Process Modelling of Geothermal Drilling System Using Digital Twin for Real-Time Monitoring and Control

Abstract

:1. Introduction

2. Literature Review

2.1. Energy and Economic Benefits of Pursuing Geothermal Drilling

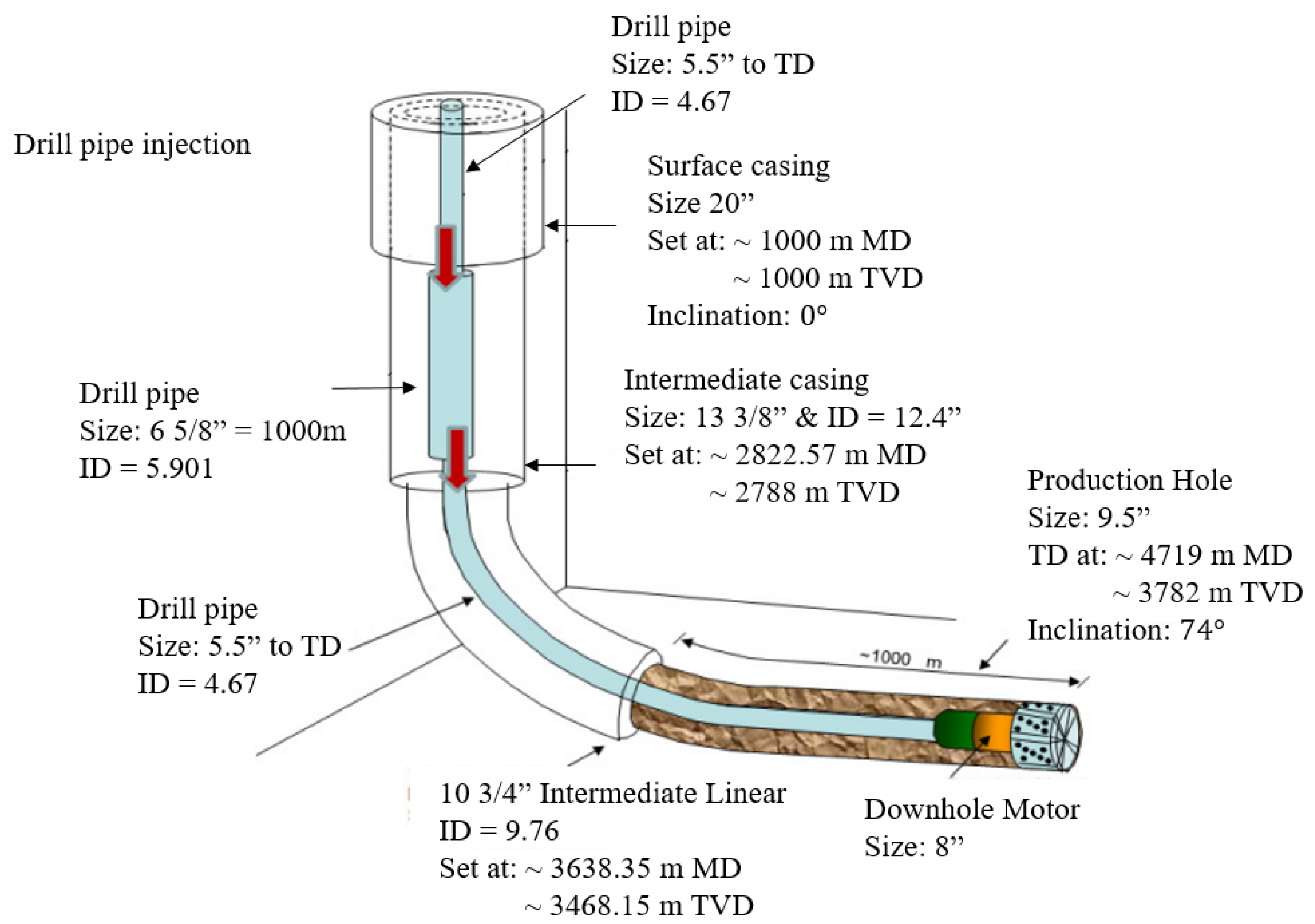

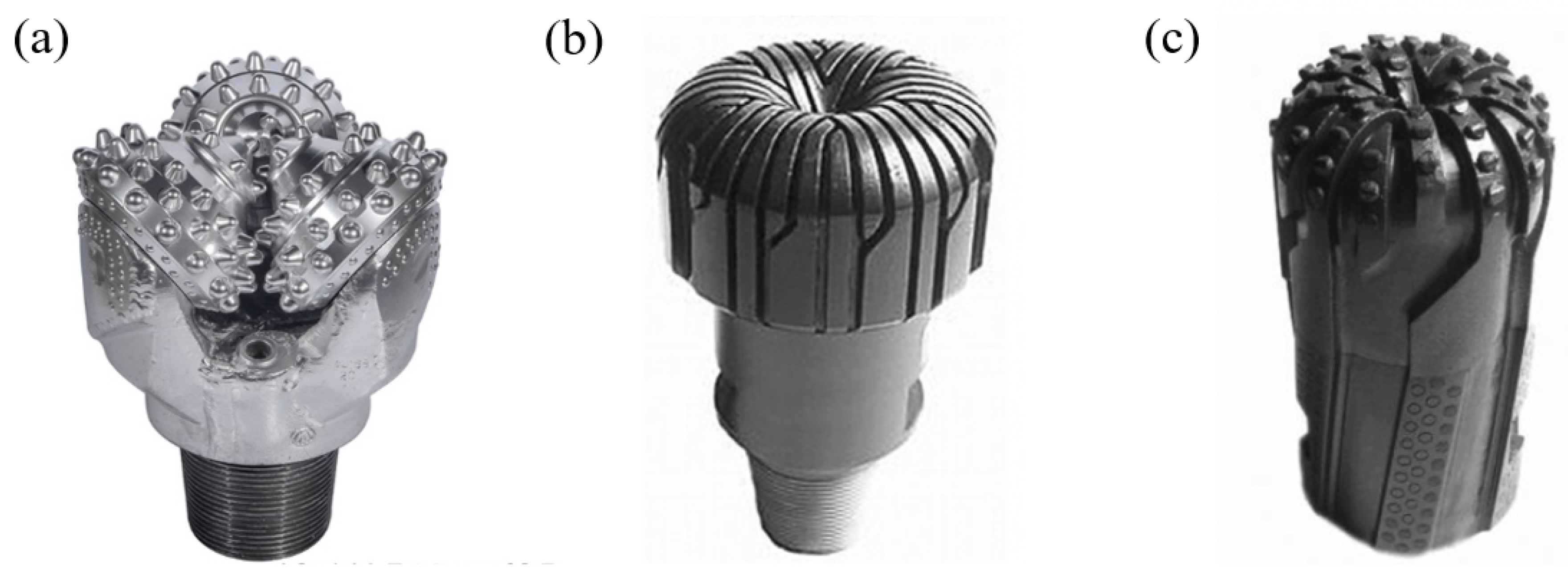

2.2. Geothermal Drilling Challenges

2.3. Current and Potential Solutions for Geothermal Cost Reduction

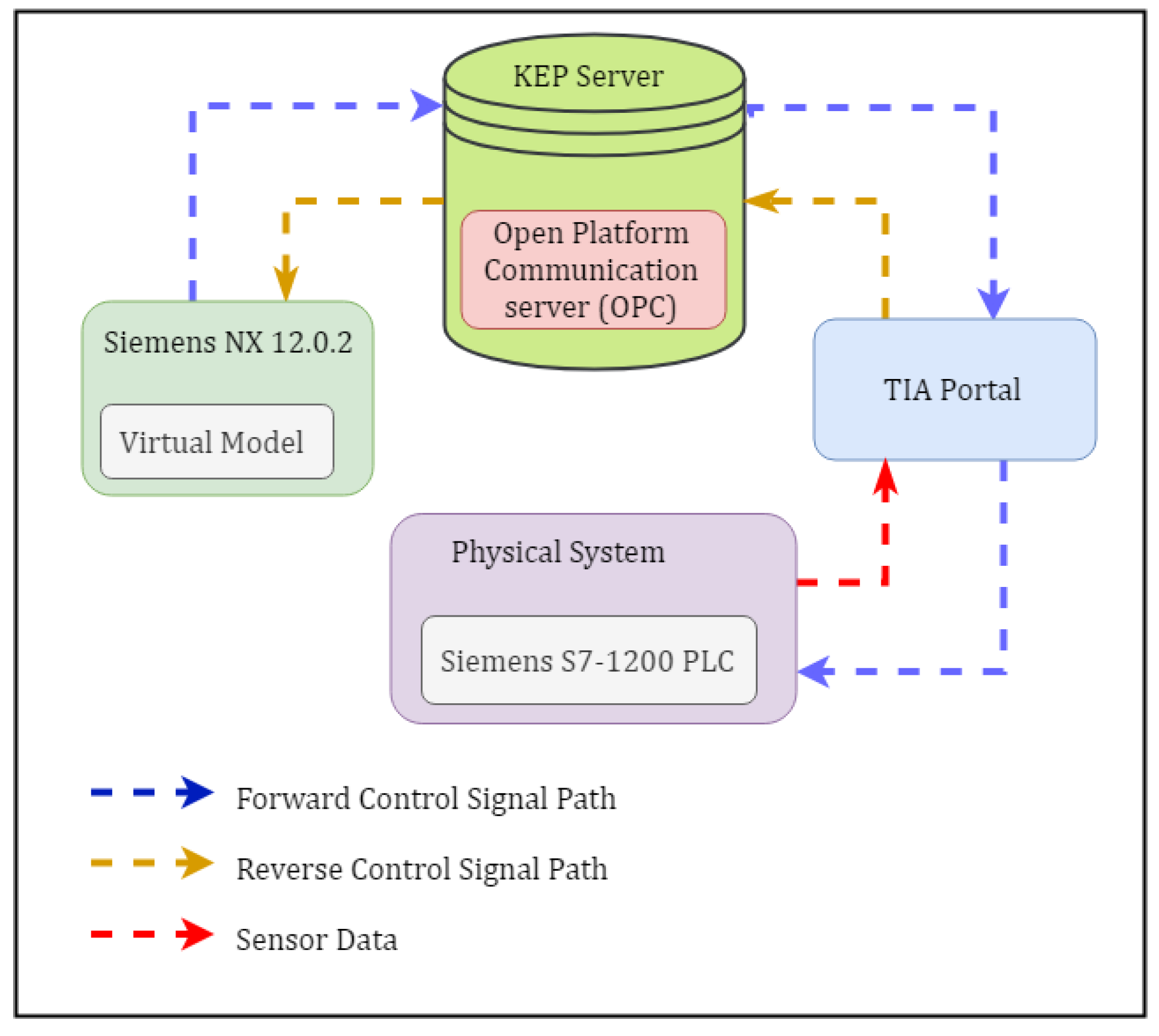

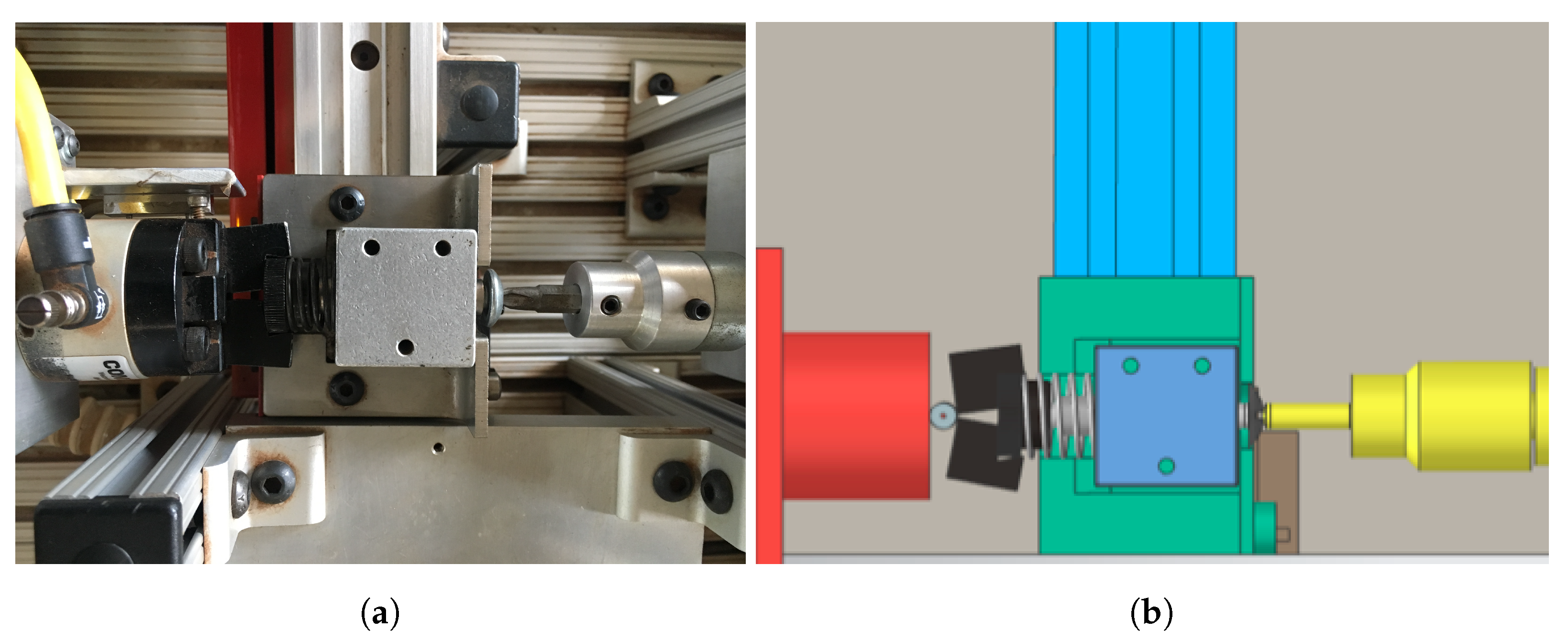

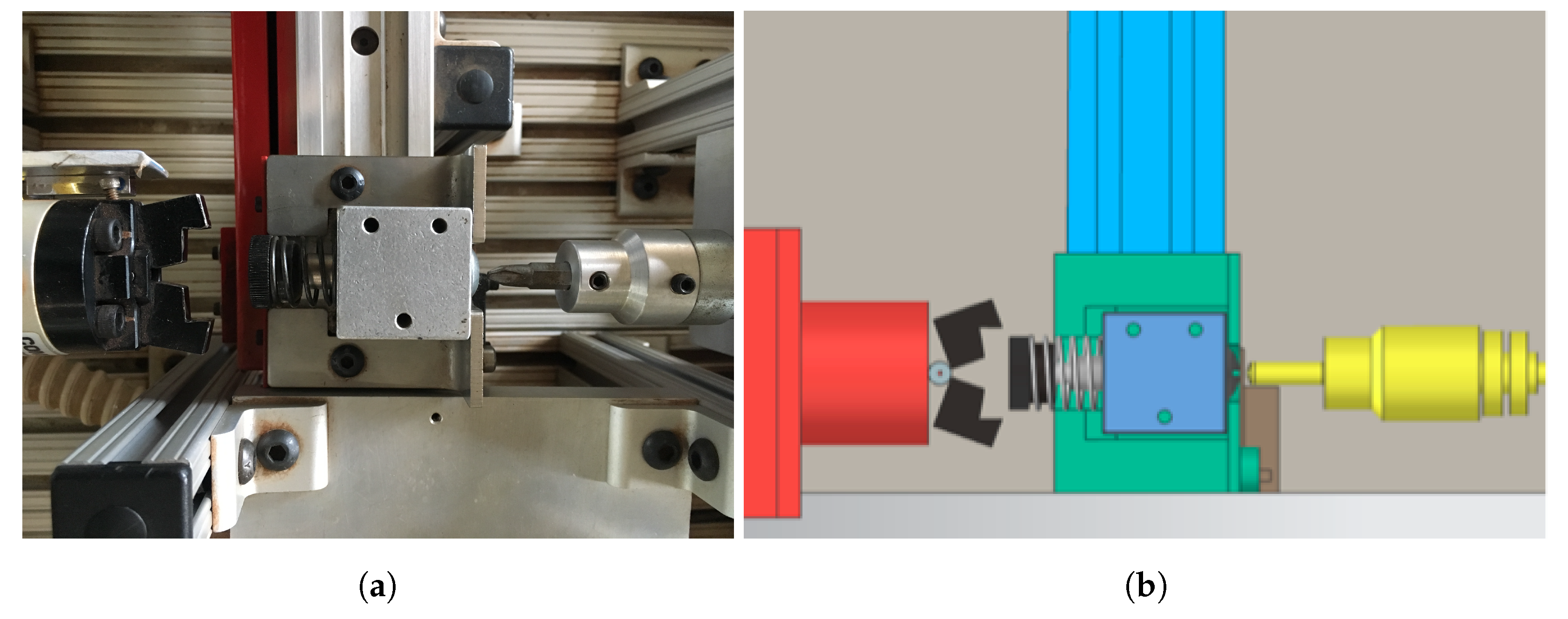

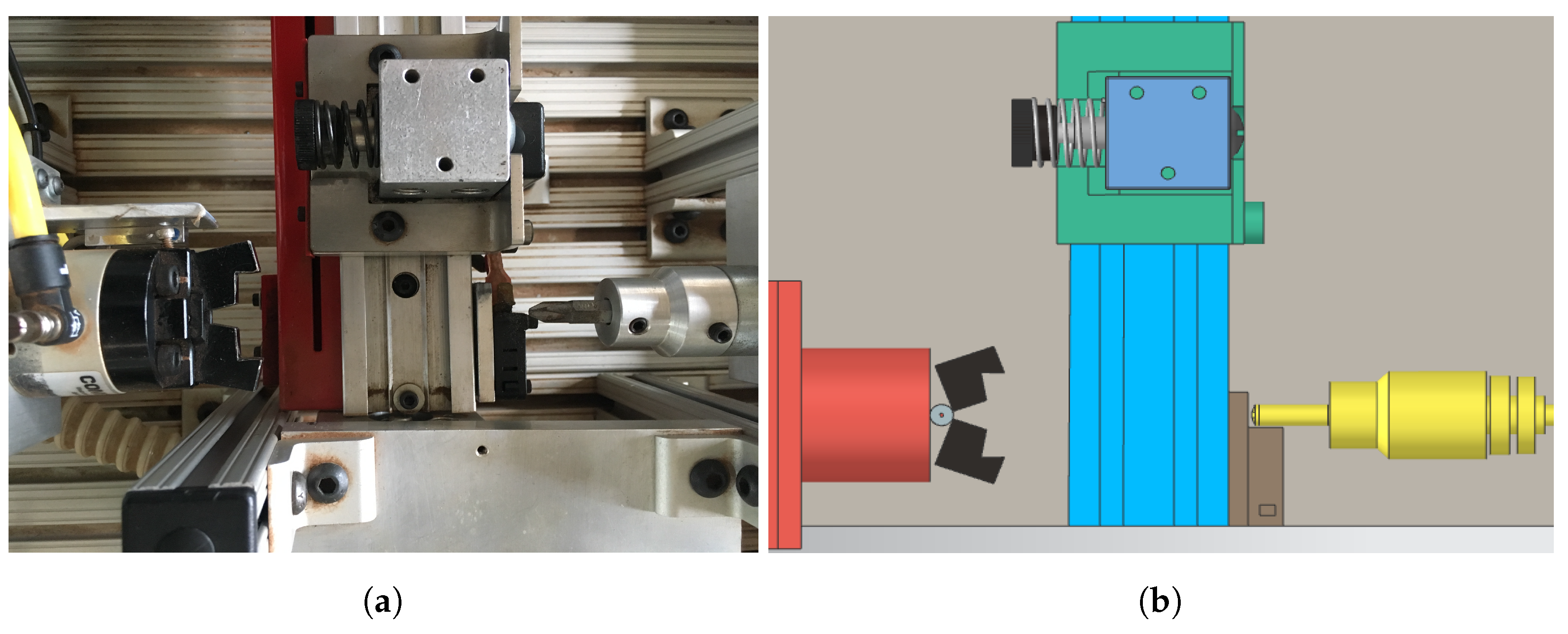

3. Design of the Digital Twin for the Torquing Station in Mechatronic Assembly System

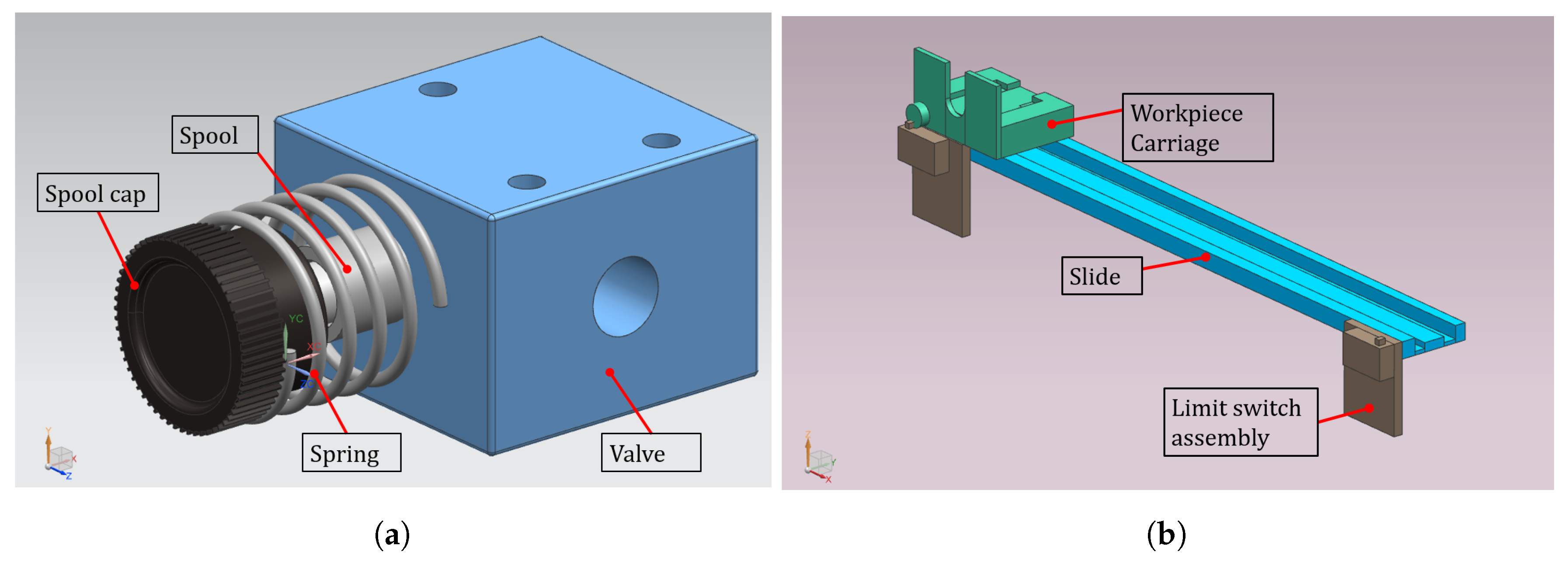

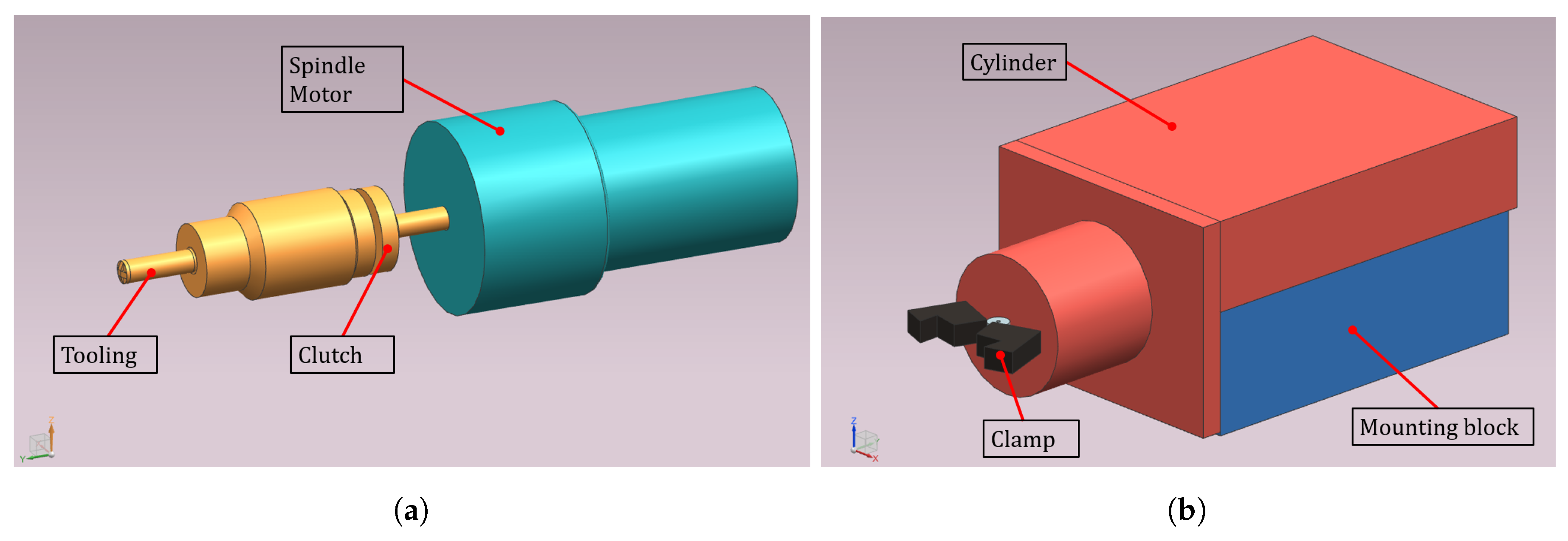

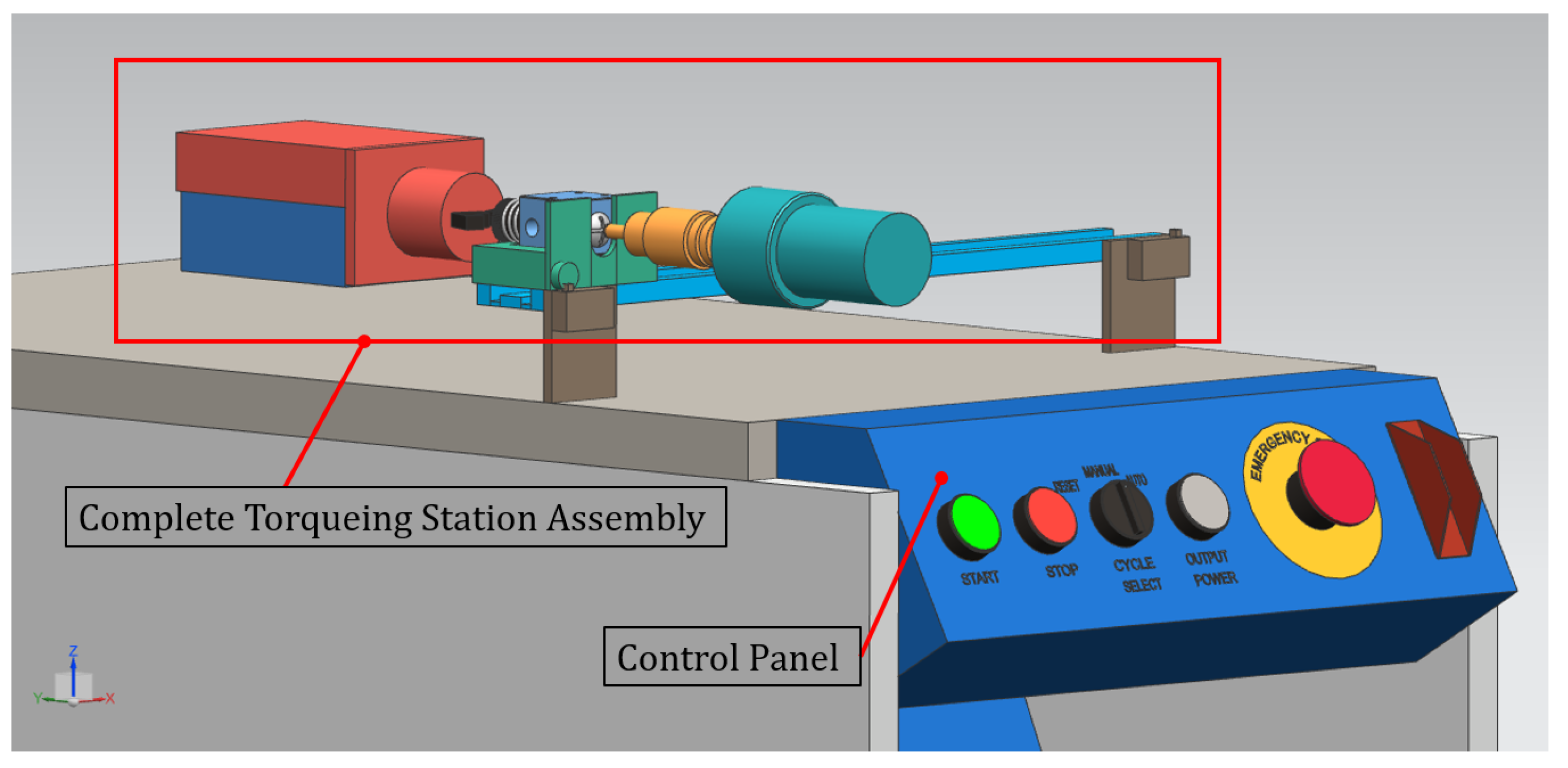

3.1. Virtual Model

3.2. Communication Platform

3.3. PLC Programming Software-TIA Portal

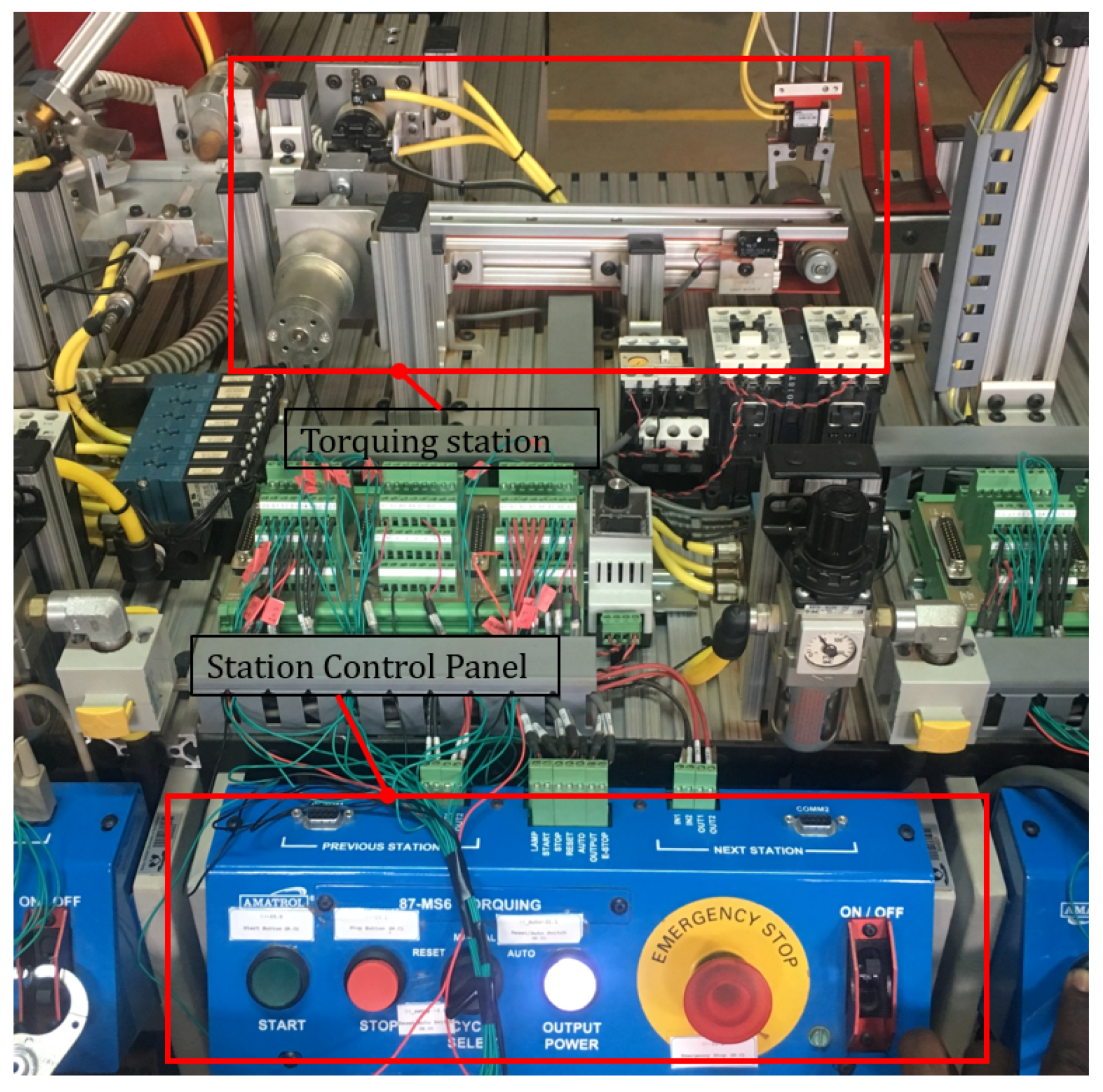

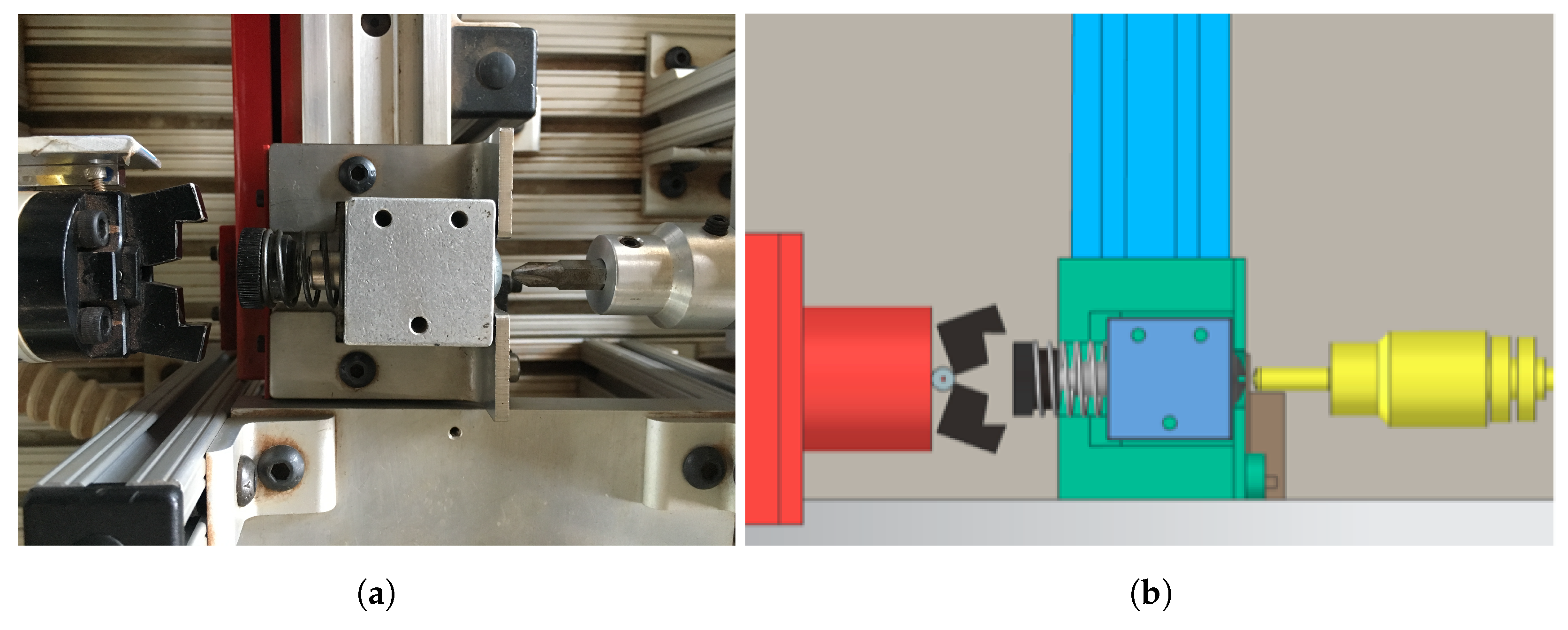

3.4. Physical System—Mechatronic Torquing Station

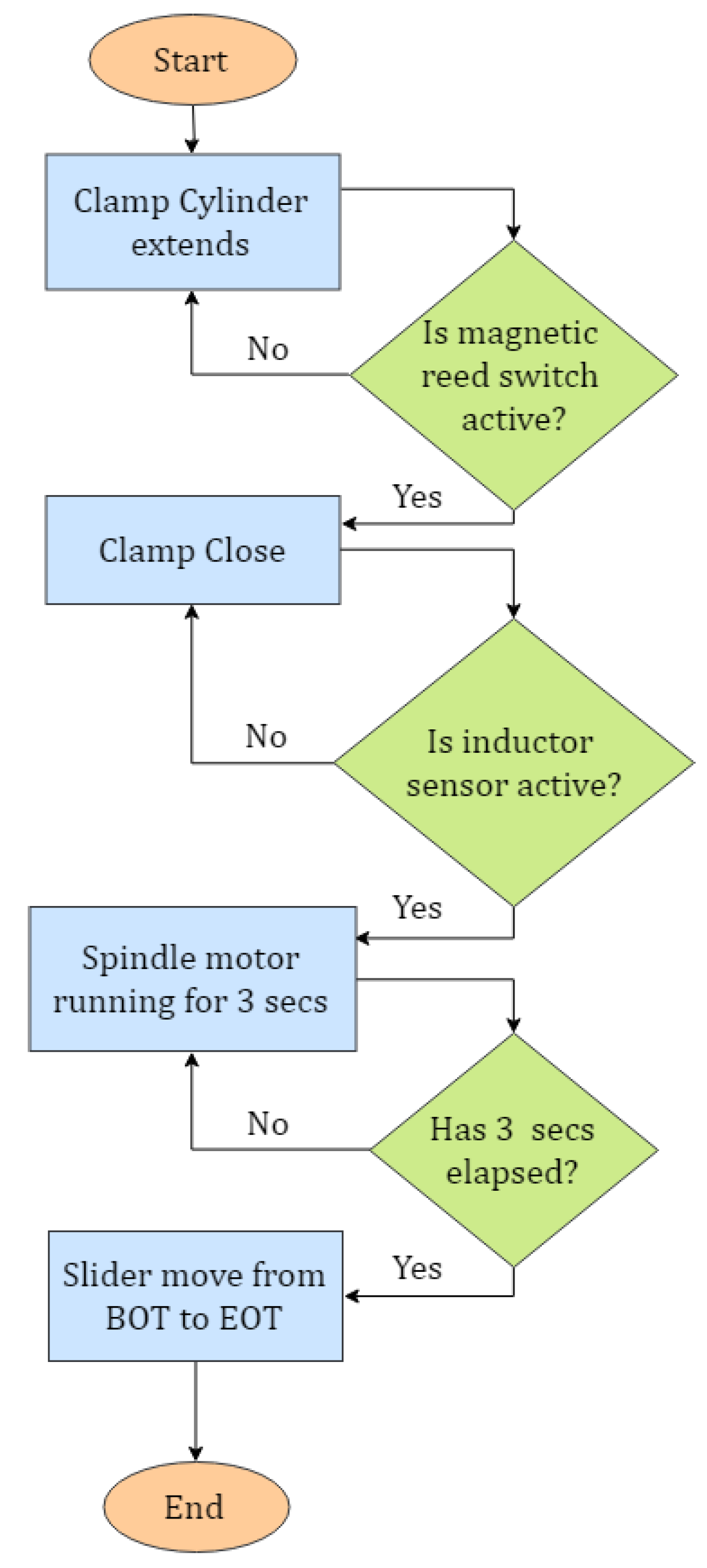

- Automatic Mode: This is the normal autonomous system operation mode, where the machine runs without interference by the user.

- Manual Mode: In the event, calibration, repair or debugging is required, the process sequence steps are controlled directly by the user who manually drives the process from one step to the next.

- Reset Mode: During Automatic or Manual mode operation, the reset button can be pressed. This returns the system to its initial position.

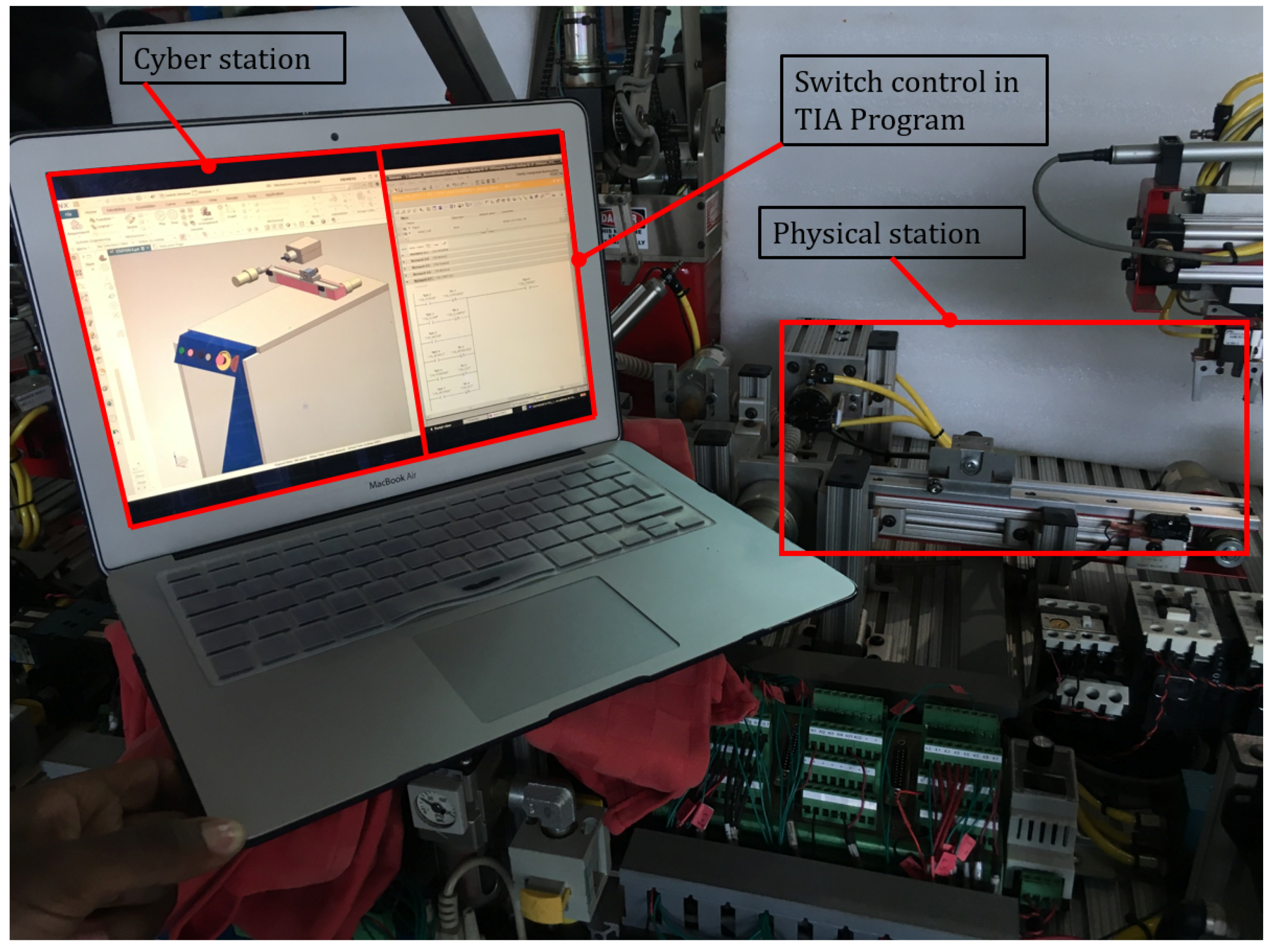

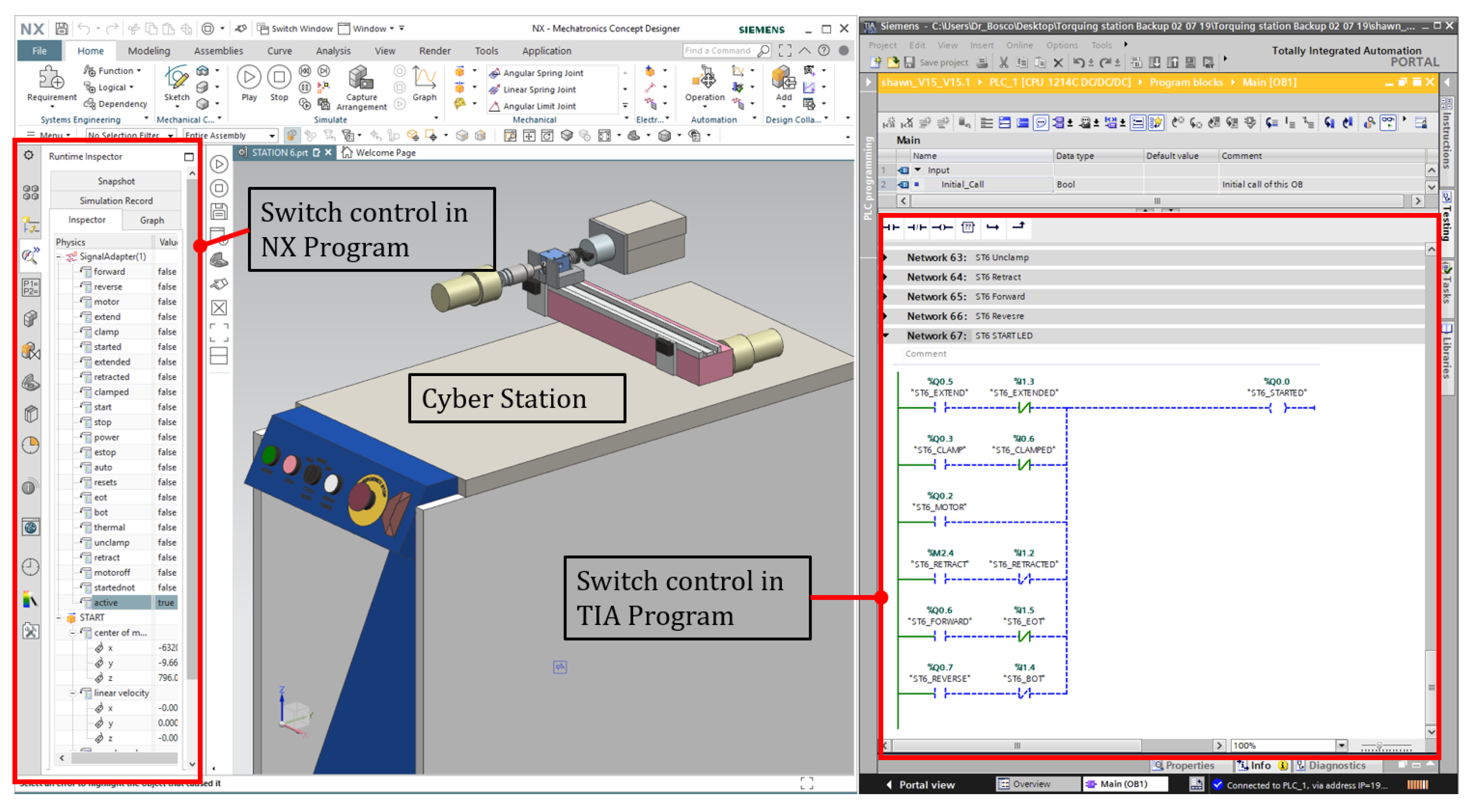

4. Implementation of the Digital Twin of a Mechatronic Assembly System

4.1. Virtual Model—CAD Design

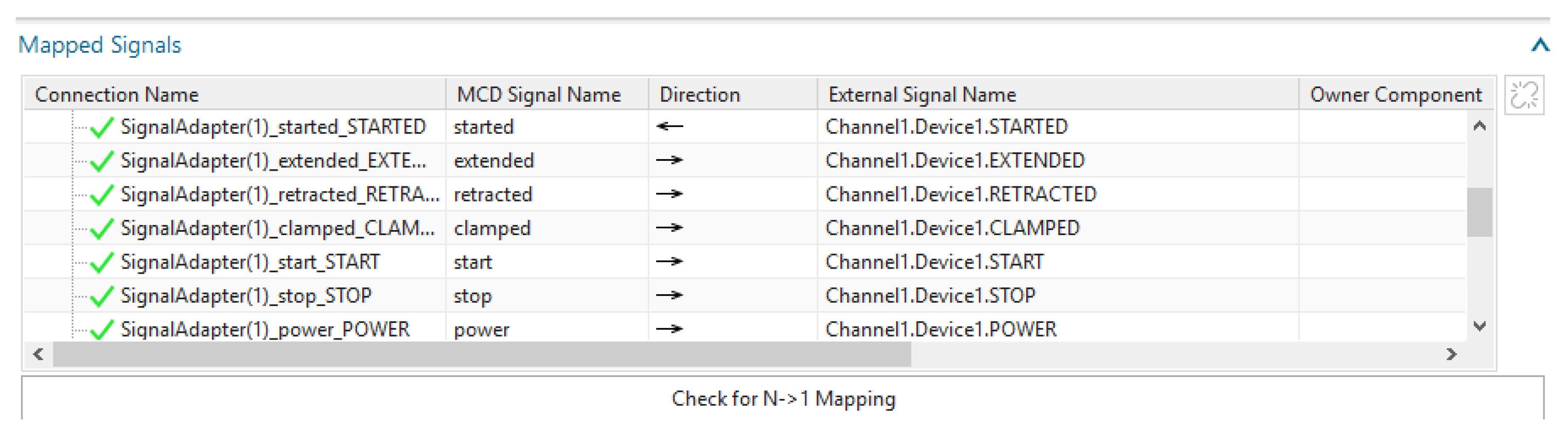

4.2. Communication

4.3. Control Sequence

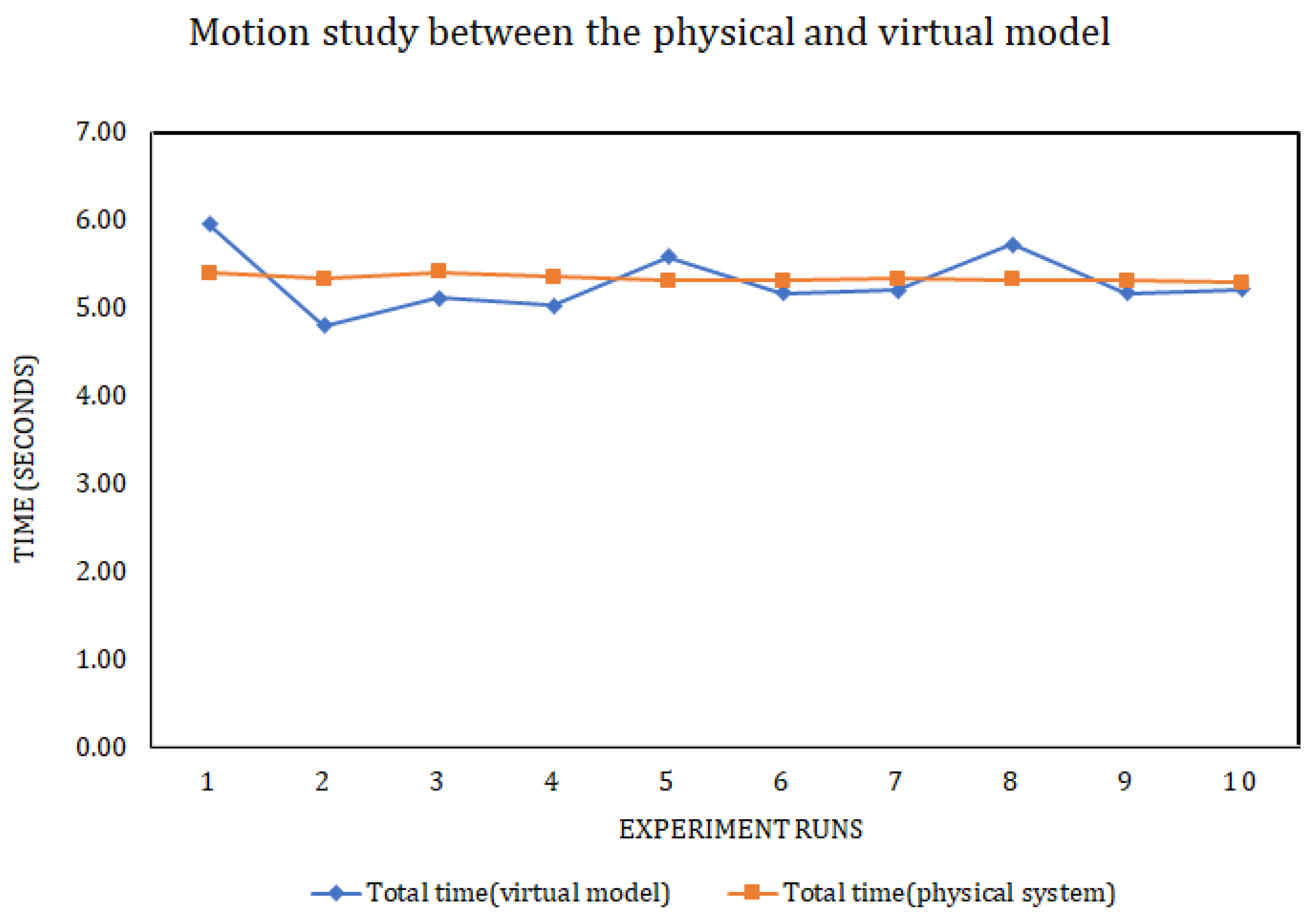

4.4. Motion Study

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lasi, H.; Fettke, P.; Kemper, H.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Qinglin, Q.; Rei, T.; Ying, Z.; Dongming, Z. Digital Twin Service towards Smart Manufacturing. 51st CIRP Conf. Manuf. Syst. 2018, 72, 237–242. [Google Scholar]

- Fei, T.; Lasi Meng, Z.; Nee, A.Y.C. Chapter 2: Application of Digital Twin. In Digital Twin Driven Smart Manufacturing; Elsevier: Amsterdam, The Netherlands, 2019; pp. 29–55. [Google Scholar]

- Repubic of Kenya, Chapter 4: Assessment of Natural Energy Resources in Kenya. In Updated Least Cost Power Development Plan (Kenya Vision 2030) Study Period: 2017–2037; Government of Kenya: Nairobi, Kenya, 2018; pp. 55–58.

- Capuano, L. Chapter 5: Geothermal Well Drilling. In Geothermal Power Generation; Capuano Engineering Co: Santa Rosa, CA, USA, 2016; pp. 107–139. [Google Scholar]

- Lukawaski, M.; Anderson, B.; Augustine, C.; Capuano, L.; Beckers, K.; Livesay, B.; Tester, J. Cost analysis of oil, gas, and geothermal well drilling. J. Pet. Sci. Eng. 2018, 118, 1–14. [Google Scholar] [CrossRef]

- Lyons, W.; Plisga, G.; Lorenz, M. Chapter 4: Drilling and Well completions. In Standard Handbook of Petroleum and Natural Gas Engineering; Elsevier: Amsterdam, The Netherlands, 2015; pp. 1–584. [Google Scholar]

- Sammat, E.; O’Shea, S.; Innes, G. Successful Controlled Pressure Drilling Application in a Geothermal Field. In Proceedings of the SPE/IADC Managed Pressured Drilling and Under-balanced Operations Conference and Exhibition, Milan, Italy, 20–21 March 2012. [Google Scholar]

- Miyazaki, K.; Ohno, T.; Karasawa, H.; Imaizumi, H. Performance of polycrystalline diamond compact bit based on laboratory tests assuming geothermal well drilling. Geothermics 2019, 80, 185–194. [Google Scholar] [CrossRef]

- Cai, Y.; Starley, B.; Cohen, P.; Lee, Y. Sensor data and information fusion to construct digital-twins virtual machine tools for cyber-physical manufacturing. Procedia Manuf. 2017, 10, 1031–1042. [Google Scholar] [CrossRef]

- Haag, S.; Anderl, R. Digital twin—Proof of concept. Manuf. Lett. 2018, 15, 64–66. [Google Scholar] [CrossRef]

| Runs | Physical Station | Virtual Station | Time Lag (Error) |

|---|---|---|---|

| Time in Seconds | Time in Seconds | Time in Seconds | |

| 1 | 5.39 | 5.95 | 0.56 |

| 2 | 5.33 | 4.79 | 0.54 |

| 3 | 5.40 | 5.11 | 0.29 |

| 4 | 5.35 | 5.02 | 0.33 |

| 5 | 5.31 | 5.58 | 0.27 |

| 6 | 5.31 | 5.17 | 0.14 |

| 7 | 5.33 | 5.20 | 0.13 |

| 8 | 5.32 | 5.72 | 0.40 |

| 9 | 5.31 | 5.17 | 0.14 |

| 10 | 5.21 | 5.21 | 0.08 |

| Mean | 5.2920 | 5.3340 | 0.2880 |

| STD | 0.3501 | 0.0360 | 0.3458 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osinde, N.O.; Byiringiro, J.B.; Gichane, M.M.; Smajic, H. Process Modelling of Geothermal Drilling System Using Digital Twin for Real-Time Monitoring and Control. Designs 2019, 3, 45. https://doi.org/10.3390/designs3030045

Osinde NO, Byiringiro JB, Gichane MM, Smajic H. Process Modelling of Geothermal Drilling System Using Digital Twin for Real-Time Monitoring and Control. Designs. 2019; 3(3):45. https://doi.org/10.3390/designs3030045

Chicago/Turabian StyleOsinde, Nahashon O., Jean B. Byiringiro, Michael M. Gichane, and Hasan Smajic. 2019. "Process Modelling of Geothermal Drilling System Using Digital Twin for Real-Time Monitoring and Control" Designs 3, no. 3: 45. https://doi.org/10.3390/designs3030045

APA StyleOsinde, N. O., Byiringiro, J. B., Gichane, M. M., & Smajic, H. (2019). Process Modelling of Geothermal Drilling System Using Digital Twin for Real-Time Monitoring and Control. Designs, 3(3), 45. https://doi.org/10.3390/designs3030045