Assessing the Performance of a Subsurface Water Retention System (SWRS) Prototype: First Evaluation of Work Productivity and Costs

Abstract

:1. Introduction

2. Results and Discussions

3. Materials and Methods

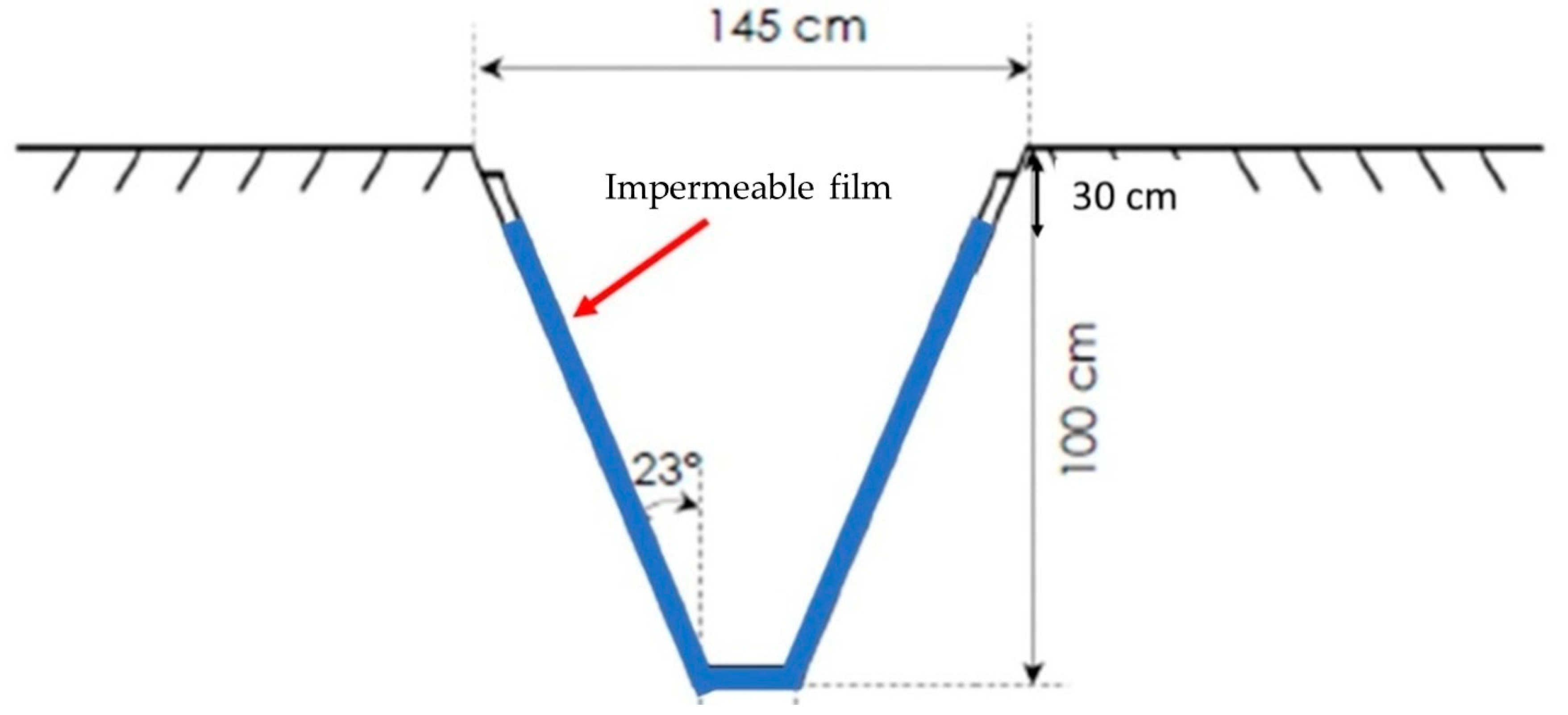

3.1. Description of the Prototype

3.2. Experimental Field and SWRS Realization

3.3. Work Productivity and Cost Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miraglia, M.; Marvin, H.J.P.; Kleter, G.A.; Battilani, P.; Brera, C.; Coni, E.; Cubadda, F.; Croci, L.; De Santis, B.; Dekkers, S.; et al. Climate change and food safety: An emerging issue with special focus on Europe. Food Chem. Toxicol. 2009, 47, 1009–1021. [Google Scholar] [CrossRef] [PubMed]

- Flavelle, C. Climate Change Could Cut World Economy by $23 Trillion in 2050, Insurance Giant Warns. New York Times, 22 April 2021. [Google Scholar]

- Giorgi, F.; Lionello, P. Climate change projections for the Mediterranean region. Glob. Planet. Change 2008, 63, 90–104. [Google Scholar] [CrossRef]

- Diffenbaugh, N.S.; Giorgi, F. Climate change hotspots in the CMIP5 global climate model ensemble. Clim. Change 2012, 114, 813–822. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ouatiki, H.; Boudhar, A.; Ouhinou, A.; Arioua, A.; Hssaisoune, M.; Bouamri, H.; Benabdelouahab, T. Trend analysis of rainfall and drought over the Oum Er-Rbia River Basin in Morocco during 1970–2010. Arab. J. Geosci. 2019, 12, 128. [Google Scholar] [CrossRef]

- Zarei, A.R.; Shabani, A.; Mahmoudi, M.R. Comparison of the climate indices based on the relationship between yield loss of rain-fed winter wheat and changes of climate indices using GEE model. Sci. Total Environ. 2019, 661, 711–722. [Google Scholar] [CrossRef] [PubMed]

- Goubanova, K.; Li, L. Extremes in temperature and precipitation around the Mediterranean basin in an ensemble of future climate scenario simulations. Glob. Planet. Change 2007, 57, 27–42. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, J.; Wang, Z.; Wei, X.; Zhu, H.; Fu, W.; Shao, M. Responses of soil aggregate stability, erodibility and nutrient enrichment to simulated extreme heavy rainfall. Sci. Total Environ. 2019, 709, 136150. [Google Scholar] [CrossRef]

- Pari, L.; Suardi, A.; Stefanoni, W.; Latterini, F.; Palmieri, N. Economic and environmental assessment of two different rain water harvesting systems for agriculture. Sustainability 2021, 13, 3871. [Google Scholar] [CrossRef]

- Mango, N.; Makate, C.; Tamene, L.; Mponela, P.; Ndengu, G. Adoption of small-scale irrigation farming as a climate-smart agriculture practice and its influence on household income in the Chinyanja Triangle, Southern Africa. Land 2018, 7, 49. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Yang, Y.; Chen, Z.; Guo, C.; Li, S. Influence of super absorbent polymer on soil water retention, seed germination and plant survivals for rocky slopes eco-engineering. Ecol. Eng. 2014, 62, 27–32. [Google Scholar] [CrossRef]

- Bruun, E.W.; Petersen, C.T.; Hansen, E.; Holm, J.K.; Hauggaard-Nielsen, H. Biochar amendment to coarse sandy subsoil improves root growth and increases water retention. Soil Use Manag. 2014, 30, 109–118. [Google Scholar] [CrossRef]

- Obst, C. Non-wetting soils: Management problems and solutions at “Pineview”, Mundulla. In Proceedings of the 2nd National Water Repellency Workshop, Perth, Australia, 1–5 August 1994; Carter, D.J., Howes, K.M.W., Eds.; pp. 137–139. [Google Scholar]

- Ismail, S.M.; Ozawa, K. Improvement of crop yield, soil moisture distribution and water use efficiency in sandy soils by clay application. Appl. Clay Sci. 2007, 37, 81–89. [Google Scholar] [CrossRef] [Green Version]

- Taylor, K.C.; Halfacre, R.G. The effect of hydrophilic polymer on media water retention and nutrient availability to Ligustrum lucidum. HortScience 1986, 21, 1159–1161. [Google Scholar]

- Silberbush, M.; Adar, E.; De Malach, Y. Use of an hydrophilic polymer to improve water storage and availability to crops grown in sand dunes I. Corn irrigated by trickling. Agric. Water Manag. 1993, 23, 303–313. [Google Scholar] [CrossRef]

- Welsh, D.A.F.; Kreuter, U.P.; Byles, J.D. Enhancing subsurface drip irrigation through vector low. In Proceedings of the 5th International Microirrigation Congress, Orlando, FL, USA, 2–6 April 1995; pp. 688–693. [Google Scholar]

- Brunstrum, L.C.; Ott, L.E.; Speer, T.L. Increasing crop yields with underground asphalt moisture barriers. In Proceedings of the 7th World Petroleum Congress, Mexico City, MX, USA, 2 April 1967. [Google Scholar]

- Hansen, C.M.; Erickson, A.E. Use of asphalt to increase water-holding capacity of droughty sand soils. Ind. Eng. Chem. Prod. Res. Dev. 1969, 8, 256–259. [Google Scholar] [CrossRef]

- Rao, K.V.P.; Varade, S.B.; Pande, H.K. Influence of subsurface barrier on growth, yield, nutrient uptake, and water requirement of rice (Oryza sativa) 1. Agron. J. 1972, 64, 578–580. [Google Scholar] [CrossRef]

- Elawady, M.N.; Abd El-Salam, M.F.; Elnawawy, M.M.; El-Farrah, M.A. Surface and subsurface irrigation effects on Spinach and sorghum. In Proceedings of the 11th Annual Conference of Misr Society of Agricultural Engineers, Kafr El-Sheikh, Egypt, 15–16 October 2003; Volume 15, p. 16. [Google Scholar]

- Awady, M.N.; Wassif, M.A.; Abd El-Salam, M.F.; El-Farrah, M.A. Moisture distribution from subsurface dripping using saline water in sandy soil. In Proceedings of the 15th Annual Conference of the Misr Society of Agricultural Engineering, Shubra El-Kheima, Egypt, 12–13 March 2008; Volume 12, p. 13. [Google Scholar]

- Aoda, M.I.A.; Ati, A.S.A.; AL-Rawi, S.S.A.-R. Subsurface Water Retention Technology (SWRT) for Water Saving and Growing Tomato in Iraqi Sandy Soils. J. Zankoy Sulaimani Part A 2018, 7, 127–134. [Google Scholar] [CrossRef]

- Hommadi, A.H. Subsurface water retention technology improves water use efficiency and water productivity for hot pepper. J. Kerbala Univ. 2018, 14, 125–135. [Google Scholar]

- Kavdir, Y.; Zhang, W.; Basso, B.; Smucker, A.J.M. Development of a new long-term drought resilient soil water retention technology. J. Soil Water Conserv. 2014, 69, 154A–160A. [Google Scholar] [CrossRef] [Green Version]

- Smucker, A.J.M. Subsurface Barrier Retention System and Methods Related Thereto. U.S. Patent 9,615,518 B2, 11 April 2017. [Google Scholar]

- Miller, S.A.; Smucker, A.J.M. A new soil water retention technology for irrigated highly permeable soils. In Proceedings of the Joint ASABE/IA Irrigation Symposium 2015: Emerging Technologies for Sustainable Irrigation, Long Beach, CA, USA, 10–12 November 2015; pp. 726–730. [Google Scholar]

- Presentation of MediOpuntia Project. Available online: http://www.panacea-h2020.eu/wp-content/uploads/2021/01/MediOpuntia-project_cactus-plantation.pdf (accessed on 20 May 2021).

- Rigamonti, L.; Borghi, G.; Martignon, G.; Grosso, M. Life cycle costing of energy recovery from solid recovered fuel produced in MBT plants in Italy. Waste Manag. 2019, 99, 154–162. [Google Scholar] [CrossRef] [PubMed]

- Kapanen, A.; Schettini, E.; Vox, G.; Itävaara, M. Performance and environmental impact of biodegradable films in agriculture: A field study on protected cultivation. J. Polym. Environ. 2008, 16, 109–122. [Google Scholar] [CrossRef]

- Briassoulis, D. Analysis of the mechanical and degradation performances of optimised agricultural biodegradable films. Polym. Degrad. Stab. 2007, 92, 1115–1132. [Google Scholar] [CrossRef]

- Briassoulis, D. An overview on the mechanical behaviour of biodegradable agricultural films. J. Polym. Environ. 2004, 12, 65–81. [Google Scholar] [CrossRef]

- Vallerani Delfino System. Available online: http://www.vallerani.com/wp/?page_id=1675 (accessed on 20 May 2021).

- Venanzi, R.; Picchio, R.; Grigolato, S.; Latterini, F. Soil and forest regeneration after different extraction methods in coppice forests. For. Ecol. Manag. 2019, 454, 117666. [Google Scholar] [CrossRef]

- Venanzi, R.; Picchio, R.; Spinelli, R.; Grigolato, S. Soil disturbance and recovery after coppicing a Mediterranean Oak stand: The effects of silviculture and technology. Sustainability 2020, 12, 4074. [Google Scholar] [CrossRef]

- Venanzi, R.; Picchio, R.; Grigolato, S.; Spinelli, R. Soil disturbance induced by silvicultural treatment in chestnut (Castanea sativa Mill.) coppice and post-disturbance recovery. Forests 2020, 11, 1053. [Google Scholar] [CrossRef]

- Picchio, R.; Latterini, F.; Mederski, P.S.; Tocci, D.; Venanzi, R.; Stefanoni, W.; Pari, L. Applications of GIS-based software to improve the sustainability of a forwarding operation in central Italy. Sustainability 2020, 12, 5716. [Google Scholar] [CrossRef]

- Picchio, R.; Venanzi, R.; Tavankar, F.; Luchenti, I.; Iranparast Bodaghi, A.; Latterini, F.; Nikooy, M.; Di Marzio, N.; Naghdi, R. Changes in soil parameters of forests after windstorms and timber extraction. Eur. J. For. Res. 2019, 138, 875–888. [Google Scholar] [CrossRef]

- Reith, S.; Frisch, J.; Winkler, B. Revision of the working time classification to optimize work processes in modern agriculture. Chem. Eng. Trans. 2017, 58, 121–126. [Google Scholar] [CrossRef]

- Latterini, F.; Stefanoni, W.; Sebastiano, S.; Baldi, G.M.; Pari, L. Evaluating the suitability of a combine harvester equipped with the sunflower header to harvest cardoon seeds: A case study in central Italy. Agronomy 2020, 10, 1981. [Google Scholar] [CrossRef]

- Stefanoni, W.; Latterini, F.; Ruiz, J.P.; Bergonzoli, S.; Palmieri, N.; Pari, L. Assessing the camelina (Camelina sativa (L.) Crantz) seed harvesting using a combine harvester: A case-study on the assessment of work performance and seed loss. Sustainability 2020, 13, 195. [Google Scholar] [CrossRef]

- Suardi, A.; Stefanoni, W.; Bergonzoli, S.; Latterini, F.; Jonsson, N.; Pari, L. Comparison between two strategies for the collection of wheat residue after mechanical harvesting: Performance and cost analysis. Sustainability 2020, 12, 4936. [Google Scholar] [CrossRef]

- Assirelli, A.; Pignedoli, S. Costo di esercizio delle macchine agricole. Cent. Ric. Prod. Anim. 2005, 5, 1–10. [Google Scholar]

- Banca d’Italia Banca d’Italia Lending Rate. American Society of Agricultural Engineers. Available online: https://www.bancaditalia.it/ (accessed on 11 July 2020).

- American Society of Agricultural Engineers ASAE standard D497.4. In Agriculture Machinery Management Data; ASAE: St. Joseph, MI, USA, 2003; pp. 373–380.

| Parameter | Details | Measure Unit | Avg. | St. Dev. |

|---|---|---|---|---|

| TFC | Started digging with excavator | ha h−1 | 3.94 | 0.37 |

| SWRS installation with prototype | ha h−1 | 0.38 | 0.06 | |

| SWRS removal with excavator | ha h−1 | 0.10 | 0.01 | |

| Overall installation | ha h−1 | 0.34 | 0.05 | |

| EFC | Started digging with excavator | ha h−1 | 3.94 | 0.37 |

| SWRS installation with prototype | ha h−1 | 0.20 | 0.07 | |

| SWRS removal with excavator | ha h−1 | 0.10 | 0.01 | |

| Overall installation | ha h−1 | 0.19 | 0.07 | |

| FE | Started digging with excavator | % | 100.00 | n.d. |

| SWRS installation with prototype | % | 52.34 | 17.52 | |

| SWRS removal with excavator | % | 100.00 | n.d. | |

| Overall installation | % | 54.40 | 17.48 |

| SWRS Installation | SWRS Removal | ||||

|---|---|---|---|---|---|

| 128 kW Tractor | SWRS Prototype | 42 kW Excavator | Total | ||

| € h−1 | 47.98 | 913.35 | 44.38 | 1005.71 | 67.38 |

| € ha−1 | 240.42 | 4576.54 | 11.26 | 4828.22 | 655.79 |

| Parameter | Value | Methodology |

|---|---|---|

| Skeleton | Trace | DM 13/09/99 G.U. n° 248 del 21/10/99 Method II.1 |

| Sand (%) | 64 | DM 13/09/99 G.U. n° 248 del 21/10/99 Method II.6 |

| Loam (%) | 22 | DM 13/09/99 G.U. n° 248 del 21/10/99 Method II.6 |

| Clay (%) | 14 | DM 13/09/99 G.U. n° 248 del 21/10/99 Method II.6 |

| Texture | sandy loam soil | DM 13/09/99 G.U. n° 248 del 21/10/99 Method II.6 |

| Porosity * (%) | 11.6 | MUAFS99 Met IV.1 |

| Moisture (%) | 17.29 | Gravimetric |

| Bulk density (g cm−3) | 1.282 | ISO 11272:2017 |

| 128 kW Tractor | SWRS Prototype | 42 kW Excavator | |||

|---|---|---|---|---|---|

| Financial costs | Investment | € | 128,830 | 40,000 | 119,000 |

| Service life | year | 10 | 10 | 10 | |

| Service life | h | 14,000 | 4000 | 14,000 | |

| Resale | % | 59.82 | 29.50 | 32.59 | |

| Resale | € | 77,071.90 | 11,800.45 | 38,786.40 | |

| Depreciation | € | 51,758.10 | 28,199.55 | 80,213.60 | |

| Annual usage | h year−1 | 400 | 400 | 400 | |

| Interest rate | % | 3 | 3 | 3 | |

| Fixed costs | Ownership costs | € year−1 | 5175.81 | 2819.95 | 8021.36 |

| Interests | € year−1 | 3088.52847 | 777.01 | 2366.80 | |

| Machine shelter | m2 | 12.78 | 6.48 | 14.384 | |

| Value of the shelter | € m−2 | 100 | 100 | 100 | |

| Value of the shelter | € year−1 | 25.56 | 13.0 | 28.8 | |

| Insurance costs | € year−1 | 322.08 | 100 | 297.5 | |

| Variable costs | Repair factor | % | 80 | 60 | 80 |

| Repairs and maintenance | € h−1 | 2.10 | 6.00 | 1.94 | |

| Fuel cost | € lt−1 | 0.57 | 0.57 | ||

| Fuel consumption | lt h−1 | 20.99 | 6.00 | ||

| Fuel consumption | € h−1 | 11.96 | 3.42 | ||

| Lubricant cost | € lt−1 | 3.03 | 3.03 | ||

| Lubricant consumption | lt h−1 | 0.29 | 0.24 | ||

| Lubricant consumption | € h−1 | 0.88 | 0.73 | ||

| Manpower costs | € h−1 | 11.5 | 11.5 | ||

| Cost of SWRS film | € m−2 | 3.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pari, L.; Stefanoni, W.; Palmieri, N.; Latterini, F. Assessing the Performance of a Subsurface Water Retention System (SWRS) Prototype: First Evaluation of Work Productivity and Costs. Inventions 2022, 7, 25. https://doi.org/10.3390/inventions7010025

Pari L, Stefanoni W, Palmieri N, Latterini F. Assessing the Performance of a Subsurface Water Retention System (SWRS) Prototype: First Evaluation of Work Productivity and Costs. Inventions. 2022; 7(1):25. https://doi.org/10.3390/inventions7010025

Chicago/Turabian StylePari, Luigi, Walter Stefanoni, Nadia Palmieri, and Francesco Latterini. 2022. "Assessing the Performance of a Subsurface Water Retention System (SWRS) Prototype: First Evaluation of Work Productivity and Costs" Inventions 7, no. 1: 25. https://doi.org/10.3390/inventions7010025

APA StylePari, L., Stefanoni, W., Palmieri, N., & Latterini, F. (2022). Assessing the Performance of a Subsurface Water Retention System (SWRS) Prototype: First Evaluation of Work Productivity and Costs. Inventions, 7(1), 25. https://doi.org/10.3390/inventions7010025