Novel Smart Glove for Ride Monitoring in Light Mobility

Abstract

1. Introduction

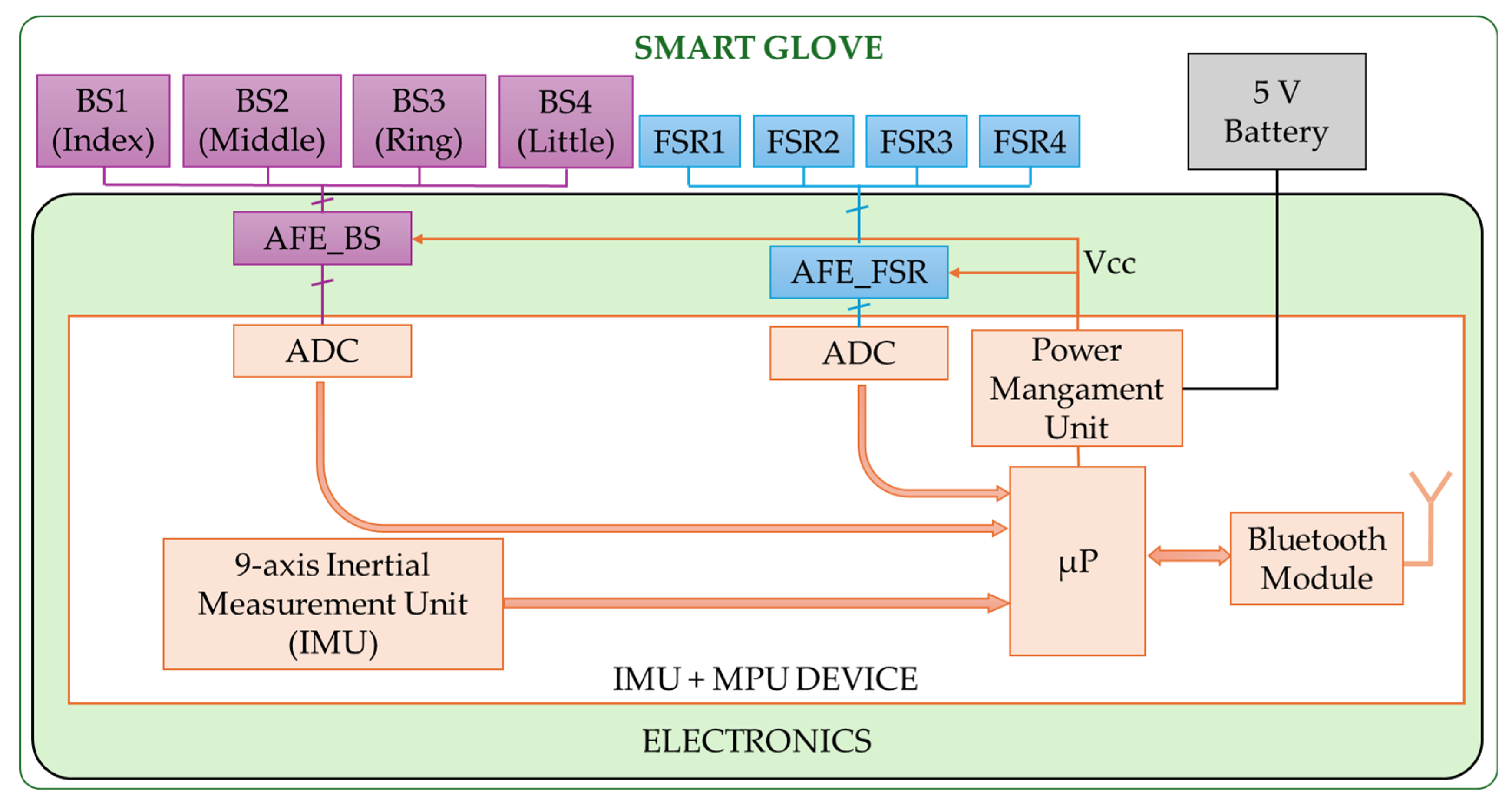

2. Smart Glove Design

- The force and the pressure exerted by the finger and by the palm on the grasped object, especially the bicycle handlebar. Excessive pressure can lead to fatigue, discomfort, or physical issues over time, while too little pressure might not provide adequate support.

- Finger flexion and extension. Like excessive pressure, improper finger positioning can lead to excessive fatigue and potential physical injuries. Furthermore, certain actions, such as braking, could enhance safety.

- The position of the back of the hand. In addition to providing a reference for reconstructing finger positioning in space based on flexion–extension measurement, it provides information about the comfort level of the fingers and hand during movements and object grasping, as well as about optimizing the posture during the ride.

- Furthermore, measuring pressure, finger movement, and hand position can also help customize the object design to meet individual users’ needs and therefore improve the user experience, well-being, and safety.

- Four printed bend sensors (BSs) for flexion–extension finger movements and their analog front-end (AFE_BS).

- Four printed force-sensitive resistors (FSRs) for finger and palm pressure and their analog front-end (AFE_FSR).

- One six-axis inertial measurement unit (IMU) for hand position.

- One microcontroller (MCU) for acquiring, elaborating, and sending the sensor signal via Bluetooth module.

2.1. Glove Material

- Lightweight and elastic fabric (3.0% Elastane, 97.0% Polyester on the back of the hand, and 24.0% Elastane, 76.0% Polyamide on the gusset), providing adequate freedom of movement and breathability during use.

- Polyester (100%) in the thumb area and the palm, the area in contact with controls like handlebars or steering wheels for a firm and secure grip. Additionally, it is wear-resistant and offers a better grip on control elements.

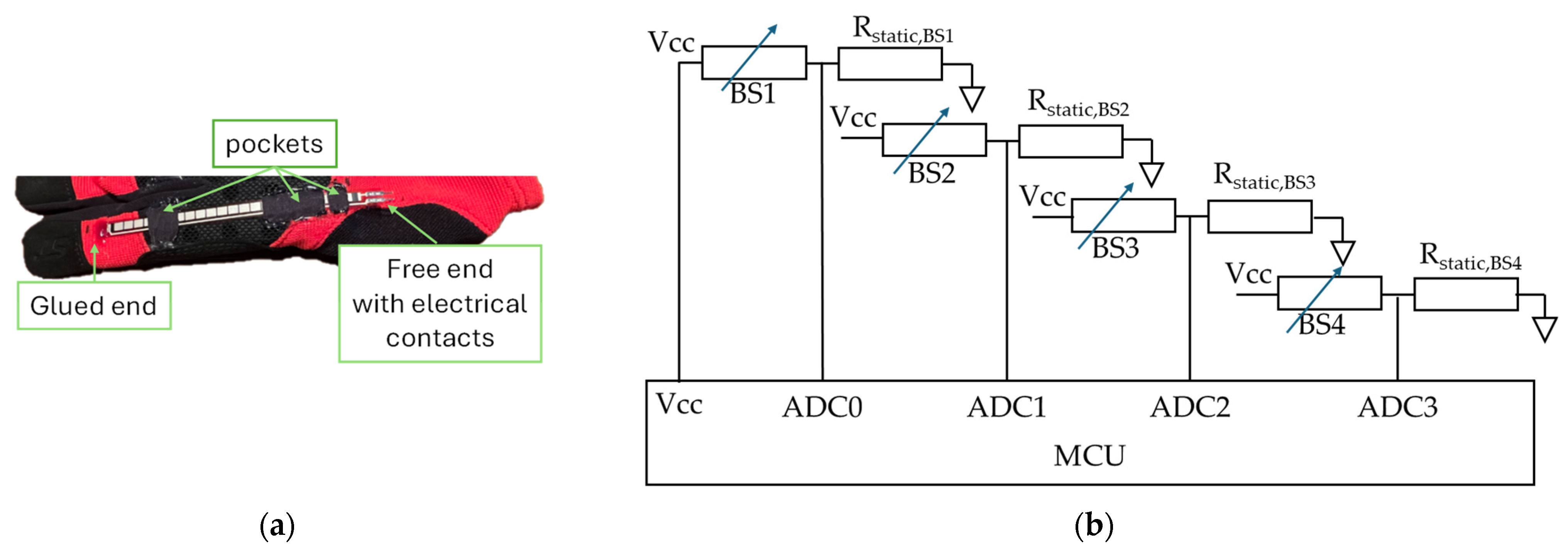

2.2. Bend Sensors

2.3. Force Sensor Resistors

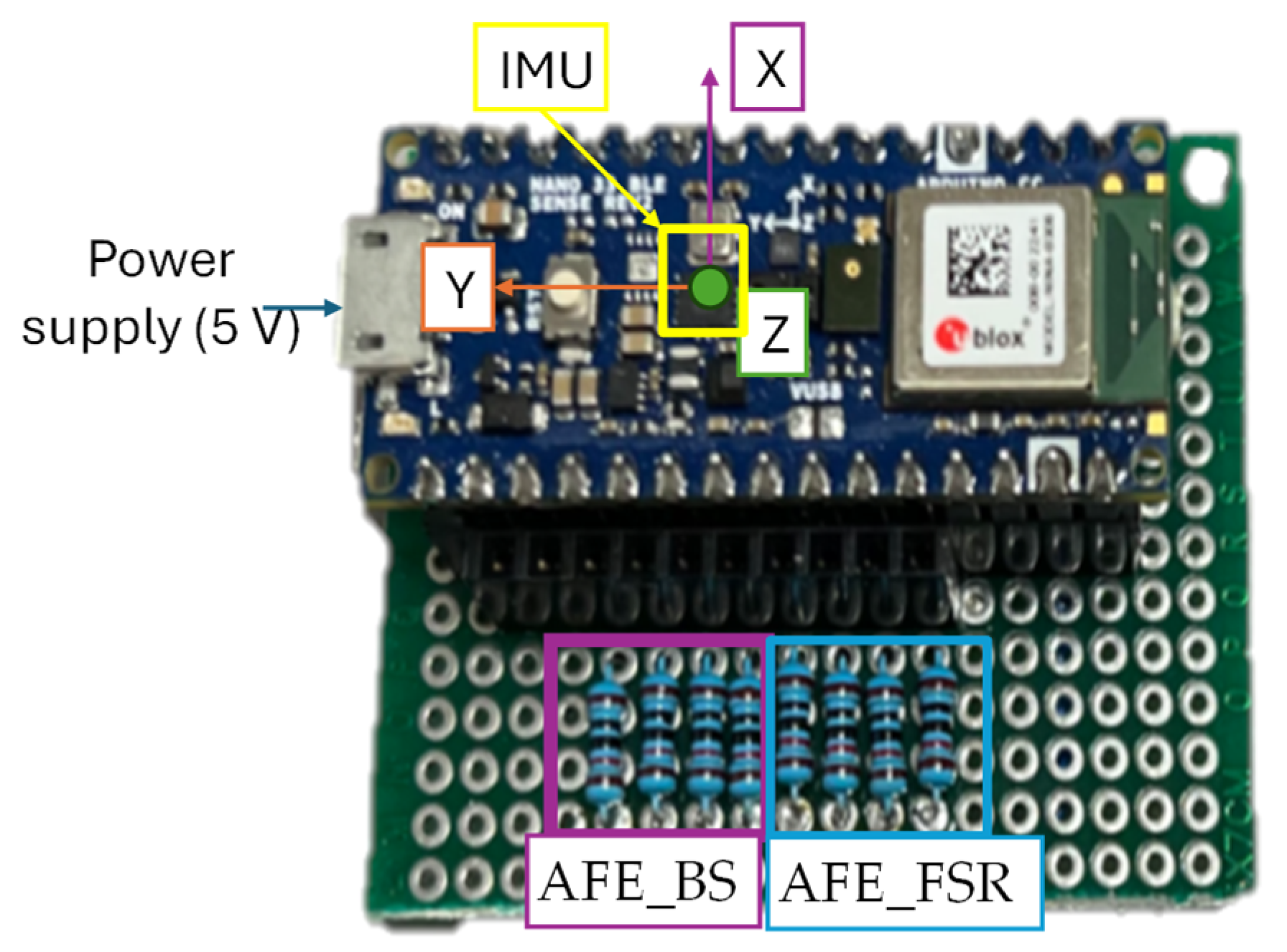

2.4. Microcontroller, Inertial Measurement Unit, and Analog Front-End Integration

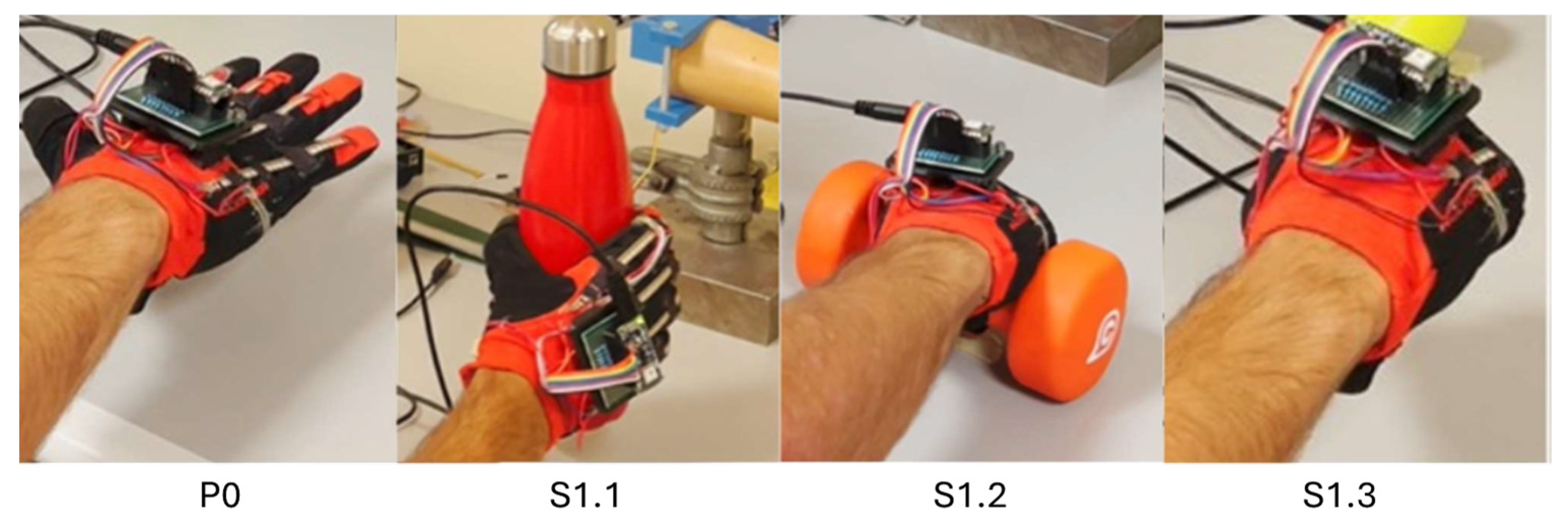

3. Characterization and Validation Protocols

3.1. Laboratory Protocol

- (S1.1)

- Grasping a cylinder with a diameter of 70 mm (a flask) for a few seconds.

- (S1.2)

- Grasping a cylinder with a diameter of 38 mm (a handlebar) for a few seconds.

- (S1.3)

- Closing the hand for a few seconds. In this position, it is estimated that the subject grasps a virtual object with a diameter of 10 mm.

- (S1.1)

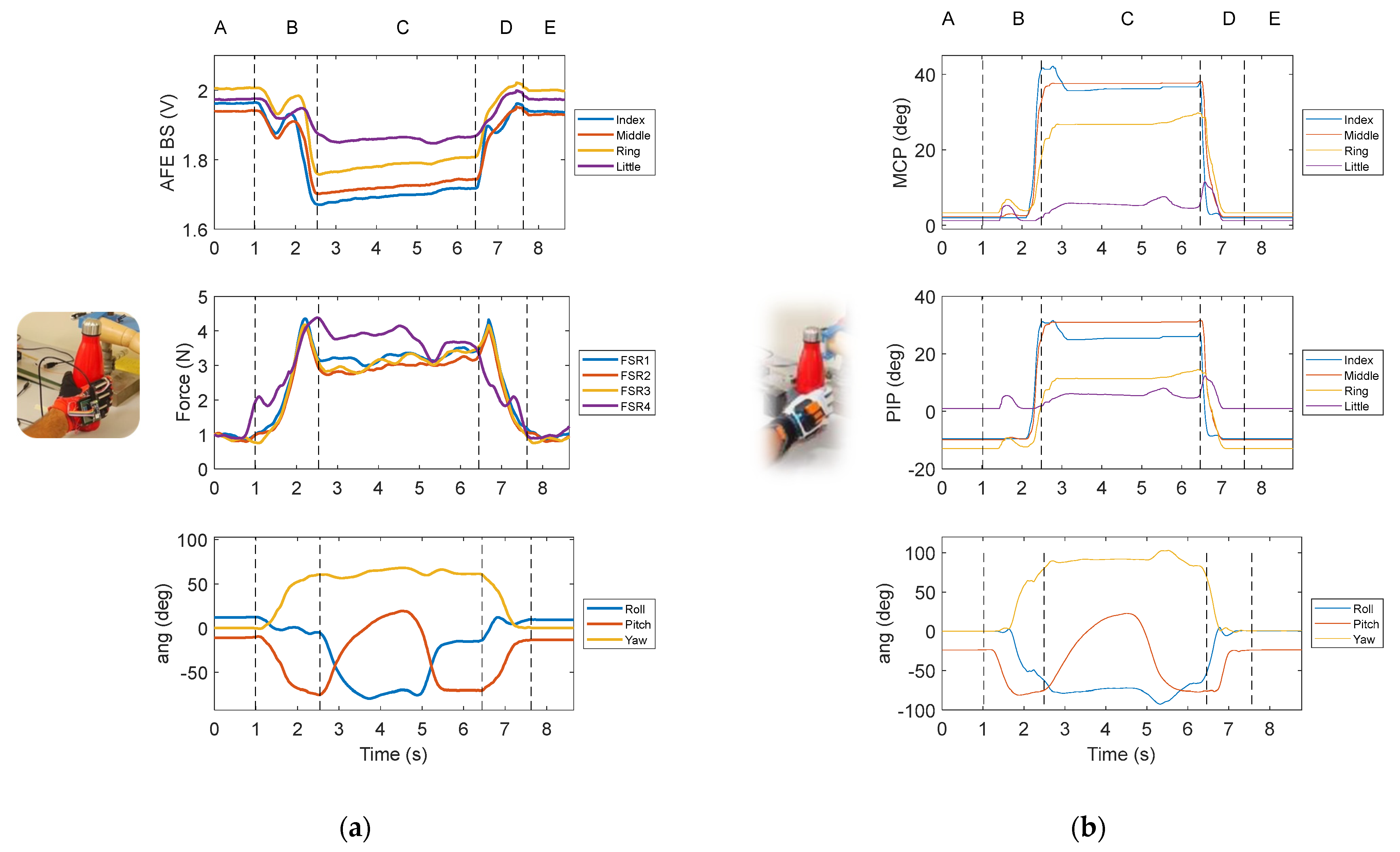

- Grasping a flask (diameter of 70 mm), simulation of the drinking action, repositioning of the flask on the table (Figure 8).

- (S1.2)

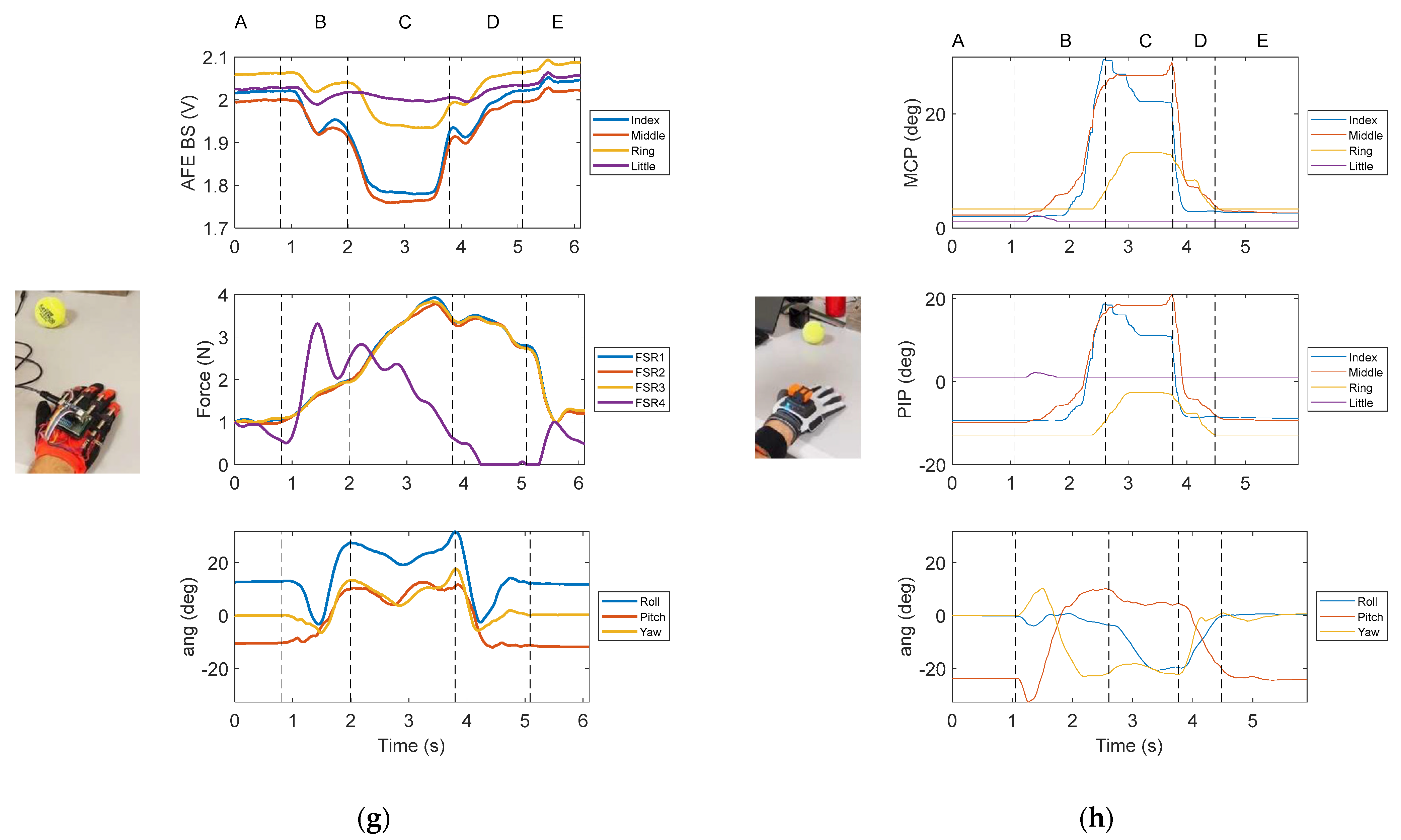

- Grasping a handlebar (diameter of 38 mm), moving the object by 20 cm on the left without lifting it.

- (S1.3)

- Grasping a tennis ball (diameter of 65 mm), moving the object by 20 cm on the left.

- (S1.4)

- Grasping a small box (48 mm × 48 mm × 66 mm), moving the object by 20 cm on the left (Figure 9).

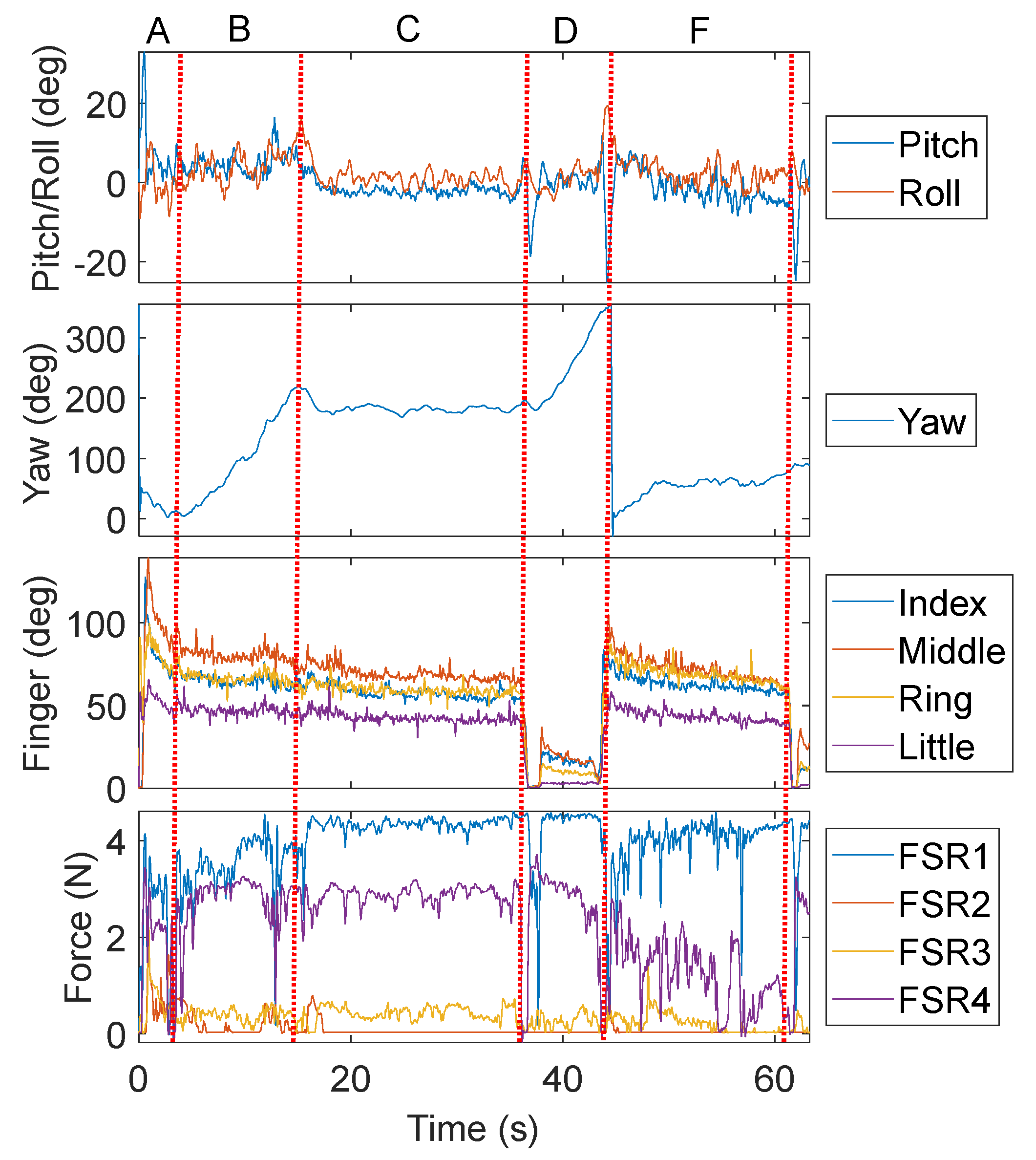

3.2. On-Field Protocol

4. Results and Discussion

4.1. Usability Results

4.2. Laboratory Results

4.3. Field Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Olieman, M.; Marin-Perianu, R.; Marin-Perianu, M. Measurement of dynamic comfort in cycling using wireless acceleration sensors. Procedia Eng. 2012, 34, 568–573. [Google Scholar] [CrossRef]

- Vanwalleghem, J.; De Baere, I.; Loccufier, M.; Van Paepegem, W. Dynamic Calibration of a Strain Gauge Based Handlebar Force Sensor for Cycling Purposes. Procedia Eng. 2015, 112, 219–224. [Google Scholar] [CrossRef]

- Doria, A.; Marconi, E.; Munoz, L.; Polanco, A.; Suarez, D. An experimental-numerical method for the prediction of on-road comfort of city bicycles. Veh. Syst. Dyn. 2021, 59, 1376–1396. [Google Scholar] [CrossRef]

- Li, Z.; Wang, W.; Liu, P.; Schneider, R.; Ragland, D.R. Investigating Bicyclists’ Perception of Comfort on Physically Separated Bicycle Paths in Nanjing, China. Transp. Res. Rec. J. Transp. Res. Board 2012, 2317, 76–84. [Google Scholar] [CrossRef]

- Zhu, S.; Zhu, F. Cycling comfort evaluation with instrumented probe bicycle. Transp. Res. Part A Policy Pract. 2019, 129, 217–231. [Google Scholar] [CrossRef]

- Cai, Y.; Li, X.; Li, J. Emotion Recognition Using Different Sensors, Emotion Models, Methods and Datasets: A Comprehensive Review. Sensors 2023, 23, 2455. [Google Scholar] [CrossRef]

- Stefana, E.; Marciano, F.; Rossi, D.; Cocca, P.; Tomasoni, G. Wearable Devices for Ergonomics: A Systematic Literature Review. Sensors 2021, 21, 777. [Google Scholar] [CrossRef]

- Huang, X.; Xue, Y.; Ren, S.; Wang, F. Sensor-Based Wearable Systems for Monitoring Human Motion and Posture: A Review. Sensors 2023, 23, 9047. [Google Scholar] [CrossRef]

- Millour, G.; Velásquez, A.T.; Domingue, F. A literature overview of modern biomechanical-based technologies for bike-fitting professionals and coaches. Int. J. Sports Sci. Coach. 2023, 18, 292–303. [Google Scholar] [CrossRef]

- Chandel, R.; Sharma, S.; Kaur, S.; Sehijpal, S.; Kumar, R. Smart watches: A review of evolution in bio-medical sector. Mater. Today Proc. 2021, 50, 1053–1066. [Google Scholar] [CrossRef]

- Angelucci, A.; Cavicchioli, M.; Cintorrino, I.; Lauricella, G.; Rossi, C.; Strati, S.; Aliverti, A. Smart Textiles and Sensorized Garments for Physiological Monitoring: A Review of Available Solutions and Techniques. Sensors 2021, 21, 814. [Google Scholar] [CrossRef] [PubMed]

- Medical, S. Starboard Medical’s Skin Temperature Sensor. Available online: https://starboardmedical.com/skin-sensors/ (accessed on 30 January 2025).

- Katsis, C.D.; Katertsidis, N.; Ganiatsas, G.; Fotiadis, D.I. Toward Emotion Recognition in Car-Racing Drivers: A Biosignal Processing Approach. IEEE Trans. Syst. Man Cybern.-Part A Syst. Hum. 2008, 38, 502–512. [Google Scholar] [CrossRef]

- Wilkinson, R.D.; Lichtwark, G.A. Evaluation of an inertial measurement unit-based approach for determining centre-of-mass movement during non-seated cycling. J. Biomech. 2021, 126, 110441. [Google Scholar] [CrossRef]

- Borghetti, M.; Lopomo, N.F.; Serpelloni, M. Characterization Method for Bending Sensor Applied for Smart Glove. In Proceedings of the 2024 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4.0&IoT), Firenze, Italy, 29–31 May 2024. [Google Scholar]

- Williams, N.W. The virtual hand: The Pulvertaft prize essay for 1996. J. Hand Surg. Am. 1997, 22, 560–567. [Google Scholar] [CrossRef]

- Simone, L.K.; Sundarrajan, N.; Luo, X.; Jia, Y.; Kamper, D.G. A low cost instrumented glove for extended monitoring and functional hand assessment. J. Neurosci. Methods 2007, 160, 335–348. [Google Scholar] [CrossRef]

- Gentner, R.; Classen, J. Development and evaluation of a low-cost sensor glove for assessment of human finger movements in neurophysiological settings. J. Neurosci. Methods 2009, 178, 138–147. [Google Scholar] [CrossRef]

- Pompili, G.; Baldi, T.L.; Barcelli, D.; Prattichizzo, D. Development of a Low-cost Glove for Thumb Rehabilitation: Design and Evaluation. In Proceedings of the 2020 IEEE International Conference on Human-Machine Systems (ICHMS), Rome, Italy, 7–9 September 2020; pp. 1–7. [Google Scholar]

- O’Flynn, B.; Torres, J.; Connolly, J.; Condell, J.; Curran, K.; Gardiner, P. Novel smart sensor glove for arthritis rehabiliation. In Proceedings of the 2013 IEEE International Conference on Body Sensor Networks, Cambridge, MA, USA, 6–9 May 2013; pp. 1–6. [Google Scholar]

- Castro, M.C.F.; Cliquet, A. A low-cost instrumented glove for monitoring forces during object manipulation. IEEE Trans. Rehabil. Eng. 1997, 5, 140–147. [Google Scholar] [CrossRef]

- Yu, H.; Zheng, D.; Liu, Y.; Chen, S.; Wang, X.; Peng, W. Data Glove with Self-Compensation Mechanism Based on High-Sensitive Elastic Fiber-Optic Sensor. Polymers 2023, 15, 100. [Google Scholar] [CrossRef]

- Büscher, G.H.; Kõiva, R.; Schürmann, C.; Haschke, R.; Ritter, H.J. Flexible and stretchable fabric-based tactile sensor. Rob. Auton. Syst. 2015, 63, 244–252. [Google Scholar] [CrossRef]

- Tavares, R.; Abreu, P.; Quintas, M. Instrumented glove for rehabilitation exercises. In Proceedings of the 2015 3rd Experiment International Conference (exp.at’15), Ponta Delgada, Portugal, 2–4 June 2015; pp. 107–108. [Google Scholar]

- O’Flynn, B.; Sanchez-Torres, J.; Tedesco, S.; Walsh, M. Challenges in the Development of Wearable Human Machine Interface Systems. In Proceedings of the Technical Digest-International Electron Devices Meeting, IEDM, San Francisco, CA, USA, 7–11 December 2019; pp. 10.4.1–10.4.4. [Google Scholar]

- Austin, E.F.J.; Kearney, C.P.; Chacon, P.J.; Winges, S.A.; Acharya, P.; Choi, J.-W. A Fabricated Force Glove That Measures Hand Forces during Activities of Daily Living. Sensors 2022, 22, 1330. [Google Scholar] [CrossRef]

- Mohd Ali, A.; Ambar, R.; Abdul Jamil, M.M. Development of Artificial Hand Gripper by using Microcontroller. Int. J. Integr. Eng. 2011, 3, 47–54. [Google Scholar]

- Park, J.; Heo, P.; Kim, J.; Na, Y. A Finger Grip Force Sensor with an Open-Pad Structure for Glove-Type Assistive Devices. Sensors 2020, 20, 4. [Google Scholar] [CrossRef]

- Spectraflex Flex Sensors. Available online: https://www.spectrasymbol.com/resistive-flex-sensors/spectraflex-flex-sensors (accessed on 30 January 2025).

- Borghetti, M.; Sardini, E.; Serpelloni, M. Evaluation of bend sensors for limb motion monitoring. In Proceedings of the IEEE MeMeA 2014—IEEE International Symposium on Medical Measurements and Applications, Lisbon, Portugal, 11–12 June 2014. [Google Scholar]

- Yu, S.-H.; Chang, J.-S.; Tsai, C.-H.D. Grasp to See—Object Classification Using Flexion Glove with Support Vector Machine. Sensors 2021, 21, 1461. [Google Scholar] [CrossRef]

- Kamper, D.G.; Cruz, E.G.; Siegel, M.P. Stereotypical Fingertip Trajectories During Grasp. J. Neurophysiol. 2003, 90, 3702–3710. [Google Scholar] [CrossRef]

- Interlink Electronics FSR® 400 Series. Available online: https://www.interlinkelectronics.com/fsr-400-series (accessed on 30 January 2025).

- Starke, J.; Chatzilygeroudis, K.; Billard, A.; Asfour, T. On Force Synergies in Human Grasping Behavior. In Proceedings of the 2019 IEEE-RAS 19th International Conference on Humanoid Robots (Humanoids), Toronto, ON, Canada, 15–17 October 2019; pp. 72–78. [Google Scholar]

- Qiang, T.G.; Yuan, L.J.; Feng, J.X. Research on virtual testing of hand pressure distribution for handle grasp. In Proceedings of the 2011 International Conference on Mechatronic Science, Electric Engineering and Computer (MEC), Jilin, China, 19–22 August 2011; pp. 1610–1613. [Google Scholar]

- Lee, J.K.; Choi, M.J. Robust Inertial Measurement Unit-Based Attitude Determination Kalman Filter for Kinematically Constrained Links. Sensors 2019, 19, 768. [Google Scholar] [CrossRef]

- Brooke, J. SUS-A quick and dirty usability scale. Usability Eval. Ind. 1996, 189, 4–7. [Google Scholar]

- Andreoni, G. Investigating and Measuring Usability in Wearable Systems: A Structured Methodology and Related Protocol. Appl. Sci. 2023, 13, 3595. [Google Scholar] [CrossRef]

- Moulaei, K.; Moulaei, R.; Bahaadinbeigy, K. The most used questionnaires for evaluating the usability of robots and smart wearables: A scoping review. Digit. Health 2024, 10, 20552076241237384. [Google Scholar] [CrossRef]

- Caeiro-Rodríguez, M.; Otero-González, I.; Mikic-Fonte, F.A.; Llamas-Nistal, M. A Systematic Review of Commercial Smart Gloves: Current Status and Applications. Sensors 2021, 21, 2667. [Google Scholar] [CrossRef]

- Henderson, J.; Condell, J.; Connolly, J.; Kelly, D.; Curran, K. Review of Wearable Sensor-Based Health Monitoring Glove Devices for Rheumatoid Arthritis. Sensors 2021, 21, 1576. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borghetti, M.; Lopomo, N.F.; Serpelloni, M. Novel Smart Glove for Ride Monitoring in Light Mobility. Instruments 2025, 9, 6. https://doi.org/10.3390/instruments9010006

Borghetti M, Lopomo NF, Serpelloni M. Novel Smart Glove for Ride Monitoring in Light Mobility. Instruments. 2025; 9(1):6. https://doi.org/10.3390/instruments9010006

Chicago/Turabian StyleBorghetti, Michela, Nicola Francesco Lopomo, and Mauro Serpelloni. 2025. "Novel Smart Glove for Ride Monitoring in Light Mobility" Instruments 9, no. 1: 6. https://doi.org/10.3390/instruments9010006

APA StyleBorghetti, M., Lopomo, N. F., & Serpelloni, M. (2025). Novel Smart Glove for Ride Monitoring in Light Mobility. Instruments, 9(1), 6. https://doi.org/10.3390/instruments9010006