Multi-Material 3D-Printing Nozzle Design Based on the Theory of Inventive Problem Solving and Knowledge Graph

Abstract

1. Introduction

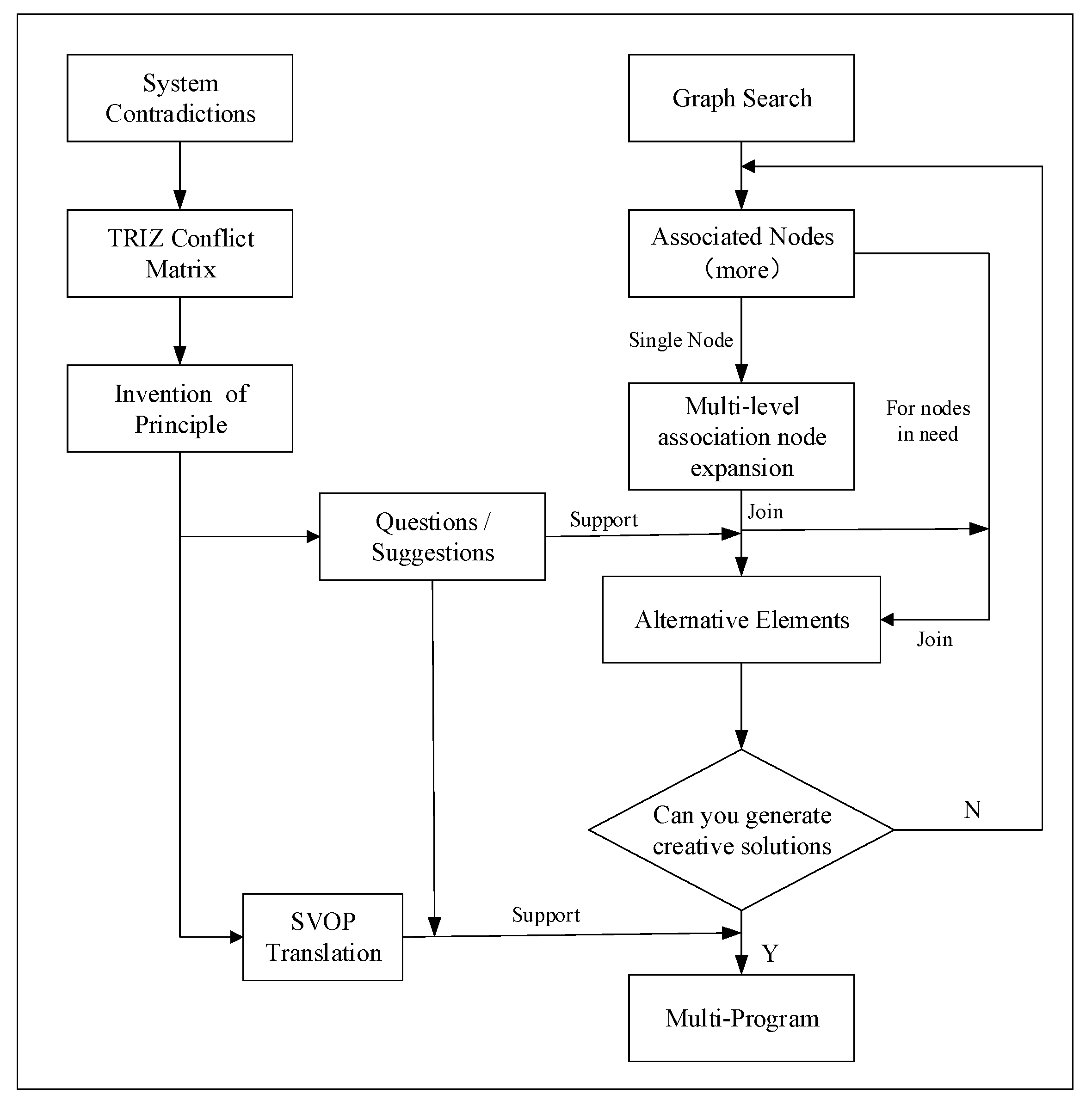

2. Design Methodology

2.1. TRIZ Problem-Solving Direction Capture

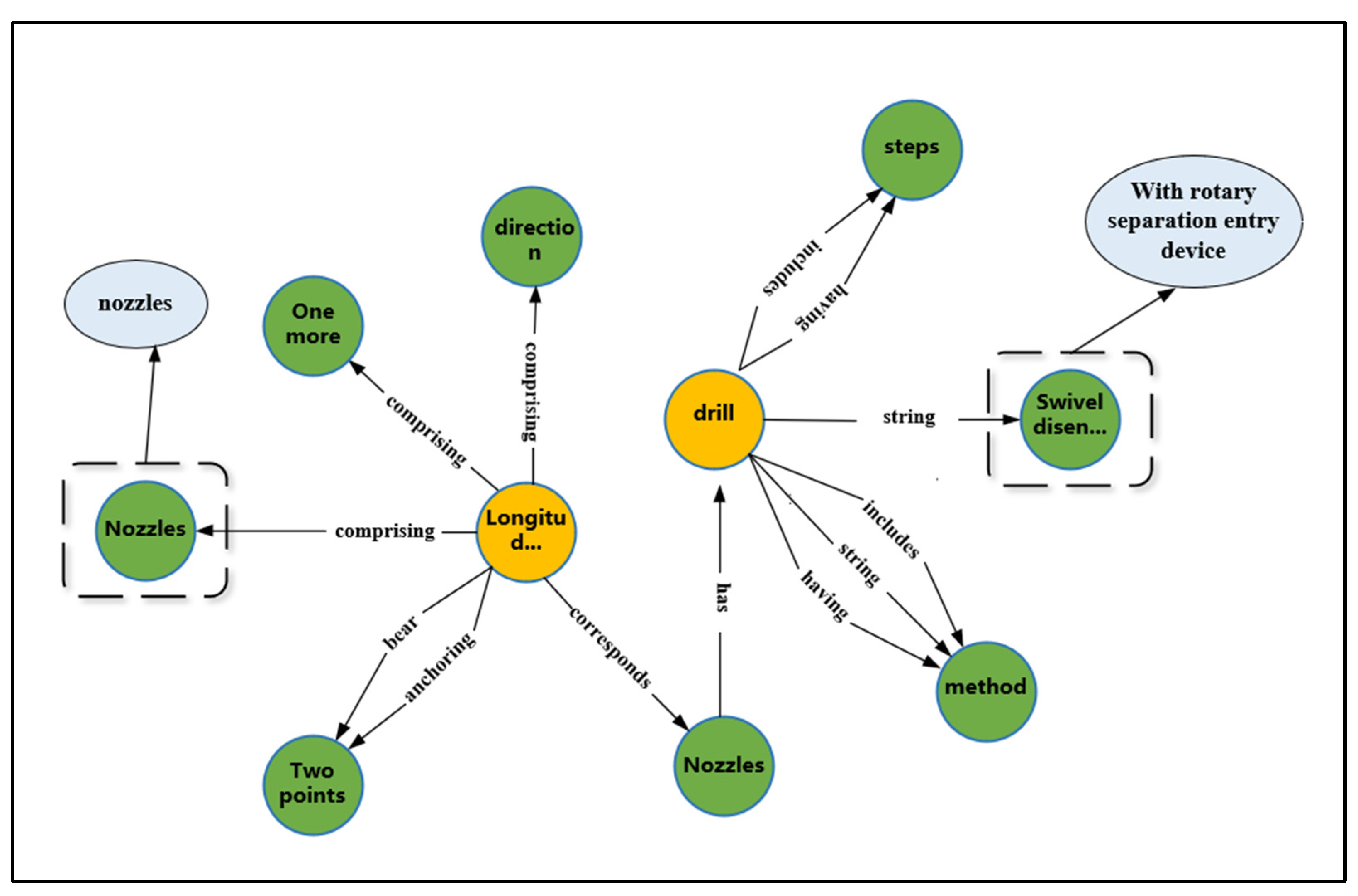

2.2. Establishment of Knowledge Graph

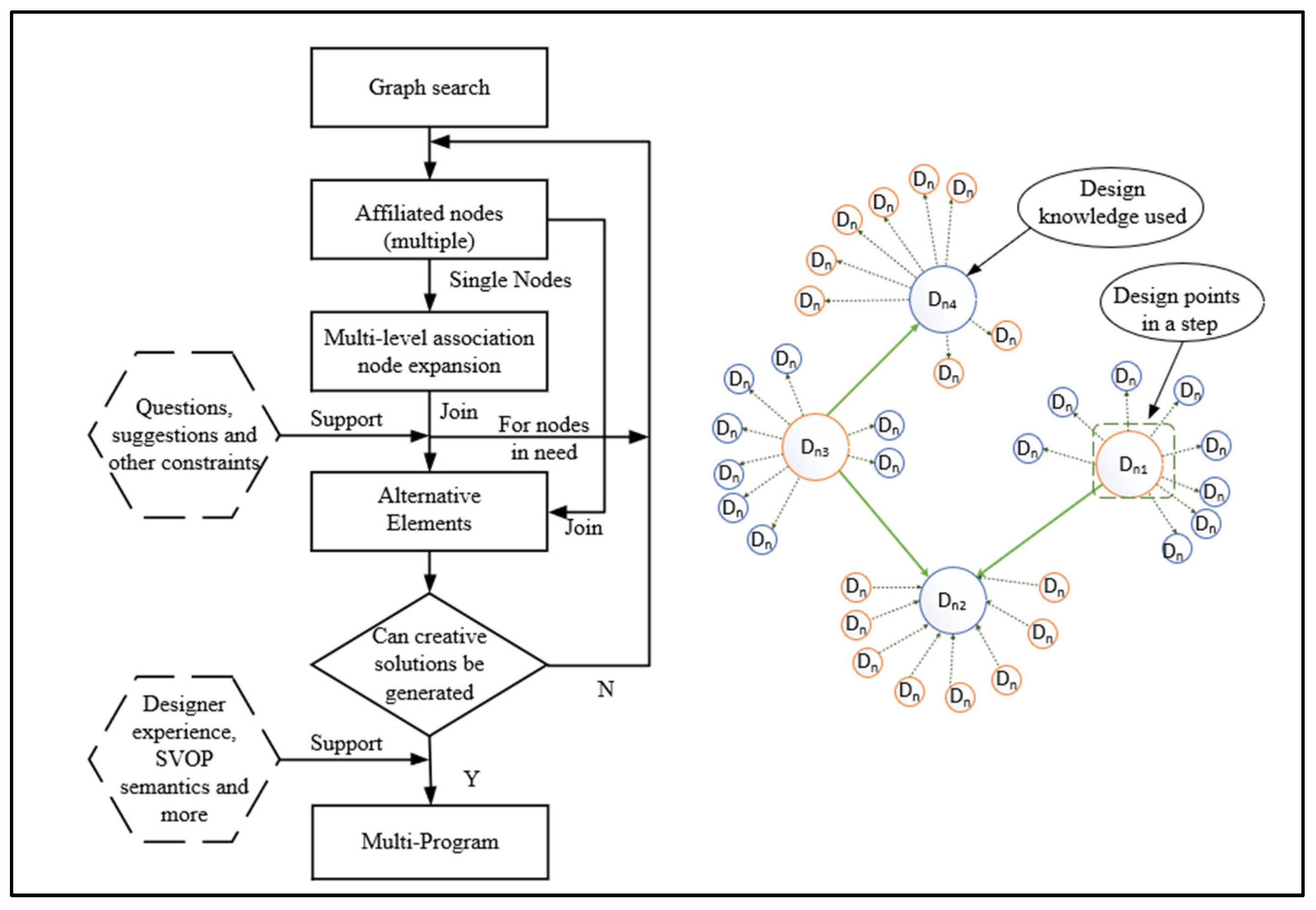

2.3. Knowledge Visualization Search Based on KG Path

2.4. Design Solution Generation

3. Case Study

- Multi-material printing is not possible due to poor spitting caused by insufficient extrusion strength of the consumables.

- Blockage problem caused by uneven temperature heating.

- The 3D-printing device cannot perform the printing in situ.

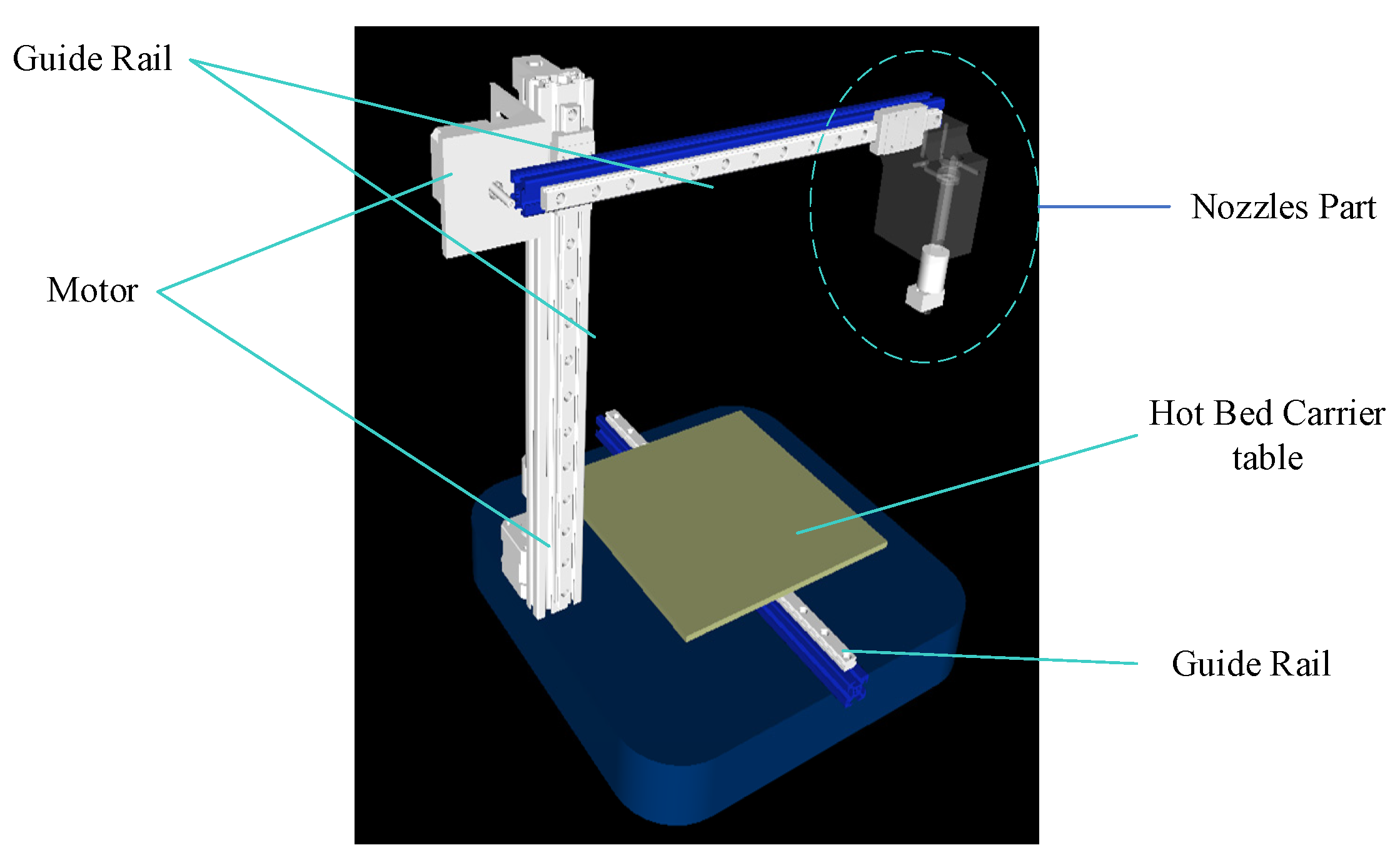

3.1. FDM 3D-Printing Mechanical Device

- Fixed and non-removable physical parts, including the nozzle body, feeding device, extrusion device, feeding tube, nozzle, etc. These parts are all modules that cannot be disassembled or physically changed during the printing process.

- Removable parts, such as the heating device. The operator can adjust the temperature by disassembling and modifying it to meet the different temperature requirements of different consumables.

- Control and detection section, including the stepper motor, temperature sensor, guide rail, etc. These parts can provide working data during operation and adjust the extrusion speed of the nozzle by adjusting its speed, making it a controllable part for the operator during use. Different nondestructive testing and monitoring can be considered for the specific design and functionality.

3.2. Problem Identification and Recommendation Formulation

3.2.1. System Contradiction

- Use of multiple consumables can lead to clogging;

- Use of multiple consumables can lead to contamination;

- Multiple nozzle replacements can be time-consuming and can affect printing accuracy.

3.2.2. Conflict Matrix

3.2.3. Inventive Principle

3.2.4. Selection Principle

3.2.5. Questions/Suggestions

3.3. Knowledge Push and Idea Generation

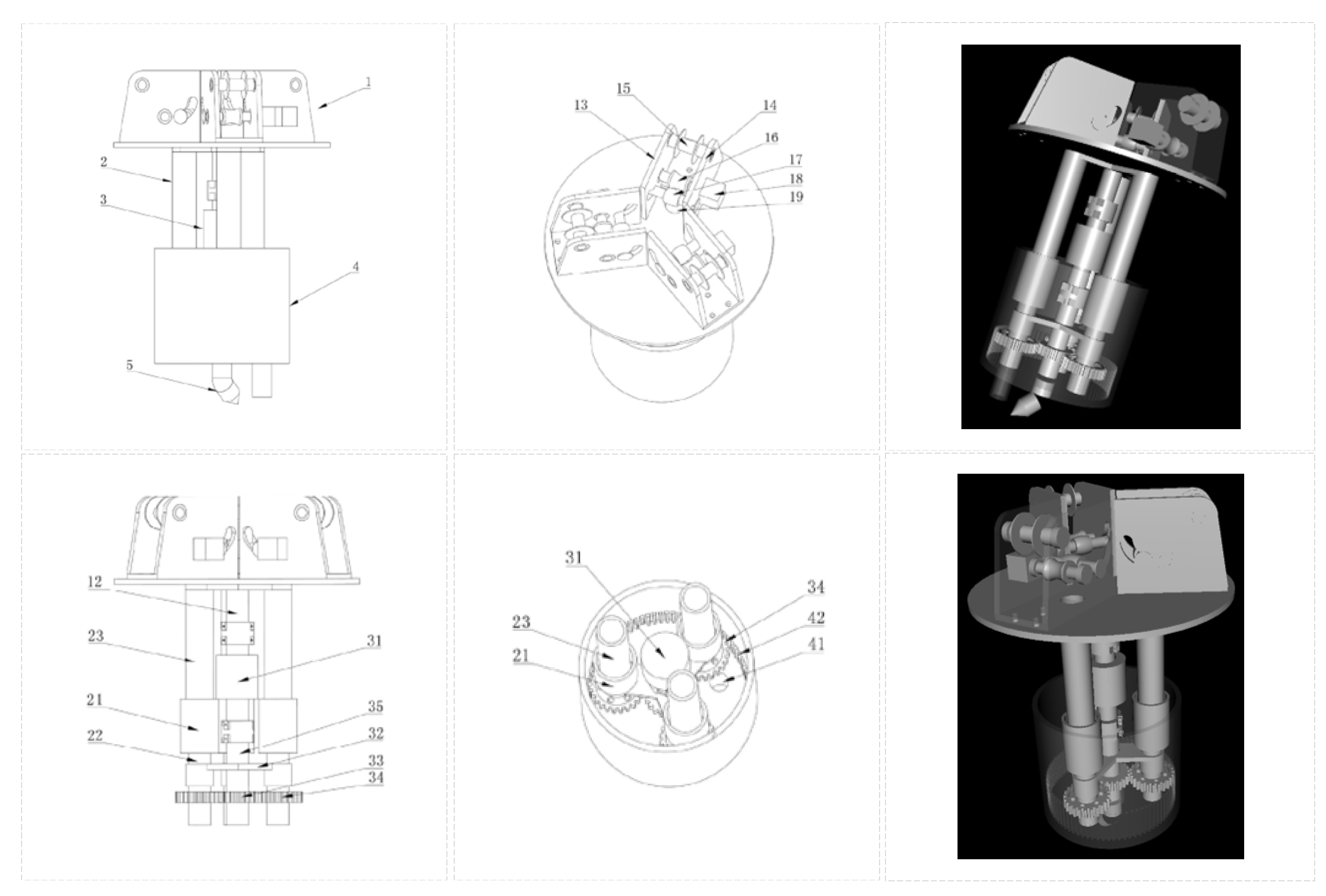

3.4. Creativity and Multi-Program Generation

3.5. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yang, W.; Jian, R. Research on intelligent manufacturing of 3D printing/copying of polymer. Adv. Ind. Eng. Polym. Res. 2019, 2, 88–90. [Google Scholar] [CrossRef]

- Alarifi, I.M. A comprehensive review on advancements of elastomers for engineering applications. Adv. Ind. Eng. Polym. Res. 2023. [Google Scholar] [CrossRef]

- Li, C.; Yang, J.; Li, Y.; Wang, L. Structure design and process parameter optimization of active mixing nozzle based on PDMS/SiC functional gradient composite. China Plast. 2023, 37, 1001–9278. [Google Scholar]

- Madhu, S.; Balasubramanian, M. Influence of nozzle design and process parameters on surface roughness of CFRP machined by abrasive jet. Mater. Manuf. Process. 2017, 32, 1011–1018. [Google Scholar] [CrossRef]

- Farid, M.U.; Bück, A.; Heineken, W.; Gohla, M.; Zobel, N. Study on nozzle design for combustion of solid materials with low melting points. Appl. Therm. Eng. 2017, 115, 832–859. [Google Scholar] [CrossRef]

- Rebollo-Muñoz, N.; Acero, A.J.; de León, J.M.; Montanero, J.M.; Gañán-Calvo, A.M. A hybrid flow focusing nozzle design to produce micron and sub-micron capillary jets. Int. J. Mass Spectrom. 2016, 403, 32–38. [Google Scholar] [CrossRef]

- Altshuller, G. 40 Principles: TRIZ Keys to Technical Innovation; Technical Innovation Center, Inc.: Worcester, MA, USA, 2003. [Google Scholar]

- Bai, Z.; Mu, L.; Lin, H.-C. Green Product Design Based on the BioTRIZ Multi-Contradiction Resolution Method. Sustainability 2020, 12, 4276. [Google Scholar] [CrossRef]

- Hu, Z.; Zhao, Y.; Chen, Y.; Xiang, D. An Improved TRIZ-CBR Model for Rapidly Innovative Design. Adv. Mater. Res. 2011, 308-310, 126–131. [Google Scholar] [CrossRef]

- Yamashina, H.; Ito, T.; Kawada, H. Innovative product development process by integrating QFD with TRIZ. J. Jpn. Soc. Precis. Eng. 2000, 66, 1705–1710. [Google Scholar] [CrossRef]

- Ogot, M. Conceptual design using axiomatic design in a TRIZ framework. Procedia Eng. 2011, 9, 736–744. [Google Scholar] [CrossRef][Green Version]

- Zolfagharian, A.; Gharaie, S.; Kouzani, A.Z.; Lakhi, M.; Ranjbar, S.; Dezaki, M.L.; Bodaghi, M. Silicon-based soft parallel robots 4D printing and multiphysics analysis. Smart Mater. Struct. 2022, 31, 115030. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Jarrah, H.R.; Xavier, M.S.; Rolfe, B.; Bodaghi, M. Multimaterial 4D printing with a tunable bending model. Smart Mater. Struct. 2023, 32, 065001. [Google Scholar] [CrossRef]

- Lee, C.H.; Chen, C.H.; Li, F.; Shie, A.J. Customized and knowledge-centric service design model integrating case-based reasoning and TRIZ. Expert Syst. Appl. 2019, 143, 113062. [Google Scholar] [CrossRef]

- Liu, L.; Li, Y.; Xiong, Y.; Cavallucci, D. A new function-based patent knowledge retrieval tool for conceptual design of innovative products. Comput. Ind. 2019, 115, 103154. [Google Scholar] [CrossRef]

- Ko, H.; Witherell, P.; Lu, Y.; Kim, S.; Rosen, D.W. Machine learning and knowledge graph based design rule construction for additive manufacturing. Addit. Manuf. 2020, 37, 101620. [Google Scholar] [CrossRef]

- Zhou, B.; Bao, J.; Li, J.; Lu, Y.; Liu, T.; Zhang, Q. A novel knowledge graph-based optimization approach for resource allocation in discrete manufacturing workshops. Robot. Comput. Manuf. 2021, 71, 102160. [Google Scholar] [CrossRef]

- Zhou, B.; Hua, B.; Gu, X.; Lu, Y.; Peng, T.; Zheng, Y.; Shen, X.; Bao, J. An end-to-end tabular information-oriented causality event evolutionary knowledge graph for manufacturing documents. Adv. Eng. Inform. 2021, 50, 101441. [Google Scholar] [CrossRef]

- Guo, L.; Yan, F.; Lu, Y.; Zhou, M.; Yang, T. An automatic machining process decision-making system based on knowledge graph. Int. J. Comput. Integr. Manuf. 2021, 34, 1348–1369. [Google Scholar] [CrossRef]

- Zhu, D.; Gong, L.; Tang, S.; Xie, J.; Mo, Z.; Zhu, M. A conceptual design approach for product innovation based on patent knowledge mapping. Comput. Integr. Manuf. Syst. 2022, 28, 3599–3614. [Google Scholar]

- Gero, J.; Milovanovic, J. The situated function-behavior-structure co-design model. CoDesign 2021, 17, 211–236. [Google Scholar] [CrossRef]

- Sampedro, G.A.R.; Agron, D.J.S.; Amaizu, G.C.; Kim, D.-S.; Lee, J.-M. Design of an In-Process Quality Monitoring Strategy for FDM-Type 3D Printer Using Deep Learning. Appl. Sci. 2022, 12, 8753. [Google Scholar] [CrossRef]

- Tamir, T.S.; Xiong, G.; Fang, Q.; Dong, X.; Shen, Z.; Wang, F.-Y. A feedback-based print quality improving strategy for FDM 3D printing: An optimal design approach. Int. J. Adv. Manuf. Technol. 2022, 120, 2777–2791. [Google Scholar] [CrossRef]

- Tlegenov, Y.; Lu, W.F.; Hong, G.S. A dynamic model for current-based nozzle condition monitoring in fused deposition modelling. Prog. Addit. Manuf. 2019, 4, 211–223. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, C.S.; Kim, S.-M.; Lee, S.W. Development of Data-Driven In-Situ Monitoring and Diagnosis System of Fused Deposition Modeling (FDM) Process Based on Support Vector Machine Algorithm. Int. J. Precis. Eng. Manuf. Technol. 2018, 5, 479–486. [Google Scholar] [CrossRef]

- Wu, H.; Yu, Z.; Wang, Y. Real-time FDM machine condition monitoring and diagnosis based on acoustic emission and hidden semi-Markov model. Int. J. Adv. Manuf. Technol. 2017, 90, 2027–2036. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, W.; Wang, G. TRIZ Advanced and Practical: The Invention Method of the Avenue to Simplicity; China Machine Press: Beijing, China, 2015. [Google Scholar]

- Huang, Z.; Guo, X.; Liu, Y.; Zhao, W.; Zhang, K. A smart conflict resolution model using multi-layer knowledge graph for conceptual design. Adv. Eng. Inform. 2023, 55, 101887. [Google Scholar] [CrossRef]

- Lai, B.; Zhao, W.; Yu, Z.; Guo, X.; Zhang, K. A multi-domain knowledge transfer method for conceptual design combine with FBS and knowledge graph. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, St. Louis, MI, USA, 14–17 August 2022; American Society of Mechanical Engineers: New York, NY, USA, 2022; p. V002T02A059. [Google Scholar]

- Siddharth, L.; Blessing, L.T.; Wood, K.L.; Luo, J. Engineering knowledge graph from patent database. J. Comput. Inf. Sci. Eng. 2022, 22, 021008. [Google Scholar] [CrossRef]

- Huang, P.; Ding, Y.; Li, J.; Xu, L.; Xie, Y. Conductivity estimation of non-magnetic materials using eddy current method. Nondestruct. Test. Eval. 2023, 38, 130–146. [Google Scholar] [CrossRef]

- Zhang, X.J.; Tang, S.Y.; Zhao, H.Y. 3D printing technology research status and key technologies. J. Mater. Eng. 2016, 44, 122–128. [Google Scholar]

- Shen, R. Research on the Design and Safety Optimization of Multi-Material 3D Printer. Master’s Thesis, Shanghai University of Applied Sciences, Shanghai, China, 2020. [Google Scholar]

- Dong, C.; Yan, Z.; Wang, L.; Zhou, L.; Sun, C.; Liu, Y. Design of 3D printing feeding device for full denture based on fused deposition molding. Sci. Technol. Perspect. 2019, 36–37. [Google Scholar] [CrossRef]

- Xu, Y. Fused deposition molding wax-based jewelry model casting process design based on 3D printing. Cast. Equip. Process 2019, 22–25. [Google Scholar]

- Wang, S.-S.; Xu, Y.; Zhou, J.-P.; Yin, Z.-T.; Zhang, X.-J. Multi nozzle bio-3D printing system based on motor extrusion deposition. Mach. Tools Hydraul. 2023, 51, 81–86. [Google Scholar]

| System Contradiction | TRIZ Contradiction | Inventive Principle | Selection Principle | Definition of the Problem or Recommendation |

|---|---|---|---|---|

| Use of multiple consumables can lead to bonding and clogging | The quantity of a substance or thing—stability | No. 15 No. 2 No. 17 No. 40 | No. 15, dynamism No. 17, multidimensionality | Q1, Q2 |

| The quantity of a substance or thing—reliability | No. 18 No. 3 No. 28 No. 40 | No. 3, local quality | Q3 | |

| Use of multiple consumables can lead to contamination | Quantity of the substance or thing—harmful factors produced by the object | No. 3 No. 35 No. 40 No. 39 | No. 3, local quality No. 39, inert environment | Q3, Q4 |

| Multiple nozzle replacement is time-consuming, and can lead toprint accuracy | The quantity of a substance or thing—productivity | No. 13 No. 29 No. 3 No. 27 | No. 3, local quality No. 29, pneumatic and hydraulic mechanism | Q3, Q5 |

| Adaptability and versatility—ease of operation process | No. 15 No. 34 No. 1 No. 16 | No. 1, split No. 15, dynamism | Q6, Q1 | |

| Adaptability and versatility—productivity | No. 35 No. 28 No. 6 No. 37 | No. 6, multifunctionality | Q7 |

| Number | Definition of the Problem or Recommendation |

|---|---|

| Q1 | The system should be designed as dynamically as possible (to make it more flexible) |

| Q2 | Should consider the object in space |

| Q3 | System design should be as localized as possible (allowing objects to perform their respective functions at their best) |

| Q4 | Vacuum environment can be considered |

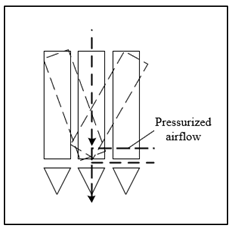

| Q5 | Pneumatic or hydraulic structure can be considered |

| Q6 | The degree of segmentation of some parts should be increased |

| Q7 | Where appropriate, make the object as versatile as possible |

| Q8 | Make spitting more stable (required by the system itself) |

| Design Knowledge from Graph | Problem Solved | Design Idea Generation |

|---|---|---|

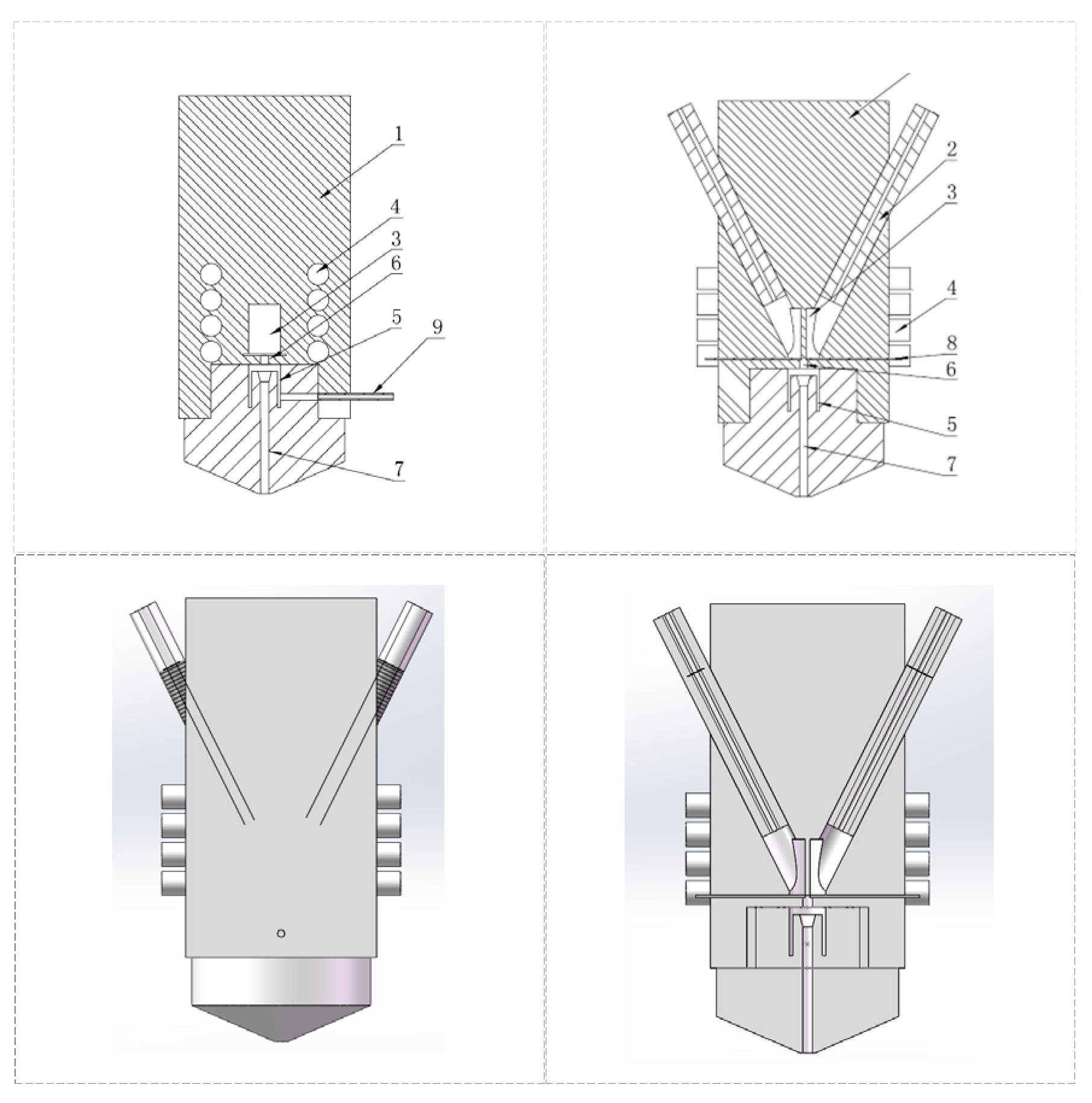

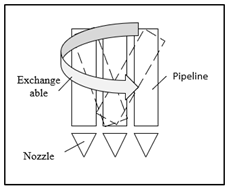

| Rotatable displaceable pipe, divided plurality groups, nozzles, having apparatus exchange, and intersect oblique acute angle | P1, P2, P3 P6, P7 |  |

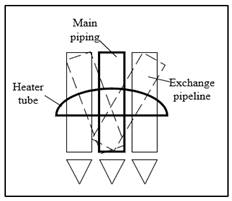

| Preheated conduit, comprising first conduit, and disposed first main body | P1, P2, P6 |  |

| Directing pressurized stream, gas, comprising pressure source, clearing outlet nozzle, comprising high pressure | P4, P5, P7 |  |

| Comprising valve element, account, spray valves, ring gap nozzle arranged, annular chamber enclosing, central chamber, and annular chamber | P1, P6 |  |

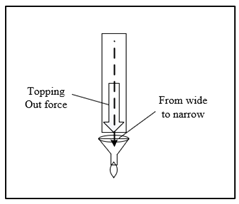

| Has ejection device and the narrowest spread | P8 |  |

| …… | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, C.; Xue, H.; Fang, K.; Zhang, K.; Tian, G. Multi-Material 3D-Printing Nozzle Design Based on the Theory of Inventive Problem Solving and Knowledge Graph. Designs 2023, 7, 103. https://doi.org/10.3390/designs7050103

Tian C, Xue H, Fang K, Zhang K, Tian G. Multi-Material 3D-Printing Nozzle Design Based on the Theory of Inventive Problem Solving and Knowledge Graph. Designs. 2023; 7(5):103. https://doi.org/10.3390/designs7050103

Chicago/Turabian StyleTian, Chenyu, Hao Xue, Kaijin Fang, Kai Zhang, and Guiyun Tian. 2023. "Multi-Material 3D-Printing Nozzle Design Based on the Theory of Inventive Problem Solving and Knowledge Graph" Designs 7, no. 5: 103. https://doi.org/10.3390/designs7050103

APA StyleTian, C., Xue, H., Fang, K., Zhang, K., & Tian, G. (2023). Multi-Material 3D-Printing Nozzle Design Based on the Theory of Inventive Problem Solving and Knowledge Graph. Designs, 7(5), 103. https://doi.org/10.3390/designs7050103