]

- Kuznetsov, P.M.; Khoroshko, L.L. Digitalization of Multi-Object Technological Projecting in Terms of Small Batch Production. Inventions 2020, 5, 38. [Google Scholar] [CrossRef]

- Simunovic, G.; Majdandzic, N.; Simunovic, K.; Lujic, R. Applying of the Typical Technological Operations in the Single Production. In AMST’02 Advanced Manufacturing Systems and Technology; International Centre for Mechanical Sciences; Kulianic, E., Ed.; Springer: Vienna, Austria, 2002; Volume 437, pp. 275–281. [Google Scholar] [CrossRef]

| № | Machine Type | Type of Machinery Designation | Machining Technique | Designation of Processing Method |

|---|---|---|---|---|

| 1 | Tun | mach1 | tapping threads | op1 |

| drilling | op2 | |||

| semi-finish turning | op3 | |||

| rough turning | op4 | |||

| finishing turning | op5 | |||

| 2 | TCNC | mach2 | tapping threads | op1 |

| drilling | op2 | |||

| semi-finish turning | op3 | |||

| rough turning | op4 | |||

| finishing turning | op5 | |||

| 3 | TFCNC | mach3 | tapping threads | op1 |

| drilling | op2 | |||

| semi-finish turning | op3 | |||

| rough turning | op4 | |||

| finishing turning | op5 | |||

| pre- | op6 | |||

| grinding | ||||

| 4 | KS | mach4 | tapping threads | op1 |

| № | Block of Surfaces | DTE | Processing Method | Machining Process Identification | |

|---|---|---|---|---|---|

| 1 | MB(1/2) | 1 | DTE(1H-1)2 | rough turning | op4 |

| 2 | DTE(2H/1-4)1 | re-grinding | op6 | ||

| rough turning | op4 | ||||

| semi-finish turning | op3 | ||||

| finishing turning | op5 | ||||

| 2 | MB(2/1) | 1 | DTE(2B/1-2)1 | drilling | op2 |

| semi-finish turning | op3 | ||||

| 2 | DTE(2B/1-1)2 | drilling | op2 | ||

| 3 | DTE(2B/2-1)1 | drilling | op2 | ||

| 4 | DTE(1B-1)1 | rough turning | op4 | ||

| 3 | MB(1/1) | 1 | DTE(1H-1)1 | rough turning | op4 |

| 2 | DTE(2H/2-1)2 | rough turning | op4 | ||

| 3 | DTE(2H/1-1)2 | rough turning | op4 | ||

| 4 | DTE(2H/2-1)1 | rough turning | op4 | ||

| 4 | MB(2/2) | 1 | DTE(2B/1-2)3 | drilling | op2 |

| semi-finish turning | op3 | ||||

| 2 | DTE(2B/1-3)4 | drilling | op2 | ||

| semi-finish turning | op3 | ||||

| rough turning | op5 | ||||

| 3 | DTE(2B/2-2)2 | drilling | op2 | ||

| semi-finish turning | op3 | ||||

| 4 | DTE(1B-1)2 | rough turning | op4 | ||

| 5 | DTE(1B-2)3 | rough turning | op4 | ||

| semi-finish turning | op3 | ||||

| 5 | MB(4/1) | 1 | DTE(4B/1-2)1 | drilling | op2 |

| thread cutting | op1 | ||||

| № | Designation of Processing Method | Processing Method | Processing Time (Working Hours) | Amount of Costs (Conventional Units) |

|---|---|---|---|---|

| 1 | op1 | tapping threads | 32 | 4800 |

| 2 | op2 | drilling | 18 | 5600 |

| 3 | op3 | semi-finish turning | 12 | 8200 |

| 4 | op4 | rough turning | 20 | 6800 |

| 5 | op5 | finishing turning | 16 | 7400 |

| 6 | op6 | re-grinding | 29 | 5800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savelyeva, N.; Nikonova, T.; Zhetessova, G.; Irina, K.; Yurchenko, V.; Černašėjus, O.; Zharkevich, O.; Dandybaev, E.; Berg, A.; Vassenkin, S.; et al. Implementation of Simulation Modeling of Single and High-Volume Machine-Building Productions. Designs 2024, 8, 24. https://doi.org/10.3390/designs8020024

Savelyeva N, Nikonova T, Zhetessova G, Irina K, Yurchenko V, Černašėjus O, Zharkevich O, Dandybaev E, Berg A, Vassenkin S, et al. Implementation of Simulation Modeling of Single and High-Volume Machine-Building Productions. Designs. 2024; 8(2):24. https://doi.org/10.3390/designs8020024

Chicago/Turabian StyleSavelyeva, Nadezhda, Tatyana Nikonova, Gulnara Zhetessova, Khrustaleva Irina, Vassiliy Yurchenko, Olegas Černašėjus, Olga Zharkevich, Essim Dandybaev, Andrey Berg, Sergey Vassenkin, and et al. 2024. "Implementation of Simulation Modeling of Single and High-Volume Machine-Building Productions" Designs 8, no. 2: 24. https://doi.org/10.3390/designs8020024

APA StyleSavelyeva, N., Nikonova, T., Zhetessova, G., Irina, K., Yurchenko, V., Černašėjus, O., Zharkevich, O., Dandybaev, E., Berg, A., Vassenkin, S., & Baimuldin, M. (2024). Implementation of Simulation Modeling of Single and High-Volume Machine-Building Productions. Designs, 8(2), 24. https://doi.org/10.3390/designs8020024