Rumen Fluid from Slaughtered Animals: A Standardized Procedure for Sampling, Storage and Use in Digestibility Trials

Abstract

1. Introduction

2. Experimental Design

3. Materials and Equipment

3.1. Collection of the Rumen Fluid at Slaughterhouse

3.2. Use of the Rumen Fluid at the Laboratory

3.3. Storage of the Rumen Fluid

4. Procedure

4.1. Collection of Rumen Fluid at the Slaughterhouse

4.2. Use of the RF at the Laboratory

4.3. Storage of Rumen Fluid and Digestibility Trial

- DM0h (%) = dry matter ante incubation

- DMresidue (% DM) = dry matter post incubation

- NDF (% DM) = neutral detergent fiber ante incubation

- NDFresidue (% NDF) = neutral detergent fiber post incubation.

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tassone, S.; Fortina, R.; Peiretti, P.G. In vitro techniques using the DaisyII incubator for the assessment of digestibility: A review. Animals 2020, 10, 775. [Google Scholar] [CrossRef] [PubMed]

- Mould, F.L.; Kliem, D.E.; Morgan, R.; Mauricio, R.M. In vitro microbial inoculum: A review of its function and properties. Anim. Feed Sci. Technol. 2005, 123–124, 31–50. [Google Scholar] [CrossRef]

- López, S. In Vitro and In Situ techniques for Estimating Digestibility. In Quantitative Aspects of Ruminant Digestion and Metabolism, 2nd ed.; CAB International: Wallingford, UK, 2005; pp. 87–121. [Google Scholar]

- Beharka, A.; Nagaraja, T.; Morrill, J.; Kennedy, G.; Klemm, R. Effects of form of the diet on anatomical, microbial and fermentative development of the rumen of neonatal calves. J. Dairy Sci. 1998, 81, 1946–1955. [Google Scholar] [CrossRef]

- Lesmeisterm, K.; Heinrichsm, A. Effects of corn processing on growth characteristics, rumen development and rumen parameters in neonatal dairy calves. J. Dairy Sci. 2004, 87, 3439–3450. [Google Scholar] [CrossRef]

- Terré, M.; Castells, L.; Fabregas, F.; Bach, A. Short communication: Comparison of pH, volatile fatty acids, and microbiome of rumen samples from preweaned calves obtained via cannula or stomach tube. J. Dairy Sci. 2013, 96, 5290–5294. [Google Scholar] [CrossRef] [PubMed]

- Spanghero, M.; Chiarevalli, M.; Colombini, S.; Fabro, C.; Froldi, F.; Mason, F.; Moschini, M.; Sarnataro, C.; Schiavon, S.; Tagliapietra, F. Rumen inoculum collected from cows at slaughter or from a continuous fermenter and preserved in warm, refrigerated, chilled or freeze-dried environments for in vitro tests. Animals 2019, 9, 815. [Google Scholar] [CrossRef] [PubMed]

- Beyihayo, G.A.; Omaria, R.; Namazzi, C.; Atuhaire, A. Comparison of in vitro digestibility using slaughtered and fistulated cattle as sources of inoculum. Uganda J. Agric. Sci. 2015, 16, 93–98. [Google Scholar] [CrossRef]

- Alba, H.D.R.; Oliveira, R.L.; Carvalho, S.T.; Itavo, L.C.; Ribeiro, O.L.; do Nascimento Junior, N.G.; Dias Freita, M.; Bezerra, L.R. Can ruminal inoculum from slaughtered cattle replace inoculum from cannulated cattle for feed evaluation research? Ciencias Agraria 2018, 5, 2133–2144. [Google Scholar] [CrossRef]

- Sarnataro, C.; Spanghero, M. In vitro rumen fermentation of feed substrates added with chestnut tannins or an extract from Stevia rebaudiana Bertoni. Anim. Nutr. 2020, 6, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Tassone, S.; Masoero, G.M.; Peiretti, P.G. Vibrational spectroscopy to predict in vitro digestibility and the maturity index of different forage crops during the growing cycle and after freeze- or oven-drying treatment. Anim. Feed Sci. Technol. 2014, 194, 12–25. [Google Scholar] [CrossRef]

- Peiretti, P.G.; Gai, F.; Tassone, S. Fatty acid profile and nutritive value of quinoa (Chenopodium quinoa Willd.) seeds and plants at different growth stages. Anim. Feed Sci. Technol. 2013, 183, 56–61. [Google Scholar] [CrossRef]

- Chaudhry, A.S. Slaughtered cattle as a source of rumen fluid to evaluate supplements for in vitro degradation of grass nuts and barley straw. Open Vet. Sci. J. 2008, 2, 16–22. [Google Scholar] [CrossRef][Green Version]

- Bioscreen Technologies Research Laboratories—Artificial Rumen By-Pass. Available online: https://www.youtube.com/watch?v=AAT63sytI0w (accessed on 8 March 2021).

- Robinson, P.H.; Campell Matthews, M.; Fadel, J.G. Influence of storage time and temperature on in vitro digestion of neutral detergent fibre at 48 h and comparison to 48 h in sacco neutral detergent fibre digestion. Anim. Feed Sci. Technol. 1999, 80, 257–266. [Google Scholar] [CrossRef]

- Wang, S.; Kreuzer, M.; Schwarm, A. Utility of an in vitro test with rumen fluid from slaughtered cattle for capturing variation in methane emission potential between cattle types and with age. Can. J. Anim. Sci. 2018, 98, 61–72. [Google Scholar] [CrossRef]

- Lutakome, P.; Kabi, F.; Tibayungwa, F.; Laswai, G.H.; Kimambo, A.; Ebong, C. Rumen liquor from slaughtered cattle as inoculum for feed evaluation. Anim. Nutr. 2017, 3, 300–308. [Google Scholar] [CrossRef] [PubMed]

- SAS System for Windows; Release 9.4; SAS Institute Inc.: Cary, NC, USA, 2021.

- Fabro, C.; Sarnataro, C.; Spanghero, M. Impacts of rumen fluid refrigerated or reconstituted from a refrigerated pellet, on gas production measured at 24h of fermentation. Anim. Feed Sci. Technol. 2020, 268, 114585. [Google Scholar] [CrossRef]

- Luchini, N.D.; Broderick, G.A.; Combs, D.K. Preservation of ruminal microorganisms for in vitro determination of ruminal protein degradation. J. Anim. Sci. 1996, 74, 1134–1143. [Google Scholar] [CrossRef] [PubMed]

- Cattani, M.; Tagliapietra, F.; Bailoni, L.; Schiavon, S. In vitro rumen feed degradability assessed with DaisyII and batch culture: Effect of sample size. Ital. J. Anim. Sci. 2009, 8, 169–171. [Google Scholar] [CrossRef]

- Tarizawa, S.; Baba, Y.; Tada, C.; Fukuda, Y.; Nakai, Y. Preservation of rumen fluid for the pretreatment of waste paper to improve methane production. Waste Manag. 2019, 87, 672–678. [Google Scholar] [CrossRef]

| DM | Ash | CP | EE | NDF | ADF | ADL | NFC | |

|---|---|---|---|---|---|---|---|---|

| Corn meal | 87.0 | 1.4 | 9.3 | 4.7 | 12.3 | 4.5 | 1.0 | 72.3 |

| Soybean meal | 90.9 | 7.0 | 51.5 | 1.5 | 11.0 | 7.3 | 1.0 | 29.0 |

| Wheat Bran | 87.0 | 8.8 | 17.0 | 4.6 | 43.2 | 13.4 | 3.6 | 28.4 |

| Beet pulp | 90.1 | 5.3 | 9.1 | 0.7 | 53.9 | 28.8 | 2.6 | 31.0 |

| Mixed hay | 90.7 | 6.6 | 8.3 | 2.2 | 60.5 | 37.9 | 4.3 | 22.4 |

| Wheat Straw | 87.8 | 7.1 | 4.9 | 1.8 | 72.5 | 40.1 | 11.2 | 13.7 |

| TMR | 86.5 | 7.5 | 14.8 | 5.7 | 23.8 | 11.0 | 1.2 | 48.1 |

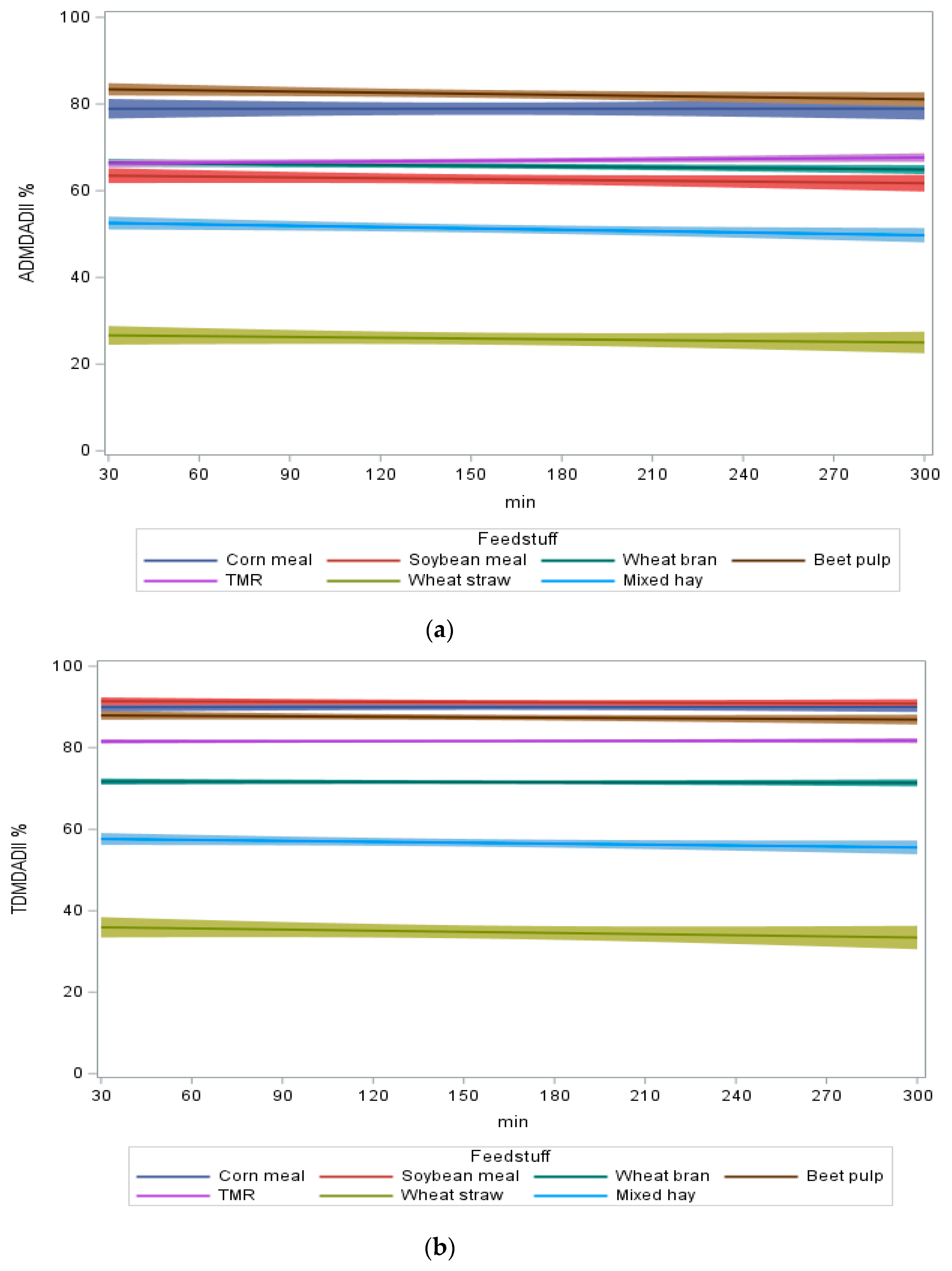

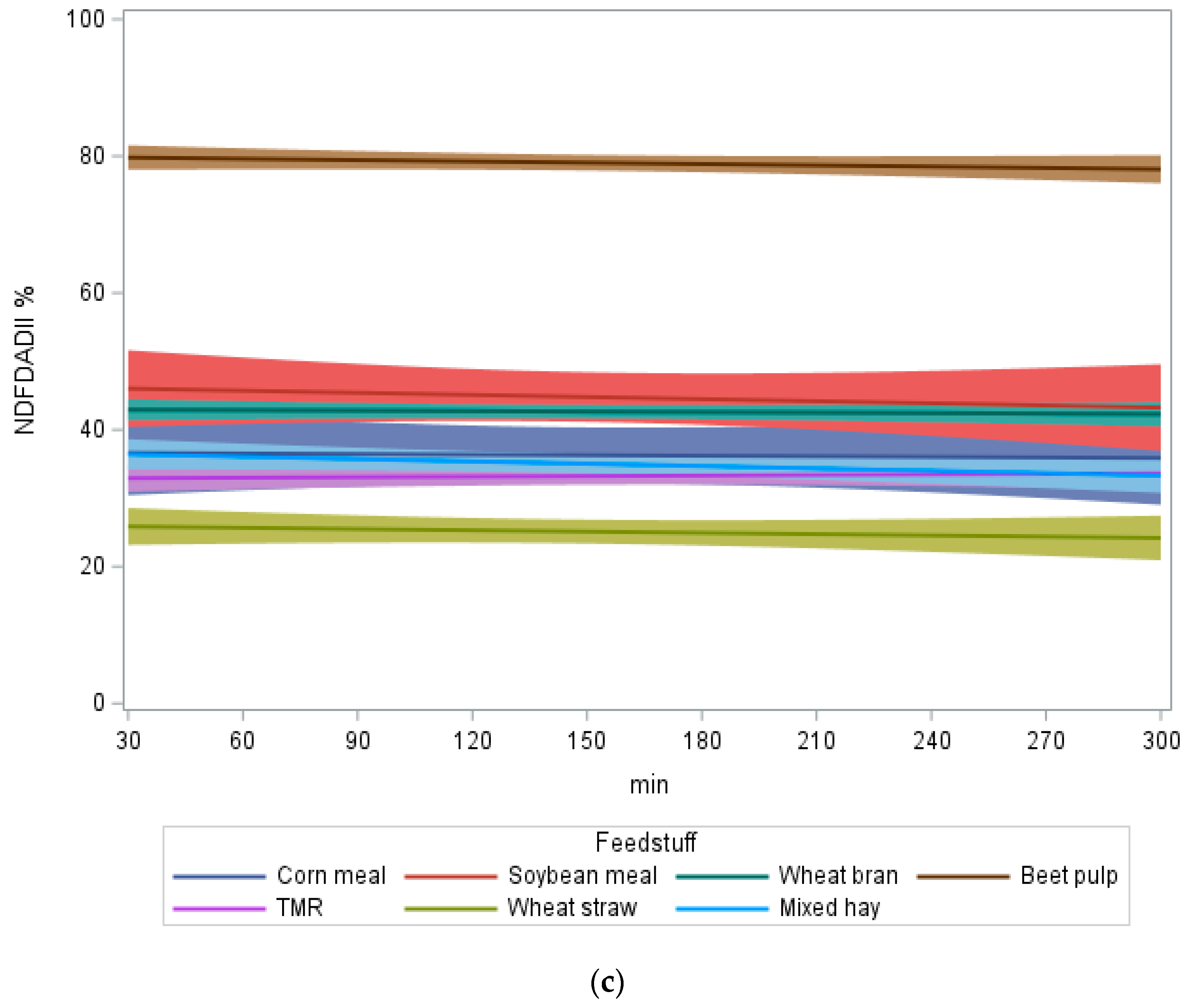

| ADMDADII | TDMDADII | NDFDADII | |

|---|---|---|---|

| Mean ± SD | Mean ± SD | Mean ± SD | |

| Corn meal | 78.9 ± 6.01 | 89.9 ± 2.71 | 36.3 ± 13.54 |

| Soybean meal | 62.7 ± 4.63 | 91.1 ± 2.32 | 44.8 ± 13.47 |

| Wheat bran | 65.7 ± 2.58 | 71.5 ± 1.93 | 42.7 ± 3.90 |

| Beet pulp | 82.4 ± 4.01 | 87.5 ± 2.68 | 79.0 ± 4.47 |

| TMR | 66.9 ± 2.45 | 81.6 ± 1.35 | 33.2 ± 4.91 |

| Wheat straw | 25.9 ± 5.95 | 34.8 ± 6.29 | 25.1 ± 5.51 |

| Mixed hay | 51.3 ± 4.09 | 56.7 ± 3.73 | 35.0 ± 5.60 |

| Feeds | Storage Times | |||

|---|---|---|---|---|

| 30′ | 90′ | 180′ | 300′ | |

| Corn meal | 13.6 | 7.3 | 7.5 | 7.6 |

| Soybean meal | 3.9 | 3.7 | 7.4 | 5.4 |

| Wheat bran | 1.0 | 3.8 | 2.2 | 1.2 |

| Beet pulp | 2.6 | 3.3 | 4.5 | 3.5 |

| TMR | 3.1 | 2.9 | 2.4 | 3.4 |

| Wheat straw | 1.2 | 2.5 | 2.0 | 5.2 |

| Mixed hay | 3.3 | 1.7 | 2.9 | 2.0 |

| 1 | Materials and equipment preparation |

| 1a | For extraction of RF at slaughterhouse: (1) thermic bottles filled with hot water (40 °C), (2) thermal bag or portable cooler box, (3) thermometer, (4) plastic beaker, (5) colander, (6) knife and spatula, (7) gloves, (8) gown, (9) nylon socks, (10) helmet, (11) goggles, (12) facemask. For collection of RF at laboratory: (1) 500 mL graduated cylinder (2) plastic beaker with hot water (40 °C) (3) funnel (4) cheesecloth (5) CO2 gas bottles (6) pH meter (7) thermometer (8) gloves (9) lab coat (10) nylon socks. |

| 1b | Fill the thermic bottles with hot water (40 °C) and place them inside a thermic bag or portable cooler box and take all material prepared at point 1. |

| 2 | Collection of rumen fluid at slaughterhouse |

| 2a | Take the rumen of the slaughtered animal (15 min from death) and place it on a clean bench. Record animal code. |

| 2b | Section the rumen (ventral sac) lengthwise with a knife. Record time and report it to the lab operator. |

| 2c | Squeeze rumen content in plastic beaker using the colander. |

| 2d | Empty hot water from thermic bottle and fill it with homogenized RF; avoid the presence of air and close it immediately. Proceed in the same way with the other bottles; perform as quickly as possible. |

| 2e | Put thermic bottles in the thermic bag and transport directly to the laboratory as quickly as possible. |

| 3 | Use of rumen fluid at laboratory |

| 3a | Place a 500 mL graduated cylinder into a plastic beaker filled with hot water (40 °C) under a hood. |

| 3b | Put a funnel with a cheesecloth upon the empty cylinder. |

| 3c | Carefully open the thermic bottle, avoid RF splashes; pour it in the cheesecloth upon the cylinder under CO2 and squeeze until the quantity for incubation is reached (400 mL for jar in DaisyII Incubator). Perform as quickly as possible. |

| 3d | Pour RF into jar or flask within 300 min from the collection, check pH and temperature of the fluid insufflating CO2 for 2 min. Perform as quickly as possible. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fortina, R.; Glorio Patrucco, S.; Barbera, S.; Tassone, S. Rumen Fluid from Slaughtered Animals: A Standardized Procedure for Sampling, Storage and Use in Digestibility Trials. Methods Protoc. 2022, 5, 59. https://doi.org/10.3390/mps5040059

Fortina R, Glorio Patrucco S, Barbera S, Tassone S. Rumen Fluid from Slaughtered Animals: A Standardized Procedure for Sampling, Storage and Use in Digestibility Trials. Methods and Protocols. 2022; 5(4):59. https://doi.org/10.3390/mps5040059

Chicago/Turabian StyleFortina, Riccardo, Sara Glorio Patrucco, Salvatore Barbera, and Sonia Tassone. 2022. "Rumen Fluid from Slaughtered Animals: A Standardized Procedure for Sampling, Storage and Use in Digestibility Trials" Methods and Protocols 5, no. 4: 59. https://doi.org/10.3390/mps5040059

APA StyleFortina, R., Glorio Patrucco, S., Barbera, S., & Tassone, S. (2022). Rumen Fluid from Slaughtered Animals: A Standardized Procedure for Sampling, Storage and Use in Digestibility Trials. Methods and Protocols, 5(4), 59. https://doi.org/10.3390/mps5040059