Manufacturing and Assembly for the Ease of Product Recycling: A Review

Abstract

1. Introduction

2. DFMA Historical Development

3. Design for Production

4. Design for Assembly/Disassembly

5. Evaluating the Ease of Disassembly

6. Evaluating the Recycling and Product Separation

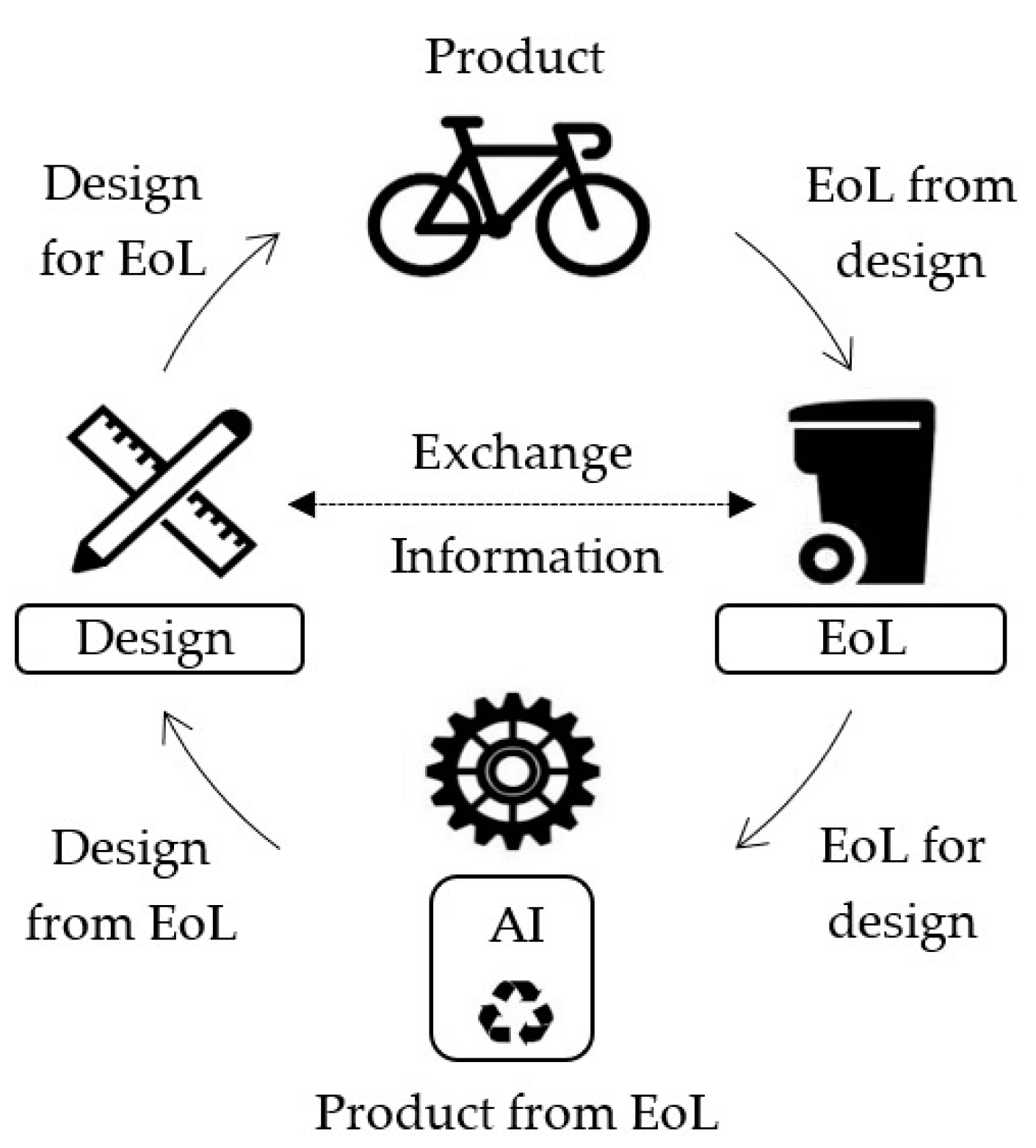

7. Reproduction and Design for Isolation

- The improvement of the product is such that it can be recovered in the best possible condition after disposal.

- Promote the residues’ elimination that cannot be recovered.

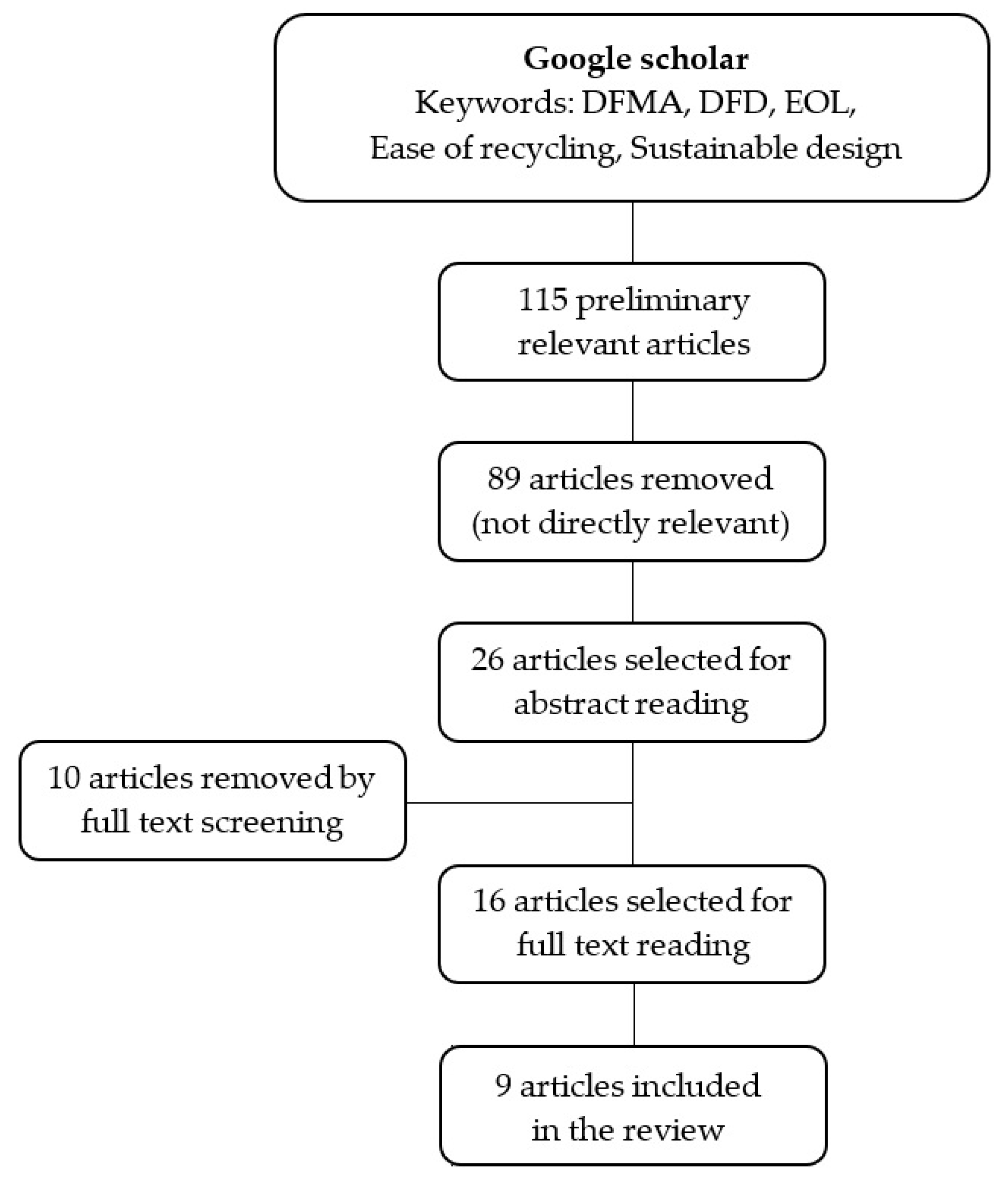

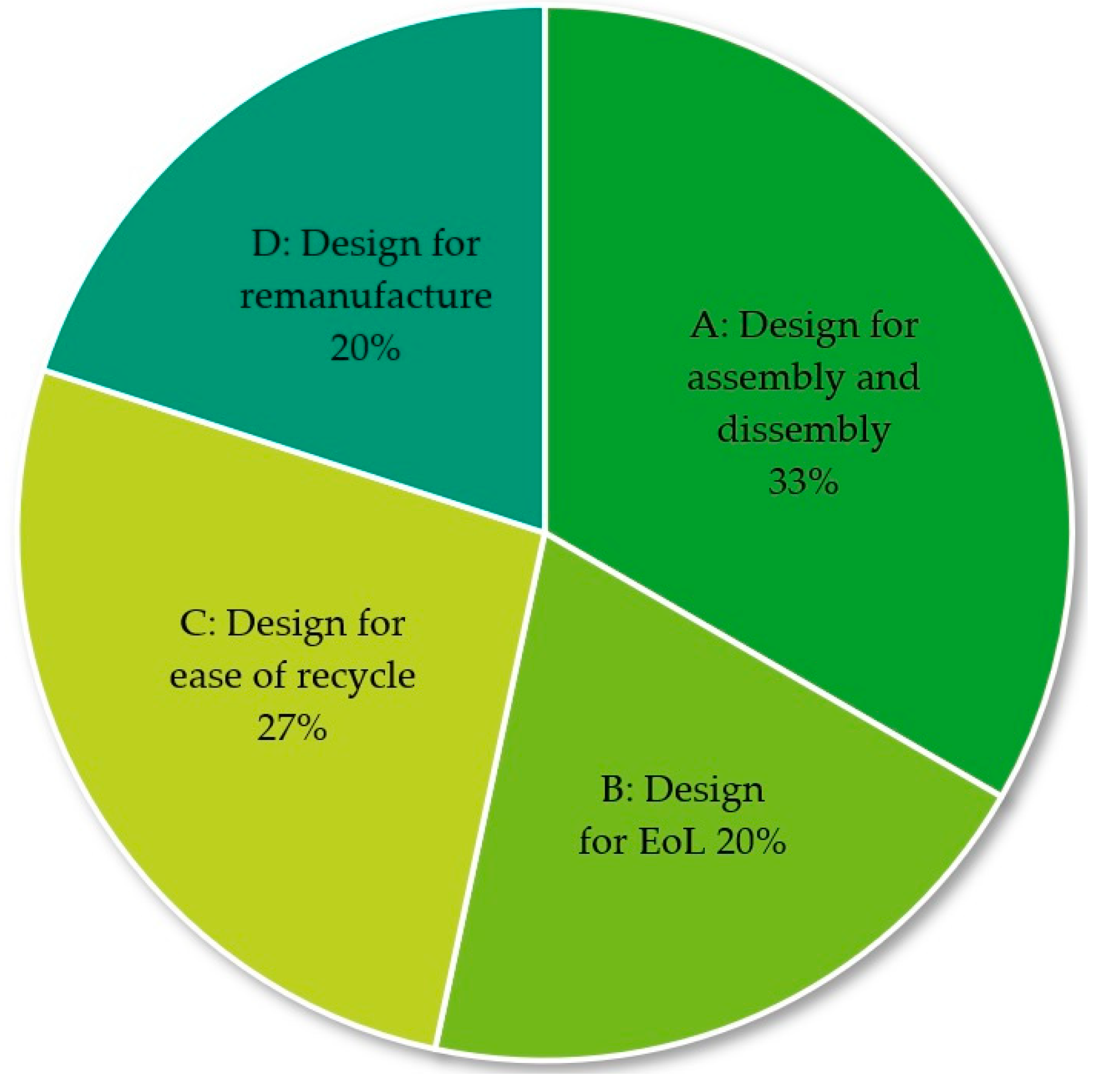

8. Review Methodology and Discussion

| No. | Title | Methodology | Conclusions |

|---|---|---|---|

| 1 | Design for and from Recycling: A circular eco-design approach to improve the circular economy [74]. | The suggested design for the recycling technique enables product designers to determine the product aspects that are the least effective in recycling and offer the most suitable suggestions for their development. | The suggested method facilitates the development of connections between designers and EoL treatment chain stakeholders. This connection may also be enhanced by recommending a complementary strategy (i.e., a method that integrates recycling tools in and out of the design procedure). |

| 2 | Design for manufacturing and assembly/disassembly: joint design of products and production systems [76]. | This article discusses the background of DFA, DFM, and related issues in today’s manufacturing in an overview. | This research investigates the cost distribution degree for a competing market across the product’s life cycle. Supply chain partners are expected to collaborate to produce the product at the present manufacturer and assembly plant. |

| 3 | Design for manufacture and assembly (DFMA) in construction: the old and the new [77]. | In this investigation, a multistage research strategy comprised of brainstorming, a review of literature, and a comparative analysis was employed. | DfMA originated in manufacturing industries and has been utilized as a panacea for chronic issues in the AEC business, including high costs, long lead times, and lower productivity. This analyzes the notion of AEC, which is renowned for its project orientation. |

| 4 | A multiple lifecycle-based approach to sustainable product configuration design [81]. | Creating a dependency diagram to characterize the optimization model scope, modeling EoL recovery techniques taking into account the flow of multiple life cycles, and formulating and solving multi-objective optimization problems with the Genetic Algorithm are the steps of the proposed method. | Decisions made throughout the design phase of a product have a substantial influence on its profitability and environmental impact over its entire life cycle. Implementing EoL techniques closes the material flow loop by reusing components and materials from one product life cycle into the next. |

| 5 | Ease of disassembly of products to support circular economy strategies [82]. | Two methods were recognized to assess partial or total separation time: direct measurement and calculation depending on product attributes. The easiest technique is for numerous operators with varying levels of competence to directly measure the separation time of products of a similar grade. | This study outlines the methods developed to assess the simplicity of product separation in support of the circular economy. The suggested technique gives organizations that apply material efficiency criteria involving product disassembly with scientific support. It assists OEMs and electronics operators with a mechanism for evaluating DFD for repair, reuse, and recycling |

| 6 | A design tool to diagnose product recyclability during the product design phase [83]. | The research describes a design tool to facilitate the creation of recyclable items. This tool is intended to determine a product’s level of recyclability and assist the designer in making better design choices. | The research describes a design tool to facilitate the creation of recyclable items. This tool is intended to determine a product’s level of recyclability and assist the designer in making better design choices. |

| 7 | A design for the EoL approach and metrics to favour closed-loop scenarios for products [84]. | Four new indicators evaluate the feasibility of each EoL scenario (reuse, remanufacturing, recycling, and incineration) to optimize product EoL management in the early design stages. | Designers can quickly assess whether predetermined goals have been achieved and whether the product, component, or part can be effectively recovered at the EoL. If targets are not met, deep or partial product redesign is necessary to improve EoL performance both environmentally and economically. |

| 8 | Design for manufacturing and assembly: A review on integration with design sustainability [85]. | This section of the DFMA and sustainability design and process research are used to determine the flow of data collecting. This section describes the actions required to explore the research topic and the rationale for using the techniques or approaches to discover, select, and investigate the information utilized to comprehend the problem. | This research proposes utilizing the DFMA approach in combination with sustainable design. DFMA tackles just a part of sustainability effects, but its application reduces product complexity and development costs, which may contribute to environmentally friendly production. |

| 9 | Development of Product Recyclability Index Utilizing Design for Assembly and Disassembly Principles [86]. | The article starts with a discussion of the fields of design for disassembly (DFD), assembly (DFA), remanufacturing (DfReman), and reuse (DfReuse). | This study provides a technique based on DFA principles for early product design recyclability prediction. The examination of which DFA characteristics impact product recyclability and to what degree was conducted using a case study approach. The case study data findings revealed a significant connection between the recyclability index of a part or subset and the insertion tables. |

- Pre-production stage: In the design stage, it is imperative to consider all aspects to increase the product’s life. Using the design approach for assembly and disassembly includes some principles of other approaches, such as design for end-of-life and recycling [74,84]. One of the most critical matters to be investigated in the pre-production phase is the selection of materials and their optimal use. Using the least diversity of materials in the design and production of a product and choosing suitable materials in such a way as to cause minor damage to the environment and reduce the growth rate of landfills is one of the reasons for the popularity and importance of the design approach for assembly and disassembly. This method also aims to minimize primary and recovered raw materials use which reduces the wastage of valuable materials and production costs. This method returns the used materials to the production cycle as raw materials or parts [83].

- Production stage: Applying an approach and producing a product only happens if it is economically profitable. The most crucial goal of the design approach for assembly and disassembly is to reduce production costs and increase the resulting net profit [85]. In this regard, various methods and models for cost estimation have been presented in the reviewed articles. Production time is also one of the influencing factors in production costs, which minimizes a significant amount of production costs. Most of the time required in production is wasted on assembling complex parts. This problem can be solved by following the design principles for assembly and disassembly and simple design with minimal components. Other features such as minimum complexity and a minimum number of components should also be considered in the design so that products can be assembled in the shortest time and disassembled efficiently and in less time, and also, if necessary, parts can be separated and re-entered into the production line with minor damage to the target parts [86]. Another result of observing design principles for assembly and disassembly is to reduce workstations and minimize operational problems in production lines [76].

- Consumption stage: every product enters its consumption stage after leaving the production line and presenting it to the market. Sustainable design approaches, intending to increase the lifespan of products, present product design with principles that can be repaired, reused, and reproduced [86]. Products designed with design patterns for assembly and disassembly are easily repaired due to the ease of opening and closing. If they are not repairable, their valuable parts are reused by disassembling and entering the consumption cycle again. A product’s multiple life cycles lead to maximum resource use and waste reduction as well [84].

- Product death stage: After passing through several life cycles, the product enters its end-of-life period if it is impossible to reuse and reproduce. At this stage, the products are disassembled, and their entry into the recycling cycle begins by separating their valuable materials. In addition to economic reasons, material recycling has important environmental reasons, such as preventing the destruction of the environment because the raw materials extraction, preventing the growth of landfill environments, and preventing the depletion of limited resources of these materials. Finally, materials that cannot be recycled are thrown away. However, the design approach for assembly and disassembly minimizes the inevitable waste at the end of each product’s life [74].

9. Conclusions

- In contrast, the design proposal for recycling allows us to determine the product aspects with the lowest performance (in terms of recycling) and to offer the most specific design suggestions for their enhancement.

- On the other hand, designing from recycling enables us to simply and objectively assess the technical, economic, and environmental benefits of utilizing recycled materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Boothroyd, G.; Dewhurst, P. Design for Assembly—Manual Assembly. Mach. Des. 1983, 55, 140–145. [Google Scholar]

- Paulo Davim, J. Sustainable Manufacturing; Wiley: New York, NY, USA, 2010. [Google Scholar]

- Hazarika, M.; Deb, S.; Dixit, U.S.; Davim, J.P. Fuzzy set-based set-up planning system with the ability for online learning. Proc. Inst. Mech. Eng. B J. Eng. 2011, 225, 247–263. [Google Scholar] [CrossRef]

- Paulo Davim, J. Modern Manufacturing Engineering; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Johnson, M.R.; Wang, M.H. Economical Evaluation of Disassembly Operations for Recycling, Remanufacturing and Reuse. Int. J. Prod. Res. 1998, 36, 3227–3252. [Google Scholar] [CrossRef]

- Zhang, H.C.; Kuo, T.C.; Lu, H.; Huang, S.H. Environmentally conscious design and manufacturing: A state-of-the-art survey. J. Manuf. Syst. 1997, 16, 352–371. [Google Scholar] [CrossRef]

- Abrishami, S.; Martín-Durán, R. BIM and DfMA: A Paradigm of New Opportunities. Sustainability 2021, 13, 9591. [Google Scholar] [CrossRef]

- Tiwari, M.K.; Sinha, N.; Kumar, S.; Rai, R.; Mukhopadhyay, S.K. A Petri Net Based Approach to Determine the Disassembly Strategy of a Product. Int. J. Prod. Res. 2002, 40, 1113–1129. [Google Scholar] [CrossRef]

- Chang, D.; Lee, C.K.M.; Chen, C.-H. Review of life cycle assessment towards sustainable product development. J. Clean. Prod. 2014, 83, 48–60. [Google Scholar] [CrossRef]

- Hatcher, G.D.; Ijomah, W.L.; Windmill, J.F.C. Design for remanufacture: A literature review and future research needs. J. Clean. Prod. 2011, 19, 17–18. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Dillon, O.W., Jr.; Rouch, K.E.; Joshi, K.J.; Venkatachalam, A.; Jaafar, I.H. Total life-cycle considerations in product design for sustainability: A framework for comprehensive evaluation. In Proceedings of the 10th International Research/Expert Conference, Barcelona-LIoret de Mar, Spain TMT 2006, Barcelona, Spain, 11–15 September 2006; pp. 1–10. [Google Scholar]

- Kerr, W.; Ryan, C. Eco-efficiency gains from remanufacturing: A case study of photocopier remanufacturing at Fuji Xerox Australia. J. Clean. Prod. 2001, 9, 75–81. [Google Scholar] [CrossRef]

- Cullen, J.M.; Allwood, J.; Carruth, M.A. Sustainable Materials: With Both Eyes Open; UIT Cambridge Limited: Cambridge, UK, 2012. [Google Scholar]

- Langston, C.; Zhang, W. DfMA: Towards an Integrated Strategy for a More Productive and Sustainable Construction Industry in Australia. Sustainability 2021, 13, 9219. [Google Scholar] [CrossRef]

- Yang, S.S.; Ong, S.K.; Nee, A.Y.C. EOL Strategy Planning for components of returned products. Int. J. Adv. Manuf. Technol. 2014, 77, 991–1003. [Google Scholar] [CrossRef]

- Krystofik, M.; Wagner, J.; Gaustad, G. Leveraging intellectual property rights to encourage green products design and remanufacturing for sustainable waste management. Resour. Conserv. Recycl. 2015, 97, 44–54. [Google Scholar] [CrossRef]

- Chancerel, P.; Maskers, C.; Hageluken, C.; Rotter, V.S. Assessment of precious metal flow during preprocessing of wate electrical and electronic equipment. J. Ind. Ecol. 2009, 13, 791–810. [Google Scholar] [CrossRef]

- Wang, F.; Huisman, J.; Meskers, C.; Schluep, M.; Stevels, A.; Hageluken, C. The best-of-two-worlds philosophy: Developing local dismantling and global infrastructure network for sustainable e-waste treatment in emerging economies. Waste Manag. 2012, 32, 2134–2146. [Google Scholar] [CrossRef]

- Naiju, C.D. DFMA for product designers: A review. Mater. Today 2021, 46, 7473–7478. [Google Scholar] [CrossRef]

- Juniani, A.I.; Singgih, M.L.; Karningsih, P.D. Design for Manufacturing, Assembly, and Reliability: An Integrated Framework for Product Redesign and Innovation. Designs 2022, 6, 88. [Google Scholar] [CrossRef]

- Peeters, J.R.; Venegas, P.; Tange, L.; Houwelingen, J.V.; Duflou, J.R. Closed loop recycling of plasticts containing flame retardants. Resour. Conserv. Recycl. 2014, 84, 35–43. [Google Scholar] [CrossRef]

- Peeters, J.R.; Venegas, P.; Kellens, K.; Wang, F.; Huisman, J.; Dewulf, W.; Duflou, J.R. Forecasting waste compositions: A case study on plastic waste of electronic display housings. Waste Manag. 2015, 46, 28–39. [Google Scholar] [CrossRef]

- Widmer, R.; Oswald-krapf, H.; Sinha-khetriwal, D.; Schenellmann, M.; Boni, H. Global prespective on e-waste. Environ. Impact Assess. Rev. 2005, 25, 436–458. [Google Scholar] [CrossRef]

- Boothroyd, G. Assembly Automation and Product Design; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Huang, G.Q. Design for X: Concurrent Engineering Imperatives; Springer Science & Business Media: New York, NY, USA, 2012. [Google Scholar]

- Gatenby, D.A.; Foo, G. Design for X (DFX): Key to competitive, profitable products. ATT Tech. J. 1990, 69, 2–13. [Google Scholar] [CrossRef]

- Kuo, T.C.; Huang, S.H.; Zhang, H.C. Design for manufacture and design for ‘X’: Concepts, applications, and perspectives. Comput. Ind. Eng. 2001, 41, 241–260. [Google Scholar] [CrossRef]

- Eastman, C.M. Cognitive processes and ill-defined problems: A case study from design. In Proceedings of the International Joint Conference on Artificial Intelligence: IJCA, Washington, DC, USA, 7–9 May 1969. [Google Scholar]

- Xie, S.Q.; Tu, Y.L.; Fung, R.Y.K.; Zhou, Z.D. Rapid one-of-a-kind Product Development via the Internet: A Literature Review of the State-of-the-art and a Proposed Platform. Int. J. Prod. Res. 2003, 41, 4257–4298. [Google Scholar] [CrossRef]

- Hague, R.; Mansour, S.; Saleh, N. Material and Design Considerations for Rapid Manufacturing. Int. J. Prod. Res. 2004, 42, 4691–4708. [Google Scholar] [CrossRef]

- Butt, J.; Jedi, S. Redesign of an In-Market Conveyor System for Manufacturing Cost Reduction and Design Effeciency Using DFMA Methodology. Designs 2020, 4, 6. [Google Scholar] [CrossRef]

- Ramana, K.V.; Rao, P.V.M. Automated Manufacturability Evaluation System for Sheet Metal Components in Mass Production. Int. J. Prod. Res. 2005, 43, 3889–3913. [Google Scholar] [CrossRef]

- Stoll, H.W. Design for Manufacture: An Overview. Appl. Mech. Rev. 1986, 39, 1356–1364. [Google Scholar] [CrossRef]

- Dean, B.V.; Salstrom, R.L. Utilization of Design for Manufacturing (DFM) Techniques. In Proceedings of the Engineering Management Conference, 1990. Management Through the Year 2000-Gaining the Competitive Advantage, Santa Clara, CA, USA, 21–24 October 1990; IEEE International. pp. 223–232. [Google Scholar]

- ElMaraghy, W.; ElMaraghy, H.; Tomiyama, T.; Monostori, L. Complexity in Engineering Design and Manufacturing. CIRP Ann. Manuf. Technol. 2012, 61, 793–814. [Google Scholar] [CrossRef]

- Dereli, T.; Filiz, I.H.; Baykasoglu, A. Optimizing Cutting Parameters in Process Planning of Prismatic Parts by Using Genetic Algorithms. Int. J. Prod. Res. 2001, 39, 3303–3328. [Google Scholar] [CrossRef]

- Giachetti, R.E. A Decision Support System for Material and Manufacturing Process Selection. J. Intell. Manuf. 1998, 9, 265–276. [Google Scholar] [CrossRef]

- Chang, X.; Rai, R.; Terpenny, J. Development and Utilization of Ontologies in Design for Manufacturing. J. Mech. Des. 2010, 132, 021009. [Google Scholar] [CrossRef]

- Ding, G.; Jiang, L.; Qin, S.; Zhu, S.; Ma, S. Computer-integrated Manufacturing System for Tube Bending. Int. J. Comput. Integr. Manuf. 2012, 25, 1059–1068. [Google Scholar] [CrossRef]

- Brennan, L.; Gupta, S.M.; Taleb, K.N. Operations Planning Issues in an Assembly/Disassembly Environment. Int. J. Oper. Prod. Manag. 1994, 14, 57–67. [Google Scholar] [CrossRef]

- Agrawal, S.; Tiwari, M.K. A Collaborative Ant Colony Algorithm to Stochastic Mixed-Model U-Shaped Disassembly Line Balancing and Sequencing Problem. Int. J. Prod. Res. 2008, 46, 1405–1429. [Google Scholar] [CrossRef]

- Bentaha, M.L.; Battaia, O.; Dolgui, A.; Hu, S.J. Second Order Conic Approximation for Disassembly Line Design with Joint Probabilistic Constraints. Eur. J. Oper. Res. 2015, 247, 957–967. [Google Scholar] [CrossRef]

- Agrawal, T.; Sao, A.; Fernandes, K.J.; Tiwari, M.J.; Kim, D.Y. A Hybrid Model of Component Sharing and Platform Modularity for Optimal Product Family Design. Int. J. Prod. Res. 2013, 51, 614–625. [Google Scholar] [CrossRef]

- Boothroyd, G.; Alting, L. Design for Assembly and Disassembly. CIRP Ann. Manuf. Technol. 1922, 41, 625–636. [Google Scholar] [CrossRef]

- Gungor, A.; Gupta, S.M. Disassembly Sequence Planning for Products with Defective Parts in Product Recovery. Comput. Ind. Eng. 1998, 35, 161–164. [Google Scholar] [CrossRef]

- Kim, H.-W.; Park, C.; Lee, D.H. Selective Disassembly Sequencing with Random Operation Times in Parallel Disassembly Environment. Int. J. Prod. Res. 2018, 56, 7243–7257. [Google Scholar] [CrossRef]

- Bentaha, M.L.; Dolgui, A.; Battaia, O.; Riggs, R.J.; Hu, J. Profit-Oriented Partial Disassembly Line Design: Dealing with Hazardous Parts and Task Processing Times Uncertainty. Int. J. Prod. Res. 2018, 56, 7220–7242. [Google Scholar] [CrossRef]

- Jiao, Z.; Xing, Y. Clamping-sequence Optimisation Based on Heuristic Algorithm for Sheet-Metal Components. Int. J. Prod. Res. 2018, 56, 7190–7200. [Google Scholar] [CrossRef]

- Afrinaldi, F.; Saman, M.Z.M.; Shaharoun, A.M. The evaluation methods of disassemblability for automotive components—A review and agenda for future research. J. Mek. 2008, 26, 49–62. [Google Scholar]

- Go, T.F.; Wahab, D.A.; Rahman, M.N.A.; Ramli, R.; Azhari, C.H. Disassemblability of end-of-life vehicle: A critical review of evaluation methods. J. Clean. Prod. 2011, 19, 1536–1546. [Google Scholar] [CrossRef]

- Kroll, E.; Beardsley, B.; Parulian, A. A Methodology to Evaluate Ease of Disassembly for Product Recycling. IIE Trans. 1996, 28, 837–846. [Google Scholar] [CrossRef]

- Kroll, E. Application of Work-Measurement analysis to product disassembly for recycling. Concurrent Eng. 1996, 4, 149–158. [Google Scholar] [CrossRef]

- Boks, C.B.; Kroll, E.; Brouwers, W.C.J.; Stevels, A.L.N. Disassembly modeling: Two applications to a Philips 21 television set. In Proceedings of the 1996 IEEE International Symposium on Electronics and the Environment, Dallas, TX, USA, 6–8 May 1996; pp. 224–229. [Google Scholar]

- Movilla, N.A.; Zwolinski, P.; Dewulf, J.; Mathieux, F. A method for manual disassembly analysis to support the ecodesign of electronic displays. Resour. Conserv. Recycl. 2016, 114, 42–58. [Google Scholar] [CrossRef]

- Dams, B.; Maskell, D.; Shea, A.; Allen, S.; Driesser, M.; Kretschmann, T.; Walker, P.; Emmitt, S. A circular construction evaluation framework to promote designing for disassembly and adaptability. J. Clean. Prod. 2021, 316, 128122. [Google Scholar] [CrossRef]

- Carrell, J.; Zhang, H.-C.; Tate, D.; Li, H. Review and future of active disassembly. Int. J. Sustain. Eng. 2009, 2, 252–264. [Google Scholar] [CrossRef]

- Ardente, F.; Mathieux, F.; Recchioni, M. Recycling of electronic displays: Analysis of pre-processing and potential ecodesign improvements. Resour. Conserv. Recycl. 2014, 92, 158–171. [Google Scholar] [CrossRef]

- Güngör, A. Evaluation of connection types in design for disassembly (DFD) using analytic network process. Comput. Ind. Eng. 2006, 50, 35–54. [Google Scholar] [CrossRef]

- Kroll, E.; Hanft, T.A. Quantitative evaluation of product disassembly for recycling. Res. Eng. Des. 1998, 10, 1–14. [Google Scholar] [CrossRef]

- Desai, A.; Mital, A. Evaluation of disassemblability to enable design for disassembly in mass production. Int. J. Ind. Ergon. 2003, 32, 265–281. [Google Scholar] [CrossRef]

- Veerakamolmal, P.; Gupta, S.M. Analysis of design efficiency for the disassembly of modular electronic products. Electron. Manuf. Eng. 1999, 9, 79–95. [Google Scholar] [CrossRef]

- Pnueli, Y.; Zussman, E. Evaluating the end-of-life value of a product andimproving it by redesign. Int. J. Prod. Res. 1997, 35, 921–942. [Google Scholar] [CrossRef]

- Yi, J.; Yu, B.; Du, L.; Li, C.; Hu, D. Research on the selectable disassembly strategy of mechanical parts based on the generalized CAD model. Int. J. Adv. Manuf. Technol. 2008, 37, 599–604. [Google Scholar] [CrossRef]

- Rizzi, F.; Bartolozzi, I.; Borghini, A.; Frey, M. Environmental Management of End-of-Life Products: Nine Factors of Sustainability in Collaborative Networks. Bus. Strategy Environ. 2013, 22, 561–572. [Google Scholar] [CrossRef]

- Mule, J.Y. Design for Disassembly Approaches on Product Development. Int. J. Sci. Eng. Res. 2012, 3, 996–1000. [Google Scholar]

- Duflou, J.R.; Seliger, G.; Kara, S.; Umeda, Y.; Ometto, A.; Willems, B. Efficiency and Feasibility of Product Disassembly: A Case-Based Study. CIRP Ann. Manuf. Technol. 2008, 57, 560–583. [Google Scholar] [CrossRef]

- Dewhurst, P. Product Design for Manufacture: Design for Disassembly. Ind. Eng. 1993, 25, 26–28. [Google Scholar]

- Takeuchi, S.; Saitou, K. Design for Optimal End-of-life Scenario via Product Embedded Disassembly. In Proceedings of the ASME 2006 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference, Philadelphia, PA, USA, 10–13 September 2006. [Google Scholar]

- Veerakamolmal, P.; Gupta, S.M. Design for Disassembly, Reuse and Recycling. In Green Electronics/Green Bottom Line: Environmentally Responsible Engineering; Goldberg, L.H., Middleton, W., Eds.; Butterworth-Heinemann: Woburn, MA, USA, 2000; pp. 69–82. [Google Scholar]

- Dini, G.; Failli, F.; Santochi, M. A Disassembly Planning Software System for the Optimization of Recycling Processes. Prod. Plan. Control. 2001, 12, 2–12. [Google Scholar] [CrossRef]

- Kara, S.; Pornprasitpol, P.; Kaebernick, H. A Selective Disassembly Methodology for End-of-life Products. Assem. Autom. 2005, 25, 124–134. [Google Scholar] [CrossRef]

- Germani, M.; Mandolini, M.; Marconi, M.; Rossi, M. An Approach to Analytically Evaluate the Product Disassemblability during the Design Process. Procedia CIRP 2014, 21, 336–341. [Google Scholar] [CrossRef]

- Bogue, R. Design for Disassembly: A Critical Twenty-first Century Discipline. Assem. Autom. 2007, 27, 285–289. [Google Scholar] [CrossRef]

- Leal, J.M.; Pompidou, S.; Charbuillet, C.; Perry, N. Design for and from Recycling: A Circular Ecodesign Approach to Improve the Circular Economy. Sustainability 2020, 12, 9861. [Google Scholar] [CrossRef]

- Paulo Davim, J. Green Manufacturing Processes and Systems; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Battaia, O.; Dolgui, A.; Heragu, S.S.; Meerkov, S.M.; Tiwari, M.K. Design for manufacturing and assembly/disassembly: Joint design of products and production systems. Int. J. Prod. Res. 2018, 56, 7181–7189. [Google Scholar] [CrossRef]

- Lu, W.; Tan, T.; Xu, J.; Wang, J.; Chen, K.; Gao, S.; Xue, F. Design for manufacture and assembly (DfMA) in construction: The old and the new. Archit. Eng. Des. Manag. 2021, 17, 77–91. [Google Scholar] [CrossRef]

- Jung, S.; Yu, J. Design for Manufacturing and Assembly (DfMA) Checklists for Off-Site Construction (OSC) Projects. Sustainability 2022, 14, 11988. [Google Scholar] [CrossRef]

- Hyun, H.; Kim, H.-G.; Kim, J.-S. Integrated Off-Site Construction Design Process including DfMA Considerations. Sustainability 2022, 14, 4084. [Google Scholar] [CrossRef]

- Abd Razak, M.I.; Khoiry, M.A.; Wan Badaruzzaman, W.H.; Hussain, A.H. DfMA for a Better Industrialised Building System. Buildings 2022, 12, 794. [Google Scholar] [CrossRef]

- Badurdeen, F.; Aydin, R.; Brown, A. A multiple lifecycle-based approach to sustainable product configuration design. J. Clean. Prod. 2018, 200, 756–769. [Google Scholar] [CrossRef]

- Vanegas, P.; Peeters, J.R.; Cattrysse, D.; Tecchio, P.; Ardente, F.; Mathieux, F.; Dewulf, W.; Duflou, J.R. Ease of disassembly of products to support circular economy strategies. Resour. Conserv. Recycl. 2018, 135, 323–334. [Google Scholar] [CrossRef]

- Aguiar, J.d.; Oliveira, L.d.; Silva, J.O.d.; Bond, D.; Scalice, R.K.; Becker, D. A design tool to diagnose product recyclability during product design phase. J. Clean. Prod. 2017, 141, 219–229. [Google Scholar] [CrossRef]

- Favi, M.G.C.; Luzi, A.; Mandolini, M.; Marconi, M. A design for EoL approach and metrics to favour closed-loop scenarios for products. Int. J. Sustain. Eng. 2017, 10, 136–146. [Google Scholar] [CrossRef]

- Fatima, S.B.A.; Effendi, M.S.M.; Rosli, M.F. Design for manufacturing and assembly: A review on integration with design sustainability. In AIP Conference Proceedings; AIP Publishing LLC.: Melville, NY, USA, 2018. [Google Scholar]

- Yadav, D.P.; Patel, D.N.; Morkos, B.W. Development of Product Recyclability Index Utilizing Design for Assembly and Disassembly Principles. ASME. J. Manuf. Sci. Eng. 2018, 140, 031015. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Purnell, P. Principles for a sustainable circular economy. Sustain. Prod. Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Grafström, J.; Aasma, S. Breaking circular economy barriers. J. Clean. Prod. 2021, 292, 126002. [Google Scholar] [CrossRef]

- Kristensen, H.S.; Mosgaard, M.A. A review of micro level indicators for a circular economy—Moving away from the three dimensions of sustainability? J. Clean. Prod. 2020, 243, 118531. [Google Scholar] [CrossRef]

- Corvellec, H.; Stowell, A.F.; Johansson, N. Critiques of the circular economy. J. Ind. Ecol. 2021, 26, 421–432. [Google Scholar] [CrossRef]

- Cullen, J.M. Circular economy: Theoretical benchmark or perpetual motion machine? J. Ind. Ecol. 2017, 21, 483–486. [Google Scholar] [CrossRef]

| No. | The Main Focus of Articles Listed in Table 1. | |||

|---|---|---|---|---|

| A | B | C | D | |

| 1 | ||||

| 2 | ||||

| 3 | ||||

| 4 | ||||

| 5 | ||||

| 6 | ||||

| 7 | ||||

| 8 | ||||

| 9 | ||||

| Demographic Characteristics | Topics Raised in the Articles | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. | Year | Research Place | Components Reduction | Complexity Reduction | Material Homogeneity | Environmental Considerations | Environmental Impact | Production Cost | Production Time | Repair | Reuse | EoL | Remanufacture | Recycle | Waste |

| 1 | 2020 | France | ✓ | ✓ | - | ✓ | ✓ | ✓ | - | ✓ | ✓ | ✓ | ✓ | - | - |

| 2 | 2018 | France | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | - | ✓ | ✓ | - | - |

| 3 | 2021 | Hong Kong | ✓ | ✓ | - | ✓ | ✓ | - | ✓ | ✓ | - | ✓ | ✓ | - | ✓ |

| 4 | 2018 | USA | ✓ | ✓ | ✓ | ✓ | ✓ | - | - | ✓ | ✓ | ✓ | ✓ | - | ✓ |

| 5 | 2018 | Italy | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | - | - | ✓ |

| 6 | 2017 | Brazil | ✓ | ✓ | - | ✓ | - | - | - | ✓ | ✓ | ✓ | - | - | - |

| 7 | 2017 | Italy | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | - | ✓ | ✓ | - | ✓ | - | - |

| 8 | 2018 | Malaysia | - | ✓ | ✓ | ✓ | ✓ | - | ✓ | ✓ | ✓ | ✓ | - | ✓ | - |

| 9 | 2018 | USA | ✓ | ✓ | - | ✓ | - | - | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahhoseini, A.; Heydari, S.; Pedrammehr, S. Manufacturing and Assembly for the Ease of Product Recycling: A Review. Designs 2023, 7, 42. https://doi.org/10.3390/designs7020042

Shahhoseini A, Heydari S, Pedrammehr S. Manufacturing and Assembly for the Ease of Product Recycling: A Review. Designs. 2023; 7(2):42. https://doi.org/10.3390/designs7020042

Chicago/Turabian StyleShahhoseini, Ahad, Sara Heydari, and Siamak Pedrammehr. 2023. "Manufacturing and Assembly for the Ease of Product Recycling: A Review" Designs 7, no. 2: 42. https://doi.org/10.3390/designs7020042

APA StyleShahhoseini, A., Heydari, S., & Pedrammehr, S. (2023). Manufacturing and Assembly for the Ease of Product Recycling: A Review. Designs, 7(2), 42. https://doi.org/10.3390/designs7020042