Abstract

Aquaculture is vital for global food security but faces challenges like disease, water quality control, and resource optimization. Digital twin technology, a real-time virtual replica of physical aquaculture systems, emerges as a transformative solution. By integrating sensors and data analytics, it enables monitoring and optimization of water quality, feed efficiency, fish health, and operations. This review explores the current adoption status of digital twins in aquaculture, highlighting applications in real-time monitoring and system optimization. It addresses key implementation challenges, including data integration and scalability, and identifies emerging opportunities for advancing sustainable, intelligent aquaculture practices.

Key Contribution:

Digital twin technology has provided tremendous assistance for the intelligent development of aquaculture.

1. Introduction

Aquaculture has become an important part of how food is produced around the world, providing much of the protein needed by people everywhere. As the global population continues to grow and natural resources become increasingly depleted, aquaculture has emerged as a vital solution for meeting the ever-increasing demand for seafood [1,2,3]. In fact, it is now the fastest-growing food production sector globally and is critical to ensuring food security, particularly in countries where access to traditional sources of animal protein is limited [4,5]. However, despite its growing importance, aquaculture still faces challenges that limit its potential for sustainable, high-quality development [6,7].

The challenges in the aquaculture sector are manifold. First, the aquaculture industry is under increasing pressure to minimize its environmental pollution, particularly in terms of water use, feed efficiency, and waste management. Traditional aquaculture practices often lead to water pollution, overuse of resources, and the spread of disease [8,9,10]. Therefore, there is an urgent need for innovations in approaches and improvements in methods to increase the sustainability of aquaculture operations and reduce their environmental impacts, while improving aquaculture efficiency. Secondly, aquaculture faces significant economic pressures. Feed, energy, and labor costs account for a significant portion of operating expenses [11,12,13,14]. The increasing costs associated with these resources, coupled with volatile market prices, make it difficult for aquaculture enterprises to remain profitable. Finally, as the global population grows and wild fish stocks are depleted, the demand for aquaculture is increasing, and the industry must move to more efficient, environmentally friendly, and sustainable production methods [15,16].

To address these challenges, digital twin (DT) technology has emerged as a powerful tool for transforming aquaculture into a more intelligent, sustainable, and efficient industry [17]. DT refers to the creation of a virtual replica of a physical system or process, which is continuously updated with real-time data collected from sensors embedded in the physical system [18,19]. This enables the simulation, monitoring, and optimization of the system’s performance by linking the physical and digital worlds. In aquaculture, digital twin technology can be applied to the entire aquaculture system, including tanks, water circulation systems, feeding systems, health monitoring systems, and waste management processes [20,21,22]. The virtual model created by the DT is constantly updated with data from Internet of Things sensors that track environmental parameters and command instructions. By monitoring the aquaculture system parameters in real time, potential problems are predicted, and information parameters are automatically adjusted to ensure that farmed organisms are growing under ideal conditions [23,24,25,26].

The application of DT technology offers several promising solutions to the challenges of the aquaculture industry. One of the most significant advantages is the ability to optimize resource utilization [27]. By integrating data from different sources, DT technology can simulate different operational scenarios and suggest strategies to reduce waste, improve feed efficiency, and reduce water and energy consumption [28,29]. This enables aquaculture systems to maximize yields while minimizing environmental impact, meeting the urgent need for sustainable agricultural practices [30,31]. Another key benefit of DT technology is its role in disease management [32]. Disease is one of the most significant risks facing the aquaculture industry and can lead directly to significant economic losses. The DT continuously monitors fish behavior, water quality, and environmental conditions, enabling aquaculture companies to detect early signs of stress or disease before it spreads. By combining this data with predictive modeling, the system can predict potential outbreaks and recommend preventative measures such as adjusting water quality or implementing targeted treatments [33,34,35]. In addition, DT technology can automate the management of aquaculture processes, helping aquaculture companies to improve productivity and economic efficiency. Automation can reduce the need for manual labor in tasks such as feeding, water quality management, and waste removal, all of which can lead to significant operational costs. Integrating machine learning and artificial intelligence (AI) algorithms into the DT can optimize these processes in real time, increasing aquaculture system productivity and profitability [36,37].

While the application of digital twin technology in aquaculture is still in its nascent stages, its potential benefits are considerable. This review aims to explore the status of digital twin adoption in the aquaculture sector, highlighting key applications in water quality monitoring, health management, and system optimization. It also addresses the challenges associated with implementing such technologies, including data integration, system scalability, and the need for interdisciplinary collaboration. Finally, the review identifies emerging opportunities that could drive the future development of intelligent aquaculture systems, offering insights into the potential for innovation and growth in this rapidly evolving field.

This review not only describes research on the application of digital twin technology in intelligent aquaculture but also delves deeper into the technological progress, existing limitations, and challenges faced in each key component (sensors, data analysis and processing, virtual models, and control systems). Compared with the existing review articles, our contribution lies in revealing the practical feasibility and future development directions of digital twin technology in aquaculture through a detailed analysis of technical implementation details and bottlenecks in practical applications. Furthermore, this review, by integrating the latest research findings, offers a systematic perspective, avoiding the mere accumulation of literature. Instead, it provides a clear direction for subsequent research by synthesizing the techniques, methods, and challenges of each part.

2. Concepts and Components of Digital Twin Technology

2.1. What Is Digital Twin Technology?

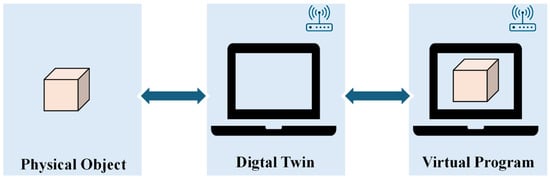

A digital twin (DT) can be regarded as the digital mapping system of one or more important and interdependent equipment systems [17,38]. A DT makes full use of physical models, sensors, operational history, and other data; integrates multi-disciplinary, multi-physical quantity, multi-scale, and multi-probability simulation processes; and completes mapping in the virtual space, thereby reflecting the entire life cycle process of the corresponding physical equipment [39,40]. The concept of DT technology has undergone significant changes in the past two decades, transitioning from initial manufacturing and engineering to transformative tools across various industries, including aquaculture [41]. The core of a DT is a virtual model of physical systems or processes, continuously updated with real-time data to achieve real-time monitoring, simulation, optimization, and predictive decision-making (Figure 1) [42,43]. In aquaculture, DT technology enables more intelligent, efficient, and sustainable practices by monitoring and simulating key aquaculture system parameters in real time, helping to promote the development of the aquaculture industry [44].

Figure 1.

Common sensors used in aquaculture.

2.2. Key Components of a Digital Twin System

A DT consists of several key components that work in concert to create a dynamic, data-driven virtual model of a physical system, including sensors, data analysis and processing platforms, virtual models, and control systems.

2.2.1. Sensors

At the heart of any DT system in aquaculture are sensors and IoT devices that collect real-time data from the physical environment. These devices measure various environmental and biological parameters critical to the health and productivity of the aquaculture system (Table 1) [45,46,47,48]. These sensors feed the collected data into a central processing unit, often connected through a cloud-based IoT platform, which sends the data to the DT model for further analysis and simulation [49].

Table 1.

Common sensors used in aquaculture.

2.2.2. Data Analytics and Processing

Once the data is collected from the sensor, it must be processed and analyzed to provide operable decisions. At this point, big data analysis, machine learning, and AI play a role [50]. The data processing platform receives data from sensors in real time and uses algorithms to analyze information and detect patterns or anomalies. Machine learning algorithms help predict the future based on historical data [51,52,53]. For example, based on past data on the health of the water environment and aquaculture organisms, machine learning models can predict when the water environment may become unhealthy or when organisms may have disease outbreaks [54]. The AI-driven system can optimize the operation process of the aquaculture system by adjusting the feeding rate, water circulation or aeration level, and other parameters according to the prediction of the model [55,56]. The processed data is continuously fed back to the digital twin model so that the system can update the virtual copy of the aquaculture system in real time. This dynamic data-driven system ensures that the aquaculture system maintains the optimal operation state and enables aquaculture managers to make real-time decisions.

2.2.3. Virtual Models

The virtual model is the core of the DT system, being a digital representation of the physical system, capturing its structure, operations, and dynamics. This model is continuously updated with data from sensors, enabling operators to simulate different scenarios and analyze the effects of potential changes before implementing them in the real world [57,58]. In the context of aquaculture, virtual models of DT typically include water systems, health models, waste management models, and feeding systems (Table 2) [59,60,61,62]. By simulating various parameters in the virtual model, aquaculture operators can test potential changes to aquaculture system management practices and see the effects of those changes in a risk-free virtual environment. This allows operators to make informed decisions that are likely to yield the best results in real-world conditions [63,64,65].

Table 2.

Category and function of virtual models.

2.2.4. Control Systems

The control system is responsible for the decision of DT model generation. Once the system determines the problem or proposes optimization suggestions, the control system will act in the physical environment [66,67,68]. These systems usually run autonomously according to preset rules or the results of predictive analysis. For example, if the DT model detects that the dissolved oxygen levels in the water are falling below the optimal threshold, it can automatically trigger the aeration system to increase oxygen levels [55,69]. Similarly, if the system detects a potential disease outbreak, the control system can activate preventative measures such as adjusting water quality, applying treatments, or isolating affected tanks [70]. The integration of automation through control systems not only enhances efficiency but also minimizes the need for manual labor, reducing costs and improving the overall sustainability of the aquaculture operation [71].

In a digital twin system, a decision support system (DSS) is not merely a data feedback tool; it should also offer an interactive interface to help operators understand the decision-making process of AI. Through graphical interfaces, 3D models and real-time simulations, operators can observe the potential impact of different decisions on aquaculture and adjust the system’s behavior when necessary. This design can enable a closer cooperative relationship between the AI system and the operator, enhancing the adaptability and reliability of the system.

3. Applications of Digital Twin Technology in Intelligent Aquaculture and Facility Optimization

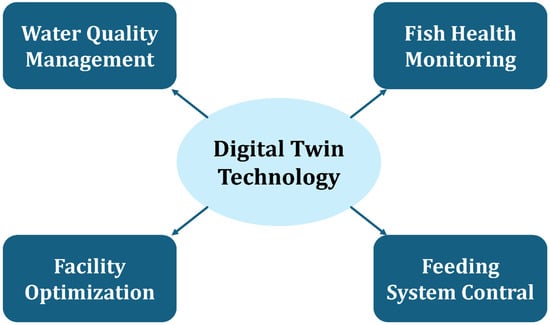

The application of DT technology in intelligent aquaculture is a growing revolution that promises to transform the way aquaculture system monitor, control, and optimize their operations. By providing real-time simulations of physical systems, DT technology can help in continuously monitoring parameters like water quality, fish behavior, and system performance, enabling predictive analysis and optimization (Figure 2) [35,71,72,73].

Figure 2.

Applications of DT in intelligent aquaculture.

3.1. Real-Time Environmental Monitoring and Control

Water quality management has been one of the primary challenges in aquaculture. Maintaining optimal conditions is crucial for the health and growth of fish. In traditional systems, water quality is usually assessed intermittently through manual tests, leading to delays in addressing critical issues like oxygen depletion or excessive waste accumulation [74,75]. DT technology allows for continuous, real-time monitoring of key water parameters, such as pH, temperature, dissolved oxygen, and ammonia levels. By combining real-time sensor data with predictive models, DT systems simulate how these environmental factors interact with each other and with fish health [76]. This enables proactive measures, allowing operators to adjust system variables such as water circulation or aeration before issues affect the fish.

Real-time monitoring is one of the most beneficial aspects of DT. With IoT sensors providing continuous streams of data, digital twin systems can instantly reflect environmental changes and predict their impact. For instance, fluctuations in water temperature or dissolved oxygen levels can be detected in real-time, and predictive algorithms can forecast these changes before they reach critical thresholds. This capability allows for proactive control of the environment, preventing sudden changes that could harm the fish [77,78]. According to Mahmoud et al. [79], an Internet of Things and DT system was established to collect environmental parameters including light intensity, humidity, and temperature, resulting in enhanced hydroponic systems that improved both plant and fish growth.

One of the major advantages of DT technology in aquaculture is its ability to simulate future environmental conditions based on historical and real-time data. By utilizing predictive modeling, the system can anticipate seasonal fluctuations, such as changes in temperature or water salinity, that directly affect the growth rates of fish. Through the DT model, the system can simulate how these changes in the environment might impact fish health, allowing aquaculture administrators to adjust their strategies in advance, reducing potential risks [23]. According to Teramoto et al. [80], the artificial neural network (ANN) and support vector machine (SVM) methods could be used to develop a model for predicting total suspended solids content based on AI and water quality parameters, using nitrite and turbidity as predictive variables. An improved graph convolutional network (FTGCN) integrating feature attention and temporal attention is proposed. Through adaptive graph learning, a multi-head self-attention mechanism, and an autoregressive module, the prediction accuracy of multivariate water quality indicators is significantly improved [81].

3.2. Fish Health Monitoring and Disease Prevention

Fish health is directly related to both the success and sustainability of aquaculture operations. In traditional systems, fish health is often assessed through visual inspection or by reacting to symptoms of disease, which can be too late to prevent outbreaks. DT technology, however, provides a more proactive approach to fish health management [10]. By integrating sensor data on water quality, fish behavior, and growth patterns and combining such data with machine learning algorithms, DT systems allow for continuous health monitoring and the early detection of diseases before they spread across the entire population.

By integrating behavioral monitoring systems, monitoring factors such as motion tracking and swimming patterns, with physiological sensors, DT systems can offer real-time insights into the health and behavior of fish [82]. These systems track subtle changes in swimming patterns, feeding behavior, and activity levels, which can serve as early indicators of stress or illness. By identifying these changes before symptoms manifest as disease, aquaculture operators can take timely preventive actions. In addition, Kim et al. [83] emphasized that a hybrid framework combining Mixed Data Sampling (MIDAS) and Overlapping Mixed Gaussian Process (OMGP) models enables accurate prediction of eel growth trajectories in aquaculture systems.

DT systems also offer powerful disease prediction capabilities. These systems combine data pertaining to fish behavior, water quality, and historical disease trends to predict the likelihood of disease outbreaks. By applying predictive analytics, the system can forecast disease risks before they occur, allowing for early interventions, such as vaccination, quarantine measures, or water treatment adjustments. Yasruddin et al. developed a stacked ensemble learning framework for fish health management which utilizes deep learning-based detection models to identify fish diseases and evaluates the impact of pH level and temperature on disease probability through logistic regression. By bridging the gap between image-based diagnosis and water quality analysis, this study provides a comprehensive and real-time diagnostic system, enhancing disease management in aquaculture [84]. Ahmed et al. [85]. propose an image-based machine learning framework using a support vector machine (SVM) with preprocessing techniques (e.g., k-means segmentation, adaptive histogram equalization) to detect diseases in salmon fish, achieving 94.12% accuracy on an augmented novel dataset.

3.3. Facility Optimization and Simulation

Optimizing aquaculture facilities is another critical application of DT. Digital twin systems can simulate different facility designs, water flow dynamics, and system configurations to determine the most efficient setups for optimal fish growth and health. The integration of computational fluid dynamics (CFD) simulations and real-time sensor data helps improve the layout of tanks, ponds, aeration systems, and waste collection units, leading to more efficient resource use and higher productivity [86].

CFD simulations are essential for optimizing water flow in aquaculture systems. By modeling how water moves through tanks, ponds, or cages, DT systems can identify potential dead zones where waste and low oxygen may accumulate. These simulations provide valuable insights into how water can be circulated more efficiently and how filtration systems can be optimized for better waste removal. An et al. used fluent software to perform computational fluid dynamics simulations on the eccentric drainage pool at the bottom and the central drainage pool at the bottom of the same circular water tank, considering the rotational flow generated by tangential water injection and the non-rotational flow generated by the low waterfall inlet, providing a reference for drainage structure design [87].

Aeration and filtration systems are integral to maintaining water quality in aquaculture systems. DT models, by simulating different system configurations, allow aquaculture systems to optimize energy consumption and waste removal. Alnemari et al. implemented a hybrid LSTM-DDPG deep learning model in a large-scale tilapia RAS (108 tanks, 3132 m3), achieving 15–20% daily energy savings and 17% cost reduction per kg while maintaining water quality via adaptive control of pumps, aeration, and temperature systems [88]. These models simulate how changes in aeration or filtration setup can improve water quality, reduce operational costs, and increase aquaculture system sustainability. Previous studies [89] reported that the application of a coupled CFD-solute transport model (CFD-STM) revealed optimal values for key aeration parameters (flow rate, bubble diameter, inlet velocity, aerator position), enhancing oxygen transfer in microporous systems. Furthermore, these studies demonstrated that minimizing bubble diameter substantially increases the oxygen transfer coefficient, offering a theoretical foundation for optimizing energy-saving practices in intermittent aeration.

3.4. Precision Feeding Systems

Precision feeding is one of the most impactful applications of DT technology in aquaculture. By integrating real-time monitoring of fish behavior, growth, and water conditions, digital twin systems can optimize feeding schedules, ensure that the right amount of feed is delivered, and minimize feed waste. This contributes to improving feed conversion ratios (FCR), reducing environmental impact, and improving aquaculture system profitability [52].

By integrating data from behavioral sensors, water quality monitors, and fish growth models, DT systems can dynamically adjust feeding schedules and feed amounts. These adjustments ensure that fish receive the optimal amount of feed at each stage of growth, reducing waste and improving feed efficiency [90]. The integration of DT in aquaculture allows for the real-time adjustment of feeding systems to optimize feed conversion ratios (FCR). By using data on fish growth and environmental conditions, these systems can adjust feed delivery and optimize feeding strategies, ultimately improving efficiency and sustainability. Budaev et al. developed the FishMet model, a new scalable stochastic simulation framework that represents the fundamental feedback loop for controlling appetite, feeding decisions, energy budget, and growth in salmonids, demonstrating good predictions of gastrointestinal transport and food intake in rainbow trout. The model is supported by server-based components and an open application programming interface for data assimilation and on-demand execution, and it could be used as a DT model [91].

The process a system with digital twin technology follows to optimize the feeding program, ensure that the right amount of feed is provided, minimize waste, and determine the exact feed consumption of the fish through real-time data collection, predictive analytics for feed requirements, automated feeding adjustments, feed waste reduction, and environmental footprint minimization is described below and shown in Figure 3.

Figure 3.

DT-driven feeding optimization and environmental impact reduction in aquaculture.

Step 1: Real-time data collection: Digital twin (DT) technology integrates various sensors (e.g., fish behavior sensors, water quality sensors) that continuously collect real-time data on key factors such as fish growth, activity levels, water temperature, oxygen levels, and feed consumption. These data points are fed into the digital model of the aquaculture system.

Step 2: Predictive analytics for feed requirements: Using the collected data, the digital twin model predicts the fish’s specific nutritional needs based on their age, size, activity levels, and environmental conditions. For example, if water temperature rises, the fish may become more active and require more feed. By simulating different feeding scenarios, the DT system optimizes feeding schedules to ensure the right amount of feed is provided at the right time.

Step 3: Automated feeding adjustments: DT systems are often integrated with automated feeding systems. These systems adjust feed delivery based on the predictions from the digital twin model. If fish are less active, the system can reduce feed delivery, minimizing waste. Conversely, if the fish are actively feeding, the system can increase feed quantities, ensuring they receive adequate nutrition. This prevents overfeeding, which can lead to wastage and water pollution.

Step 4: Feed waste reduction: By continuously monitoring feed consumption, the DT system can fine-tune feeding programs to ensure that the exact amount of feed is provided. This dynamic adjustment reduces excess feed, which is a major contributor to pollution in aquaculture systems. Feed waste is minimized, and the system can optimize feeding efficiency, ensuring maximum feed conversion ratios (FCRS), which reduces environmental pollution due to uneaten feed.

Step 5: Environmental footprint minimization: Through optimized feed management, DT technology also helps minimize the environmental footprint of aquaculture. By ensuring that only the required amount of feed is used, DT reduces nutrient overload in the water, leading to less water contamination and a lower risk of eutrophication. Furthermore, DT systems can optimize energy consumption related to water circulation and aeration, further reducing the carbon footprint of the aquaculture operation.

4. Challenges and Limitations of Digital Twin Technology in Aquaculture

While the integration of DT technology into intelligent aquaculture has the potential to revolutionize the industry, there are several challenges and limitations that need to be addressed for successful implementation. These challenges are primarily related to technical barriers, data management issues, economic factors, and the complexity of system integration in real-world aquaculture environments.

4.1. Technical Challenges

DT systems in aquaculture require advanced hardware and software to collect, process, and analyze large amounts of data from multiple sources in real time. The technical challenges of deploying DT systems in aquaculture are centered around sensor integration, data synchronization, and the accuracy of virtual models [23,92]. These challenges can lead to inefficiencies, inaccuracies in predictive simulations, and difficulties in scaling systems for larger aquaculture systems.

One of the main technical hurdles in implementing DT systems is the integration of IoT sensors for real-time data collection. Sensors play a pivotal role in gathering data on water quality, fish behavior, feeding patterns, and waste levels [71]. However, the accuracy and reliability of these sensors can be affected by several factors, including environmental interference, calibration issues, and connectivity issues (Table 3). Another major technical challenge is data synchronization across multiple devices and platforms. DT systems in aquaculture typically require the integration of data from a variety of sources, such as sensors, actuators, and control systems. Ensuring that these disparate data streams are synchronized in real time is essential for the accurate simulation of physical systems. The complexity increases as the aquaculture system scales up, requiring the synchronization of data from the system.

Table 3.

Challenges for sensors in aquaculture digital twin systems.

4.2. Data Management Issues

Data management is a critical challenge for the effective use of DT in aquaculture. The sheer volume of sensor data generated by these systems can be overwhelming, and storing, processing, and analyzing this data efficiently presents significant hurdles. Additionally, managing data quality, security, and privacy are concerns that must be addressed to ensure the success of DT adoption in the aquaculture industry [33].

DT systems in aquaculture require handling vast amounts of real-time data. Sensors provide continuous data on water quality, fish behavior, and other operational parameters, which need to be processed and analyzed almost instantaneously. This reliance on big data and real-time analytics requires advanced computational resources, powerful cloud platforms, and sophisticated algorithms. As DT systems collect and store large amounts of sensitive data related to aquaculture operations, fish health, and environmental conditions, data privacy and security become important concerns [93]. Ensuring that the data is protected from cyber threats and unauthorized access is crucial for maintaining trust in the system. Moreover, with data being transmitted across multiple platforms and devices, ensuring secure data encryption and access controls becomes essential.

4.3. Economic and Financial Barriers

While the long-term benefits of DT technology in aquaculture are clear, the initial capital investment required to implement these systems can be significant. This includes the costs associated with sensor installation, cloud computing infrastructure, software development, and training. For smaller aquaculture systems or those in developing regions, these costs may present a barrier to adopting DT technology [31,50].

The upfront investment required to implement a DT system can be prohibitively high, especially for small- and medium-sized aquaculture operations. These systems require the installation of IoT sensors, an advanced computing infrastructure, and specialized software, which can represent a large financial burden for many aquaculture systems. Additionally, aquaculture system may require specialized training for their staff to effectively use and maintain the system. In addition to the high initial investment, there are ongoing costs associated with maintaining and upgrading DT systems. As aquaculture technology evolves, DT systems may need to be regularly updated or expanded to incorporate new sensors, devices, or software features, which can result in additional expenses, especially for aquaculture systems that are already operating on thin profit margins.

4.4. Integration and Interoperability

The integration of DT systems into existing aquaculture system management processes can be complex, particularly in legacy aquaculture systems that may not have been designed with smart technology in mind. Ensuring that DT models can integrate seamlessly with existing aquaculture system equipment, management software, and control systems is essential for achieving full operational efficiency.

Older aquaculture systems that rely on traditional methods of water quality management, feeding, and waste removal may face challenges in integrating DT with existing systems. Compatibility issues between legacy systems and new technologies can lead to inefficiencies, errors in data synchronization, and increased operational complexity. The complexity of DT systems also presents a barrier to widespread adoption, particularly among operators who may not have technical expertise. Successful implementation requires not only the integration of advanced technology but also comprehensive user training to ensure that aquaculture operators can interpret the data provided by the system and make informed decisions.

5. Conclusions

In conclusion, DT technology holds immense potential to revolutionize the aquaculture industry by enabling real-time monitoring, precise system optimization, and efficient resource management. By integrating IoT sensors, machine learning, and simulation models, DT systems provide a practical approach to enhancing aquaculture operations. These technologies enable just-in-time interventions for water quality control, early detection and prevention of diseases, and optimization of critical processes such as feed scheduling and operational workflows. This shift from reactive to predictive operations results in tangible, real-world improvements, making aquaculture more productive and sustainable.

In practice, the application of DT technology translates to improved fish health management, reduced operational costs, and minimized environmental impacts. By optimizing feed efficiency, controlling waste management, and improving energy use, DT systems ensure more sustainable practices, leading to higher-quality yields and resource conservation. While challenges like high initial costs and data integration complexities remain, DT technology has already proven its value in enhancing both economic viability and environmental stewardship across various aquaculture systems.

Looking forward, the integration of AI, automation, and renewable energy technologies with DT will further enhance the autonomy of aquaculture operations. These innovations will enable self-optimizing systems that can predict and address potential bottlenecks or environmental stressors in real time, with minimal human intervention. This level of autonomy will not only reduce operational costs but also promote continuous, adaptive control tailored to the specific needs of the aquaculture environment. As the industry moves towards smart aquaculture, the widespread adoption of DT systems will be crucial in meeting the increasing global demand for sustainable seafood production while minimizing the environmental footprint and ensuring the long-term resilience and profitability of aquaculture enterprises.

Author Contributions

Conceptualization, J.C. and Z.C.; investigation, Y.X. and H.L.; software, Z.C. and J.C.; supervision, Y.S., C.Q., Y.X., X.Z. and K.Q.; writing—original draft, J.C.; writing—review and editing, X.Z., Z.C. and K.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Key Research and Development Program of China [grant number 2023YFD2400401, 2023YFD2400400], the National Natural Science Foundation of China [grant number 42406189], the Key R&D Program of Shandong Province, China [grant number 2023CXGC010412], the earmarked fund for CARS-47, and the Qingdao Natural Science Foundation [grant number 23-2-1-67-zyyd-jch].

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Hanif, M. Development of the Integrated multi-trophic aquaculture (IMTA) System in the World; Article Review. J. Aquac. Sci. 2022, 7, 95–104. [Google Scholar] [CrossRef]

- Gkikas, D.C.; Gkikas, M.C.; Theodorou, J.A. Fostering Sustainable Aquaculture: Mitigating Fish Mortality Risks Using Decision Trees Classifiers. Appl. Sci. 2024, 14, 2129. [Google Scholar] [CrossRef]

- Zhao, Y.; Qin, H.; Xu, L.; Yu, H.; Chen, Y. A review of deep learning-based stereo vision techniques for phenotype feature; behavioral analysis of fish in aquaculture. Artif. Intell. Rev. 2024, 58, 1–61. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, J.; Tolba, A.; Alqahtani, F.; Qi, X.; Shen, Y. A Data-Driven Intelligent Management Scheme for Digital Industrial Aquaculture based on Multi-object Deep Neural Network. Math. Biosci. Eng. 2023, 20, 10428–10443. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Gui, F. The Application and Research of New Digital Technology in Marine Aquaculture. J. Mar. Sci. Eng. 2023, 11, 401. [Google Scholar] [CrossRef]

- Rowan, N.J. The role of digital technologies in supporting and improving fishery and aquaculture across the supply chain—Quo Vadis? Aquac. Fish. 2023, 8, 365–374. [Google Scholar] [CrossRef]

- Choi, W.; Lee, S.; Baek, S.; Lee, S.; Seo, J.; Shin, D.; Jeong, H.; Sung, Y. Numerical analysis of thermal and hydrodynamic characteristics in aquaculture tanks with different tank structures. Ocean Eng. 2023, 287, 115880. [Google Scholar] [CrossRef]

- Behroozi, L.; Couturier, M.F. Prediction of water velocities in circular aquaculture tanks using an axisymmetric CFD model. Aquac. Eng. 2019, 85, 114–128. [Google Scholar] [CrossRef]

- Che, Z.; Zhou, Y.; Zhao, C.; Ren, X.; Liu, H.; Sun, W.; Liu, H.; Li, M. Experimental study on sewage collection and related performance of square arc angle aquaculture tank. Aquac. Int. 2023, 32, 3017–3040. [Google Scholar] [CrossRef]

- Føre, M.; Alver, M.O.; Alfredsen, J.A.; Rasheed, A.; Hukkelås, T.; Bjelland, H.V.; Su, B.; Ohrem, S.J.; Kelasidi, E.; Norton, T.; et al. Digital Twins in intensive aquaculture—Challenges, opportunities and future prospects. Comput. Electron. Agric. 2024, 218, 108676. [Google Scholar] [CrossRef]

- Huggins, D.L.; Piedrahita, R.H.; Rumsey, T. Use of computational fluid dynamics (CFD) for aquaculture raceway design to increase settling effectiveness. Aquac. Eng. 2005, 33, 167–180. [Google Scholar] [CrossRef]

- Le, N.-B.-v.; Woo, H.; Lee, D.; Huh, J.-H. AgTech: A Survey on Digital Twins Based Aquaculture Systems. IEEE Access 2024, 12, 125751–125767. [Google Scholar] [CrossRef]

- Li, W.; Du, Z.; Xu, X.; Bai, Z.; Han, J.; Cui, M.; Li, D. A review of aquaculture: From single modality analysis to multimodality fusion. Comput. Electron. Agric. 2024, 226, 109367. [Google Scholar] [CrossRef]

- Makisha, N.A.; Vladislavovna Beresneva, Y.; Vyacheslavovich Osmin, V.; Dabrowski, W. Digital models for assessing the impact of aeration processes on reservoir aquaculture. BIO Web Conf. 2024, 107, 03011. [Google Scholar] [CrossRef]

- Laktuka, K.; Kalnbalkite, A.; Sniega, L.; Logins, K.; Lauka, D. Towards the sustainable intensification of aquaculture: Exploring possible ways forward. Sustainability 2023, 15, 16952. [Google Scholar] [CrossRef]

- Kruk, S.R.; Bush, S.R.; Phillips, M. Federating ‘Aquaculture 4.0’ for data-driven social and environmental sustainability. Mar. Policy 2024, 169, 106355. [Google Scholar] [CrossRef]

- Aheleroff, S.; Xu, X.; Zhong, R.Y.; Lu, Y. Digital Twin as a Service (DTaaS) in Industry 4.0: An Architecture Reference Model. Adv. Eng. Inform. 2021, 47, 101225. [Google Scholar] [CrossRef]

- Duarte, F.J.; Silva, L.O.; Dias, B.; Pereira, T.F.; Machado, R.J. Towards a Digital Ocean Ontology Using the OApIS Approach. In Proceedings of the 2024 IEEE International Conference on Engineering, Technology, and Innovation (ICE/ITMC), Funchal, Portugal, 24–28 June 2024; pp. 1–9. [Google Scholar]

- Jeremiah, S.R.; El Azzaoui, A.; Xiong, N.N.; Park, J.H. A comprehensive survey of digital twins: Applications, technologies and security challenges. J. Syst. Archit. 2024, 151, 103120. [Google Scholar] [CrossRef]

- Lambertini, A.; Menghini, M.; Cimini, J.; Odetti, A.; Bruzzone, G.; Bibuli, M.; Mandanici, E.; Vittuari, L.; Castaldi, P.; Caccia, M.; et al. Underwater Drone Architecture for Marine Digital Twin: Lessons Learned from SUSHI DROP Project. Sensors 2022, 22, 744. [Google Scholar] [CrossRef] [PubMed]

- Lv, Z.; Lv, H.; Fridenfalk, M. Digital Twins in the Marine Industry. Electronics 2023, 12, 2025. [Google Scholar] [CrossRef]

- Purcell, W.; Neubauer, T. Digital Twins in Agriculture: A State-of-the-art review. Smart Agric. Technol. 2023, 3, 100094. [Google Scholar] [CrossRef]

- Lima, A.C.; Royer, E.; Bolzonella, M.; Pastres, R. Digital twins for land-based aquaculture: A case study for rainbow trout (Oncorhynchus mykiss). Open Res. Eur. 2022, 2, 16. [Google Scholar] [CrossRef] [PubMed]

- Lan, H.-Y.; Ubina, N.A.; Cheng, S.-C.; Lin, S.-S.; Huang, C.-T. Digital Twin Architecture Evaluation for Intelligent Fish Farm Management Using Modified Analytic Hierarchy Process. Appl. Sci. 2022, 13, 141. [Google Scholar] [CrossRef]

- Skákala, J.; Awty-Carroll, K.; Menon, P.P.; Wang, K.; Lessin, G. Future digital twins: Emulating a highly complex marine biogeochemical model with machine learning to predict hypoxia. Front. Mar. Sci. 2023, 10, 1058837. [Google Scholar] [CrossRef]

- Semeraro, C.; Lezoche, M.; Panetto, H.; Dassisti, M. Digital twin paradigm: A systematic literature review. Comput. Ind. 2021, 130, 103469. [Google Scholar] [CrossRef]

- He, B.; Bai, K.-J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2020, 9, 1–21. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Reyes Yanes, A.; Abbasi, R.; Martinez, P.; Ahmad, R. Digital Twinning of Hydroponic Grow Beds in Intelligent Aquaponic Systems. Sensors 2022, 22, 7393. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, M.A.; Lakhan, A.; Abdulkareem, K.H.; Abd Ghani, M.K.; Marhoon, H.A.; Kadry, S.; Nedoma, J.; Martinek, R.; Zapirain, B.G. Industrial Internet of Water Things architecture for data standarization based on blockchain and digital twin technology☆. J. Adv. Res. 2024, 66, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Tzachor, A.; Hendel, O.; Richards, C.E. Digital twins: A stepping stone to achieve ocean sustainability? npj Ocean Sustain. 2023, 2, 16. [Google Scholar] [CrossRef]

- Zhang, J.; He, S.; Zou, G. Design of digital twin system for aquaculture. In Proceedings of the 2023 5th International Conference on Internet of Things, Automation and Artificial Intelligence, Nanchang China, 24–26 November 2023; pp. 824–829. [Google Scholar]

- Vasilijevic, A.; Brönner, U.; Dunn, M.; García-Valle, G.; Fabrini, J.; Stevenson-Jones, R.; Bye, B.L.; Mayer, I.; Berre, A.; Ludvigsen, M.; et al. A Digital Twin of the Trondheim Fjord for Environmental Monitoring—A Pilot Case. J. Mar. Sci. Eng. 2024, 12, 1530. [Google Scholar] [CrossRef]

- Yu, Z.; Du, P.; Yi, L.; Luo, W.; Li, D.; Zhao, B.; Li, L.; Zhang, Z.; Zhang, J.; Zhang, J.; et al. Coastal Zone Information Model: A comprehensive architecture for coastal digital twin by integrating data, models, and knowledge. Fundam. Res. 2024, in press. [CrossRef]

- Su, B.; Bjørnson, F.O.; Tsarau, A.; Endresen, P.C.; Ohrem, S.J.; Føre, M.; Fagertun, J.T.; Klebert, P.; Kelasidi, E.; Bjelland, H.V. Towards a holistic digital twin solution for real-time monitoring of aquaculture net cage systems. Mar. Struct. 2023, 91, 103469. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Zhabitskii, M.; Andrienko, Y. A Digital Twin of Intensive Aquabiotechnological Production Based on a Closed Ecosystem Modeling & Simulation. In Proceedings of the 33rd European Modeling & Simulation Symposium (EMSS 2021), Online, 15–17 September 2021; pp. 247–252. [Google Scholar]

- Zhabitskii, M.G.; Andryenko, Y.A.; Malyshev, V.N.; Chuykova, S.V.; Zhosanov, A.A. Digital transformation model based on the digital twin concept for intensive aquaculture production using closed water circulation technology. IOP Conf. Ser. Earth Environ. Sci. 2021, 723, 032064. [Google Scholar] [CrossRef]

- Thelen, A.; Zhang, X.; Fink, O.; Lu, Y.; Ghosh, S.; Youn, B.D.; Todd, M.D.; Mahadevan, S.; Hu, C.; Hu, Z. A comprehensive review of digital twin—Part 1: Modeling and twinning enabling technologies. Struct. Multidiscip. Optim. 2022, 65, 1–55. [Google Scholar] [CrossRef]

- Pylianidis, C.; Osinga, S.; Athanasiadis, I.N. Introducing digital twins to agriculture. Comput. Electron. Agric. 2021, 184, 105942. [Google Scholar] [CrossRef]

- Hamzah, A.; Aqlan, F.; Baidya, S. Drone-based digital twins for water quality monitoring: A systematic review. Digit. Twins Appl. 2024, 1, 131–160. [Google Scholar] [CrossRef]

- Gonzalez Jimenez, M.A.; Rakotonirina, A.D.; Sainte-Rose, B.; Cox, D.J. On the Digital Twin of The Ocean Cleanup Systems—Part I: Calibration of the Drag Coefficients of a Netted Screen in OrcaFlex Using CFD and Full-Scale Experiments. J. Mar. Sci. Eng. 2023, 11, 1943. [Google Scholar] [CrossRef]

- Park, H.; Park, D.-H.; Jo, S.-K. A Method for Optimizing Water Quality of the Aquafarm Using Application Independent Digital Twins. In Proceedings of the 2023 14th International Conference on Information and Communication Technology Convergence (ICTC), Jeju Island, Republic of Korea, 11–13 October 2023; pp. 1173–1177. [Google Scholar]

- Ubina, N.A.; Lan, H.-Y.; Cheng, S.-C.; Chang, C.-C.; Lin, S.-S.; Zhang, K.-X.; Lu, H.-Y.; Cheng, C.-Y.; Hsieh, Y.-Z. Digital twin-based intelligent fish farming with Artificial Intelligence Internet of Things (AIoT). Smart Agric. Technol. 2023, 5, 100285. [Google Scholar] [CrossRef]

- Xu, L.; Yu, H.; Qin, H.; Chai, Y.; Yan, N.; Li, D.; Chen, Y. Digital Twin for Aquaponics Factory: Analysis, Opportunities, and Research Challenges. IEEE Trans. Ind. Inform. 2024, 20, 5060–5073. [Google Scholar] [CrossRef]

- Alves, R.G.; Maia, R.F.; Lima, F. Development of a Digital Twin for smart farming: Irrigation management system for water saving. J. Clean. Prod. 2023, 388, 135920. [Google Scholar] [CrossRef]

- Chen, G.; Yang, J.; Huang, B.; Ma, C.; Tian, F.; Ge, L.; Xia, L.; Li, J. Toward digital twin of the ocean: From digitalization to cloning. Intell. Mar. Technol. Syst. 2023, 1, 3. [Google Scholar] [CrossRef]

- Sasaki, Y.; Nishikawa, R.; Komeyama, K. Non-invasive swimming speed estimation method based on tail-beat frequency determined from fish length measurement using stereo-cameras. Fish. Sci. 2024, 90, 1001–1010. [Google Scholar] [CrossRef]

- Ghandar, A.; Ahmed, A.; Zulfiqar, S.; Hua, Z.; Hanai, M.; Theodoropoulos, G. A Decision Support System for Urban Agriculture Using Digital Twin: A Case Study With Aquaponics. IEEE Access 2021, 9, 35691–35708. [Google Scholar] [CrossRef]

- Le, N.-B.-V.; Huh, J.-H. AgTech: Building Smart Aquaculture Assistant System Integrated IoT and Big Data Analysis. IEEE Trans. AgriFood Electron. 2024, 2, 471–482. [Google Scholar] [CrossRef]

- Lee, S.Y.; Jeong, D.Y.; Choi, J.; Jo, S.K.; Park, D.H.; Kim, J.G. LSTM model to predict missing data of dissolved oxygen in land-based aquaculture farm. ETRI J. 2024, 46, 1047–1060. [Google Scholar] [CrossRef]

- Chen, L.; Yang, X.; Sun, C.; Wang, Y.; Xu, D.; Zhou, C. Feed intake prediction model for group fish using the MEA-BP neural network in intensive aquaculture. Inf. Process. Agric. 2020, 7, 261–271. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, H.; Zhang, X.; Zhang, P.; Tu, W.; Gu, L. Fish behavior recognition based on an audio-visual multimodal interactive fusion network. Aquac. Eng. 2024, 107, 102471. [Google Scholar] [CrossRef]

- Måløy, H. EchoBERT: A transformer-based approach for behavior detection in echograms. IEEE Access 2020, 8, 218372–218385. [Google Scholar] [CrossRef]

- Almansa, C.; Masaló, I.; Reig, L.; Piedrahita, R.; Oca, J. Influence of tank hydrodynamics on vertical oxygen stratification in flatfish tanks. Aquac. Eng. 2014, 63, 1–8. [Google Scholar] [CrossRef]

- Khater, E.S.; Bahnasawy, A.; El-Ghobashy, H.; Shaban, Y.; Elsheikh, F.; El-Reheem, S.A.; Aboegela, M. Mathematical model for predicting oxygen concentration in tilapia fish farms. Sci. Rep. 2021, 11, 24130. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Fu, X.; Xue, Y.; Chang, X.; Bai, X. A review on basic theory and technology of agricultural energy internet. IET Renew. Power Gener. 2023, 18, 1318–1331. [Google Scholar] [CrossRef]

- Mohammadi Moghadam, M.; Rajabi Islami, H.; Ezam, M.; Mousavi, S.A. Optimizing flow uniformity and velocity fields in aquaculture tanks by modifying water inlets and nozzles arrangement: A computational fluid dynamics study. Aquac. Eng. 2024, 106, 102431. [Google Scholar] [CrossRef]

- Labatut, R.A.; Ebeling, J.M.; Bhaskaran, R.; Timmons, M.B. Modeling hydrodynamics and path/residence time of aquaculture-like particles in a mixed-cell raceway (MCR) using 3D computational fluid dynamics (CFD). Aquac. Eng. 2015, 67, 39–52. [Google Scholar] [CrossRef]

- Zhou, Y.; Xue, B.; Liu, H.; Liu, H.; Liu, Y.; Ma, Z.; Ren, X.; Zhao, Y.; Du, S. Numerical simulation of bionic fish group movement in a land-based aquaculture tank. Aquac. Eng. 2024, 104, 102388. [Google Scholar] [CrossRef]

- Gorle, J.M.R.; Terjesen, B.F.; Summerfelt, S.T. Influence of inlet and outlet placement on the hydrodynamics of culture tanks for Atlantic salmon. Int. J. Mech. Sci. 2020, 188, 105944. [Google Scholar] [CrossRef]

- Sin, M.G.; An, C.H.; Cha, S.J.; Kim, M.J.; Kim, H.N. A method for minimizing the zone of low water flow velocity in a bottom center drain circular aquaculture tank. J. World Aquac. Soc. 2021, 52, 1221–1233. [Google Scholar] [CrossRef]

- An, C.-H.; Sin, M.-G.; Kim, M.-J.; Jong, I.-B.; Song, G.-J.; Choe, C. Effect of bottom drain positions on circular tank hydraulics: CFD simulations. Aquac. Eng. 2018, 83, 138–150. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, Y.; Ren, X.; Liu, S.; Liu, H.; Li, M. Numerical modeling and application of the effects of fish movement on flow field in recirculating aquaculture system. Ocean Eng. 2023, 285, 115432. [Google Scholar] [CrossRef]

- Terjesen, B.F.; Summerfelt, S.T.; Nerland, S.; Ulgenes, Y.; Fjæra, S.O.; Megård Reiten, B.K.; Selset, R.; Kolarevic, J.; Brunsvik, P.; Bæverfjord, G.; et al. Design, dimensioning, and performance of a research facility for studies on the requirements of fish in RAS environments. Aquac. Eng. 2013, 54, 49–63. [Google Scholar] [CrossRef]

- Ohrem, S.J.; Kelasidi, E.; Bloecher, N. Analysis of a novel autonomous underwater robot for biofouling prevention and inspection in fish farms. In Proceedings of the 2020 28th Mediterranean conference on control and automation (MED), Saint-Rapha, France, 15–18 September 2020; pp. 1002–1008. [Google Scholar]

- Skaldebø, M.; Ohrem, S.J.; Amundsen, H.B.; Kelasidi, E.; Bloecher, N. Framework for autonomous navigation for a permanent resident aquaculture net grooming robot. In Proceedings of the 2023 31st Mediterranean Conference on Control and Automation (MED), Limassol, Cyprus, 26–29 June 2023; pp. 356–363. [Google Scholar]

- López-Barajas, S.; Sanz, P.J.; Marín-Prades, R.; Gómez-Espinosa, A.; González-García, J.; Echagüe, J. Inspection operations and hole detection in fish net cages through a hybrid underwater intervention system using deep learning techniques. J. Mar. Sci. Eng. 2023, 12, 80. [Google Scholar] [CrossRef]

- Gorgan-Mohammadi, F.; Rajaee, T.; Zounemat-Kermani, M. Decision tree models in predicting water quality parameters of dissolved oxygen and phosphorus in lake water. Sustain. Water Resour. Manag. 2022, 9, 1. [Google Scholar] [CrossRef]

- Fang, X.; Wang, H.; Liu, G.; Tian, X.; Ding, G.; Zhang, H. Industry application of digital twin: From concept to implementation. Int. J. Adv. Manuf. Technol. 2022, 121, 4289–4312. [Google Scholar] [CrossRef]

- Alver, M.O.; Føre, M.; Alfredsen, J.A. Effect of cage size on oxygen levels in Atlantic salmon sea cages: A model study. Aquaculture 2023, 562, 738831. [Google Scholar] [CrossRef]

- Føre, M.; Frank, K.; Norton, T.; Svendsen, E.; Alfredsen, J.A.; Dempster, T.; Berckmans, D. Precision fish farming: A new framework to improve production in aquaculture. Biosyst. Eng. 2018, 173, 176–193. [Google Scholar] [CrossRef]

- Lien, A.M.; Schellewald, C.; Stahl, A.; Frank, K.; Skøien, K.R.; Tjølsen, J.I. Determining spatial feed distribution in sea cage aquaculture using an aerial camera platform. Aquac. Eng. 2019, 87, 102018. [Google Scholar] [CrossRef]

- Burke, M.; Grant, J.; Filgueira, R.; Stone, T. Oceanographic processes control dissolved oxygen variability at a commercial Atlantic salmon farm: Application of a real-time sensor network. Aquaculture 2021, 533, 736143. [Google Scholar] [CrossRef]

- Alver, M.O.; Skøien, K.R.; Føre, M.; Aas, T.S.; Oehme, M.; Alfredsen, J.A. Modelling of surface and 3D pellet distribution in Atlantic salmon (Salmo salar L.) cages. Aquac. Eng. 2016, 72, 20–29. [Google Scholar] [CrossRef]

- Alver, M.O.; Føre, M.; Alfredsen, J.A. Predicting oxygen levels in Atlantic salmon (Salmo salar) sea cages. Aquaculture 2022, 548, 737720. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, G.; Wang, Y.; Li, D.; Li, W. Numerical investigations on temperature and flow field performance of octagonal culture tank under different physical parameters for fish growth based on computational fluid dynamics. Comput. Electron. Agric. 2022, 195, 106821. [Google Scholar] [CrossRef]

- Chahid, A.; N’Doye, I.; Majoris, J.E.; Berumen, M.L.; Laleg-Kirati, T.M. Fish growth trajectory tracking using Q-learning in precision aquaculture. Aquaculture 2022, 550, 737838. [Google Scholar] [CrossRef]

- Mahmoud, M.M.M.; Darwish, R.; Bassiuny, A.M. Development of an economic smart aquaponic system based on IoT. J. Eng. Res. 2024, 12, 886–894. [Google Scholar] [CrossRef]

- Teramoto, T.; Wasielesky, W.; Krummenauer, D.; Bueno, G.W.; Proença, D.C.; Gaona, C.A.P. Appling machine learning for estimating total suspended solids in BFT aquaculture system. Aquac. Eng. 2024, 106, 102439. [Google Scholar] [CrossRef]

- Ni, Q.J.; Cao, X.H.; Tan, C.Q.; Peng, W.Q.; Kang, X.Y. An improved graph convolutional network with feature and temporalattention for multivariate water quality prediction. Environ. Sci. Pollut. Res. 2023, 30, 11516–11529. [Google Scholar] [CrossRef] [PubMed]

- Brijs, J.; Føre, M.; Gräns, A.; Clark, T.D.; Axelsson, M.; Johansen, J.L. Bio-sensing technologies in aquaculture: How remote monitoring can bring us closer to our farm animals. Philos. Trans. R. Soc. B. 2021, 376, 20200218. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Park, E.; Cho, S.; Kwon, K.; Ko, Y.M. Probabilistic Modeling of Fish Growth in Smart Aquaculture Systems. Trans. Internet Inf. Syst. 2023, 17, 2259–2277. [Google Scholar]

- Yasruddin, M.L.; Husin, Z.M.; Ismail, A.H.; Keong, T.W. Smart aquaculture: An advanced intelligent predictive analysis of disease risks and recommendation system for managing fish health. Neural Comput. Appl. 2025, 37, 14499–14520. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Aurpa, T.T.; Azad, M.A.K. Fish Disease Detection Using Image Based Machine Learning Techniquein Aquaculture. J. King Saud Univ.-Comput. Inf. Sci. 2022, 34, 5170–5182. [Google Scholar] [CrossRef]

- Ren, X.; Hu, Y.; Zhou, Y.; Du, S.; Sun, W.; Liu, H.; Liu, Y. Numerical simulation of inlet placement on sewage characteristics in the rounded square aquaculture tank with single inlet. J. Oceanol. Limnol. 2024, 42, 1359–1382. [Google Scholar] [CrossRef]

- An, C.-H.; Kim, U.-S.; Kim, K.-H.; Jon, R.-G.; Sin, M.-G. Self-cleaning performance of three bottom drain modes in circular culture tank: Experimental and numerical study. Aquac. Eng. 2023, 101, 102329. [Google Scholar] [CrossRef]

- Alnemari, A.M.; Elmessery, W.M.; Moghanm, F.S.; Espinosa, V.; Shams, M.Y.; Elwakeel, A.E.; Saeed, O.; Eid, M.H.; Alhag, S.K.; Al-Shuraym, L.A.; et al. Energy optimization in large-scale recirculating aquaculture systems: Implementation and performance analysis of a hybrid deep learning approach. Aquac. Eng. 2025, 111, 102561. [Google Scholar] [CrossRef]

- Yu, G.; Zhang, S.; Chen, X.; Li, D.; Li, W.; Wang, Y. Numerical investigations on dissolved oxygen field performance of octagonal culture tank based on computational fluid dynamics. Comput. Electron. Agric. 2024, 218, 108737. [Google Scholar] [CrossRef]

- Du, Z.; Cui, M.; Xu, X.; Bai, Z.; Han, J.; Li, W.; Li, D. Harnessing multimodal data fusion to advance accurate identification of fish feeding intensity. Biosyst. Eng. 2024, 246, 135–149. [Google Scholar] [CrossRef]

- Budaev, S.; Dumitru, M.L.; Enberg, K.; Handeland, S.O.; Higginson, A.D.; Kristiansen, T.S.; Opdal, A.F.; Railsback, S.F.; Rønnestad, I.; Vollset, K.W.; et al. Premises for a digital twin of the Atlantic salmon in its world: Agency, robustness, subjectivity and prediction. Aquac. Fish. 2024, 4, e153. [Google Scholar] [CrossRef]

- Komarudin, M.; Septama, H.D.; Yulianti, T.; Yudamson, A.; Hendri, J.; Arafat, M.A.D. Multi node sensors for water quality monitoring towards precision aquaculture. IOP Conf. Ser Earth Environ. Sci. 2021, 739, 012026. [Google Scholar] [CrossRef]

- Mileti, A.; Arduini, D.; Watson, G.; Giangrande, A. Blockchain traceability in trading biomasses obtained with an Integrated Multi-Trophic Aquaculture. Sustainability 2022, 15, 767. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).