HTS Accelerator Magnet and Conductor Development in Europe

Abstract

1. Introduction

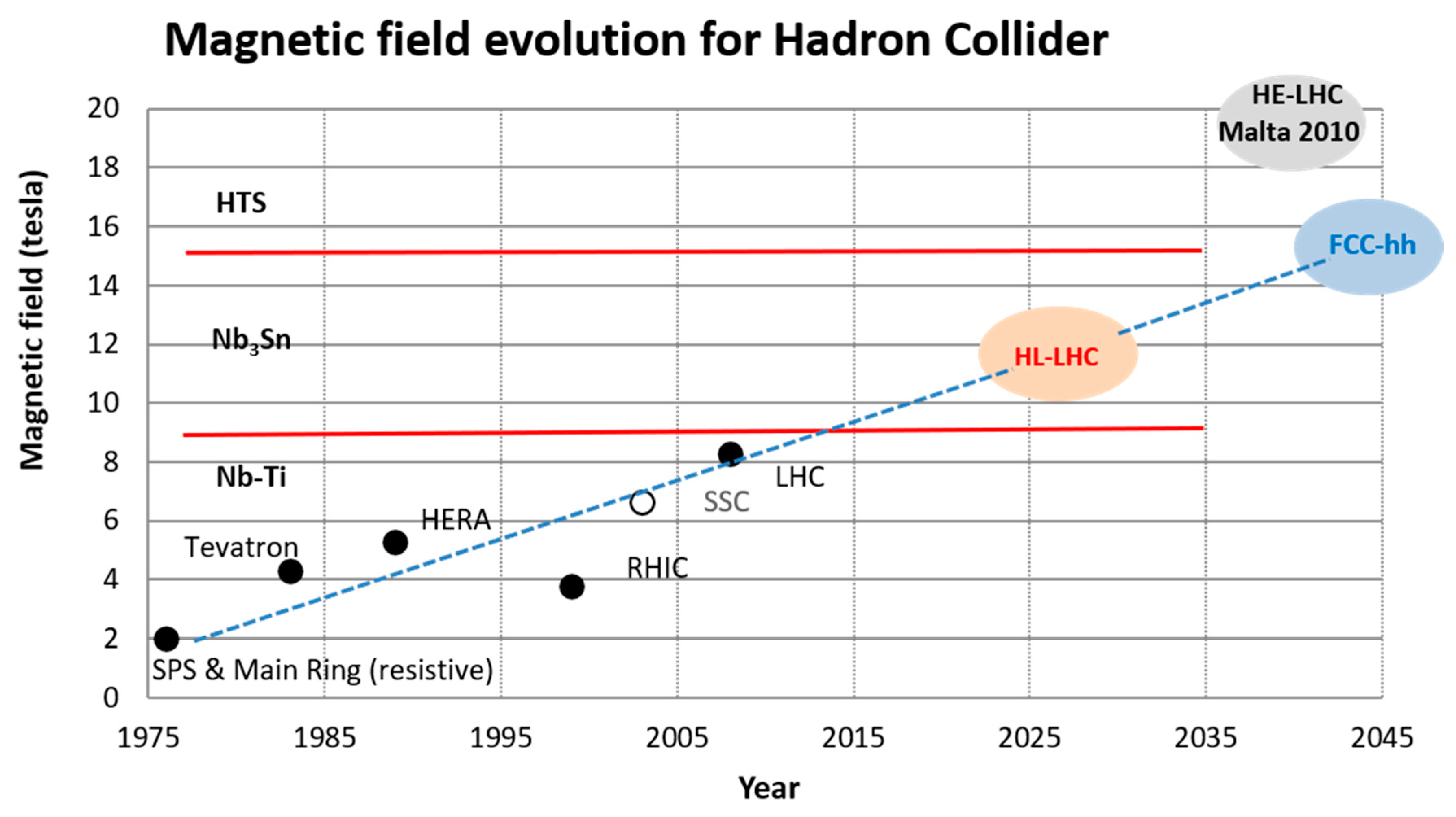

2. Accelerator and Magnets

3. The FP7-EuCARD HTS Racetrack Magnet

- The magnet is a stack of flat coils in racetrack shape—i.e., the coil end is not flared, leaving no access to the coil midplane (no bore). The coils are wound as flat pancakes. Three pancakes, or coil layers, are above the midplane and three exactly symmetrical ones are in the bottom coil.

- The conductor is composed of two REBCO tapes, 12 mm wide, soldered face to face to form a pair that sandwich a pure-Cu ribbon in the center (for a total of 70 µm of copper in the sandwich when the few µm of copper coating on the side (see Figure 3 left are included). The stack is about 200 µm thick and a 130 µm Cu-Be ribbon is soldered on each side, so the total conductor thickness is about 460 µm. The conductor is then insulated with polyester film. Finally, two conductor units are co-wound to form a high current cable. A schematic of the cable is shown in Figure 3.

- The cable described above is not transposed, and the inner conductor of the cable has smaller inductance than the outer one. To compensate for this effect, each pancake on the top part (wrt to the midplane) is connected to its bottom symmetrical companion in such a way that the current in the inner conductor is in series with the outer conductor of the same cable of the bottom pancake. The coil layout and magnet mechanics are depicted in Figure 4. The magnet is first assembled for a stand-alone test with a demountable structure, where the force and prestress can be adjusted. The structure is also easily demountable to allow for various assembly trials. For the final configuration, as a high-field insert inside Fresca2 a more compact structure is necessary to keep the e.m. forces; see Figure 4.

4. The FP7-EuCARD2 and H2020-ARIES Programs: Overview

- CERN, Geneva, CH, (general coordinator and participating in all tasks and, in particular, responsible for the design and construction of one type of magnet and magnet testing);

- CEA-Saclay, FR, (in charge of coordinating magnet design and responsible for the design and construction of one type of magnet);

- Bruker HTS (BHTS), Alzenau, DE, the industry in charge of developing and manufacturing the REBCO tapes (including re-coating after tape punching);

- KIT (Karlsruhe Institute of Technology), DE, in charge of producing the Roebel cable (punching of the tapes and assembly in the cable of meandered tapes);

- University of Geneva (CH), University of Twente (NL), and University of Southampton (UK), in charge of the various characterizations of the conductor, both in the form of tape and cable;

- INFN-LASA (Milan branch of the Italian Institute for Nuclear Physics), in charge of preparing a test station and carrying out one test;

- Tampere University in Finland, in charge of quench protection simulation;

- INP of Grenoble (FR), in charge of special magnet design;

- DTI, the Danish Institute of Technology, giving support to the magnet design and construction.

4.1. Objectives of EuCARD2.

- A high current density in the coil package (typically 400 A/mm2) at the relevant field in order to make magnets of a reasonable size and affordable cost. For our case, this translates to the following requirements:

- -

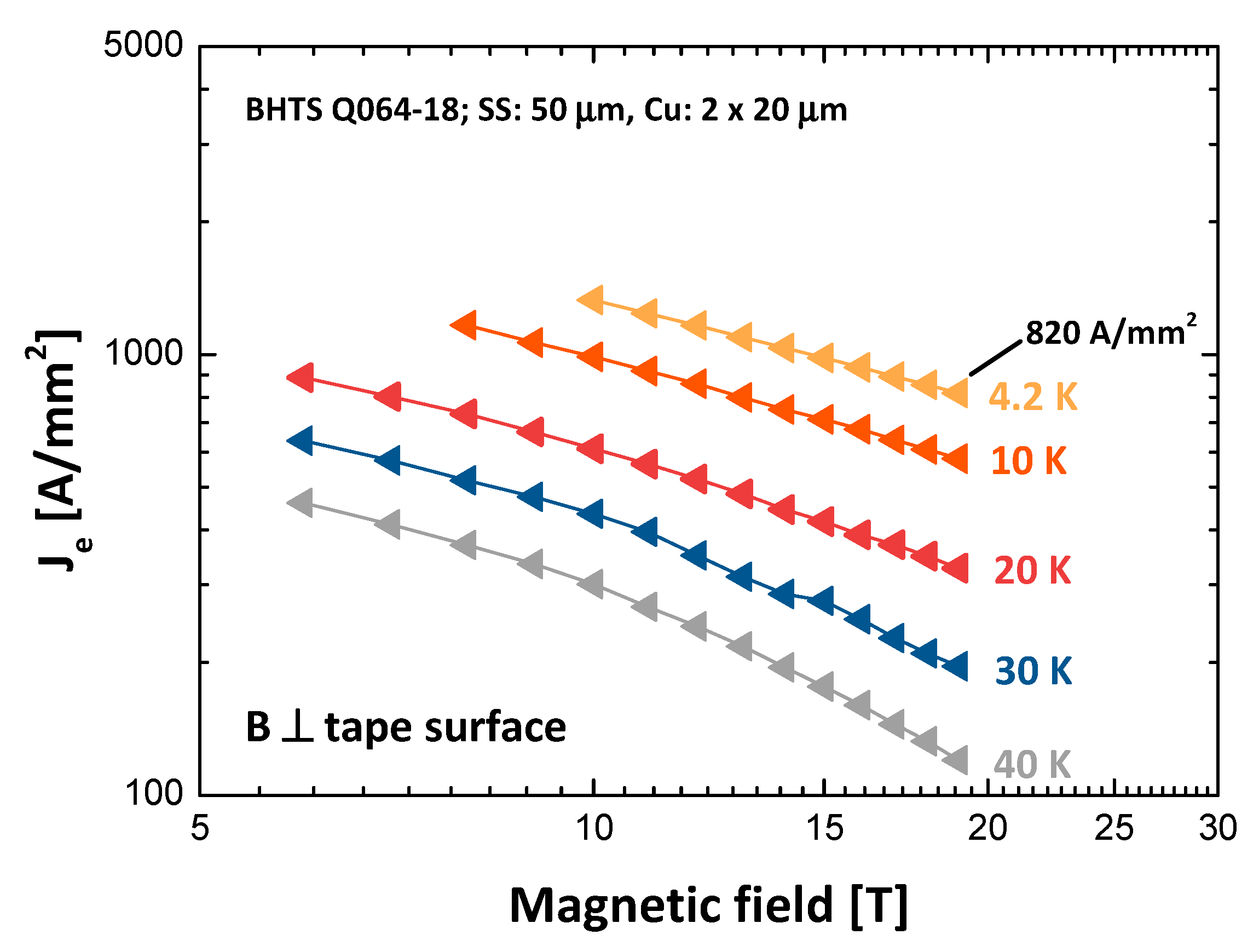

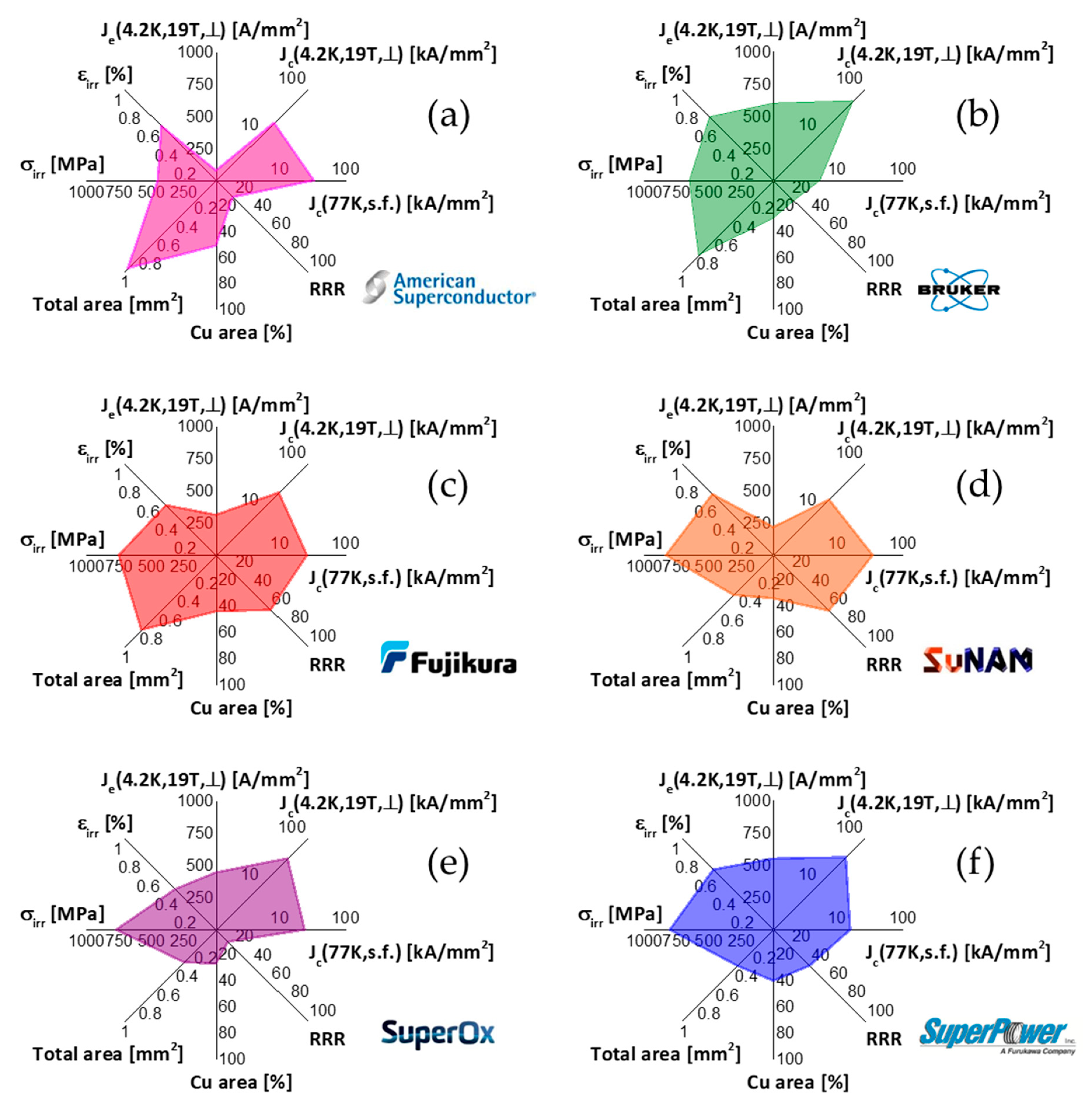

- High current density over the whole tape or wire cross-section, called Jengineering. Our goal was Je > 400 A/mm2@20 T and 4.2 K (taken as a reference operating temperature), with the magnetic field perpendicular to the broad face of the tape (worst direction).

- -

- A compact cable with a high filling factor to avoid the excessive dilution of the current density in the coil package.

- -

- Thin and robust insulation.

- Operating current in the conductor in the 5–20 kA range—i.e., a 10 kA-class cable.

- Multi-strand conductor with strand transposition and contact resistance among strands low enough to enable current transfer but high enough to avoid field-quality disruption during ramp. Strands are flat REBCO tape rather than round wire, as in the LTS cables.

- Control of field quality within a few units (one unit being 100 ppm of the main field). In this initial R&D phase, a few tens of units are considered sufficient both for magnetization and for winding geometry.

- Produce a 10 kA-class conductor of at least 20–30 m unit length (requiring in total approximately 1 km of 12 mm-wide tape). For this, we set goals for a tape of Je = 400–600 A/mm2 at 20 T, 4.2 K.

- Build various small dipole magnets with some accelerator characteristics (accessible bore for beam bending, high-order harmonics of the order of 0.1%) to qualify the conductor in near-to-operating conditions.

- A coil block design, called Aligned Blocks or AB dipole—i.e., with Roebel cable positioned such that the tape broad face was parallel to field lines for maximizing the current density) and flared ends. This design was pursued mainly by CERN.

- A classical cosθ design to explore synergy with a design commonly used in the accelerator domain. This design was taken up by CEA.

- A coil block design based on stacked tape (rather than Roebel cable similar to the previous two layouts). The design was proposed and developed by INPG (Institut d’Ingégnerie, Grenoble, Fr).

4.2. Objectives of ARIES

5. The Conductor R&D Programs in EuCARD2 and ARIES

5.1. Progress in the Performance of REBCO Tapes: Fabrication

- (i)

- Increasing the thickness of the superconducting layer;

- (ii)

- Increasing the critical current density, Jc, of the superconducting layer by introducing artificial pinning centers;

- (iii)

- Reduction in the substrate thickness.

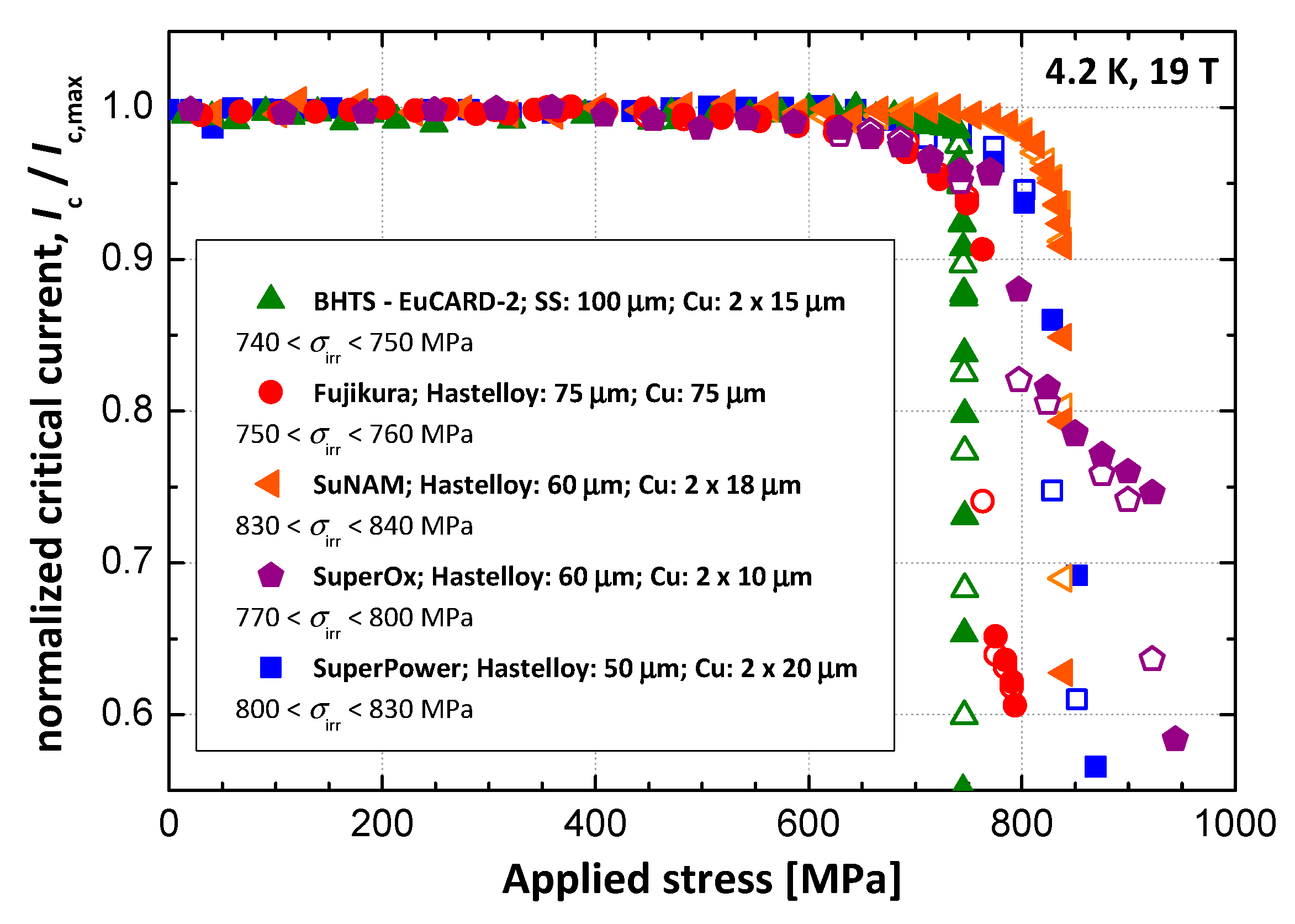

5.2. Progress in the Performance of REBCO Tapes: Characterization

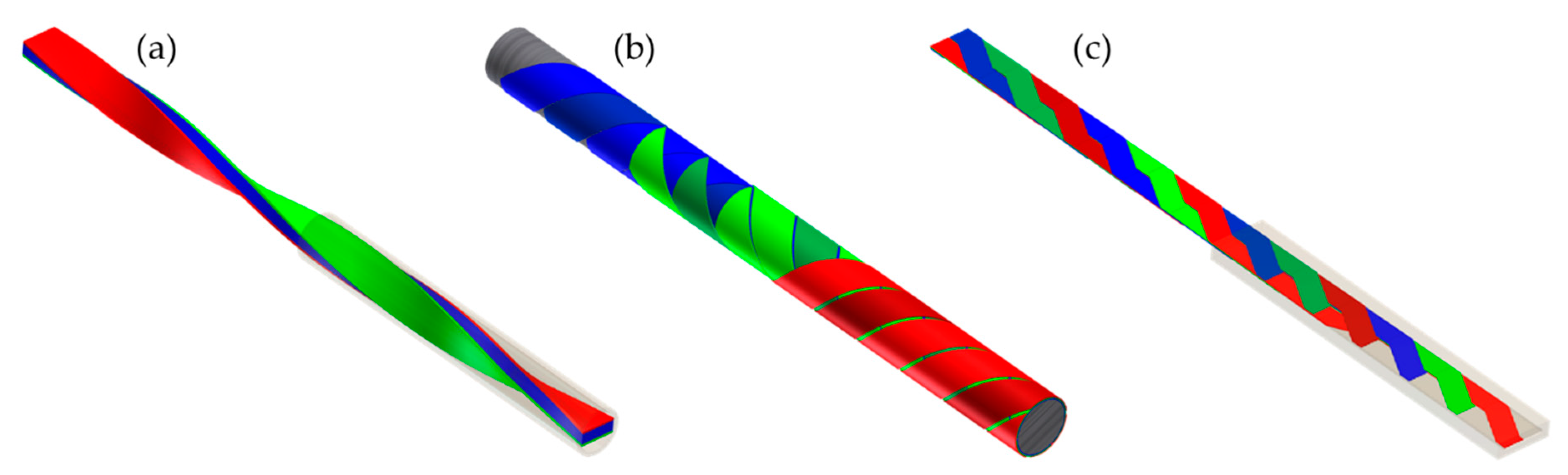

5.3. Development of a 10-kA Class REBCO Cable

5.3.1. REBCO Roebel Cable Design Evolution

5.3.2. Transverse Stress Tolerance of REBCO Roebel Cables

5.3.3. AC Loss and Inter-Tape Resistance of REBCO Roebel Cables

6. Magnet(s) Design and Technology

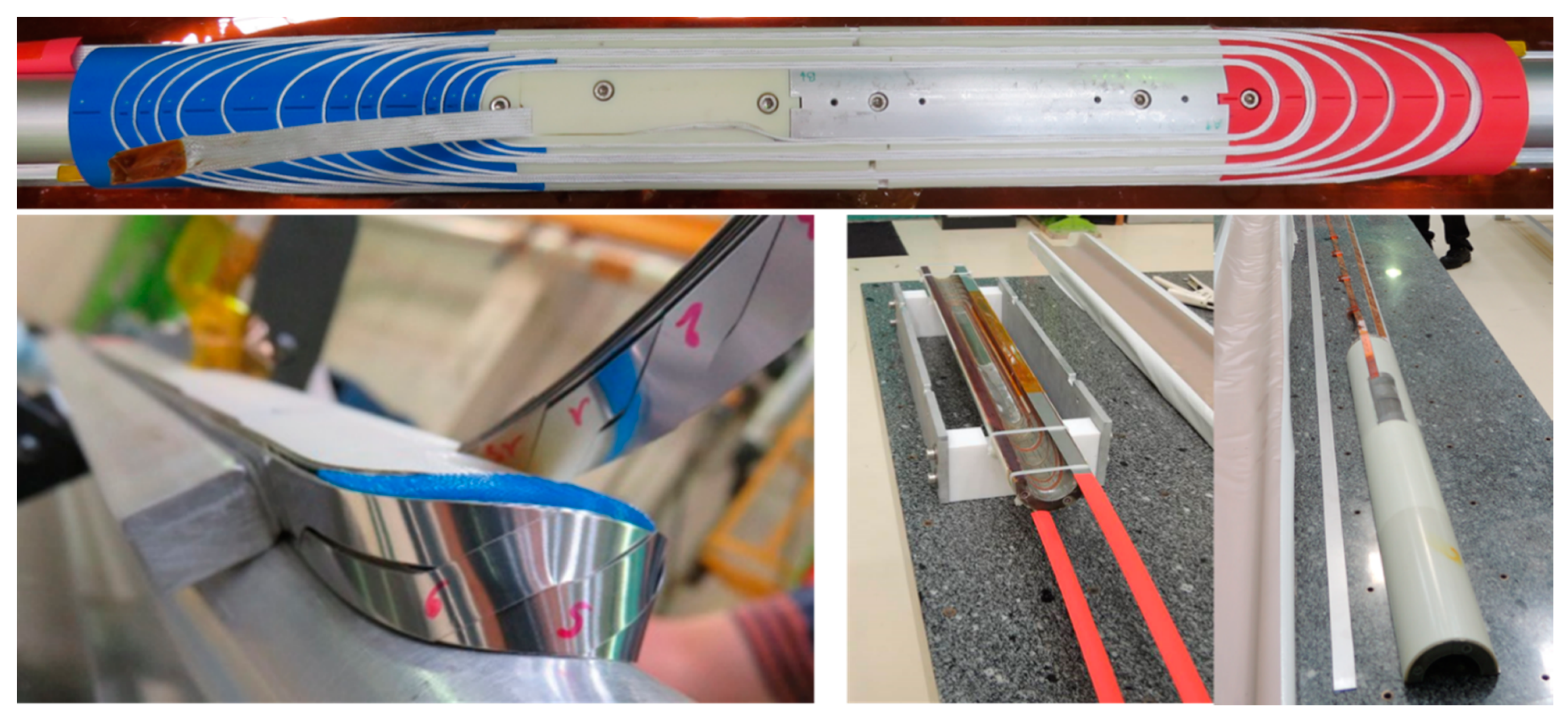

6.1. Reference Magnet Design: AB Feather Magnets

6.2. The EuCARD2 Cosθ Dipole

6.3. The EuCARD2 Stacked Tape Dipole

6.4. Magnet Technology

7. Magnet Test and Results

7.1. Results on FeatherM0 Coils

7.2. Results of AB Dipoles: First Two FeatherM2 Magnets

- There is evidence of current sharing among tapes, as anticipated by the measurement of losses on cables. However, it seems that current sharing is larger than expected, with contact resistance in the range of 10 µΩ. This helps to short-circuit local defects, but also makes the quench onset easy to detect.

- The transition is so smooth that we could increase performance by 10% and reach 3.35 T by increasing the ramp rate.

- The effect of energy dissipation in the copper ring, a feature that may be useful for future high-field magnets [79], is visible in accelerating the current decay.

- The absence of training—i.e., of repeated quenches to reach the maximum current for a given temperature [71]—is remarkable; even considering that it is a low field and small-energy magnet, this confirms the benefit of a large temperature margin.

- The first cooldown did not degrade the quenching performance. However, a subsequent thermal cycle saw a degradation of about 10% but the cooldown was not properly controlled. More verifications are under way.

- The first campaign of magnetic measurements showed a considerable number of field errors due to the coupling current among tapes, decaying with an 80 s time constant, and a relatively small contribution of intra-tape persistent current [85] of about 0.15–0.2% (15–20 units). The current decay might be triggered by low but not negligible internal resistance. While favorable from a field quality point of view, this last effect needs to be understood through more investigation.

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ATLAS Collaboration. Observation of a new particle in the search for the Standard Model Higgs boson with the ATLAS detector at the LHC. Phys. Lett. B 2012, 716, 1–29. [Google Scholar] [CrossRef]

- CMS Collaboration. Observation of a new boson at a mass of 125 GeV with the CMS experiment at the LHC. Phys. Lett. B 2012, 716, 30–61. [Google Scholar] [CrossRef]

- Brüning, O. Report LHC Full Energy Exploitation Study: Operation at 7 TeV; CERN-ACC-2017-0086; CERN: Geneva, Switzerland, 2017. [Google Scholar]

- Rossi, L.; Brüning, O. Progress with the High Luminosity LHC Project at CERN. In Proceedings of the 10th International Particle Accelerator Conference, IPAC2019, Melbourne, Australia, 19–24 May 2019; JACoW Publishing: Geneva, Switzerland, 2019; pp. 17–22, ISBN 978-3-95450-208-0. [Google Scholar] [CrossRef]

- Brüning, O.; Rossi, L. The High Luminosity Large Hadron Collider; Advanced Series on Directions in High Energy Physics; World Scientific: Singapore, 2015; Volume 24, IBSN 1793-1339. [Google Scholar]

- Bottura, L.; De Rijk, G.; Rossi, L.; Todesco, E. Advanced accelerator magnets for upgrading the LHC. IEEE Trans. Appl. Supercond. 2012, 22, 4002008. [Google Scholar] [CrossRef]

- Todesco, E.; Annarella, M.; Ambrosio, G.; Apollinari, G.; Ballarino, A.; Bajas, H.; Bajko, M.; Bordini, B.; Bossert, R.; Bottura, L.; et al. Progress on HL-LHC Nb3Sn magnets. IEEE Trans. Appl. Supercond. 2018, 28, 1–9. [Google Scholar] [CrossRef]

- Assmann, R.; Bailey, R.; Brüning, O.; Dominguez, O.; de Rijk, G.; Jimenez, J.M.; Myers, S.; Rossi, L.; Tavian, L.; Todesco, E.; et al. First Thoughts on a Higher-Energy LHC; CERN-ATS-2010-177; CERN: Geneva, Switzerland, 2010. [Google Scholar]

- Rossi, L.; Todesco, E. Conceptual design of 20T dipoles for high energy LHC. In The High-Energy Large Hadron Collider; Todesco, E., Zimmermann, F., Eds.; CERN-2011-003; CERN: Geneva, Switzerland, 2011; pp. 13–19. [Google Scholar]

- Benedikt, M.; Brunner, O.; Goddard, B.; Gutleber, J.; Jimenez, J.M.; Mangano, M.; Mertens, V.; Osborne, J.; Riegler, W.; Schulte, D.; et al. Future Circular Collider Study—Volume 3 FCC-hh Conceptual Design Report; CERN-ACC-2018-0058; CERN: Geneva, Switzerland, 2018. [Google Scholar]

- Rochepault, E.; Ferracin, P. CEA–CERN block-type dipole magnet for cable testing: Fresca2, ch 12. In Nb3Sn Accelerator Magnets; Schoerling, D., Zlobin, A.V., Eds.; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Rossi, L. Eucard2: WP on Magnets for HE-LHC: A First Description; CERN Report, EDMS n.1152224; CERN: Geneva, Switzerland, 2011. [Google Scholar]

- Rossi, L.; Badel, A.; Bajko, M.; Ballarino, A.; Bottura, L.; Dhallé, M.M.J.; Durante, M.; Fleiter, J.; Kario, A.; Kirby, G.; et al. The EuCARD-2 future magnets project: The European collaboration for accelerator quality HTS magnets. IEEE Trans. Appl. Supercond. 2015, 25. [Google Scholar] [CrossRef]

- Bottura, L.; Rossi, L. Technical and Economical Comparison YBCO/Bi-2212 Magnets; EuCARD2-Mil-MS68-Final, CERN EDMS n. 1325245; CERN: Geneva, Switzerland, 2016; Available online: http://eucard2.web.cern.ch/science/milestones (accessed on 26 August 2020).

- Weijers, H.W.; Hannahs, S.T.; Murphy, T.P.; Markiewicz, W.D.; Gavrilin, A.V.; Voran, A.J.; Viouchkov, Y.L.; Gundlach, S.R.; Noyes, P.D.; Abraimov, D.V.; et al. Progress in the development and construction of a 32-T superconducting magnet. IEEE Trans. Appl. Supercond. 2016, 26, 4300807. [Google Scholar] [CrossRef]

- Yoon, S.; Kim, J.; Cheon, K.; Lee, H.; Hahn, S.; Moon, S.-H. 26 T 35 mm all-GdBa2Cu3O7−x multi-width no-insulation super-conducting magnet. Supercond. Sci. Technol. 2016, 29, 04LT04. [Google Scholar] [CrossRef]

- Liu, J.; Wang, L.; Qin, L.; Wang, Q.; Dai, Y. Recent development of the 25 T all-superconducting magnet at IEE. IEEE Trans. Appl. Supercond. 2018, 28, 4301305. [Google Scholar] [CrossRef]

- Senatore, C.; Alessandrini, M.; Lucarelli, A.; Tediosi, R.; Uglietti, D.; Iwasa, Y. Progresses and challenges in the development of high-field solenoidal magnets based on RE123 coated conductors. Supercond. Sci. Technol. 2014, 27, 103001. [Google Scholar] [CrossRef]

- Jiang, J.; Bradford, G.; Hossain, S.I.; Brown, M.D.; Cooper, J.; Miller, E.; Huang, Y.; Miao, H.; Parrell, J.A.; White, M.; et al. High-performance Bi-2212 round wires made with recent powders. IEEE Trans. Appl. Supercond. 2019, 29, 6400405. [Google Scholar] [CrossRef]

- Scanlan, R.; Dieterich, D.; Higley, H. Conductor development for high field dipole magnets. IEEE Trans. Appl. Supercond. 2000, 10, 288–293. [Google Scholar] [CrossRef]

- Larbalestier, D.C.; Jiang, J.; Trociewitz, U.P.; Kametani, F.; Scheuerlein, C.; Dalbancanassy, M.; Matras, M.; Chen, P.; Craig, N.C.; Lee, P.J.; et al. Isotropic round-wire multifilament cuprate superconductor for generation of magnetic fields above 30 T. Nat. Mater. 2014, 13, 375–381. [Google Scholar] [CrossRef]

- Takayasu, M.; Chiesa, L.; Bromberg, L.; Minervini, J.V. HTS twisted stacked-tape cable conductor. Supercond. Sci. Technol. 2012, 25, 014011. [Google Scholar] [CrossRef]

- Uglietti, D.; Wesche, R.; Bruzzone, P. Design and strand tests of a fusion cable composed of coated conductor tapes. IEEE Trans. Appl. Supercond. 2014, 24, 4800704. [Google Scholar] [CrossRef]

- Celentano, G.; De Marzi, G.; Fabbri, F.; Muzzi, L.; Tomassetti, G.; Anemona, A.; Chiarelli, S.; Seri, M.; Bragagni, A.; Della Corte, A. Design of an industrially feasible twisted-stack HTS cable-in-conduit conductor for fusion application. IEEE Trans. Appl. Supercond. 2014, 24, 4601805. [Google Scholar] [CrossRef]

- van der Laan, D.C.; Noyes, P.D.; Miller, G.E.; Weijers, H.W.; Willering, G.P. Characterization of a high-temperature super-conducting conductor on round core cables in magnetic fields up to 20 T. Supercond. Sci. Technol. 2013, 26, 045005. [Google Scholar] [CrossRef]

- Goldacker, W.; Grilli, F.; Pardo, E.; Kario, A.; Schlachter, S.I.; Vojenčiak, M. Roebel cables from REBCO coated conductors: A one-century-old concept for the superconductivity of the future. Supercond. Sci. Technol. 2014, 27, 093001. [Google Scholar] [CrossRef]

- Devaux, M.; Debray, F.; Fleiter, J.; Fazilleau, P.; Lecrevisse, T.; Pes, C.; Rey, J.M.; Rifflet, J.M.; Sorbi, M.; Stenvall, A.; et al. HTS insert magnet design study. IEEE Trans. Appl. Supercond. 2012, 22, 4203605. [Google Scholar] [CrossRef]

- Badel, A.; Ballarino, A.; Barth, C.; Bottura, L.; Dhalle, M.M.J.; Fleiter, J.; Goldacker, W.; Himbele, J.; Kario, A.; Rossi, L.; et al. Advances in the development of a 10-kA class REBCO cable for the EuCARD2 demonstrator magnet. IEEE Trans. Appl. Supercond. 2016, 26, 480390. [Google Scholar] [CrossRef]

- Abraimov, D.; Ballarino, A.; Barth, C.; Bottura, L.; Dietrich, R.; Francis, A.; Jaroszynski, J.; Majkic, G.S.; McCallister, J.; Polyanskii, A.; et al. Double disordered YBCO coated conductors of industrial scale: High currents in high magnetic field. Supercond. Sci. Technol. 2015, 28, 114007. [Google Scholar] [CrossRef]

- Goyal, A.; Norton, D.P.; Kroeger, D.M.; Christen, D.K.; Paranthaman, M.; Specht, E.D.; Budai, J.D.; He, Q.; Saffian, B.; List, F.A.; et al. Conductors with controlled grain boundaries: An approach to the next generation, high temperature superconducting wire. J. Mater. Res. 1997, 12, 2924–2940. [Google Scholar] [CrossRef]

- Groves, J.; Arendt, P.; Kung, H.; Foltyn, S.; DePaula, R.; Emmert, L.; Storer, J. Texture development in IBAD MgO films as a function of deposition thickness and rate. IEEE Trans. Appl. Supercond. 2001, 11, 2822–2825. [Google Scholar] [CrossRef]

- Usoskin, A.; Kirchhoff, L.; Knoke, J.; Prause, B.; Rutt, A.; Selskij, V.; Farrell, D. Processing of long-length YBCO coated conductors based on stainless steel tapes. IEEE Trans. Appl. Supercond. 2007, 17, 3235–3238. [Google Scholar] [CrossRef]

- Nagaishi, T.; Shingai, Y.; Konishi, M.; Taneda, T.; Ota, H.; Honda, G.; Kato, T.; Ohmatsu, K. Development of REBCO coated conductors on textured metallic substrates. Phys. C Supercond. 2009, 469, 1311–1315. [Google Scholar] [CrossRef]

- Igarashi, M.; Kakimoto, K.; Hanyu, S.; Tashita, C.; Hayashida, T.; Hanada, Y.; Fujita, S.; Morita, K.; Nakamura, N.; Sutoh, Y.; et al. Remarkable progress in fabricating RE123 coated conductors by IBAD/PLD technique at Fujikura. J. Phys. Conf. Ser. 2010, 234, 022016. [Google Scholar] [CrossRef]

- Usoskin, A.; Knoke, J.; García-Moreno, F.; Issaev, A.; Dzick, J.; Sievers, S.; Freyhardt, H. Large-area HTS-coated stainless steel tapes with high critical currents. IEEE Trans. Appl. Supercond. 2001, 11, 3385–3388. [Google Scholar] [CrossRef]

- Oh, S.S.; Ha, H.S.; Kim, H.S.; Ko, R.K.; Song, K.J.; Ha, D.W.; Kim, T.H.; Lee, N.J.; Youm, D.; Yang, J.S.; et al. Development of long-length SmBCO coated conductors using a batch-type reactive co-evaporation method. Supercond. Sci. Technol. 2008, 21, 034003. [Google Scholar] [CrossRef]

- Matias, V.; Rowley, J.; Coulter, Y.; Maiorov, B.; Holesinger, T.; Yung, C.; Glyantsev, V.; Moeckly, B. YBCO films grown by reactive co-evaporation on simplified IBAD-MgO coated conductor templates. Supercond. Sci. Technol. 2010, 23, 014018. [Google Scholar] [CrossRef]

- Malozemoff, A.P.; Fleshler, S.; Rupich, M.; Thieme, C.; Li, X.; Zhang, W.; Otto, A.; Maguire, J.; Folts, D.; Yuan, J.; et al. Progress in high temperature superconductor coated conductors and their applications. Supercond. Sci. Technol. 2008, 21, 034005. [Google Scholar] [CrossRef]

- Selvamanickam, V.; Galinski, G.B.; Carota, G.; DeFrank, J.; Trautwein, C.; Haldar, P.; Balachandran, U.; Chudzik, M.; Coulter, J.Y.; Arendt, P.N.; et al. High-current Y–Ba–Cu–O superconducting films by metal organic chemical vapor deposition on flexible metal substrates. Physica C 2000, 333, 155–162. [Google Scholar] [CrossRef]

- Takahashi, K.; Kobayashi, H.; Yamada, Y.; Ibi, A.; Fukushima, H.; Konishi, M.; Miyata, S.; Shiohara, Y.; Kato, T.; Hirayama, T. Investigation of thick PLD-GdBCO and ZrO2 doped GdBCO coated conductors with high critical current on PLD-CeO2 capped IBAD-GZO substrate tapes. Supercond. Sci. Technol. 2006, 19, 924. [Google Scholar] [CrossRef]

- Emergo, R.L.S.; Wu, J.Z.; Aytug, T.; Christen, D.K. Thickness dependence of superconducting critical current density in vicinal YBa2Cu3O7−δ thick films. Appl. Phys. Lett. 2004, 85, 618. [Google Scholar] [CrossRef]

- Ibi, A.; Iwai, H.; Takahashi, K.; Muroga, T.; Miyata, S.; Watanabe, T.; Yamada, Y.; Shiohara, Y. Investigations of thick YBCO coated conductor with high critical current using IBAD-PLD method. Phys. C Supercond. 2005, 426, 910–914. [Google Scholar] [CrossRef]

- MacManus-Driscoll, J.L.; Foltyn, S.R.; Jia, Q.X.; Wang, H.; Serquis, A.; Civale, L.; Maiorov, B.; Hawley, M.E.; Maley, M.P.; Peterson, D.E. Strongly enhanced current densities in superconducting coated conductors of YBa2Cu3O7−x + BaZrO3. Nat. Mater. 2004, 3, 439–443. [Google Scholar] [CrossRef]

- Matsumoto, K.; Mele, P. Artificial pinning center technology to enhance vortex pinning in YBCO coated conductors. Supercond. Sci. Technol. 2009, 23, 014001. [Google Scholar] [CrossRef]

- Tobita, H.; Notoh, K.; Higashikawa, K.; Inoue, M.; Kiss, T.; Kato, T.; Hirayama, T.; Yoshizumi, M.; Izumi, T.; Shiohara, Y. Fabrication of BaHfO3 doped Gd1Ba2Cu3O7−δ coated conductors with the high Ic of 85 A/cm-w under 3T at liquid nitrogen temperature (77 K). Supercond. Sci. Technol. 2012, 25, 062002. [Google Scholar] [CrossRef]

- Matsushita, T.; Nagamizu, H.; Tanabe, K.; Kiuchi, M.; Otabe, E.S.; Tobita, H.; Yoshizumi, M.; Izumi, T.; Shiohara, Y.; Yokoe, D.; et al. Improvement of flux pinning performance at high magnetic fields in GdBa2Cu3Oy coated conductors with BHO nano-rods through enhancement of BcSupercond. Sci. Technol. 2012, 25, 125003. [Google Scholar]

- Selvamanickam, V.; Yao, Y.; Chen, Y.; Shi, T.; Liu, Y.; Khatri, N.; Liu, J.; Lei, C.; Galstyan, E.; Majkic, G. The low-temperature, high-magnetic-field critical current characteristics of Zr-added (Gd,Y)Ba2Cu3Ox superconducting tapes. Supercond. Sci. Technol. 2012, 25, 125013. [Google Scholar] [CrossRef]

- Usoskin, A.; Senatore, C.; Kario, A.; Goldacker, W.; Meledin, A.; Abraimov, D.; Larbalestier, D.; Betz, U.; Hofacker, F.; Rutt, A.; et al. Double-Disordered HTS-Coated conductors and their assemblies aimed for ultra-high fields: Large area tapes. IEEE Trans. Appl. Supercond. 2018, 28, 6602506. [Google Scholar] [CrossRef]

- Usoskin, A.; Betz, U.; Gnilsen, J.; Noll-Baumann, S.; Schlenga, K. Long-length YBCO coated conductors for ultra-high field applications: Gaining engineering current density via pulsed laser deposition/alternating beam-assisted deposition route. Supercond. Sci. Technol. 2019, 32, 094005. [Google Scholar] [CrossRef]

- Senatore, C.; Barth, C.; Bonura, M.; Kulich, M.; Mondonico, G. Field and temperature scaling of the critical current density in commercial REBCO coated conductors. Supercond. Sci. Technol. 2016, 29, 014002. [Google Scholar] [CrossRef]

- Barth, C.; Mondonico, G.; Senatore, C. Electro-mechanical properties of REBCO coated conductors from various industrial manufacturers at 77 K, self-field and 4.2 K, 19 T. Supercond. Sci. Technol. 2015, 28, 045011. [Google Scholar] [CrossRef]

- Bonura, M.; Senatore, C. High-field thermal transport properties of REBCO coated conductors. Supercond. Sci. Technol. 2015, 28, 025001. [Google Scholar] [CrossRef]

- Bonura, M.; Senatore, C. Transverse thermal conductivity of REBCO coated conductors. IEEE Trans. Appl. Supercond. 2015, 25, 6601304. [Google Scholar] [CrossRef]

- Bonura, M.; Senatore, C. An equation for the quench propagation velocity valid for high field magnet use of REBCO coated conductors. Appl. Phys. Lett. 2016, 108, 242602. [Google Scholar] [CrossRef]

- Fleiter, J.; Ballarino, A.; Bottura, L.; Tixador, P. Electrical characterization of REBCO Roebel cables. Supercond. Sci. Technol. 2013, 26, 65014. [Google Scholar] [CrossRef]

- Goldacker, W.; Nast, R.; Kotzyba, G.; Schlachter, S.I.; Frank, A.; Ringsdorf, B.; Schmidt, C.; Komarek, P. High current DyB-CO-ROEBEL assembled coated conductor (RACC). J. Phys. Conf. Ser. 2006, 43, 901–904. [Google Scholar] [CrossRef]

- Fleiter, J.; Ballarino, A.; Bottura, L.; Goldacker, W.; Kario, A. Characterization of Roebel cables for potential use in high-field magnets. IEEE Trans. Appl. Supercond. 2015, 25, 4802404. [Google Scholar] [CrossRef]

- Uglietti, D.; Wesche, R.; Bruzzone, P. Effect of transverse load on the critical current of a coated conductor Roebel cable. Supercond. Sci. Technol. 2013, 26, 074002. [Google Scholar] [CrossRef]

- Kirby, G.; Rossi, L.; Badel, A.; Bajko, M.; Ballarino, A.; Bottura, L.; Dhalle, M.; Durante, M.; Fazilleau, P.; Fleiter, J.; et al. Status of the demonstrator magnets for the EuCARD-2 future magnets project. IEEE Trans. Appl. Supercond. 2016, 26, 1–7. [Google Scholar] [CrossRef]

- Otten, S.L.; Dhallé, M.; Gao, P.; Wessel, W.A.J.; Kario, A.; Kling, A.; Goldacker, W. Enhancement of the transverse stress tolerance ofREBCO Roebel cables by epoxy impregnation. Supercond. Sci. Technol. 2015, 28, 065014. [Google Scholar] [CrossRef]

- Gao, P.; Wessel, S.; Dhalle, M.; Otten, S.; Kario, A.; Van Nugteren, J.; Kirby, G.; Bottura, L.; ten Kate, H. Effect of resin impregnation on the transverse pressure dependence of the critical current in ReBCO Roebel cables. Supercond. Sci. Technol. 2019, 32, 055006. [Google Scholar] [CrossRef]

- Van Nugteren, J.; Van Nugteren, B.; Gao, P.; Bottura, L.; Dhalle, M.; Goldacker, W.; Kario, A.; Kate, H.T.; Kirby, G.; Krooshoop, E.; et al. Measurement and numerical evaluation of AC losses in a ReBCO Roebel cable at 4.5 K. IEEE Trans. Appl. Supercond. 2016, 26, 8201407. [Google Scholar] [CrossRef]

- Yang, Y.; Pelegrin, J.; Young, E.A.; Nast, R.; Kario, A.; Goldacker, W. AC losses of Roebel cables with striated 2G REBCO strands. IEEE Trans. Appl. Supercond. 2018, 28, 6602105. [Google Scholar] [CrossRef]

- Gao, P.; Dhalle, M.; Van Nugteren, B.; Norder, H.; Kario, A.; Otten, S.; Goldacker, W.; van Nugteren, J.; Kirby, G.; De Rijk, G.; et al. Inter-strand resistance and AC loss in resin-filler impregnated ReBCO Roebel cables. Supercond. Sci. Technol. 2019, 32, 125002. [Google Scholar] [CrossRef]

- van Nugteren, J. High Temperature Superconductor Accelerator Magnets. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2016. [Google Scholar]

- Van Nugteren, J.; Kirby, G.A.; De Rijk, G.; Rossi, L.; Kate, H.H.J.T.; Dhalle, M.M.J. Study of a 5 T research dipole insert-magnet using an anisotropic ReBCO Roebel cable. IEEE Trans. Appl. Supercond. 2015, 25, 1–5. [Google Scholar] [CrossRef]

- Murtomaki, J.S.; Van Nugteren, J.; Kirby, G.; Rossi, L.; Ruuskanen, J.; Stenvall, A.; Murtomaeki, J.S. Mechanical effects of the non-uniform current distribution on HTS coils for accelerators wound with REBCO Roebel cable. IEEE Trans. Appl. Supercond. 2017, 27, 1. [Google Scholar] [CrossRef]

- Haro, E.; Stenvall, A.; Van Nugteren, J.; Kirby, G. Hot spot temperature in an HTS coil: Simulations with MIITs and finite element method. IEEE Trans. Appl. Supercond. 2015, 25, 1–7. [Google Scholar] [CrossRef]

- Ruuskanen, J.; Stenvall, A.; Lahtinen, V. Predicting heat propagation in Roebel-cable-based accelerator magnet prototype: One-dimensional approach with coupled turns. IEEE Trans. Appl. Supercond. 2016, 27, 1–5. [Google Scholar] [CrossRef]

- Kirby, G.A.; Van Nugteren, J.; Ballarino, A.; Bottura, L.; Chouika, N.; Clement, S.; Datskov, V.; Fajardo, L.; Fleiter, J.; Gauthier, R.; et al. Accelerator-quality HTS dipole magnet demonstrator designs for the EuCARD-2 5-T 40-mm clear aperture magnet. IEEE Trans. Appl. Supercond. 2014, 25, 1–5. [Google Scholar] [CrossRef][Green Version]

- Rossi, L.; Bottura, L. Superconducting magnets for particle accelerators. In Reviews of Accelerator Science and Technology; World Scientific Publishing Company: Singapore, 2012; Volume 5. [Google Scholar] [CrossRef]

- Lorin, C.; Segreti, M.; Ballarino, A.; Bottura, L.; Durante, M.; Fazilleau, P.; Fleiter, J.; Kirby, G.; van Nugteren, J.; Pes, C.; et al. Cos-θ design of dipole inserts made of REBCO-Roebel or BSCCO-Rutherford cables. IEEE Trans. Appl. Supercond. 2015, 25. [Google Scholar] [CrossRef]

- Lorin, C.; Durante, M.; Fazilleau, P.; Kirby, G.; Rossi, L. Development of a Roebel-cable-based cos ϑ dipole: Design and windability of magnet ends. IEEE Trans. Appl. Supercond. 2016, 26. [Google Scholar] [CrossRef]

- Durante, M.; Lorin, C.; Lecrevisse, T.; Segreti, M.; Kirby, G.; Van Nugteren, J. Manufacturing of the EuCARD2 Roebel-based Cos-Theta coils at CEA saclay. IEEE Trans. Appl. Supercond. 2020, 30, 1–5. [Google Scholar] [CrossRef]

- Himbele, J.J.; Badel, A.; Tixador, P. HTS dipole magnet for a particle accelerator using a twisted stacked cable. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Himbele, J.J.; Badel, A.; Tixador, P.; Ciceron, J.; Pasquet, R.; Voisin, E.; Forest, F.; Schneider, M. Partially insulated twisted stacked cable for HTS insert of a particle accelerator. IEEE Trans. Appl. Supercond. 2017, 27, 1–5. [Google Scholar] [CrossRef]

- Kirby, G.A.; Van Nugteren, J.; Bajas, H.; Benda, V.; Ballarino, A.; Bajko, M.; Bottura, L.; Broekens, K.; Canale, M.; Chiuchiolo, A.; et al. First cold powering test of REBCO Roebel wound coil for the EuCARD2 future magnet development project. IEEE Trans. Appl. Supercond. 2017, 27, 1–7. [Google Scholar] [CrossRef]

- Chiuchiolo, A.; Bajas, H.; Bajko, M.; Bottura, L.; Consales, M.; Cusano, A.; Giordano, M.; Perez, J.C. Advances in fiber optic sensors technology development for temperature and strain measurements in superconducting magnets and devices. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Murtomaki, J.S.; Van Nugteren, J.; Kirby, G.; De Rijk, G.; Rossi, L.; Stenvall, A. ICED—Inductively coupled energy dissipater for future high-field accelerator magnets. IEEE Trans. Appl. Supercond. 2018, 28, 1–15. [Google Scholar] [CrossRef]

- Murtomaeki, J.S.; Kirby, G.; Van Nugteren, J.; Contat, P.-A.; De Frutos, O.S.; Fleiter, J.; Pincot, F.O.; De Rijk, G.; Rossi, L.; Ruuskanen, J.; et al. 10 kA joints for HTS Roebel cables. IEEE Trans. Appl. Supercond. 2018, 28, 1–6. [Google Scholar] [CrossRef]

- Sarasola, X.; Bruzzone, P.; Sedlak, K.; Stepanov, B.; van Nugteren, J.; Kirby, G.; de Rijk, G. Test of HTS demonstrator coils at high field and variable temperature in the SULTAN facility. In Proceedings of the Eucas2019, Glasgow, UK, 1–5 September 2019. [Google Scholar]

- Ballarino, A. Cable Options for Eucard2. 2013. Available online: https://indico.cern.ch/event/298113/contributions/1660445/attachments/560315/771919/Amalia_EUCARD2_2014.pdf (accessed on 26 August 2020).

- Van Nugteren, J.; Kirby, G.; Bajas, H.; Bajko, M.; Ballarino, A.; Bottura, L.; Chiuchiolo, A.; Contat, P.-A.; Dhalle, M.; Durante, M.; et al. Powering of an HTS dipole insert-magnet operated standalone in helium gas between 5 and 85 K. Supercond. Sci. Technol. 2018, 31, 065002. [Google Scholar] [CrossRef]

- Rossi, L.; Chiuchiolo, A.; Dhalle, M.; Durante, M.; Fazilleau, P.; Fleiter, J.; Gao, P.; Goldacker, W.; Kario, A.; Kirby, G.; et al. The EuCARD2 future magnets program for particle accelerator high-field dipoles: Review of results and next steps. IEEE Trans. Appl. Supercond. 2017, 28, 1–10. [Google Scholar] [CrossRef]

- Petrone, C.; Van Nugteren, J.; Bajas, H.; Bottura, L.; Kirby, G.; Rossi, L.; Russenschuck, S. Measurement and analysis of the dynamic effects in an HTS dipole magnet. IEEE Trans. Appl. Supercond. 2018, 28, 1–4. [Google Scholar] [CrossRef]

- Van Nugteren, J.; Kirby, G.; Murtomaki, J.; DeRijk, G.; Rossi, L.; Stenvall, A. Toward REBCO 20 T+ dipoles for accelerators. IEEE Trans. Appl. Supercond. 2018, 28, 1–9. [Google Scholar] [CrossRef]

| EuCARD2 | ARIES | |||

|---|---|---|---|---|

| Parameter | Ultimate Target | Minimum | Ultimate Target | Minimum |

| Je(4.2 K, 20 T) (A/mm2) | 600 | 400 | 1000 | 600 |

| σ(Ic) (%) | ≤10 | |||

| μ0ΔM (1 T, 4.2 K) (mT) | ≤300 | |||

| Allowable σtransverse (MPa) | >100 | |||

| Allowable εlongitudinal (%) | >±0.3 | |||

| Unit Length (m) | ≥100 | >50 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rossi, L.; Senatore, C. HTS Accelerator Magnet and Conductor Development in Europe. Instruments 2021, 5, 8. https://doi.org/10.3390/instruments5010008

Rossi L, Senatore C. HTS Accelerator Magnet and Conductor Development in Europe. Instruments. 2021; 5(1):8. https://doi.org/10.3390/instruments5010008

Chicago/Turabian StyleRossi, Lucio, and Carmine Senatore. 2021. "HTS Accelerator Magnet and Conductor Development in Europe" Instruments 5, no. 1: 8. https://doi.org/10.3390/instruments5010008

APA StyleRossi, L., & Senatore, C. (2021). HTS Accelerator Magnet and Conductor Development in Europe. Instruments, 5(1), 8. https://doi.org/10.3390/instruments5010008