Determination of Modules in Pleasurable Design to Fulfil Customer Requirements and Provide a Customized Product in the Food Industry

Abstract

1. Introduction

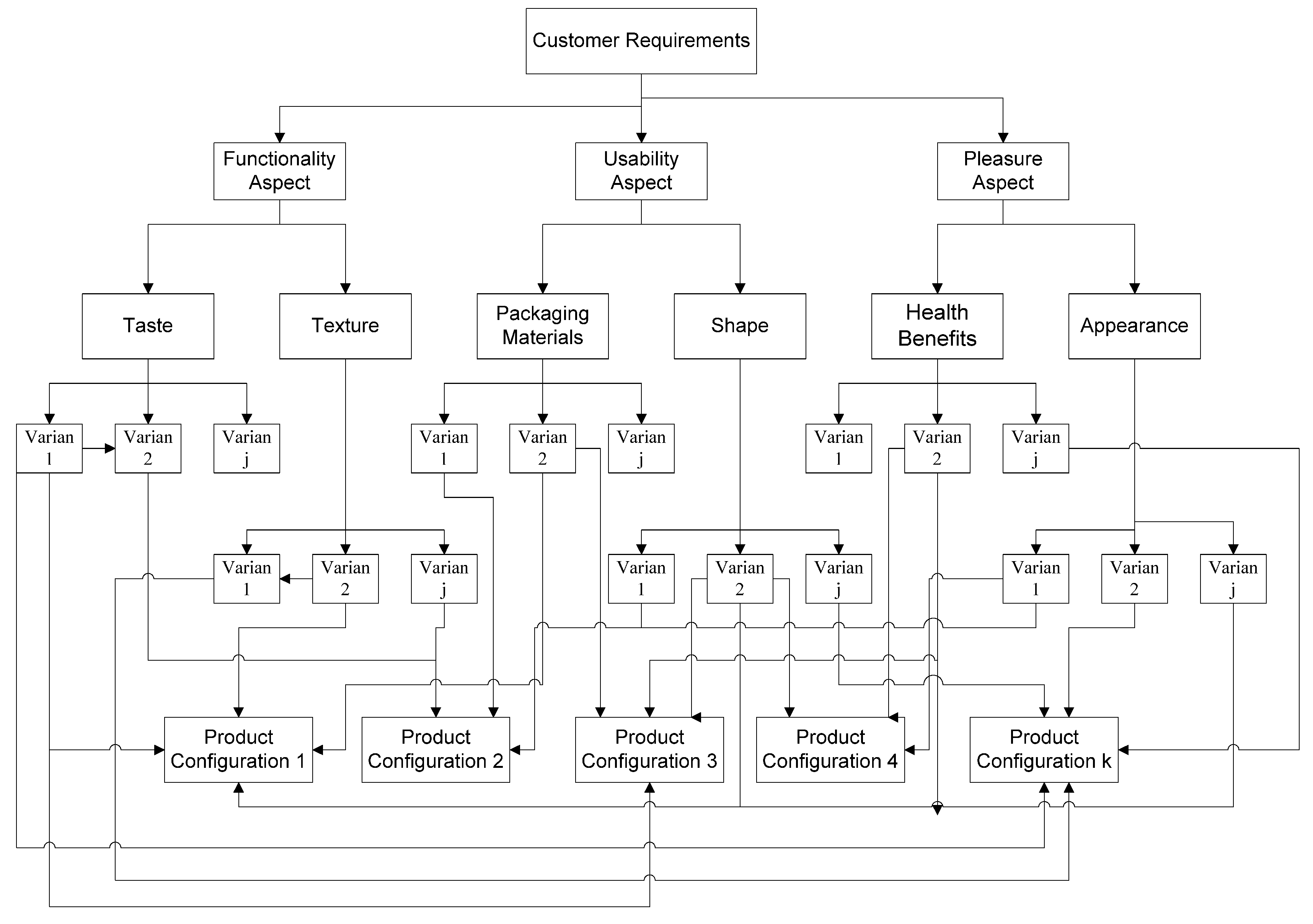

2. Materials and Methods

2.1. Data Collection

2.2. Data Analysis

2.2.1. Descriptive Analysis

2.2.2. Conjoint Analysis

- = total utility of each product configuration alternative

- = a constant

- = utility of product configuration alternative k for attribute i and level j

- m = number of attributes

- n = number of levels

2.2.3. Decision-Making Trial and Evaluation Laboratory (DEMATEL)

3. Results and Discussion

3.1. Descriptive Analysis

3.1.1. Functionality Aspect

3.1.2. Usability Aspect

3.1.3. Pleasure Aspect

3.2. Product Configuration with Conjoint Analysis

3.2.1. Product Configuration

3.2.2. Ranking of Product Configuration

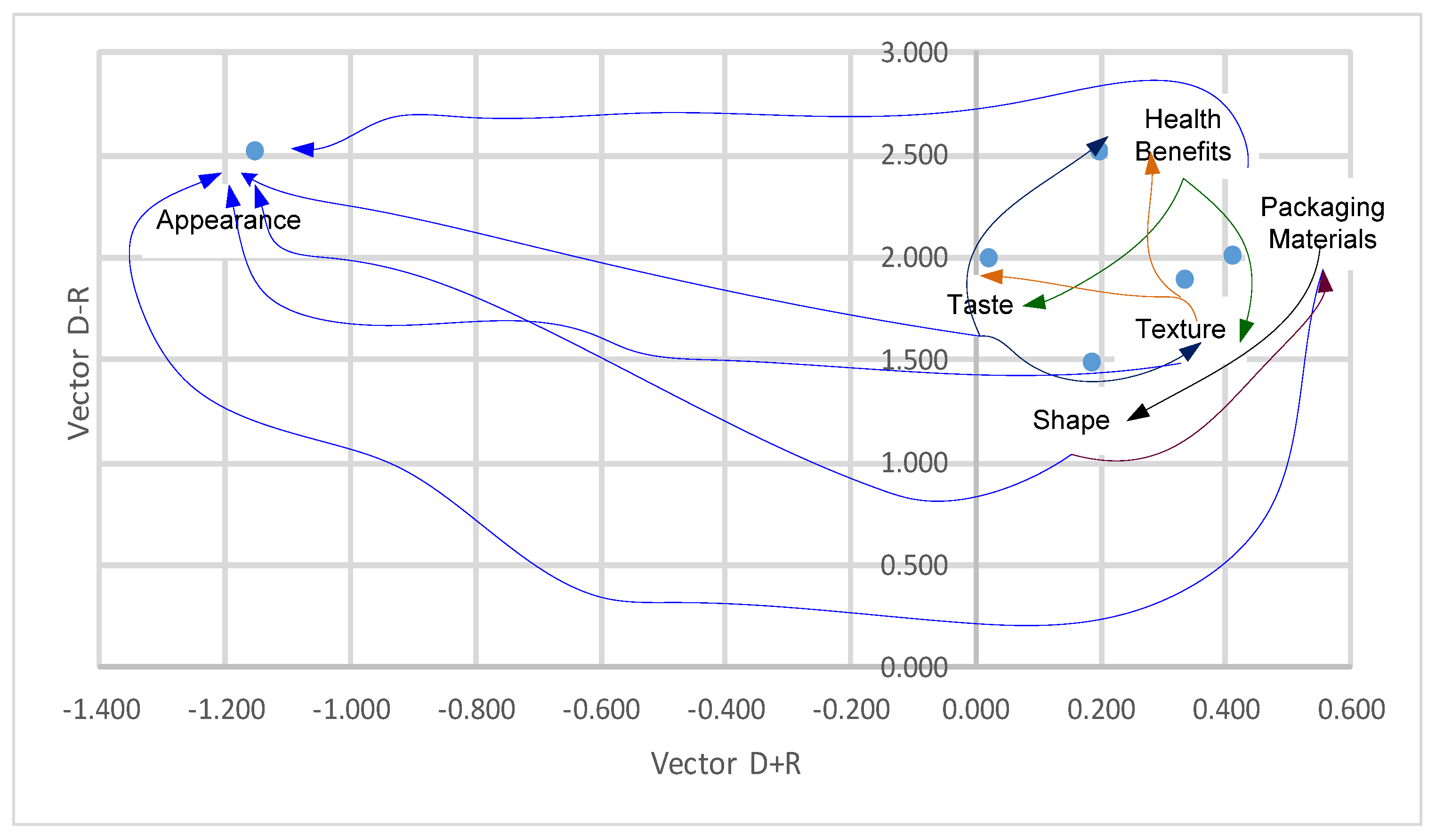

3.3. Determination of Modules with DEMATEL

3.3.1. Relationship between Attributes

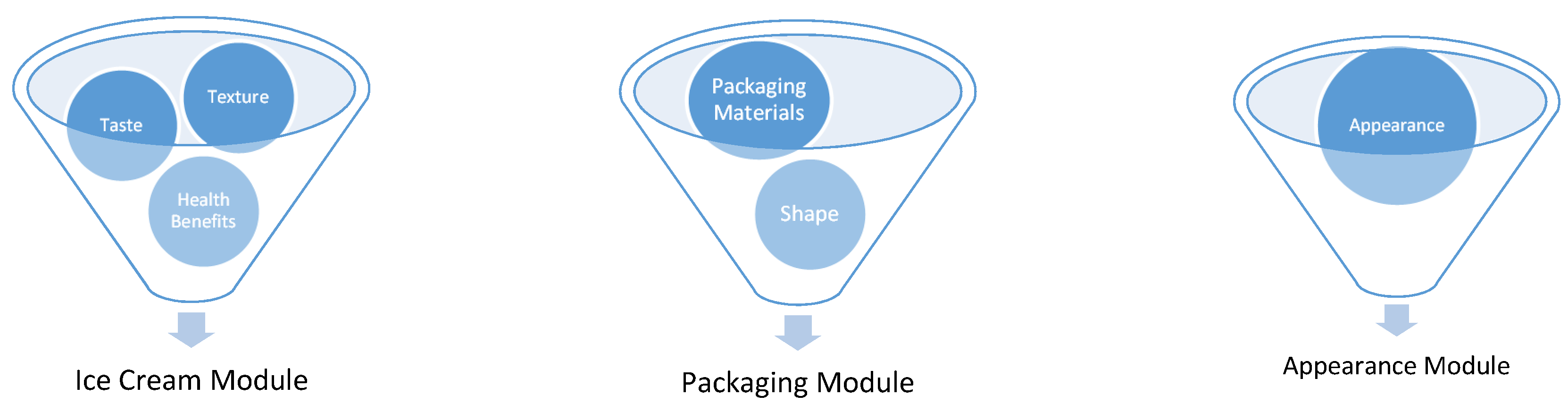

3.3.2. Types of Modules

Ice-Cream Module

Packaging Module

Appearance Module

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Frutos, J.D.; Borenstein, D. A framework to support customer-company interaction in mass customization environments. Comput. Ind. 2004, 54, 115–135. [Google Scholar] [CrossRef]

- Akkerman, R.; van Donk, D.P. Product mix variability with correlated demand in two-stage food manufacturing with intermediate storage. Int. J. Prod. Econ. 2009, 121, 313–322. [Google Scholar] [CrossRef]

- McIntosh, R.I.; Matthews, J.; Mullineux, G.; Medland, A.J. Late customisation: Issues of mass customisation in the food industry. Int. J. Prod. Res. 2010, 48, 1557–1574. [Google Scholar] [CrossRef]

- van Donk, D.P. Make to stock or make to order: The decoupling point in the food processing industries. Int. J. Prod. Econ. 2001, 69, 297–306. [Google Scholar] [CrossRef]

- Soman, C.A.; van Donk, D.P.; Gaalman, G. Combined make-to-order and make-to-stock in a food production system. Int. J. Prod. Econ. 2004, 90, 223–235. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Psarommatis, F. Design and operation of manufacturing networks for mass customisation. CIRP Ann. Manuf. Technol. 2013, 62, 467–470. [Google Scholar] [CrossRef]

- Davis, S.M. Future Perfect; Addison-Wesley Publishing Company, Inc.: Toronto, ON, Canada, 1987. [Google Scholar]

- Pine, B.J.; Victor, B.; Boynton, A.C. Making mass customization work. Harvard Bus. Rev. 1993, 71, 108–111. [Google Scholar]

- Xu, X. Position of customer order decoupling point in mass customization. In Proceedings of the Sixth International Conference on Machine Learning and Cybernetics, Hong Kong, China, 19–22 August 2007; pp. 302–307. [Google Scholar]

- Mourtzis, D.; Doukas, M. The Evolution of manufacturing systems: From craftsmanship to the era of customisation. In Handbook of Research on Design and Management of Lean Production Systems; IGI Global: Hershey, PA, USA, 2014; pp. 1–29. [Google Scholar]

- Mourtzis, D.; Doukas, M. Design and planning of manufacturing networks for mass customisation and personalisation: Challenges and Outlook. Procedia CIRP 2014, 19, 1–13. [Google Scholar] [CrossRef]

- da Silveira, G.; Borenstein, D.; Fogliatto, H.S. Mass customization: Literature review and research directions. Int. J. Prod. Econ. 2001, 72, 1–13. [Google Scholar] [CrossRef]

- Gangurde, S.R.; Akarte, M.M. Customer preference oriented product design using AHP-modified TOPSIS approach. Benchmarking Int. J. 2013, 20, 549–564. [Google Scholar] [CrossRef]

- Watcharapanyawong, K.; Sirisoponsilp, S.; Sophatsathit, P. A Model of mass customization for engineering production system development in textile and apparel industries in Thailand. Syst. Eng. Procedia 2011, 2, 382–397. [Google Scholar] [CrossRef]

- Dong, B.; Jia, H.; Li, Z.; Dong, K. Implementing mass customization in garment industry. Syst. Eng. Procedia 2012, 3, 372–380. [Google Scholar] [CrossRef]

- Matthews, J.; Singh, B.; Mullineux, G.; Medland, T. Constraint-based approach to investigate the process flexibility of food processing equipment. Comput. Ind. Eng. 2006, 51, 809–820. [Google Scholar] [CrossRef]

- Boland, M. Perspective: Mass customisation of food. J. Sci. Food Agric. 2006, 86, 7–9. [Google Scholar] [CrossRef]

- Boland, M. Innovation in the food industry: Personalised nutrition and mass customization. Innov. Manag. Policy Pract. 2008, 10, 53–60. [Google Scholar] [CrossRef]

- Matthews, J.; McIntosh, R.I.; Mullineux, G. Contrasting opportunities for mass customization in food manufacture and food process. In Mass Customization: Engineering and Managing Global Operations; Fogliatto, F.S., da Silveira, G.J.C., Eds.; Springer: London, UK, 2011; pp. 353–374. [Google Scholar]

- Kusiak, A.; Huang, C.C. Development of modular products. IEEE Trans. Compon. Packag. Manuf. Technol. Part A 1996, 19, 523–538. [Google Scholar] [CrossRef]

- Agard, B.; Kusiak, A. Data Mining for Subassembly Selection. J. Manuf. Sci. Eng. 2004, 126, 627–631. [Google Scholar] [CrossRef]

- Da Cunha, C.; Agard, B.; Kusiak, A. Design for Cost: Module-Based Mass Customization. IEEE Trans. Autom. Sci. Eng. 2007, 4, 350–359. [Google Scholar] [CrossRef]

- Agard, B.; Bassetto, S. Modular design of product families for quality and cost. Int. J. Prod. Res. 2013, 51, 1648–1667. [Google Scholar] [CrossRef]

- Brun, A.; Zorzini, M. Evaluation of product customization strategies through modularization and postponement. Int. J. Prod. Econ. 2009, 120, 205–220. [Google Scholar] [CrossRef]

- Sosa, M.E.; Eppinger, S.D.; Rowles, C.M. A network approach to define modularity of components in complex products. J. Mech. Des. 2007, 129, 1118–1129. [Google Scholar] [CrossRef]

- Song, W.; Sakao, T. A customization-oriented framework for design of sustainable product/service system. J. Clean. Prod. 2017, 140, 1672–1685. [Google Scholar] [CrossRef]

- Jordan, P.W. Designing Pleasurable Products; E-Library; Taylor & Francis: London, UK, 2000. [Google Scholar]

- Fandos, C.; Flavián, C. Intrinsic and extrinsic quality attributes, loyalty and buying intention: An analysis for a PDO product. Br. Food J. 2006, 108, 646–662. [Google Scholar] [CrossRef]

- Iop, S.C.F.; Teixeira, E.; Deliza, R. Consumer research: Extrinsic variables in food studies. Br. Food J. 2006, 108, 894–903. [Google Scholar] [CrossRef]

- Espejel, J.; Fandos, C.; Flavián, C. The role of intrinsic and extrinsic quality attributes on consumer behaviour for traditional food products. Manag. Serv. Qual. 2007, 17, 681–701. [Google Scholar] [CrossRef]

- Hersleth, M.; Monteleone, E.; Segtnan, A.; Næs, T. Effects of evoked meal contexts on consumers’ responses to intrinsic and extrinsic product attributes in dry-cured ham. Food Qual. Prefer. 2015, 40, 191–198. [Google Scholar] [CrossRef]

- Lee, P.Y.; Lusk, K.; Mirosa, M.; Oey, I. An attribute prioritization-based segmentation of the Chinese consumer market for fruit juice. Food Qual. Prefer. 2015, 46, 1–8. [Google Scholar] [CrossRef]

- Ma, L.; Li, B.; Han, F.; Yan, S.; Wang, L.; Sun, J. Evaluation of the chemical quality traits of soybean seeds, as related to sensory attributes of soymilk. Food Chem. 2015, 173, 694–701. [Google Scholar] [CrossRef]

- Verain, M.C.D.; Sijtsema, S.J.; Antonides, G. Consumer segmentation based on food-category attribute importance: The relation with healthiness and sustainability perceptions. Food Qual. Prefer. 2016, 48, 99–106. [Google Scholar] [CrossRef]

- Massaglia, S.; Borra, D.; Peano, C.; Sottile, F.; Merlino, V.M. Consumer preference heterogeneity evaluation in fruit and vegetable purchasing decisions using the best—Worst approach. Foods 2019, 8, 266. [Google Scholar] [CrossRef]

- Wedowati, E.R.; Singgih, M.L.; Gunarta, I.K. Design For Mass Customization In Food Industry: Literature Review And Research Agenda. In Proceedings of the 7th International Conference on Operations and Supply Chain Management (OSCM), Phuket, Thailand, 18–21 December 2016; pp. 726–737. [Google Scholar]

- Stan, V.; Caemmerer, B.; Cattan-jallet, R. Customer loyalty development: The role of switching costs. J. Appl. Bus. Res. 2013, 29, 1541–1554. [Google Scholar] [CrossRef][Green Version]

- Fogliatto, F.S.; da Silveira, G.J.C. Mass customization: A method for market segmentation and choice menu design. Int. J. Prod. Econ. 2008, 111, 606–622. [Google Scholar] [CrossRef]

- Wang, C.H. Integrating Kansei engineering with conjoint analysis to fulfil market segmentation and product customisation for digital cameras. Int. J. Prod. Res. 2015, 53, 2427–2438. [Google Scholar] [CrossRef]

- Hailu, G.; Boecker, A.; Henson, S.; Cranfield, J. Consumer valuation of functional foods and nutraceuticals in Canada. A conjoint study using probiotics. Appetite 2009, 52, 257–265. [Google Scholar] [CrossRef] [PubMed]

- Annunziata, A.; Vecchio, R. Consumer perception of functional foods: A conjoint analysis with probiotics. Food Qual. Prefer. 2013, 28, 348–355. [Google Scholar] [CrossRef]

- Endrizzi, I. A conjoint study on apple acceptability: Sensory characteristics and nutritional information. Food Qual. Prefer. 2015, 40, 39–48. [Google Scholar] [CrossRef]

- Shan, L.C. Consumer evaluations of processed meat products reformulated to be healthier—A conjoint analysis study. Meat Sci. 2017, 131, 82–89. [Google Scholar] [CrossRef]

- Imam, A.; Zadeh, M.N.; Dubey, L.R. Dairy Marketing Strategies in the Context of Globalization: Issues and Challenges. Int. J. Trade Econ. Financ. 2011, 2, 138–143. [Google Scholar] [CrossRef]

- Si, S.; You, X.; Liu, H.; Zhang, P. DEMATEL Technique: A Systematic Review of the State-of-the-Art Literature on Methodologies and Applications. Hindawi Math. Probl. Eng. 2018, 2018, 3696457. [Google Scholar] [CrossRef]

- Wang, C.H.; Wang, J. Combining fuzzy AHP and fuzzy Kano to optimize product varieties for smart cameras: A zero-one integer programming perspective. Appl. Soft Comput. J. 2014, 22, 410–416. [Google Scholar] [CrossRef]

- Calegari, L.P.; Barbosa, J.; Marodin, G.A.; Fettermann, D.C. A conjoint analysis to consumer choice in Brazil: Defining device attributes for recognizing customized foods characteristics. Food Res. Int. 2018, 109, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Jaggi, S. Descriptive Statistics and Exploratory Data Analysis. Indian Agric. Stat. Res. Inst. 2003, 1, 1–18. [Google Scholar]

- Lee, W.S.; Huang, A.Y.; Chang, Y.Y.; Cheng, C.M. Analysis of decision making factors for equity investment by DEMATEL and Analytic Network Process. Expert Syst. Appl. 2011, 38, 8375–8383. [Google Scholar] [CrossRef]

- McCullough, P.R. A User’s Guide to Conjoint Analysis. Mark. Res. 2002, 14, 18–23. [Google Scholar]

- De Pelsmaeker, S.; Schouteten, J.J.; Lagast, S.; Dewettinck, K.; Gellynck, X. Is taste the key driver for consumer preference? A conjoint analysis study. Food Qual. Prefer. 2017, 62, 323–331. [Google Scholar] [CrossRef]

- Vilela, A.; Bacelar, E.; Pinto, T.; Anjos, R.; Correia, E.; Gonçalves, B.; Cosme, F. Beverage and food fragrance biotechnology, novel applications, sensory and sensor techniques: An overview. Foods 2019, 8, 643. [Google Scholar] [CrossRef]

- Park, M.; Yoo, J. Benefits of mass customized products: Moderating role of product involvement and fashion innovativeness. Heliyon 2018, 4, e00537. [Google Scholar] [CrossRef]

| No. | Authors | Products | Product Attributes |

|---|---|---|---|

| 1. | Fandos and Flavian [28] | Meat: ham | Intrinsic: fine, flavor, delicate, aroma, appearance, and color Extrinsic: shapely, elongated and rounded form of the ham, brand |

| 2. | Iop et al. [29] | Food products | Intrinsic: color, aroma, flavor, and texture Extrinsic: brand, price, and context |

| 3. | Espejel et al. [30] | Traditional food | Intrinsic: color, flavor, smell, and appearance Extrinsic: brand, denomination of origin, and traditional product image |

| 4. | Hersleth et al. [31] | dry-cured ham | Intrinsic: sensory quality (appearance, aroma, flavor, and texture) Extrinsic: price, nutritional value, and processing conditions |

| 5. | Lee et al. [32] | Fruit juice | Extrinsic: brand, nutrient content, ingredient labels, shelf life, price, and manufacturing country |

| 6. | Ma et al. [33] | Soy milk | Intrinsic: sensory attribute (soymilk aroma, smoothness in the mouth, thickness in the mouth, sweetness, color, appearance, and overall acceptability), oil and protein content, fatty acids, soluble solid |

| 7. | Verain et al. [34] | Milk, meat, fruit and vegetable, and fish | Attributes: sustainability, health, taste, and price |

| 8. | Massaglia et al. [35] | Fruit and vegetable | Attributes: brand, organic label, quality certifications, origin, price, offer, appearance, local, geographical indication label, seasonality, variety, freshness |

| 9. | The present paper | Ice cream | Functionality: taste, color, aroma, texture, and nutritional content Usability: shape, size, and materials packagingPleasure: brand/image, health benefits, appearance, and packaging design |

| No. | Authors | Products | Strengths | Weaknesses |

|---|---|---|---|---|

| 1. | Fogliatto and Silveira [38] | Laptop, natural gas | Designing choice menus for MC with CA to balance the trade-off between flexibility and complexity. | Implications for modularity and bundled choice have not been considered. |

| 2. | Wang and Wang [46] | Smart cameras | Using a combination of fuzzy AHP, fuzzy Kano, and ZOIP to analyse customer preferences, customer perceptions and optimal product varieties for distinct segments. | Market segmentation has not considered customer demographic profiles. |

| 3. | Wang [39] | Digital cameras | Integrating KE, CA, RST, and GRA to effectively perform market segmentation and efficiently conduct product customization. | Product configuration has not considered customer need, affordable prices and consumer demographics. |

| 4. | Verain et al. [34] | Food products | This study has considered market segmentation, and the product attributes synergize healthiness and sustainability. | This study has not reviewed the product configuration according to market segments. |

| 5. | Calegari et al. [47] | Food products | Using the CBCA method to define device attributes to recognize the characteristics of customized foods. | The sample dispersion for product development focuses on specific population profiles. |

| 6. | The present paper | Ice cream | Using a combination of conjoint analysis and DEMATEL to determine the type of module. Review of product design attributes using pleasurable design (functionality, usability, and pleasure) | The product design has not considered market segmentation. |

| Aspects | |||||

|---|---|---|---|---|---|

| Functionality | Usability | Pleasure | |||

| Attributes | Percentage Who Choose | Attributes | Percentage Who Choose | Attributes | Percentage Who Choose |

| Taste | 97.78 | Packaging materials | 84.44 | Health benefits | 73.33 |

| Texture | 86.67 | Expiry date | 72.89 | Appearance | 73.33 |

| Nutrition | 68.00 | Shape | 70.67 | Brand/Image | 65.33 |

| Aroma | 47.56 | Size | 68.89 | Packaging design | 56.89 |

| Colour | 43.11 | ||||

| Storability | 35.56 | ||||

| Attributes | |||||||

|---|---|---|---|---|---|---|---|

| Taste | Percent Age Who Choose | Shape | Percent Age Who Choose | Health Benefits | Percent Age Who Choose | Appearance | Percent Age Who Choose |

| Chocolate | 94.22 | Cup | 75.56 | No preservatives | 74.67 | With topping | 61.33 |

| Vanilla | 79.56 | Cone | 69.33 | Low sugar | 71.56 | Coated with chocolate sauce | 60.44 |

| Strawberry | 76.00 | Stick | 68.89 | Low fat | 69.33 | With pieces of various fruits | 46.67 |

| Durian | 41.33 | Pack | 49.78 | Natural dye | 68.00 | Coated with chocolate and nuts | 45.78 |

| Blueberry | 24.22 | Sandwich | 23.56 | Natural flavourings | 63.56 | ||

| Caramel | 20.00 | Low calorie | 50.67 | ||||

| Grape | 24.22 | High protein | 48.44 | ||||

| Apple | 8.00 | Organics ingredients | 38.22 | ||||

| Functionality | Usability | Pleasure | |||

|---|---|---|---|---|---|

| Taste | Texture | Packaging Materials | Shape | Health Benefits | Appearance |

| Chocolate | Very soft | Edible | Cup | No preservatives | With topping |

| Vanilla | Soft | Non-edible | Cone | Low sugar | Coated with chocolate sauce |

| Strawberry | Slightly soft | Stick | Low fat | With pieces of various fruits | |

| Durian | |||||

| Product Configurations | Functionality | Usability | Pleasure | |||

|---|---|---|---|---|---|---|

| Taste | Texture | Packaging Materials | Shape | Health Benefits | Appearance | |

| 1 | Durian | Very soft | Non-edible | Cup | Low fat | With topping |

| 2 | Strawberry | Slightly soft | Edible | Cup | No preservatives | With pieces of various fruits |

| 3 | Chocolate | Slightly soft | Edible | Cup | Low fat | With topping |

| 4 | Strawberry | Very soft | Non-edible | Cup | Low sugar | With topping |

| 5 | Chocolate | Very soft | Edible | Cup | No preservatives | With topping |

| 6 | Chocolate | Slightly soft | Non-edible | Stick | Low sugar | Coated with chocolate sauce |

| 7 | Chocolate | Soft | Non-edible | Cup | Low sugar | Coated with chocolate sauce |

| 8 | Vanilla | Slightly soft | Edible | Cone | Low sugar | With topping |

| 9 | Durian | Soft | Edible | Cup | No preservatives | Coated with chocolate sauce |

| 10 | Vanilla | Very soft | Edible | Cone | Low fat | With topping |

| 11 | Strawberry | Very soft | Edible | Cone | No preservatives | Coated with chocolate sauce |

| 12 | Durian | Soft | Edible | Cone | Low sugar | With topping |

| 13 | Chocolate | Soft | Non-edible | Stick | No preservatives | With topping |

| 14 | Chocolate | Very soft | Edible | Cup | Low sugar | Coated with chocolate sauce |

| 15 | Strawberry | Soft | Non-edible | Cone | Low sugar | With topping |

| 16 | Vanilla | Soft | Non-edible | Cup | No preservatives | With pieces of various fruits |

| 17 | Vanilla | Very soft | Non-edible | Stick | No preservatives | Coated with chocolate sauce |

| 18 | Strawberry | Soft | Non-edible | Stick | Low fat | Coated with chocolate sauce |

| 19 | Chocolate | Very soft | Edible | Cone | No preservatives | Coated with chocolate sauce |

| 20 | Durian | Slightly soft | Edible | Cone | No preservatives | Coated with chocolate sauce |

| 21 | Chocolate | Soft | Edible | Cone | No preservatives | With topping |

| 22 | Chocolate | Very soft | Edible | Cone | Low sugar | With pieces of various fruits |

| 23 | Chocolate | Soft | Edible | Cone | Low fat | With pieces of various fruits |

| 24 | Durian | Very soft | Non-edible | Stick | Low sugar | Coated with chocolate sauce |

| 25 | Vanilla | Soft | Edible | Cup | Low sugar | With pieces of various fruits |

| Attribute (Importance Values) | Variant | Utility Estimate |

|---|---|---|

| Taste (42.899) | Chocolate | 2.659 |

| Vanilla | −0.942 | |

| Strawberry | 0.363 | |

| Durian | −2.080 | |

| Shape (13.678) | Cup | 0.524 |

| Cone | −0.134 | |

| Stick | −0.390 | |

| Health (9.133) | No preservatives | 0.491 |

| Low sugar | −0.040 | |

| Low fat | −0.451 | |

| Appearance (14.813) | With topping | 0.403 |

| Coated with chocolate sauce | 0.270 | |

| With pieces of various fruits | −0.674 | |

| Texture (11.168) | Very soft | −0.423 |

| Soft | −0.847 | |

| Slightly soft | −1.270 | |

| Packaging (8.309) | Edible | −1.843 |

| Non-edible | −3.687 | |

| (Constant) | 15.508 | |

| Product Configuration | Total Utility | Ranking | Product Configuration | Total Utility | Ranking |

|---|---|---|---|---|---|

| 1 | 10.791 | 22 | 14 | 16.655 | 2 |

| 2 | 12.102 | 14 | 15 | 11.566 | 18 |

| 3 | 15.530 | 5 | 16 | 10.373 | 24 |

| 4 | 12.648 | 12 | 17 | 10.827 | 21 |

| 5 | 17.319 | 1 | 18 | 10.766 | 23 |

| 6 | 13.050 | 11 | 19 | 16.528 | 3 |

| 7 | 14.387 | 7 | 20 | 10.942 | 20 |

| 8 | 11.682 | 17 | 21 | 16.237 | 4 |

| 9 | 12.023 | 15 | 22 | 15.053 | 6 |

| 10 | 12.118 | 13 | 23 | 14.218 | 9 |

| 11 | 14.232 | 8 | 24 | 9.158 | 25 |

| 12 | 10.967 | 19 | 25 | 11.686 | 16 |

| 13 | 14.137 | 10 |

| Attributes | Dij | Rij | D − R | D + R |

|---|---|---|---|---|

| Taste | 1.007552 | 0.985029 | 0.022522 | 1.992581 |

| Texture | 1.113212 | 0.777655 | 0.335558 | 1.890867 |

| Packaging materials | 1.208472 | 0.799273 | 0.409199 | 2.007745 |

| Shape | 0.835585 | 0.649899 | 0.185686 | 1.485484 |

| Health benefits | 1.361617 | 1.162462 | 0.199155 | 2.524079 |

| Appearance | 0.685985 | 1.838104 | −1.152119 | 2.524089 |

| Attributes | Taste | Texture | Packaging Materials | Shape | Health Benefits | Appearance |

|---|---|---|---|---|---|---|

| Taste | √ | √ | √ | √ | ||

| Texture | √ | √ | √ | √ | ||

| Packaging materials | √ | √ | √ | √ | ||

| Shape | √ | √ | √ | |||

| Health benefits | √ | √ | √ | √ | ||

| Appearance | √ |

| Modules | Variants |

|---|---|

| 1 | Chocolate taste, very soft textured, no preservatives |

| 2 | Chocolate taste, very soft textured, low sugar |

| 3 | Chocolate taste, soft textured, no preservatives |

| 4 | Chocolate taste, slightly soft textured, low fat |

| 5 | Chocolate taste, soft textured, low sugar |

| 6 | Strawberry taste, very soft textured, no preservatives |

| 7 | Chocolate taste, soft textured, low fat |

| 8 | Chocolate taste, slightly soft textured, low sugar |

| 9 | Strawberry taste, very soft textured, low sugar |

| 10 | Vanilla taste, very soft textured, low fat |

| 11 | Strawberry taste, slightly soft textured, no preservatives |

| 12 | Durian taste, soft textured, no preservatives |

| 13 | Vanilla taste, soft textured, low sugar |

| 14 | Vanilla taste, slightly soft textured, low sugar |

| 15 | Strawberry taste, soft textured, low sugar |

| 16 | Durian taste, soft textured, low sugar |

| 17 | Durian taste, slightly soft textured, no preservatives |

| 18 | Vanilla taste, very soft textured, no preservatives |

| 19 | Durian taste, very soft textured, low fat |

| 20 | Strawberry taste, soft textured, low fat |

| 21 | Vanilla taste, soft textured, no preservatives |

| 22 | Durian taste, very soft textured, low sugar |

| Modules | Variants |

|---|---|

| 1 | Edible cup |

| 2 | Edible cone |

| 3 | Non-edible cup |

| 4 | Non-edible stick |

| 5 | Non-edible cone |

| Modules | Variants |

|---|---|

| 1 | Topping |

| 2 | Chocolate sauce |

| 3 | Pieces of various fruits |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wedowati, E.R.; Singgih, M.L.; Gunarta, I.K. Determination of Modules in Pleasurable Design to Fulfil Customer Requirements and Provide a Customized Product in the Food Industry. Designs 2020, 4, 7. https://doi.org/10.3390/designs4010007

Wedowati ER, Singgih ML, Gunarta IK. Determination of Modules in Pleasurable Design to Fulfil Customer Requirements and Provide a Customized Product in the Food Industry. Designs. 2020; 4(1):7. https://doi.org/10.3390/designs4010007

Chicago/Turabian StyleWedowati, Endang Retno, Moses Laksono Singgih, and I Ketut Gunarta. 2020. "Determination of Modules in Pleasurable Design to Fulfil Customer Requirements and Provide a Customized Product in the Food Industry" Designs 4, no. 1: 7. https://doi.org/10.3390/designs4010007

APA StyleWedowati, E. R., Singgih, M. L., & Gunarta, I. K. (2020). Determination of Modules in Pleasurable Design to Fulfil Customer Requirements and Provide a Customized Product in the Food Industry. Designs, 4(1), 7. https://doi.org/10.3390/designs4010007