Abstract

This article provides an overview of various microwave-assisted techniques, such as microwave-assisted extraction (MAE), microwave-assisted organic synthesis (MAOS), microwave-assisted pyrolysis (MAP), microwave-assisted hydrothermal treatment (MAHT), microwave-assisted acid hydrolysis (MAAH), microwave-assisted organosolv (MAO), microwave-assisted alkaline hydrolysis (MAA), microwave-assisted enzymatic hydrolysis (MAEH), and microwave-assisted fermentation (MAF). Microwave-assisted biomass pretreatment has emerged as a promising method to improve the efficiency of biomass conversion processes, in particular microwave-assisted pyrolysis (MAP). The focus is on microwave-assisted pyrolysis, detailing its key components, including microwave sources, applicators, feedstock characteristics, absorbers, collection systems, and reactor designs. Based on different studies reported in the literature and a mathematical model, a mechanical design of a microwave oven adapted for pyrolysis is proposed together with a computer-aided design and a finite element analysis. The semi-continuous system is designed for a 40 L capacity and a power of 800 W. The material with which the vessel was designed is suitable for the proposed process. The challenges, opportunities, and future directions of microwave-assisted technologies for the sustainable use of biomass resources are presented.

1. Introduction

Biomass pretreatments are processes that alter specific physical and chemical properties of lignocellulosic biomass to enhance its digestibility and convertibility into various biofuels and biochemicals. These processes target physical properties such as particle size, crystallinity, and porosity, while also modifying chemical properties such as lignin content and structure, hemicellulose solubilization, and cellulose accessibility. Pretreatments aim to reduce particle size, decrease cellulose crystallinity, increase porosity, remove or alter lignin, solubilize hemicellulose, and expose cellulose fibers. Additionally, they may cleave specific chemical bonds, alter pH, and sometimes form inhibitory compounds. By modifying these properties, pretreatments overcome the recalcitrance of lignocellulosic biomass, ultimately facilitating more efficient conversion into valuable products [1]. These pretreatments are crucial for several reasons. Firstly, they break down the recalcitrant lignocellulose structure, making it more accessible to enzymes and microorganisms, thereby improving the efficiency of bioconversion processes [2]. Secondly, they increase the surface area of biomass, allowing for better interaction with enzymes and microorganisms, which enhances the conversion of biomass into biofuels and biochemicals [3]. Additionally, pretreatments can remove or reduce the concentration of inhibitors, such as phenolic compounds, that can inhibit microbial growth and enzyme activity, thereby improving the overall efficiency of bioconversion processes, such as fermentation, enzymatic hydrolysis, anaerobic digestion, syngas fermentation, and hydrothermal valorization [1].

The valorization of biomass waste is of paramount importance in the transition towards a greener, more resource-efficient, and climate-resilient economy, aligning with the United Nations’ Sustainable Development Goals [4]. Biomass waste, including agricultural, municipal, and industrial waste streams, represents a significant untapped resource that can be converted into a wide range of valuable products, such as energy, chemicals, and materials [5]. However, the recalcitrant nature of lignocellulosic biomass, the main component of many biomass waste streams, poses a challenge for efficient conversion. Pretreatment methods are crucial for enhancing the digestibility and convertibility of biomass by breaking down the complex lignocellulose structure, increasing surface area, and reducing inhibitors [6]. Common pretreatment approaches include mechanical, chemical, thermal, and biological methods, which can be optimized to improve the efficiency of bioconversion processes and lead to higher yields of biofuels, biochemicals, and other value-added products [7]. By valorizing biomass waste and employing effective pretreatment strategies, the environmental impact of waste disposal can be reduced, and the principles of the circular economy can be promoted, contributing to a more sustainable future.

Pretreatment of lignocellulosic biomass is a crucial step in the conversion of these materials into valuable products. Various pretreatment methods have been developed to disrupt the recalcitrant structure of lignocellulose and improve the accessibility of cellulose and hemicellulose [8]. These pretreatment techniques can be broadly classified into physical, chemical, physicochemical, and biological approaches.

Physical pretreatments, such as milling, grinding, and extrusion, aim to reduce the particle size and crystallinity of cellulose, thereby increasing the surface area and accessibility for subsequent processing. Chemical pretreatments, on the other hand, utilize acids, alkalis, or organic solvents to solubilize and remove the lignin and hemicellulose components, making the cellulose more susceptible to enzymatic hydrolysis [9]. Physicochemical pretreatments, like steam explosion and liquid hot water treatment, combine physical and chemical methods to achieve efficient biomass deconstruction [2]. Biological pretreatments employ microorganisms, particularly fungi and bacteria, to selectively degrade the lignin component, leaving the cellulose and hemicellulose intact for further processing [10].

This microwave pretreatment seeks to take advantage of microwave radiation to facilitate access to the cellulose in subsequent processes, which can be physical or chemical, to achieve higher yields. One of the subsequent processes can be pyrolysis [11]. The advantages of pretreatment are the reduction of energy consumption for the heating and energy transfer processes. This is followed by a reduction of the processing time, where the decomposition of the biomass is more effective in reducing lignin and hemicellulose and increasing access to cellulose. Finally, it highlights the versatility in the conditions adjustable to the type of biomass [12,13]. Conventional microwave pretreatment, being versatile, allows process innovation such as microwave-assisted pyrolysis pretreatment (MAP), which has several advantages over conventional microwave treatment, including higher yields of products such as bio-oil and gas and reduced carbon formation. It also has environmental benefits by reducing emissions compared to conventional processes and minimizing the use of additional chemical additives in the process [14,15,16]. It is important to mention that this process presents certain advantages that are likely to incline industries to select it over conventional heating methods. The advantages are that its heating is done volumetrically, penetrating the material uniformly, making the energy transfer faster, and reducing the time to reach the desired temperatures. It can achieve energy efficiencies 50–70% higher than conventional methods. It also provides accessibility to power control for better product quality and consistency. Likewise, the equipment used takes up less space, and finally, the chemical reactions occur in an accelerated way. However, this system has some limitations, which include the type of biomass, as the dielectric property can affect the heating efficiency. So far, these have been laboratory-scale equipment, and scaling up has been an obstacle that requires further research and development [12,17,18,19]. Some of these processes are shown in Table 1.

Table 1.

Applications of microwave-assisted pyrolysis.

Microwave-assisted processes have also emerged as efficient and versatile methods for synthesizing various nanocomposites and functional materials. Recent studies have demonstrated the effectiveness of this approach in producing reduced graphene oxide (rGO)-based materials with enhanced properties. For instance, the in situ deposition of rGO on Ti foil using a simple microwave-assisted hydrothermal method has been reported, showcasing the potential for direct fabrication of graphene-based coatings [20]. Similarly, a one-step microwave–hydrothermal synthesis of rGO-TiO2 nanocomposites has shown promise for enhanced electrochemical oxygen evolution reactions [21]. The versatility of this technique is further exemplified by the preparation of Zn-ZnO(Nw)-rGO electrodes for supercapacitor applications [22] and the development of TiO2/RGO/Ni(OH)2/NF electrodes with high performance for supercapacitors [23]. Additionally, rGO-ZnO nanocomposites with high electrocatalytic effects on water oxidation have been successfully obtained using the microwave–hydrothermal method. These studies collectively highlight the efficiency of microwave-assisted processes in producing well-dispersed, highly functional nanocomposites with improved electrochemical properties. Furthermore, detailed chemical and morphological analyses of rGO/ZnO composites obtained through this method have provided valuable insights into the formation mechanisms and structural characteristics of these materials [24], contributing to a deeper understanding of the microwave-assisted synthesis process.

The design of a microwave-assisted pyrolysis system represents a novel and necessary approach to improving the efficiency and scalability of biomass conversion processes. The key novelty of the design lies in its comprehensive integration of mathematical modeling, CAD design, and finite element analysis (FEA) to optimize the system performance. The mathematical model developed for systems accurately captures the complex interactions between microwave energy, biomass feedstock, and pyrolysis products, enabling a deeper understanding of the underlying mechanisms [25]. The CAD design of the reactor is then optimized to maximize microwave energy absorption and ensure uniform heating of the biomass, with specifications tailored to the specific application. The FEA results further validate the design, demonstrating the ability to achieve the desired temperature profiles and reaction conditions for efficient pyrolysis. By integrating these advanced modeling and simulation techniques, the researchers have developed a novel approach to designing a highly efficient microwave-assisted pyrolysis system that can be scaled up for industrial applications, addressing the growing need for sustainable and cost-effective biomass conversion technologies.

2. Microwave-Assisted Pretreatment

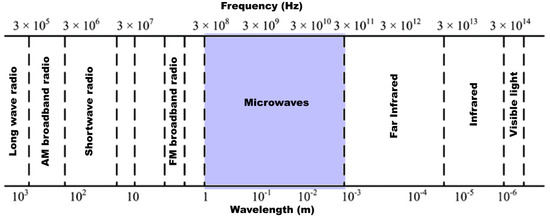

Microwave-assisted processes are chemical reactions that use microwave energy to heat and transform materials. The wavelength of microwaves ranges from about 1 mm to 0.1 m, corresponding to frequencies between 300 MHz and 300 GHz [26] (Figure 1). This range includes the entire super high frequency (SHF) band, which is commonly used in microwave communication systems. The mechanism of microwave-assisted processes involves the interaction between the microwave radiation and the molecules of the material being heated. There are three main mechanisms that contribute to the heating process:

Figure 1.

Frequency of microwaves adapted from [11].

Dipolar Polarization: This mechanism occurs when the microwave radiation aligns the dipoles of the molecules, causing them to rotate and generate heat. This is the primary mechanism for heating polar molecules such as water and organic compounds [27].

Ionic Conduction: This mechanism occurs when the microwave radiation causes the ions in the material to move back and forth, generating heat through friction. This mechanism is important for heating ionic compounds such as salts and acids [28].

Interfacial Polarization: This mechanism occurs when the microwave radiation causes the ions at the interface between two materials to move, generating heat through friction. This mechanism is important for heating materials with high surface areas, such as catalysts [29].

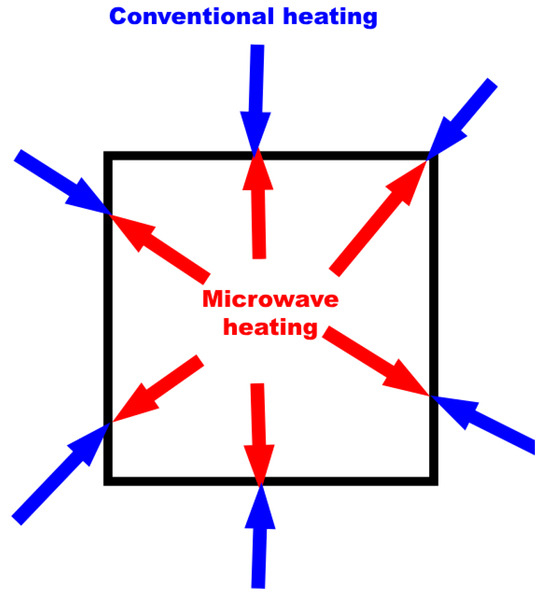

The microwave-assisted process works by exposing the material to microwave radiation, which causes the molecules to heat up and react (Figure 2). The microwave radiation is absorbed by the material, causing the molecules to vibrate and rotate, which generates heat. The heat is then used to drive the chemical reaction, allowing for faster and more efficient processing [30].

Figure 2.

Heat transfer via conventional heating and microwave heating. Adapted from [31].

Microwave-assisted processes cover a broad range of applications, including the following:

Dry Media Synthesis: This method uses microwave energy to synthesize compounds without the use of solvents [32].

Neat Reaction: This method uses microwave energy to synthesize compounds without the use of solvents or catalysts [33].

Solvent-Mediated Synthesis: This method uses microwave energy to synthesize compounds in the presence of solvents [34].

Microwave-Assisted Extraction: This method uses microwave energy to extract compounds from plant tissues [35].

Overall, microwave-assisted processes offer several advantages over traditional heating methods, including faster reaction times, higher yields, and lower energy consumption (Table 2).

Table 2.

Advantages and disadvantages of applications of microwave-assisted processes.

There are different types of microwave-assisted techniques, such as microwave-assisted extraction (MAE), microwave-assisted organic synthesis (MAOS), microwave-assisted pyrolysis (MAP), microwave-assisted hydrothermal treatment (MAHT), microwave-assisted acid hydrolysis (MAAH), microwave-assisted organosolv (MAO), microwave-assisted alkaline hydrolysis (MAA), microwave-assisted enzymatic hydrolysis (MAEH), and microwave-assisted fermentation (MAF).

2.1. Types of Microwaves

Microwave-assisted processes have revolutionized the field of chemistry by offering a rapid, efficient, and selective method for synthesizing a wide range of compounds. These processes utilize microwave energy to accelerate chemical reactions, allowing for the rapid synthesis of complex molecules in a matter of minutes or even seconds [36]. The versatility of microwave-assisted processes has led to their widespread adoption in various fields, including pharmaceuticals, agrochemicals, biotechnology, and materials science [35]. The range of microwave processes includes the following:

Microwave-assisted extraction (MAE) is a technique that combines microwave energy with traditional solvent extraction methods to extract compounds from plant materials. The process involves heating the plant materials mixed with solvents using microwave energy, which causes the solvent to absorb the energy and heat up rapidly. This rapid heating increases the kinetic energy of the solvent molecules, allowing them to penetrate deeper into the plant material and break down the cell walls, releasing the compounds. MAE reduces the extraction time compared to traditional methods, improves the yields of extracted compounds, and can extract thermolabile substances that are difficult to extract using traditional methods. The technique is cost-effective and has been widely used in various industries, including pharmaceuticals, cosmetics, and food processing [37].

Microwave-assisted organic synthesis (MAOS) is a technique that uses microwave energy to accelerate chemical reactions. The process involves heating the reaction mixture with microwave energy, which causes the solvent to heat up rapidly and uniformly. This rapid heating accelerates the chemical reaction, allowing it to proceed faster and more efficiently. MAOS can reduce the reaction time from hours or days to minutes or even seconds, improving the yields and selectivity of the reaction. Additionally, MAOS can reduce energy consumption by using microwave energy, which is more efficient than traditional heating methods [38].

Microwave-assisted pyrolysis (MAP) is a novel method for converting biomass into chemicals and fuels. It involves heating biomass with microwave energy, which selectively activates various chemicals, allowing the production of bio-oil and biochar. MAP has several advantages over traditional pyrolysis methods, including faster reaction times, improved yields, and reduced energy consumption. The technique is particularly useful for converting biomass into bio-oil, which can be used as a renewable energy source. Additionally, MAP can be used to produce biochar, which has applications in various industries, including agriculture and construction [39].

Microwave-assisted hydrothermal treatment (MAHT) is a novel method that combines microwave energy with hydrothermal treatment to convert biomass into various products such as biofuels, chemicals, and biomaterials. This technique uses microwave energy to rapidly heat the biomass, breaking down its complex structure and facilitating the conversion process. MAHT offers several advantages over traditional hydrothermal treatment methods, including faster reaction times, improved yields, and reduced energy consumption. Additionally, MAHT can be scaled up for commercial applications, making it a promising technology for converting biomass into valuable products while reducing environmental impact [40].

Microwave-assisted acid hydrolysis (MAAH) is a technique that uses microwave energy to accelerate the acid hydrolysis of proteins and other biomolecules. In this process, the sample is mixed with an acidic solution, such as hydrochloric acid or trifluoroacetic acid, and then exposed to microwave radiation. The microwave energy rapidly heats the reaction mixture, leading to faster cleavage of the chemical bonds and more efficient hydrolysis compared to conventional heating methods. MAAH has several advantages, including reduced reaction times, improved yields, and the ability to hydrolyze thermally labile compounds. It has been widely used in various applications, such as the hydrolysis of proteins for amino acid analysis, the generation of peptides for mass spectrometry analysis, and the extraction of bioactive compounds from plant materials. The technique’s ability to accelerate hydrolysis reactions while maintaining the integrity of the target molecules makes it a valuable tool in analytical chemistry, proteomics, and natural product research [41].

Microwave-assisted organosolv (MAO) is a method of biomass pretreatment that combines microwave irradiation with organosolv, a solvent-based process, to break down lignocellulosic biomass. In MAO, biomass is mixed with an organosolv solution, such as ethanol, and then exposed to microwave energy, which rapidly heats the reaction mixture. This rapid heating accelerates the breakdown of lignin and other biomass components, making it easier to extract cellulose and other valuable compounds. MAO has been shown to be effective in delignifying biomass, improving the efficiency of subsequent enzymatic hydrolysis, and producing biofuels and biochemicals. The technique has been applied to various biomass sources, including spruce bark, black spruce, and sugar cane bagasse, and has been found to be a promising approach for the sustainable production of bio-based products [42].

Microwave-assisted alkaline pretreatment (MAA) is a method of biomass pretreatment that combines microwave energy with alkaline solutions to break down lignocellulosic biomass. In this process, biomass is mixed with an alkaline solution, such as sodium hydroxide or calcium hydroxide, and then exposed to microwave energy. The microwave energy rapidly heats the reaction mixture, accelerating the breakdown of lignin and other biomass components, making it easier to extract cellulose and other valuable compounds. MAA has been shown to be effective in enhancing enzymatic digestibility, improving the yield of reducing sugars, and reducing the energy required for subsequent hydrolysis steps [43].

Microwave-assisted enzymatic hydrolysis (MAEH) is a technique that combines microwave energy with enzymatic hydrolysis to break down complex biomolecules, such as starch, proteins, and cellulose, into simpler components. In this process, a substrate is mixed with an enzyme and then exposed to microwave energy, which rapidly heats the reaction mixture, accelerating the enzymatic reaction. MAEH has been shown to improve the efficiency and yield of enzymatic hydrolysis, reducing the reaction time and energy consumption compared to traditional methods [44].

Microwave-assisted fermentation (MAF) is a novel method that combines microwave energy with fermentation to enhance the efficiency and productivity of fermentation processes. In MAF, microorganisms are exposed to microwave energy, which rapidly heats the reaction mixture, accelerating the fermentation process. This technique has been shown to improve the yield and quality of fermentation products, such as biofuels, biochemicals, and pharmaceuticals. MAF has been applied to various fermentation processes, including ethanol production from biomass, and has been found to be a promising approach for the sustainable production of bio-based products [45].

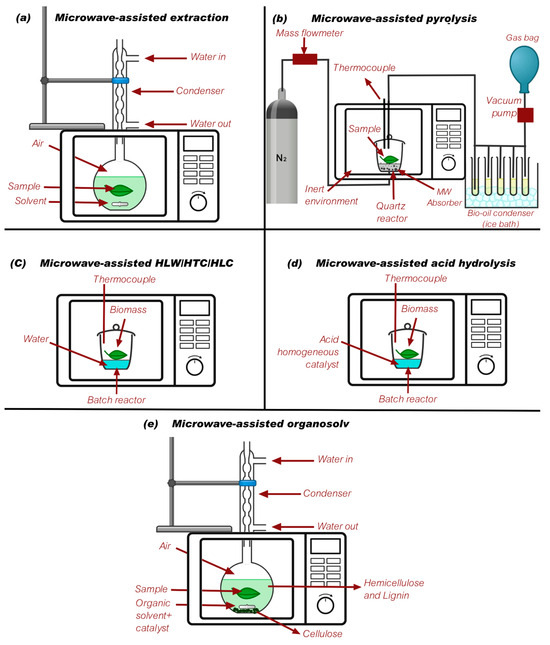

Figure 3 shows the different types of microwaves.

Figure 3.

Types of microwaves adapted from [46].

Microwave-assisted extraction (MAE) is characterized by higher yield, selectivity, extraction efficiency, reduced time and solvent consumption, less environmental pollution, and reduced degradation of thermolabile constituents. Its disadvantages include lack of robustness to outliers, infeasibility for reaction monitoring, expensive equipment, indistinguishable nature of graphs, larger error terms not penalized adequately, a tendency to penalize underestimates more than overestimates, and limited solvent choices [47,48,49]. The advantages of microwave-assisted organosolv (MAO) include high efficiency and productivity, uniform distribution, easy recovery and reuse of organic solvents, fast heating rates, and high temperatures. Its disadvantages are high capital investment, unsuitability for scaling up, and infeasibility for monitoring [50,51,52]. The advantages of microwave-assisted pyrolysis (MAP) include uniform heating of large particulate feed, no requirement for fluidization, fast switching on and off controls, time and energy savings, and minimal ash content in the liquid product. Its disadvantages include the complexity of the microwave heating phenomena, the need for proper heating control devices, limited feedstock options, limited scale-up potential, and high capital cost [53,54,55,56]. The advantages of microwave-assisted hydrothermal treatment (MAHT) are high efficiency and productivity in the hydrothermal process, uniform distribution of heat during the pretreatment process, rapid heat generation that leads to shorter treatment times, energy efficiency, and higher yields at lower operating costs. Its disadvantages include low penetration of radiation in bulk products during microwave heating, the complexity of the microwave heating phenomena that leads to challenges in control, agitation issues with high substrate loading in the microwave reactor, unsuitability for all types of feedstock, and limited versatility [51,57,58]. Finally, the advantages of microwave-assisted acid hydrolysis (MAAH) include high uniformity and selectivity, short process time, and lower energy requirements compared to traditional heating methods. Its disadvantages are high capital investment, unsuitability for scaling up, and infeasibility for monitoring [58,59].

The valorization products obtained from different feedstocks using microwave technology are presented in Table 3.

Table 3.

Reports of agroindustrial waste valorized via microwave processes.

2.2. Microwave-Assisted Pyrolysis

Microwave-assisted pyrolysis is a thermochemical process that utilizes microwave energy to heat and decompose organic materials, such as biomass or plastic waste, in an oxygen-deficient environment. This process offers several advantages over conventional pyrolysis, including rapid and uniform heating, improved product yields and selectivity, and potential energy savings.

The mechanism of microwave-assisted pyrolysis involves the direct and selective heating of the feedstock material by microwave radiation, leading to rapid, volumetric heating. Microwaves are electromagnetic waves with frequencies ranging from 300 MHz to 300 GHz. In microwave-assisted pyrolysis, the feedstock material is exposed to microwave radiation, typically at frequencies of 2.45 GHz or 915 MHz, which are allocated for industrial and scientific applications [67,68,69]. The heating mechanism in microwave-assisted pyrolysis is based on the interaction between the microwave radiation and the dielectric properties of the feedstock material. The dielectric properties determine the ability of the material to absorb and dissipate microwave energy in the form of heat [70]. When the feedstock material is exposed to microwave radiation, the oscillating electric field causes the dipoles (polar molecules) and ions present in the material to rotate and align with the alternating field. This constant reorientation and friction between the molecules and ions generate heat within the material through dielectric heating [71].

One of the key advantages of microwave-assisted pyrolysis is the selective heating of the feedstock material. Different components of the feedstock, such as cellulose, hemicellulose, and lignin in biomass, have different dielectric properties and, therefore, absorb microwave energy at different rates and temperatures. This selective heating can lead to improved product selectivity and control over the pyrolysis process [72]. Additionally, microwave heating is a volumetric heating process, meaning that the entire volume of the material is heated simultaneously, unlike conventional heating methods where heat is transferred from the surface to the interior [73]. This volumetric heating results in rapid and uniform heating, reducing temperature gradients and hot spots within the material [74].

The rapid and selective heating provided by microwave-assisted pyrolysis can significantly influence the reaction kinetics and product distribution compared to conventional pyrolysis. The higher heating rates and lower activation energies associated with microwave heating can lead to different reaction pathways and product compositions [75].

Microwave-assisted pyrolysis involves several key components and processes. The main parts are presented below.

2.2.1. Microwave Source

Microwave sources are devices that generate electromagnetic radiation in the microwave frequency range, typically between 300 MHz and 300 GHz. One category is vacuum tube devices, which include the magnetron (a high-power vacuum tube that generates microwaves using the interaction of an electron beam with a magnetic field, widely used in microwave ovens, radar systems, and industrial heating applications), the klystron (a linear-beam vacuum tube that amplifies or generates microwaves through velocity modulation of an electron beam, commonly used in particle accelerators, radar systems, and satellite communication systems), and the traveling-wave tube (TWT) (a vacuum tube that amplifies microwaves by transferring energy from an electron beam to a propagating electromagnetic wave, used in satellite communication systems, radar systems, and electronic warfare systems). Another category is solid-state devices, such as the Gunn diode (a solid-state device that generates microwaves through the transfer of electrons in a bulk semiconductor material, used in low-power applications like local oscillators in microwave receivers and transmitters), the IMPATT diode (a solid-state device that generates microwaves through the avalanche breakdown of a reverse-biased semiconductor junction, used in low-power applications such as radar systems and communication systems), and MMICs (Monolithic Microwave Integrated Circuits, which are integrated circuits that combine various solid-state microwave components on a single semiconductor substrate, used in wireless communication systems, radar systems, and satellite communication systems).

Other types of microwave sources include the maser (Microwave Amplification by Stimulated Emission of Radiation, a device that amplifies or generates microwaves through the stimulated emission of radiation from atoms or molecules, used in radio astronomy, spectroscopy, and long-distance communication systems), the backward-wave oscillator (BWO) (a vacuum tube that generates microwaves through the interaction of an electron beam with a periodic structure, used as tunable microwave sources in applications like spectroscopy and plasma diagnostics), and the gyrotron (a vacuum tube that generates high-power microwaves through the cyclotron motion of electrons in a magnetic field, used in plasma heating for nuclear fusion reactors, radar systems, and material processing applications) [76]. The choice of a particular microwave source depends on factors such as the desired frequency range, power level, efficiency, and application requirements.

2.2.2. Microwave Applicator

A microwave applicator is a crucial component in microwave-assisted pyrolysis systems, responsible for efficiently coupling the microwave energy with the feedstock material and ensuring uniform heating. Applicators can be designed as single-mode cavities or multimode cavities, depending on the application and requirements. Single-mode cavities support a single resonant mode of the microwave field and are used for small-scale applications or when precise control over the field distribution is required, such as cylindrical cavities and rectangular waveguides [77]. Multimode cavities support multiple resonant modes, resulting in a more complex field distribution, and are commonly used for larger-scale applications or when uniform heating of larger volumes is desired, such as rectangular cavities and hexagonal cavities [78]. The choice of materials for the applicator is crucial, with common options including ceramics [79], quartz glass [80], and refractory metals [81], as they must be transparent to microwave radiation while withstanding high temperatures and potentially corrosive environments.

Efficient coupling of the microwave energy into the applicator is essential for effective heating, and several techniques are employed, including waveguide coupling, antenna coupling, and slot coupling [82]. Achieving uniform heating within the applicator is also crucial for consistent and efficient pyrolysis, and strategies such as mode stirrers, material agitation, and applicator design optimization are used to improve heating uniformity. Mode stirrers continuously change the microwave field distribution, promoting uniform heating, while material agitation ensures uniform exposure to the microwave field. Applicator design optimization involves using computational electromagnetic simulations to optimize the shape and dimensions of the applicator for more uniform field distributions. By carefully designing and optimizing the microwave applicator, researchers and engineers can ensure efficient and uniform heating of the feedstock material, leading to improved process control and product quality in microwave-assisted pyrolysis applications [83].

2.2.3. Feedstock Material

The feedstock material can be biomass (e.g., wood, agricultural residues), plastics, or other organic waste materials that are to be pyrolyzed. The dielectric properties of the feedstock play a crucial role in its ability to absorb microwave energy. Biomass feedstocks are commonly used in microwave-assisted pyrolysis processes [84]. These include lignocellulosic biomass such as wood chips, sawdust, and agricultural residues like corn stover, wheat straw, and sugarcane bagasse. Sewage sludge and forest biomass are also suitable feedstocks [85]. Plastic waste feedstocks, including mixed plastic waste streams and waste automotive engine oil, can also be utilized in microwave-assisted pyrolysis. The feedstock characteristics significantly affect the process, similar to conventional pyrolysis. Factors like particle size, moisture content, and inorganic and organic composition of the feedstock influence the heating behavior, product yields, and selectivity [86].

The unique features of microwave heating strongly depend on the physical and chemical properties of the biomass feedstock. The dielectric properties of the feedstock determine its ability to absorb and dissipate microwave energy. Different components of biomass feedstocks, such as cellulose, hemicellulose, and lignin, have varying dielectric properties, leading to selective heating and activation at different temperatures [87]. This can improve product selectivity compared to conventional pyrolysis. Additionally, microwave absorbers or susceptors, like carbon materials and metal oxides, can be added to the feedstock to enhance microwave energy absorption and heating efficiency. The choice of feedstock and its characteristics play a crucial role in the heating behavior, product distribution, and selectivity of the microwave-assisted pyrolysis process [88].

2.2.4. Microwave Absorbers

Many biomass feedstocks have low dielectric properties, making them poor absorbers of microwave energy [89]. This can lead to inefficient heating and nonuniform temperature distribution during the pyrolysis process. To overcome this challenge, microwave absorbers or susceptors are added to the feedstock. These materials are highly microwave-absorbing and can convert electromagnetic energy into heat through various mechanisms, such as dielectric heating, conduction, and interfacial polarization [90]. Common examples include carbon-based materials like activated carbon, carbon black, graphite, and biochar, as well as metal oxides like silicon carbide (SiC), ferrites (e.g., NiFe2O4), and magnetite (Fe3O4) [91].

The microwave absorption mechanisms of these materials vary. Carbon-based materials have good electrical conductivity and can absorb microwaves through conduction and interfacial polarization mechanisms [92]. Metal oxides, on the other hand, are typically semiconductors or insulators and absorb microwaves through dielectric heating and interfacial polarization mechanisms [93]. In addition to enhancing microwave absorption, some of these materials can also act as catalysts in the pyrolysis process, influencing the product distribution and selectivity. For example, metal oxides like SiC and Fe3O4 have been reported to catalyze the cracking of larger molecules, leading to increased gas and liquid product yields [94]. The amount of microwave absorber/susceptor added to the feedstock needs to be optimized, as too little may not provide sufficient heating, while excessive amounts can lead to overheating, hotspot formation, and potential agglomeration or sintering of the material.

2.2.5. Product Collection System

The pyrolysis of biomass or waste feedstocks under microwave heating results in the formation of three main product fractions: bio-oil, syngas (a mixture of gases like hydrogen, carbon monoxide, methane, etc.), and solid char/biochar [95]. To effectively collect and separate these fractions, microwave-assisted pyrolysis systems employ various components and setups. The hot vapor stream from the pyrolysis reactor is passed through a series of condensers, typically water-cooled or air-cooled, to condense the condensable vapors (bio-oil) while allowing the non-condensable gases (syngas) to pass through [96]. The non-condensable gases (syngas) are collected in gas sampling bags or cylinders for further analysis and potential utilization, such as combustion for energy recovery or catalytic upgrading [97]. The solid char or biochar residue remaining in the pyrolysis reactor is collected separately, often after cooling, for potential applications like soil amendment and activated carbon production or as a solid fuel [98].

The distribution and composition of the pyrolysis products are influenced by several factors. The type of feedstock (e.g., biomass, plastic waste), its composition (e.g., cellulose, hemicellulose, lignin content), and physical properties (e.g., particle size, moisture content) significantly affect the product distribution and composition [99]. Process conditions such as microwave power, heating rate, temperature, residence time, and the presence of catalysts or additives can be optimized to favor the formation of desired products (e.g., higher bio-oil yield, increased syngas production). The unique feature of microwave heating, where different components of the feedstock can be selectively heated due to their varying dielectric properties, can lead to improved product selectivity compared to conventional pyrolysis [100].

Additionally, the addition of catalysts or microwave absorbers/susceptors can influence the product distribution and composition by promoting specific reactions or cracking pathways. Depending on the system design, additional filtration or separation units may be employed to remove particulates, tar, or other impurities from the bio-oil or syngas streams.

2.2.6. Pyrolysis Reactor

The pyrolysis reactor is a crucial component in microwave-assisted pyrolysis systems, as it serves as the vessel where the feedstock material is heated and the pyrolysis reactions take place. These reactors are designed to withstand the high temperatures required for pyrolysis, typically ranging from 400 °C to 900 °C, depending on the feedstock and desired product distribution [101]. The reactors are also designed to provide an oxygen-deficient or inert atmosphere, which is essential for the pyrolysis process to occur efficiently.

There are two main approaches to the design of pyrolysis reactors in microwave-assisted systems. In one approach, the pyrolysis reactor is integrated with the microwave applicator, where the feedstock material is directly heated by the microwave radiation within the reactor vessel. This design is commonly used for batch processing of feedstocks, such as biomass or plastic waste. The reactor vessel is typically made of materials that are transparent to microwave radiation, such as quartz or certain ceramics, allowing the microwaves to penetrate and heat the feedstock. In the other approach, the pyrolysis reactor is a separate unit from the microwave applicator. The feedstock material is first heated by the microwave radiation in the applicator, and then the heated material is transferred to the pyrolysis reactor, where the pyrolysis reactions take place. This approach is often used for continuous processing of feedstocks, where the heated material can be continuously fed into the pyrolysis reactor.

2.2.7. Temperature and Pressure Control

Temperature monitoring and control are essential in microwave-assisted pyrolysis due to the unique heating mechanisms involved. Microwave heating can lead to nonuniform temperature distributions within the feedstock, making it difficult to measure the actual temperature accurately. Additionally, microwave radiation can interfere with conventional temperature measurement techniques, such as thermocouples or infrared thermometers, leading to inaccurate readings. To overcome these challenges, various temperature monitoring techniques are employed, including fiber-optic temperature sensors (immune to microwave interference), infrared thermography (mapping temperature distributions on surfaces), and computational modeling (predicting temperature distributions) [102]. Temperature control systems, such as feedback loops and control algorithms, are integrated with the microwave power supply to maintain the desired temperature profiles during the pyrolysis process.

Pressure monitoring and control are essential for maintaining an oxygen-deficient or inert atmosphere within the pyrolysis reactor. Pressure gauges, such as manometers or digital pressure sensors, are used to monitor the pressure within the reactor. Automated control valves are employed to regulate the flow of inert gases or vacuum systems, maintaining the desired pressure levels during the pyrolysis process. Proper pressure control is crucial for preventing air ingress, which can lead to undesired oxidation reactions and affect the product quality and yield. By integrating temperature and pressure monitoring and control systems, researchers and engineers can ensure the safe and efficient operation of microwave-assisted pyrolysis systems, maintain the desired process conditions, and optimize the product quality and yield.

Microwave-assisted pyrolysis has emerged as a promising technology for the valorization of various biomasses and feedstocks. The advantages of this technique, including energy efficiency, selective activation of chemicals, and high heating rates, make it an attractive option for improving processes in different industries. The ability to control the reaction conditions and optimize the yield of bio-oil and biochar makes microwave-assisted pyrolysis a valuable tool for the production of renewable energy and the development of sustainable products. Furthermore, the potential for microwave-assisted pyrolysis to be used with different biomasses and feedstocks opens new opportunities for the valorization of waste materials and the production of valuable chemicals. As the world continues to grapple with the challenges of climate change and sustainable development, the use of microwave-assisted pyrolysis is likely to play an increasingly important role in the development of innovative and sustainable solutions.

Table 4 presents different conditions and value-added products that were obtained by previous researchers using different conditions of microwave-assisted pyrolysis.

Table 4.

Microwave-assisted pyrolysis conditions reported in the literature.

The investment required for the installation of a MAP system is high and will depend on the power supply system. They have realized MAP systems connected to solar energy and to the grid. The systems connected to solar energy have an investment of around 3.5 million euros to process 1125 tons of raw material per year and a return on investment of 1.6 years, while the systems connected to the grid are less expensive, and their return on investment is calculated at half a year, although it must be a decision that is compared with the environmental benefits. The MAP system has a carbon intensity of −57.6 g CO2-eq/MJ for biofuels, which is attributed to the use of electricity, and for this reason, solar energy retrofitting was implemented. Additionally, they effectively transform agricultural leftovers into beneficial goods, lessening the environmental impact of disposing of garbage. In addition to recycling biomass, the method turns waste materials into biofuels and fertilizers, supporting environmentally friendly waste management techniques [110,111].

3. Biomass Specifications

The specifications of the biomass feedstock play a crucial role in influencing the performance and outcomes of microwave-assisted pyrolysis (MAP). Several key parameters of the biomass need to be considered:

Moisture Content: Biomass with high moisture content (>10%) is better suited for MAP as the polar water molecules absorb microwave energy efficiently, leading to rapid heating and pyrolysis. Dry biomass with low moisture content may not couple well with the microwave field, resulting in uneven heating and lower conversion efficiency [86,112].

Particle Size and Surface Area: Smaller particle sizes and higher surface area-to-volume ratios enhance the interaction between the biomass and microwave energy, improving heat transfer and reaction kinetics. Larger particle sizes can lead to uneven heating and incomplete pyrolysis, reducing the yield and quality of the products [35].

Composition and Structural Properties: The relative proportions of cellulose, hemicellulose, and lignin in the biomass influence the pyrolysis pathways and product distribution. Biomass with higher lignin content tends to produce more char, while cellulose-rich biomass favors the formation of bio-oil. The structural properties, such as crystallinity and porosity, also affect the microwave absorption and heat transfer within the biomass [113].

Dielectric Properties: The dielectric properties, including dielectric constant and loss factor, determine the ability of the biomass to absorb and convert microwave energy into heat. Biomass with higher dielectric loss factors, such as lignocellulosic materials, are more suitable for MAP as they can efficiently convert microwave energy into heat [114].

Ash Content and Mineral Composition: The presence of inorganic minerals and ash in the biomass can influence the pyrolysis reactions and the quality of the products. Certain minerals, such as alkali and alkaline earth metals, can catalyze the pyrolysis reactions and affect the composition of the bio-oil and biochar [114].

By understanding the influence of these biomass specifications, researchers can optimize the MAP process parameters, such as microwave power, heating rate, and residence time, to maximize the yield and quality of the desired products (bio-oil, biochar, and syngas). Additionally, pretreatment methods, such as size reduction, drying, and demineralization, can be employed to tailor the biomass properties and further enhance the performance of the MAP process.

4. Designed Development

4.1. Mathematical Model

This phenomenon of microwave heating in certain materials is given by Maxwell’s equations, which drive the propagation of microwave radiation where the absorption and diffusion of heat from the material are guided. Therefore, Equation (1) describes the nonlinear steady-state diffusion characterizing the thermal behavior [115,116].

Lambert’s law expresses the microwave energy exponentially as a function of the penetration distance from the surface according to the attenuation factor as an analytical solution to Maxwell’s equation for microwaves in the sphere, as shown in Equation (2) [117,118].

where P(Z) corresponds to the energy absorbed by the object as a function of the penetration distance from the surface Z in meters, Po is the intensity of the radiation in Bacquerel, and β is the attenuation factor in decibels. The attenuation factor varies with time and position during the cycle, giving rise to a mathematical solution, which is Equation (3) for the absorbed energy (Q) [117,118].

Heating in a microwave oven does not occur uniformly; therefore, the microwave power can be calculated with Equation (4).

where Cp is the heat capacity of water (kcal/°C·kg), is the weight of water (kg/l), ΔT is the temperature rise of water (°C), and t is the length of time the microwave is energized in seconds [119].

It is also important to note the wavelength at which the resonance (λ) is given, as shown in Equation (5).

where M, N, and P are the wavenumbers or half-waves of variation of the E field in the W, D, and H directions. Besides, W, D, and H are the width, depth, and height of the cavity [120].

4.2. Specifications and CAD Design

The basic structure of the domestic microwave oven consists of the cavity magnetron, high-voltage power source, high-voltage capacitor, magnetron control circuit, short waveguide, metal cooking chamber, and stirring and control panel. However, an adaptation was made in its structure, where its parts are the microwave cavity, cooling water inlet, condenser tube, cooling water outlet, connecting tube, irradiation microwave zone, boiling flask with organic solvent, soil example, and magnetron from this design, together with the theory of microwave-assisted pyrolysis pretreatment [119].

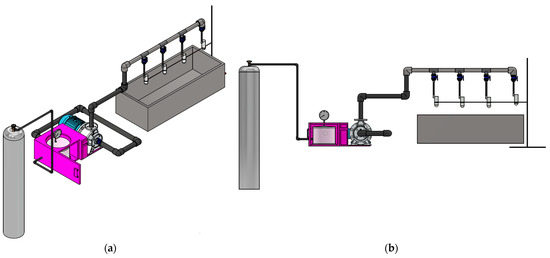

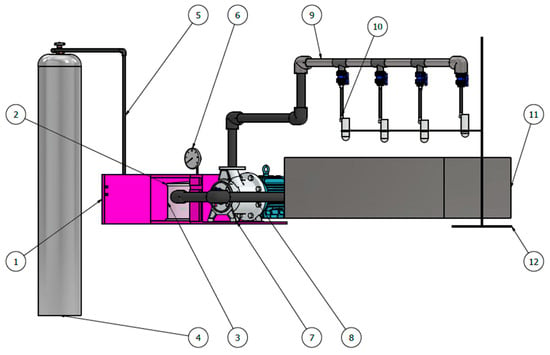

A continuous system was designed for the microwave-assisted pyrolysis process. This design was based on the selection and adaptation of conventional microwaves with a power output of 800 W, which was selected based on the literature. Based on the measurements of the furnace and capacity, the first adaptation is made, which consists of the entry of the glass container in the upper part of the furnace, resulting in the container having a capacity of approximately 40 L. The glass vessel has two inlets, the first is a manual inlet for liquids and solids, and the second is the gas inlet on the side. This inlet is controlled by the regulating valve, and the filling is intended to be fast, approximately in 5 min with a flow rate of 0.13 L/s. A thermometer for temperature control was also placed on the top of the glass vessel. The second adaptation involves the outlet of the liquid and gas for condensation and separation. It consists of a pumping system from the glass vessel to the condensation tubes, which are regulated by two-way ball valves and supported by a tee, and from the water tank under them.

The design that has been established is shown in Figure 4, and the materials used are 304 stainless steel for the equipment, such as the furnace and tank. For the piping, stainless steel and rubber were used in some parts. Finally, quartz was chosen for the glass vessel. A summary of the microwave design features is shown in Table 5.

Figure 4.

Design for microwave-assisted pyrolysis. (a) Left side view of the design and (b) front side view of the design.

Table 5.

Characteristics of design.

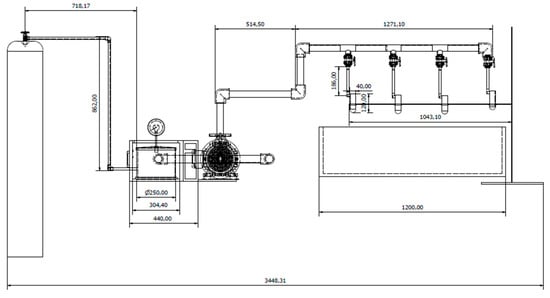

The equipment is designed in Inventor program version 2023. Based on the above explanation, the microwave was designed to assist pyrolysis, and from the microwave oven, the scale for the whole procedure was established. Figure 5 shows the parts of the design, and Figure 6 illustrates the dimensions.

Figure 5.

Parts of the design for microwave-assisted pyrolysis. 1. Microwave oven. 2. Glass vessel lid. 3. Glass vessel. 4. Gas bullet. 5. Gas piping. 6. Thermometer. 7. Pump. 8. Pump piping. 9. Condensation piping. 10. Condensation tubes. 11. Condensation tank. 12. Tee support.

Figure 6.

Dimensions of the design for microwave-assisted pyrolysis.

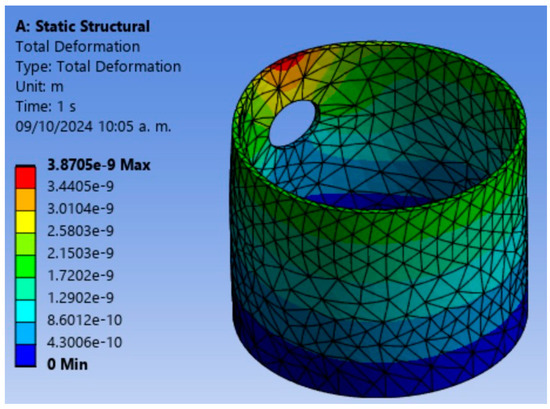

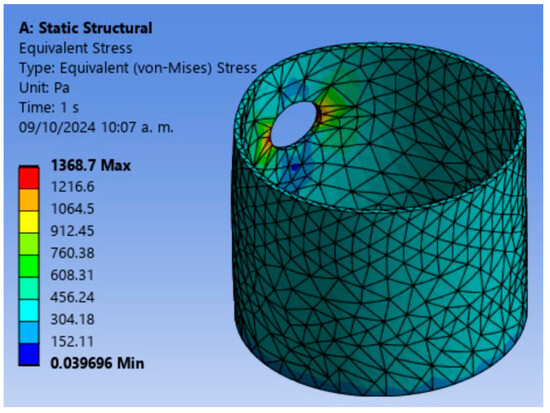

4.3. Finite Element Analysis

The analysis was performed in Ansys software version 2024. In the semi-continuous microwave design, the glass vessel was the main part of the reaction due to the contact it had with the materials used in the pretreatment. For the finite element analysis, the properties of quartz, which is the material designated for the reaction vessel, were defined. The characteristics of quartz are a density of 2650 kg/m3 and a modulus of elasticity of 37 GPa. In addition, boundary conditions have been established where the fixed support is at the bottom of the vessel, a force is defined by the vessel lid, and finally, a force is defined by the volume and weight that the vessel can handle. For the analysis, a solution of the total deformation and the von Mises stress is established.

Figure 7 shows that the vessel undergoes minimal deformation, with the largest deformation being 3.8705 × 10−9 m, which occurs in a small portion near the inlet and outlet holes of the vessel. It is also observed that the minimum deformation occurs near the fixed support of the reactor, and from there upwards, the value starts to increase to approximately 2.1504 × 10−9 m. Therefore, it is evident that the vessel is resistant to this process, along with the loads it has, and will fulfill its function.

Figure 7.

Total deformation for the glass vessel.

Figure 8 shows the behavior of the glass vessel with respect to the Von Mises stress. It is evident that the minimum stress of the vessel corresponds to 0.0396 Pa, which occurs in minimal regions at the bottom. Also, the maximum stress of 1368, 7 Pa is not very pronounced in the vessel; however, it is observed in red, yellow, and orange. It is the stress in the area of the holes that seems to be the most critical part. Finally, the stress of 304.18 Pa is pronounced in a light blue color in 85% of the vessel. Now, the maximum tensile stress of the material is 535 Pa; the vessel mostly complies with this value. However, it is essential to review the critical areas where it exceeds this value.

Figure 8.

Equivalent stress for the glass vessel.

5. Conclusions

In conclusion, microwave-assisted pretreatment, particularly microwave-assisted pyrolysis (MAP), has emerged as a highly effective and versatile method for enhancing biomass conversion processes. The integration of various microwave-assisted techniques, such as MAE, MAOS, MAHT, and MAAH, has led to significant advancements in biomass valorization, demonstrating the potential to achieve high yields of valuable products with efficiencies reaching up to 80%.

The success of MAP can be attributed to its unique heating mechanism, which allows for rapid and uniform heating of biomass materials. This results in improved reaction kinetics and product selectivity compared to conventional heating methods. For instance, studies have shown that MAP can achieve heating rates of up to 200 °C/min, significantly reducing reaction times from hours to minutes. This rapid heating not only enhances process efficiency but also contributes to reducing energy consumption by up to 50% compared to traditional pyrolysis methods.

The design of a specialized microwave oven adapted for joint pyrolysis processes represents a significant step towards addressing the challenges of scaling up MAP technology. With a capacity of 40 L and featuring a quartz vessel, this system demonstrates the potential for larger-scale applications. The incorporation of an argon injection system and a condensation system for liquid and gaseous products further enhances its versatility. This prototype-scale design, with its carefully evaluated construction materials, proves that MAP can be effectively scaled up while maintaining process integrity and safety.

Looking forward, continued research and development in microwave-assisted technologies are essential to further optimize process parameters and expand the range of biomass feedstocks that can be effectively utilized. Current research indicates that MAP can process a wide variety of biomass types, including agricultural residues, forestry waste, and algal biomass, with conversion efficiencies varying from 60% to 90% depending on the feedstock and process conditions. As the technology matures, it is expected that these efficiencies will improve, potentially reaching 95% for certain feedstocks. Moreover, the economic viability of MAP is promising, with some studies suggesting that it could reduce overall processing costs by 20–30% compared to conventional pyrolysis methods, primarily due to reduced energy consumption and improved product yields.

6. Challenges or Future Prospective

Microwave-assisted pyrolysis (MAP) of biomass faces several challenges that need to be addressed for its wider adoption and commercialization. One of the primary challenges is the design and optimization of microwave reactors suitable for large-scale operations. Current research is largely limited to laboratory-scale experiments, and scaling up the process while maintaining efficiency and product quality remains a significant hurdle. The nonuniform heating patterns in microwave systems, particularly for larger volumes of biomass, can lead to inconsistent pyrolysis results and potential hotspot formation. Additionally, the selection and integration of appropriate microwave absorbers and catalysts that can withstand the harsh pyrolysis conditions while enhancing process efficiency and product selectivity remain ongoing areas of research.

Looking towards the future, there are promising prospects for MAP technology. The development of advanced microwave reactor designs that incorporate better temperature control, uniform heating, and continuous processing capabilities could significantly improve the scalability and efficiency of the process. Future research should focus on the evaluation of different absorbent-catalyst integrations and the exploration of synergistic effects between microwave heating and catalysis. There is also potential for combining MAP with other technologies, such as torrefaction or gasification, to create more versatile and efficient biomass conversion systems. As the technology matures, it could play a crucial role in the sustainable production of biofuels and biochemicals, contributing to the transition towards a more circular bioeconomy. However, to realize these prospects, continued research and development efforts, along with pilot-scale demonstrations, will be essential to overcome the current limitations and optimize the MAP process for industrial applications.

Author Contributions

Conceptualization, C.A.G.F., P.A.R.C. and A.S.L.P.; data curation, A.S.L.P.; formal analysis, A.S.L.P.; funding acquisition, A.S.L.P. and C.A.G.F.; investigation, P.A.R.C. and A.S.L.P.; methodology, P.A.R.C.; project administration, C.A.G.F.; resources, C.A.G.F.; software, P.A.R.C.; supervision, A.S.L.P. and C.A.G.F.; visualization, P.A.R.C.; writing—original draft, P.A.R.C. and A.S.L.P.; writing—review and editing, A.S.L.P. and C.A.G.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by COLCIENCIAS through the financial support approved for the project titled “Implementation of a hydrothermal biorefinery to produce chemical products with high added value, using residual biomass from agro-industrial processes, in an intersectoral alliance (academy-industry)”, Call 914, Contract 101-2022, code 1101-914-91642.

Data Availability Statement

All data presented is included in this paper.

Acknowledgments

We would like to thank Facultad de Ciencias, Departamento de Química de la Universidad Nacional de Colombia-Bogotá.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Maurya, D.P.; Singla, A.; Negi, S. An overview of key pretreatment processes for biological conversion of lignocellulosic biomass to bioethanol. 3 Biotech 2015, 5, 597–609. [Google Scholar] [CrossRef] [PubMed]

- Brodeur, G.; Yau, E.; Badal, K.; Collier, J.; Ramachandran, K.B.; Ramakrishnan, S. Chemical and Physicochemical Pretreatment of Lignocellulosic Biomass: A Review. Enzym. Res. 2011, 2011, 787532. [Google Scholar] [CrossRef]

- Mahalaxmi, S.; Williford, C. Biochemical Conversion of Biomass to Fuels. In Handbook of Climate Change Mitigation and Adaptation; Springer International Publishing: Cham, Switzerland, 2017; pp. 1777–1811. [Google Scholar] [CrossRef]

- Lizundia, E.; Luzi, F.; Puglia, D. Organic waste valorisation towards circular and sustainable biocomposites. Green Chem. 2022, 24, 5429–5459. [Google Scholar] [CrossRef]

- Kalak, T. Potential Use of Industrial Biomass Waste as a Sustainable Energy Source in the Future. Energies 2023, 16, 1783. [Google Scholar] [CrossRef]

- Blasi, A.; Verardi, A.; Lopresto, C.G.; Siciliano, S.; Sangiorgio, P. Lignocellulosic Agricultural Waste Valorization to Obtain Valuable Products: An Overview. Recycling 2023, 8, 61. [Google Scholar] [CrossRef]

- Amin, F.R.; Khalid, H.; Zhang, H.; Rahman, S.U.; Zhang, R.; Liu, G.; Chen, C. Pretreatment methods of lignocellulosic biomass for anaerobic digestion. AMB Express 2017, 7, 72. [Google Scholar] [CrossRef] [PubMed]

- Shafiei, M.; Kumar, R.; Karimi, K. Pretreatment of Lignocellulosic Biomass. In Lignocellulose-Based Bioproducts; Springer: Berlin/Heidelberg, Germany, 2015; pp. 85–154. [Google Scholar] [CrossRef]

- Behera, S.; Arora, R.; Nandhagopal, N.; Kumar, S. Importance of chemical pretreatment for bioconversion of lignocellulosic biomass. Renew. Sustain. Energy Rev. 2014, 36, 91–106. [Google Scholar] [CrossRef]

- Mattanovich, D.; Sauer, M.; Gasser, B. Yeast Biotechnology: Teaching the Old Dog New Tricks. In New Microbial Technologies for Advanced Biofuels; Apple Academic Press: Williston, VT, USA, 2015; pp. 107–116. [Google Scholar] [CrossRef]

- Hu, X.; Ma, D.; Zhang, G.; Ling, M.; Hu, Q.; Liang, K.; Lu, J.; Zheng, Y. Microwave-assisted pyrolysis of waste plastics for their resource reuse: A technical review. Carbon Resour. Convers. 2023, 6, 215–228. [Google Scholar] [CrossRef]

- Mikulski, D.; Kłosowski, G. High-pressure microwave-assisted pretreatment of softwood, hardwood and non-wood biomass using different solvents in the production of cellulosic ethanol. Biotechnol. Biofuels Bioprod. 2023, 16, 19. [Google Scholar] [CrossRef]

- Hoang, A.T.; Nižetić, S.; Ong, H.C.; Mofijur, M.; Ahmed, S.; Ashok, B.; Bui, V.T.V.; Chau, M.Q. Insight into the recent advances of microwave pretreatment technologies for the conversion of lignocellulosic biomass into sustainable biofuel. Chemosphere 2021, 281, 130878. [Google Scholar] [CrossRef]

- Ludlow-Palafox, C.; Chase, H.A. Microwave-Induced Pyrolysis of Plastic Wastes. Ind. Eng. Chem. Res. 2001, 40, 4749–4756. [Google Scholar] [CrossRef]

- Pandey, S.; Erbaugh, J.T. Driving sustainable uptake: A systematic review of global literature on policies governing woody biomass for energy. Discov. Sustain. 2024, 5, 28. [Google Scholar] [CrossRef]

- Ethaib, S.; Omar, R.; Kamal, S.M.M.; Biak, D.R.A.; Zubaidi, S.L. Microwave-Assisted Pyrolysis of Biomass Waste: A Mini Review. Processes 2020, 8, 1190. [Google Scholar] [CrossRef]

- Li, Y.; Campos, L.C.; Hu, Y. Microwave pretreatment of wastewater sludge technology—A scientometric-based review. Environ. Sci. Pollut. Res. 2024, 31, 26432–26451. [Google Scholar] [CrossRef] [PubMed]

- Jablonowski, N.D.; Pauly, M.; Dama, M. Microwave Assisted Pretreatment of Szarvasi (Agropyron elongatum) Biomass to Enhance Enzymatic Saccharification and Direct Glucose Production. Front. Plant Sci. 2022, 12, 767254. [Google Scholar] [CrossRef]

- Mohabeer, C.; Guilhaume, N.; Laurenti, D.; Schuurman, Y. Microwave-Assisted Pyrolysis of Biomass with and without Use of Catalyst in a Fluidised Bed Reactor: A Review. Energies 2022, 15, 3258. [Google Scholar] [CrossRef]

- Romeiro, F.C.; Silva, S.C.; Nossol, E.; Lima, R.C. One step microwave-hydrothermal synthesis of rGO–TiO2nanocomposites for enhanced electrochemical oxygen evolution reaction. New J. Chem. 2020, 44, 6825–6832. [Google Scholar] [CrossRef]

- Volfkovich, Y.M.; Rychagov, A.Y.; Sosenkin, V.E.; Baskakov, S.A.; Kabachkov, E.N.; Shulga, Y.M. Supercapacitor Properties of rGO-TiO2 Nanocomposite in Two-component Acidic Electrolyte. Materials 2022, 15, 7856. [Google Scholar] [CrossRef]

- Guo, J.; Liu, H.; Li, D.; Wang, J.; Djitcheu, X.; He, D.; Zhang, Q. A minireview on the synthesis of single atom catalysts. RSC Adv. 2022, 12, 9373–9394. [Google Scholar] [CrossRef]

- Munnik, P.; de Jongh, P.E.; de Jong, K.P. Recent Developments in the Synthesis of Supported Catalysts. Chem. Rev. 2015, 115, 6687–6718. [Google Scholar] [CrossRef]

- Babu, S.J.; Muniyappa, M.; Rao, V.N.; Mudike, R.; Shastri, M.; Tathagata, S.; Shivaramu, P.D.; Shankar, M.V.; Ananda Kumar, C.S.; Rangappa, D. Enhanced photocatalytic hydrogen evolution from reduced graphene oxide-defect rich TiO2-x nanocomposites. Int. J. Hydrogen Energy 2022, 47, 40242–40253. [Google Scholar] [CrossRef]

- Yang, Y.; Shahbeik, H.; Shafizadeh, A.; Masoudnia, N.; Rafiee, S.; Zhang, Y.; Pan, J.; Tabatabaei, M.; Aghbashlo, M. Biomass microwave pyrolysis characterization by machine learning for sustainable rural biorefineries. Renew. Energy 2022, 201, 70–86. [Google Scholar] [CrossRef]

- Vollmer, M. Physics of the microwave oven. Phys. Educ. 2003, 39, 74–81. [Google Scholar] [CrossRef]

- Sun, J.; Wang, W.; Yue, Q. Review on Microwave-Matter Interaction Fundamentals and Efficient Microwave-Associated Heating Strategies. Materials 2016, 9, 231. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave material processing-a review. AIChE J. 2011, 58, 330–363. [Google Scholar] [CrossRef]

- Muley, P.D.; Wang, Y.; Hu, J.; Shekhawat, D. Microwave-assisted heterogeneous catalysis. In Catalysis; The Royal Society of Chemistry: London, UK, 2021; Volume 33, pp. 1–37. [Google Scholar] [CrossRef]

- Catalytic conversion of CO2 into fuels and chemicals: A green ccu option. In Industrial Catalysis and Separations; Apple Academic Press: Williston, VT, USA, 2014; pp. 186–249. [CrossRef]

- Palma, V.; Barba, D.; Cortese, M.; Martino, M.; Renda, S.; Meloni, E. Microwaves and Heterogeneous Catalysis: A Review on Selected Catalytic Processes. Catalysts 2020, 10, 246. [Google Scholar] [CrossRef]

- Jha, A. Microwave Assisted Synthesis of Organic Compounds and Nanomaterials. In Nanofibers—Synthesis, Properties and Applications; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- de la Hoz, A.; Díaz-Ortiz, A.; Prieto, P. Microwave-Assisted Green Organic Synthesis. In Alternative Energy Sources for Green Chemistry; The Royal Society of Chemistry: London, UK, 2016; pp. 1–33. [Google Scholar] [CrossRef]

- Patneedi, C.; Prasadu, D.; Sekhar, C.; Rao, V. Microwave Mediated Synthesis in Pharmaceutical Chemistry. Rasayan J. Chem. 2015, 2015, 8. [Google Scholar]

- Al-Qahtani, A.M. A Comprehensive Review in Microwave Pyrolysis of Biomass, Syngas Production and Utilisation. Energies 2023, 16, 6876. [Google Scholar] [CrossRef]

- Lew, A.; Krutzik, P.O.; Hart, M.E.; Chamberlin, A.R. Increasing Rates of Reaction: Microwave-Assisted Organic Synthesis for Combinatorial Chemistry. J. Comb. Chem. 2001, 4, 95–105. [Google Scholar] [CrossRef]

- Desai, M.; Parikh, J.; Parikh, P.A. Extraction of Natural Products Using Microwaves as a Heat Source. Sep. Purif. Rev. 2010, 39, 1–32. [Google Scholar] [CrossRef]

- Jun, C.; Chung, J.; Lee, D.; Loupy, A.; Chatti, S. Solvent-Free Chelation-Assisted Intermolecular Hydroacylation: Effect of Microwave Irradiation in the Synthesis of Ketone from Aldehyde and 1-Alkene by Rh(I) Complex. Tetrahedron Lett. 2001, 42, 4803–4805. [Google Scholar] [CrossRef]

- Muhammad, W.; Isa, M.; Habib, S.; Seah, C.; Hafriz, R.; Shamsuddin, A. Assessment of biochar, bio-oil and biogas production from lemon myrtle waste via microwave assisted catalytic pyrolysis using CaO based catalyst and zeolite catalyst. Energy Convers. Manag. X 2023, 20, 100481. [Google Scholar] [CrossRef]

- Gao, Y.; Remón, J.; Matharu, A.S. Microwave-assisted hydrothermal treatments for biomass valorisation: A critical review. Green Chem. 2021, 23, 3502–3525. [Google Scholar] [CrossRef]

- Kamath, V.; Suvarna, D.; Gayathri, D.; Rao, V. Microwave Accelerated Dilute Acid Hydrolysis of Pongamia Pressed Oil Cake for Release of Fermentable Sugars. Adv. Biores. 2018, 9, 109–118. [Google Scholar]

- Meindl, A.; Petutschnigg, A.; Schnabel, T. Microwave-Assisted Lignin Extraction—Utilizing Deep Eutectic Solvents to Their Full Potential. Polymers 2022, 14, 4319. [Google Scholar] [CrossRef] [PubMed]

- Nomanbhay, S.M.; Hussain, R.; Palanisamy, K. Microwave-Assisted Alkaline Pretreatment and Microwave Assisted Enzymatic Saccharification of Oil Palm Empty Fruit Bunch Fiber for Enhanced Fermentable Sugar Yield. J. Sustain. Bioenergy Syst. 2013, 3, 7–17. [Google Scholar] [CrossRef]

- Das, A.; Banik, B.K. Microwave-assisted enzymatic reactions. In Microwaves in Chemistry Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 245–281. [Google Scholar] [CrossRef]

- Beluhan, S.; Mihajlovski, K.; Šantek, B.; Šantek, M.I. The Production of Bioethanol from Lignocellulosic Biomass: Pretreatment Methods, Fermentation, and Downstream Processing. Energies 2023, 16, 7003. [Google Scholar] [CrossRef]

- Pérez, A.S.L.; Castro, J.J.L.; Fajardo, C.A.G. Application of Microwave Energy to Biomass: A Comprehensive Review of Microwave-Assisted Technologies, Optimization Parameters, and the Strengths and Weaknesses. J. Manuf. Mater. Process. 2024, 8, 121. [Google Scholar] [CrossRef]

- Dertli, H.; Saloglu, D. A valorization approach of food industry wastewater using microwave-assisted extraction. In Advanced Technologies in Wastewater Treatment; Elsevier: Amsterdam, The Netherlands, 2023; pp. 155–178. [Google Scholar] [CrossRef]

- Álvarez-Viñas, M.; Rivas, S.; Torres, M.D.; Domínguez, H. Microwave-Assisted Extraction of Carrageenan from Sarcopeltis skottsbergii. Mar. Drugs 2023, 21, 83. [Google Scholar] [CrossRef]

- Gotama, B.; Rahman, A.K.; Ahmad, A.; Hariyadi, A. Extraction of rice bran oil using microwave-assisted extraction and green solvents. IOP Conf. Series Earth Environ. Sci. 2022, 1105, 012052. [Google Scholar] [CrossRef]

- Avelino, F.; da Silva, K.T.; de Souza Filho, M.d.S.M.; Mazzetto, S.E.; Lomonaco, D. Microwave-assisted organosolv extraction of coconut shell lignin by Brønsted and Lewis acids catalysts. J. Clean. Prod. 2018, 189, 785–796. [Google Scholar] [CrossRef]

- Avelino, F.; Marques, F.; Soares, A.K.L.; Silva, K.T.; Leitão, R.C.; Mazzetto, S.E.; Lomonaco, D.; Avelino, F.; Marques, F.; Soares, A.K.L.; et al. Microwave-Assisted Organosolv Delignification: A Potential Eco-Designed Process for Scalable Valorization of Agroindustrial Wastes. Ind. Eng. Chem. Res. 2019, 58, 10698–10706. [Google Scholar] [CrossRef]

- Goyal, H.; Chen, T.-Y.; Chen, W.; Vlachos, D.G. A review of microwave-assisted process intensified multiphase reactors. Chem. Eng. J. 2022, 430, 133183. [Google Scholar] [CrossRef]

- Zhou, N.; Zhou, J.; Dai, L.; Guo, F.; Wang, Y.; Li, H.; Deng, W.; Lei, H.; Chen, P.; Liu, Y.; et al. Syngas production from biomass pyrolysis in a continuous microwave assisted pyrolysis system. Bioresour. Technol. 2020, 314, 123756. [Google Scholar] [CrossRef]

- Bing, W.; Hongbin, Z.; Zeng, D.; Yuefeng, F.; Yu, Q.; Rui, X. Microwave fast pyrolysis of waste tires: Effect of microwave power on product composition and quality. J. Anal. Appl. Pyrolysis 2020, 155, 104979. [Google Scholar] [CrossRef]

- Robinson, J.; Binner, E.; Vallejo, D.B.; Perez, N.D.; Al Mughairi, K.; Ryan, J.; Shepherd, B.; Adam, M.; Budarin, V.; Fan, J.; et al. Unravelling the mechanisms of microwave pyrolysis of biomass. Chem. Eng. J. 2022, 430, 132975. [Google Scholar] [CrossRef]

- López-Salazar, H.; Camacho-Díaz, B.H.; Ocampo, M.L.A.; Jiménez-Aparicio, A.R. Microwave-assisted extraction of functional compounds from plants: A Review. Bioresources 2023, 18, 6614–6638. [Google Scholar] [CrossRef]

- Yao, J.; Karlsson, M.; Lawoko, M.; Odelius, K.; Hakkarainen, M. Microwave-assisted organosolv extraction for more native-like lignin and its application as a property-enhancing filler in a light processable biobased resin. RSC Sustain. 2023, 1, 1211–1222. [Google Scholar] [CrossRef]

- Vaidya, A.A.; Murton, K.D.; Smith, D.A.; Dedual, G. A review on organosolv pretreatment of softwood with a focus on enzymatic hydrolysis of cellulose. Biomass—Convers. Biorefin. 2022, 12, 5427–5442. [Google Scholar] [CrossRef]

- Aguilar-Reynosa, A.; Romaní, A.; Rodríguez-Jasso, R.M.; Aguilar, C.N.; Garrote, G.; Ruiz, H.A. Microwave heating processing as alternative of pretreatment in second-generation biorefinery: An overview. Energy Convers. Manag. 2017, 136, 50–65. [Google Scholar] [CrossRef]

- Xie, Q.; Chen, Z.; Zhou, Y.; Pan, T.; Duan, Y.; Yu, S.; Liang, X.; Wu, Z.; Ji, W.; Nie, Y. Efficient treatment of oily sludge via fast microwave-assisted pyrolysis, followed by thermal plasma vitrification. Molecules 2023, 28, 4036. [Google Scholar] [CrossRef] [PubMed]

- Lam, S.S.; Russell, A.D.; Lee, C.L.; Chase, H.A. Microwave-heated pyrolysis of waste automotive engine oil: Influence of operation parameters on the yield, composition, and fuel properties of pyrolysis oil. Fuel 2012, 92, 327–339. [Google Scholar] [CrossRef]

- Bu, Q.; Lei, H.; Ren, S.; Wang, L.; Holladay, J.; Zhang, Q.; Tang, J.; Ruan, R. Phenol and phenolics from lignocellulosic biomass by catalytic microwave pyrolysis. Bioresour. Technol. 2011, 102, 7004–7007. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Kuan, W.; Lo, S.; Lin, C. Total recovery of resources and energy from rice straw using microwave-induced pyrolysis. Bioresour. Technol. 2008, 99, 8252–8258. [Google Scholar] [CrossRef]

- Du, Z.; Li, Y.; Wang, X.; Wan, Y.; Chen, Q.; Wang, C.; Lin, X.; Liu, Y.; Chen, P.; Ruan, R. Microwave-assisted pyrolysis of microalgae for biofuel production. Bioresour. Technol. 2011, 102, 4890–4896. [Google Scholar] [CrossRef]

- Chemat, F.; Poux, M. Microwave assisted pyrolysis of urea supported on graphite under solvent-free conditions. Tetrahedron Lett. 2001, 42, 3693–3695. [Google Scholar] [CrossRef]

- Hu, Z.; Ma, X.; Chen, C. A study on experimental characteristic of microwave-assisted pyrolysis of microalgae. Bioresour. Technol. 2012, 107, 487–493. [Google Scholar] [CrossRef]

- Azwar, E.; Mahari, W.A.W.; Rastegari, H.; Tabatabaei, M.; Peng, W.; Tsang, Y.F.; Park, Y.-K.; Chen, W.-H.; Lam, S.S. Progress in thermochemical conversion of aquatic weeds in shellfish aquaculture for biofuel generation: Technical and economic perspectives. Bioresour. Technol. 2021, 344, 126202. [Google Scholar] [CrossRef]

- Kurian, V.; Gill, M.; Dhakal, B.; Kumar, A. Recent trends in the pyrolysis and gasification of lignocellulosic biomass. In Biofuels and Bioenergy; Elsevier: Amsterdam, The Netherlands, 2022; pp. 511–552. [Google Scholar] [CrossRef]

- Lam, S.S.; Liew, R.K.; Jusoh, A.; Chong, C.T.; Ani, F.N.; Chase, H.A. Progress in waste oil to sustainable energy, with emphasis on pyrolysis techniques. Renew. Sustain. Energy Rev. 2016, 53, 741–753. [Google Scholar] [CrossRef]

- Sumnu, G.; Sahin, S. Recent Developments in Microwave Heating. In Emerging Technologies for Food Processing; Elsevier: Amsterdam, The Netherlands, 2005; pp. 419–444. [Google Scholar] [CrossRef]

- Yang, C.; Shang, H.; Li, J.; Fan, X.; Sun, J.; Duan, A. A Review on the Microwave-Assisted Pyrolysis of Waste Plastics. Processes 2023, 11, 1487. [Google Scholar] [CrossRef]

- Li, J.; Lin, L.; Ju, T.; Meng, F.; Han, S.; Chen, K.; Jiang, J. Microwave-assisted pyrolysis of solid waste for production of high-value liquid oil, syngas, and carbon solids: A review. Renew. Sustain. Energy Rev. 2024, 189, 113979. [Google Scholar] [CrossRef]

- Meloni, E.; Iervolino, G.; Palma, V. Basics of Microwave Heating and Recent Advances. In Advances in Microwave-Assisted Heterogeneous Catalysis; Royal Society of Chemistry: London, UK, 2023; pp. 1–24. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.-W. Microwave processing: Fundamentals and applications. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1055–1071. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Chiueh, P.-T.; Kuan, W.-H.; Lo, S.-L. Microwave pyrolysis of lignocellulosic biomass: Heating performance and reaction kinetics. Energy 2016, 100, 137–144. [Google Scholar] [CrossRef]

- Samsonov, S.V.; Denisov, G.G.; Bogdashov, A.A.; Gachev, I.G. Gyro-TWT and Gyro-BWO with a Microwave Circuit in the Form of Zigzag Quasi-optical Transmission Line. In Proceedings of the 2021 Photonics & Electromagnetics Research Symposium (PIERS), Hangzhou, China, 21–25 November 2021; pp. 2790–2799. [Google Scholar]

- Prapuchanay, E.; Puangngernmak, N.; Chalermwisutkul, S. A single mode cylindrical microwave cavity for heating applications of liquid material. In Proceedings of the 2012 9th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON 2012), Phetchaburi, Thailand, 16–18 May 2012; pp. 1–4. [Google Scholar]

- Mehdizadeh, M. Microwave Multimode Cavities for Material Heating. In Microwave/RF Applicators and Probes for Material Heating, Sensing, and Plasma Generation; Elsevier: Amsterdam, The Netherlands, 2010; pp. 151–182. [Google Scholar] [CrossRef]

- Okawa, T.; Utaki, H.; Takada, T. The application of microwave ceramics. In Proceedings of the 1994 IEEE International Symposium on Applications of Ferroelectrics, University Park, PA, USA, 7–10 August 1994; pp. 367–371. [Google Scholar]

- Abdullah, S.; You, K.Y.; Chong, C.Y.; Ali, M.S.M. Milk Pasteurization and Characterization Using Mono-Mode Microwave Reactor and Slotted Coaxial Antenna. In Handbook of Research on Energy-Saving Technologies for Environmentally-Friendly Agricultural Development; IGI Global: Hershey, PA, USA, 2020; pp. 107–138. [Google Scholar] [CrossRef]

- Mondal, A.; Agrawal, D.; Upadhyaya, A. Microwave Sintering of Refractory Metals/alloys: W, Mo, Re, W-Cu, W-Ni-Cu and W-Ni-Fe Alloys. J. Microw. Power Electromagn. Energy 2010, 44, 28–44. [Google Scholar] [CrossRef] [PubMed]

- Andrade, N.M.; Hooten, S.; Fortuna, S.A.; Han, K.; Yablonovitch, E.; Wu, M.C. Inverse design optimization for efficient coupling of an electrically injected optical antenna-LED to a single-mode waveguide. Opt. Express 2019, 27, 19802–19814. [Google Scholar] [CrossRef]

- Frediani, M.; Frediani, P.; Innocenti, G.; Mellone, I.; Simoni, R.; Oteri, G. Microwave-Assisted Pyrolysis Process: From a Laboratory Scale to an Industrial Plant. In Recent Microwave Technologies; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Knight, D.R.; Goldsworthy, M.; Smith, P. Are biomass feedstocks sustainable? A systematic review of three key sustainability metrics. GCB Bioenergy 2024, 16, e13187. [Google Scholar] [CrossRef]

- Fodah, A.E.M.; Ghosal, M.K.; Behera, D. Microwave-assisted pyrolysis of agricultural residues: Current scenario, challenges, and future direction. Int. J. Environ. Sci. Technol. 2021, 19, 2195–2220. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, P.; Liu, S.; Peng, P.; Min, M.; Cheng, Y.; Anderson, E.; Zhou, N.; Fan, L.; Liu, C.; et al. Effects of feedstock characteristics on microwave-assisted pyrolysis—A review. Bioresour. Technol. 2017, 230, 143–151. [Google Scholar] [CrossRef]

- Ellison, C.R.; Hoff, R.; Mărculescu, C.; Boldor, D. Investigation of microwave-assisted pyrolysis of biomass with char in a rectangular waveguide applicator with built-in phase-shifting. Appl. Energy 2019, 259, 114217. [Google Scholar] [CrossRef]

- Bartoli, M.; Frediani, M.; Briens, C.; Berruti, F.; Rosi, L. An Overview of Temperature Issues in Microwave-Assisted Pyrolysis. Processes 2019, 7, 658. [Google Scholar] [CrossRef]

- Nzediegwu, C.; Naeth, M.A.; Chang, S.X. Biochar production from lignocellulosic and nonlignocellulosic biomass using conventional and microwave heating. In Biochar in Agriculture for Achieving Sustainable Development Goals; Elsevier: Amsterdam, The Netherlands, 2022; pp. 85–95. [Google Scholar] [CrossRef]

- Motasemi, F.; Afzal, M.T.; Salema, A.A.; Mouris, J.; Hutcheon, R. Microwave dielectric characterization of switchgrass for bioenergy and biofuel. Fuel 2014, 124, 151–157. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Basak, T.; Srinivasan, R. Microwave heating characteristics of graphite based powder mixtures. Int. Commun. Heat Mass Transf. 2013, 48, 22–27. [Google Scholar] [CrossRef]