Conveyor-Belt Dryers with Tangential Flow for Food Drying: Development of Drying ODEs Useful to Design and Process Adjustment

Abstract

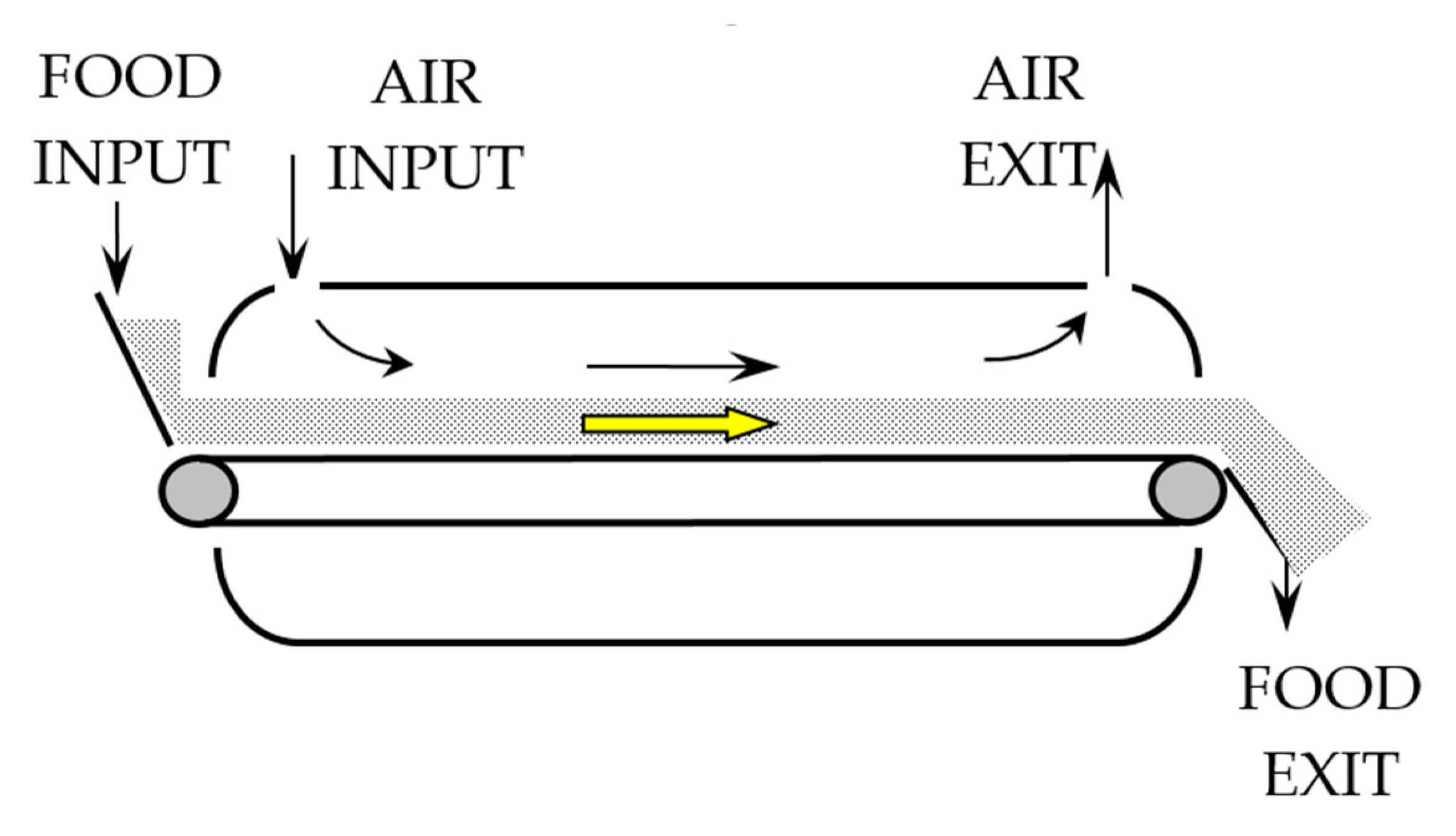

:1. Introduction

2. Materials and Methods

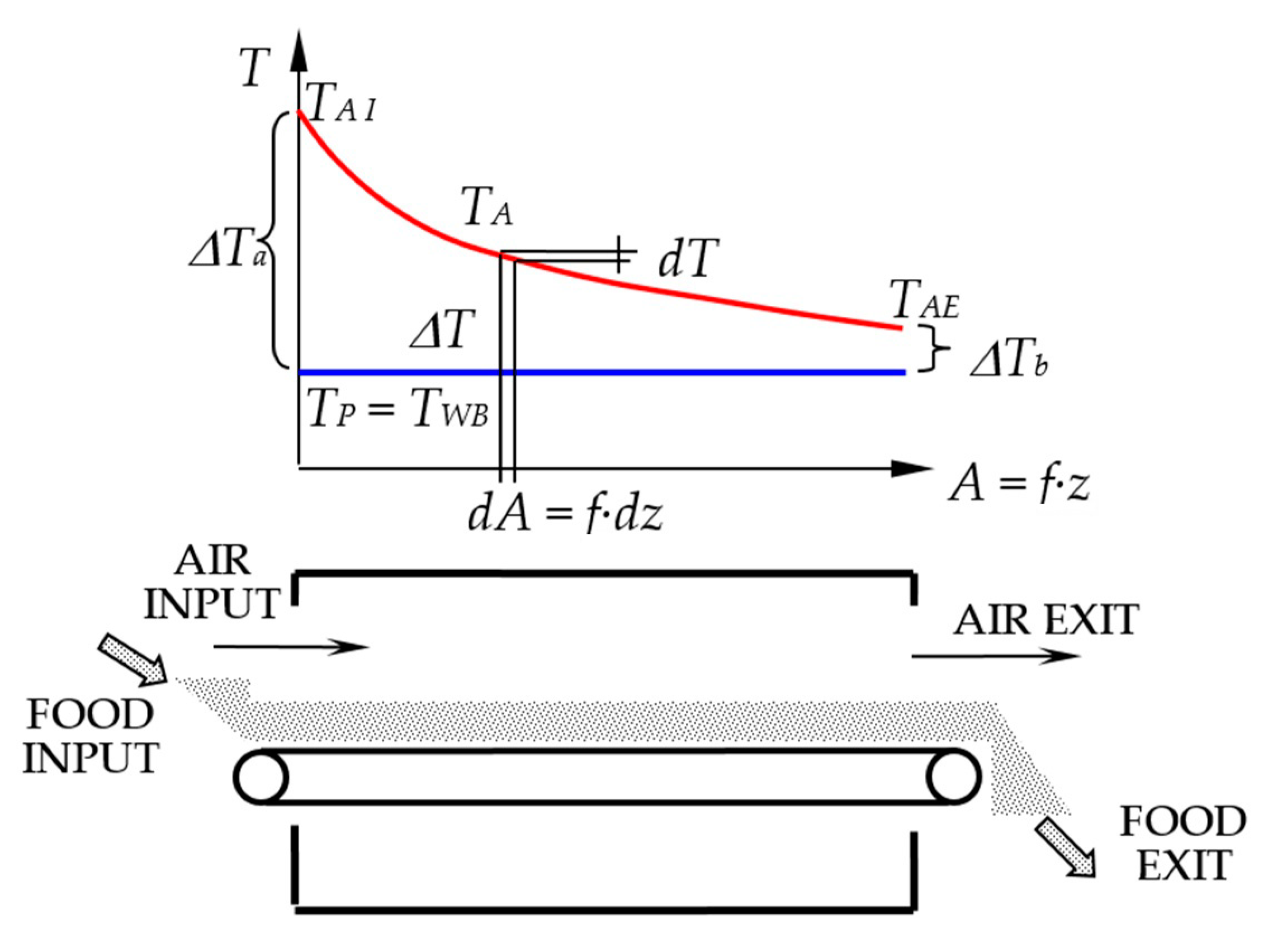

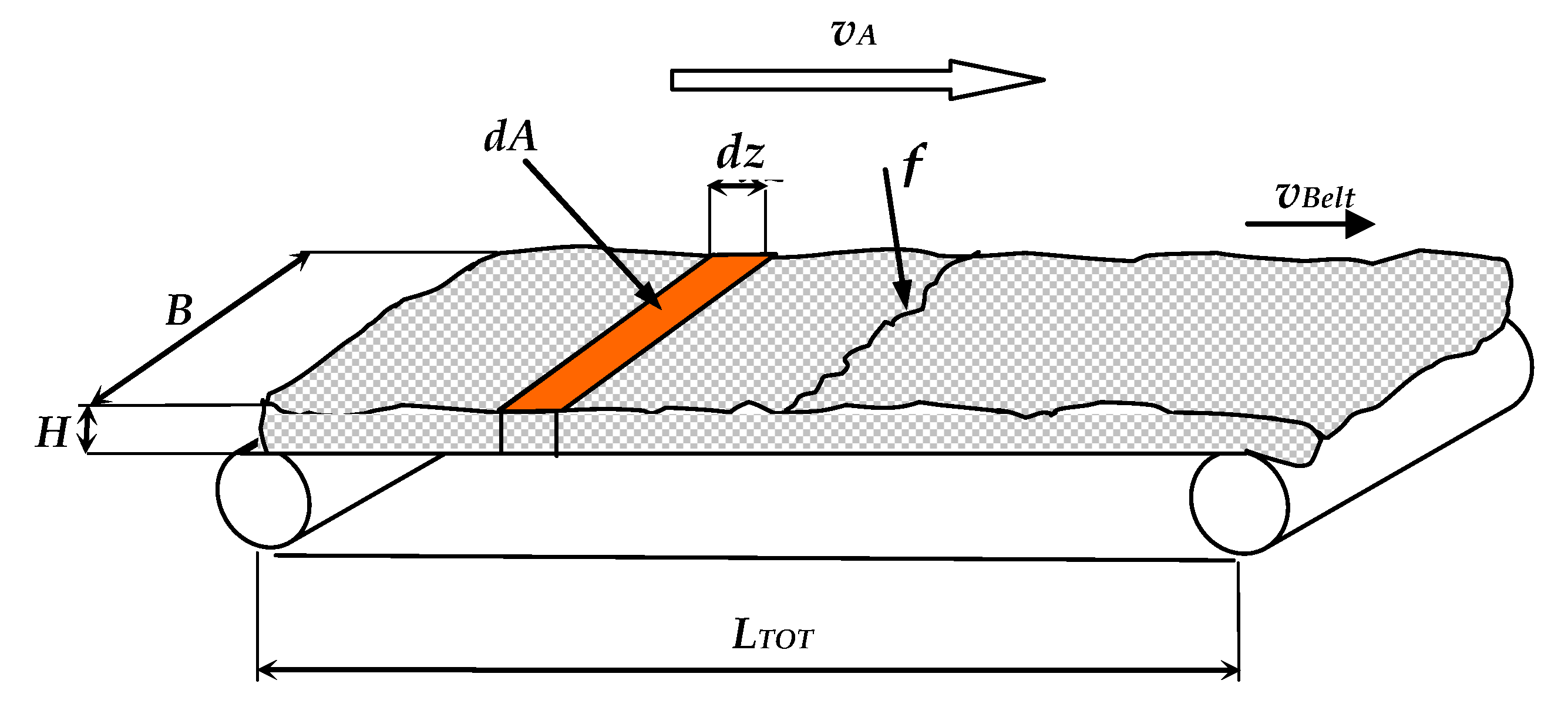

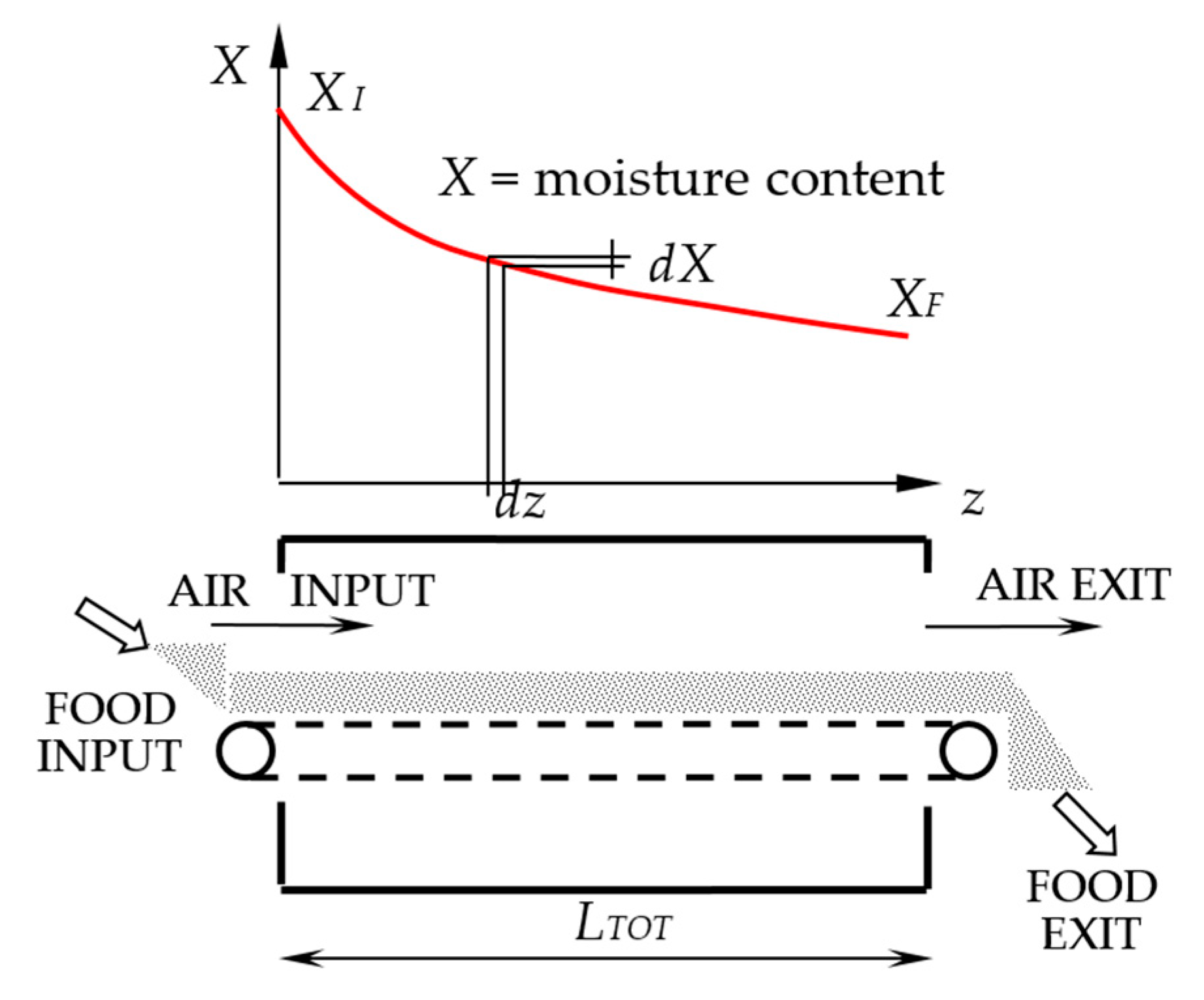

2.1. Mathematical Analysis of the Drying Rate Along the Belt Dryer

2.2. Adjustment of Parameters of the Dryer

2.3. Experimental Equipment

3. Results and Discussion

3.1. Experimental Results

3.2. Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Omolola, A.O.; Jideani, A.I.O.; Kapila, P.F. Quality properties of fruits as affected by drying operation. Crit. Rev. Food Sci. Nutr. 2017, 57, 95–108. [Google Scholar] [CrossRef]

- Caccavale, P.; De Bonis, M.V.; Ruocco, G. Conjugate heat and mass transfer in drying: A modeling review. J. Food Eng. 2016, 176, 28–35. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Rodrigues, S.; Law, C.L.; Mujumdar, A.S. Drying of exotic tropical fruits: A comprehensive review. Food Bioprocess Technol. 2011, 4, 163–185. [Google Scholar] [CrossRef]

- Kaleta, A.; Gornicki, K.; Winiczenko, R.; Chojnacka, A. Evaluation of drying models of apple (var. Ligol) dried in a fluidized bed dryer. Energy Convers. Manag. 2013, 67, 179–185. [Google Scholar] [CrossRef]

- Marquez, C.A.; de Michelis, A. Comparison of drying kinetics for small fruits with and without particle shrinkage considerations. Food Bioprocess Technol. 2011, 4, 1212–1218. [Google Scholar] [CrossRef]

- Tzempelikos, D.A.; Mitrakos, D.; Vouros, A.P.; Bardakas, A.V.; Filios, A.E.; Margaris, D.P. Numerical modeling of heat and mass transfer during convective drying of cylindrical quince slices. J. Food Eng. 2015, 156, 10–21. [Google Scholar] [CrossRef]

- Bezerra, C.V.; Meller Da Silva, L.H.; Correa, D.F.; Rodrigues, A.M.C. A modeling study for moisture diffusivities and moisture transfer coefficients in drying of passion fruit peel. Int. J. Heat Mass Tran. 2015, 85, 750–755. [Google Scholar] [CrossRef]

- García-Alvarado, M.A.; Pacheco-Aguirre, F.M.; Ruiz-Lopez, I.I. Analytical solution of simultaneous heat and mass transfer equations during food drying. J. Food Eng. 2014, 142, 39–45. [Google Scholar] [CrossRef]

- Ertekin, C.; Firat, M.Z. A comprehensive review of thin layer drying models used in agricultural products. Crit. Rev. Food Sci. Nutr. 2017, 57, 701–717. [Google Scholar] [CrossRef]

- Fernando, W.J.N.; Low, H.C.; Ahmad, A.L. Dependence of the effective diffusion coefficient of moisture with thickness and temperature in convective drying of sliced materials. A study on slices of banana, cassava and pumpkin. J. Food Eng. 2011, 102, 310–316. [Google Scholar] [CrossRef]

- Friso, D. A Mathematical Solution for Food Thermal Process Design. Appl. Math. Sci. 2015, 9, 255–270. [Google Scholar] [CrossRef]

- Friso, D.; Baldoin, C. Mathematical Modelling and Experimental Assessment of Agrochemical Drift using a Wind Tunnel. Appl. Math. Sci. 2015, 9, 5451–5463. [Google Scholar] [CrossRef]

- Friso, D. An Approximate Analytic Solution to a Non-Linear ODE for Air Jet Velocity Decay through Tree Crops Using Piecewise Linear Emulations and Rectangle Functions. Appl. Sci. 2019, 9, 5440. [Google Scholar] [CrossRef] [Green Version]

- Akdas, S.; Baslar, M. Dehydration and degradation kinetics of bioactive compounds for mandarin slices under vacuum and oven drying conditions. J. Food Process. Preserv. 2015, 39, 1098–1107. [Google Scholar] [CrossRef]

- Askari, G.R.; Emam-Djomeh, Z.; Mousavi, S.M. Heat and mass transfer in apple cubes in a microwave-assisted fluidized bed drier. Food Bioprod. Process. 2013, 91, 207–215. [Google Scholar] [CrossRef]

- Ben Mabrouk, S.; Benali, E.; Oueslati, H. Experimental study and numerical modelling of drying characteristics of apple slices. Food Bioprod. Process. 2012, 90, 719–728. [Google Scholar] [CrossRef]

- Esfahani, J.A.; Vahidhosseini, S.M.; Barati, E. Three-dimensional analytical solution for transport problem during convection drying using Green’s function method (GFM). Appl. Therm. Eng. 2015, 85, 264–277. [Google Scholar] [CrossRef]

- Esfahani, J.A.; Majdi, H.; Barati, E. Analytical two-dimensional analysis of the transport phenomena occurring during convective drying: Apple slices. J. Food Eng. 2014, 123, 87–93. [Google Scholar] [CrossRef]

- Golestani, R.; Raisi, A.; Aroujalian, A. Mathematical modeling on air drying of apples considering shrinkage and variable diffusion coefficient. Dry. Technol. 2013, 31, 40–51. [Google Scholar] [CrossRef]

- Bon, J.; Rossellò, C.; Femenia, A.; Eim, V.; Simal, S. Mathematical modeling of drying kinetics for Apricots: Influence of the external resistance to mass transfer. Dry. Technol. 2007, 25, 1829–1835. [Google Scholar] [CrossRef]

- Barati, E.; Esfahani, J.A. A new solution approach for simultaneous heat and mass transfer during convective drying of mango. J. Food Eng. 2011, 102, 302–309. [Google Scholar] [CrossRef]

- Corzo, O.; Bracho, N.; Alvarez, C.; Rivas, V.; Rojas, Y. Determining the moisture transfer parameters during the air-drying of mango slices using biot-dincer numbers correlation. J. Food Process. Eng. 2008, 31, 853–873. [Google Scholar] [CrossRef]

- Janjai, S.; Lamlert, N.; Intawee, P.; Mahayothee, B.; Haewsungcharern, M.; Bala, B.K.; Müller, J. Finite element simulation of drying of mango. Biosyst. Eng. 2008, 99, 523–531. [Google Scholar] [CrossRef]

- Villa-Corrales, L.; Flores-Prieto, J.J.; Xamàn-Villasenor, J.P.; García-Hernàndez, E. Numerical and experimental analysis of heat and moisture transfer during drying of Ataulfo mango. J. Food Eng. 2010, 98, 198–206. [Google Scholar] [CrossRef]

- Corzo, O.; Bracho, N.; Pereira, A.; Vàsquez, A. Application of correlation between Biot and Dincer numbers for determining moisture transfer parameters during the air drying of coroba slices. J. Food Process. Preserv. 2009, 33, 340–355. [Google Scholar] [CrossRef]

- Guiné, R.P. Pear drying: Experimental validation of a mathematical prediction model. Food Bioprod. Process. 2008, 86, 248–253. [Google Scholar] [CrossRef]

- Kaya, A.; Aydin, O.; Dincer, I. Experimental and numerical investigation of heat and mass transfer during drying of Hayward kiwi fruits (Actinidia Deliciosa Planch). J. Food Eng. 2008, 88, 323–330. [Google Scholar] [CrossRef]

- Lemus-Mondaca, R.A.; Zambra, C.E.; Vega-Gàlvez, A.; Moraga, N.O. Coupled 3D heat and mass transfer model for numerical analysis of drying process in papaya slices. J. Food Eng. 2013, 116, 109–117. [Google Scholar] [CrossRef]

- Ramsaroop, R.; Persad, P. Determination of the heat transfer coefficient and thermal conductivity for coconut kernels using an inverse method with a developed hemispherical shell model. J. Food Eng. 2012, 110, 141–157. [Google Scholar] [CrossRef]

- Sabarez, H.T. Mathematical modeling of the coupled transport phenomena and color development: Finish drying of trellis-dried sultanas. Dry. Technol. 2014, 32, 578–589. [Google Scholar] [CrossRef]

- Baini, R.; Langrish, T.A.G. Choosing an appropriate drying model for intermittent and continuous drying of bananas. J. Food Eng. 2007, 79, 330–343. [Google Scholar] [CrossRef]

- Da Silva, W.P.; Silva, C.M.D.P.S.; Gomes, J.P. Drying description of cylindrical pieces of bananas in different temperatures using diffusion models. J. Food Eng. 2013, 117, 417–424. [Google Scholar] [CrossRef]

- Da Silva, W.P.; Hamawand, I.; Silva, C.M.D.P.S. A liquid diffusion model to describe drying of whole bananas using boundary-fitted coordinates. J. Food Eng. 2014, 137, 32–38. [Google Scholar] [CrossRef]

- Castro, A.M.; Mayorga, E.Y.; Moreno, F.L. Mathematical modelling of convective drying of fruits: A review. J. Food Eng. 2018, 223, 152–167. [Google Scholar] [CrossRef]

- Chandra Mohan, V.P.; Talukdar, P. Three dimensional numerical modeling of simultaneous heat and moisture transfer in a moist object subjected to convective drying. Int. J. Heat Mass Tran. 2010, 53, 4638–4650. [Google Scholar] [CrossRef]

- Defraeye, T. When to stop drying fruit: Insights from hygrothermal modelling. Appl. Therm. Eng. 2017, 110, 1128–1136. [Google Scholar] [CrossRef] [Green Version]

- Defraeye, T.; Radu, A. International Journal of Heat and Mass Transfer Convective drying of fruit: A deeper look at the air-material interface by conjugate modeling. Int. J. Heat Mass Tran. 2017, 108, 1610–1622. [Google Scholar] [CrossRef] [Green Version]

- Fanta, S.W.; Abera, M.K.; Ho, Q.T.; Verboven, P.; Carmeliet, J.; Nicolai, B.M. Microscale modeling of water transport in fruit tissue. J. Food Eng. 2013, 118, 229–237. [Google Scholar] [CrossRef]

- Da Silva, W.P.; e Silva, C.M.; e Silva, D.D.; de Araújo Neves, G.; de Lima, A.G. Mass and heat transfer study in solids of revolution via numerical simulations using finite volume method and generalized coordinates for the Cauchy boundary condition. Int. J. Heat Mass Tran. 2010, 53, 1183–1194. [Google Scholar] [CrossRef]

- Aversa, M.; Curcio, S.; Calabro, V.; Iorio, G. An analysis of the transport phenomena occurring during food drying process. J. Food Eng. 2007, 78, 922–932. [Google Scholar] [CrossRef]

- Da Silva, W.P.; Precker, J.W.; e Silva, D.D.; e Silva, C.D.; de Lima, A.G. Numerical simulation of diffusive processes in solids of revolution via the finite volume method and generalized coordinates. Int. J. Heat Mass Tran. 2009, 52, 4976–4985. [Google Scholar] [CrossRef]

- Datta, A.K. Porous media approaches to studying simultaneous heat and mass transfer in food processes. I: Problem formulations. J. Food Eng. 2007, 80, 80–95. [Google Scholar] [CrossRef]

- Defraeye, T. Advanced computational modelling for drying processes—A review. Appl. Energy 2014, 131, 323–344. [Google Scholar] [CrossRef]

- Defraeye, T.; Verboven, P.; Nicolai, B. CFD modelling of flow and scalar exchange of spherical food products: Turbulence and boundary-layer modelling. J. Food Eng. 2013, 114, 495–504. [Google Scholar] [CrossRef] [Green Version]

- Erbay, Z.; Icier, F. A review of thin layer drying of foods: Theory, modeling, and experimental results. Crit. Rev. Food Sci. Nutr. 2010, 50, 441–464. [Google Scholar] [CrossRef]

- Giner, S.A. Influence of Internal and External Resistances to Mass Transfer on the constant drying rate period in high-moisture foods. Biosyst. Eng. 2009, 102, 90–94. [Google Scholar] [CrossRef]

- Khan, F.A.; Straatman, A.G. A conjugate fluid-porous approach to convective heat and mass transfer with application to produce drying. J. Food Eng. 2016, 179, 55–67. [Google Scholar] [CrossRef]

- Lamnatou, C.; Papanicolaou, E.; Belessiotis, V.; Kyriakis, N. Conjugate heat and mass transfer from a drying rectangular cylinder in confined air flow. Numer. Heat Tran. 2009, 56, 379–405. [Google Scholar] [CrossRef]

- Oztop, H.F.; Akpinar, E.K. Numerical and experimental analysis of moisture transfer for convective drying of some products. Int. Commun. Heat Mass Tran. 2008, 35, 169–177. [Google Scholar] [CrossRef]

- Ruiz-Lòpez, I.I.; García-Alvarado, M.A. Analytical solution for food-drying kinetics considering shrinkage and variable diffusivity. J. Food Eng. 2007, 79, 208–216. [Google Scholar] [CrossRef]

- Vahidhosseini, S.M.; Barati, E.; Esfahani, J.A. Green’s function method (GFM) and mathematical solution for coupled equations of transport problem during convective drying. J. Food Eng. 2016, 187, 24–36. [Google Scholar] [CrossRef]

- Van Boekel, M.A.J.S. Kinetic modeling of food quality: A critical review. Compr. Rev. Food Sci. Food Saf. 2008, 7, 144–158. [Google Scholar] [CrossRef]

- Wang, W.; Chen, G.; Mujumdar, A.S. Physical interpretation of solids drying: An overview on mathematical modeling research. Dry. Technol. 2007, 25, 659–668. [Google Scholar] [CrossRef]

- Friso, D. Ingegneria Dell’industria Agroalimentare (Food Engineering Operations), 1st ed.; CLEUP: Padova, Italy, 2018; Volume 2, pp. 98–105. [Google Scholar]

- Geankoplis, C.J. Transport Process Unit Operations, 3rd ed.; Prentice-Hall International: Englewood Cliffs, NJ, USA, 1993; pp. 520–562. [Google Scholar]

- Salemović, D.R.; Dedić, A.D.; Ćuprić, N.L. Two-dimensional mathematical model for simulation of the drying process of thick layers of natural materials in a conveyor-belt dryer. Therm. Sci. 2017, 21, 1369–1378. [Google Scholar] [CrossRef] [Green Version]

- Salemović, D.R.; Dedić, A.D.; Ćuprić, N.L. A mathematical model and simulation of the drying process of thin layers of potatoes in a conveyor-belt dryer. Therm. Sci. 2015, 19, 1107–1118. [Google Scholar] [CrossRef]

- Xanthopoulos, G.; Okoinomou, N.; Lambrinos, G. Applicability of a single-layer drying model to predict the drying rate of whole figs. J. Food Eng. 2017, 81, 553–559. [Google Scholar] [CrossRef]

- Khankari, K.K.; Patankar, S.V. Performance analysis of a double-deck conveyor dryer—A computational approach. Dry. Technol. 1999, 17, 2055–2067. [Google Scholar] [CrossRef]

- Kiranoudis, C.T.; Maroulis, Z.B.; Marinos-Kouris, D. Dynamic Simulation and Control of Conveyor-Belt Dryers. Dry. Technol. 1994, 12, 1575–1603. [Google Scholar] [CrossRef]

- Pereira de Farias, R.; Deivton, C.S.; de Holanda, P.R.H.; de Lima, A.G.B. Drying of Grains in Conveyor Dryer and Cross Flow: A Numerical Solution Using Finite-Volume Method. Rev. Bras. Pr. Agroind. 2004, 6, 1–16. [Google Scholar] [CrossRef]

- Kiranoudis, C.T.; Markatos, N.C. Pareto design of conveyor-belt dryers. J. Food Eng. 2000, 46, 145–155. [Google Scholar] [CrossRef]

- Friso, D. Conveyor-belt dryers with tangential flow for food drying: Mathematical modeling and design guidelines for final moisture content higher than the critical value. Inventions 2020, 5, 22. [Google Scholar] [CrossRef]

- Friso, D.; Bortolini, L.; Tono, F. Exergetic analysis and exergy loss reduction in the milk pasteurization for Italian cheese production. Energies 2020, 13, 750. [Google Scholar] [CrossRef] [Green Version]

- Friso, D. Energy saving with total energy system for cold storage in Italy: Mathematical modeling and simulation, exergetic and economic analysis. Appl. Math. Sci. 2014, 8, 6529–6546. [Google Scholar] [CrossRef]

- Cerruto, E.; Balsari, P.; Oggero, G.; Friso, D.; Guarella, A.; Raffaelli, M. Operator safety during pesticide application in greenhouses: A survey on Italian situation. Acta Hortic. 2008, 801, 1507–1514. [Google Scholar] [CrossRef]

| Quantity | Symbol | Value |

|---|---|---|

| Belt width | BI (m) | 0.3 |

| Belt length | LTOT (m) | 6.0 |

| Alfalfa bulk height | HI (m) | 0.05 |

| Air section | AA (m2) | 0.15 |

| Form factor·Convective heat transfer coefficient [63] | F·α (W·m−3·K−1) | 5144 |

| Transverse dimension (Figure 3)·Convect. heat transf. coeff. | f·α = BI·HI·F·α (W·m−1·K−1) | 77.16 |

| Air mass flow rate [63] | GAI (kg·s−1) | 0.354 |

| Alfalfa input moisture content (D.B.) | Xl | 1.892 ± 0.110 |

| Alfalfa input moisture content (W.B.) | YI (%) | 65.4 ± 1.3 |

| Alfalfa input bulk density | ρBulkI (kg·m−3) | 197 ± 7.5 |

| Thermal energy [63] | r (kJ·kg−1) | 2617 |

| Belt Speed | Air Input Velocity | Air Input Temperature | Air Exit Temperature | Alfalfa Exit Moisture Cont. |

|---|---|---|---|---|

| vBelt (m/s) | vAI (m/s) | TAI ± S.D. (°C) | TAE ± S.D. (°C) | XF ± S.D. |

| 0.005 | 2.6 | 119.2 ± 1.3 | 58.3 ± 1.2 | 0.332 ± 0.016 |

| 0.005 | 2.5 | 99.5 ± 1.1 | 51.8 ± 0.9 | 0.667 ± 0.023 |

| 0.006 | 2.6 | 119.2 ± 1.3 | 59.1 ± 1.1 | 0.607 ± 0.022 |

| 0.006 | 2.5 | 99.5 ± 1.1 | 52.2 ± 0.9 | 0.879 ± 0.025 |

| Belt Speed | Air Input Temperature | Air Exit Temperature | Experimental Alfalfa Exit Moisture Cont. | Calculated Alfalfa Exit Moisture Cont. | Relat. Error |

|---|---|---|---|---|---|

| vBelt (m/s) | TAI (°C) | TAE (°C) | XF | XF | (%) |

| 0.005 | 119.2 | 58.3 | 0.332 | 0.272 | 18.1 |

| 0.005 | 99.5 | 51.8 | 0.667 | 0.623 | 6.6 |

| 0.006 | 119.2 | 59.1 | 0.607 | 0.559 | 7.9 |

| 0.006 | 99.5 | 52.2 | 0.879 | 0.843 | 4.1 |

| vBelt (m/s) | TAI (°C) | TAE (°C) | Δ (W) | δ(%) | ||

|---|---|---|---|---|---|---|

| 0.005 | 119.2 | 58.3 | 21,666 | 20,857 | −809 | −3.73 |

| 0.005 | 99.5 | 51.8 | 16,970 | 16,378 | −592 | −3.48 |

| 0.006 | 119.2 | 59.1 | 21,382 | 20,631 | −751 | −3.51 |

| 0.006 | 99.5 | 52.2 | 16,828 | 16,253 | −575 | −3.42 |

| Belt Speed | Air Input Temperature | Air Exit Temperature | Experimental Alfalfa Exit Moisture Cont. | Calculated Alfalfa Exit Moisture Cont. | Relat. Error |

|---|---|---|---|---|---|

| vBelt (m/s) | TAI (°C) | TAE (°C) | XF | XF | (%) |

| 0.005 | 119.2 | 58.3 | 0.332 | 0.329 | 0.9 |

| 0.005 | 99.5 | 51.8 | 0.667 | 0.668 | 0.09 |

| 0.006 | 119.2 | 59.1 | 0.607 | 0.606 | 0.13 |

| 0.006 | 99.5 | 52.2 | 0.879 | 0.880 | 0.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Friso, D. Conveyor-Belt Dryers with Tangential Flow for Food Drying: Development of Drying ODEs Useful to Design and Process Adjustment. Inventions 2021, 6, 6. https://doi.org/10.3390/inventions6010006

Friso D. Conveyor-Belt Dryers with Tangential Flow for Food Drying: Development of Drying ODEs Useful to Design and Process Adjustment. Inventions. 2021; 6(1):6. https://doi.org/10.3390/inventions6010006

Chicago/Turabian StyleFriso, Dario. 2021. "Conveyor-Belt Dryers with Tangential Flow for Food Drying: Development of Drying ODEs Useful to Design and Process Adjustment" Inventions 6, no. 1: 6. https://doi.org/10.3390/inventions6010006

APA StyleFriso, D. (2021). Conveyor-Belt Dryers with Tangential Flow for Food Drying: Development of Drying ODEs Useful to Design and Process Adjustment. Inventions, 6(1), 6. https://doi.org/10.3390/inventions6010006