Abstract

The importance of sustainable design for achieving sustainable development goals (SDG) has become increasingly prevalent. Agility for sustainable design development is a project management approach that aims to provide a flexible and efficient way of developing new products. However, the application of agility for sustainable design development is not well-defined, with unknown processes and benefits. To address this, this study aims to explore the benefits of theoretical research and the application of agility in sustainable design. The study critically examines the application of agility in sustainable design development through a literature review. The results identify eight integration directions of agility that contribute to sustainable design, providing a better understanding of agility and enabling its implementation in the development of new products. This study seeks to create a more coherent and rigorous system of theory and practice for sustainable design.

1. Introduction

Sustainable development aims to fulfil the needs and wants of people while also ensuring that future generations can achieve the same without compromising their own needs [1]. This is crucial, especially in the current global market environment, where sustainable strategies are essential for providing consumers with safe and effective products or services, improving economic and social benefits [2,3,4], and reducing the environmental impact of production by promoting recycling. Sustainability involves preserving natural resources and ensuring their long-term availability. Sustainable design is focused on minimizing negative impacts on the environment and user health while also providing benefits such as increased durability, conservation, waste reduction, and better health conditions.

In today’s fiercely competitive global market, many companies are required to adopt a sustainable design approach to meet diversified demands and rapidly changing market conditions [5,6]. Implementing a reconfigurable manufacturing system, integrating new resources and components, and adopting flexible and agile production methods are essential for companies to cope with crises, prolong manufacturing system lifecycles, and achieve sustainable development [7]. Agility can be a solution for sustainable design, as it offers a more open, accessible, and reconfigurable control system to deal with unpredictable market and enterprise changes [8,9]. From a management perspective, agility means planning and executing work in a way that incorporates changes as a critical part of the process [10]. Agility helps companies measure team performance, identify bottlenecks, and make data-driven decisions to correct them using indicators such as lead time, cycle time, and throughput. For business organizations, agility means thriving in a constantly and unpredictably changing environment.

The methodology of agility emerged in the 1990s [11,12,13], particularly in software development and manufacturing. In software development, agility refers to a flexible process that can adapt to changes in requirements and delivery times [14]. This approach aims to increase productivity, respond to changing requirements and competition, make progress in small but effective increments, and reduce process and documentation bureaucracy. In industrial production, agility approaches prioritize decisions when allocating production resources. By packaging and sequencing backlogs in an integrated style, they address the product growth trend in change requests [15]. However, enterprises must also consider changes in customer needs and the market environment to ensure high-quality products and improve competitiveness [16,17]. These changes require a large number of decisions to be made in the execution process of sustainable design. Additionally, sustainable design practice must also consider technological solutions, social culture, quality of life, and innovation [18], as well as require a more systematic approach [19].

It has been shown that agility plays an important role in the development of sustainable design [20,21,22,23]. However, there is still much uncertainty surrounding the application of agility in sustainable design, including the processes involved and its potential benefits. Therefore, this study aims to investigate and discuss the benefits of integrating agility into sustainable design. By better understanding the synergistic effects of agility and its impact, we can develop an innovative approach to sustainable design that fits best.

2. Background of Study

The concept of human development includes not only economic growth but also considers the basic needs of society and the impact on the environment [24]. Sustainable design is a form of environmentally friendly design that has been developed in recent years [3,25,26,27,28,29,30,31]. Many design methods and tools have been introduced to focus on environmental protection. These tools can be categorized into three types: life cycle assessment (LCA) based tools, checklist-based tools, and quality function deployment (QFD) based tools. They can be used in the form of guidelines, standards, checklists, comparative tools, and analytical methods to help product designers conduct preliminary analyses on design content and meet environmental requirements [32]. However, some of these tools may be too complicated and difficult to use.

2.1. The Development of Sustainable Design

In [24], introduced the concept of a triple-bottom-line in sustainable development. He proposed that measuring the sustainable performance of enterprises involves considering environmental quality, economic prosperity, and social justice. Furthermore, it emphasized that for enterprises to succeed sustainably, they need to meet the characteristics of the “seven dimensions of sustainable future outlined.” These include markets, values, transparency, life cycle technology, partnerships, time, and corporate governance. Although the triple-bottom-line concept is popular in sustainable development, some scholars argue that environmental factors may overshadow the other two elements [24,33].

Design experts have explored various approaches to implement sustainable design. They act as facilitators, researchers, and educators, providing tools to generate new ideas and knowledge while considering user experience [34]. These designers should also prioritize social responsibility and establish organizations that promote sustainable development in product design. User needs and experience are vital in design interventions, and methods such as participatory design [35], user-centered design, and design thinking have proven useful [36]. Additionally, sustainable design methods such as Design for X [37], Inclusive Design [38], Product Lifecycle Design [39], and Quality Functional Deployment for Environment (QFDE) have been introduced to manage product development sustainably. These methods prioritize reducing the environmental impact of products while prioritizing consumer needs and transforming them into design goals [40].

Sustainable design methods are classified by experts into various categories, such as frameworks, checklists and guidelines, quantitative analysis and evaluation methods, software and expert systems, and organizational tools [41]. While these methods do not aim to achieve balanced development across the three dimensions of TBL, they can make it easier for enterprises to achieve their sustainable goals. However, socially responsible designers have limited power to drive progress, resulting in slower progress. Additionally, these design methods often overlook the economic factors that serve as the material basis for sustainability, and they do not consider the status of enterprises in sustainable design. Thus, there is a need for more enterprise-centric sustainable design methods that can meet the needs of enterprises.

Sustainable design has become increasingly focused on new technologies and market dynamics. This approach not only ensures sustainability goals are met for new products but also helps enterprises develop and innovate. The fuzzy quality function deployment (fuzzy QFD) approach prioritizes customer needs, sustainability parameters, and measures to handle increased competition in the electronics market. In [42], the authors proposed the Print CAD project, which applies computer-aided engineering and integrates QFD and TRIZ to address design strategies’ impact on the environment. An intelligent knowledge deployment method that uses the demand-function-knowledge deployment model matrix to select, configure, and rank candidate solutions based on their carbon footprint, with interactive genetic algorithms capturing user feedback, has been proposed [43]. Moreover, a virtual factory design system has been presented to improve small and medium-sized enterprises’ collaboration ability, cope with competition and changes, and promote sustainable innovation [39].

2.2. Agility

Due to market globalization, companies are facing extreme competition. In response to changing and dynamic customer demands, enterprises are constantly seeking an agile manufacturing model [44,45,46,47]. Agility is the capacity of a company to detect changes in its business environment and reconfigure its resources, processes, and strategies to respond quickly to those changes. This model promotes corporate cooperation, focusing on knowledge, people, technology, and processes, and enables companies to adapt to change and seize opportunities to grow in turbulent market environments [48]. Originally from the software development industry, “agile” has expanded to include project management, strategic alliances, knowledge transfer, and information sharing [12]. The four dimensions of agility have been defined as (1) delivering value to customers, (2) being prepared for change, (3) valuing human knowledge and skills, and (4) building virtual partnerships. Agile manufacturing is the ability of an organization to produce cost-effectively within a short period. It integrates enterprise management and technology and coordinates enterprise production activities from a human perspective [48].

The concept of agility involves focusing on the future, collaborating with customers, experimenting and iterating, authorizing decisions, and more. It is compatible with ideas such as flexibility, participation, shared goals, continuous learning, risk management, and networking to create an agile structure that encompasses workflow, management practices, technical requirements, culture, and time management [49]. Strategic agility is crucial for businesses to maintain a competitive edge. A systematic approach has been proposed for identifying and prioritizing agility indicators that align with strategic goals [50]. Agile manufacturing builds upon the principles of lean manufacturing [51]. Moreover, implementing agility in product life cycle management enhances team flexibility, adaptability, and overall product planning and competitiveness has been presented [13]. Agile manufacturing can increase flexibility, speed, quality, service, and efficiency and positively impact the performance of small and medium-sized enterprises [12]. Empirical research has been suggested to identify predictors of agile manufacturing and refine the framework to help managers focus on key areas, reduce rigidity, and improve organizational flexibility [52].

The culture, leadership, and system of a company are crucial factors for improving its adaptability and agility [53]. A linear regression model was presented to identify predictors of agile manufacturing and restructured the agile manufacturing framework based on empirical research [52]. Through this process, managers were able to pinpoint areas that required attention, leading to a reduction in the rigidity of the agile manufacturing paradigm and organizational structure. A qualitative analysis of the inherent capabilities of SMEs to achieve a business model of strategic agility was explored [54]. Leadership unity and resource mobility were found to be inherent capabilities of SMEs, while strategic sensitivity and resourcefulness were identified as crucial for overcoming challenges. Moreover, principles for agility in industrial design include establishing a people-oriented team, continuously producing valuable adaptive designs, and adopting lightweight technologies. They also called for the establishment of a design management platform to explore design ideas [55].

Agile manufacturing requires several key factors, including strategy, technology, system, and people [56]. Additionally, virtual enterprise tools, physically distributed manufacturing architecture and teams, rapid partnership formation tools, concurrent engineering, integrated product/production/business information systems, rapid prototyping, e-commerce, and other elements are necessary for agility in manufacturing. Researchers highlight the importance of building alliances to achieve agility [57]. The flexible formation and disbandment of alliances can help enterprises find suitable partners. Agile product design also employs various strategies and tools to respond quickly to market needs and reconfigure [51]. To achieve sustainable design, it is necessary to consider the product life cycle.

2.3. Integrated Sustainable Design Method with Agility

Enterprises must face the global market as an external environment. To compete, they focus on price, quality, function, service, and technology upgrades to gain a competitive advantage. Meeting market demands quickly and shortening product delivery time is a top priority. Sustainability is also crucial, and enterprises aim to improve the sustainability of their products throughout the entire product life cycle. To achieve agility in sustainable product development, enterprises use strategies such as Concurrent Engineering (CE), Virtual Enterprise (VE), Modularization, and Supply Chain Integration. These strategies help enterprises influence the entire product life cycle and improve sustainability efficiently.

Throughout the product lifecycle, agility is crucial in handling uncertainty and unpredictable changes, especially in the design and manufacturing process. It allows for collaboration, integration of customers in the development chain, knowledge reuse, and rapid configuration of products and processes [58]. Translating customer needs into clear technical solutions is the main objective of product design activity. To formalize, represent, manage, and store information related to the design process, information technology (IT) is required. A well-designed modular product architecture helps manage product changes and upgrades, product assortment, and component standardization [59]. Modularity is beneficial in providing configuration for the functions of sustainable products, facilitating the generalization of design, and affecting the life cycle activities of products at the same time [60,61]. Sustainable design requires the collaboration of staff from different fields [62]. Hence, information sharing, conflict resolution, team building, and the use of concurrent engineering in design projects are crucial. Storage and sharing technologies, such as cloud computing and big data [63,64], should be combined with the product design system framework [65] and cooperate with multi-purpose design, multiple lifecycle design [60,66], adaptive design [67], cradle to cradle design [68], and other design concepts. Such a combination will result in a two-way presentation of sustainability and agility. Research on agility from the perspective of business operations is also emerging. Through interviews with eight Australian manufacturing companies, they found that agility, as a collaborative paradigm, emphasizes information sharing among companies, promotes the diversification of core competitiveness of companies, and maintains the vitality of companies [69]. However, in [70], the authors pointed out the lack of research on the combination of agility in business operations through a survey of the US auto manufacturing industry.

After conducting a literature review, it was found that many sustainable design papers focus on agility. However, there is a lack of cohesive research in this field, and up-to-date reviews on the impact of agility on sustainable design are scarce. In [71], integrating agility and sustainability, two different paradigms, can lead to the development of emerging enterprises in an ideal state. This integration can enhance the enterprise. In [72], the authors have pointed out that agility is a crucial feature in the processes and systems of Industry 4.0. Whether it involves subtractive manufacturing or additive design, agility stands out, while sustainability requires improved aspects.

The growth of sustainable design and agility is ongoing. Sharing up-to-date developments can benefit researchers, practitioners, and readers by providing a better understanding of the latest advances in agility for sustainable design. It can also impact business management and production theory while contributing to the development of manufacturing processes. A thorough literature review involves identifying, evaluating, and interpreting the current literature in a systematic, transparent, and repeatable process. This approach helps create a robust knowledge base by gathering insights from a range of studies. Additionally, analyzing literature in a specific field can inspire researchers by highlighting accumulated knowledge and trends, leading to future discoveries and innovations [72].

3. Method

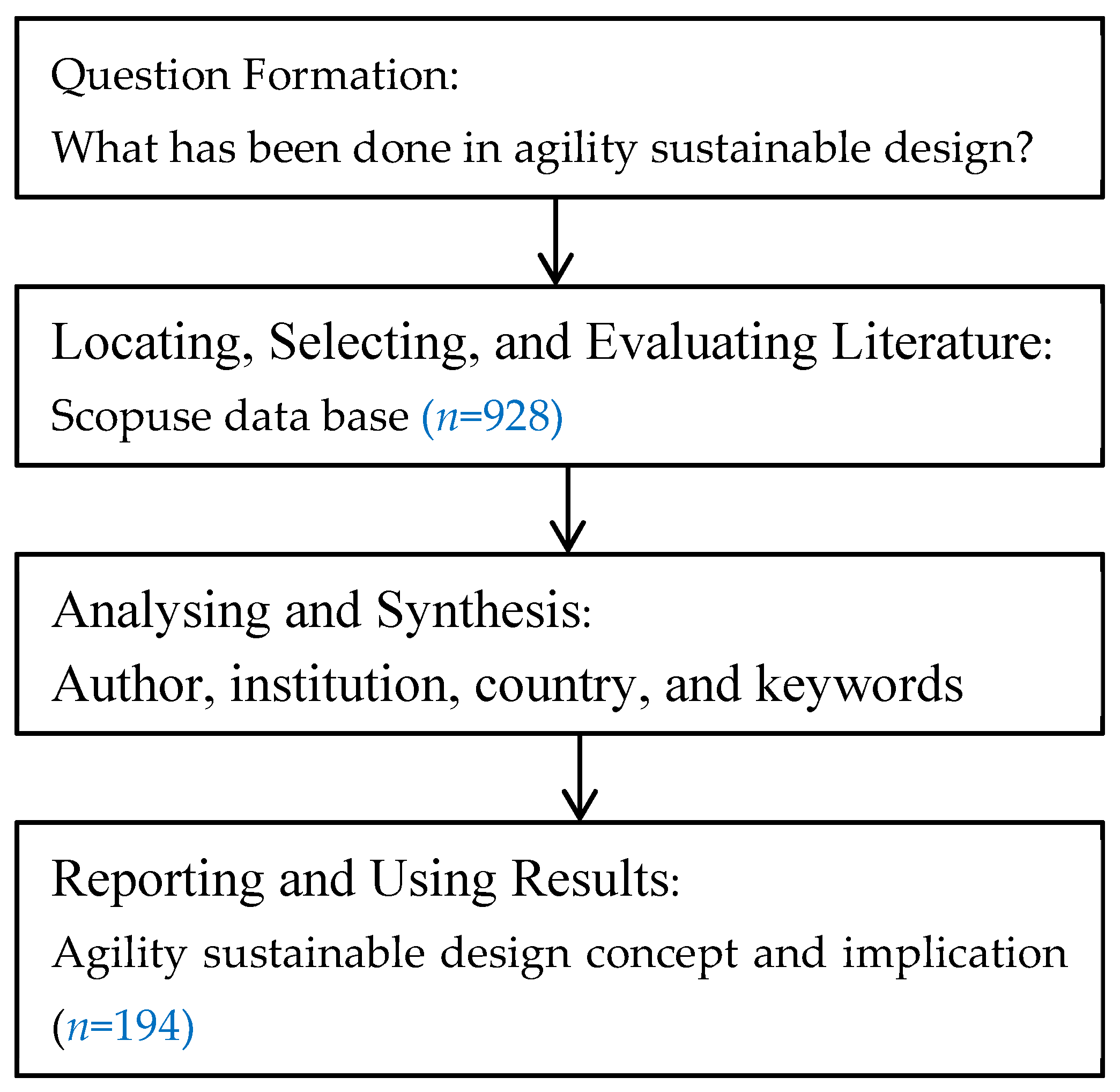

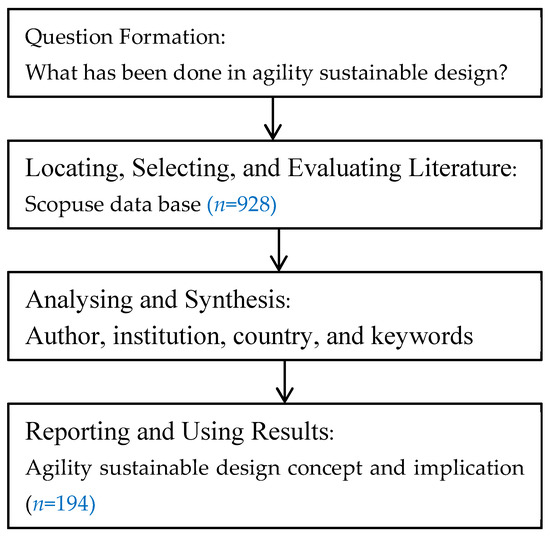

The aim of this study is to explore and discuss the advantages of incorporating agility in sustainable design development. We used a secondary data method to gather information by focusing on sustainable design journals that have a significant impact and analyzing research hotspots using anchor keywords. A systematic literature review is an in-depth analysis of research in a particular field, which involves following a transparent process, clear procedures, and examples that can be replicated in the future [73]. This review will provide insights into the current research trends and gaps and guide future research [74]. Our review emphasizes the current state of research on the use of agility in sustainable design development, adhering to the principles of transparency, inclusiveness, interpretability, and heuristics in a systematic literature review. This study process involves four steps, as depicted in Figure 1, leading to a transparent, reproducible, and reliable assessment of the literature.

Figure 1.

Flow diagram for systematic literature review.

Step 1—Question Formation: To guide the examination and eliminate any confusion, the initial stage will clearly state the question to be investigated [75]. The aim of this research is to comprehend the methods and outcomes of sustainable design that have integrated agility over time. During the literature review and analysis, this study will also highlight guidelines for developing a sustainable design approach that incorporates agility. To accomplish this, the review questions will be sorted into four categories: Position, Theme, Means, and Impact.

Step 2—Locating, Selecting, and Evaluating Literature: To begin the second stage, we must first locate potential studies. Our selection criteria for data sources are high-impact journal articles. We used Google Scholar to create an initial list of publications in the field and then employed Scopus to collect data sources that ensure high impact. Scopus contains thousands of journals that cover all scientific fields, so we entered phrases like “sustainable design” and “product sustainability” to retrieve a large number of relevant journals. To narrow down our results and find articles that specifically address the impact of agility on sustainable design, we applied the “agility” filter. Although the number of articles that met our criteria was not large, we did not limit our search time. These articles are credible, accurate, and meet the principles of stability and reproducibility in literature review. We also downloaded the metadata of each potential article as a research information system (RIS) file. This format includes information such as author, title, year, source publication name, volume, issue, page, citation counts, source publications, document types, affiliations, correspondence addresses, abstracts, author keywords, and index keywords, which will be used for later analysis.

To determine if articles in the RIS file list are suitable for further analysis, we examined their titles, keywords, and abstracts. Our exclusion criterion is based on their direct relevance to RIS documents. If it’s unclear from the title and abstract, we read the entire article to ensure it discusses agility or sustainable design. For tricky situations, we consult with authors who specialize in sustainable design or agility research for a definitive opinion. We strive to remove personal bias from the screening process to promote inclusivity. Any articles unrelated to agility or sustainable design, such as research notes, book reviews, or editor’s forewords, are removed from the list. We identified five documents containing a total of 928 relevant articles.

Step 3—Analyzing and Synthesis: Once the literature has been gathered and assessed, the next step is to conduct a systematic review using analysis and synthesis (Briner, Mary, and Denyer, 2012). Analysis allows for a detailed examination of the literature, while synthesis helps to establish connections between different documents. By utilizing both techniques, previously unnoticed information can be uncovered and reinterpreted. To effectively present the knowledge system, research gap, and future research direction of the target article, this study will adopt a scientific knowledge visualization bibliometric method that incorporates social network analysis and graph theory. Descriptive analysis, based on author, institution, country, and keywords, will be utilized to aid in the analysis and synthesis process, and the findings will be presented in Section 4 [29,76].

Step 4—Reporting and Using Results: Researchers conduct a systematic literature review to gain insights into the current state of knowledge in a particular field [76]. The study will present known information in the Findings section and highlight areas where knowledge is lacking in the Discussion section. The research will also provide models to illustrate the latest technologies.

Despite using an authoritative database to collect literature, limitations existed during the information analysis process. Some publications were restricted access, and information from other forms of literature, such as books, was incomplete. As a result, the analysis results may have been affected by these limitations.

4. Result and Discussion

4.1. Descriptive Analysis of Selected Literature

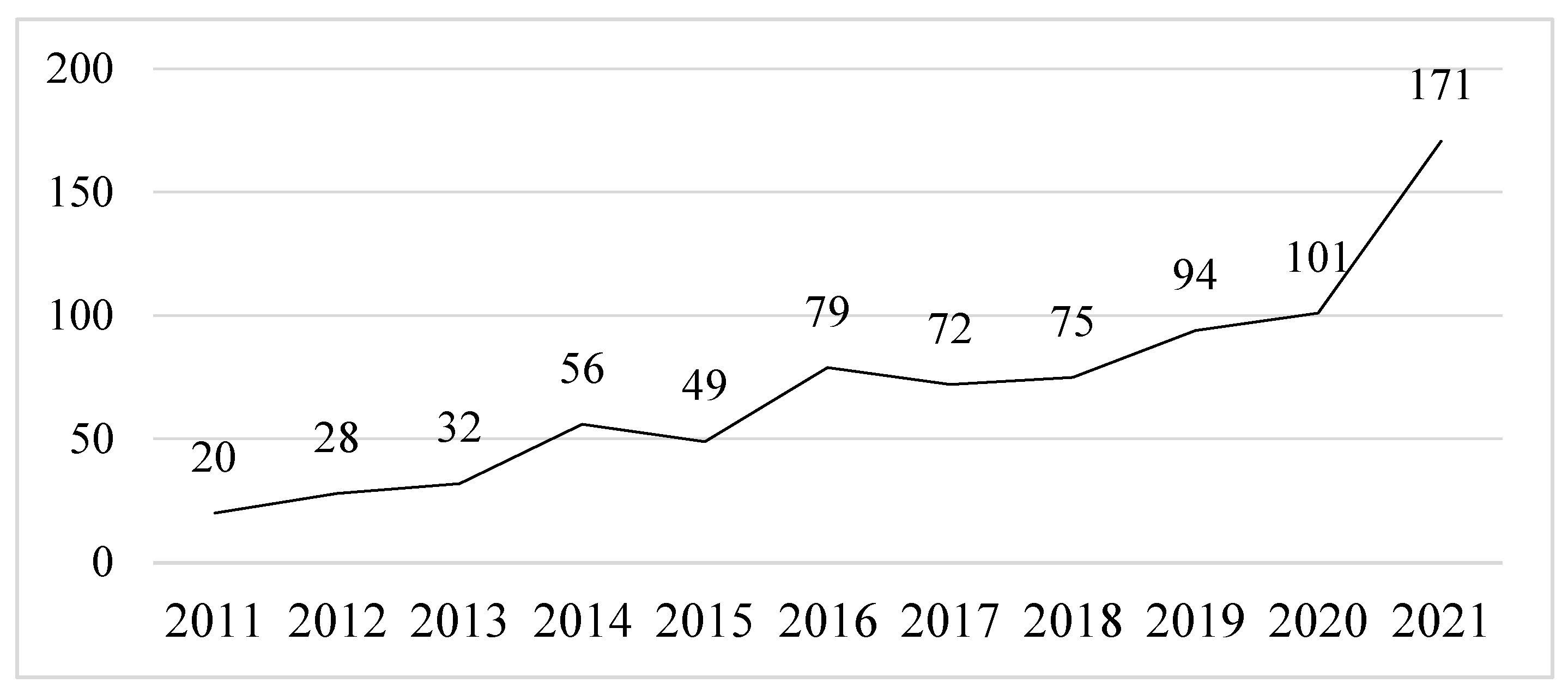

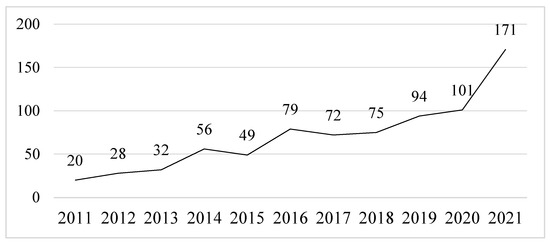

The goal of this study is to examine sustainable design methods that incorporate agility. To begin, we screened articles related to the topic from the Scopus database. Through a systematic literature review, we sorted out 928 articles published between 2011 and 2022. We analyzed the publication time of the articles to understand the popularity of current research (see Figure 1). The Modularity is Q = 0.7713, the Weighted Mean Silhouette is S = 0.9026, and the Harmonic Mean is (Q, S) = 0.8318. It is worth noting that not all articles published in 2022 were included in our research. To show the development trend of the studies, we excluded the number of articles published in 2022 in Figure 2. The vertical axis represents the number of publications, and the horizontal axis represents the publication time. We found that the number of publications has been increasing annually and has grown significantly since 2020, as shown in the time distribution chart.

Figure 2.

Diagram of publication distribution by year.

In the academic field, academic journals are the primary means of sharing research findings. The level of importance of a journal is often determined by the number of citations it receives. Table 1 presents the top 10 journals with the highest number of citations. It also provides information about the number and percentage of articles published in these journals as well as their impact factor (IF) for 2021. All the journals listed have an IF greater than 3, indicating their high quality. The Journal of Cleaner Production has the highest percentage of published papers at 28%, followed by the International Journal of Production Economics at 19%, which is also considered the most influential journal.

Table 1.

The distribution of 10 journals.

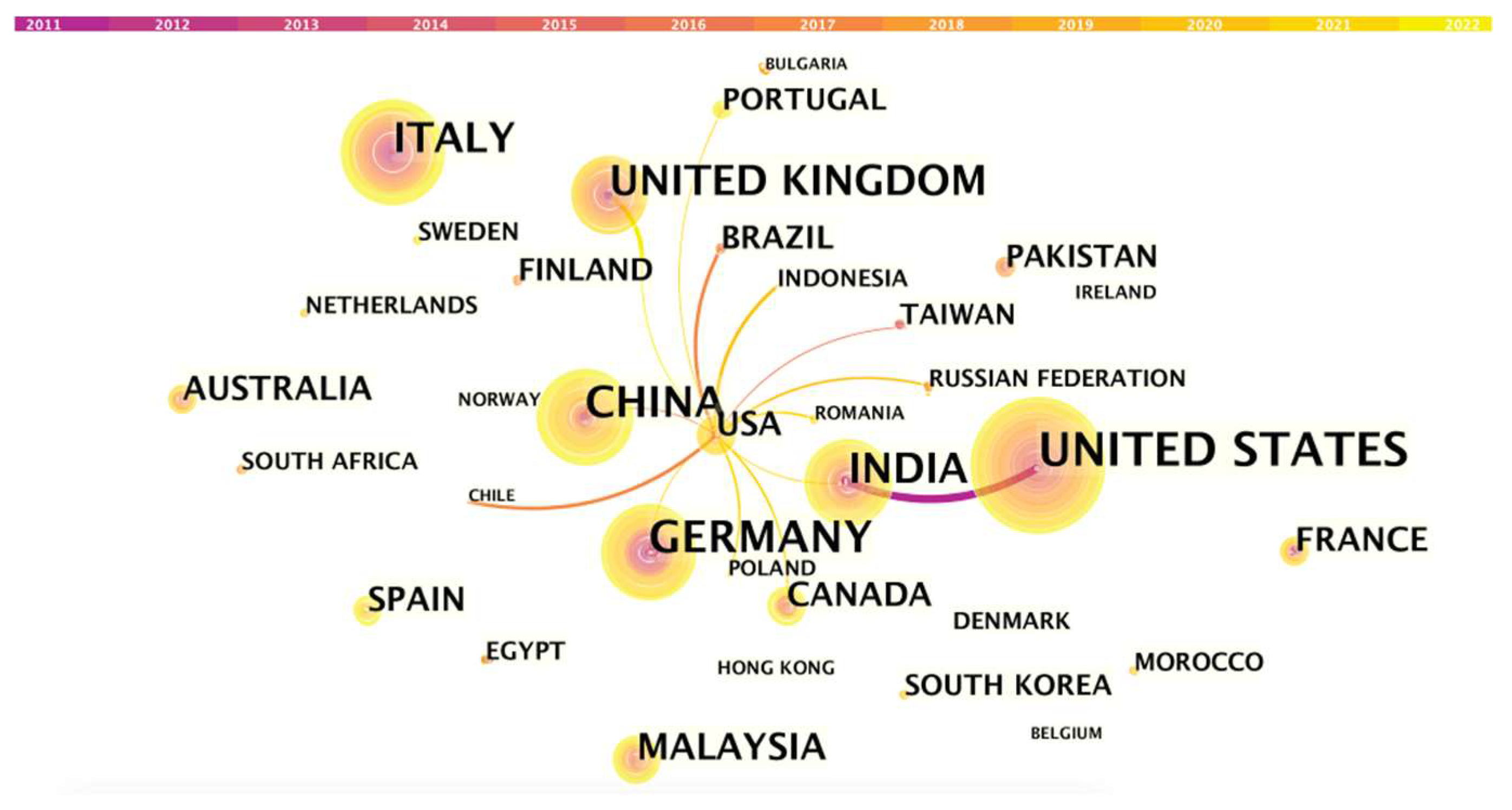

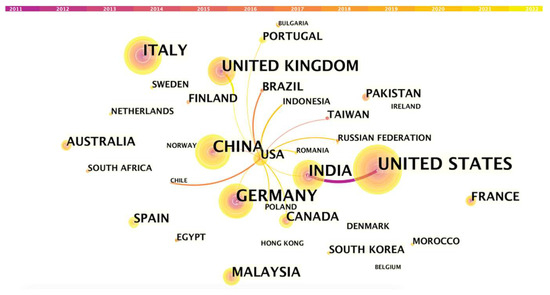

In Figure 3, we can see a network of co-authorship in agility sustainable design research for various countries. The threshold for inclusion in the network is 3, resulting in 33 nodes. The network density is 0.0151. The size of each node represents the number of papers that the country has published in this field. The distance and thickness of the links between nodes indicate the level of cooperation between countries. The United States stands out as the country with the largest number of papers in this field and the highest level of cooperation with other countries. Several other countries, such as China, the United Kingdom, Germany, India, and Canada, have also published many papers and have collaborated with the United States in this field. However, it is worth noting that some papers refer to the United States using different names, such as “USA” and “UNITED STATES.” While the number of published papers using “UNITED STATES” is the largest, papers using “USA” show wider cooperation. India, in particular, has established a cooperative relationship with the United States in the field of agility sustainable design since 2011. Other countries in the network do not show significant cooperation with each other except for their cooperation with the United States. Italy, for instance, has many published papers, but it rarely cooperates with other countries in this field.

Figure 3.

The country’s co-authorship network.

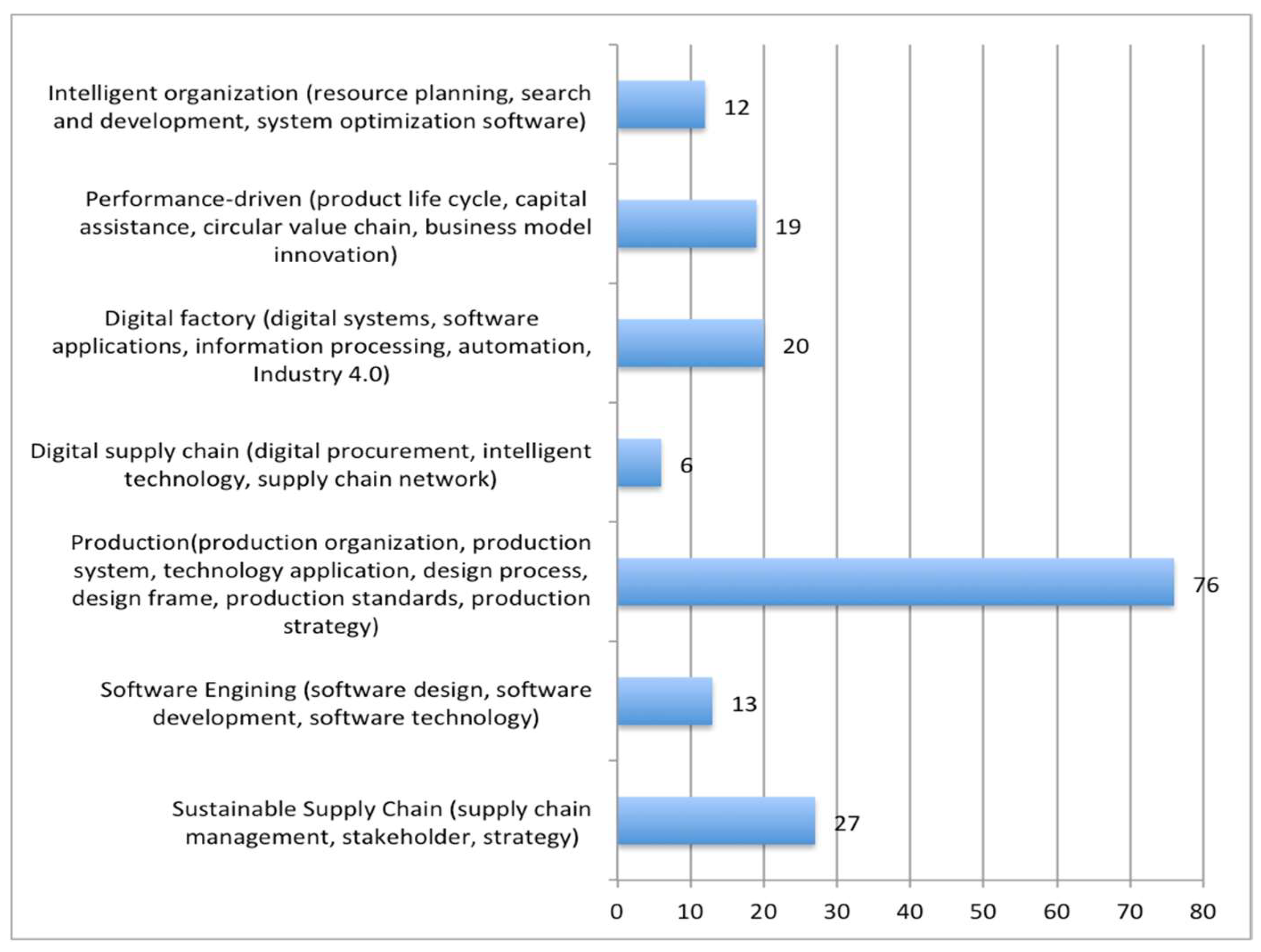

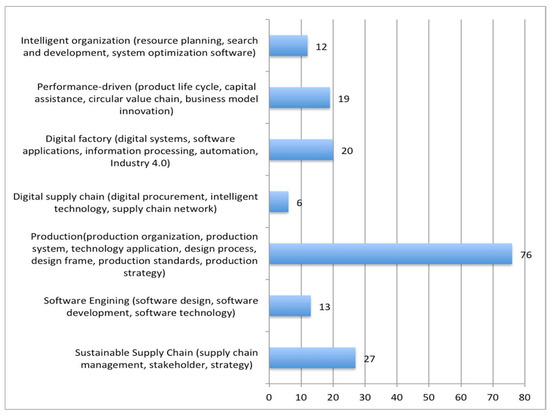

Out of the 30 countries involved in the collaboration network for sustainable design in agility, 14 countries make up approximately 47 percent. A total of 174 papers have been identified, which have identified seven key areas of research (refer to Figure 4): (1) Sustainable supply chain; (2) Software engineering; (3) Production; (4) Sustainable Supply Chain and Software Engineering; (5) Software Engineering and Production; (6) Sustainable Supply Chain and Production; and (7) Sustainable Supply Chain, Software Engineering and Production. Most of the studies selected belonged to the production field, including production organization, production system, technology application, design process, design framework, production standard, and production strategy.

Figure 4.

Distribution by research area.

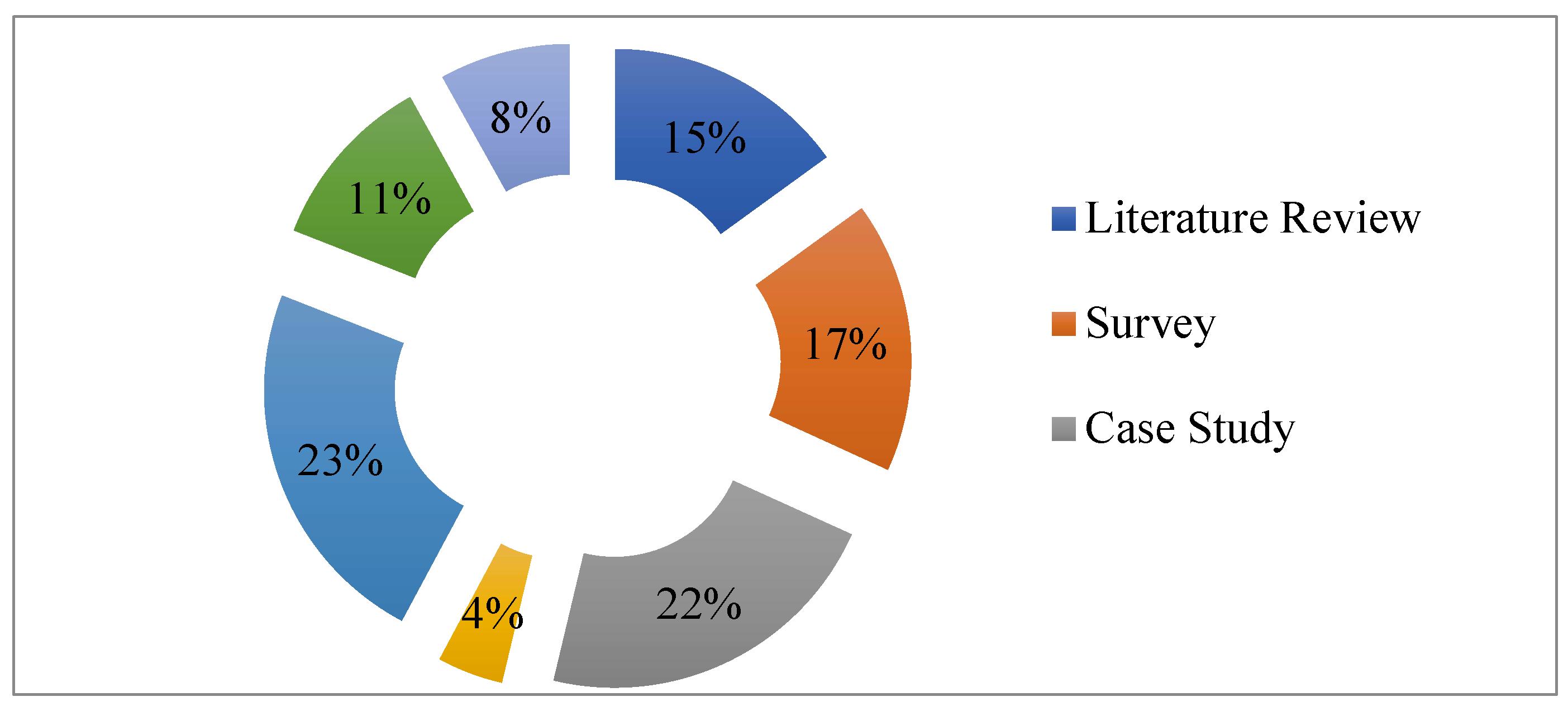

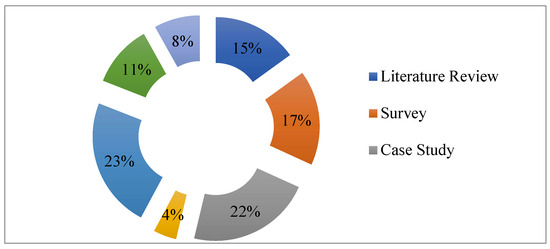

In Figure 5, it is evident that the literature selected can be categorized into different types, including literature review, survey, case study, mathematical models, simulation model, explanatory structural model, and miscellaneous. The research shows that simulation models and case studies are currently the most commonly used methods in agility sustainable design.

Figure 5.

Distribution by research method.

In the field of sustainable design for agility, research techniques vary in popularity. Simulation technology models make up 23% of research, while case studies account for 22%. Survey-based statistical methods are becoming more common. The literature, including literature reviews and structural models based on them, makes up 17% of the research. Mathematical modelling is the least used technique, comprising only 4% of research.

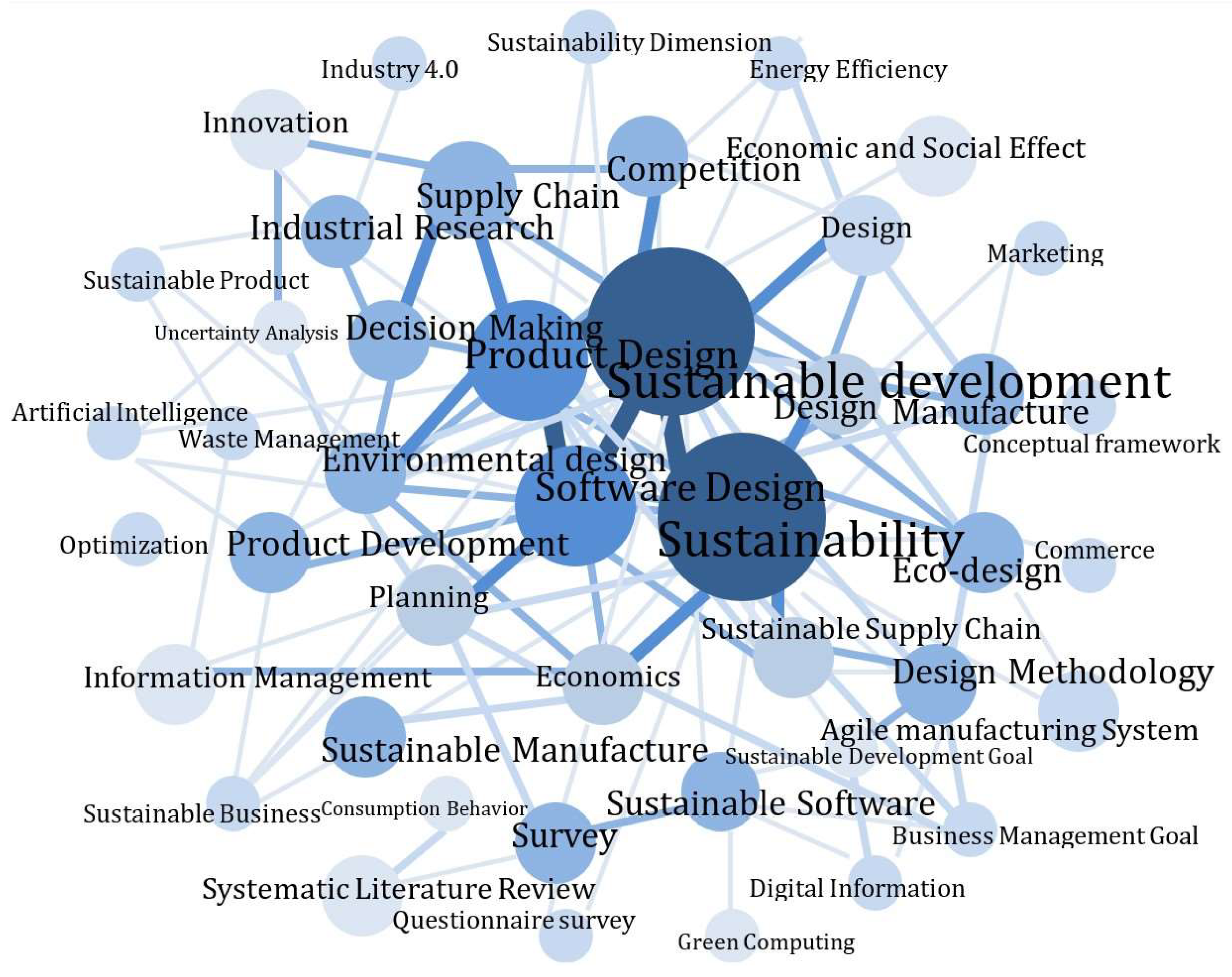

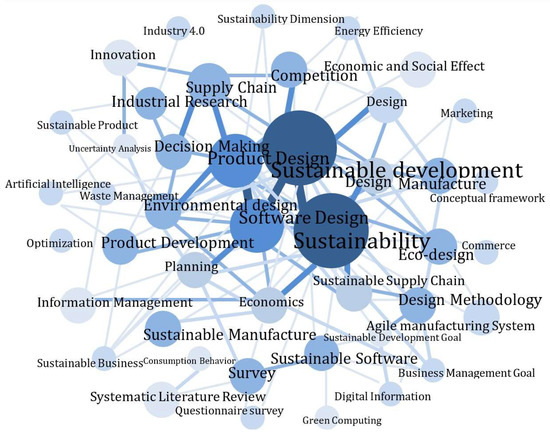

The article’s core information can be displayed through keywords, as shown in Figure 6. By analyzing the co-occurrence of keywords, the hot topics in the field of sustainable design research can be more intuitively reflected. Each node represents a keyword, and the size of the node indicates the frequency of keyword co-occurrence. The 20 keywords with the highest frequency and their centrality are shown. The analysis of keywords reveals that sustainable development is the focus of all papers, followed by sustainability, which also appears frequently. Product design, supply chain, software design, and manufacture are among the high-frequency keywords in the second tier. However, word strings related to agility are less frequent.

Figure 6.

Keywords co-occurrence network.

4.2. Descriptive Analysis of Sustainable Design Method with Agility

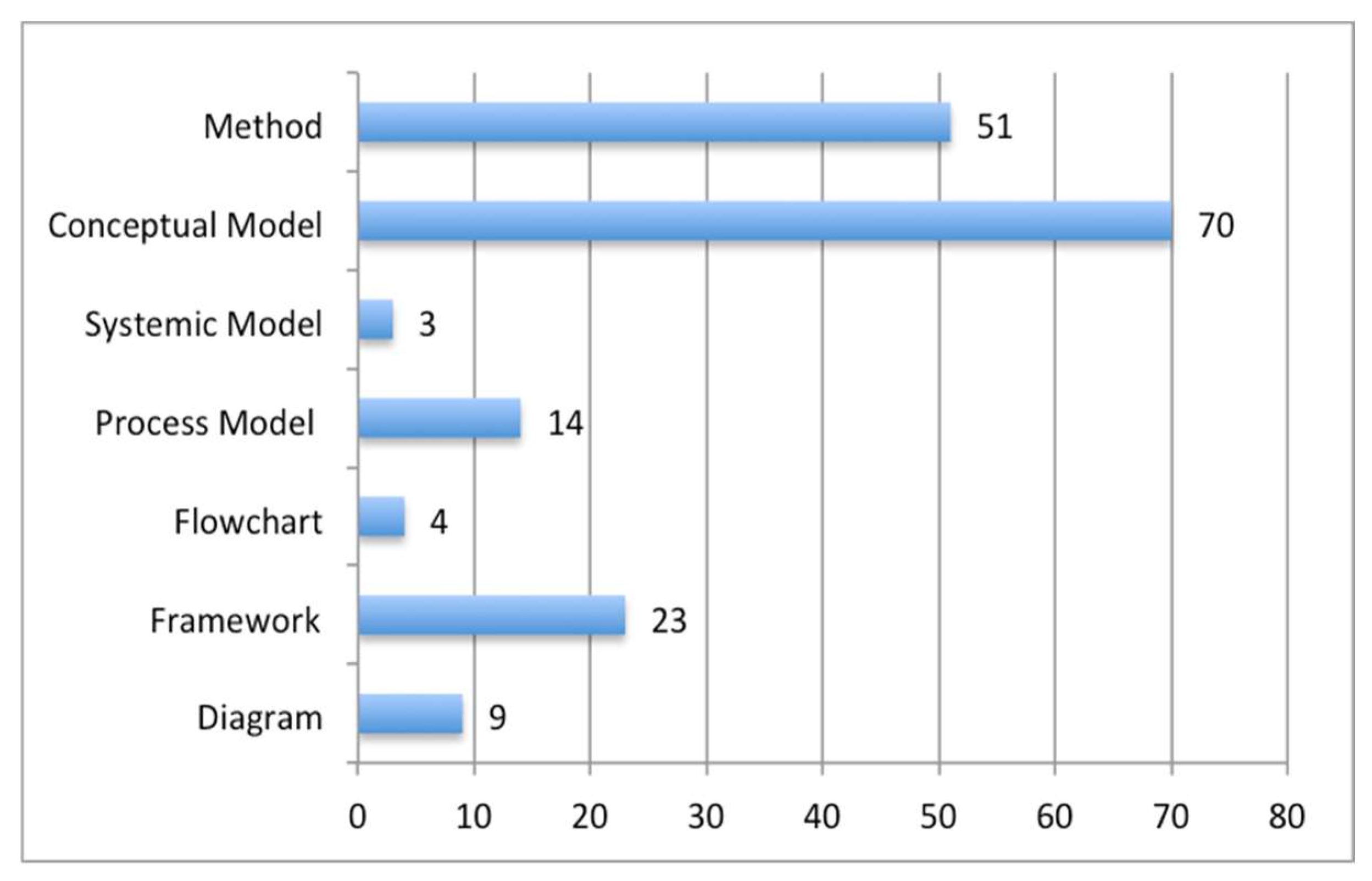

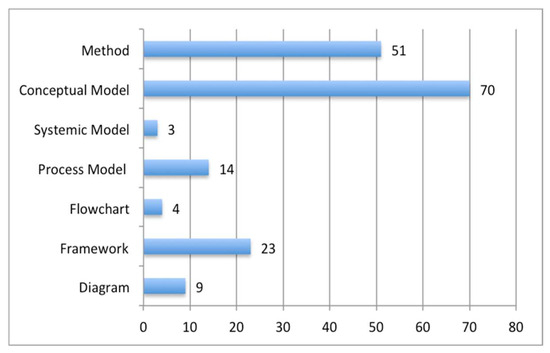

A thorough second analysis was performed on 174 papers. Based on their features and attributes, 45 models were categorized into seven method categories: diagrams, frameworks, flowcharts, process models, system models, conceptual models, and methods. This categorization facilitates a descriptive analysis and comprehension of each model’s nature. You can find a depiction of the methods and their references in Figure 7.

Figure 7.

Distribution by sustainable design with agility method approach.

Some models, about 5 percent, are presented as diagrams portraying various sustainability measures such as structured functional deployment, system specifications, materials assessment [77,78,79], environmental performance monitoring, decision-making [80], and lean and green strategies [78,81]. These models include a reconfigurable manufacturing system (RMS) and aim to enhance the company’s sustainability capabilities using green materials and products. While this approach can respond quickly to market changes and produce high-quality, sustainable products at low cost, there are still internal challenges that need further discussion. The goal is to maintain sustainability throughout the production process and collection formation through continuous improvement of the production system.

Research has shown that the framework for evolvable production systems theory has been incorporated into real management [82], and steps have been taken towards organizational agility [83]. Sustainability standards and regulations requirements have been integrated into the design process [84], and there has been a demonstration of the relationship between human agency theory, institutional theory, ecological modernization theory, and sustainable manufacturing [85]. A multi-objective sustainability approach has been implemented [86], and enterprise resource planning has been integrated with sustainable development and corporate decision-making [87]. Innovative modular, flexible batch or continuous production technologies have been combined with fully automated production methods [88,89], and new product development is being driven by smart services and sustainable development combined with digitalization. Multi-layered collaboration is being emphasized [90]. Furthermore, a module-based design process framework has been presented to realize a customized product service system flexibly according to user needs [64].

Approximately 12 percent of the total models are represented by the “flowchart”, “process model”, and “system model” approaches, which consist of 21 models. The flowchart models apply the Waterfall, Vee, and Spiral process models to sustainable design processes [91] and manufacturing systems [92], integrating systems engineering. A 6R approach, which involves redesigning, reusing, remanufacturing, recycling, and reducing, has been proposed to task through machines [93]. This approach involves three steps: finding manufacturing resources that need to be reused in the product, modularizing the structure of the product, and producing with complex machines and tools. The process maximizes the use of critical manufacturing resources, making it cost-effective for SMEs to adopt complex robots. The “process model” is a sustainable design method that is specific to a particular stage. The evaluation of manufacturing and assembly based on a set of key indicators has been suggested to improve supply chain sustainability and resilience in [94,95,96]. This approach can have a preventative effect on product sustainability and influence early design stages. Six selection criteria to evaluate building information are introduced using information modelling (BIM) and visual programming language (VPL) tools to realize real-time iteration of information, inspiring designers during the design stage [97].

In sustainable design, specific systems are illustrated through system models. A multi-objective mixed integer linear programming (MILP) model has been presented in [98]. It can address various challenges in a multi-period, multi-stage, multi-product supply chain, reuse, and disposal decisions. This model can help in site selection, supply, production, distribution, collection, quarantine, and recycling. Meanwhile, industrial design principles have been proposed based on agility in [55]. The first principle is to focus on human-centered design and building a self-organizing team. The second principle is adaptive design, which produces valuable designs over time. The third principle is using lightweight design methods and techniques. These principles form the basis of the computer-aided industrial design system, which includes a design information management platform. This platform can guide designers to innovate systematically and based on theory and time.

When discussing sustainable design, the assumptions made are known as conceptual models. This approach covers various topics such as international and contemporary issues, innovative products, manufacturing systems, business models, organizational management, and performance measurement. It also explores the relationship between sustainable manufacturing enterprise design [92], situation-behavior-process-learning-action-performance, organizational flexibility [99], rapid prototyping (RP) evaluation criteria [100], collaboration and learning impact on organizational development [101], communication channels, and learning capabilities impact on standards implementation in SMEs [102], Green Lean Six Sigma in product development [103], and the relationship between culture, leadership, and systems. A survey shows that culture, leadership, and systems are crucial factors for organizational success [53]. To adapt to change, it is essential to design organizations that make use of their vast knowledge base. Diagnostic tools are necessary to identify strengths and weaknesses, initiate discussions, and provide a measurement baseline.

Sustainable design approaches are becoming increasingly common and are characterized by methodological innovations. Various approaches have been proposed, such as the integration of lean and smart manufacturing methods [104], manufacturing planning and control (MPC) [105], digital transformation of enterprises [106], iterative design in phases [107], and the application of cloud manufacturing in information management, service composition and evaluation, system application, and sustainable development [108]. Another proposed approach is the merging of subtractive and additive manufacturing to achieve sustainability in design. This approach is compatible with Industry 4.0 and has four desirable process-level characteristics (speed, sustainability, agility, and customer focus) and three system-level characteristics (connectivity, data collection, and automation). The authors of this approach concluded that subtractive manufacturing is almost as fast and agile as additive manufacturing but needs improvement in terms of sustainability and customer focus, while additive manufacturing is strong in terms of agility and customer focus but needs improvement in terms of production speed and sustainability.

4.3. Sustainable Design Integrated Agility Concept

Through the classification of selected studies and proposed agility sustainable design, seven research fields have been identified in this study. These include sustainable supply chain, software engineering, production, digital supply chain, digital factory, performance-driven, and intelligent organization. Considerations have been made for each of these seven main research areas of agility sustainable design.

- (a)

- Sustainable Supply Chain: Creating a sustainable supply chain involves implementing ethical and environmentally responsible practices. The focus of sustainable design is to ensure that the supply chain is sustainable. Key topics include selecting, managing, and maintaining stakeholders. In today’s unpredictable market, designing a sustainable supply chain involves developing resilience and flexibility in businesses while also using life cycle assessment techniques to achieve agility in the process.

- (b)

- Software Engineering: Research on sustainable design in the field of Software Engineering has a specific focus on agility. This involves improving iteration, communication, collaboration, process simplification, design simplicity, and flexibility during the development process. The literature emphasizes the significance of lifecycle analysis in implementing agility, as well as the importance of coherent, self-organizing agile teams that facilitate collaboration.

- (c)

- Production: The production field has the highest number of papers. When studying sustainable agility methods, it is important to focus on the integration of organizational structure and individual management processes in production. To implement an agile, sustainable approach in the production field, it is crucial to have a clear understanding of the company’s situation as well as the market and competition. Enterprises need to be able to quickly gather and understand information, set clear goals, and create flexible plans based on forecasts. Studies have shown that agility is important in the selection of solutions for sustainable design. Identifying relevant risks and opportunities is also crucial in the practice of agile sustainable methods. Moreover, organizations must have the ability to learn and accumulate lessons to successfully implement an agile, sustainable approach.

- (d)

- Digital Supply Chain: The digital supply chain involves using digital technology and data analysis to make informed decisions, improve performance, and respond quickly to changes in the supply chain. To achieve an agile and sustainable approach, both organizational management and technical aspects must be considered. Organizational management can benefit from open and dynamic systems, self-organizing and self-learning capabilities, adaptive capabilities, visibility, monitoring and feedback control, collaborative capabilities, circular economy and industrial symbiosis, and data-driven analysis and modelling. Technology can provide advantages such as real-time inventory control, custom assembly and modular production, flexible capacity sharing, risk mitigation inventory, alternate shipping routes, multiple procurement risks, closed-loop supply chains, collaborative robotics, additive manufacturing, and augmented and virtual reality.

- (e)

- Digital Factory: A digital factory is a technological system that allows companies to share digital information seamlessly throughout their entire operational process. Research in the field of digital factories highlights the crucial role of IT in industrial production. Among the important sustainable design methods of digital factories with agility characteristics are data modelling, data analysis, and the Internet of Things. Parallel design and additive technology serve as the main solutions within this field.

- (f)

- Performance Driven: The performance-driven field focused on agility sustainable design aims to enhance the overall performance of the enterprise. The agility sustainable design method covers sustainable product-service systems, product and service diversity, management, technology, product and service innovation, collaborative innovation, business collaboration, information sharing, and enterprise learning.

- (g)

- Intelligent organization: Organizations that prioritize free and open information exchange are viewed as intelligent models. The concept of intelligent organization has gained attention as a research field in recent years, primarily focused on the challenges businesses will face in the Industry 4.0 era. Studies have predicted that this new industrial ecology will offer enterprises opportunities to embrace smart technologies, which in turn will provide agility and flexibility. Sustainable design will also expand and encompass various areas of social development, including user experience design, cloud-based computer-supported collaborative work, social product development, smart innovation and business value chain design, collaboration for product realization crowdsourcing, open architecture product and service platform design, human-centered cyber-physical work system design, networked manufacturing system design, cyber-physical production system design, recycling, machine learning and artificial intelligence for data-informed design, dynamic risk management for cyber-physical socio-technical systems, cybersecurity, and verification and validation for design research.

Therefore, agile sustainable design prioritizes decision-making and risk management, information sharing, process adaptability, and collaboration in peer-reviewed research. While these aspects go beyond traditional sustainable design methods, they can create an even more advantageous environment for implementing sustainable design practices.

4.4. Implication of Agility in Sustainable Design

After analyzing various literary works, the eight sustainable design methods for achieving agility were discovered.

- (a)

- Highly Autonomous Organization. Enterprises are facing an increasingly complex living environment and a consumer-centered market. As a result, they need to adopt new management models to achieve higher levels of customization and deeper customer relationships. An organization’s cognitive ability can enhance its capacity to process information and deal with uncertainty. This cognitive ability can also impact an enterprise’s autonomy and its ability to take flexible and agile action. SMEs are representative of highly autonomous organizations that achieve a competitive position by coexisting with large enterprises through informal strategies and flexible structures [109]. Entrepreneurial thinking plays a significant role in highly autonomous organizations, promoting high-speed innovation and ensuring that SMEs improve their performance in fierce competition [110].

- (b)

- Establish an Organizational Learning Model. In today’s globalized business world, companies must work to bridge cultural gaps within their supply chain. This involves establishing a continuous learning model and promoting mutual learning between organizations [83]. When unexpected challenges arise, it is crucial for companies to build resilience through experimentation, absorption, and innovation. Managers must also engage in democratic dialogue with employees across different cultures and borders rather than relying on traditional top-down strategies. Continuous learning is key to improving team efficiency and driving innovation and can help employees realize their full potential [49]. By fostering a shared language and culture, organizations can build trust and collaboration among team members, ultimately leading to greater success [53].

- (c)

- Establishing an Agile Mode of Organizational Collaboration. When organizations collaborate, they can complement each other’s resources and achieve diversity. Coordination is easier when partners share the same sustainability and agility requirements, allowing them to take systematic actions and mobilize resources. This collaboration can also lead to coordinated innovation for enterprises [111]. In today’s professional supply chain process, internal multi-disciplinary organizations need to communicate and balance effectively. Collaboration should not only occur between parallel organizations but also between organizations with parallel production based on organizational learning. Collaboration capabilities are essential for supply chain integration. To meet customer demands, supply chain efficiency and performance rely on organizational knowledge, information exchange, employee capabilities, and business processes. Agile collaboration in organizations seeks simplified procedures and seamless connections. In [72], authors suggest that organizations can resist environmental interference by generating new knowledge through collaboration. High-frequency collaboration brings energy to organizations and allows them to respond flexibly to changing environments [72].

- (d)

- Management and Decision-making are Agile-oriented. To create an organization that operates with agility, its managers must be highly attuned to both internal and external changes. They must also establish a system that enables timely and effective communication across different fields, offer genuine commitment and support to their team, establish common goals, and enhance the team’s capacity to act quickly. When faced with uncertainty and high-risk situations, the organization must be able to quickly reassign resources. This is why adopting an agile management approach is essential for promoting internal coordination and external cooperation within the organization, as well as for facilitating knowledge sharing and flow. Through implicit management methods, organizational managers reduce central control and provide participants with the space they need to utilize their tacit knowledge [53]. Agile decision-making involves leaders being able to accurately identify and refine key information, react swiftly, and utilize available resources and information. This depends on the knowledge base and experience of the entire team. Therefore, the primary objective of agile management is to foster trust among project participants and ensure that knowledge flows freely within the team.

- (e)

- Combining Lean and Flexible Paradigms. Eliminating non-value-added activities and improving efficiency are crucial strategies for SMEs to achieve sustainable development. Through the implementation of lean and flexible paradigms, businesses can reduce waste, inventory, and rework while increasing output, flexibility, and delivery time. Additionally, these strategies improve the ability to solve problems, standardize work, and advance processes. A flexible labor force and maintaining production stability are also essential components of lean thinking [112]. To successfully implement lean and flexible paradigms, collaboration among enterprises and updated knowledge is necessary. Streamlined institutional processes and organizational management strategies are driving factors for success. When combined with the triple bottom line theory, a lean and flexible paradigm can make positive contributions to sustainable strategies [113]. The application of information processing technology and network communication is also vital for the success of these paradigms. Developing a strategic awareness of continuous renewal and transformation is necessary for organizations to form an agile, sustainable paradigm. Making decisions that benefit future development according to the current situation and maintaining excellent operation and vigorous development are also essential.

- (f)

- Application of Digital Technology. Incorporating digital tools and technologies is known as digitalization, which can enhance the business processes of enterprises by making them more efficient. This, in turn, provides a foundation for the implementation of agility and sustainability. By utilizing digital technology, enterprises can obtain diversified information, and the analysis function of big data can provide predictions for enterprise decisions [114]. Search technology can help enterprises interpret subtle signals after communicating with partners and take targeted actions. AI can assist in management by providing a system that simplifies thinking and procedures [115]. Furthermore, digital technology can detect organizational activities and improve the quality of work. Digital technology has made it easier for all stakeholders in the value chain to connect. Remote collaboration, virtual processes, and real-time connections have brought unprecedented efficiency and convenience to enterprises [116]. Digital technology has also shown the advantages of high efficiency and energy conservation in product lifecycle management, which is essential for enterprise sustainability [117]. The Internet of Things system, machine learning system, process optimization technology, quality improvement technology, talent-increasing manufacturing system, and flexible manufacturing system are all key driving factors of the sustainable development of enterprise agility derived from digital technology.

- (g)

- Adopt the Modularization Strategy. Modularization involves breaking down system components into units that are closely connected while avoiding accidental interaction with other modules [118,119]. This design and management strategy in complex systems allows for the separation or recombination of modules without changing other components, maximizing flexibility and agility. In the supply chain, modularization emphasizes outsourcing of key technologies by module suppliers who must be flexible and agile in dealing with customers [120]. This improves the overall competitive strength of the supply chain and promotes differentiation of enterprise competitiveness, benefiting resource allocation. Modular design in the production process improves the universality and standardization of components, facilitating modification, combination, and product customization for production agility. In product service systems, modular strategies cope with changing customer needs by dividing and reconfiguring components to optimize service performance, cost, and response time [64]. However, applying modular concepts requires information sharing, organizational collaboration, and digital technology to master data, maintain close communication with partners, respond quickly to changes, and reconfigure resources for a competitive advantage.

- (h)

- Adopt a Reconfigurable System. The idea of a reconfigurable system is widely used in the manufacturing industry. It involves modularization, which allows companies to quickly remove, adjust, add, or change the component structure to adapt to production needs. This helps businesses cope with changes in market demand and reduces time and cost. By using appropriate modularization and system reconfiguration, a company can form other product families after completing a series of products. This strengthens the enterprise’s ability to respond to changes by forming component and product families [78]. The concept of reconfigurable systems is also applied in enterprise and supply chain systems to deal with and adapt to changes in complex structures. Whether in production or enterprise and supply chain systems, reconfiguration depends on the application capability of digital technology [121].

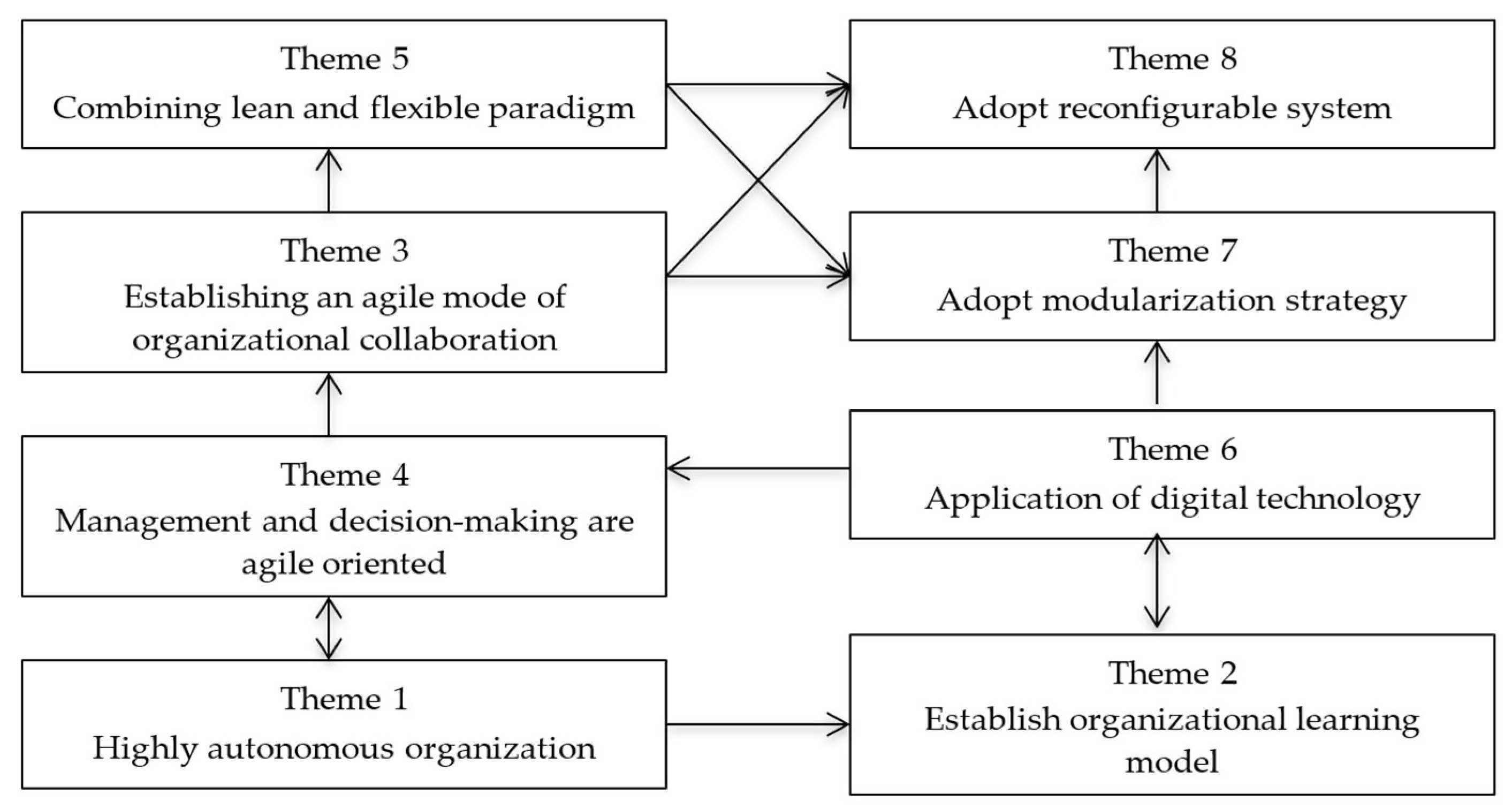

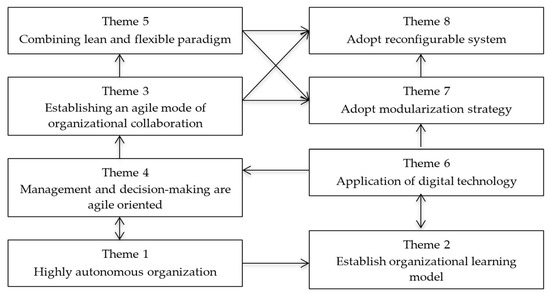

To understand the research focus of agility sustainable design, a literature review is conducted. By using a keyword network, areas where there is a lack of knowledge can be identified and addressed. This review is important for the ongoing development of the research field and its future agenda. Figure 8 illustrates the relationship between the nine topics.

Figure 8.

The relationships among 8 themes.

There has been research on sustainable design agility, but it has mostly focused on specific parts of the organization rather than the system. Agility means adapting to changes and requires an organization-wide approach [122]. This involves improving adaptability and transforming the organization to achieve sustainable design goals. Many studies have proposed narrow design strategies for specific units of the enterprise. However, to effectively use agility for sustainable design, it is important to recognize that agility is needed to cope with the complexity and changing needs faced by sustainable design. The actions and understanding of participants will affect the role of agility in practice. Without considering agility from a systemic level, it may result in static and inflexible approaches that do not achieve the desired results.

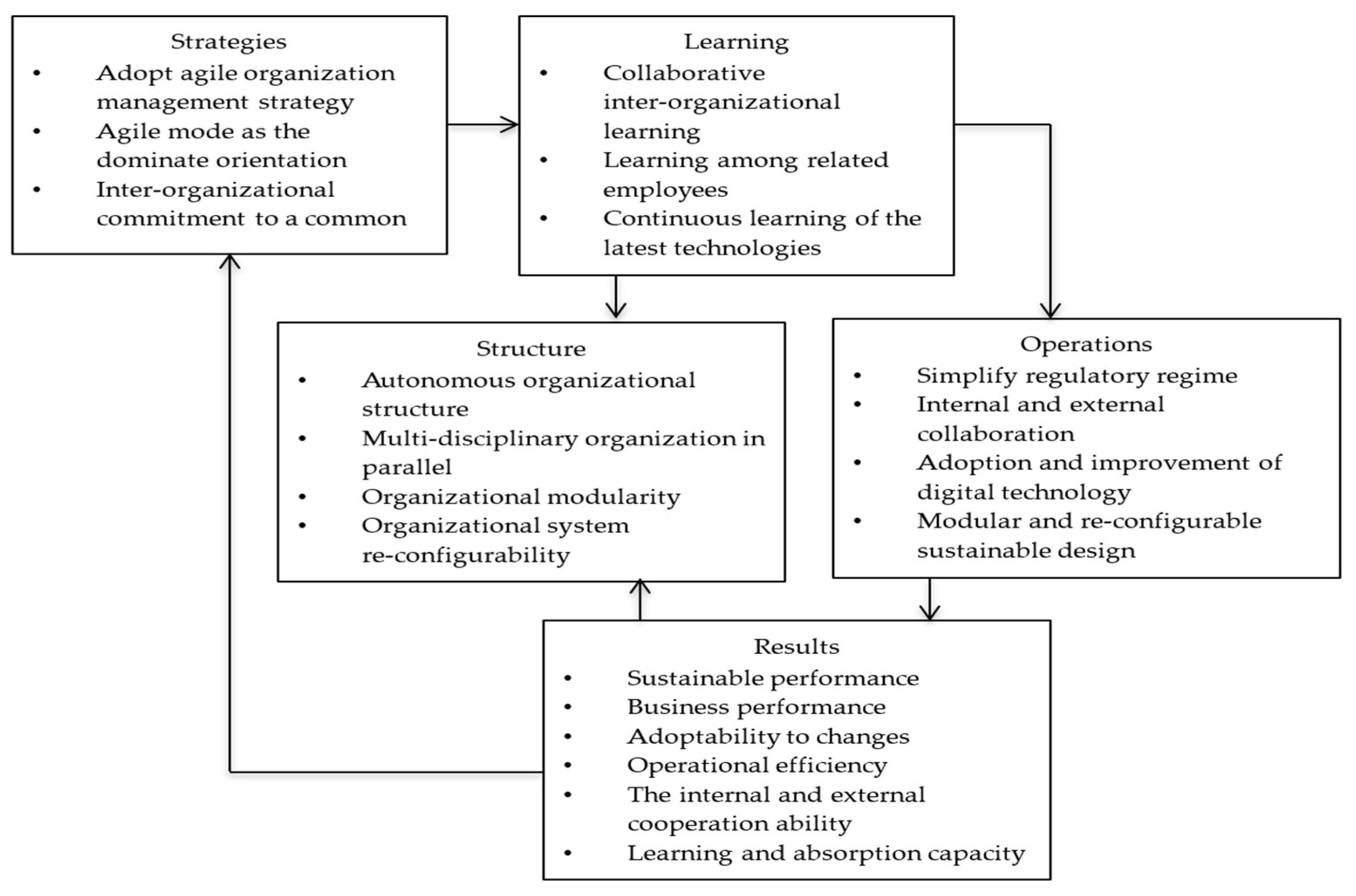

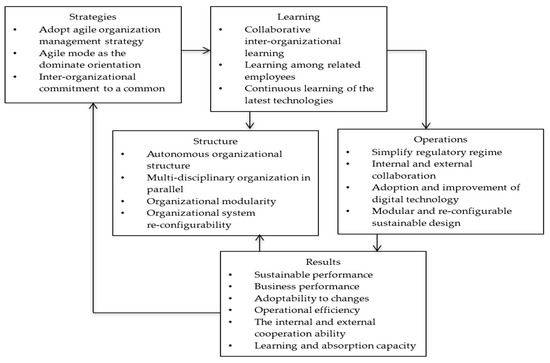

In Figure 9, the system map method is shown to develop a model that provides a better understanding of the relationship between different factors. By using systematic thinking, it becomes possible to comprehend the connection between agility in sustainable design and various backgrounds. This involves identifying the structural and interdependent knowledge structure between variables. The operation of agility in sustainable design begins with the enterprise strategy, with the agile organizational management strategy and model forming the foundation for achieving agility. The common goal of cooperative enterprises is to ensure that agility is sustainably implemented. Senior managers strongly support and enforce agility in sustainable design, taking the initiative to customize long-term strategies to combat temporary errors and uncertainties. Learning is the key factor for enterprises to achieve agility. SMEs lacking in talent and knowledge can easily implement and adopt learning. Access to knowledge and information through different channels not only helps SMEs improve their technical expertise but also provides more business opportunities and cooperation. The enterprise’s structured setting is determined through strategy and learning, with agility reflected in the details of the enterprise structure setting, such as the consideration of parallel mode, modular mode, and reconstruction method when changes are required.

Figure 9.

Application system of agility of sustainable design.

The research highlights that agility is crucial for businesses. Achieving this requires a culture that emphasizes agility in all aspects of management and production. Sustainable design is a key component of agility, with its success leading to sustainable performance and profits. Enterprise managers can use this as a key driving force to adopt an agile approach. Our research has reviewed the literature on agility in sustainable design and identified models that decision-makers in management can use to develop alternative strategies and decision-making ideas.

To sum it up, sustainable design ensures that the products and services offered by businesses are environmentally safe. Meanwhile, agility plays a significant role in all aspects of organizational operations. It brings knowledge, technology, and talent to sustainability, making sustainable design more straightforward and reducing the time required for the process. Agility also helps companies adapt to changes during the sustainable design process. As a result, agility is crucial in supporting sustainable design practices, particularly in small and medium-sized enterprises, to ensure that sustainable design activities run smoothly.

5. Conclusions

Sustainable design research is having a growing impact on corporate practices. This study suggests repeating critical review studies to uncover new phenomena and agendas relevant to academia and practitioners.

- (a)

- In today’s business world, research on agility is becoming increasingly important. This study covers a wide range of agility-related topics and has found that 66% of research on management agility focuses on the production stage of a product. With the emergence of new technologies, sustainable design and agility practices can go beyond what is currently found in peer-reviewed literature. Future research could focus on the agility of specific product research and development, which may require more meetings, seminars, technical documents, or business reports to narrow the existing gap. Additionally, enterprise agility is reflected in every step of the supply chain, making it interesting to study the production and management links in the supply chain and the stakeholders’ changing perception of agility.

- (b)

- At present, only 10 percent of research has considered the incorporation of agility in all aspects of production organizations. In the future, researchers should focus on the role of agility in sustainable R&D cooperation among enterprises. This will benefit society as a whole and make it easier to achieve sustainable development. Achieving sustainability is a complex process that requires the joint efforts of various organizations, enterprises, supply chains, science and technology, processes, stakeholders, and consumers. Evaluating the strength of sustainable design capability reveals the innovation capacity of enterprises and highlights the level of sustainable development of the supply chain and society. Therefore, it is essential to further understand the impact of agility on sustainable design.

This system overview, being a research article, has certain limitations. The data sources used are primarily focused on manufacturing and digital technologies associated with product production, R&D, and output. It is important to note that the conclusions drawn from this study may not apply to other R&D systems, businesses, or sustainable management areas. To increase the applicability of the theory, future research should consider a wider range of studies.

Author Contributions

Conceptualization, Z.Z. and H.A.; validation, Z.Z. and R.C.M.; investigation, Z.Z.; and H.A.; writing—original draft preparation, Z.Z.; writing—review and editing, Z.Z.; R.C.M. and H.A.; visualization, Z.Z.; supervision, H.A.; project administration, H.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no funding.

Data Availability Statement

Not applicable.

Acknowledgments

The author thanks the Heilongjiang Provincial Art Science Planning General Project of Heilongjiang Provincial Department of Culture, China (Approval No.: 2019C028) for providing data sources for this paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Le, T.T.; Tran, P.Q.; Lam, N.P.; Tra, M.N.L.; Uyen, P.H.P. Corporate social responsibility, green innovation, environment strategy and corporate sustainable development. Oper. Manag. Res. 2023, 2023, 1–21. [Google Scholar] [CrossRef]

- Manda, B.M.K.; Bosch, H.; Karanam, S.; Beers, H.; Bosman, H.; Rietveld, E.; Worrell, E.; Patel, M.K. Value creation with life cycle assessment: An approach to contextualize the application of life cycle assessment in chemical companies to create sustainable value. J. Clean. Prod. 2016, 126, 337–351. [Google Scholar] [CrossRef]

- He, F.; Miao, X.; Wong, C.W.Y.; Lee, S. Contemporary corporate eco-innovation research: A systematic review. J. Clean. Prod. 2018, 174, 502–526. [Google Scholar] [CrossRef]

- Palomares-Aguirre, I.B.S.; Barnett, M.; Layrisse, F. Built to scale? How sustainable business models can better serve the base of the pyramid. J. Clean. Prod. 2018, 172, 4506–4513. [Google Scholar] [CrossRef]

- Agarwal, V.; Hameed, A.Z.; Malhotra, S.; Mathiyazhagan, K.; Alathur, S.; Appolloni, A. Role of Industry 4.0 in agile manufacturing to achieve sustainable development. Bus. Strategy Environ. 2022. online version. [Google Scholar] [CrossRef]

- Hariyani, D.; Mishra, S. Structural equation modeling of drivers for the adoption of an integrated sustainable-green-lean-six sigma-agile manufacturing system (ISGLSAMS) in Indian manufacturing organizations. Clean. Circ. Bioecon. 2023, 4, 100037. [Google Scholar] [CrossRef]

- Kombaya Touckia, J.; Hamani, N.; Kermad, L. Digital twin framework for reconfigurable manufacturing systems (RMSs): Design and simulation. Int. J. Adv. Manuf. Technol. 2022, 120, 5431–5450. [Google Scholar] [CrossRef] [PubMed]

- Almoslehy, S.A.M.; Alkahtani, M.S. Key approaches, risks, and product performance in managing the development process of complex products sustainably. Sustainability 2021, 13, 4727. [Google Scholar] [CrossRef]

- Wan, G.; Dong, X.; Dong, Q.; He, Y.; Zeng, P. Design and implementation of agent-based robotic system for agile manufacturing: A case study of ARIAC 2021. Robot. Comput.-Integr. Manuf. 2022, 77, 102349. [Google Scholar] [CrossRef]

- Joshi, M.P. Strategic agility: Linking strategic framework to agile framework. In Senior Leadership Teams and the Agile Organization; Routledge: London, UK, 2023; pp. 82–102. [Google Scholar]

- Chow, T.; Cao, D. A survey study of critical success factors in agile software projects. J. Syst. Softw. 2008, 81, 961–971. [Google Scholar] [CrossRef]

- Leite, M.; Braz, V. Agile manufacturing practices for new product development: Industrial case studies. J. Manuf. Technol. Manag. 2016, 27, 560–576. [Google Scholar] [CrossRef]

- Altunel, H. Agile Project Management in Product Life Cycle. Int. J. Inf. Technol. Proj. Manag. 2017, 8, 50–63. [Google Scholar] [CrossRef]

- Aoyama, M. Web-Based Agile Software Development. IEEE Softw. 1998, 15, 56–65. [Google Scholar] [CrossRef]

- Daneva, M.; Van Der Veen, E.; Amrit, C.; Ghaisas, S.; Sikkel, K.; Kumar, R.; Ajmeri, N.; Ramteerthkar, U.; Wieringa, R. The Journal of Systems and Software Agile requirements prioritization in large-scale outsourced system projects: An empirical study. J. Syst. Softw. 2013, 86, 1333–1353. [Google Scholar] [CrossRef]

- Haeruddin, M.I.W.; Musa, M.I.; Kurniawan, A.W. Marketing Strategy Analysis in A Global Market. J. Manag. Econ. Rev. 2023, 1, 17–24. [Google Scholar]

- Zhao, Y.; Peng, B.; Iqbal, K.; Wan, A. Does market orientation promote enterprise digital innovation? Based on the survey data of China’s digital core industries. Ind. Mark. Manag. 2023, 109, 135–145. [Google Scholar] [CrossRef]

- Ross, D.A.; Engineering, M.; Design, P.S.; Knowledge, E.; Phase, C.D. Exploring the effectiveness of providing structured design-for-the-environment strategies during conceptual design. J. Mech. Des. 2022, 144, 032001. [Google Scholar] [CrossRef]

- Keitsch, M. Sustainable Design: A Brief Appraisal of its Main Concepts. Sustain. Dev. 2012, 20, 180–188. [Google Scholar] [CrossRef]

- Rashid, N.; Khan, S.U. Using agile methods for the development of green and sustainable software: Success factors for GSD vendors. J. Softw. Evol. Process 2018, 30, e1927. [Google Scholar] [CrossRef]

- Udokporo, C.K.; Anosike, A.; Lim, M.; Nadeem, S.P.; Garza-Reyes, J.A.; Ogbuka, C.P. Impact of Lean, Agile and Green (LAG) on business competitiveness: An empirical study of fast moving consumer goods businesses. Resour. Conserv. Recycl. 2020, 156, 104714. [Google Scholar] [CrossRef]

- Galán, O.A.A.; Valdéz, J.L.C.; Medina, H.F.; Contreras, G.A.V.; Sumuano, J.L.S. Proposal of a sustainable agile model for software development. Int. J. Adv. Comput. Sci. Appl. 2020, 11, 42–49. [Google Scholar] [CrossRef]

- Endres, M.; Bican, P.M.; Wöllner, T. Sustainability meets agile: Using Scrum to develop frugal innovations. J. Clean. Prod. 2022, 347, 130871. [Google Scholar] [CrossRef]

- Wang, C.N.; Yang, C.Y.; Cheng, H.C. A Fuzzy Multicriteria Decision-Making (MCDM) Model for Sustainable Supplier Evaluation and Selection Based on Triple Bottom Line Approaches in the Garment Industry. Processes 2019, 7, 400. [Google Scholar] [CrossRef]

- Andersen, M.M. On the faces and phases of eco-innovation on the dynamics of the greening of the economy. In Proceedings of the Druid Summer Conference 2010, London, UK, 16–18 June 2010. [Google Scholar]

- Crespi, F.; Mazzanti, M.; Managi, S. Green growth, eco-innovation and sustainable transitions. Environ. Econom. Policy Stud. 2016, 18, 137–141. [Google Scholar] [CrossRef]

- De Jesus, A.; Antunes, P.; Santos, R.; Mendonça, S. Eco-innovation in the transition to a circular economy: An analytical literature review. J. Clean. Prod. 2016, 172, 2999–3018. [Google Scholar] [CrossRef]

- Mazzanti, M. Eco-innovation and sustainability: Dynamic trends, geography and policies. J. Environ. Plan. Manag. 2018, 61, 1851–1860. [Google Scholar] [CrossRef]

- Hazarika, N.; Zhang, X. Evolving theories of eco-innovation: A systematic review. Sustain. Prod. Consum. 2019, 19, 64–78. [Google Scholar] [CrossRef]

- Kanda, W.; del Río, P.; Hjelm, O.; Bienkowska, D. A technological innovation systems approach to analyse the roles of intermediaries in eco-innovation. J. Clean. Prod. 2019, 227, 1136–1148. [Google Scholar] [CrossRef]

- Mouzakitis, Y.; Adamides, E.D. The bottom-up side of eco-innovation: Mapping the dynamics of sustainable grassroots innovations. In Smart Innovation, Systems and Technologies; Springer: Singapore, 2019; Volume 155. [Google Scholar] [CrossRef]

- Kim, S.; Moon, S.K. Sustainable platform identification for product family design. J. Clean. Prod. 2017, 143, 567–581. [Google Scholar] [CrossRef]

- Melles, G.D.; de Vere, I.; Misic, V. Socially responsible design: Thinking beyond the triple bottom line to socially responsive and sustainable product design. CoDesign 2011, 7, 143–154. [Google Scholar] [CrossRef]

- Sanders, E.B.; Stappers, P.J.; Sanders, E.B.; Co-creation, P.J.S. Co-creation and the new landscapes of design. Co-Design 2008, 4, 5–18. [Google Scholar] [CrossRef]

- Morelli, N. Social Innovation and New Industrial Contexts: Can Designers “Industrialize” Socially Responsible Solutions? Design Issues 2007, 23, 3–21. [Google Scholar] [CrossRef]

- Brown, B.T.; Wyatt, J. Design Thinking for Social Innovation. Stanf. Soc. Inn. Rev. 2010, 12, 29–43. [Google Scholar] [CrossRef]

- Holt, R.; Barnes, C. Towards an integrated approach to “ Design for X”: An agenda for decision-based DFX research. Res. Eng. Des. 2010, 21, 123–136. [Google Scholar] [CrossRef]

- Gagnon, B.; Leduc, R.; Savard, L. From a conventional to a sustainable engineering design process: Different shades of sustainability. J. Eng. Des. 2012, 23, 49–74. [Google Scholar] [CrossRef]

- Hao, Y.P.; Helo, P.; Shamsuzzoha, A. Virtual factory system design and implementation: Integrated sustainable manufacturing. Int. J. Syst. Sci. Oper. Logistics. 2018, 5, 116–132. [Google Scholar] [CrossRef]

- Younesi, M.; Roghanian, E. A framework for sustainable product design: A hybrid fuzzy approach based on Quality Function Deployment for Environment. J. Clean. Prod. 2015, 108, 385–394. [Google Scholar] [CrossRef]

- Buchert, T.; Halstenberg, F.A.; Bonvoisin, J.; Lindow, K.; Stark, R. Target-driven selection and scheduling of methods for sustainable product development. J. Clean. Prod. 2017, 161, 403–421. [Google Scholar] [CrossRef]

- Francia, D.; Caligiana, G.; Liverani, A.; Frizziero, L.; Donnici, G. PrinterCAD: A QFD and TRIZ integrated design solution for large size open moulding manufacturing. Int. J. Interact. Des. Manuf. 2018, 12, 81–94. [Google Scholar] [CrossRef]

- Guo, X.; Zhao, W.; Hu, H.; Li, L.; Liu, Y.; Wang, J.; Zhang, K. A smart knowledge deployment method for the conceptual design of low-carbon products. J. Clean. Prod. 2021, 321, 128994. [Google Scholar] [CrossRef]

- Wilding, R.D. Short-term strategic management in mass customized markets. Logist. Inf. Manag. 1997, 10, 199–207. [Google Scholar]

- Maskell, B. Insight from industry The age of agile manufacturing. Supply Chain. Manag. Int. J. 2001, 6, 5–11. [Google Scholar] [CrossRef]

- Jin-Hai, L.; Anderson, A.R.; Harrison, R.T. The evolution of agile manufacturing. Bus. Process Manag. J. 2003, 9, 170–189. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Lai, K.; Cheng, T.C.E. Responsive supply chain: A competitive strategy in a networked economy. J. Omega 2008, 36, 549–564. [Google Scholar] [CrossRef]

- Geyi, D.G.; Yusuf, Y.; Menhat, M.S.; Abubakar, T.; Ogbuke, N.J. Agile capabilities as necessary conditions for maximising sustainable supply chain performance: An empirical investigation. Int. J. Prod. Econ. 2020, 222, 107501. [Google Scholar] [CrossRef]

- Holbeche, L.S. Organisational effectiveness and agility. J. Organ. Eff. 2018, 5, 302–313. [Google Scholar] [CrossRef]

- Nejatian, M.; Zarei, M.H.; Rajabzadeh, A.; Azar, A.; Khadivar, A. Paving the path toward strategic agility: A methodological perspective and an empirical investigation. J. Enterp. Inf. Manag. 2019, 32, 538–562. [Google Scholar] [CrossRef]

- Mengoni, M.; Germani, M.; Mandorli, F. A structured agile design approach to support customisation in wellness product development. Int. J. Comput. Integr. Manuf. 2009, 22, 42–54. [Google Scholar] [CrossRef]

- Khatri, A.; Garg, D.; Dangayach, G.S. An empirical investigation of agility factors in select Indian manufacturing industries. Int. J. Bus. Inf. Syst. 2018, 28, 42–66. [Google Scholar] [CrossRef]

- Nold, H.; Michel, L. The performance triangle: A model for corporate agility. Leadersh. Organ. Dev. J. 2016, 37, 341–356. [Google Scholar] [CrossRef]

- Arbussa, A.; Bikfalvi, A.; Marquès, P. Strategic agility-driven business model renewal: The case of an SME. Manag. Dec. 2017, 55, 271–293. [Google Scholar] [CrossRef]

- Yang, G.; Zhang, X. Construction of computer-aided industrial design system based on agility. Int. J. Comput. Sci. Math. 2015, 6, 492–500. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Yusuf, Y.Y. International Journal of Agile manufacturing: A taxonomy of strategic and technological imperatives. Int. J. Prod. Res. 2010, 2013, 37–41. [Google Scholar] [CrossRef]

- Sarkis, J.; Talluri, S.; Gunasekaran, A. A strategic model for agile virtual enterprise partner selection. Int. J. Oper. Prod. Manag. 2007, 27, 1213–1234. [Google Scholar] [CrossRef]

- Mondragon, A.E.C.; Lyons, A.C.; Kehoe, D.F. Assessing the value of information systems in supporting agility in high-tech manufacturing enterprises. Int. J. Oper. Prod. Manag. 2004, 24, 1219–1246. [Google Scholar] [CrossRef]

- Lin, B. International Journal of Production Original equipment manufacturers (OEM) manufacturing strategy for network innovation agility: The case of Taiwanese manufacturing networks. Int. J. Prod. Res. 2004, 42, 943–957. [Google Scholar] [CrossRef]

- Go, T.F.; Wahab, D.A.; Hishamuddin, H. Multiple generation life-cycles for product sustainability: The way forward. J. Clean. Prod. 2015, 95, 16–29. [Google Scholar] [CrossRef]

- Chiu, M.; Chu, C. Review of Sustainable Product Design from Life Cycle Perspectives. Int. J. Precis. Eng. Manuf. 2012, 13, 1259–1272. [Google Scholar] [CrossRef]

- Ostergaard, K.J.; Summers, J.D. Development of a systematic classification and taxonomy of collaborative design activities. J. Eng. Des. 2009, 20, 57–81. [Google Scholar] [CrossRef]

- Misceo, M.; Buonamici, R.; Buttol, P.; Naldesi, L.; Grimaldi, F.; Rinaldi, C. TESPI (Tool for Environmental Sound Product Innovation): A simplified software tool to support environmentally conscious design in SMEs. Environ. Conscious Manuf. IV 2004, 5583, 186–192. [Google Scholar] [CrossRef]

- Song, W.; Sakao, T. A customization-oriented framework for design of sustainable product/service system. J. Clean. Prod. 2017, 140, 1672–1685. [Google Scholar] [CrossRef]

- Dunmade, I. Design for Multipurpose Use: An application of DfE concept in a developing economy. Environ. Cons. Manuf. IV 2004, 5583, 193–199. [Google Scholar] [CrossRef]

- Dunmade, I.; Rosentrater, K. Designing for multi-lifecycle to promote industrial ecology philosophy. Environ. Cons. Manuf. VI 2006, 6385, 178–184. [Google Scholar] [CrossRef]

- Gu, P.; Xue, D.; Nee, A.Y.C. Adaptable design: Concepts, methods, and applications. Proc. IMechE 2009, 223, 1367–1387. [Google Scholar] [CrossRef]

- Nielsen, K.; Brunoe, T.D.; Nielsen, K.; Ditlev, T.; Cradle, B.; Supply, C.L. Cradle to Cradle Products, Modularity and Closed Loop Supply Chains; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Perera, S.; Soosay, C.; Sandhu, S. Investigating the strategies for supply chain agility and competitiveness. Asian J. Bus. Account. 2019, 12, 279–312. [Google Scholar] [CrossRef]

- El-Khalil, R.; Mezher, M.A. The mediating impact of sustainability on the relationship between agility and operational performance. Oper. Res. Perspect. 2020, 7, 100171. [Google Scholar] [CrossRef]

- Singh, A.K.; Vinodh, S. Modeling and performance evaluation of agility coupled with sustainability for business planning. J. Manag. Dev. 2017, 36, 109–128. [Google Scholar] [CrossRef]

- Chiang, C.T.; Kou, T.C.; Koo, T.L. A systematic literature review of the it-based supply chain management system: Towards a sustainable supply chain management model. Sustainability 2021, 13, 2547. [Google Scholar] [CrossRef]

- Briner, R.B.; Mary, Q.; Denyer, D. Systematic Review and Evidence Synthesis as a Practice and Scholarship Tool. In The Oxford Handbook of Evidence-Based Management; Oxford Library of Psychology: Oxford, UK, 2012; pp. 112–129. [Google Scholar] [CrossRef]

- Sharma, V.; Raut, R.D.; Mangla, S.K.; Narkhede, B.E.; Luthra, S.; Gokhale, R. A systematic literature review to integrate lean, agile, resilient, green and sustainable paradigms in the supply chain management. Bus. Strategy Environ. 2021, 30, 1191–1212. [Google Scholar] [CrossRef]

- Counsell, C.; Do, W.; Come, Q. Formulating Questions and Locating Primary Studies for Inclusion in Systematic Reviews. Ann. Int. Med. 1997, 127, 380–387. [Google Scholar] [CrossRef]

- Xavier, A.F.; Naveiro, R.M.; Aoussat, A.; Reyes, T. Systematic literature review of eco-innovation models: Opportunities and recommendations for future research. J. Clean. Prod. 2017, 149, 1278–1302. [Google Scholar] [CrossRef]

- Dekkers, S.; Wijnhoven, S.W.P.; Braakhuis, H.M.; Soeteman-Hernandez, L.G.; Sips, A.J.A.M.; Tavernaro, I.; Kraegeloh, A.; Noorlander, C.W. Safe-by-Design part I: Proposal for nanospecific human health safety aspects needed along the innovation process. NanoImpact 2020, 18, 100227. [Google Scholar] [CrossRef]

- Kurniadi, K.A.; Ryu, K. Maintaining Sustainability in Reconfigurable Manufacturing Systems Featuring Green-BOM. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 755–767. [Google Scholar] [CrossRef]

- Zolfani, S.H.; Chatterjee, P. Comparative evaluation of sustainable design based on Step-Wise Weight Assessment Ratio Analysis (SWARA) and Best Worst Method (BWM) methods: A. Symmetry 2019, 11, 74. [Google Scholar] [CrossRef]

- Roy, J.; Das, S.; Kar, S.; Pamučar, D. An Extension of the CODAS Approach Using Interval-Valued Intuitionistic Fuzzy Set for Sustainable Material Selection in Construction Projects with Incomplete Weight Information. Symmetry 2019, 11, 393. [Google Scholar] [CrossRef]

- Moro, S.R.; Cauchick-Miguel, P.A.; Campos, L.M.S. Product-service systems towards eco-effective production patterns: A Lean-Green design approach from a literature review. Total Qual. Manag. Bus. Excell. 2021, 32, 1046–1064. [Google Scholar] [CrossRef]

- Maffei, A.; Onori, M. Evolvable production systems: Environment for new business models. Key Eng. Mater. 2011, 467–469, 1592–1597. [Google Scholar] [CrossRef]

- Manuj, I.; Omar, A.; Yazdanparast, A. The quest for competitive advantage in global supply chains: The role of interorganizational learning. Transp. J. 2013, 52, 463–492. [Google Scholar] [CrossRef]

- Eddy, D.; Krishnamurty, S.; Grosse, I.; Witherell, P.; Wileden, J.; Lewis, K. An integrated approach to information modeling for the sustainable design of products. J. Comput. Inf. Sci. Eng. 2014, 14, 021011. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Singh, T. Building theory of sustainable manufacturing using total interpretive structural modelling. Int. J. Syst. Sci. Op. Logist. 2015, 2, 231–247. [Google Scholar] [CrossRef]

- Varsei, M. Sustainable Supply Chain Management: An Integrated Model for Optimising Supply Chain Network Design. Ph.D. Thesis, Australian Institute of Business, Adelaide, Australia, 2017; p. 212. Available online: https://www.researchgate.net/publication/319056482 (accessed on 30 June 2023).

- Chofreh, A.G.; Goni, F.A.; Klemeš, J.J. Sustainable enterprise resource planning systems implementation: A framework development. J. Clean. Prod. 2018, 198, 1345–1354. [Google Scholar] [CrossRef]

- Shi, R.; Guest, J.S. BioSTEAM-LCA: An Integrated Modeling Framework for Agile Life Cycle Assessment of Biorefineries under Uncertainty. ACS Sustain. Chem. Eng. 2020, 8, 18903–18914. [Google Scholar] [CrossRef]

- Uhlenbrock, L.; Sixt, M.; Tegtmeier, M.; Schulz, H.; Hagels, H.; Ditz, R.; Strube, J. Natural products extraction of the future-Sustainable manufacturing solutions for societal needs. Processes 2018, 6, 177. [Google Scholar] [CrossRef]

- Liu, M.; Hansen, S.; Tu, Q. Sustaining collaborative software development through strategic consortium. J. Strateg. Inf. Syst. 2021, 30, 101671. [Google Scholar] [CrossRef]

- Bersson, T.F.; Mazzuchi, T.; Sarkani, S. A framework for application of system engineering process models to sustainable design of high performance buildings. J. Green Build. 2012, 7, 171–192. [Google Scholar] [CrossRef]

- Garbie, I.H. A methodology for the reconfiguration process in manufacturing systems. J. Manuf. Technol. Manag. 2014, 25, 891–915. [Google Scholar] [CrossRef]

- Bi, Z.M.; Liu, Y.; Baumgartner, B.; Culver, E.; Sorokin, J.N.; Peters, A.; Cox, B.; Hunnicutt, J.; Yurek, J.; O’Shaughnessey, S. Reusing industrial robots to achieve sustainability in small and medium-sized enterprises (SMEs). Ind. Robot 2015, 42, 264–273. [Google Scholar] [CrossRef]

- Jabbarzadeh, A.E.; Fahimnia, B.; Sabouhi, F. Resilient and sustainable supply chain design: Sustainability analysis under disruption risks. Int. J. Prod. Res. 2018, 56, 5945–5968. [Google Scholar] [CrossRef]

- Mari, S.I.; Lee, Y.H.; Memon, M.S. Sustainable and resilient garment supply chain network design with fuzzy multi-objectives under uncertainty. Sustainability 2016, 8, 1038. [Google Scholar] [CrossRef]

- Peruzzini, M.; Pellicciari, M. Application of early sustainability assessment to support the design of industrial systems. Industrial Eng. Manag. Syst. 2018, 17, 209–225. [Google Scholar] [CrossRef]

- Cavalliere, C.; Dell’Osso, G.R.; Favia, F.; Lovicario, M. BIM-based assessment metrics for the functional flexibility of building designs. Autom. Constr. 2019, 107, 102925. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Goli, A.; Ghasemi, P.; Goodarzian, F. Designing a sustainable closed-loop supply chain network of face masks during the COVID-19 pandemic: Pareto-based algorithms. J. Clean. Prod. 2022, 333, 130056. [Google Scholar] [CrossRef]

- Shalender, K.; Singh, N. Understanding product flexibility using SAP-LAP approach. J. Strateg. Mark. 2014, 22, 104–116. [Google Scholar] [CrossRef]