A Study of the Mixing Performance of Different Impeller Designs in Stirred Vessels Using Computational Fluid Dynamics

Abstract

1. Introduction

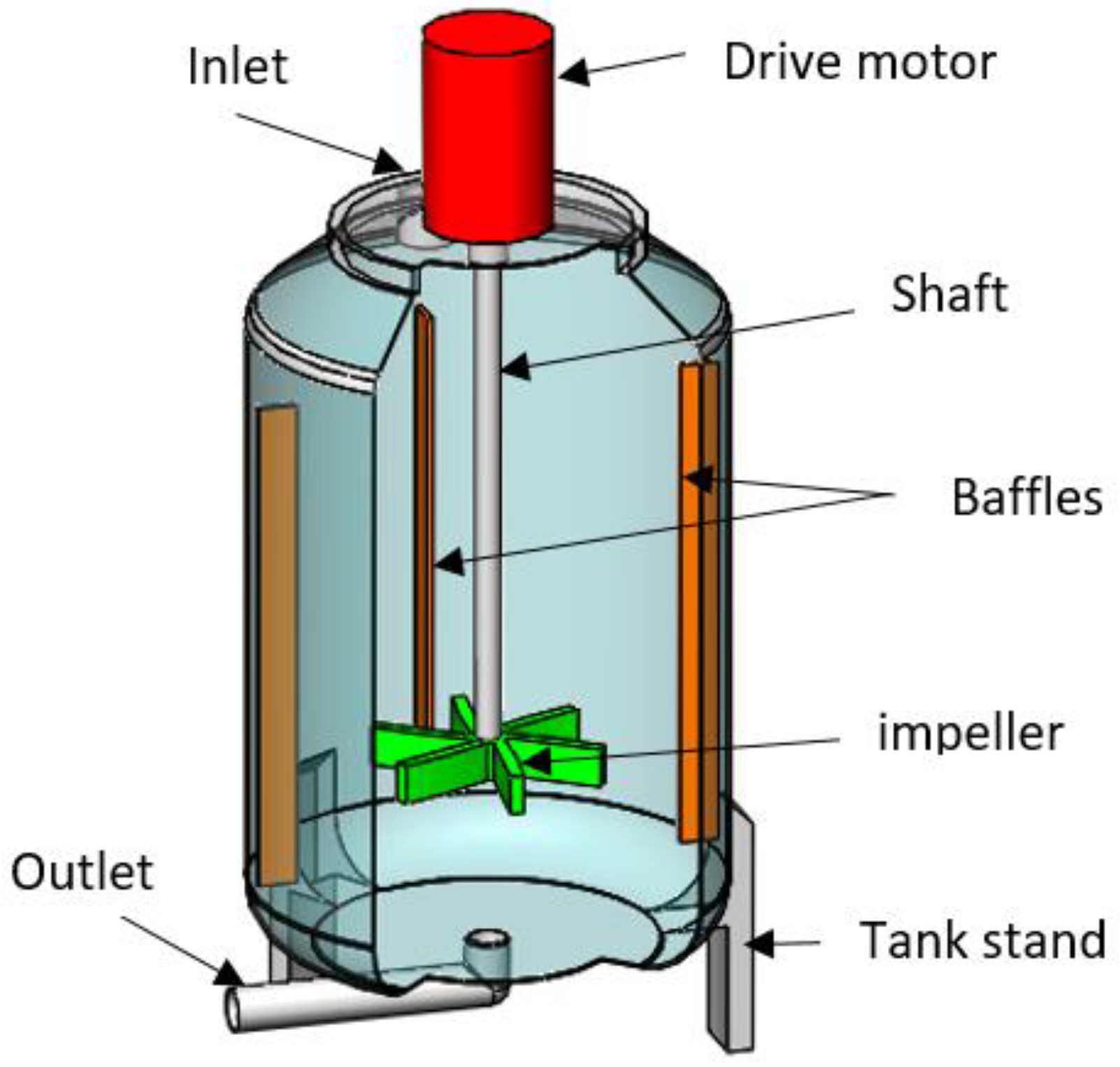

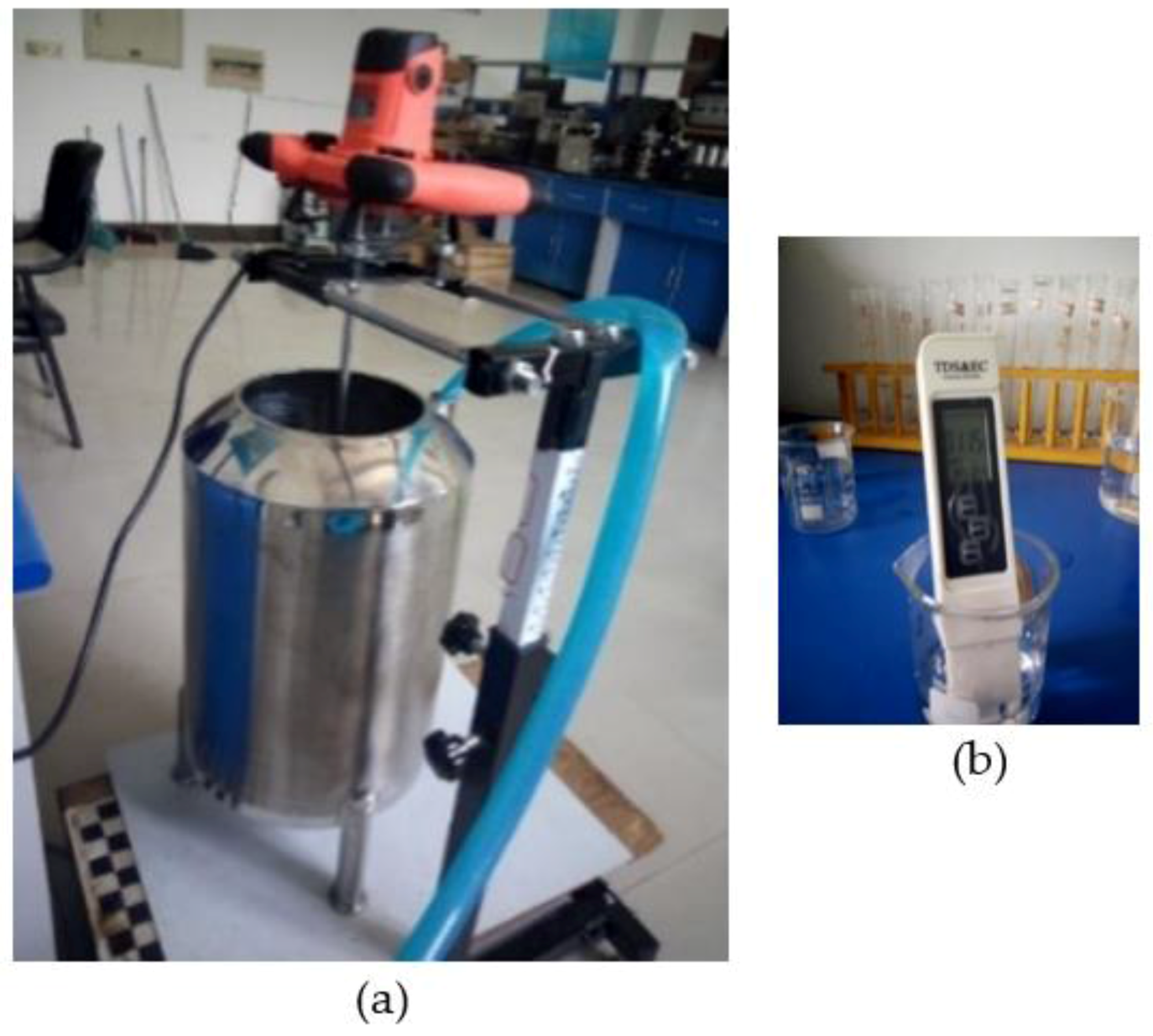

2. Materials and Methods

2.1. Experimental Set-Up

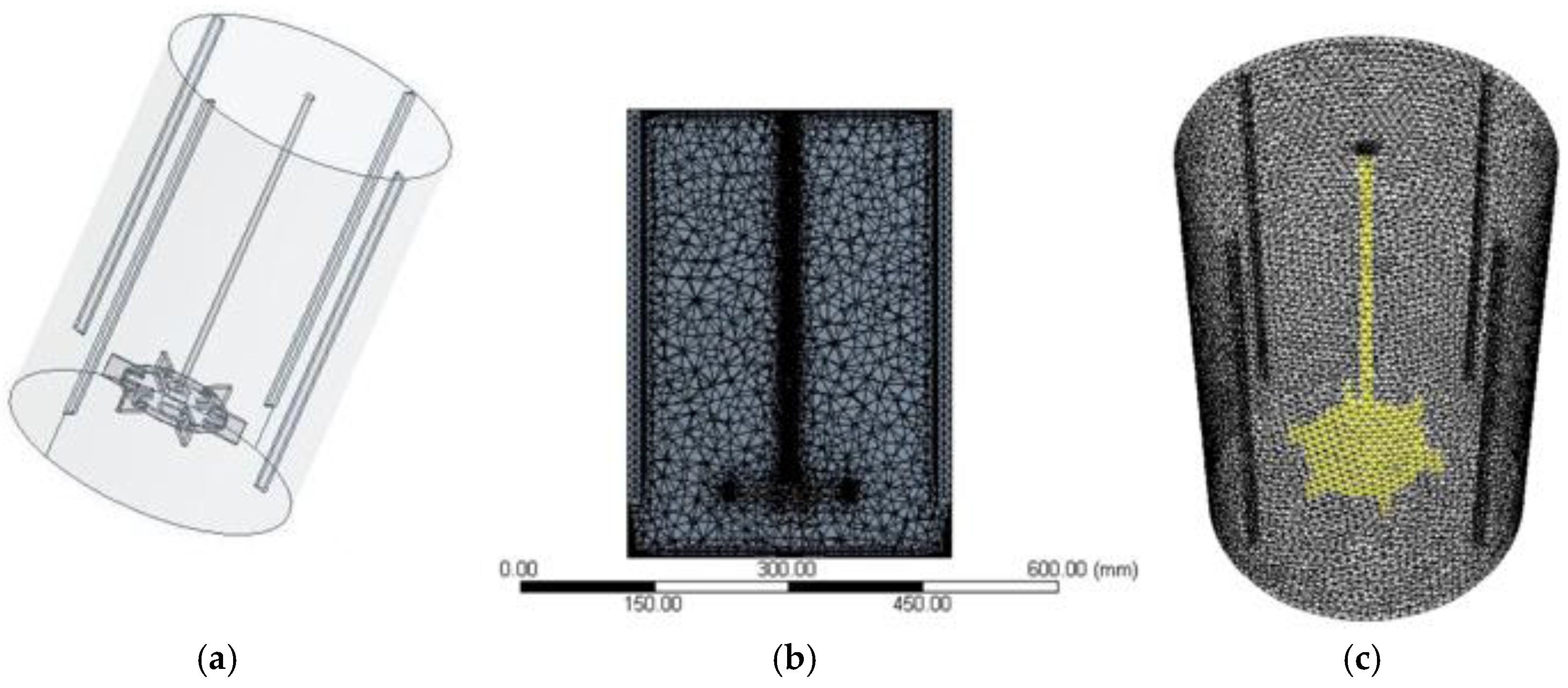

2.2. Numerical Modeling

2.2.1. Meshing and Pre-Processing

2.2.2. Simulation Set up and Computation

3. Results and Discussion

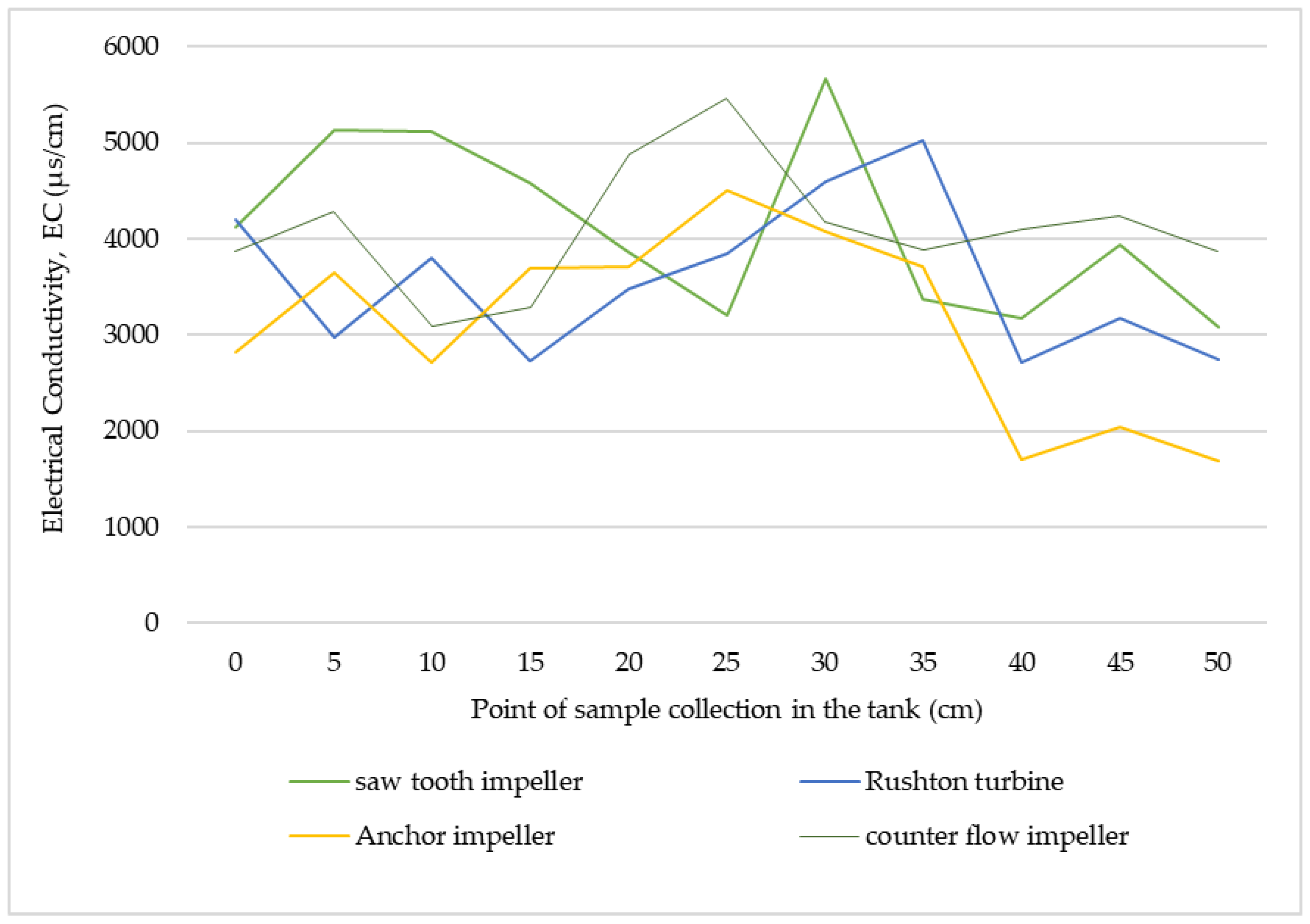

3.1. Analysis of the Experimental Concentration Distribution

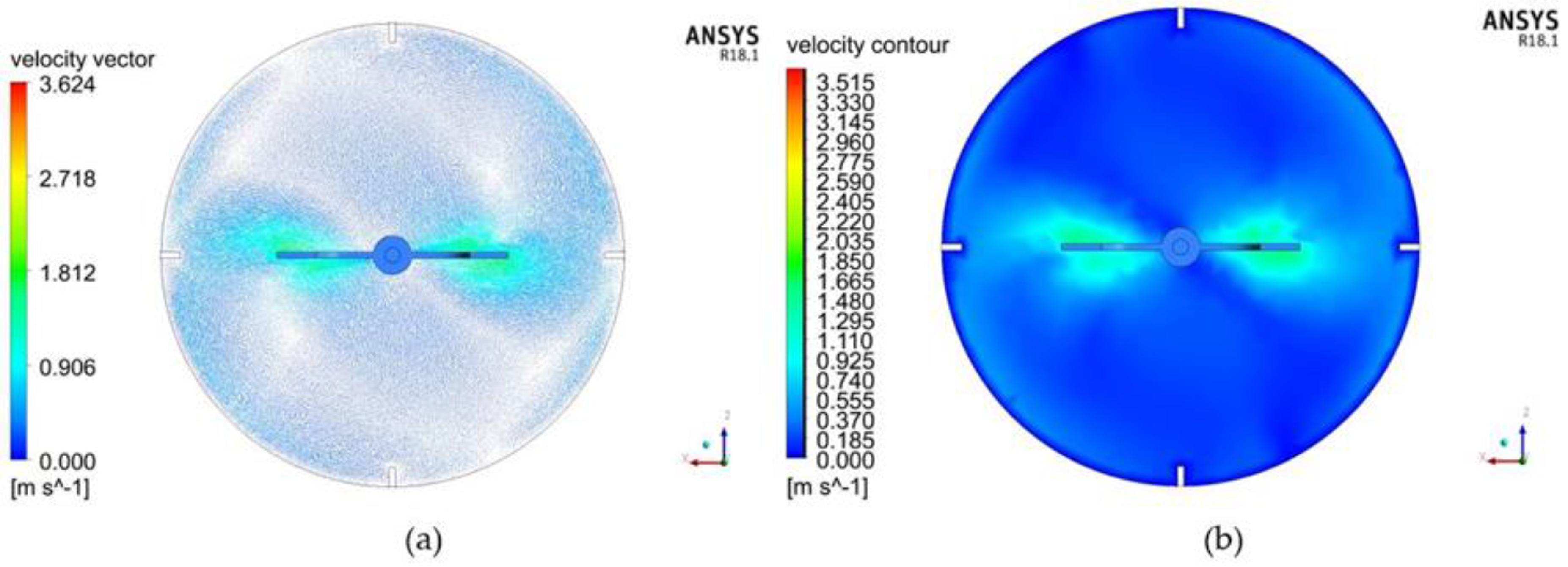

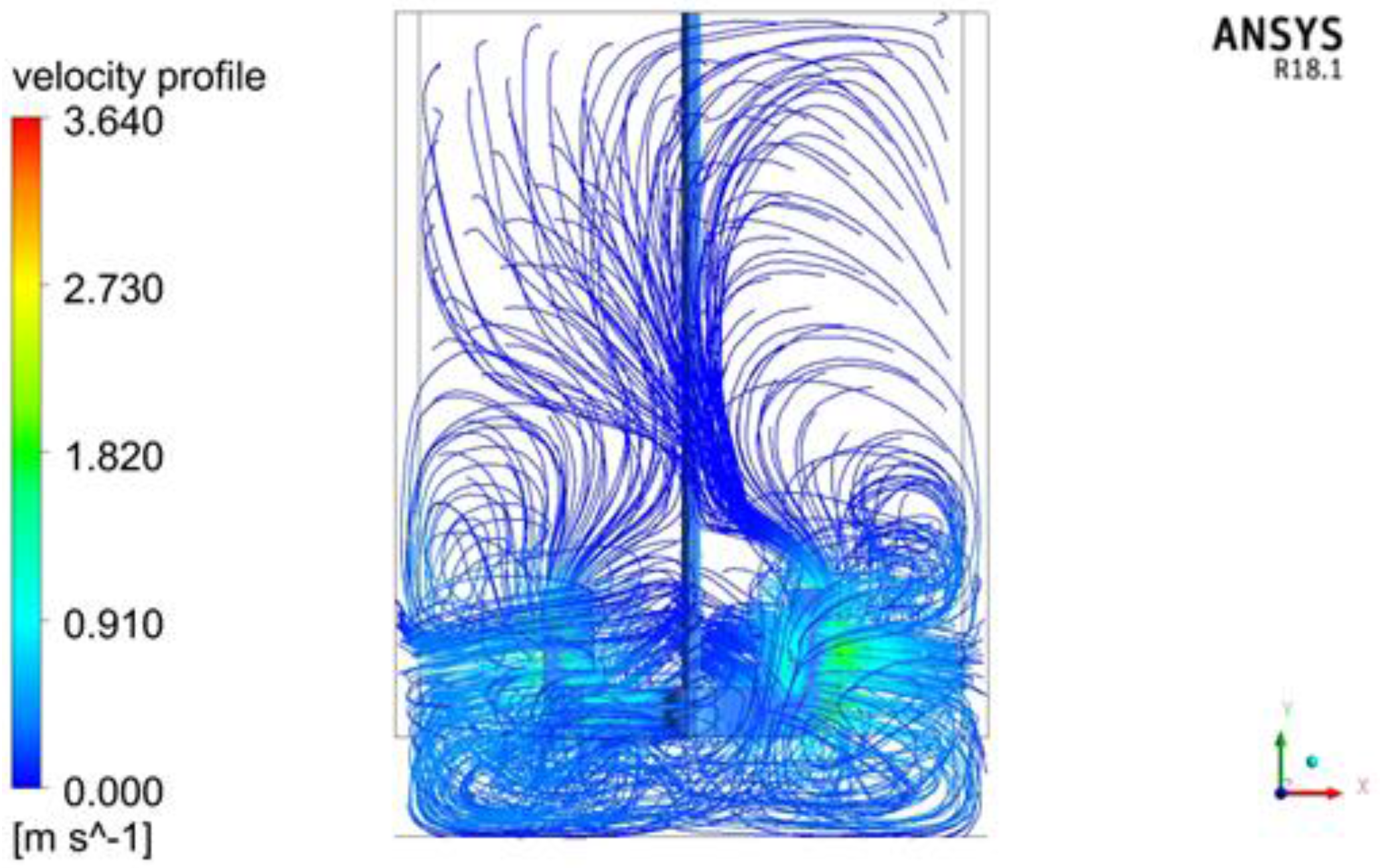

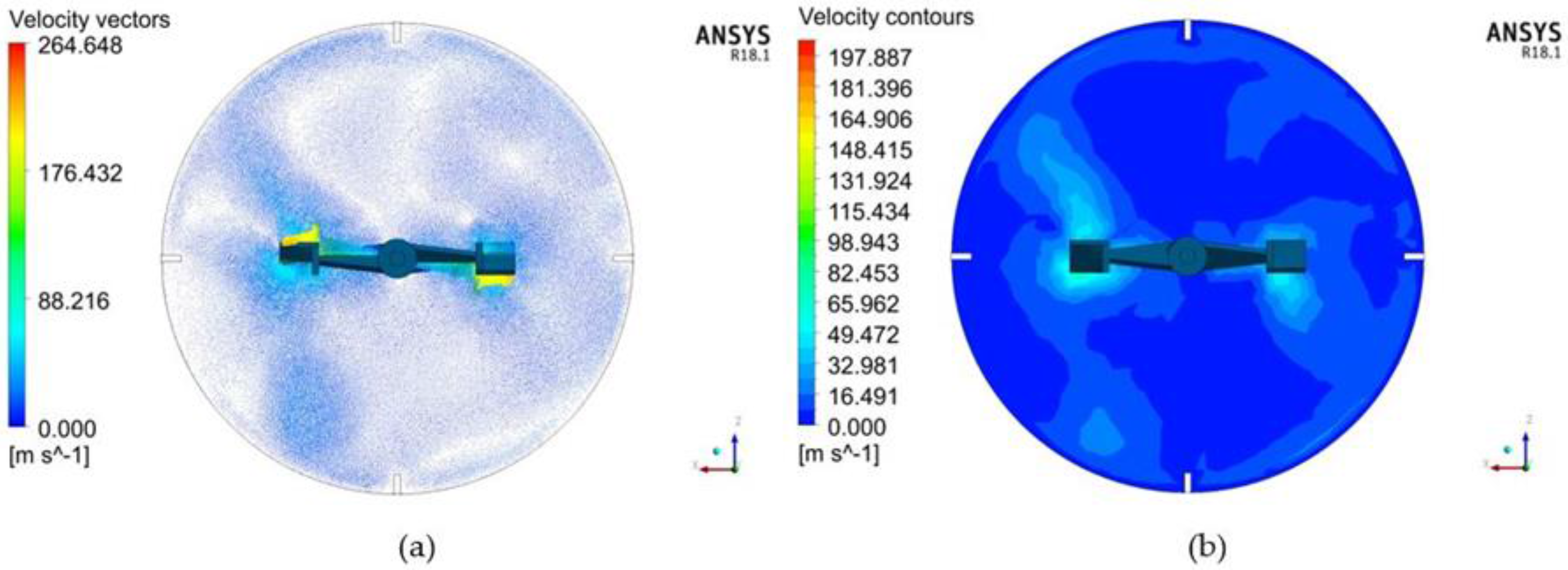

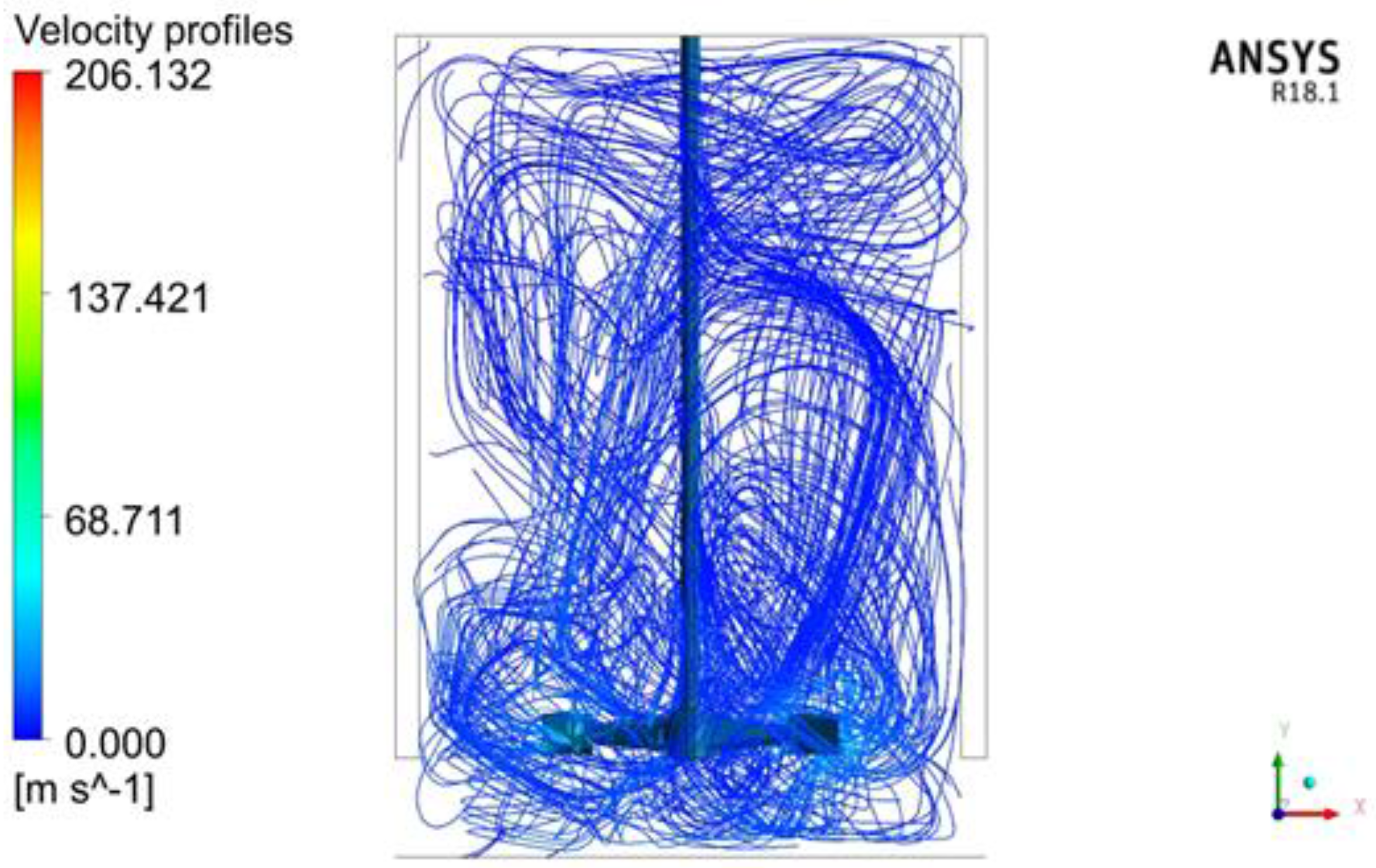

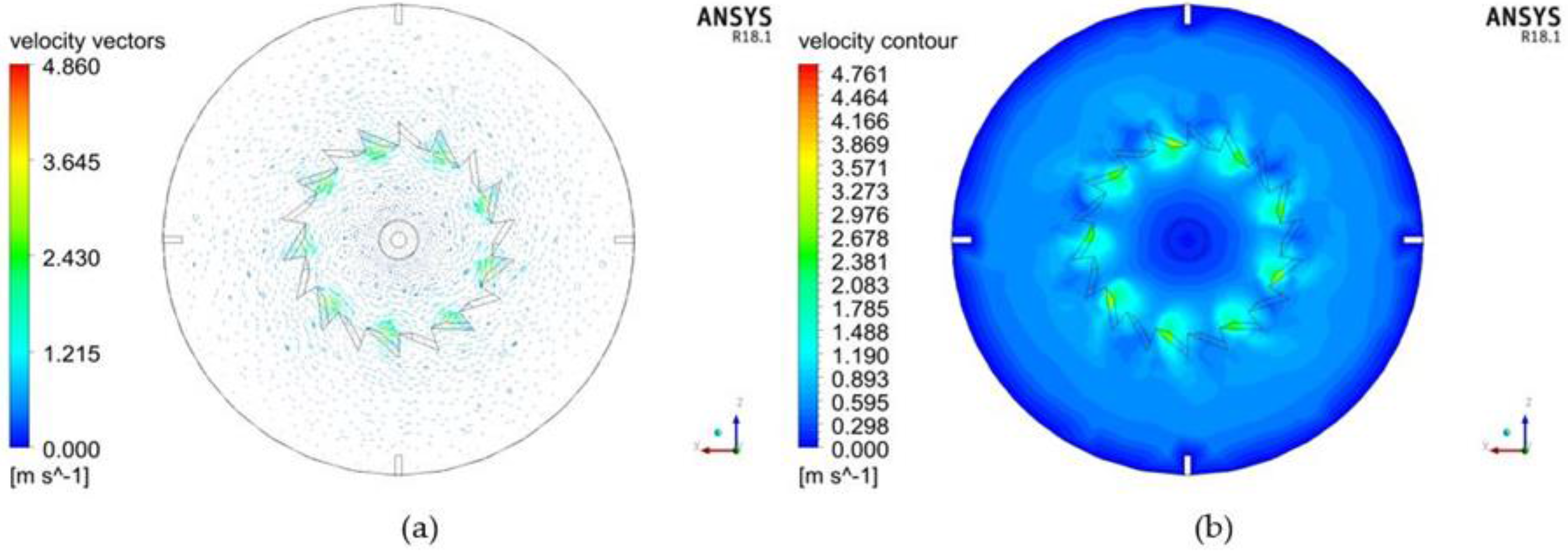

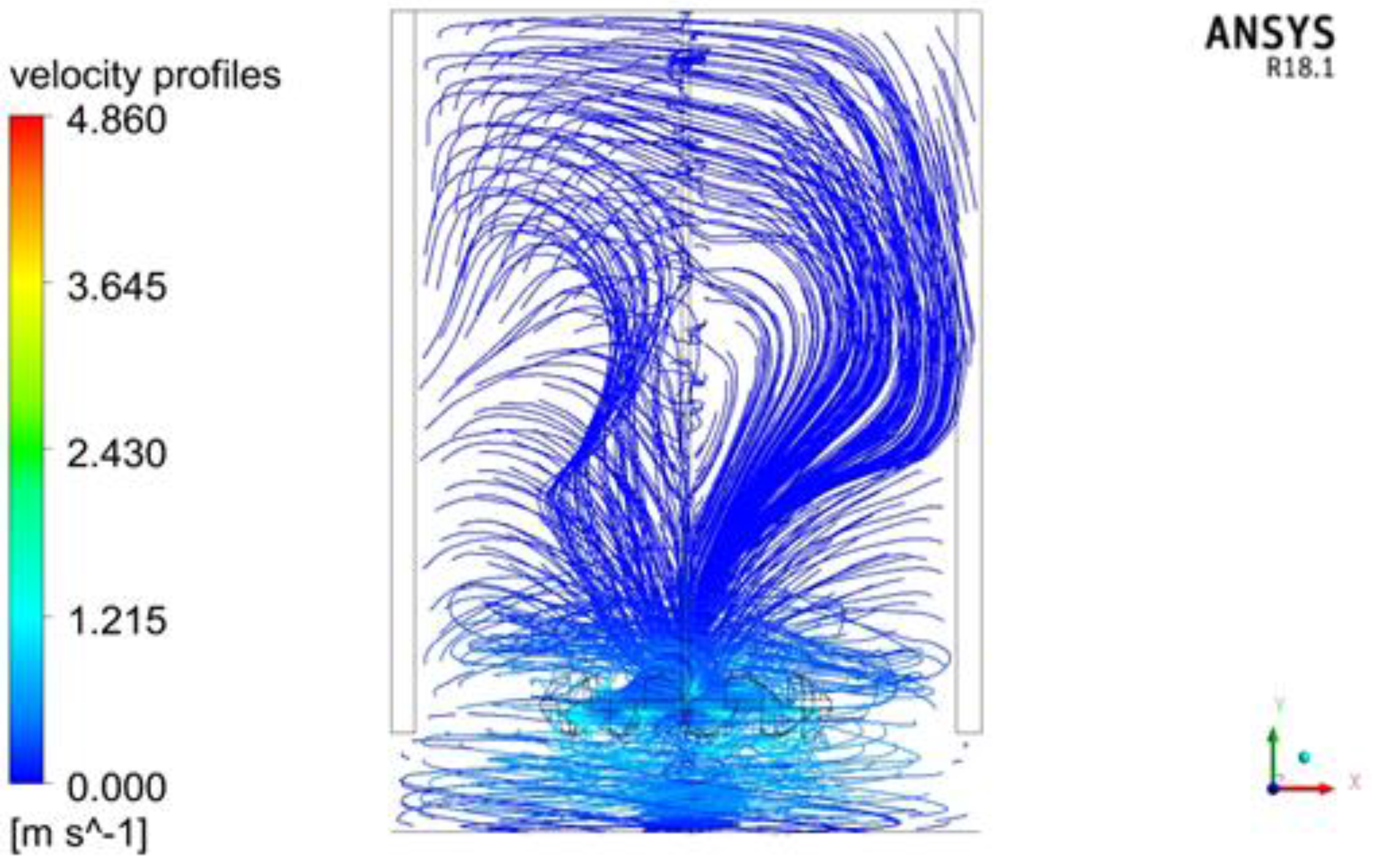

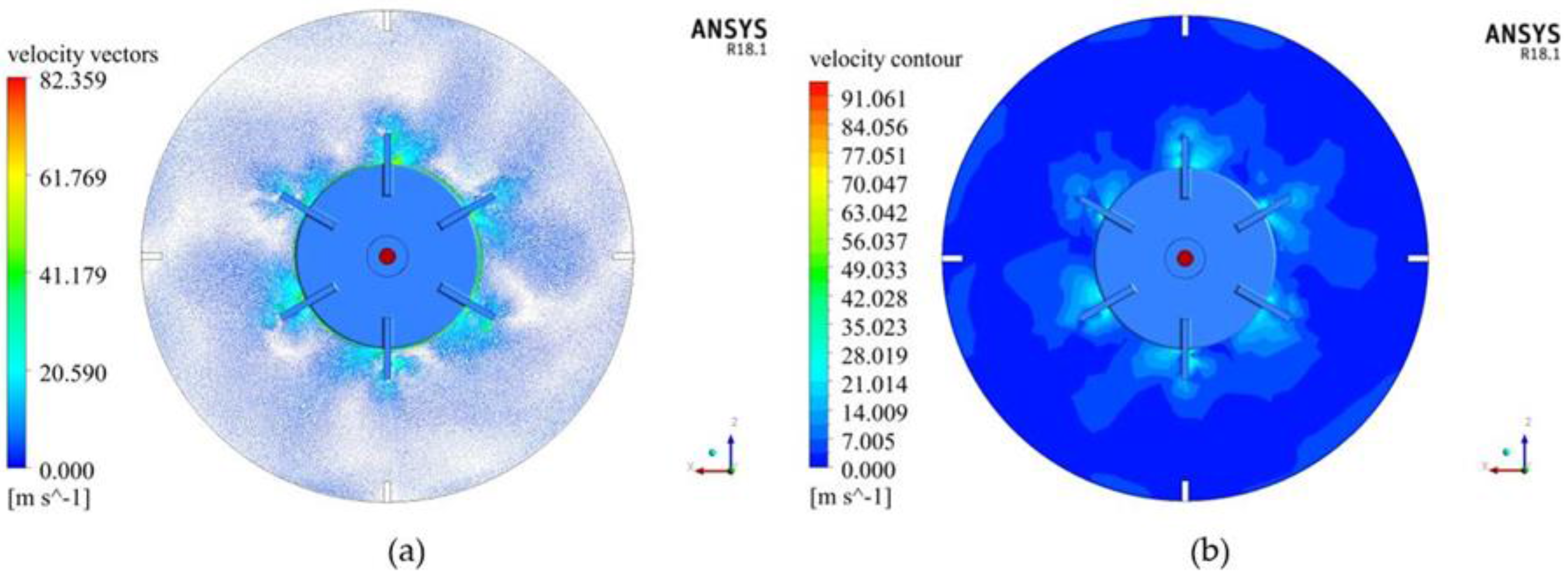

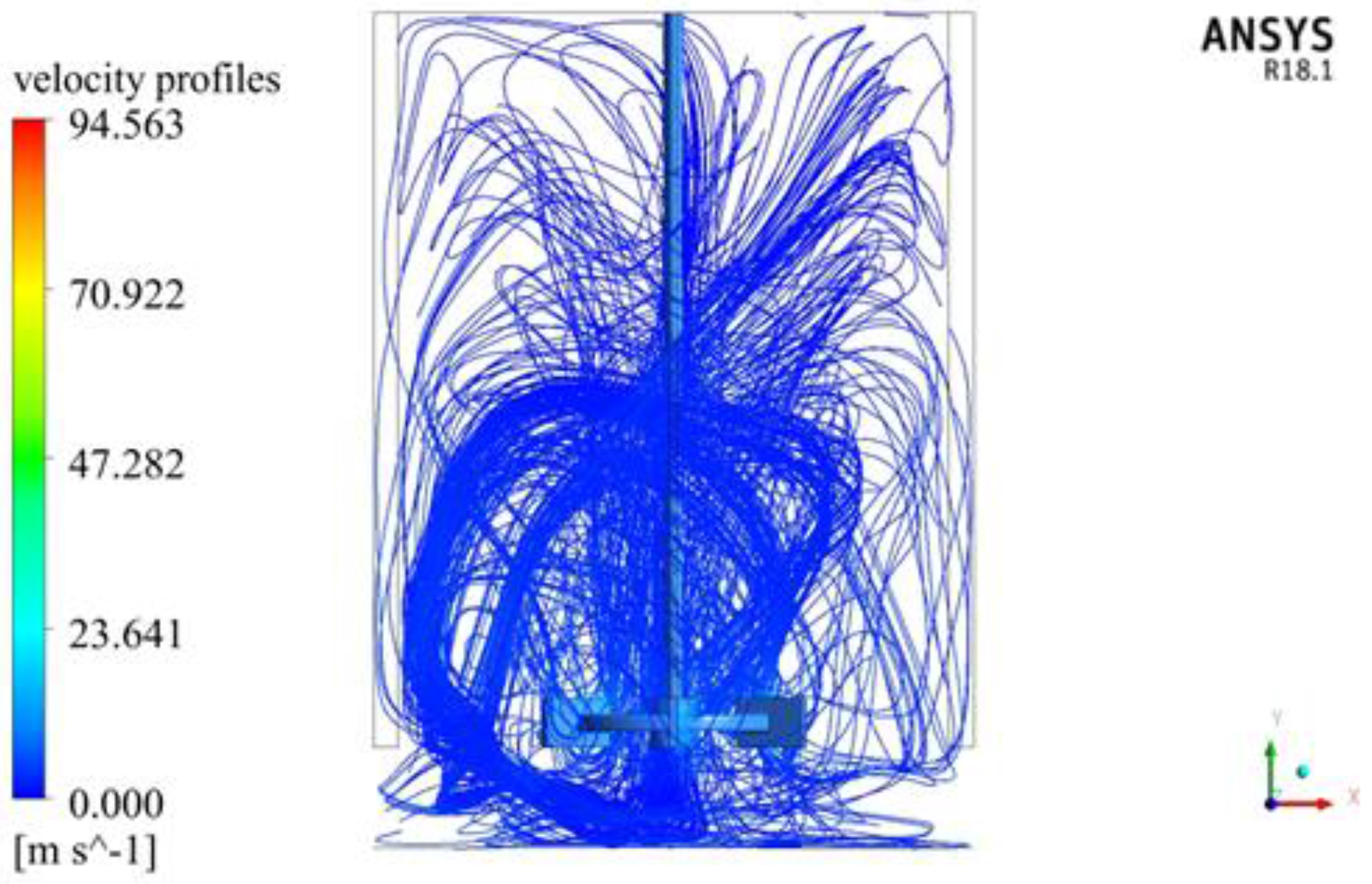

3.2. CFD Post-Process Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zadghaffari, R.; Moghaddas, J.S.; Revstedt, J. A Study on Liquid-Liquid Mixing in a Stirred Tank with a 6-Blade Rushton Turbine. Iran. J. Chem. Eng. 2008, 5, 12–22. [Google Scholar]

- Aubin, J.; Kresta, S.M.; Bertrand, J.; Xuereb, C.; Fletcher, D.F. Alternate Operating Methods for Improving the Performance of a Continuous Stirred Tank Reactor. Chem. Eng. Res. Des. 2006, 84, 569–582. [Google Scholar] [CrossRef]

- Tatterson, G.B. Fluid Mixing and Gas Dispersion in Agitated Tanks; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- Mak, A.T.C. Solid-Liquid Mixing in Mechanically Agitated Vessels. Ph.D. Thesis, University of London, London, UK, 1992. [Google Scholar]

- Delvigne, F.; Destain, J.; Thonart, P. Structured Mixing Model for Stirred Bioreactors: An Extension to the Stochastic Approach. Chem. Eng. J. 2005, 113, 1–12. [Google Scholar] [CrossRef]

- Raju, R.; Balachandar, S.; Hill, D.F.; Adriana, R.J. Reynolds Number Scaling of Flow in a Stirred Tank with Rushton Turbine. Part II—Eigen Decomposition of Fluctuation. Chem. Eng. Sci. 2005, 60, 3185–3198. [Google Scholar] [CrossRef]

- Isabela, M.P.; Leandro, S.O. CDF Modelling and Simulation of Transesterification Reactions of Vegetable Oils with an Alcohol in Baffled Stirred Tank Reactor. Appl. Mech. Mater. 2013, 390, 86–90. [Google Scholar]

- Seyed, H.; Dineshkumar, P.; Farhad, E.M.; Mehrab, M. Study of Solid-Liquid Mixing in Agitated Tanks through Computational Fluid Dynamics Modeling. Ind. Eng. Chem. Res. 2010, 49, 4426–4435. [Google Scholar]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics. In The Finite Volume Method, 2nd ed.; Pearson Education: New York, NY, USA, 2007. [Google Scholar]

- Zhang, Z.; Liu, H.; Zhu, S.P.; Zhao, F. Application of CFD in ship engineering design practice and ship hydrodynamics. J. Hydrodyn. 2006, 18, 315–322. [Google Scholar] [CrossRef]

- Zlokarnik, M. Scale-Up in Chemical Engineering, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2006. [Google Scholar]

- Pakzad, L.; Ein-Mozaffari, F.; Chan, P. Using computational fluid dynamics modeling to study the mixing of pseudoplastic fluids with a Scaba 6SRGT impeller. Chem. Eng. Process. 2008, 47, 2218–2227. [Google Scholar] [CrossRef]

- Ge, C.-Y.; Wang, J.-J.; Gu, X.-P.; Feng, L.-F. CFD simulation and PIV measurement of the flow field generated by modified pitched blade turbine impellers. Chem. Eng. Res. Des. 2014, 92, 1027–1036. [Google Scholar] [CrossRef]

- Cokljat, D.; Slack, M.; Vasquez, S.A.; Bakker, A.; Montante, G. Reynolds-Stress Model for Eulerian Multiphase. Prog. Comput. Fluid Dyn. 2006, 6, 168–178. [Google Scholar] [CrossRef]

- Khopkar, A.R.; Kasat, G.R.; Pandit, A.B.; Ranade, V.V. Computational Fluid Dynamics Simulation of the Solid Suspension in a Stirred Slurry Reactor. Ind. Eng. Chem. Res. 2006, 45, 4416–4428. [Google Scholar] [CrossRef]

- Zalc, J.M.; Szalai, E.S.; Alvarez, M.M.; Muzzio, F.J. Using CFD to understand chaotic mixing in laminar stirred tanks. AIChE J. 2002, 48, 2124–2134. [Google Scholar] [CrossRef]

- Tatterson, G.B. Scale-Up and Design of Industrial Mixing Processes; McGraw-Hill: New York, NY, USA, 1994. [Google Scholar]

- Jiusheng, L.; Yibin, M.; Bei, L. Field evaluation of fertigation uniformity as affected by injector type and manufacturing variability of emitters. Irrig. Sci. 2007, 25, 117–125. [Google Scholar]

- Leschziner, M.A.; Drikakis, D. Turbulence and turbulent flow computation in aeronautics. Aeronaut. J. 2002, 106, 349–384. [Google Scholar]

- ANSYS Fluent User Guide. Available online: http://www.ansys.fem.ir/ansys_fluent (accessed on 12 November 2017).

- Paul, E.L.; Atiemo-Obeng, V.A.; Kresta, S.M. Handbook of Industrial Mixing: Science and Practice; Wiley-Interscience: New York, NY, USA, 2004. [Google Scholar]

- Dagadu, C.P.K.; Stegowsk, Z.; Furman, L.; Akaho, E.H.K.; Danso, K.A. Determination of Flow Structure in a Gold Leaching Tank by CFD Simulation. J. Appl. Math. Phys. 2014, 2, 510–519. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The Numerical Computation of Turbulent Flows. Comput. Meth. Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Kresta, S.M.; Wood, P.E. Prediction of the Three-Dimensional Turbulent Flow in Stirred Tanks. AIChE J. 1991, 37, 448–460. [Google Scholar] [CrossRef]

- Barrue, H.; Bertrand, J.; Cristol, B.; Xuereb, C. Eulerian Simulation of Dense Solid-Liquid Suspension in Multi-Stage Stirred Vessel. J. Chem. Eng. Jpn. 2001, 34, 585–594. [Google Scholar] [CrossRef]

- Oshinowo, L.M.; Bakker, A. CFD Modeling of solids Suspensions in Stirred Tanks. Presented at the Symposium on Computational Modeling of Metals, Minerals and Materials, TMS Annual Meeting, Seattle, WA, USA, 17–21 February 2002. [Google Scholar]

- Leonard, A. Energy cascade in large-eddy simulations of turbulent fluid flow. Adv. Geophys. 1974, 18, 237–248. [Google Scholar]

- Pope, S. Turbulent Flows; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Luo, J.Y.; Issa, R.I.; Gosman, A.D. Prediction of Impeller Induced Flows in Mixing Vessels Using Multiple Frames of Reference. Inst. Chem. Eng. Symp. Ser. 1994, 136, 549–556. [Google Scholar]

- Khopkar, A.R.; Mavros, P.; Ranade, V.V.; Bertrand, J. Simulation of Flow Generated by an Axial Flow Impeller: Batch and Continuous Operation. Chem. Eng. Res. Des. 2004, 82, 737–751. [Google Scholar] [CrossRef][Green Version]

- Akiti, O.; Yeboah, A.; Bai, G. Hydrodynamic effects on mixing and competitive reactions in laboratory reactors. Chem. Eng. Sci. 2005, 60, 2341–2354. [Google Scholar] [CrossRef]

- McDonough, R.J. Mixing for the Process Industries; Van Nostrand Reinhold: New York, NY, USA, 1992. [Google Scholar]

- Musgrove, M.; Ruszkowski, S.; Van den Akker, H.; Derksen, J. Influence of impeller type and agitation conditions on the drop size of immiscible liquid dispersions. In Proceedings of the 10th European Conference on Mixing, Delft, The Netherlands, 2–5 July 2000; Elsevier Science: Amsterdam, The Netherlands, 2000; pp. 165–172. [Google Scholar]

- Divyamaan, W.; Ranjeet, P.U.; Moses, O.T.; Vishnu, K.P. CFD simulation of solid-liquid stirred tanks. Adv. Powder Technol. 2012, 23, 445–453. [Google Scholar]

- Drikakis, D. Advances in turbulent flow computations using high-resolution methods. Prog. Aerosp. Sci. 2003, 39, 405–424. [Google Scholar] [CrossRef]

- Som, S.; Senecal, P.K.; Pomraning, E. Comparison of RANS and LES Turbulence Models against Constant Volume Diesel Experiments. In Proceedings of the 24th Annual Conference on Liquid Atomization and Spray Systems (ILASS Americas), San Antonio, TX, USA, 20–23 May 2012. [Google Scholar]

| Parameter | Symbol | Value (mm) |

|---|---|---|

| Tank diameter | T | 360 |

| Tank height | H | 500 |

| Impeller diameter | D = T/2 | 180 |

| Impeller blade height | h | 10 |

| Baffle length | L | 440 |

| Baffle width | B = D/12 | 15 |

| Impeller clearance | C = D/3 | 60 |

| Type of Impeller | Mean EC |

|---|---|

| saw tooth impeller | 4113.5 |

| Rushton turbine | 3571.4 |

| Anchor impeller | 3119.0 |

| counter flow impeller | 4101.9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torotwa, I.; Ji, C. A Study of the Mixing Performance of Different Impeller Designs in Stirred Vessels Using Computational Fluid Dynamics. Designs 2018, 2, 10. https://doi.org/10.3390/designs2010010

Torotwa I, Ji C. A Study of the Mixing Performance of Different Impeller Designs in Stirred Vessels Using Computational Fluid Dynamics. Designs. 2018; 2(1):10. https://doi.org/10.3390/designs2010010

Chicago/Turabian StyleTorotwa, Ian, and Changying Ji. 2018. "A Study of the Mixing Performance of Different Impeller Designs in Stirred Vessels Using Computational Fluid Dynamics" Designs 2, no. 1: 10. https://doi.org/10.3390/designs2010010

APA StyleTorotwa, I., & Ji, C. (2018). A Study of the Mixing Performance of Different Impeller Designs in Stirred Vessels Using Computational Fluid Dynamics. Designs, 2(1), 10. https://doi.org/10.3390/designs2010010