Abstract

Measurement of physics processes at new energy frontier experiments requires excellent spatial, time, and energy resolutions to resolve the structure of collimated high-energy jets. In a future Muon Collider, beam-induced backgrounds (BIB) represent the main challenge in the design of the detectors and of the event reconstruction algorithms. The technology and the design of the calorimeters should be chosen to reduce the effect of the BIB, while keeping good physics performance. Several requirements can be inferred: (i) high granularity to reduce the overlap of BIB particles in the same calorimeter cell; (ii) excellent timing (of the order of 100 ps) to reduce the out-of-time component of the BIB; (iii) longitudinal segmentation to distinguish the signal showers from the fake showers produced by the BIB. Moreover, the calorimeter should operate in a very harsh radiation environment, withstanding yearly a neutron flux of 10 n1MeV/cm2 and a dose of 100 krad. Our proposal consists of a semi-homogeneous electromagnetic calorimeter based on Lead Fluoride Crystals (PbF2) readout by surface-mount UV-extended Silicon Photomultipliers (SiPMs): the Crilin calorimeter. In this paper, we report the mechanical design for the development of a small-scale prototype, consisting of 2 layers of 3 × 3 crystals.

1. Introduction

The Muon Collider environment [1] is not so clean as one might expect, since the presence of the beam-induced background (BIB), produced by the decay of muons and subsequent interactions, may pose limitations on the physics performance [2]. Although the BIB can be partially mitigated by a proper design of the machine-detector interface, for instance using two shielding tungsten nozzles in the detector region [3], it poses requirements on the detector development [4].

BIIB particles at a Muon Collider have a number of characteristic features: low momentum, displaced origin and asynchronous time of arrival. The BIB flux has been simulated to be in the order of 300 on the surface of the electromagnetic calorimeter (ECAL), with energy spectrum peaked around 1.8 MeV. One of the most promising options for ECAL, proposed by the CALICE collaboration, is a sandwich of tungsten and silicon sensors [5] that combines a mature technology with the possibility to implement fine segmentation. However, if this technology well sited the Muon Collider environment, its implementation in a barrel calorimeter needs of about 64 million silicon sensors. Moreover, future developments should implement a precise timing measurement in these sensors (<100 ps) in order to make them usable at a Muon Collider.

In this paper, we propose a cheaper alternative as electromagnetic barrel calorimeter for the Muon Collider: Crilin [], a semi-homogeneous crystal calorimeter with longitudinal information. It is based on Lead Fluoride (PbF2) crystals readout by surface mounted UV extended Silicon Photomultipliers (SiPMs). Crilin has a modular architecture made of stackable and interchangeable sub-modules composed of matrices of 10 × 10 × 40 mm3 PbF2 crystals, where each crystal is individually readout by 2 series of 2 UV-extended surface mount SiPMs each. It can provide: high response speed, good pileup capability, great light collection hence good energy resolution throughout the whole dynamic range, resistance to radiation, and fine granularity which is also scalable with SiPMs pixel dimensions.

2. The Crilin Prototype

First studies on ECAL crystal dimensions have shown that a basic configuration with 10 × 10 × 40 mm3 allows a good separation of BIB from signal with O(5 GeV) energy deposit per crystal. In this regard, the choice of SiPMs with 15 μm pixels, with the measured Light Yield (LY) of 1 p.e./MeV at an earlier existing 2-crystals prototype (Proto-0 [6]), would guarantee an excellent linearity in the response.

In order to validate the design choices, the proposal is to build a larger prototype, called Proto-1. The design will be optimized with the simulation studies starting from dimensions of 0.7 RM and 8.5 X0 (∼0.3 ). This size comes from a compromise of an acceptable containment of 100 GeV electrons and cost constraints. Results will be extrapolated to the optimum length of the Muon Collider calorimeter of the order of 20 X0. The proposal is to build Proto-1 with two layers of 3 × 3 PbF2 crystals, each readout with UV-extended SiPMs (Hamamatsu S14160-3015PS SMD sensors [7]), as already done in Proto-0. These new SiPMs were already tested with an ultra-fast blue laser (400 nm, 100 ps) and new electronics front-end (FEE) that showed a dynamic range from 0 to 2 V, a rise time of ∼2 ns with full signal in ∼70 ns and a less than 50 ps even at charge as low as 100 pC (∼250 Np.e.) [8].

Proto-1 operational temperature will be 0/−10 °C and the performance will be validated in a dedicated test beam.

Specifically, our goals are: (1) perform a complete operational test of the prototype, including operation with cooling; (2) obtain data for a complete analysis of digitized signals from the detector for electrons and minimum-ionising particles; (3) test the cluster reconstruction capability and measure the time resolution; (4) measure longitudinal and transverse shower profile and compare with results obtained in simulation.

3. Mechanics

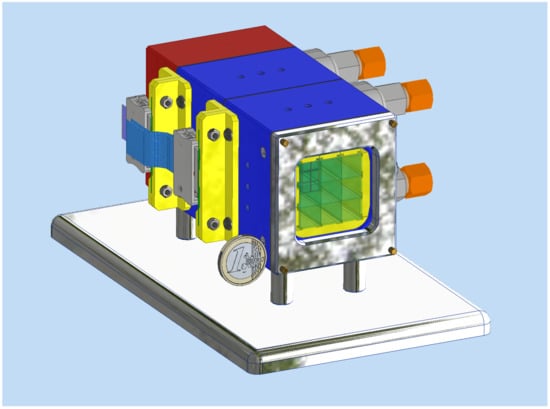

In the current design, the prototype consists of two sub-modules, each composed of a 3 × 3 crystal matrix. The modules are arranged in a series and assembled by bolting, thus obtaining a compact and small calorimeter, as shown in Figure 1.

Figure 1.

CAD 3D model of Crilin Prototype (Proto-1).

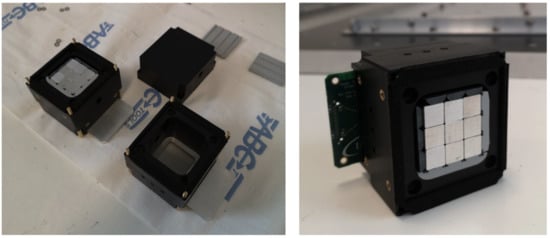

The mechanics have been realized from the mechanical workshop of the Laboratori Nazionali di Frascati of INFN and assembled with fake aluminium crystals, as shown in Figure 2.

Figure 2.

Mechanics of the Proto-1 asembled with fake aluminium crystals.

Each crystal matrix is housed in a light-tight case which also embeds the front-end electronic boards and the heat exchange needed to cool down the SiPMs. The mechanical architecture of the prototype comprises the following key elements:

- The cases, which house each crystal matrix and embed the front-end electronic boards. They are manufactured in common acrylonitrile butadiene styrene (ABS) plastic to minimize the thermal exchange with both the external environment and between the modules.

- The locking plates, to which the positioning and blocking of crystals are entrusted, also manufactured in ABS. This solution eases the assembling, positioning, and locking of the crystal matrix.

- The hydraulic connectors, which transport dry gas into the individually sealed modules; the dry gas is circulated inside the active volume of the prototype to prevent condensation.

- In between the modules are installed seals, which make each sub-module light-tight. The modules are bolted together using special screws that allow assembling the modules in series. Tedlar® windows close the calorimeter at either end.

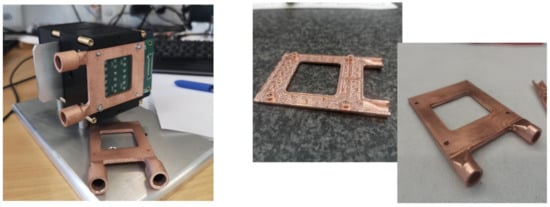

The on-detector electronics and SiPMs must be cooled during operation, so as to improve and stabilize the performance of SiPMs against irradiation. Our design is capable of removing the heat load due to the increased photosensor leakage current after exposure to the expected 10 n1MeV/cm2 fluence, along with the power dissipated by the amplification circuitry. The total heat load was estimated as 350 mW per channel. The Crilin cooling system consists of a cooling plant and a cold plate heat exchanger (see Figure 3), in direct contact with the electronic board. It will provide the optimum operating temperature for the electronics and SiPMs at 0/−10 °C.

Figure 3.

For comparison the cooling exchangers have been realized at CERN in 3D metal printer technology (left) and at the mechanical workshop of Sezione of Ferrara of INFN with the Computer Numerical Control (CNC) milling machine (right).

To improve the thermal performance of the cold plate, a complex cross-section pin fin arrays for forced convection heat exchange has been chosen to provide high thermal performance in a compact size. Pin fin arrays are formed on both top and bottom side of the cold plate; the cold plate is made by brazing top and bottom plates. The coolant inlet pipe and the outlet pipe are also connected to the cold plate by brazing. The use of pin fins increases heat transfer through two main mechanisms: increasing the wetted surface area over which convective heat transfer can occur, and promoting turbulent flow in the inter-fin region of the array. This turbulence is generated mainly by interrupting boundary layers on the channel walls, and inducing vorticity at the base and in the wake of the fins. Four geometrically different cross sections micro pin-fins are under investigation using experimental and computation means: a conventional circular shape, a hydrofoil shape, a modified hydrofoil shape and a symmetric convex lens shape.

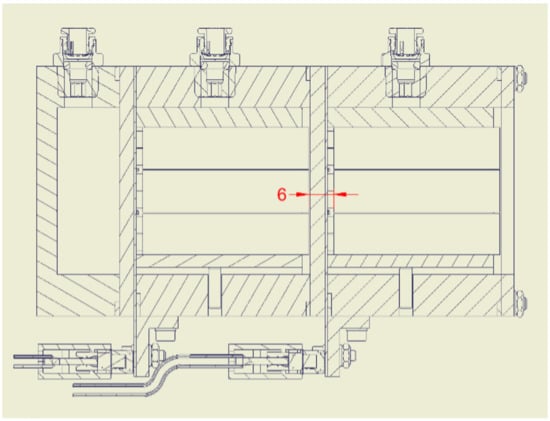

The cooling plant supplies the cold plate with a glycol-based water solution at the required flow, temperature, and pressure. Hydraulic connectors, transport dry gas into the individually sealed modules. The dry gas is fluxed inside the active volume of the prototype to prevent condensation, see Figure 4.

Figure 4.

Top view of the calorimeter.

4. Conclusions

Crilin is a semi-homogeneous calorimeter with longitudinal segmentation and superior timing resolution (less then 100 ps for each individual readout channel), capable to work in a very hard radiation environment. A Crilin prototype, composed of two layers of nine crystals each and operating at −10/0 °C, will be built during 2022. Our goal is to test its performance with 500 MeV electrons at BTF and with a high energy beam (>100 GeV) at CERN at end of 2022.

Author Contributions

Methodology, D.P.; Writing—original draft, A.S. and I.S. All authors have read and agreed to the published version of the manuscript.

Funding

This project has received funding from the European Union’s Horizon 2020 Research and Innovation program under GA no 101004761.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

This work was developed within the framework of the International Muon Collider Collaboration (https://muoncollider.web.cern.ch, accessed on 14 September 2022), where the Physics and Detector Group aims to evaluate potential detector R&D to optimize experiment design in the multi-TeV energy regime.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Muon Collider Web Page. Available online: https://muoncollider.web.cern.ch/ (accessed on 14 September 2022).

- Muon Accelerator Program. Available online: https://map.fnal.gov/ (accessed on 14 September 2022).

- Mokhov, N.V.; Striganov, S.I. Detector Backgrounds at Muon Colliders. Phys. Procedia 2012, 37, 2015–2022. [Google Scholar] [CrossRef]

- Mokhov, N.V.; James, C.C. Technical Publications: Fermilab-FN-1058-APC. 2018. Available online: https://lss.fnal.gov/lists/fermilab-reports-fn.html (accessed on 14 September 2022).

- Linssen, L.; Miyamoto, A.; Stanitzki, M.; Weerts, H. Physics and Detectors at CLIC: CLIC Conceptual Design Report. arXiv 2012, arXiv:1202.5940. [Google Scholar]

- Moulson, M. Talk Given at AIDAinnova 1st Annual Meeting, 28–31 March 2002. Available online: https://indico.cern.ch/event/1104064/contributions/4801240/attachments/2417197/4136687/Moulson_220329WP8.pdf (accessed on 14 September 2022).

- Hamamatsu SiPMs Datasheet. Available online: https://www.hamamatsu.com/content/dam/hamamatsu-photonics/sites/documents/99_SALES_LIBRARY/ssd/s14160-1310ps_etc_kapd1070e.pdf (accessed on 14 September 2022).

- Ceravolo, S.; Colao, F.; Curatolo, C.; Di Meco, E.; Diociaiuti, E.; Lucchesi, D.; Paesani, D.; Pastrone, N.; Saputi, A.; Sarra, I.; et al. Crilin: A CRystal calorImeter with Longitudinal InformatioN for a future Muon Collider. J. Instrum. 2022, 17, P09033. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).