Getting Fit in a Sustainable Way: Design and Optimization of a Low-Cost Regenerative Exercise Bicycle

Abstract

:1. Introduction

2. Methodology

2.1. Design Specifications

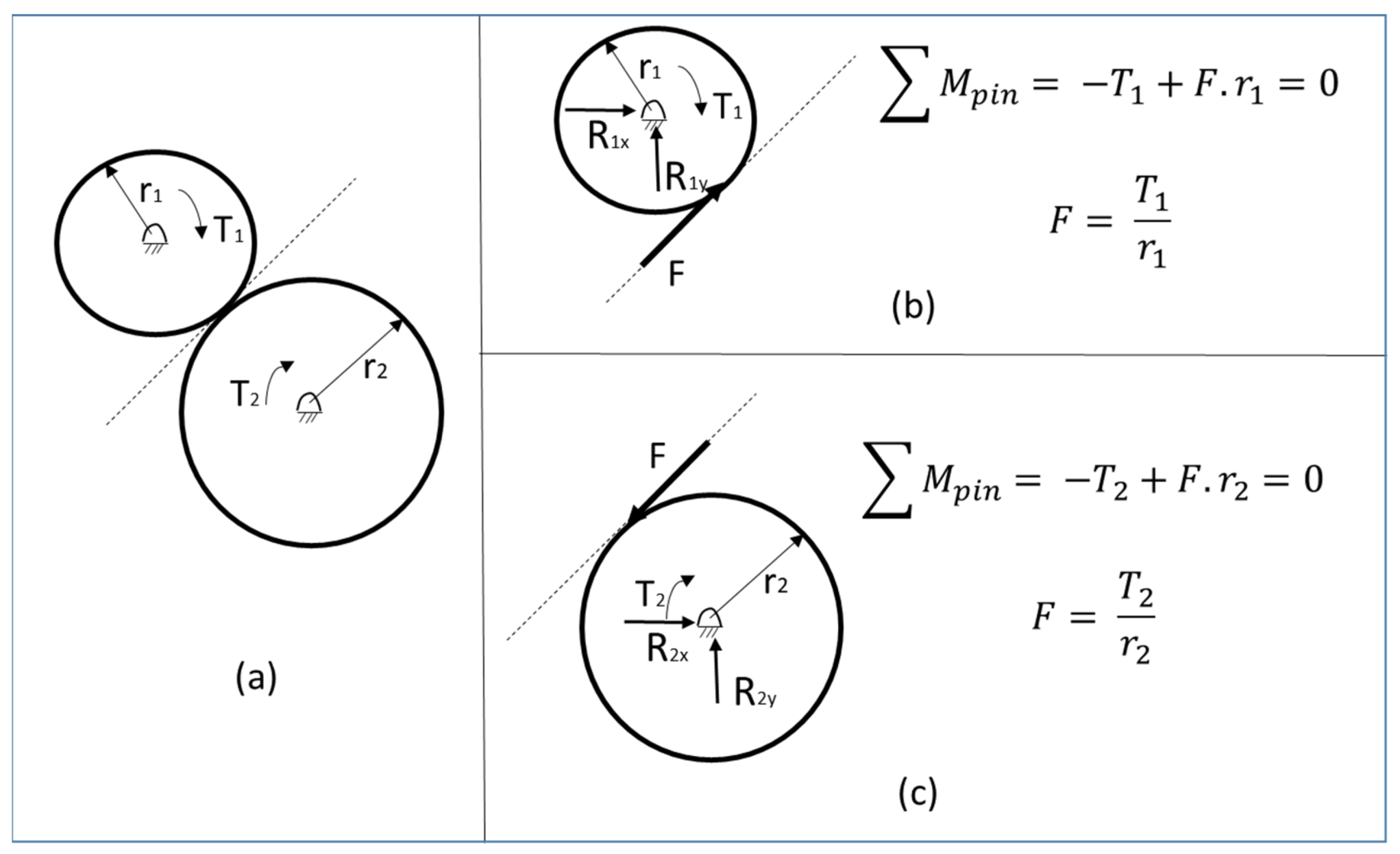

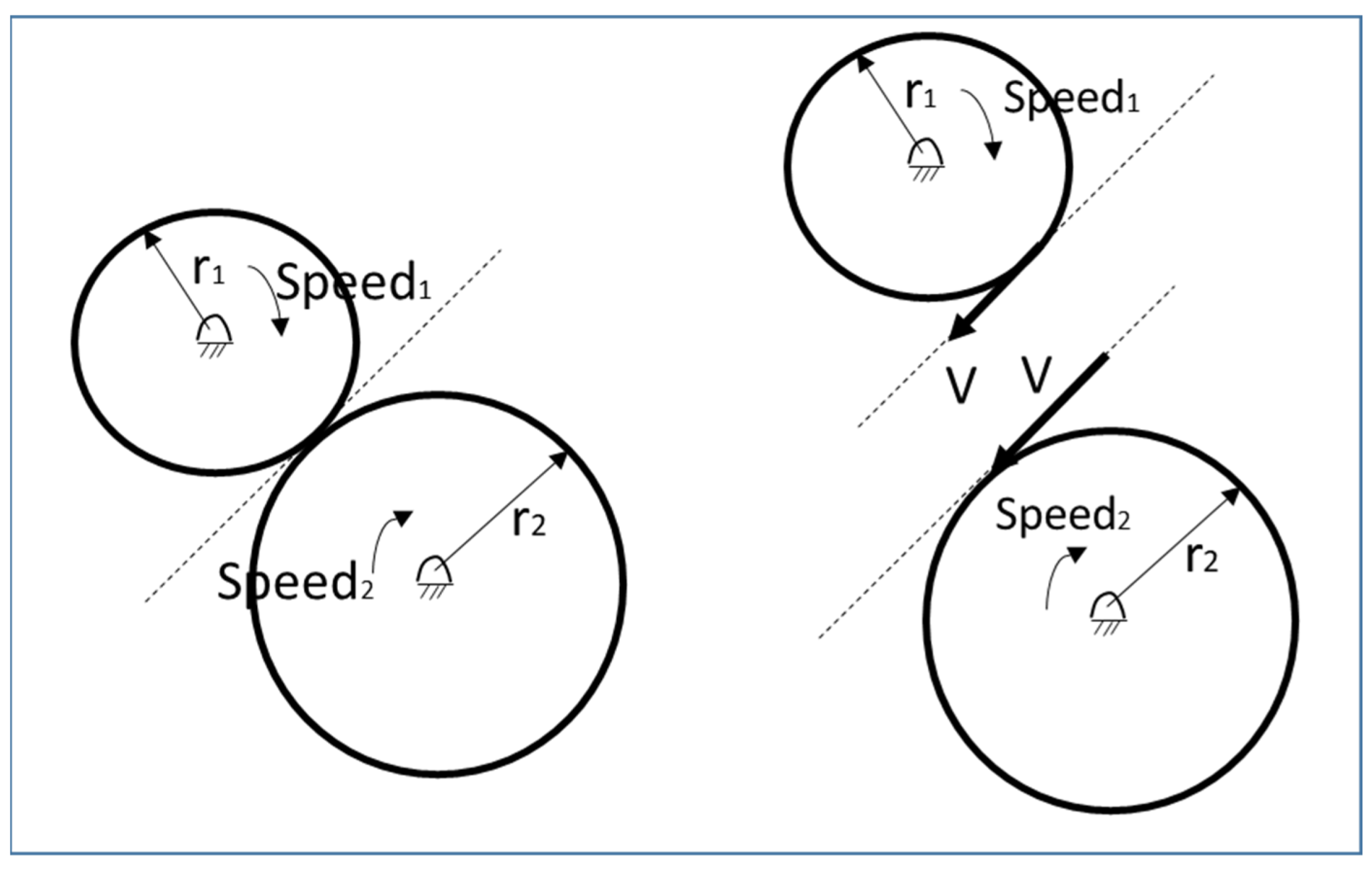

2.1.1. Friction Drive Transmission

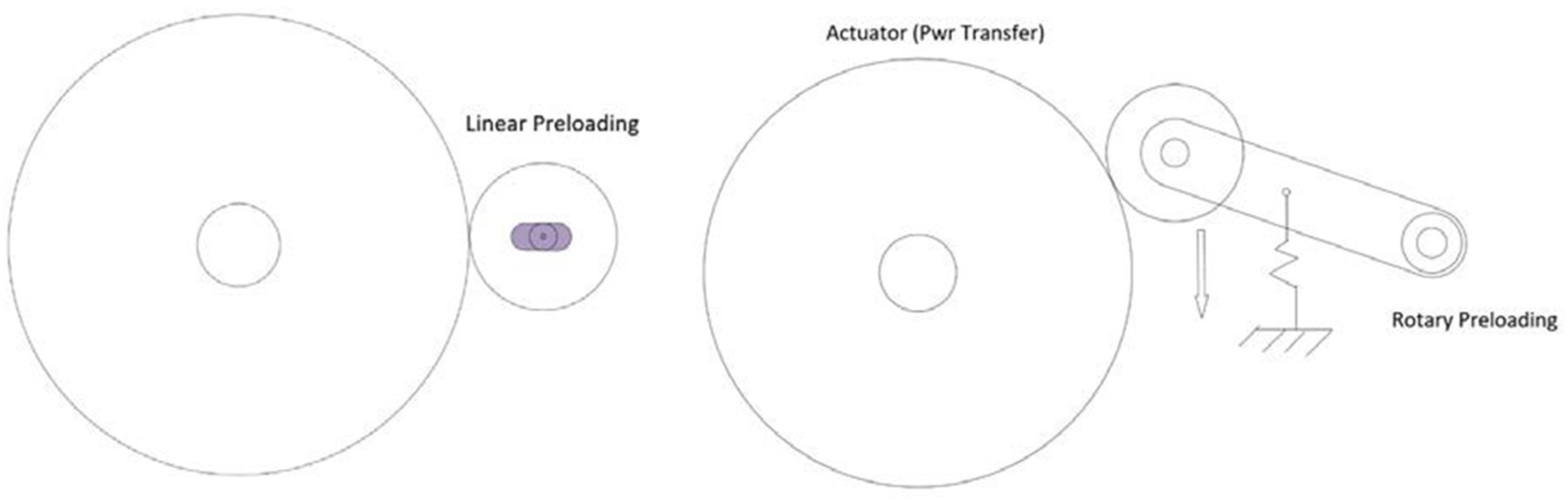

- Linear Preloading: The linear preloading method utilizes an oblong hole to mount the motor using a screw and a nut. The motor wheel is pushed against the flywheel and then tightens the nut.

- Rotary Preloading: The motor is mounted on a pivot arm, and a spring is attached to apply the pressure against the flywheel.

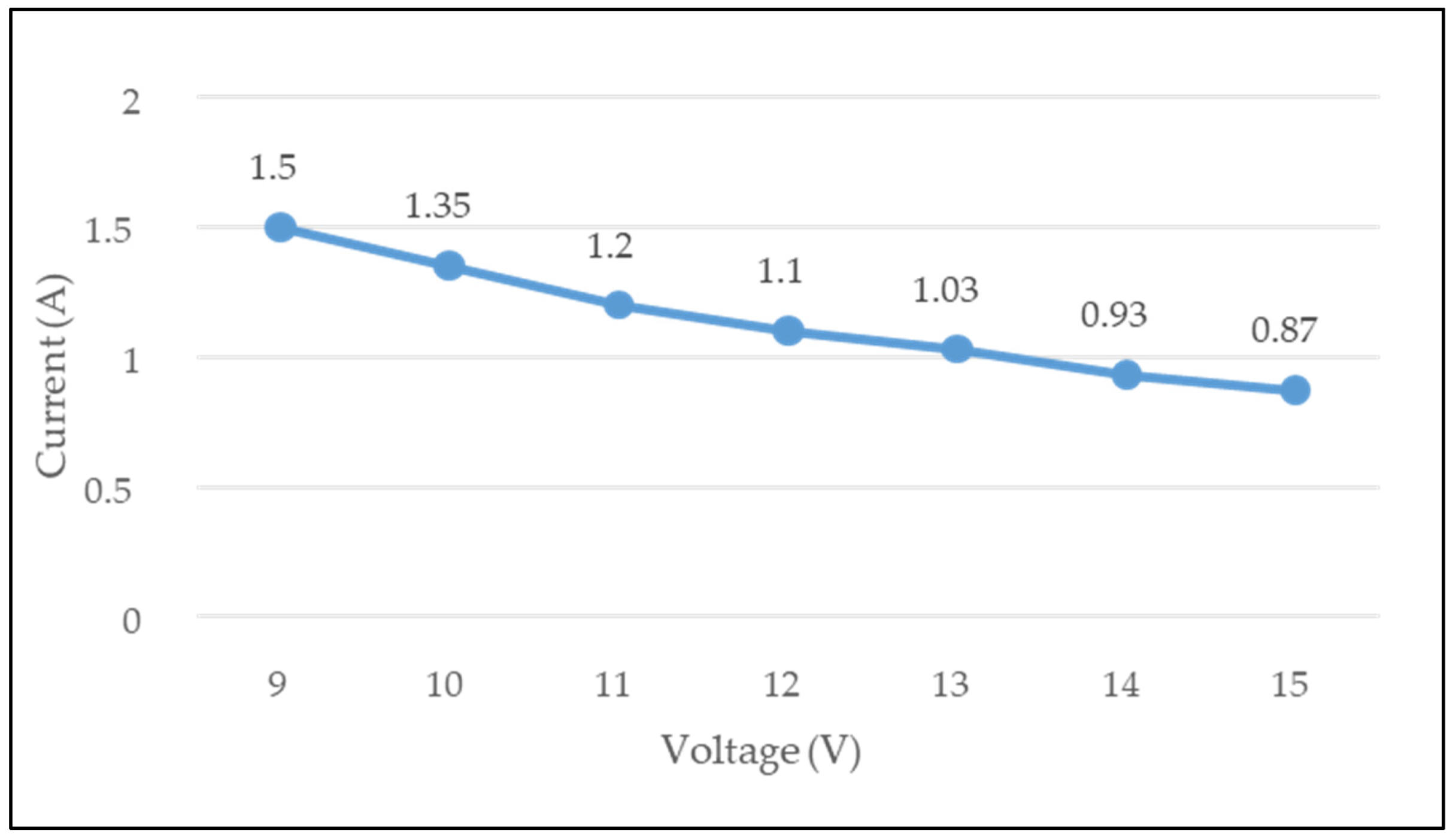

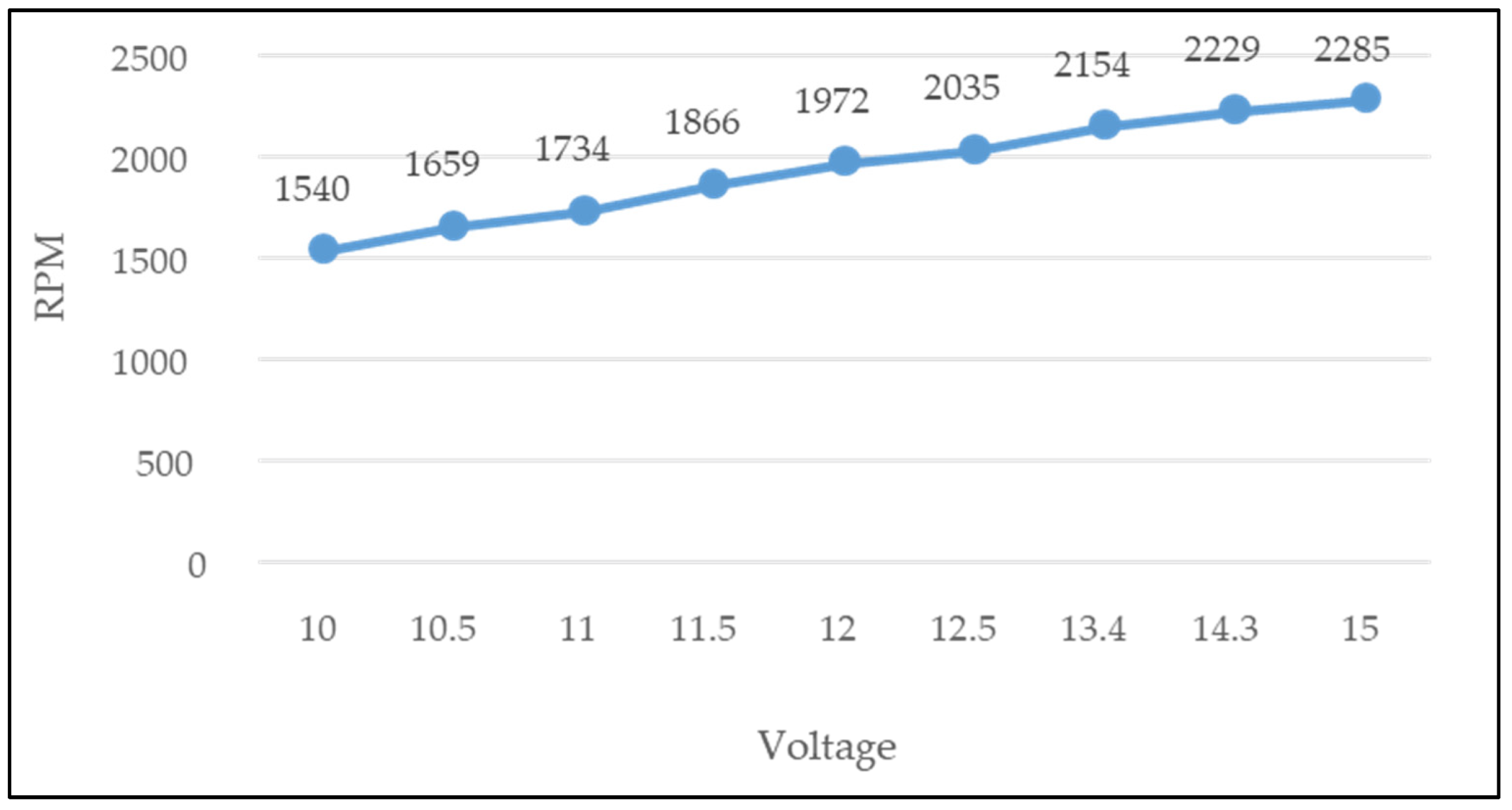

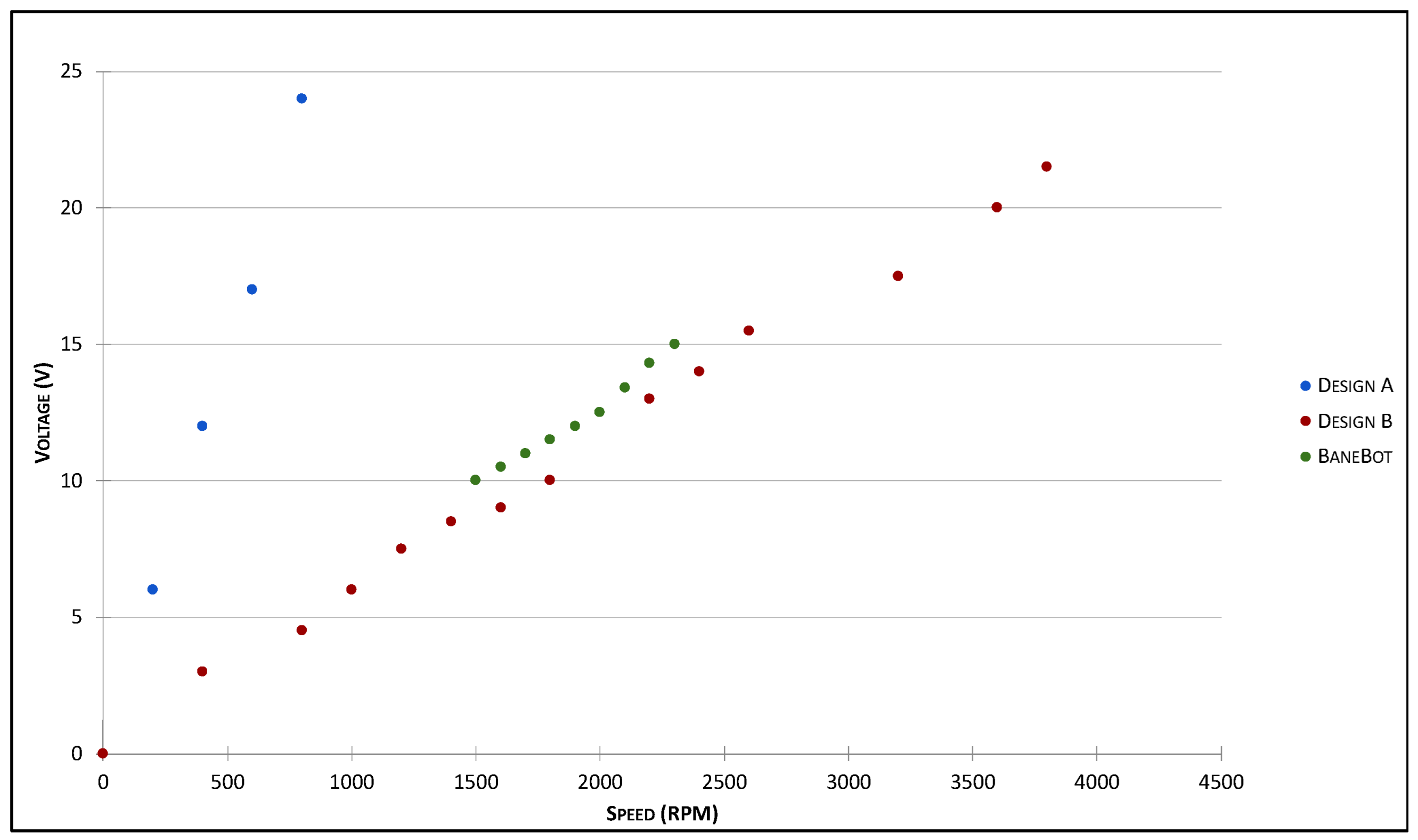

2.1.2. Choosing the Motor

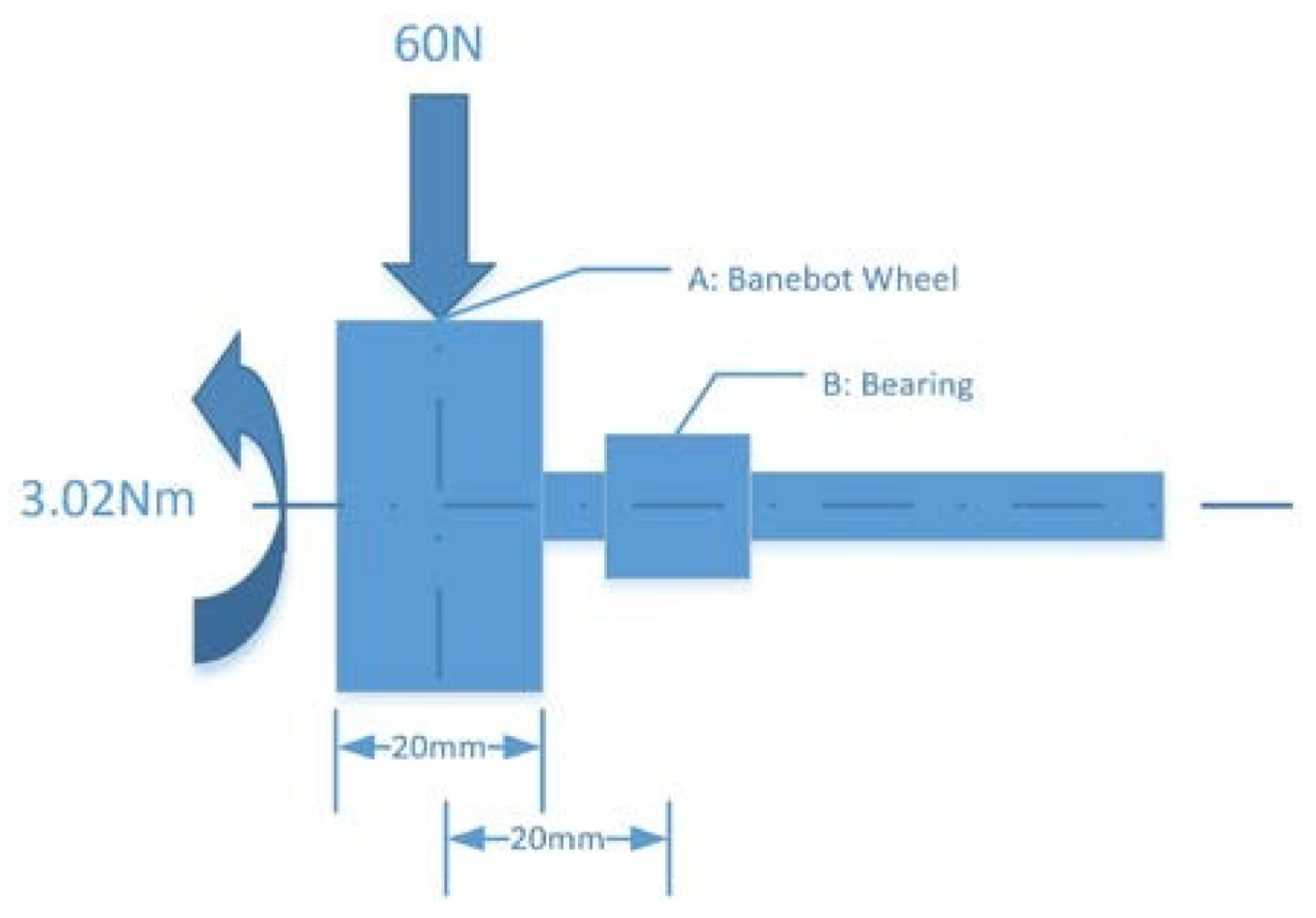

2.1.3. Design of Shaft

2.1.4. Components and Cost

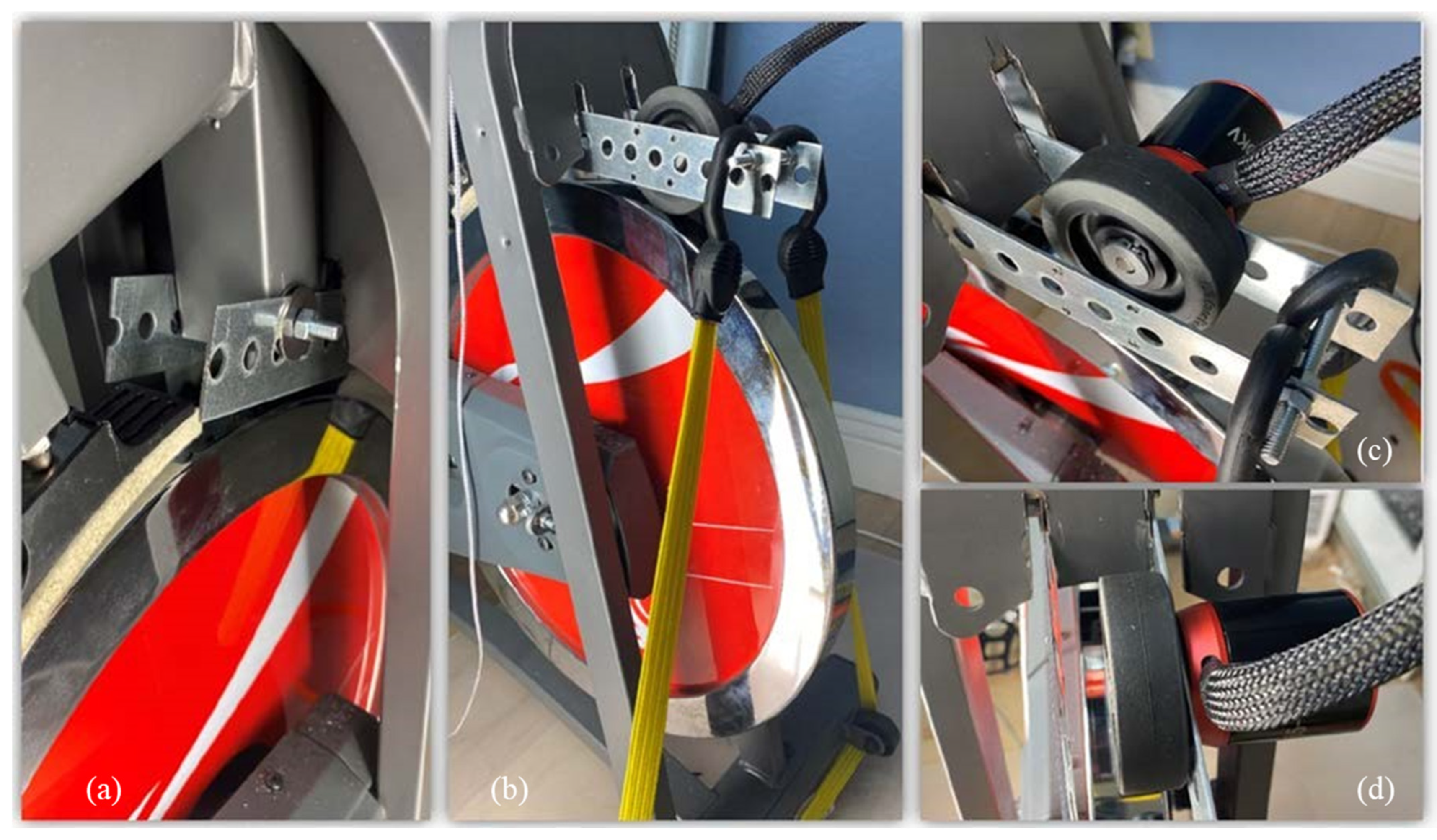

2.2. Prototype Building

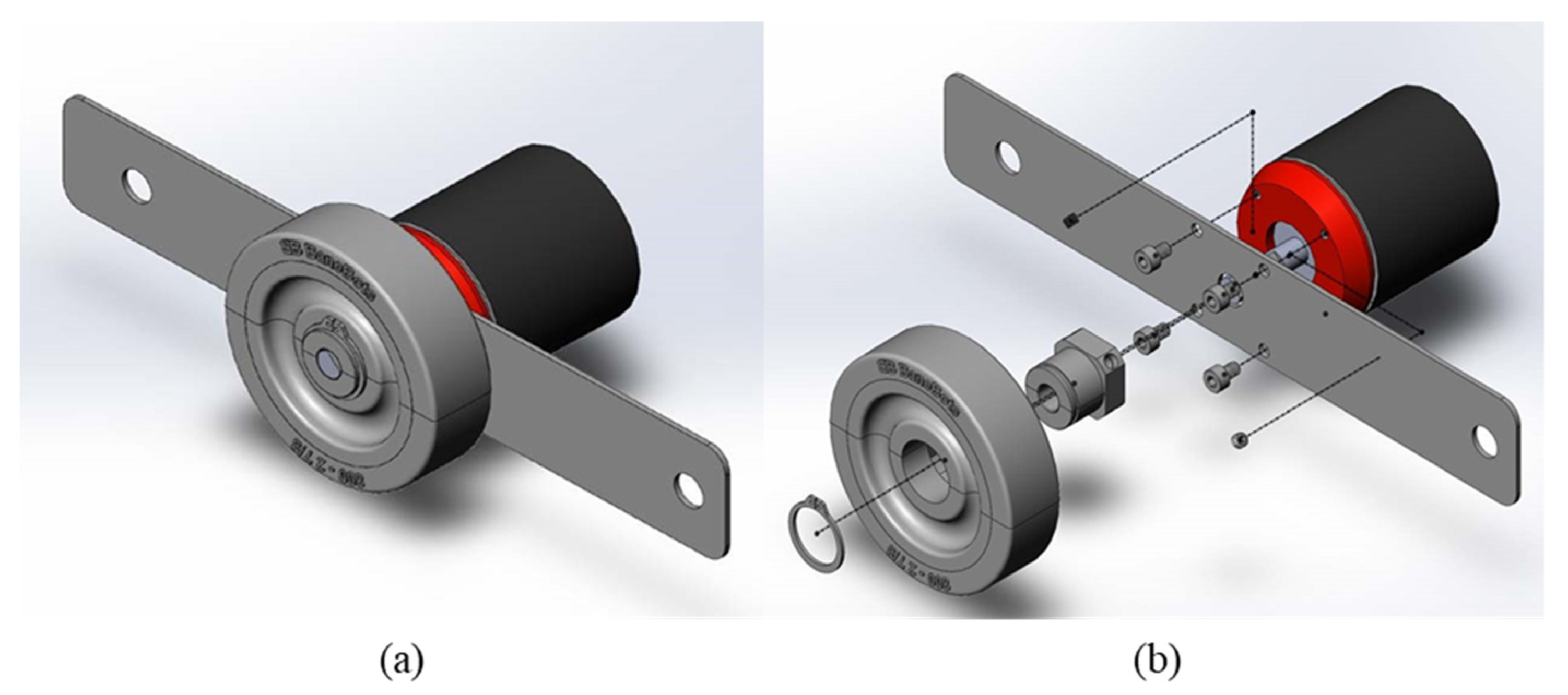

2.2.1. Motor Assembly

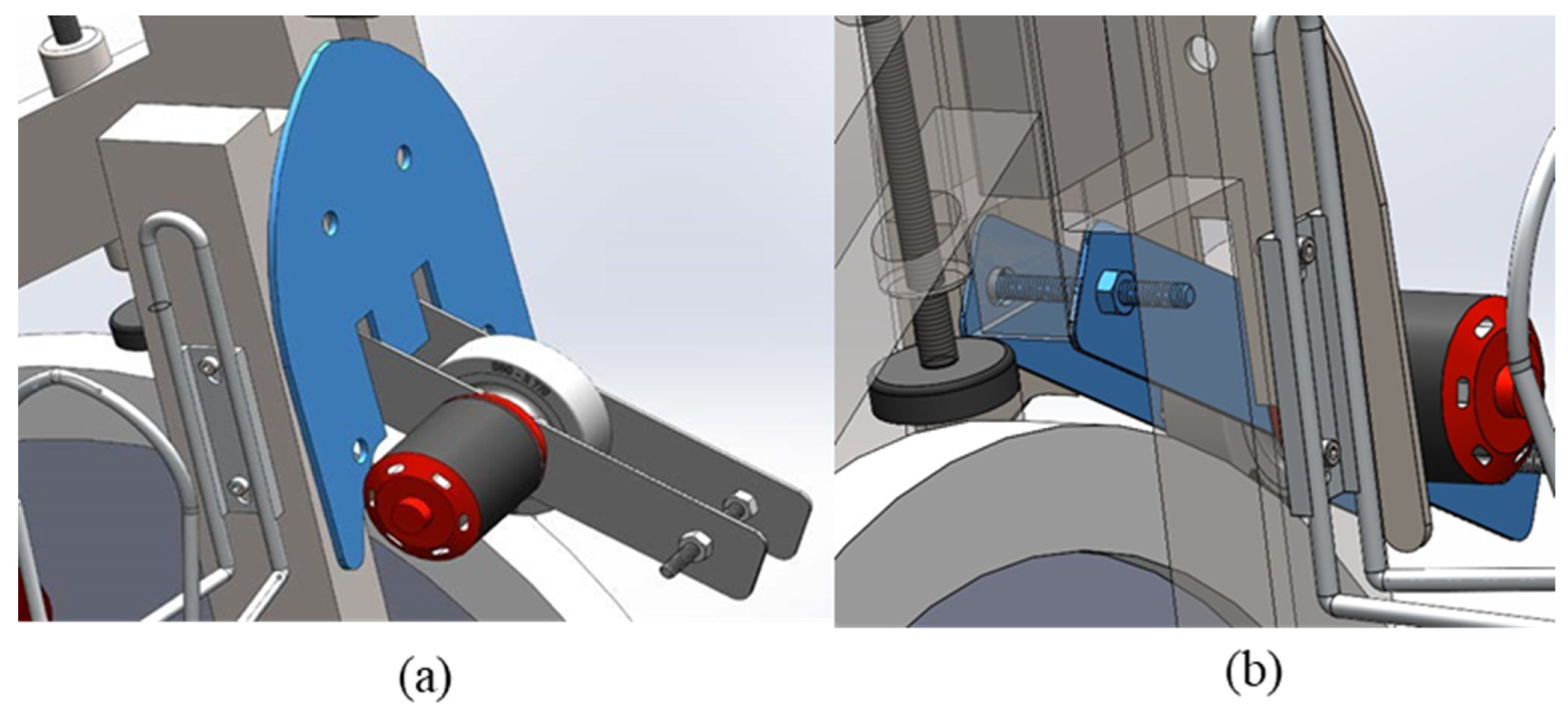

2.2.2. Mounting the Motor Assembly to the Spin Bike Frame

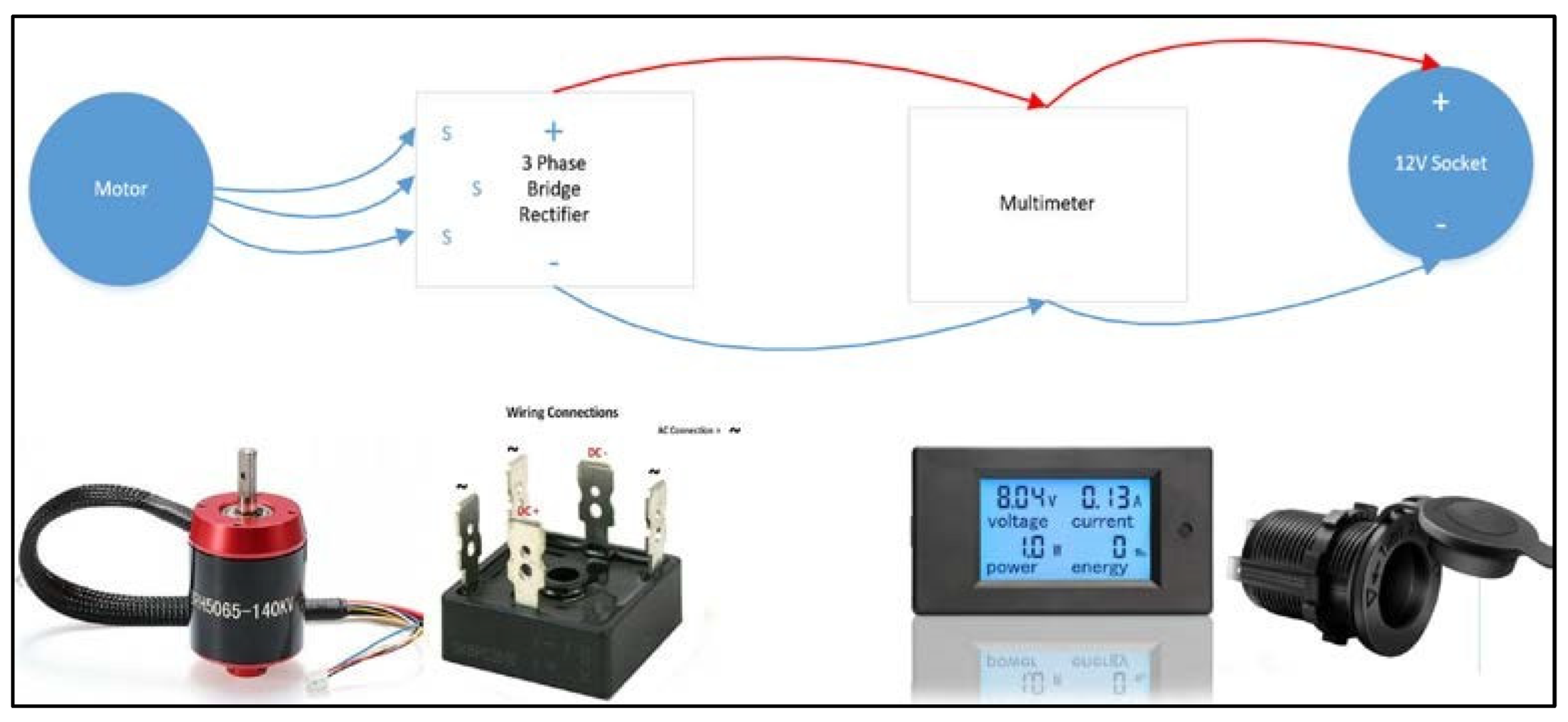

2.3. Electrical Components and Connections

3. Data Characterization and Comparison with Similar Work

3.1. The Setup

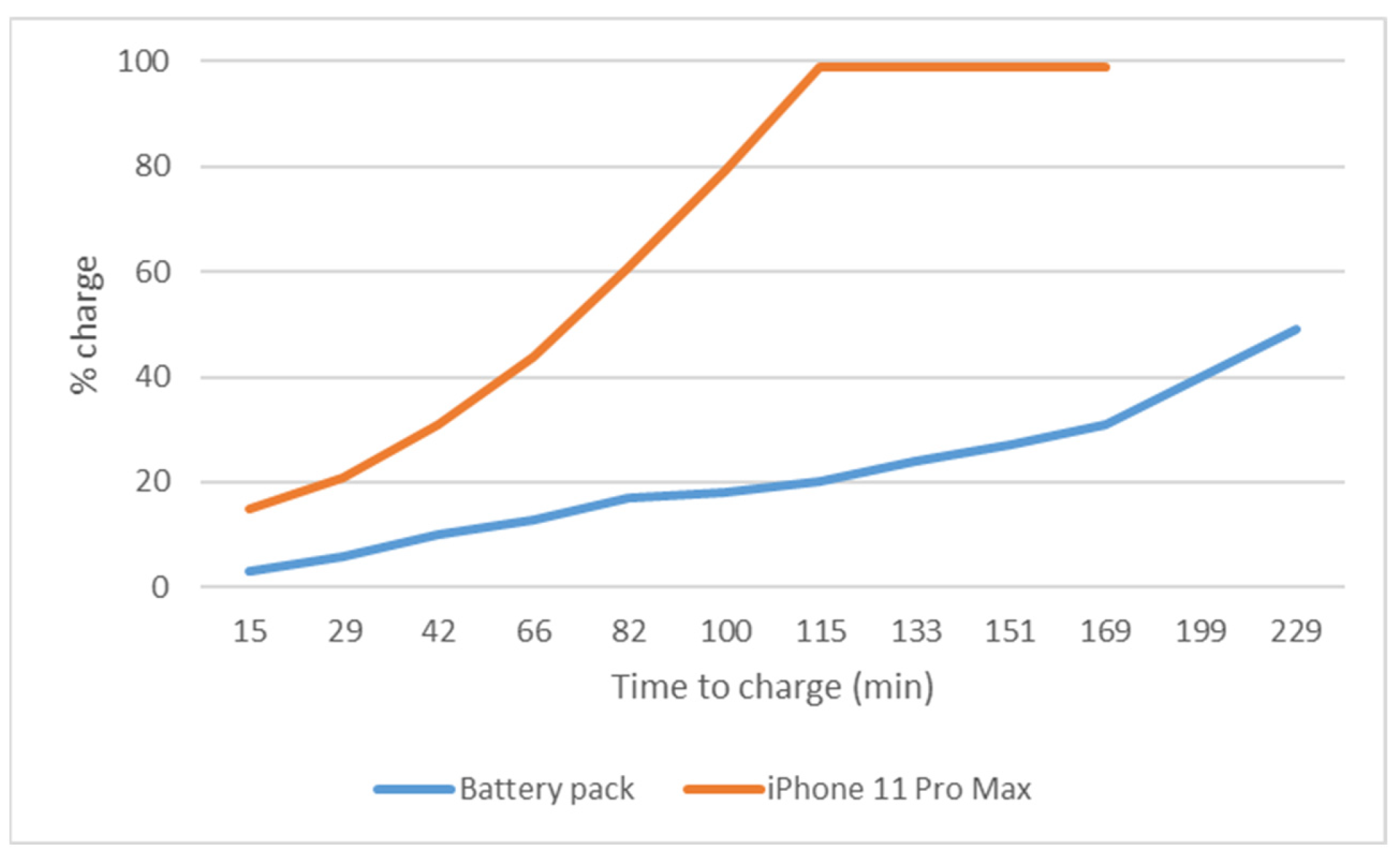

3.2. Results and Discussion

3.3. Comparison with Existing Studies

4. Design Optimization

4.1. Modularity Design

4.2. Components to Be Manufactured

- The control box housing will be an injection-molded ABS. ABS is used for its nonconductive property to prevent users from getting an electrical shock during operation.

- The mounting plate allows the motor assembly to be easily attached to the spin bike frame and flywheel.

- Motor mount bracket with holes’ footprint matches that of the motor footprint.

- The control box base will be made from sheet metal. This will help dissipate the heat from the 3-phase bridge rectifier.

- MT30 Wire harness allows for modular connection between the motor assembly and the control box. This will save substantial assembly time for not having to solder the wires into the connector.

4.3. Plastic Injection Molding Design Considerations

- Injection molding is the cheapest process at scale for plastic

- Consistent, repeatable reproduction of a part

- Mid to high-volume manufacturing

- The greatest variety of materials, colors, and configurations

- Can handle a variety of sizes and shapes

- Custom cosmetics from polish to texturing

4.4. Design for Manufacturability and Assembly (DFMA)

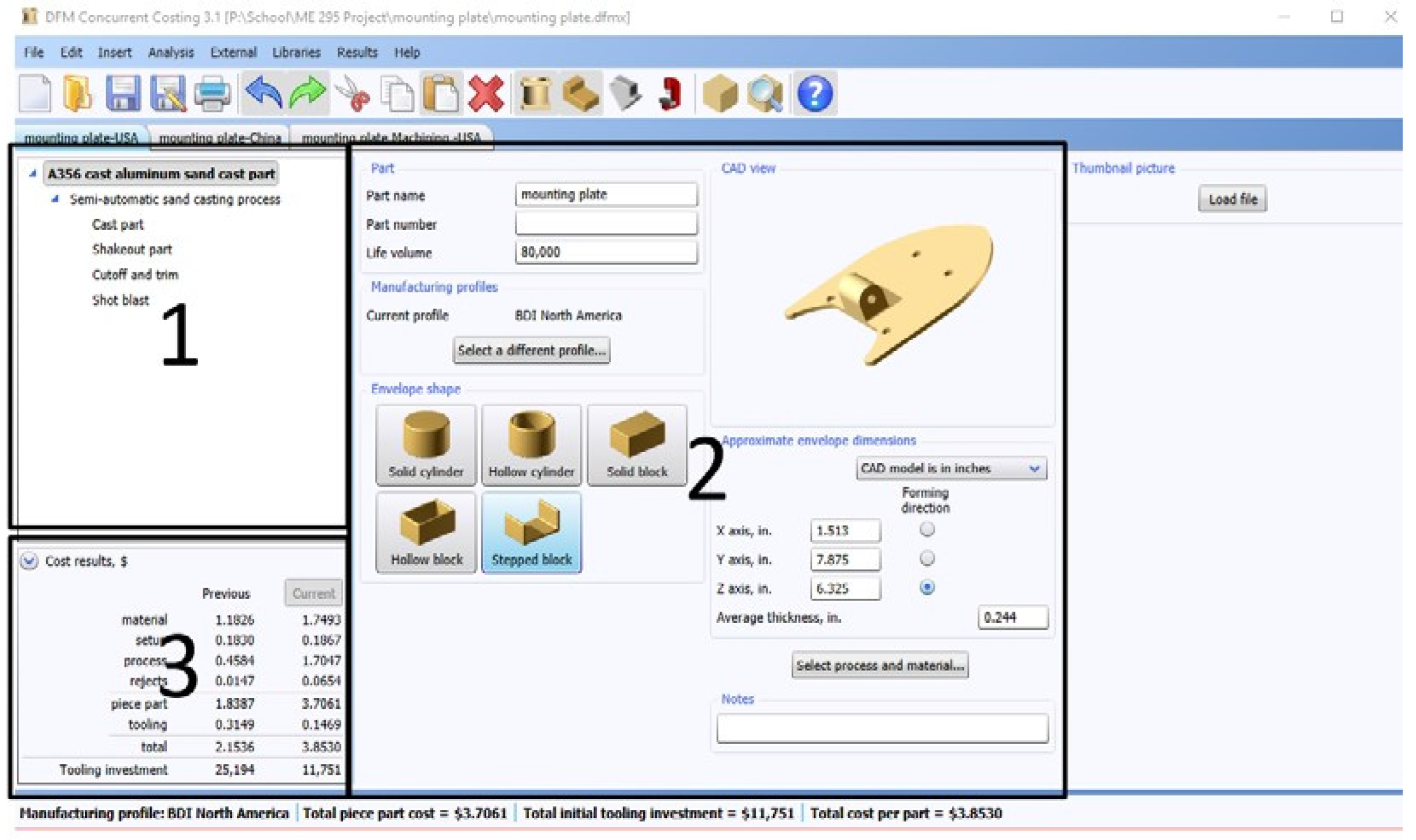

- The process chart is in the upper left. This area shows the list of steps involved in manufacturing the part.

- The question panel is on the right-hand side, where the part details are entered.

- The result box on the lower left shows the cost results regarding materials, setup, process, and rejects. Depending on the manufacturing process, we can also calculate a tooling investment. We add up the four buckets of costs shown at the top to give a part cost and amortize the tooling investment over the specified manufacturing life volume. By adding those together, we can get the total price in DFM concurrent costing.

5. Cost Analysis

5.1. Costed Bill of Materials (BOM)

5.2. Return on Investment

6. Contributions of This Work

7. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nazarko, Ł.; Žemaitis, E.; Wróblewski, Ł.K.; Šuhajda, K.; Zajączkowska, M. The Impact of Energy Development of the European Union Euro Area Countries on CO2 Emissions Level. Energies 2022, 15, 1425. [Google Scholar] [CrossRef]

- Murdock, H.E.; Gibb, D.; André, T.; Sawin, J.L.; Brown, A.; Ranalder, L.; Collier, U.; Dent, C.; Epp, B.; Hareesh Kumar, C.; et al. Renewables 2021 Global Status Report. In Proceedings of the Technical Report No. Renewable Energy Policy Network for the 21st Century, Online, 28 June 2021; Ren21: Paris, France, 2021. [Google Scholar]

- Qian, F.; Xu, T.; Zuo, L. Design, Optimization and Testing of a Piezoelectric Footwear Energy Harvester. Energy Convesrion Manag. 2018, 171, 1352–1364. [Google Scholar] [CrossRef]

- Wu, H.; Tang, L.; Yang, Y.; Sih, C. A Novel Two-degrees-of-freedom Piezoelectric Energy Harvester. J. Intell. Mater. Syst. Struct. 2014, 24, 357–368. [Google Scholar] [CrossRef]

- Zhao, J.; You, Z. A Shoe-Embedded Piezoelectric Energy Harvester for Wearable Sensors. Sensors 2014, 14, 12497–12510. [Google Scholar] [CrossRef]

- Toprak, A.; Tigli, O. Piezoelectric Energy Harvesting: State of the Art and Challenges. Appl. Phys. Rev. 2014, 1, 031104. [Google Scholar] [CrossRef]

- Fan, K.; Xia, P.; Li, R.; Guo, J.; Tan, Q.; Wei, D. An Innovative Energy Harvesting Backpack Strategy through a Flexible Mechanical Motion Rectifier. Energy Convers. Manag. 2022, 264, 115731. [Google Scholar] [CrossRef]

- Donelan, J.; Li, Q.; Naing, V.; Hoffer, J.A.; Weber, D.J.; Kuo, A.D. Biomechanical energy harvesting, generating electricity during walking with minimal user effort. Science 2008, 319, 807–810. [Google Scholar] [CrossRef]

- Fan, J.; Xiong, C.H.; Huang, Z.K.; Wang, C.B.; Chen, W.B. A lightweight biomechanical energy harvester with high power density and low metabolic cost. Energy Convers. Manag. 2019, 195, 641–649. [Google Scholar] [CrossRef]

- Zou, H.; Li, M.; Zhao, L.; Liao, X.; Gao, Q.; Yan, G.; Du, R.; Wei, K.; Zhang, W. Cooperative compliant traction mechanism for human-friendly biomechanical energy harvesting. Energy Convers. Manag. 2022, 258, 115523. [Google Scholar] [CrossRef]

- Shi, H.U.; Luo, S.; Xu, J.; Mei, X. Hydraulic system based energy harvesting method from human walking induced backpack load motion. Energy Convers. Manag. 2021, 229, 113790. [Google Scholar] [CrossRef]

- Shi, H.U.; Yue, Y.; Wang, H.; Xu, J.; Mei, X. Design and performance analysis of human walking induced energy recovery system by means of hydraulic energy conversion and storage. Energy Convers. Manag. 2020, 217, 113008. [Google Scholar] [CrossRef]

- Wang, W.; Cao, J.Y.; Zhang, N.; Lin, J.; Liao, W.H. Magnetic-spring based energy harvesting from human motions: Design, modeling and experiments. Energy Convers. Manag. 2017, 132, 189–197. [Google Scholar] [CrossRef]

- Zou, H.; Zhao, L.; Gao, Q.; Zuo, L.; Liu, F.; Tan, T.; Wei, T.; Zhang, W. Mechanical modulations for enhancing energy harvesting: Principles, methods and applications. Appl. Energy 2019, 255, 113871. [Google Scholar] [CrossRef]

- Bowers, B.J.; Arnold, D.P. Spherical, Rolling Magnet Generators for Passive Energy Harvesting from Human Motion. J. Micromech. Microeng. 2009, 19, 094008. [Google Scholar] [CrossRef]

- Rao, Y.; Cheng, S.; Arnold, D.P. An Energy Harvesting System for Passively Generating Power from Human Activities. J. Micromech. Microeng. 2013, 23, 114012. [Google Scholar] [CrossRef]

- Sirigireddy, P.; Eladi, P.B. Numerical Design of Novel Piezoelectric Generating Structure that Effectively Utilizes the Force Generated from Human Motion. In Proceedings of the 2020 IEEE International Conference on Power Electronics, Smart Grid and Renewable Energy (PESGRE2020), Cochin, India, 2–4 January 2020. [Google Scholar]

- Saha, C.; O’donnell, T.; Wang, N.; Mccloskey, P. Electromagnetic Generator for Harvesting Energy from Human Motion. Sens. Actuators A Phys. 2008, 147, 248–253. [Google Scholar] [CrossRef]

- Oh, Y.; Kwon, D.-S.; Eun, Y.; Kim, W.; Kim, M.-O.; Ko, H.-J.; Kang, S.G.; Kim, J. Flexible Energy Harvester with Piezoelectric and Thermoelectric Hybrid Mechanisms for Sustainable Harvesting. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 6, 691–698. [Google Scholar] [CrossRef]

- Su, M.; Brugger, J.; Kim, B. Simply Structured Wearable Triboelectric Nanogenerator Based on a Hybrid Composition of Carbon Nanotubes and Polymer Layer. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 683–698. [Google Scholar] [CrossRef]

- Seo, B.; Cha, Y.; Kim, S.; Choi, W. Rational Design for Optimizing Hybrid Thermo-Triboelectric Generators Targeting Human Activities. ACS Energy Lett. 2019, 4, 2069–2074. [Google Scholar] [CrossRef]

- Visconti, P.; Bagordo, L.; Velázquez, R.; Cafagna, D.; De Fazio, R. Available Technologies and Commercial Devices to Harvest Energy by Human Trampling in Smart Flooring Systems: A Review. Energies 2022, 15, 432. [Google Scholar] [CrossRef]

- Blechman, A.; Braker, G.; Chodnicki, B.; Dubow, E.; Pernia, K.; Sy, T.; Thompson, M.; Tucker, J. A Study of the Benefits of Retrofitting Cardiovascular Exercise Equipment of a Gym with Human Energy Harvesting Technology. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2009. [Google Scholar]

- Haji, M.N.; Lau, K.; Agogino, A.M. Human Power Generation in Fitness Facilities. In Proceedings of the ASME 2010 4th International Conference on Energy Sustainability, Phoenix, AZ, USA, 17–22 May 2010. [Google Scholar]

- Hilario, A.J. Energy Harvesting from Elliptical Machines Using Four-Switch Buck-Boost Topology. Master’s Thesis, California Polytechnic State University, San Luis Obispo, CA, USA, 2011. [Google Scholar]

- Lum, M.; Yuen, J. Energy Harvesting from Elliptical Machines: Dc Converter Troubleshooting. Master’s Thesis, Department of Electrical Engineering, California Polytechnic University at San Louis Obispo, San Luis Obispo, CA, USA, 2009. [Google Scholar]

- Barois, R.; Caverly, M.; Marshall, K. An Investigation into Using Electricity Harvesting Elliptical Machines as a Renewable Energy Source. UBC Undergrad. Res. 2010. [Google Scholar] [CrossRef]

- Chalermthai, B.; Sada, N.; Sarfraz, O.; Radi, B. Recovery of Useful Energy from Lost Human Power in Gymnasium. In Proceedings of the 2015 IEEE 15th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 10–13 June 2015; IEEE: Piscataway, NJ, USA, 2015. [Google Scholar]

- Thiruchelvam, V.; Hammad, C.; Medni, S. Design of Controls, Monitoring and a Energy Storage System for a Energy Harvesting Gymnasium Equipment. In Proceedings of the MATEC Web of Conferences, Cape Town, South Africa, 1–3 February 2016. [Google Scholar]

- Suhalka, R.; Khandelwal, M.C.; Sharma, K.K.; Sanghi, A. Generation of Electrical Power Using Bicycle Pedal. Int. J. Recent Res. Rev. 2014, 7, 63–67. [Google Scholar]

- Ullah, M.T.; Karim, M.A.B.; Uddin, M.H.; Tauseef, G.M. Harvesting Green Energy from Wastage Energy of Human Activities Using Gymnasium Bicycle at Chittagong City. In Proceedings of the 2015 3rd International Conference on Green Energy and Technology (ICGET), Dhaka, Bangladesh, 11 September 2015; IEEE: Piscataway, NJ, USA, 2015. [Google Scholar]

- Boesel, A. Interview with Adam Boesel, Green Micro Gym, 2011 (Audio). 2011. Available online: https://pdxscholar.library.pdx.edu/sustainhist/32/ (accessed on 27 February 2022).

- Tgo. The Great Outdoor Gym Company. 2021. Available online: https://www.tgogc.com/ (accessed on 27 February 2022).

- Ahsan-Uz-Zaman, K.; Ullah, K.M.; Mishir, M.; Alam, M. Generation of Electrical Power Using Gymnasium Bicycle. In Proceedings of the 2017 IEEE Region 10 Humanitarian Technology Conference (R10-HTC), Dhaka, Bangladesh, 21–23 December 2017; IEEE: New York, NY, USA, 2017. [Google Scholar]

- Gibson, T. These Exercise Machines Turn Your Sweat into Electricity. Available online: https://spectrum.ieee.org/these-exercise-machines-turn-your-sweat-into-electricity (accessed on 27 February 2022).

- Ihsan, M.; Viswanathan, V. Self-Powering Gyms: A Case Study on Energy Harvesting from a Static Bicycle. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Salt Lake City, UT, USA, 10–14 November 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Otto, K.N.; Wood, K. Product Design: Techniques in Reverse Engineering and New Product Development; Tsinghua University Press: Beijing, China, 2003. [Google Scholar]

- Ai, X.; Wilmer, M.; Lawrentz, D. Development of Friction Drive Transmission. J. Tribol. 2005, 127, 857–864. [Google Scholar] [CrossRef]

- Anyanwu, S.I.; Anthony, A.E. Design and Fabrication of a Pedal Operated Power Generator. Innov. Syst. Des. Eng. 2016, 7, 11–13. [Google Scholar]

- Patowary, T.; Hasan, M.; Karim, K. Generation of Electricity by Pedal Power. Master’s Thesis, Department of Electrical and Electronic Engineering, Islamic University of Technology (IUT), Gazipur, Bangladesh, 2016. [Google Scholar]

- Rosato, D.V.; Rosato, M.G. Injection Molding Handbook; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Boothroyd, G. Design for Manufacture and Assembly: The Boothroyd-Dewhurst Experience. In Design for X; Springer: Dordrecht, The Netherlands, 1996. [Google Scholar]

- Boothroyd, G. Design for Assembly—The Key to Design for Manufacture. Int. J. Adv. Manuf. Technol. 1987, 2, 3–11. [Google Scholar] [CrossRef]

|  |  |  |  |  | |

|---|---|---|---|---|---|---|

| Customer Needs | DESIGN A | DESIGN B | DESIGN C | DESIGN D | DESIGN E | DESIGN F |

| Power generation efficiency | S | 0 | 0 | 0 | 0 | 0 |

| Universality | S | 0 | 0 | −1 | 0 | 0 |

| Portability and compactness | S | 0 | 0 | −1 | 1 | 1 |

| Works with multiple power sources | S | 0 | 0 | 0 | 0 | 0 |

| Integrated USB for mobile devices | S | 0 | 0 | 0 | 0 | 0 |

| Low noise | S | 0 | 0 | 0 | 0 | 0 |

| Environment: home or commercial | S | 0 | 0 | 0 | 0 | 0 |

| Ergonomic | S | −1 | −1 | 1 | 1 | 0 |

| Aesthetics | S | −1 | −1 | 1 | 1 | 1 |

| Durability | S | −1 | 0 | 0 | −1 | 0 |

| Energy storage | S | 0 | 0 | 0 | 0 | 0 |

| Safety | S | 0 | 0 | 1 | 0 | 1 |

| Maintenance | S | −1 | 0 | 0 | −1 | 0 |

| Cost | S | 0 | 0 | 0 | 0 | 1 |

| TOTAL + | 0 | 0 | 0 | 3 | 3 | 4 |

| TOTAL − | 0 | −4 | −2 | −2 | −2 | 0 |

| SUM | 0 | −4 | −2 | 1 | 1 | 4 |

| Items | Cost (USD) | |

|---|---|---|

| Sunny Health Spin Bike | 299 | |

| RC Motor | 81.89 | |

| 35 Amp 3 phase bridge rectifier | 12 | |

| DC meter | 20 | |

| 12 GA Wire | 11 | |

| Female Disconnects | 8 | |

| Female Bullet Connector | 11 | |

| Heat Shrink Tubing | 7 | |

| MT60 e wire bullet connectors | 17 | |

| All-Thread rods | 21 | |

| Nuts | 5 | |

| Lock Washer | 6 | |

| Loctite Threadlocker | 6 | |

| Washers | 12 | |

| BaneBots Hub | 4 | |

| BaneBots Wheel | 3 | |

| Project box | 24 | |

| 12 V car sockets | 36 | |

| 12 V Socket Splitter | 12 | |

| Wago Connectors | 9 | |

| 12 V Jackery Battery | 250 | Optional |

| Power Inverter DC to AC | 30 | Optional |

| USB Car Charger Adaptor | 10 | Optional |

| $1000.00 |

| Trial | Duration (min) | Average Voltage | Average Energy (WH) | Calories | Power (W) | Battery % | Phone % | Battery Accumulation | Phone Two % |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 15 | 12.00 | 13.25 | 105 | 53.00 | 3 | 15 | 3 | - |

| 2 | 14 | 11.50 | 11.43 | 110 | 49.00 | 3 | 16 | 6 | - |

| 3 | 13 | 13.00 | 11.05 | 108 | 51.00 | 4 | 25 | 10 | - |

| 4 | 24 | 11.50 | 23.20 | 176 | 58.00 | 3 | 24 | 13 | - |

| 5 | 16 | 14.00 | 15.73 | 150 | 59.00 | 4 | 18 | 17 | - |

| 6 | 18 | 11.00 | 13.96 | 70 | 46.53 | 1 | 9 | 18 | - |

| 7 | 15 | 11.20 | 11.90 | 120 | 47.60 | 2 | 3 | 20 | - |

| 8 | 18 | 11.50 | 11.39 | 60 | 37.95 | 4 | N/A | 24 | - |

| 9 | 18 | 11.40 | 11.29 | 140 | 37.62 | 3 | N/A | 27 | - |

| 10 | 18 | 13.00 | 12.71 | 120 | 42.38 | 4 | N/A | 31 | - |

| 11 | 30 | 14.00 | 31.85 | 260 | 63.70 | 10 | 35 | 41 | 30 |

| 12 | 30 | 13.45 | 57.75 | 315 | 115.50 | 9 | 30 | 52 | 25 |

| Trial | Trial Duration | Total Duration | Average Voltage | Average Current | Battery% Accumulation (Theoretical) | Battery% Accumulation (Experimental) |

|---|---|---|---|---|---|---|

| 1 | 15 | 15 | 12 | 4.34 | 6.46 | 3 |

| 2 | 14 | 29 | 11.5 | 4.3 | 12.43 | 6 |

| 3 | 13 | 42 | 13 | 4.23 | 17.88 | 10 |

| 4 | 24 | 66 | 11.5 | 4.13 | 27.71 | 13 |

| 5 | 16 | 82 | 14 | 4.21 | 34.41 | 17 |

| 6 | 18 | 100 | 11 | 4.23 | 41.95 | 18 |

| 7 | 15 | 115 | 11.2 | 4.25 | 48.27 | 20 |

| 8 | 18 | 133 | 11.5 | 3.3 | 54.17 | 24 |

| 9 | 18 | 151 | 11.4 | 3.3 | 60.06 | 27 |

| 10 | 18 | 169 | 13 | 3.26 | 65.88 | 31 |

| 11 | 30 | 199 | 14 | 4.55 | 69.27 | 41 |

| 12 | 30 | 229 | 13.45 | 8.59 | 94.83 | 52 |

| Level of Experience | % Charge on the Battery Pack | Time to Charge (h) | Comparison with a Wall Outlet |

|---|---|---|---|

| Little or no exercise | 31 | 2.82 | Slower than the wall outlet |

| 100 | 9.10 (projected) | ||

| Weekend biker | 18 | 1 | Faster than the wall outlet |

| 100 | 5.56 (projected) |

| Part # | Description | SYS $ | Cost | Cateo | QTY | Source | Total |

|---|---|---|---|---|---|---|---|

| 30,001 | PACKAGING | $3.00 | $3.30 | BOXES | 1 | DFM ESTIMATE | $3.30 |

| 30,002 | FLAT MOUNTING BAR BRACKET REVB | $0.24 | $0.27 | BRACKET | 2 | DFM ESTIMATE | $0.53 |

| 30,003 | 14 GA HARNESS WITH T30 CONNECTOR | $1.08 | $1.19 | ELECTRONIC | 1 | DFM ESTIMATE | $1.19 |

| 30,004 | 35A 3 PHASE BRIDGE RECTIFIER | $2.66 | $2.92 | HARNESS | 1 | ALIEXPRESS | $2.92 |

| 30,005 | DC VOLTAGE METER | $10.06 | $11.07 | ELECTRONIC | 1 | ALIEXPRESS | $11.07 |

| 30,006 | 12 VOLT SOCKET | $1.73 | $1.90 | ELECTRONIC | 2 | ALIEXPRESS | $3.81 |

| 30,007 | 3.1A DUAL USB CAR CHARGER | $1.86 | $2.05 | ELECTRONIC | 1 | ALIEXPRESS | $2.05 |

| 30,008 | 5 PORT WAGO CONNECTOR | $0.18 | $0.20 | ELECTRONIC | 2 | ALIEXPRESS | $0.39 |

| 30,009 | 14 GA WIRES | $0.50 | $0.55 | ELECTRONIC | 1 | ALIEXPRESS | $0.55 |

| 30,010 | WIRE HARNESS SPADE T30 | $1.25 | $1.38 | ELECTRONIC | 1 | DFM ESTIMATE | $1.38 |

| 30,011 | 1/4″-20 HEX NUT | $0.05 | $0.05 | HARDWARE | 8 | MCMASTER | $0.43 |

| 30,012 | Zinc Yellow-Chromate Plated Hex Head Screw, Grade 8 Steel, 1/4″-20 Thread Size, 2-1/2″ Long, Fully Threaded | $0.73 | $0.80 | HARDWARE | 2 | MCMASTER | $1.60 |

| 30,013 | Zinc Yellow-Chromate Plated Hex Head Screw, Grade 8 Steel, 1/4″-20 Thread Size, 3/4″ Long | $0.12 | $0.14 | HARDWARE | 4 | MCMASTER | $0.55 |

| 30,014 | M5 BOLT FOR CONTROL BOX AND RECTIFIER | $0.12 | $0.13 | HARDWARE | 5 | MCMASTER | $0.66 |

| 30,015 | M5 NUTS | $0.02 | $0.02 | HARDWARE | 1 | MCMASTER | $0.02 |

| 30,016 | M4X.7MM SOCKET HEAD SCREW | $0.09 | $0.10 | HARDWARE | 4 | MCMASTER | $0.39 |

| 30,017 | UBOLT WITH MOUNTING PLATE | $1.42 | $1.56 | HARDWARE | 1 | MCMASTER | $1.56 |

| 30,018 | CONTROL BOX | $1.07 | $1.18 | HOUSING | 1 | DFM ESTIMATE | $1.18 |

| 30,019 | CONTROL BOX BASE | $0.40 | $0.44 | HOUSING | 1 | DFM ESTIMATE | $0.44 |

| 30,020 | RACERSTAR BRH5065-140kV MOTOR | $46.95 | $51.65 | MOTOR | 1 | ALIEXPRESS | $51.65 |

| 30,021 | BANEBOT T81 HUB, 8MM SHAFT 60A | $3.15 | $3.47 | MOTOR HUB | 1 | BANEBOTS.COM | $3.47 |

| 30,022 | BANEBOTS WHEEL, 2-7/8″X0.8″, HUB MOUNT, 60A, | $2.45 | $2.70 | MOTOR WHEEL | 1 | BANEBOTS.COM | $2.70 |

| 30,023 | RECEPTICAL MOUNTING PLATE | $1.93 | $2.12 | MOUNTING | 1 | DFM ESTIMATE | $2.12 |

| 30,024 | BUNGEE CORD WITH HOOKS 1M | 3.933 | $4.33 | MOUNTING | 1 | ALIEXPRESS | $4.33 |

| 30,025 | 6″ 14G Red Wire with spade connector-pre-stripped end | $0.20 | $0.22 | Harness | 3 | DFM ESTIMATE | $0.66 |

| 30,026 | 6″ 14G Blk Wire with spade connector-pre-stripped end | $0.20 | $0.22 | Harness | 3 | DFM ESTIMATE | $0.66 |

| MATERIALS COST | 99.59 | ||||||

| LABOR COST | 3.87 | ||||||

| TOTAL COST | $103.46 | ||||||

| Wh/Day | Wh/Year | kWh | Savings on Electricity | ROI (Years) | |

|---|---|---|---|---|---|

| Regular cycling exercise can produce | 200 | 73,000 | 73 | 11.68 | 34.25 |

| In a gym with average usage time of 8 h/day | 1600 | 584,000 | 584 | 93.44 | 4.28 |

| In a regular household of 4 with 2 h of usage per day | 400 | 146,000 | 146 | 23.36 | 17.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pham, H.; Bandaru, A.P.; Bellannagari, P.; Zaidi, S.; Viswanathan, V. Getting Fit in a Sustainable Way: Design and Optimization of a Low-Cost Regenerative Exercise Bicycle. Designs 2022, 6, 59. https://doi.org/10.3390/designs6030059

Pham H, Bandaru AP, Bellannagari P, Zaidi S, Viswanathan V. Getting Fit in a Sustainable Way: Design and Optimization of a Low-Cost Regenerative Exercise Bicycle. Designs. 2022; 6(3):59. https://doi.org/10.3390/designs6030059

Chicago/Turabian StylePham, Huy, Aseesh Paul Bandaru, Pranav Bellannagari, Sohail Zaidi, and Vimal Viswanathan. 2022. "Getting Fit in a Sustainable Way: Design and Optimization of a Low-Cost Regenerative Exercise Bicycle" Designs 6, no. 3: 59. https://doi.org/10.3390/designs6030059

APA StylePham, H., Bandaru, A. P., Bellannagari, P., Zaidi, S., & Viswanathan, V. (2022). Getting Fit in a Sustainable Way: Design and Optimization of a Low-Cost Regenerative Exercise Bicycle. Designs, 6(3), 59. https://doi.org/10.3390/designs6030059