Comparative Analysis of Various Hyperelastic Models and Element Types for Finite Element Analysis

Abstract

:1. Introduction

2. Hyperelastic Material Models

2.1. Neo-Hookean

2.2. Mooney–Rivlin

2.3. Two-Term Reduced Polynomial

2.4. Two-Term Polynomial

2.5. Yeoh

2.6. Arruda–Boyce

2.7. Three-Term Ogden

2.8. Van Der Waals

2.9. Marlow

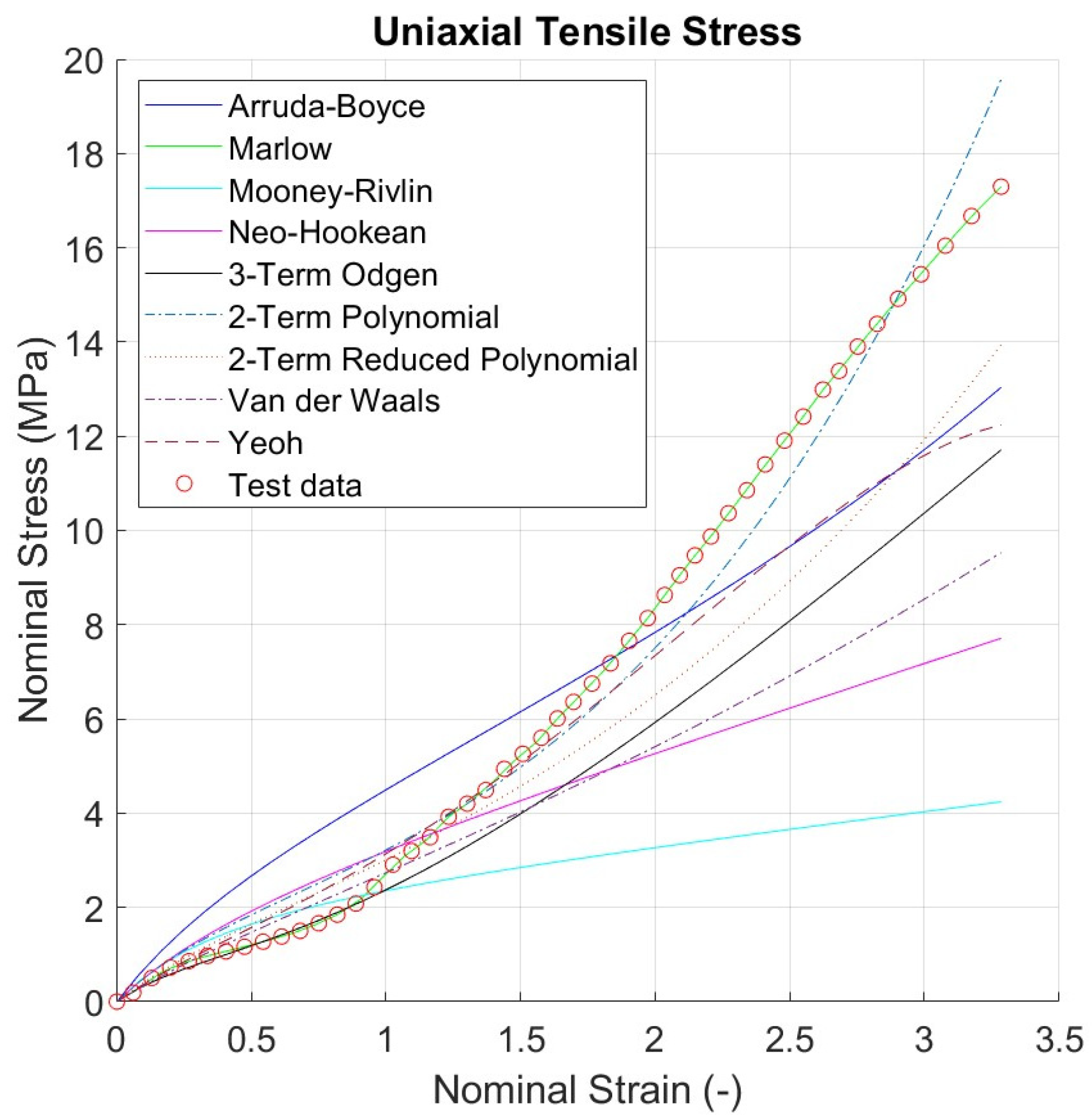

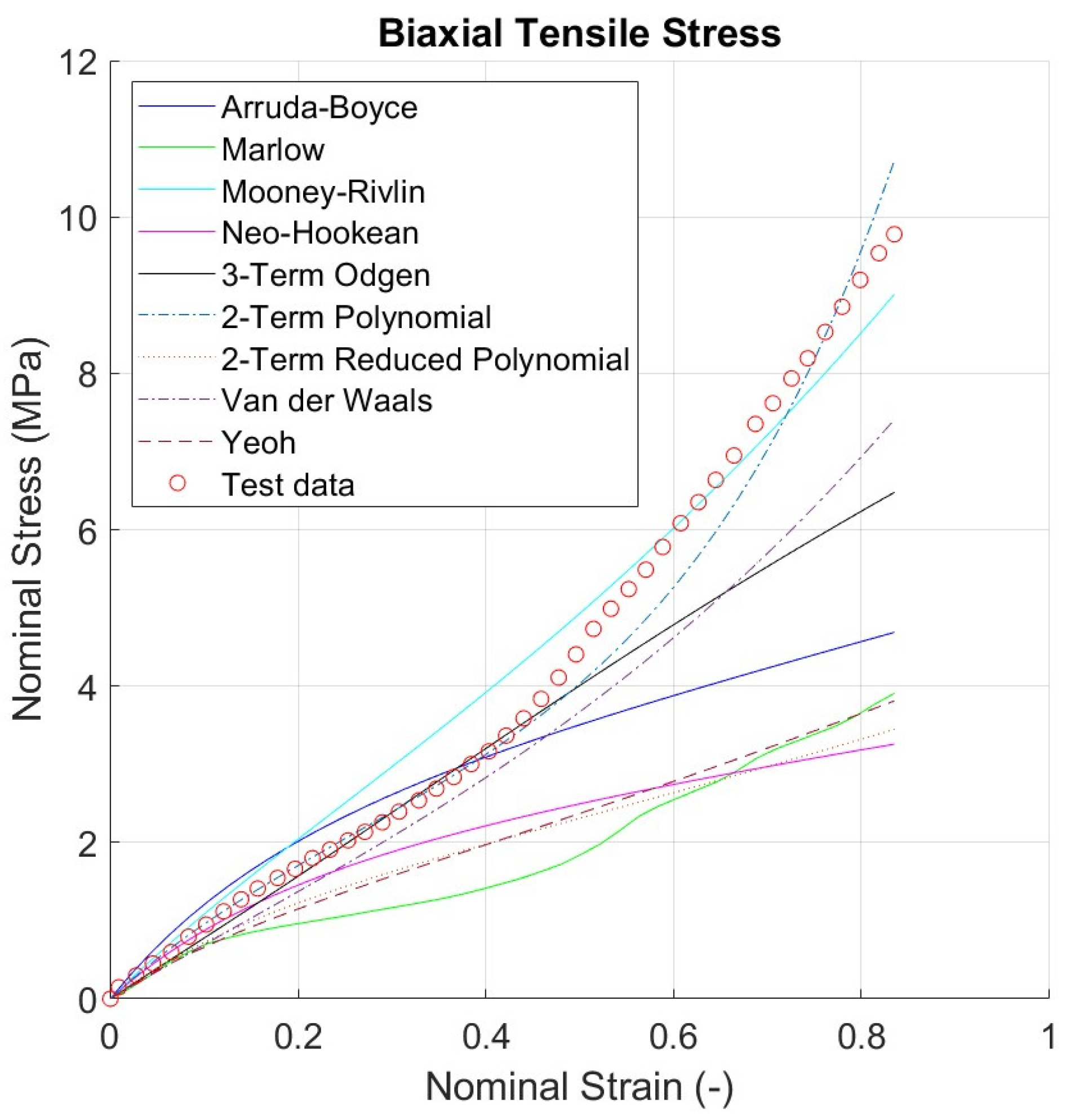

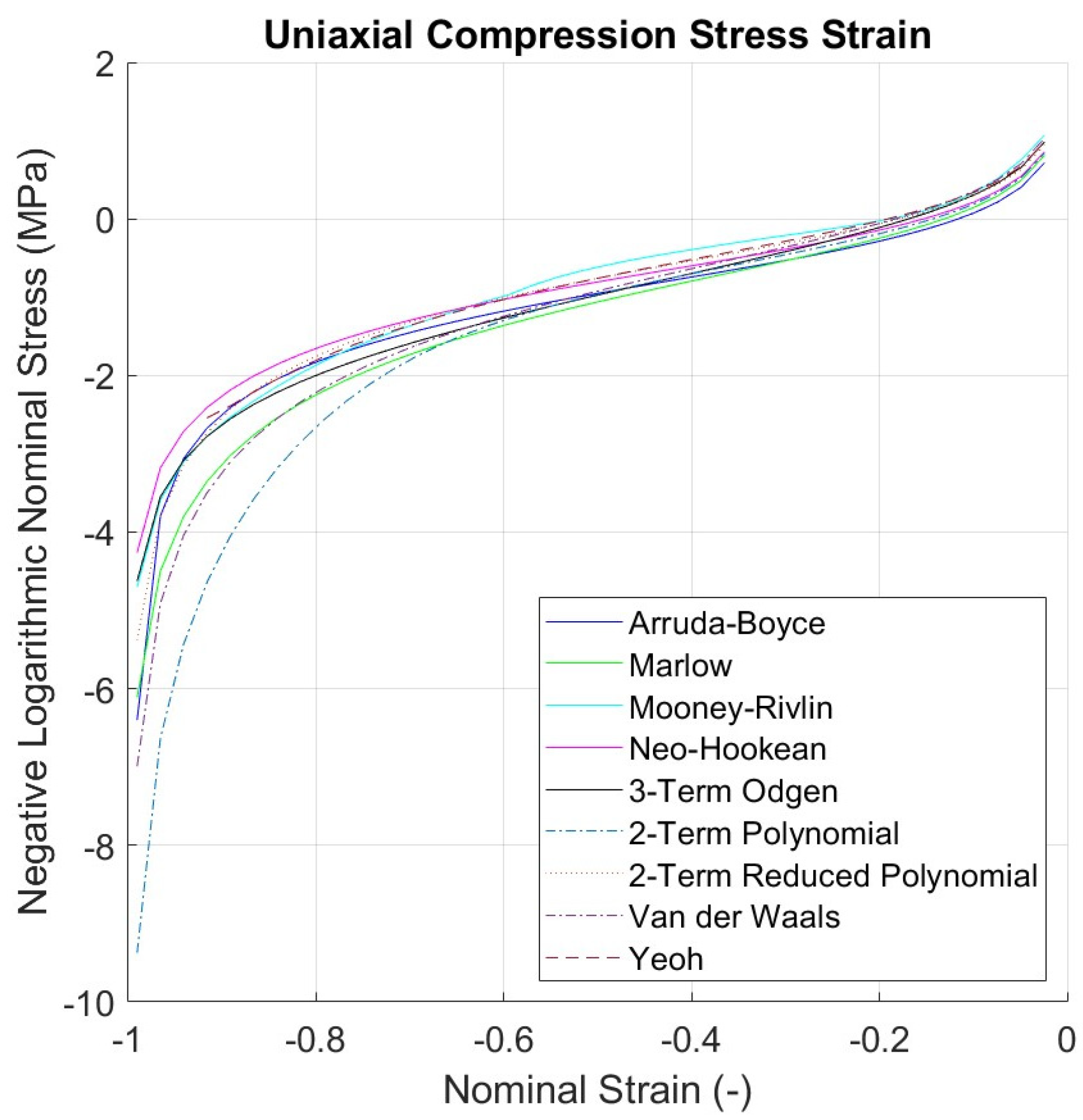

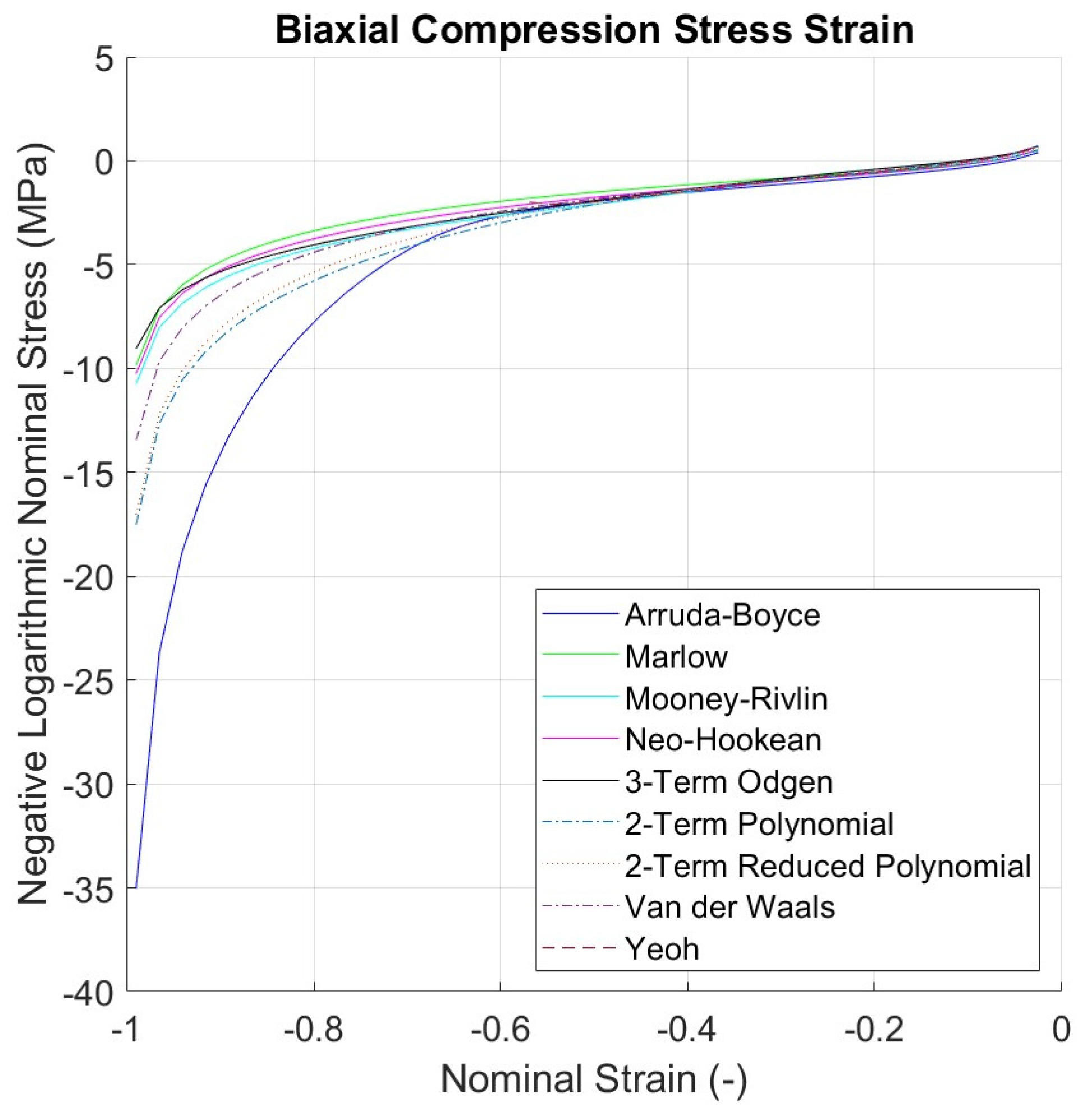

3. Curve Fitting for Hyperelastic Models

3.1. Elastomer Mechanical Test Data

3.2. Test Data Fitting

3.3. Curve Fitting Results for Each Hyperelastic Model

4. Finite Element Analysis

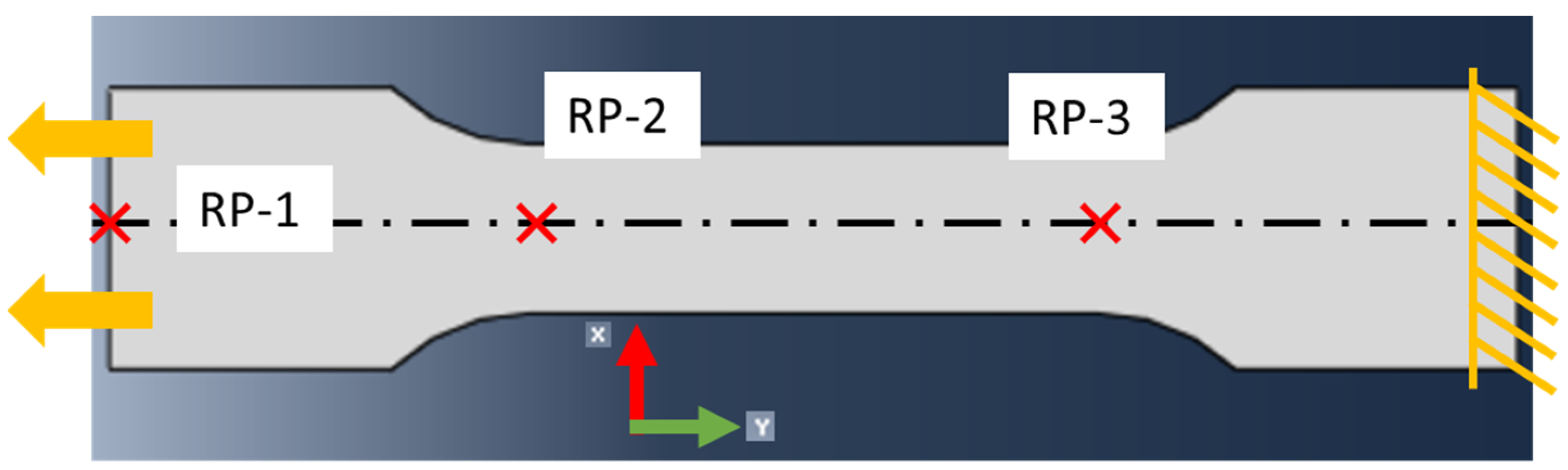

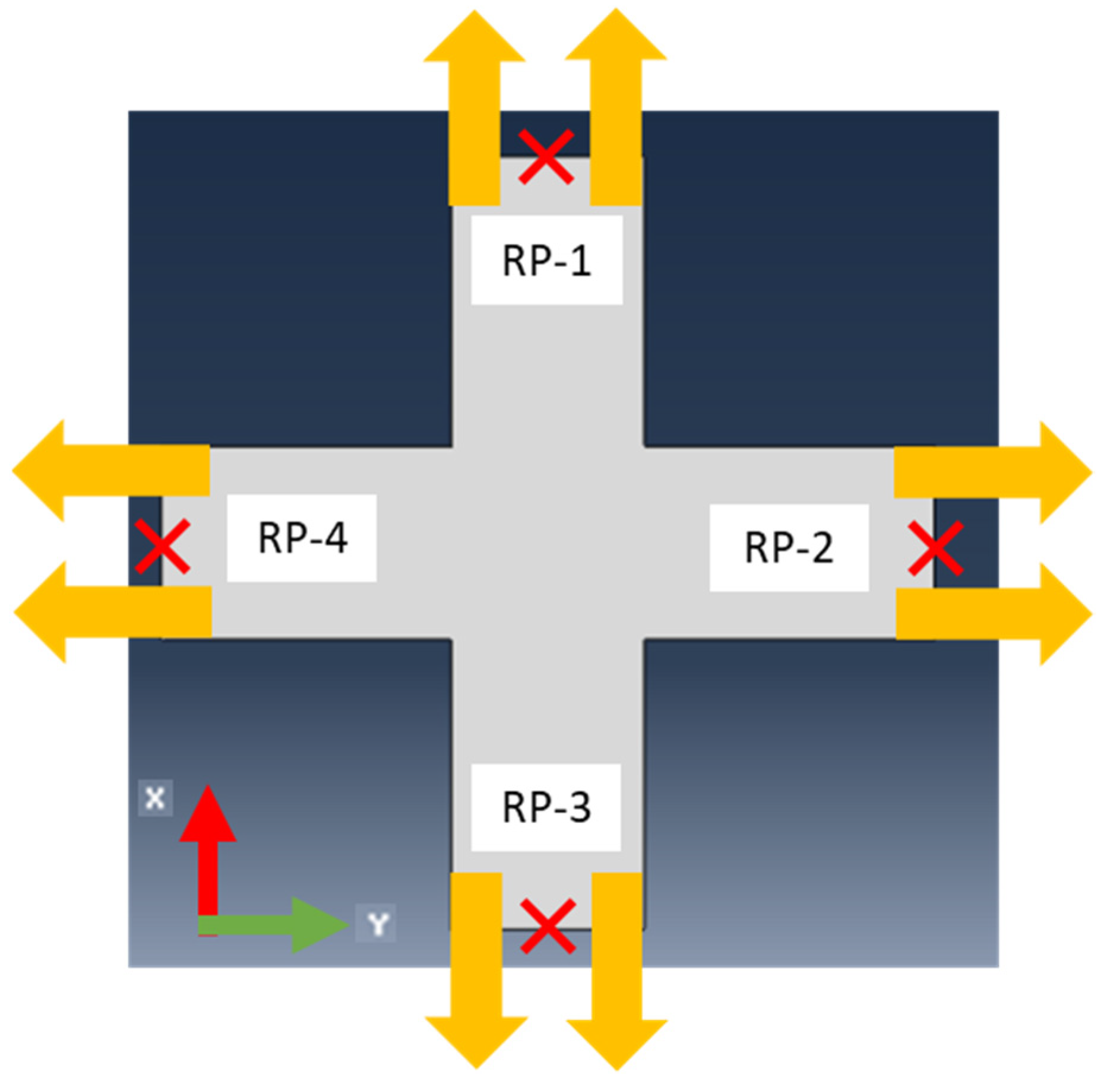

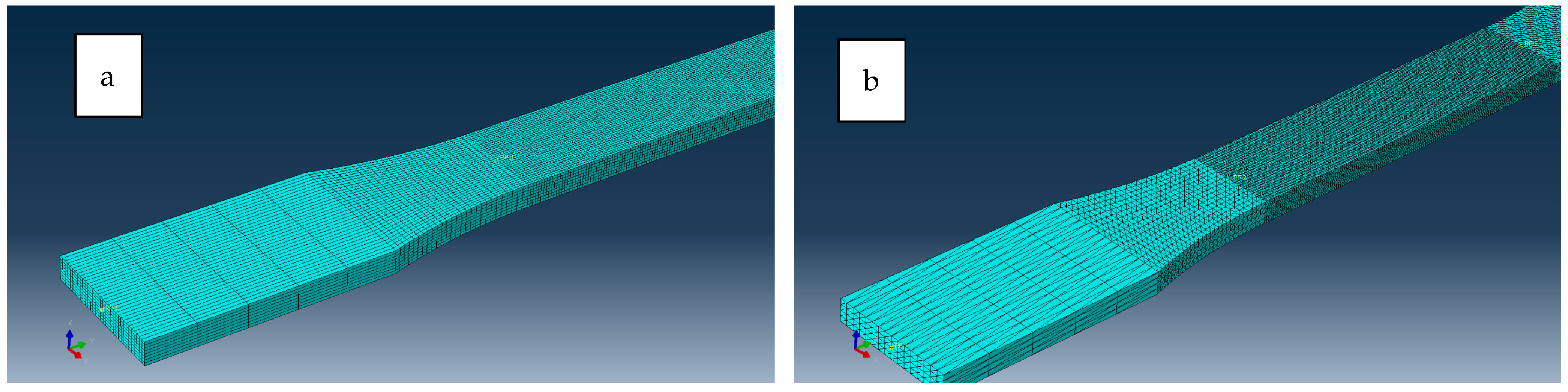

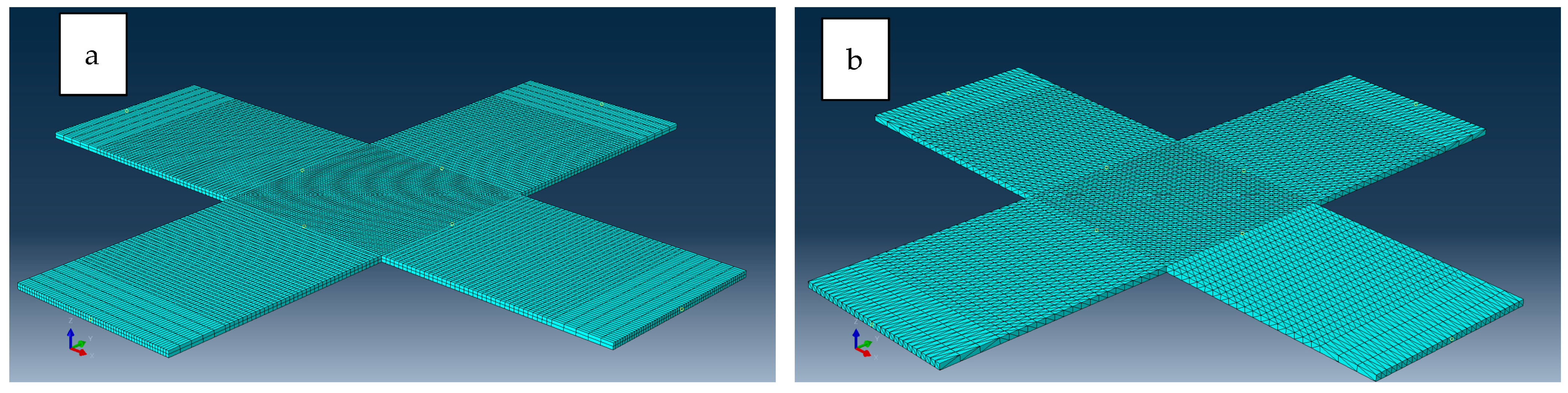

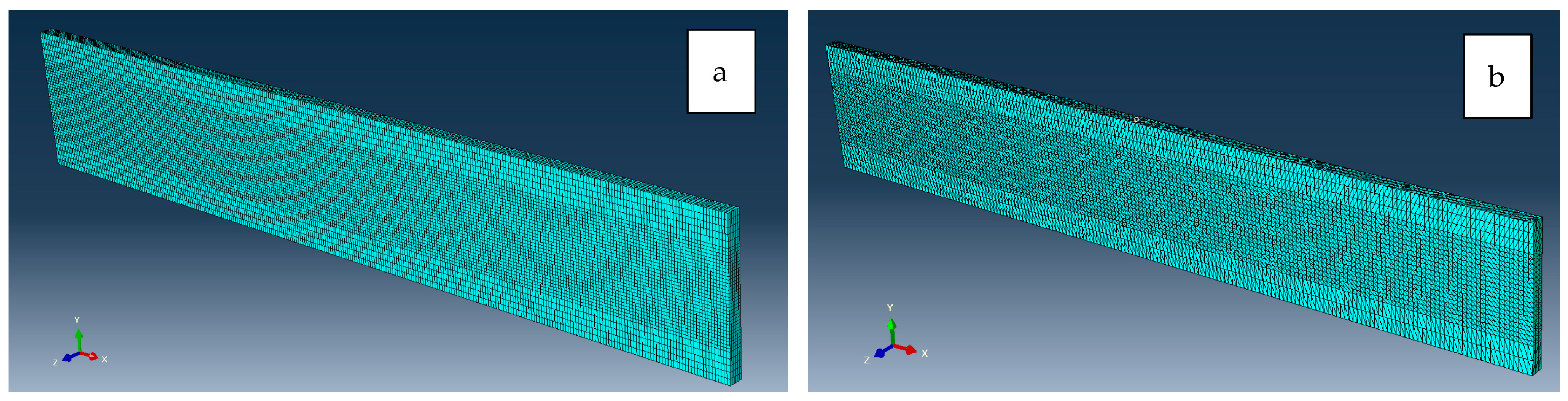

Numerical Simulations Setup

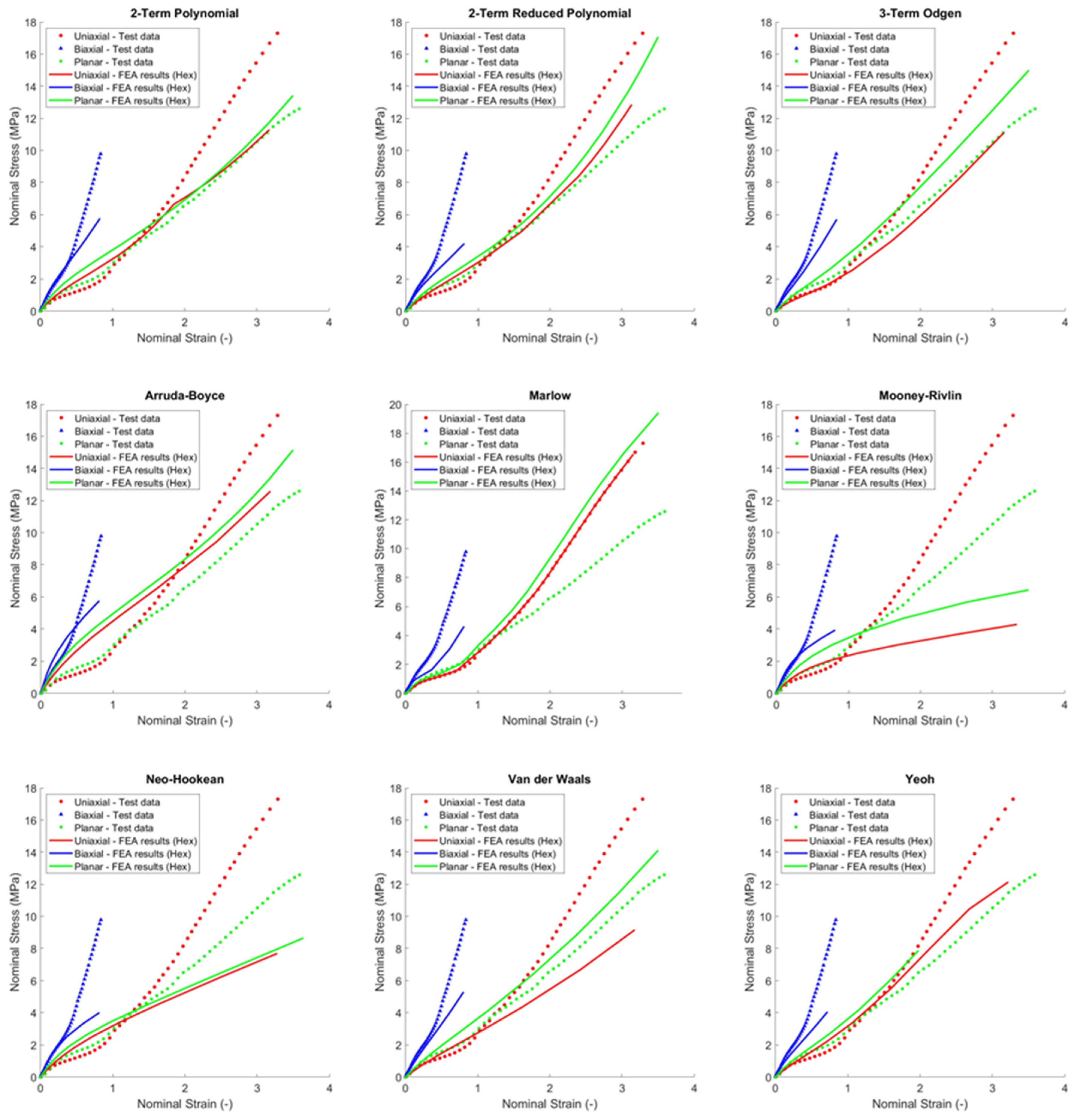

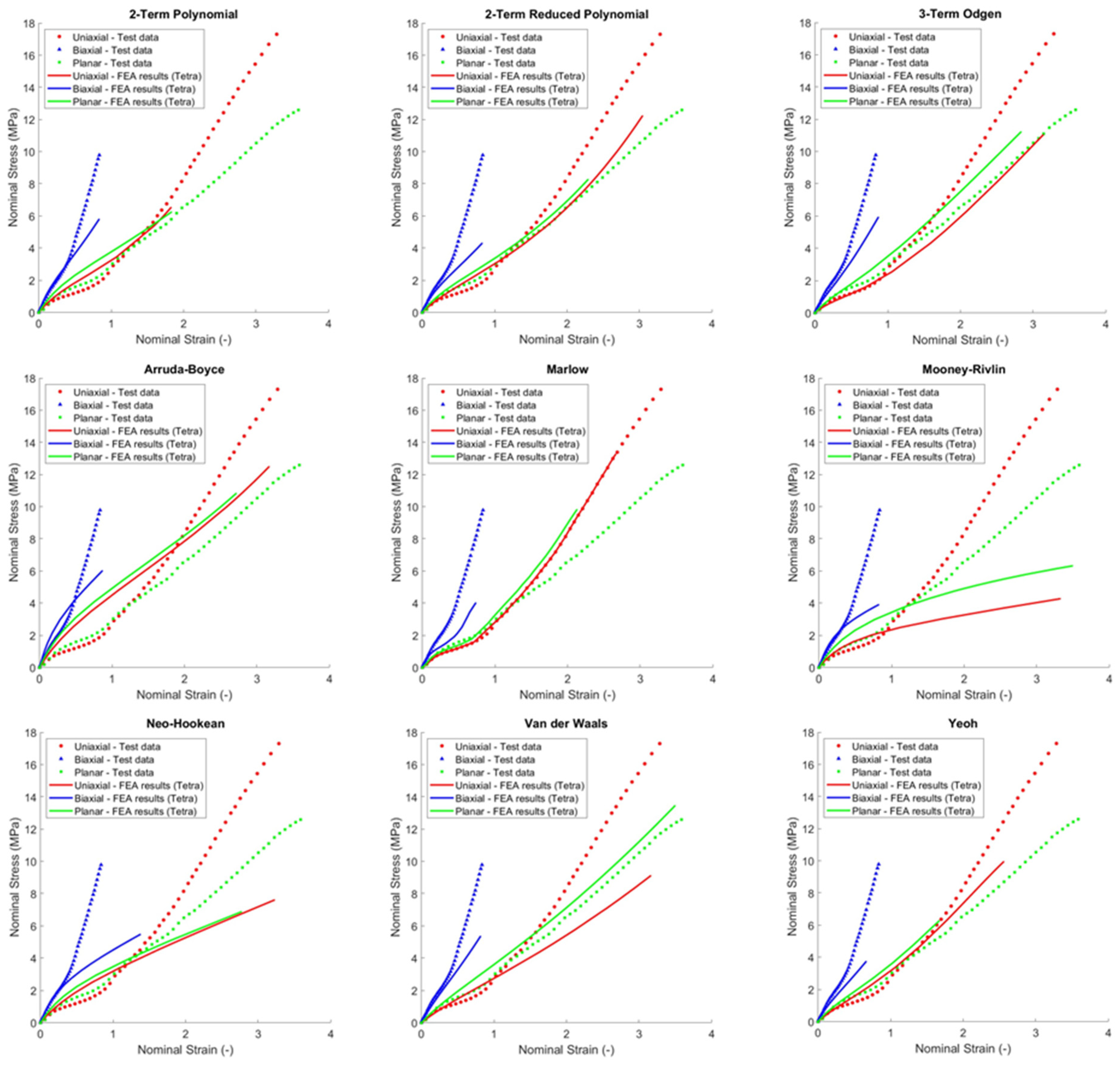

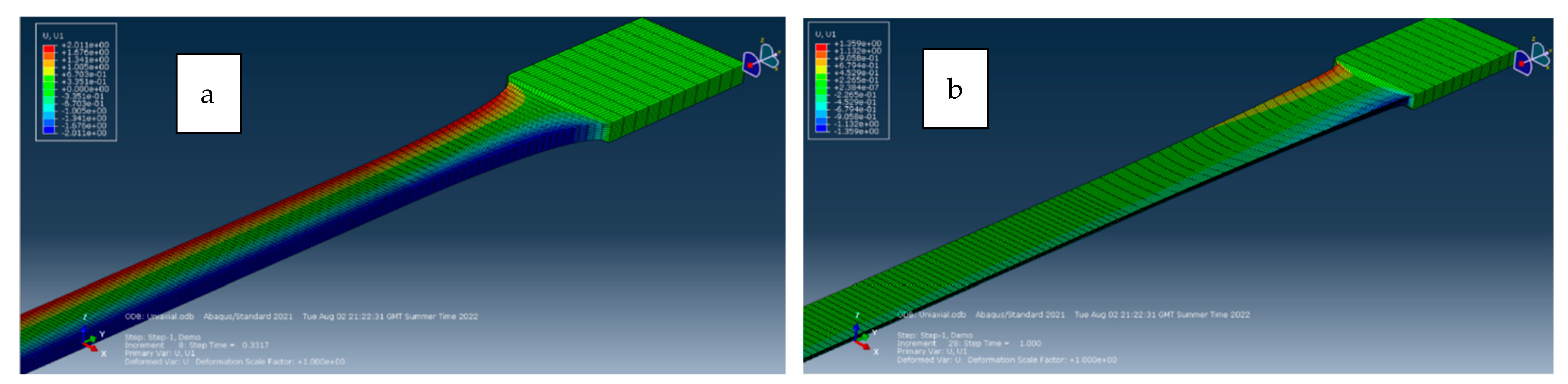

5. Numerical Simulation Results

6. Discussion

6.1. Uniaxial Tension Simulations

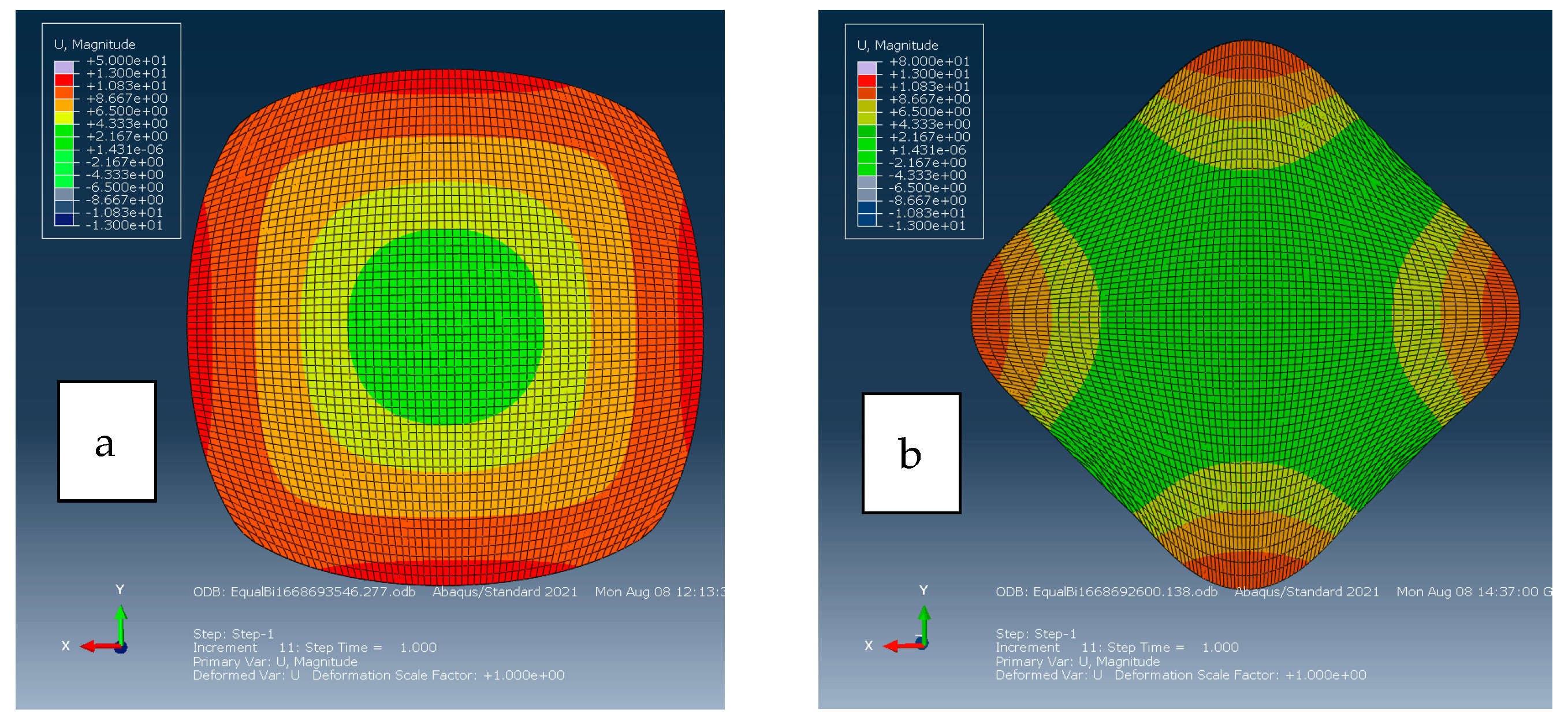

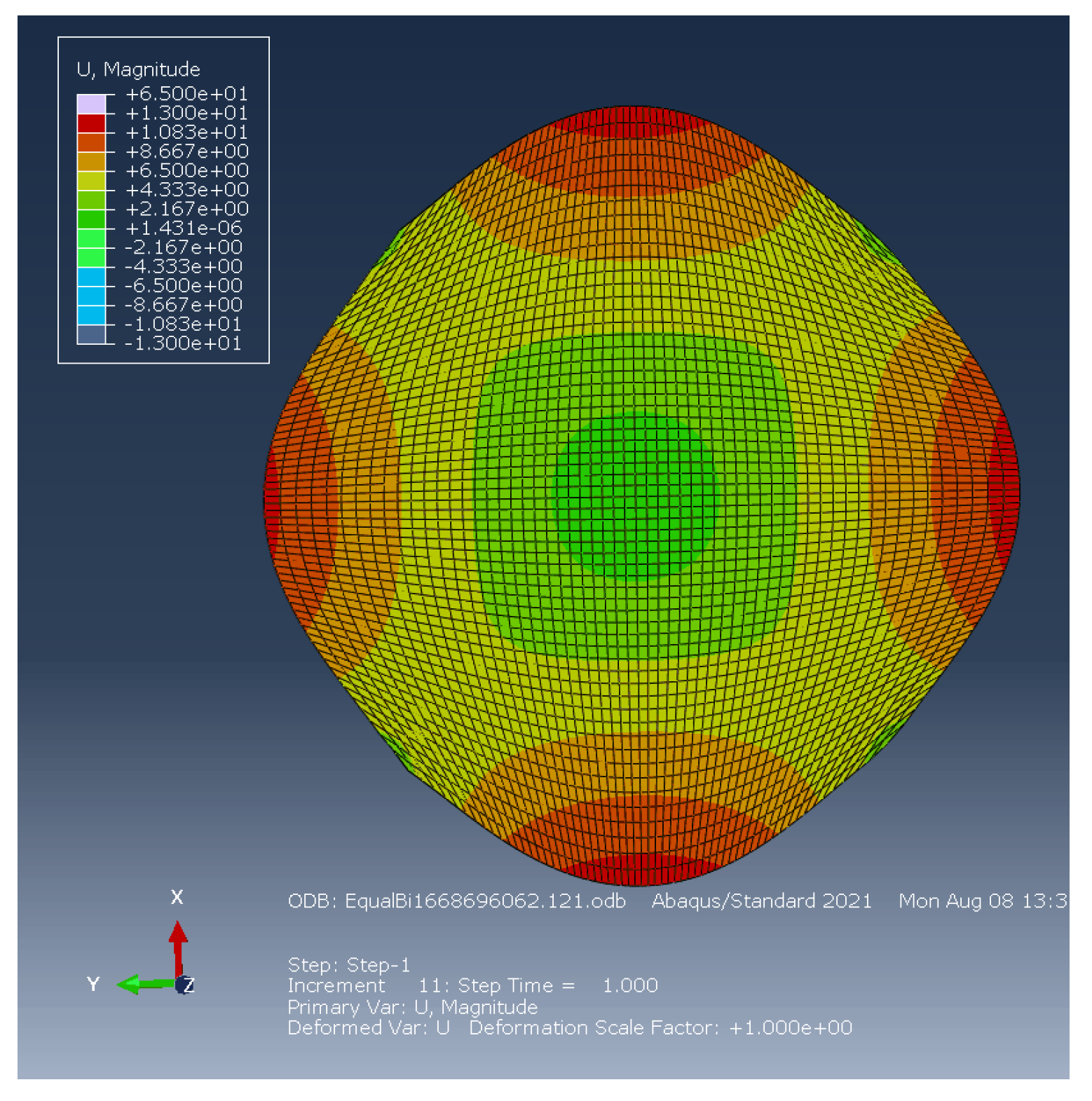

6.2. Biaxial Tensile Simulations

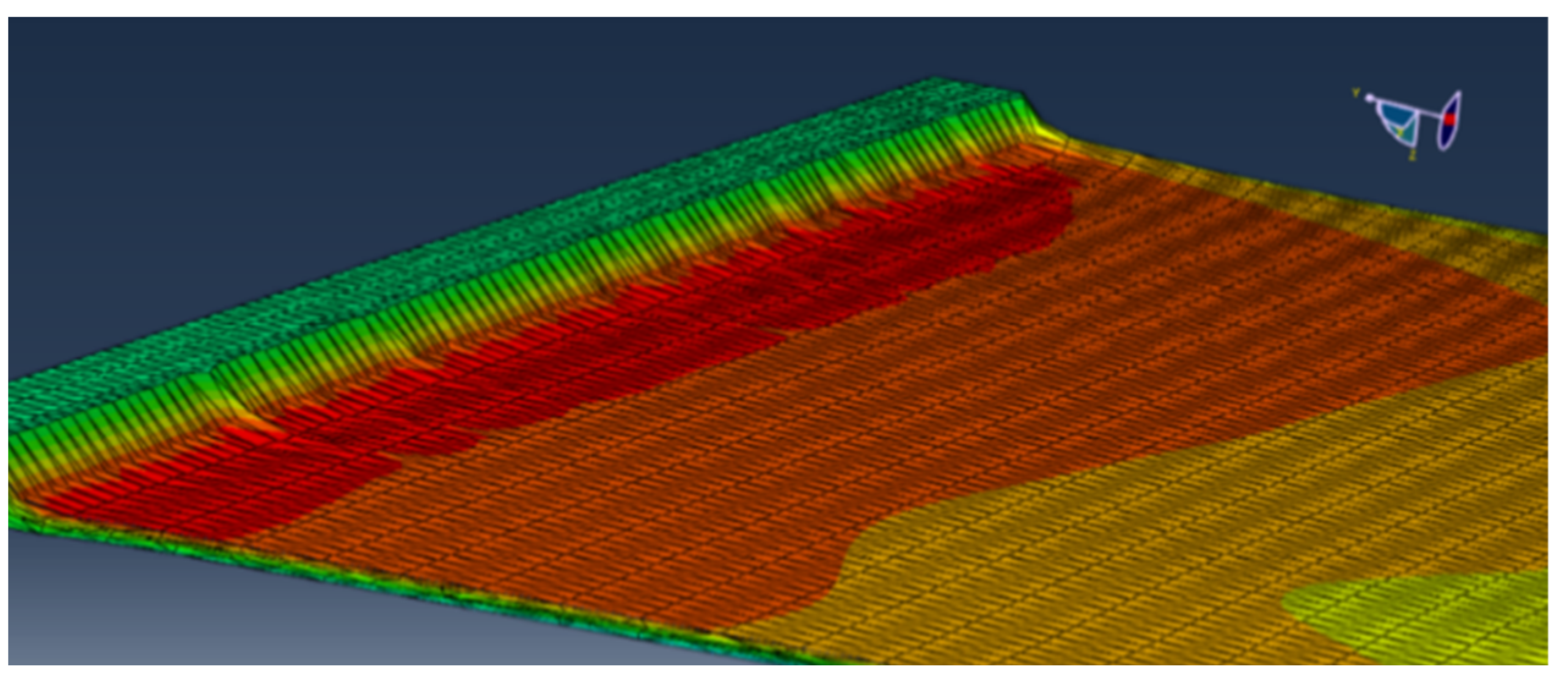

6.3. Planar Shear Simulations

7. Conclusions

- The material parameters from each hyperelastic model were employed to create stress–strain prediction curves for the material element. Through uniaxial, biaxial, and planar shear simulations, several observations were made:

- For uniaxial tensile, reduced polynomial and van der Waals models are stable in the smaller strain range (0 to 0.3) whilst two-term polynomial and Yeoh models are stable in a larger range between 0 and 1.5.

- For biaxial tensile, all the nine models investigated here can accurately predict the material behaviour up to 0.1, with Mooney–Rivlin, neo-Hookean, and two polynomial term models that can also provide an accurate response in the strain range between 0.1 and 0.3.

- For planar shear, all the nine models investigated here can accurately predict the material behaviour up to 0.5, with the Marlow model that can predict the response in a strain range up to 1, the reduced polynomial model that can match also in the strain range between 1.1 and 1.6, and the two polynomial term model that matches experimental results in the range of 1.9 and 3.2.

- From the biaxial simulation results shown in Figure 18 and Figure 19, it can be concluded that the geometry and configuration of the specimen used in the biaxial test dictates the maximum biaxial stress levels achievable in simulations before instability occurs. For this reason, divergence between biaxial tensile test and simulation results for biaxial strain greater than 0.3 is observed as shown in Figure 14 and Figure 15.

- Hexagonal elements allowed for a greater shear strain range (approximately 30% greater) compared to tetrahedral elements, as observed comparing Figure 14 and Figure 15. In addition, tetrahedral elements might pose simulation convergence challenges due to excessive distortion in higher shear strain scenarios as shown in Figure 20.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bergstrom, J.S. Mechanics of Solid Polymers; William Andrew Publishing: Norwich, NY, USA, 2015. [Google Scholar]

- Guo, Z.; Sluys, L.J. Constitutive Modelling of Hyperelastic Rubber-like Materials. HERON 2008, 53, 109–132. [Google Scholar]

- Mooney, M. A Theory of Large Elastic Deformation. J. Appl. Phys. 1940, 11, 582. [Google Scholar] [CrossRef]

- Wood, R.D. Nonlinear Continuum Mechanics for Finite Element Analysis, 2nd ed.; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Steinmann, P.; Hossain, M.; Possart, G. Hyperelastic Models for Rubber-Like Materials: Consistent Tangent Operators and Suitability for Trelor’s Data. Arch. Appl. Mech. 2012, 82, 1183–1217. [Google Scholar] [CrossRef]

- Anandan, S.; Lim, C.Y.; Tan, B.T.; Anggraini, V.; Raghunandan, M.E. Numerical and Experimental Investigation of Oil Palm Shell Reinforced Rubber Composites. Polymers 2020, 12, 314. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.J.; Lee, J.; Woo, C.S.; Kim, B.K.; Lee, S.B. An Experimental Study and Finite Element Analysis of Weatherstrip. Int. J. Precis. Eng. Manuf. 2011, 12, 97–104. [Google Scholar] [CrossRef]

- Luo, R.K. Complete Loading-Unloading-Deflection Prediction for Antivibration System Design Using Hyperelastic-Dissipation Approach. J. Mater. Des. Appl. 2022, 234, 859–872. [Google Scholar] [CrossRef]

- Marckmann, G.; Verron, E. Comparison of Hyperelastic Models for Rubber-like Materials. Rubber Chem. Technol. 2006, 79, 835–858. [Google Scholar] [CrossRef]

- He, H.; Zhang, Q.; Zhang, Y.; Chen, J.; Zhang, L.; Li, F. A Comparative Study of 85 Hyperelastic Constitutive Models for Both Unfilled Rubber and Highly Filled Rubber Nanocomposite Material. Nano Mater. Sci. 2022, 4, 65–82. [Google Scholar] [CrossRef]

- Dal, H.; Açıkgöz, K.; Badienia, Y. On the Performance of Isotropic Hyperelastic Constitutive Models for Rubber-like Materials: A State of the Art Review. Appl. Mech. Rev. 2021, 73, 020802. [Google Scholar] [CrossRef]

- Ricker, A.; Wriggers, P. Systematic Fitting and Comparison of Hyperelastic Continuum Models. Arch. Comput. Methods Eng. 2023, 30, 2257–2288. [Google Scholar] [CrossRef]

- Mahnken, R. Strain Mode-Dependent Weighting Functions in Hyperelasticity Accounting for Verification, Validation, and Stability of Material Parameters. Arch. Appl. Mech. 2022, 92, 713–754. [Google Scholar] [CrossRef]

- Anssari-Benam, A.; Horgan, C.O. A Three-Parameter Structurally Motivated Robust Constitutive Model for Isotropic Incompressible Unfilled and Filled Rubber-like Materials. Eur. J. Mech. A Solid 2022, 95, 104605. [Google Scholar] [CrossRef]

- Jiang, M.; Dai, J.; Dong, G.; Wang, Z. A Comparative Study of Invariant-Based Hyperelastic Models for Silicone Elastomers Under Biaxial Deformation With The Virtual Fields Method. J. Mech. Behav. Biomed. Mater. 2022, 136, 105522. [Google Scholar] [CrossRef]

- Ehret, A.E.; Stracuzzi, A. Variations on Ogden’s Model: Close and Distantrelatives. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2022, 380, 20210322. [Google Scholar] [CrossRef]

- Zienkiewicz, O.C.; Taylor, R.L.; Zhu, J.Z. The Finite Element Method: Its Basis and Fundamentals, 7th ed.; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Bai, Y. Effect of Loading History in Necking and Fracture; Massachusetts Institute of Technology: Cambridge, MA, USA, 2008. [Google Scholar]

- Pal, S.; Naskar, K. Machine Learning Model Predict Stress-Strain Plot for Marlow Hyperelastic Material Design. Mater. Today Commun. 2021, 27, 102213. [Google Scholar] [CrossRef]

- Kim, B.; Lee, S.B.; Lee, J.; Cho, S.; Park, H.; Yeom, S.; Park, S.H. A Comparison among Neo-Hookean Model, Mooney-Rivlin Model, and Ogden Model for Chloroprene Rubber. Int. J. Precis. Eng. Manuf. 2012, 13, 759–764. [Google Scholar] [CrossRef]

- Avanzini, A.; Battini, D. Integrated Experimental and Numerical Comparison of Different Approaches for Planar Biaxial Testing of a Hyperelastic Material. Adv. Mater. Sci. Eng. 2016, 2016, 6014129. [Google Scholar] [CrossRef]

| Model Name | Material Parameters |

|---|---|

| Neo-Hookean | = 0.911, = 0 |

| Mooney–Rivlin | = 0.351, = 0.644, = 0 |

| Two-Term Reduced Polynomial | = 0.747, = 0.0284, = 0, = 0 |

| Two-Term Polynomial | = 0.672, = 0.267, = −0.132, = 0.0835, = 0.0608, = 0, = 0 |

| Yeoh | = 0.678, = 0.0592, = −0.00147, = 0, = 0, = 0 |

| Arruda–Boyce | = 2.44, = 4.50, = 0 |

| Three-Term Ogden | = 0.957, = 1.165, = 0.744, = −432, = 211, = 223, = 0, = 0, = 0 |

| Van der Waals | = 1.19, = 384, = −0.594, = 0.318, = 0 |

| Marlow | No Material Parameter |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, P.-S.; Le Roux de Bretagne, O.; Grasso, M.; Brighton, J.; StLeger-Harris, C.; Carless, O. Comparative Analysis of Various Hyperelastic Models and Element Types for Finite Element Analysis. Designs 2023, 7, 135. https://doi.org/10.3390/designs7060135

Lin P-S, Le Roux de Bretagne O, Grasso M, Brighton J, StLeger-Harris C, Carless O. Comparative Analysis of Various Hyperelastic Models and Element Types for Finite Element Analysis. Designs. 2023; 7(6):135. https://doi.org/10.3390/designs7060135

Chicago/Turabian StyleLin, Po-Sen, Olivier Le Roux de Bretagne, Marzio Grasso, James Brighton, Chris StLeger-Harris, and Owen Carless. 2023. "Comparative Analysis of Various Hyperelastic Models and Element Types for Finite Element Analysis" Designs 7, no. 6: 135. https://doi.org/10.3390/designs7060135

APA StyleLin, P.-S., Le Roux de Bretagne, O., Grasso, M., Brighton, J., StLeger-Harris, C., & Carless, O. (2023). Comparative Analysis of Various Hyperelastic Models and Element Types for Finite Element Analysis. Designs, 7(6), 135. https://doi.org/10.3390/designs7060135