Bridging Nature and Engineering: Protein-Derived Materials for Bio-Inspired Applications

Abstract

1. Introduction

| Endogenous Proteins | Applications | Structural Characteristics | Reference |

|---|---|---|---|

| Collagen |

|

| [28,29,30,31,32] |

| Silk fibroin |

|

| [24,33,34,35,36,37,38,39] |

| Fibrillins |

|

| [40,41,42,43,44,45,46,47] |

| Keratins |

|

| [48,49,50,51,52] |

| Elastin |

|

| [53,54,55,56,57,58,59,60,61,62,63] |

| Resilin |

|

| [64,65,66,67,68,69] |

| Wheat glutenin |

|

| [70,71,72,73,74,75,76,77,78,79,80,81,82,83] |

| Spongin |

|

| [1,5,76,77,78,79,80,81,82,84,85,86,87,88] |

| Conchiolin |

|

| [70,71,72,73,89,90,91,92,93,94,95,96,97,98,99,100,101] |

| Cyanophycin |

|

| [102,103,104,105,106,107,108,109,110,111,112,113,114] |

2. Fibrous Proteins

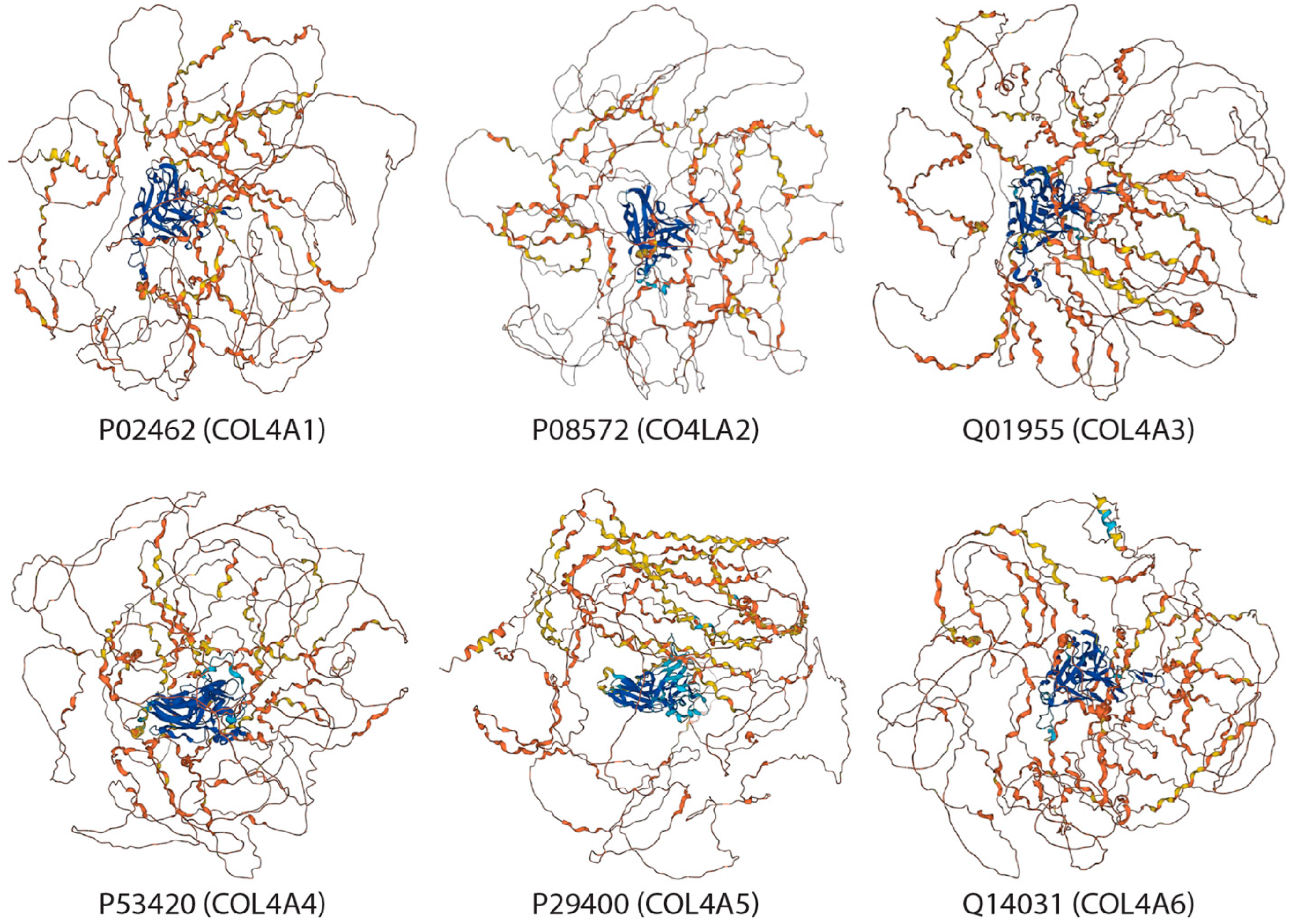

2.1. Collagen

2.2. Silk Fibroin

2.3. Fibrillins

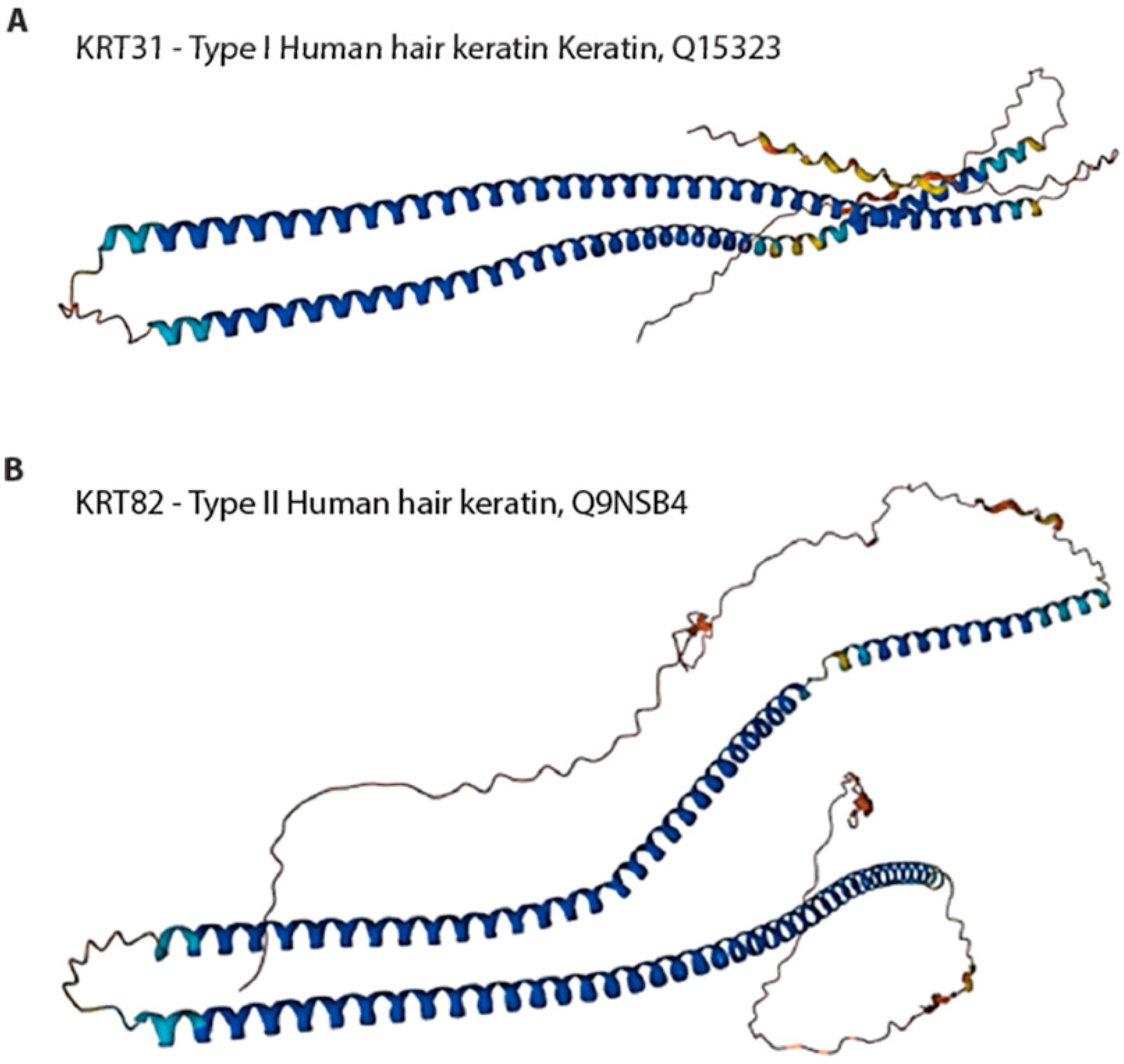

2.4. Keratins

2.5. The Development and Utilization of Fibrous Proteins

3. Elastomeric Proteins

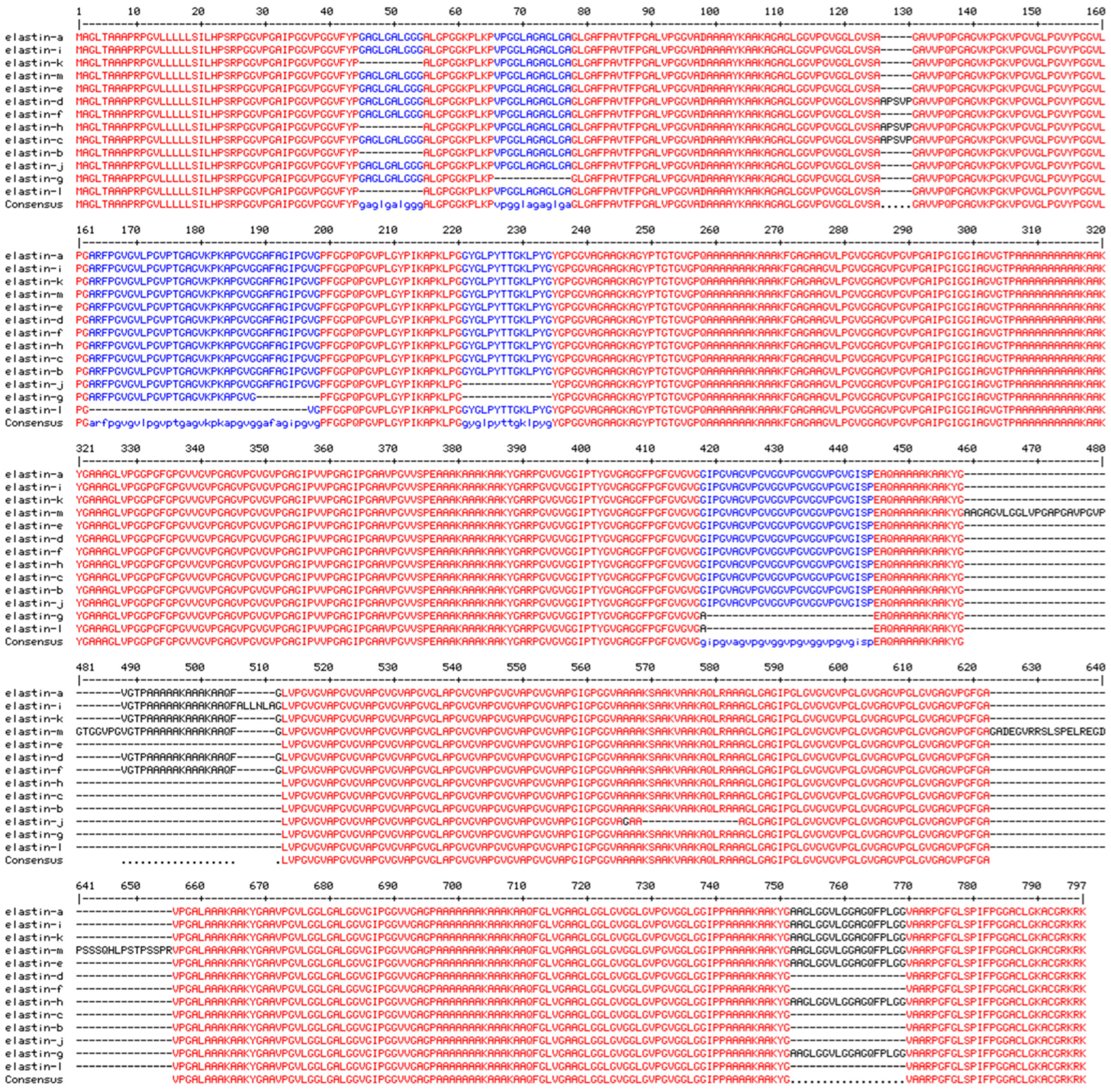

3.1. Elastin

3.2. Resilin

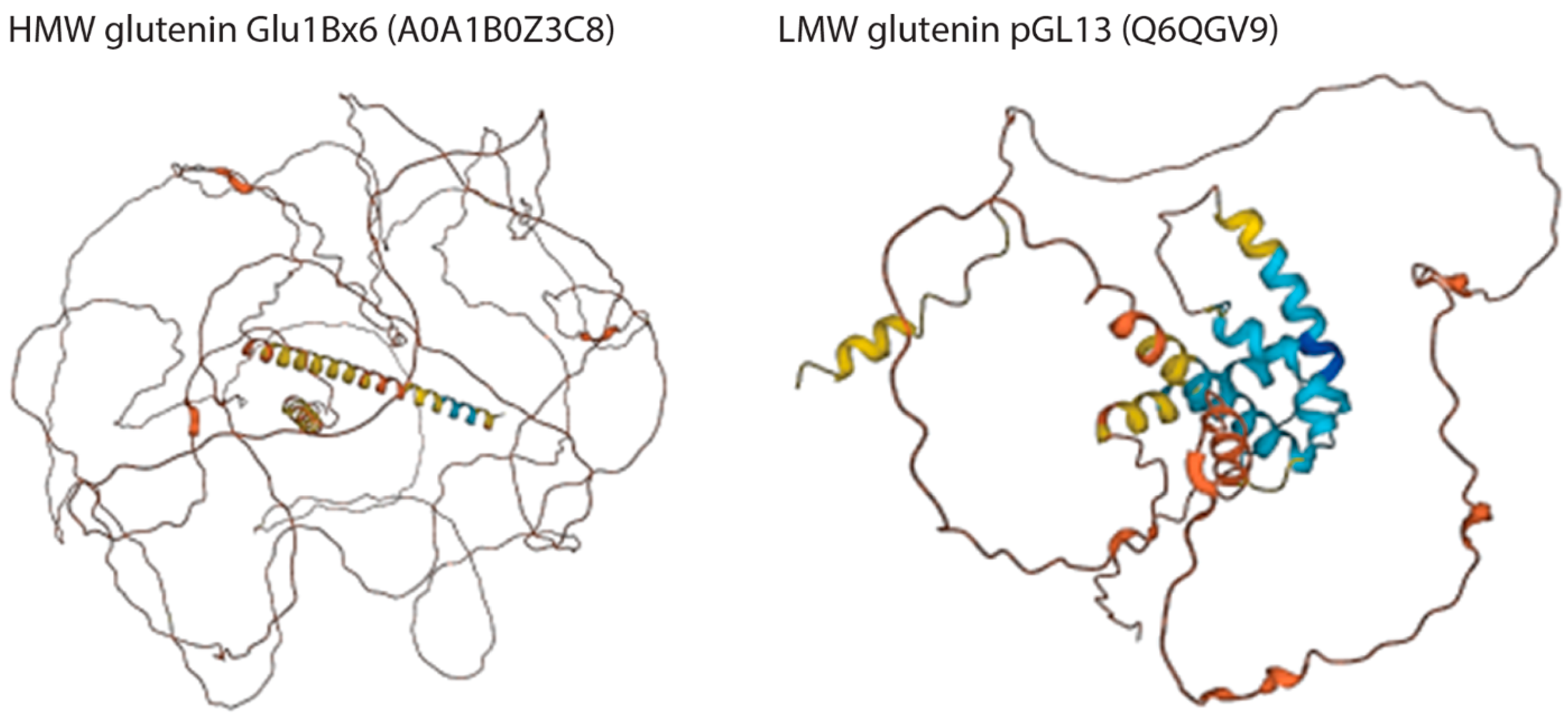

3.3. Wheat Glutenin

4. Adhesive/Extracellular Matrix Proteins

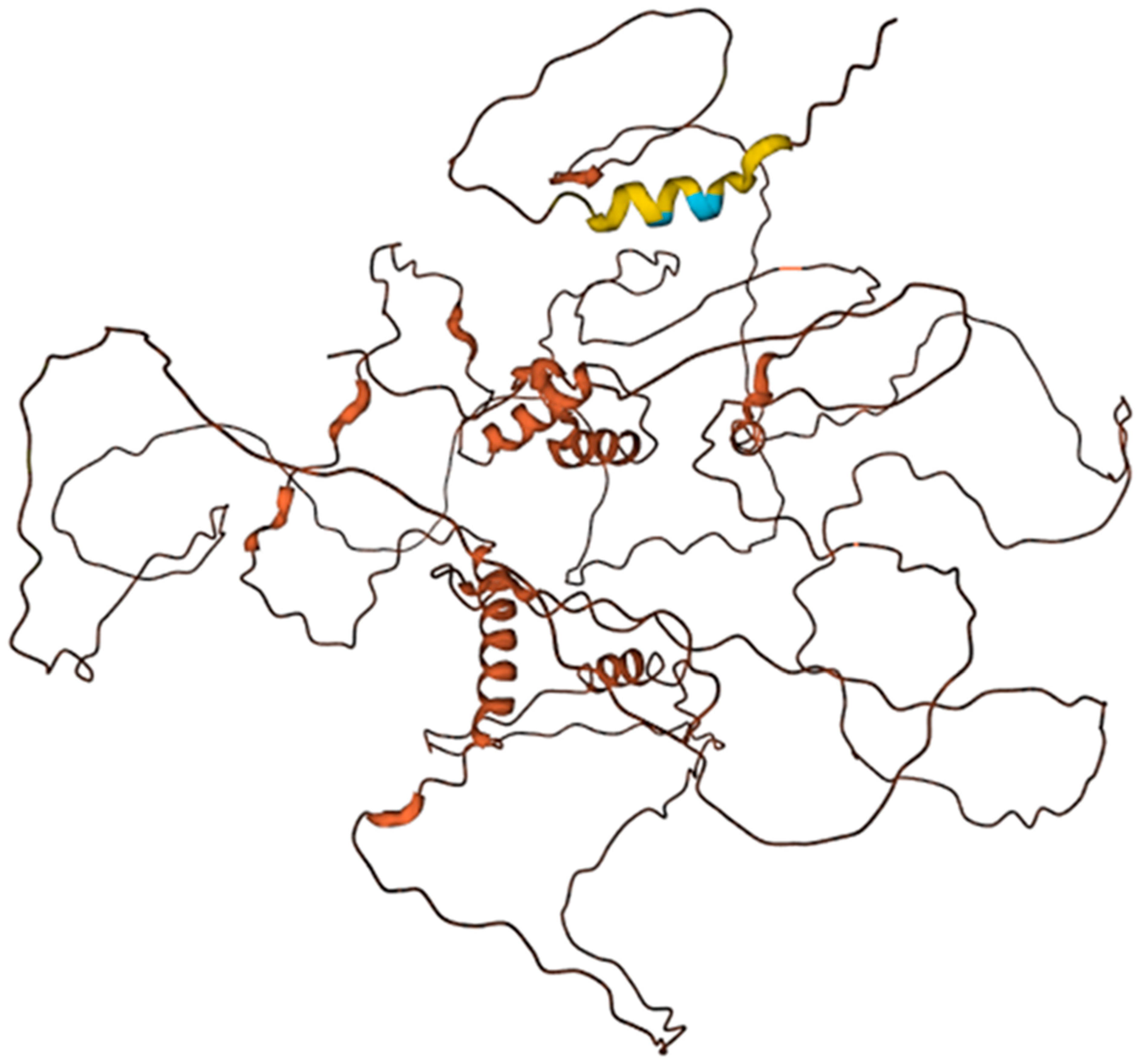

4.1. Spongin

4.2. Conchiolin

5. Cyanophycin

Cyanophycin-Based Biopolymers

6. Protein Hydrogels

7. Fabrication of Protein Fabrics

8. Perspectives

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lau, W.W.; Shiran, Y.; Bailey, R.M.; Cook, E.; Stuchtey, M.R.; Koskella, J.; Velis, C.A.; Godfrey, L.; Boucher, J.; Murphy, M.B. Evaluating scenarios toward zero plastic pollution. Science 2020, 369, 1455–1461. [Google Scholar] [CrossRef]

- He, Y.X.; Zhang, N.N.; Li, W.F.; Jia, N.; Chen, B.Y.; Zhou, K.; Zhang, J.; Chen, Y.; Zhou, C.Z. N-Terminal domain of Bombyx mori fibroin mediates the assembly of silk in response to pH decrease. J. Mol. Biol. 2012, 418, 197–207. [Google Scholar] [CrossRef]

- Kane, I.A.; Clare, M.A.; Miramontes, E.; Wogelius, R.; Rothwell, J.J.; Garreau, P.; Pohl, F. Seafloor microplastic hotspots controlled by deep-sea circulation. Science 2020, 368, 1140–1145. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- Borrelle, S.B.; Ringma, J.; Law, K.L.; Monnahan, C.C.; Lebreton, L.; McGivern, A.; Murphy, E.; Jambeck, J.; Leonard, G.H.; Hilleary, M.A. Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution. Science 2020, 369, 1515–1518. [Google Scholar] [CrossRef]

- Kadumudi, F.B.; Hasany, M.; Pierchala, M.K.; Jahanshahi, M.; Taebnia, N.; Mehrali, M.; Mitu, C.F.; Shahbazi, M.A.; Zsurzsan, T.G.; Knott, A. The Manufacture of Unbreakable Bionics via Multifunctional and Self-Healing Silk–Graphene Hydrogels. Adv. Mater. 2021, 33, 2170276. [Google Scholar] [CrossRef]

- Gorrasi, G.; Sorrentino, A.; Lichtfouse, E. Back to plastic pollution in COVID times. Environ. Chem. Lett. 2021, 19, 1–4. [Google Scholar] [CrossRef]

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the future? The impact of biodegradable polymers on the environment and on society. Angew. Chem. Int. Ed. 2019, 58, 50–62. [Google Scholar] [CrossRef]

- Chiellini, E.; Solaro, R. Biodegradable polymeric materials. Adv. Mater. 1996, 8, 305–313. [Google Scholar] [CrossRef]

- Li, K.; Jin, S.; Jiang, S.; Li, X.; Li, J.; Shi, S.Q.; Li, J. Bioinspired mineral–organic strategy for fabricating a high-strength, antibacterial, flame-retardant soy protein bioplastic via internal boron–nitrogen coordination. Chem. Eng. J. 2022, 428, 132616. [Google Scholar] [CrossRef]

- Chen, L.; Qiang, T.; Chen, X.; Ren, W.; Zhang, H.J. Fabrication and evaluation of biodegradable multi-cross-linked mulch film based on waste gelatin. Chem. Eng. J. 2021, 419, 129639. [Google Scholar] [CrossRef]

- Pang, X.; Zhuang, X.; Tang, Z.; Chen, X. Polylactic acid (PLA): Research, development and industrialization. Biotechnol. J. 2010, 5, 1125–1136. [Google Scholar] [CrossRef]

- Ghorpade, V.M.; Gennadios, A.; Hanna, M.A. Laboratory composting of extruded poly (lactic acid) sheets. Bioresour. Technol. 2001, 76, 57–61. [Google Scholar] [CrossRef]

- Sun, C.; Wei, S.; Tan, H.; Huang, Y.; Zhang, Y. Progress in upcycling polylactic acid waste as an alternative carbon source: A review. Chem. Eng. J. 2022, 446, 136881. [Google Scholar] [CrossRef]

- Li, F.; Liu, T.; Gu, W.; Gao, Q.; Li, J.; Shi, S.Q. Bioinspired super-tough and multifunctional soy protein-based material via a facile approach. Chem. Eng. J. 2021, 405, 126700. [Google Scholar] [CrossRef]

- Liu, Y.; Shao, Z.; Vollrath, F. Elasticity of spider silks. Biomacromolecules 2008, 9, 1782–1786. [Google Scholar] [CrossRef]

- Rising, A.; Widhe, M.; Johansson, J.; Hedhammar, M. Spider silk proteins: Recent advances in recombinant production, structure-function relationships and biomedical applications. Cell Mol. Life Sci. 2011, 68, 169–184. [Google Scholar] [CrossRef]

- Foo, C.W.P.; Bini, E.; Huang, J.; Lee, S.Y.; Kaplan, D.l. Solution behavior of synthetic silk peptides and modified recombinant silk proteins. Appl. Phys. A 2006, 82, 193–203. [Google Scholar] [CrossRef]

- Rising, A.; Johansson, J. Toward spinning artificial spider silk. Nat. Chem. Biol. 2015, 11, 309–315. [Google Scholar] [CrossRef]

- Sun, J.; Su, J.; Ma, C.; Göstl, R.; Herrmann, A.; Liu, K.; Zhang, H. Fabrication and mechanical properties of engineered protein-based adhesives and fibers. Adv. Mater. 2020, 32, 1906360. [Google Scholar] [CrossRef]

- Xiao, T.; Wang, Y.; Wei, H.; Yu, P.; Jiang, Y.; Mao, L. Electrochemical monitoring of propagative fluctuation of ascorbate in the live rat brain during spreading depolarization. Angew. Chem. Int. Ed. 2019, 58, 6616–6619. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Yu, Q.; Wen, J.; Li, C.; Guo, Z.; Wang, X.; Wang, N. Ultrafast and highly selective uranium extraction from seawater by hydrogel-like spidroin-based protein fiber. Angew. Chem. 2019, 131, 11911–11916. [Google Scholar] [CrossRef]

- Lewis, R.V. Spider silk: Ancient ideas for new biomaterials. Chem. Rev. 2006, 106, 3762–3774. [Google Scholar] [CrossRef] [PubMed]

- Kluge, J.A.; Rabotyagova, O.; Leisk, G.G.; Kaplan, D.L. Spider silks and their applications. Trends Biotechnol. 2008, 26, 244–251. [Google Scholar] [CrossRef] [PubMed]

- Hardy, J.G.; Rőmer, L.M.; Scheibel, T.R. Polymeric materials based on silk proteins. Polymer 2008, 49, 4309–4327. [Google Scholar] [CrossRef]

- Wang, X.; Pang, Z.; Chen, C.; Xia, Q.; Zhou, Y.; Jing, S.; Wang, R.; Ray, U.; Gan, W.; Li, C. All-natural, degradable, rolled-up straws based on cellulose micro-and nano-hybrid fibers. Adv. Funct. Mater. 2020, 30, 1910417. [Google Scholar] [CrossRef]

- Song, P.; Wang, H. High-performance polymeric materials through hydrogen-bond cross-linking. Adv. Mater. 2020, 32, 1901244. [Google Scholar] [CrossRef] [PubMed]

- Shoulders, M.D.; Raines, R.T. Collagen structure and stability. Annu. Rev. Biochem. 2009, 78, 929–958. [Google Scholar] [CrossRef] [PubMed]

- Myllyharju, J.; Kivirikko, K.I. Collagens, modifying enzymes and their mutations in humans, flies and worms. Trends Genet. 2004, 20, 33–43. [Google Scholar] [CrossRef]

- Gordon, M.K.; Hahn, R.A. Collagens. Cell Tissue Res. 2010, 339, 247–257. [Google Scholar] [CrossRef]

- Wess, T.J. Collagen fibril form and function. Adv. Protein Chem. 2005, 70, 341–374. [Google Scholar] [PubMed]

- Kadler, K.E.; Baldock, C.; Bella, J.; Boot-Handford, R.P. Collagens at a glance. J. Cell Sci. 2007, 120, 1955–1958. [Google Scholar] [CrossRef]

- Heim, M.; Keerl, D.; Scheibel, T. Spinnenseide: Vom löslichen Protein zur außergewöhnlichen Faser. Angew. Chem. 2009, 121, 3638–3650. [Google Scholar] [CrossRef]

- Omenetto, F.G.; Kaplan, D.L. New opportunities for an ancient material. Science 2010, 329, 528–531. [Google Scholar] [CrossRef] [PubMed]

- Hearle, J.W. Protein fibers: Structural mechanics and future opportunities. J. Mater. Sci. 2007, 42, 8010–8019. [Google Scholar] [CrossRef]

- Scheibel, T. Protein fibers as performance proteins: New technologies and applications. Curr. Opin. Biotechnol. 2005, 16, 427–433. [Google Scholar] [CrossRef] [PubMed]

- Sponner, A.; Unger, E.; Grosse, F.; Weisshart, K. Differential polymerization of the two main protein components of dragline silk during fibre spinning. Nat. Mater. 2005, 4, 772–775. [Google Scholar] [CrossRef] [PubMed]

- Motta, A.; Migliaresi, C.; Faccioni, F.; Torricelli, P.; Fini, M.; Giardino, R. Fibroin hydrogels for biomedical applications: Preparation, characterization and in vitro cell culture studies. J. Biomater. Sci. Polym. Ed. 2004, 15, 851–864. [Google Scholar] [CrossRef]

- Sah, M.; Pramanik, K. Preparation, characterization and in vitro study of biocompatible fibroin hydrogel. Afr. J. Biotechnol. 2011, 10, 7878–7892. [Google Scholar]

- Sabatier, L.; Miosge, N.; Hubmacher, D.; Lin, G.; Davis, E.C.; Reinhardt, D.P. Fibrillin-3 expression in human development. Matrix Biol. 2011, 30, 43–52. [Google Scholar] [CrossRef]

- Corson, G.M.; Charbonneau, N.L.; Keene, D.R.; Sakai, L.Y. Differential expression of fibrillin-3 adds to microfibril variety in human and avian, but not rodent, connective tissues. Genomics 2004, 83, 461–472. [Google Scholar] [CrossRef]

- Zhang, H.; Apfelroth, S.D.; Hu, W.; Davis, E.C.; Sanguineti, C.; Bonadio, J.; Mecham, R.P.; Ramirez, F. Structure and expression of fibrillin-2, a novel microfibrillar component preferentially located in elastic matrices. J. Cell Biol. 1994, 124, 855–863. [Google Scholar] [CrossRef]

- Hubmacher, D.; Tiedemann, K.; Reinhardt, D.P. Fibrillins: From biogenesis of microfibrils to signaling functions. Curr. Top. Dev. Biol. 2006, 75, 93–123. [Google Scholar]

- Baldock, C.; Koster, A.J.; Ziese, U.; Rock, M.J.; Sherratt, M.J.; Kadler, K.E.; Shuttleworth, C.A.; Kielty, C.M. The supramolecular organization of fibrillin-rich microfibrils. J. Cell Biol. 2001, 152, 1045–1056. [Google Scholar] [CrossRef] [PubMed]

- Kielty, C.M.; Sherratt, M.J.; Shuttleworth, C.A. Elastic fibres. J. Cell Sci. 2002, 115, 2817–2828. [Google Scholar] [CrossRef]

- Visconti, R.P.; Barth, J.L.; Keeley, F.W.; Little, C.D. Codistribution analysis of elastin and related fibrillar proteins in early vertebrate development. Matrix Biol. 2003, 22, 109–121. [Google Scholar] [CrossRef] [PubMed]

- Rosenbloom, J.; Abrams, W.R.; Mecham, R. Extracellular matrix 4: The elastic fiber. FASEB J. 1993, 7, 1208–1218. [Google Scholar] [CrossRef]

- Katoh, K.; Shibayama, M.; Tanabe, T.; Yamauchi, K. Preparation and physicochemical properties of compression-molded keratin films. Biomaterials 2004, 25, 2265–2272. [Google Scholar] [CrossRef] [PubMed]

- Lewis, D.M.; Rippon, J.A. The Coloration of Wool and Other Keratin Fibres; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Negri, A.P.; Cornell, H.J.; Rivett, D.E. A model for the surface of keratin fibers. Text. Res. J. 1993, 63, 109–115. [Google Scholar] [CrossRef]

- Chen, Q.; Gao, K.; Peng, C.; Xie, H.; Zhao, Z.K.; Bao, M. Preparation of lignin/glycerol-based bis (cyclic carbonate) for the synthesis of polyurethanes. Green. Chem. 2015, 17, 4546–4551. [Google Scholar] [CrossRef]

- Lee, C.H.; Kim, M.S.; Chung, B.M.; Leahy, D.J.; Coulombe, P.A. Structural basis for heteromeric assembly and perinuclear organization of keratin filaments. Nat. Struct. Mol. Biol. 2012, 19, 707–715. [Google Scholar] [CrossRef] [PubMed]

- Gosline, J.; Lillie, M.; Carrington, E.; Guerette, P.; Ortlepp, C.; Savage, K. Elastic proteins: Biological roles and mechanical properties. Philos. Trans. R. Soc. London. Ser. B Biol. Sci. 2002, 357, 121–132. [Google Scholar] [CrossRef] [PubMed]

- Sage, H. Structure-function relationships in the evolution of elastin. J. Investig. Dermatol. 1982, 79, 146–153. [Google Scholar] [CrossRef][Green Version]

- Faury, G. Function–structure relationship of elastic arteries in evolution: From microfibrils to elastin and elastic fibres. Pathol. Biol. 2001, 49, 310–325. [Google Scholar] [CrossRef]

- Sage, H.; Gray, W. Studies on the evolution of elastin--I. Phylogenetic distribution. Comp. Biochem. Physiol. B Comp. Biochem. 1979, 64, 313–327. [Google Scholar] [CrossRef] [PubMed]

- Davis, E.C. Stability of elastin in the developing mouse aorta: A quantitative radioautographic study. Histochemistry 1993, 100, 17–26. [Google Scholar] [CrossRef] [PubMed]

- Shapiro, S.; Endicott, S.; Province, M.; Pierce, J.; Campbell, E. Marked longevity of human lung parenchymal elastic fibers deduced from prevalence of D-aspartate and nuclear weapons-related radiocarbon. J. Clin. Investig. 1991, 87, 1828–1834. [Google Scholar] [CrossRef]

- Keeley, F.W.; Bellingham, C.M.; Woodhouse, K.A. Elastin as a self–organizing biomaterial: Use of recombinantly expressed human elastin polypeptides as a model for investigations of structure and self–assembly of elastin. Philos. Trans. R. Soc. Lond. Ser. B Biol. Sci. 2002, 357, 185–189. [Google Scholar] [CrossRef] [PubMed]

- Pepe, A.; Guerra, D.; Bochicchio, B.; Quaglino, D.; Gheduzzi, D.; Ronchetti, I.P.; Tamburro, A.M. Dissection of human tropoelastin: Supramolecular organization of polypeptide sequences coded by particular exons. Matrix Biol. 2005, 24, 96–109. [Google Scholar] [CrossRef]

- Tamburro, A.M.; Bochicchio, B.; Pepe, A. Dissection of human tropoelastin: Exon-by-exon chemical synthesis and related conformational studies. Biochemistry 2003, 42, 13347–13362. [Google Scholar] [CrossRef]

- Muiznieks, L.D.; Keeley, F.W. Proline periodicity modulates the self-assembly properties of elastin-like polypeptides. J. Biol. Chem. 2010, 285, 39779–39789. [Google Scholar] [CrossRef] [PubMed]

- Rauscher, S.; Baud, S.; Miao, M.; Keeley, F.W.; Pomes, R. Proline and glycine control protein self-organization into elastomeric or amyloid fibrils. Structure 2006, 14, 1667–1676. [Google Scholar] [CrossRef] [PubMed]

- Weis-Fogh, T. Molecular interpretation of the elasticity of resilin, a rubber-like protein. J. Mol. Biol. 1961, 3, 648–667. [Google Scholar] [CrossRef]

- Weis-Fogh, T. Thermodynamic properties of resilin, a rubber-like protein. J. Mol. Biol. 1961, 3, 520–531. [Google Scholar] [CrossRef]

- Truong, M.Y.; Dutta, N.K.; Choudhury, N.R.; Kim, M.; Elvin, C.M.; Nairn, K.M.; Hill, A.J. The effect of hydration on molecular chain mobility and the viscoelastic behavior of resilin-mimetic protein-based hydrogels. Biomaterials 2011, 32, 8462–8473. [Google Scholar] [CrossRef] [PubMed]

- Renner, J.N.; Cherry, K.M.; Su, R.S.-C.; Liu, J.C. Characterization of resilin-based materials for tissue engineering applications. Biomacromolecules 2012, 13, 3678–3685. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Tong, Z.; Jia, X.; Kiick, K.L. Resilin-like polypeptide hydrogels engineered for versatile biological function. Soft Matter 2013, 9, 665–673. [Google Scholar] [CrossRef] [PubMed]

- McGann, C.L.; Levenson, E.A.; Kiick, K.L. Resilin-based hybrid hydrogels for cardiovascular tissue engineering. Macromol. Chem. Phys. 2013, 214, 203–213. [Google Scholar] [CrossRef]

- Johansson, E.; Malik, A.H.; Hussain, A.; Rasheed, F.; Newson, W.R.; Plivelic, T.; Hedenqvist, M.S.; Gällstedt, M.; Kuktaite, R. Wheat gluten polymer structures: The impact of genotype, environment, and processing on their functionality in various applications. Cereal Chem. 2013, 90, 367–376. [Google Scholar] [CrossRef]

- Wieser, H. Chemistry of gluten proteins. Food Microbiol. 2007, 24, 115–119. [Google Scholar] [CrossRef]

- Wrigley, C.W. Giant proteins with flour power. Nature 1996, 381, 738–739. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Rabu, J.; Goulin, K.; Sainlaud, C.; Chen, F.; Johansson, E.; Olsson, R.T.; Hedenqvist, M.S. Flexible strength-improved and crack-resistant biocomposites based on plasticised wheat gluten reinforced with a flax-fibre-weave. Compos. Part. A Appl. Sci. Manuf. 2017, 94, 61–69. [Google Scholar] [CrossRef]

- Richter, R.; Hejazi, M.; Kraft, R.; Ziegler, K.; Lockau, W. Cyanophycinase, a peptidase degrading the cyanobacterial reserve material multi-L-arginyl-poly-L-aspartic acid (cyanophycin) Molecular cloning of the gene of Synechocystis sp. PCC 6803, expression in Escherichia coli, and biochemical characterization of the purified enzyme. Eur. J. Biochem. 1999, 263, 163–169. [Google Scholar] [PubMed]

- Brahney, J.; Hallerud, M.; Heim, E.; Hahnenberger, M.; Sukumaran, S. Plastic rain in protected areas of the United States. Science 2020, 368, 1257–1260. [Google Scholar] [CrossRef] [PubMed]

- Ehrlich, H.; Wysokowski, M.; Żółtowska-Aksamitowska, S.; Petrenko, I.; Jesionowski, T. Collagens of poriferan origin. Mar. Drugs 2018, 16, 79. [Google Scholar] [CrossRef] [PubMed]

- Szatkowski, T.; Wysokowski, M.; Lota, G.; Pęziak, D.; Bazhenov, V.V.; Nowaczyk, G.; Walter, J.; Molodtsov, S.L.; Stöcker, H.; Himcinschi, C. Novel nanostructured hematite–spongin composite developed using an extreme biomimetic approach. RSC Adv. 2015, 5, 79031–79040. [Google Scholar] [CrossRef]

- Szatkowski, T.; Kopczyński, K.; Motylenko, M.; Borrmann, H.; Mania, B.; Graś, M.; Lota, G.; Bazhenov, V.V.; Rafaja, D.; Roth, F. Extreme biomimetics: A carbonized 3D spongin scaffold as a novel support for nanostructured manganese oxide (IV) and its electrochemical applications. Nano Res. 2018, 11, 4199–4214. [Google Scholar] [CrossRef]

- Zdarta, J.; Norman, M.; Smułek, W.; Moszyński, D.; Kaczorek, E.; Stelling, A.L.; Ehrlich, H.; Jesionowski, T. Spongin-based scaffolds from Hippospongia communis demosponge as an effective support for lipase immobilization. Catalysts 2017, 7, 147. [Google Scholar] [CrossRef]

- Zdarta, J.; Antecka, K.; Frankowski, R.; Zgoła-Grześkowiak, A.; Ehrlich, H.; Jesionowski, T. The effect of operational parameters on the biodegradation of bisphenols by Trametes versicolor laccase immobilized on Hippospongia communis spongin scaffolds. Sci. Total Environ. 2018, 615, 784–795. [Google Scholar] [CrossRef]

- Norman, M.; Żółtowska-Aksamitowska, S.; Zgoła-Grześkowiak, A.; Ehrlich, H.; Jesionowski, T. Iron (III) phthalocyanine supported on a spongin scaffold as an advanced photocatalyst in a highly efficient removal process of halophenols and bisphenol A. J. Hazard. Mater. 2018, 347, 78–88. [Google Scholar] [CrossRef]

- Ashouri, V.; Adib, K.; Rahimi-Nasrabadi, M. Pre-concentration and extraction of fenitrothion using a prefabricated 3D spongin-based skeleton of marine demosponge: Optimization by experimental design. Appl. Phys. A 2020, 126, 860. [Google Scholar] [CrossRef]

- Zarrintaj, P.; Manouchehri, S.; Ahmadi, Z.; Saeb, M.R.; Urbanska, A.M.; Kaplan, D.L.; Mozafari, M. Agarose-based biomaterials for tissue engineering. Carbohydr. Polym. 2018, 187, 66–84. [Google Scholar] [CrossRef] [PubMed]

- Campos, F.; Bonhome-Espinosa, A.B.; Chato-Astrain, J.; Sánchez-Porras, D.; García-García, Ó.D.; Carmona, R.; López-López, M.T.; Alaminos, M.; Carriel, V.; Rodriguez, I.A. Evaluation of fibrin-agarose tissue-like hydrogels biocompatibility for tissue engineering applications. Front. Bioeng. Biotechnol. 2020, 8, 596. [Google Scholar] [CrossRef] [PubMed]

- Yazdi, M.K.; Taghizadeh, A.; Taghizadeh, M.; Stadler, F.J.; Farokhi, M.; Mottaghitalab, F.; Zarrintaj, P.; Ramsey, J.D.; Seidi, F.; Saeb, M.R. Agarose-based biomaterials for advanced drug delivery. J. Control. Release 2020, 326, 523–543. [Google Scholar] [CrossRef] [PubMed]

- López-Marcial, G.R.; Zeng, A.Y.; Osuna, C.; Dennis, J.; García, J.M.; O’Connell, G.D. Agarose-based hydrogels as suitable bioprinting materials for tissue engineering. ACS Biomater. Sci. Eng. 2018, 4, 3610–3616. [Google Scholar] [CrossRef] [PubMed]

- Numata, K. How to define and study structural proteins as biopolymer materials. Polym. J. 2020, 52, 1043–1056. [Google Scholar] [CrossRef]

- Jesionowski, T.; Norman, M.; Żółtowska-Aksamitowska, S.; Petrenko, I.; Joseph, Y.; Ehrlich, H. Marine spongin: Naturally prefabricated 3D scaffold-based biomaterial. Mar. Drugs 2018, 16, 88. [Google Scholar] [CrossRef] [PubMed]

- Andrade, P.; Portugal, L.; Rondon, E.; Toffoli-Kadri, M.; Cepa Matos, M.d.F. Effect of powdered shells treatment of the snail Megalobulimus lopesi on wounds of diabetic rats. Acta Cir. Bras. 2018, 33, 185–196. [Google Scholar] [CrossRef] [PubMed]

- Ehrlich, H.; Martinović, R.; Joksimović, D.; Petrenko, I.; Schiaparelli, S.; Wysokowski, M.; Tsurkan, D.; Stelling, A.L.; Springer, A.; Gelinsky, M.; et al. Conchixes: Organic scaffolds which resemble the size and shapes of mollusks shells, their isolation and potential multifunctional applications. Appl. Phys. A 2020, 126, 562. [Google Scholar] [CrossRef]

- Heldreth, B. Hydrolyzed Source Proteins as Used in Cosmetics. 2012. Available online: http://www.cir-safety.org/sites/default/files/hprtns052012slr.pdf (accessed on 9 December 2023).

- Latire, T.; Legendre, F.; Bigot, N.; Carduner, L.; Kellouche, S.; Bouyoucef, M.; Carreiras, F.; Marin, F.; Lebel, J.M.; Galéra, P.; et al. Shell extracts from the marine bivalve Pecten maximus regulate the synthesis of extracellular matrix in primary cultured human skin fibroblasts. PLoS ONE 2014, 9, e99931. [Google Scholar] [CrossRef]

- Latire, T.; Legendre, F.; Bouyoucef, M.; Marin, F.; Carreiras, F.; Rigot-Jolivet, M.; Lebel, J.-M.; Galéra, P.; Serpentini, A. Shell extracts of the edible mussel and oyster induce an enhancement of the catabolic pathway of human skin fibroblasts, in vitro. Cytotechnology 2017, 69, 815–829. [Google Scholar] [CrossRef]

- Yaqub, N.; Bullen, R.; Atkinson, H. Cleansing Composition. U.S. Patent US20040258650A1, 19 May 2015. [Google Scholar]

- Su, J.; Zhao, K.; Ren, Y.; Zhao, L.; Wei, B.; Liu, B.; Zhang, Y.; Wang, F.; Li, J.; Liu, Y. Biosynthetic structural proteins with super plasticity, extraordinary mechanical performance, biodegradability, biocompatibility and information storage ability. Angew. Chem. Int. Ed. 2022, 61, e202117538. [Google Scholar] [CrossRef]

- Rasheed, F. Production of Sustainable Bioplastic Materials from Wheat Gluten Proteins; Faculty of Landscape Planning, Horticulture and Agriculture Science: Uppsala, Sweden, 2011. [Google Scholar]

- Rasel, H.; Johansson, T.; Gällstedt, M.; Newson, W.; Johansson, E.; Hedenqvist, M. Development of bioplastics based on agricultural side-stream products: Film extrusion of Crambe abyssinica/wheat gluten blends for packaging purposes. J. Appl. Polym. Sci. 2016, 133, 42442. [Google Scholar] [CrossRef]

- Guerette, P.A.; Hoon, S.; Seow, Y.; Raida, M.; Masic, A.; Wong, F.T.; Ho, V.H.; Kong, K.W.; Demirel, M.C.; Pena-Francesch, A. Accelerating the design of biomimetic materials by integrating RNA-seq with proteomics and materials science. Nat. Biotechnol. 2013, 31, 908–915. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Ebrahimi, D.; Dinjaski, N.; Tarakanova, A.; Buehler, M.J.; Wong, J.Y.; Kaplan, D.L. Synergistic integration of experimental and simulation approaches for the de novo design of silk-based materials. Acc. Chem. Res. 2017, 50, 866–876. [Google Scholar] [CrossRef]

- Choi, K.R.; Jang, W.D.; Yang, D.; Cho, J.S.; Park, D.; Lee, S.Y. Systems metabolic engineering strategies: Integrating systems and synthetic biology with metabolic engineering. Trends Biotechnol. 2019, 37, 817–837. [Google Scholar] [CrossRef] [PubMed]

- Xia, X.-X.; Qian, Z.-G.; Ki, C.S.; Park, Y.H.; Kaplan, D.L.; Lee, S.Y. Native-sized recombinant spider silk protein produced in metabolically engineered Escherichia coli results in a strong fiber. Proc. Natl. Acad. Sci. USA 2010, 107, 14059–14063. [Google Scholar] [CrossRef] [PubMed]

- Du, J.; Li, L.; Zhou, S. Microbial production of cyanophycin: From enzymes to biopolymers. Biotechnol. Adv. 2019, 37, 107400. [Google Scholar] [CrossRef]

- Simon, R.D.; Weathers, P. Determination of the structure of the novel polypeptide containing aspartic acid and arginine which is found in cyanobacteria. Biochim. Biophys. Acta (BBA)-Protein Struct. 1976, 420, 165–176. [Google Scholar] [CrossRef]

- Conrad, U. Polymers from plants to develop biodegradable plastics. Trends Plant Sci. 2005, 10, 511–512. [Google Scholar] [CrossRef]

- Gupta, M.; Carr, N. Enzyme activities related to cyanophycin metabolism in heterocysts and vegetative cells of Anabaena spp. Microbiology 1981, 125, 17–23. [Google Scholar] [CrossRef][Green Version]

- Obst, M.; Oppermann-Sanio, F.B.; Luftmann, H.; Steinbüchel, A. Isolation of cyanophycin-degrading bacteria, cloning and characterization of an extracellular cyanophycinase gene (cphE) from Pseudomonas anguilliseptica strain BI: The cphE gene from P. anguilliseptica BI encodes a cyanophycin-hydrolyzing enzyme. J. Biol. Chem. 2002, 277, 25096–25105. [Google Scholar] [CrossRef]

- Hellier, M.; Holdsworth, C.; McColl, I.; Perrett, D. Dipeptide absorption in man. Gut 1972, 13, 965–969. [Google Scholar] [CrossRef] [PubMed]

- Bankar, S.B.; Nimbalkar, P.R.; Chavan, P.V.; Singhal, R.S. Microbial polyamino acids: An overview for commercial attention. In Role of Materials Science in Food Bioengineering, Handbook of Food Bioengineering; Academic Press: Cambridge, MA, USA, 2018; pp. 381–412. [Google Scholar]

- Hai, T.; Ahlers, H.; Gorenflo, V.; Steinbüchel, A. Axenic cultivation of anoxygenic phototrophic bacteria, cyanobacteria, and microalgae in a new closed tubular glass photobioreactor. Appl. Microbiol. Biotechnol. 2000, 53, 383–389. [Google Scholar] [CrossRef] [PubMed]

- Sallam, A.; Steinbüchel, A. Dipeptides in nutrition and therapy: Cyanophycin-derived dipeptides as natural alternatives and their biotechnological production. Appl. Microbiol. Biotechnol. 2010, 87, 815–828. [Google Scholar] [CrossRef] [PubMed]

- Santos, S.; Torcato, I.; Castanho, M.A. Biomedical applications of dipeptides and tripeptides. Pept. Sci. 2012, 98, 288–293. [Google Scholar] [CrossRef] [PubMed]

- Frommeyer, M.; Wiefel, L.; Steinbüchel, A. Features of the biotechnologically relevant polyamide family “cyanophycins” and their biosynthesis in prokaryotes and eukaryotes. Crit. Rev. Biotechnol. 2016, 36, 153–164. [Google Scholar] [CrossRef] [PubMed]

- Mooibroek, H.; Oosterhuis, N.; Giuseppin, M.; Toonen, M.; Franssen, H.; Scott, E.; Sanders, J.; Steinbüchel, A. Assessment of technological options and economical feasibility for cyanophycin biopolymer and high-value amino acid production. Appl. Microbiol. Biotechnol. 2007, 77, 257–267. [Google Scholar] [CrossRef] [PubMed]

- Neumann, K.; Stephan, D.P.; Ziegler, K.; Hühns, M.; Broer, I.; Lockau, W.; Pistorius, E.K. Production of cyanophycin, a suitable source for the biodegradable polymer polyaspartate, in transgenic plants. Plant Biotechnol. J. 2005, 3, 249–258. [Google Scholar] [CrossRef]

- Andreeva, A.; Howorth, D.; Chothia, C.; Kulesha, E.; Murzin, A.G. SCOP2 prototype: A new approach to protein structure mining. Nucleic Acids Res. 2014, 42, 11847. [Google Scholar] [CrossRef]

- Shadwick, R.E. Elastic energy storage in tendons: Mechanical differences related to function and age. J. Appl. Physiol. 1990, 68, 1033–1040. [Google Scholar] [CrossRef] [PubMed]

- Owczarzy, A.; Kurasiński, R.; Kulig, K.; Rogóż, W.; Szkudlarek, A.; Maciążek-Jurczyk, M. Collagen—Structure, properties and application. Eng. Biomater. 2020, 23, 17–23. [Google Scholar] [CrossRef]

- Safiya, N.; Casparus, J.R.V. Collagen: From Waste to Gold. In Biotechnological Applications of Biomass; Thalita Peixoto, B., Thiago Olitta, B., Luiz Carlos, B., Eds.; IntechOpen: Rijeka, Croatia, 2020. [Google Scholar] [CrossRef]

- Jumper, J.; Evans, R.; Pritzel, A.; Green, T.; Figurnov, M.; Ronneberger, O.; Tunyasuvunakool, K.; Bates, R.; Žídek, A.; Potapenko, A.; et al. Highly accurate protein structure prediction with AlphaFold. Nature 2021, 596, 583–589. [Google Scholar] [CrossRef] [PubMed]

- Varadi, M.; Anyango, S.; Deshpande, M.; Nair, S.; Natassia, C.; Yordanova, G.; Yuan, D.; Stroe, O.; Wood, G.; Laydon, A.; et al. AlphaFold Protein Structure Database: Massively expanding the structural coverage of protein-sequence space with high-accuracy models. Nucleic Acids Res. 2021, 50, D439–D444. [Google Scholar] [CrossRef] [PubMed]

- Thilagavathi, G.; Viju, S. Silk as a suture material. In Advances in Silk Science and Technology; Woodhead Publishing: Cambridge, UK, 2015; pp. 219–232. [Google Scholar]

- Yu, H.-S.; Shen, Y.-H.; Yuan, G.-X.; Hu, Y.-G.; Xu, H.-E.; Xiang, Z.-H.; Zhang, Z. Evidence of selection at melanin synthesis pathway loci during silkworm domestication. Mol. Biol. Evol. 2011, 28, 1785–1799. [Google Scholar] [CrossRef] [PubMed]

- Babu, K.M. Silk: Processing, Properties and Applications; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Guo, Y.; Shen, Y.-H.; Sun, W.; Kishino, H.; Xiang, Z.-H.; Zhang, Z. Nucleotide diversity and selection signature in the domesticated silkworm, Bombyx mori, and wild silkworm, Bombyx mandarina. J. Insect Sci. 2011, 11, 155. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Pereira, R.F.; Silva, M.M.; de Zea Bermudez, V. Bombyx mori silk fibers: An outstanding family of materials. Macromol. Mater. Eng. 2015, 300, 1171–1198. [Google Scholar] [CrossRef]

- Heim, M.; Keerl, D.; Scheibel, T. Spider Silk: From Soluble Protein to Extraordinary Fiber. Angew. Chem. Int. Ed. 2009, 48, 3584–3596. [Google Scholar] [CrossRef]

- Lu, W.; Shi, R.; Li, X.; Ma, S.; Yang, D.; Shang, D.; Xia, Q. A review on complete silk gene sequencing and de novo assembly of artificial silk. Int. J. Biol. Macromol. 2024, 264, 130444. [Google Scholar] [CrossRef]

- Hsia, Y.; Gnesa, E.; Jeffery, F.; Tang, S.; Vierra, C. Spider silk composites and applications. Met. Ceram. Polym. Compos. Var. Uses 2011, 2, 303–324. [Google Scholar]

- Kuhbier, J.W.; Reimers, K.; Kasper, C.; Allmeling, C.; Hillmer, A.; Menger, B.; Vogt, P.M.; Radtke, C. First investigation of spider silk as a braided microsurgical suture. J. Biomed. Mater. Res. Part. B Appl. Biomater. 2011, 97, 381–387. [Google Scholar] [CrossRef] [PubMed]

- Chung, H.; Kim, T.Y.; Lee, S.Y. Recent advances in production of recombinant spider silk proteins. Curr. Opin. Biotechnol. 2012, 23, 957–964. [Google Scholar] [CrossRef] [PubMed]

- Keten, S.; Xu, Z.; Ihle, B.; Buehler, M.J. Nanoconfinement controls stiffness, strength and mechanical toughness of β-sheet crystals in silk. Nat. Mater. 2010, 9, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Yarger, J.L.; Cherry, B.R.; Van Der Vaart, A. Uncovering the structure–function relationship in spider silk. Nat. Rev. Mater. 2018, 3, 1–11. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, F.; Jiang, X.; Cao, M.; Wang, S.; Zou, H.; Cao, Y.; Xian, M.; Liu, H. Microbial production of amino acid-modified spider dragline silk protein with intensively improved mechanical properties. Prep. Biochem. Biotechnol. 2016, 46, 552–558. [Google Scholar] [CrossRef] [PubMed]

- Copeland, C.G.; Bell, B.E.; Christensen, C.D.; Lewis, R.V. Development of a process for the spinning of synthetic spider silk. ACS Biomater. Sci. Eng. 2015, 1, 577–584. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Deng, Q.; Liu, X.Y.; Yang, D. Engineered large spider eggcase silk protein for strong artificial fibers. Adv. Mater. 2013, 25, 1216–1220. [Google Scholar] [CrossRef] [PubMed]

- Adrianos, S.L.; Teulé, F.; Hinman, M.B.; Jones, J.A.; Weber, W.S.; Yarger, J.L.; Lewis, R.V. Nephila clavipes flagelliform silk-like GGX motifs contribute to extensibility and spacer motifs contribute to strength in synthetic spider silk fibers. Biomacromolecules 2013, 14, 1751–1760. [Google Scholar] [CrossRef]

- Andersson, M.; Jia, Q.; Abella, A.; Lee, X.-Y.; Landreh, M.; Purhonen, P.; Hebert, H.; Tenje, M.; Robinson, C.V.; Meng, Q. Biomimetic spinning of artificial spider silk from a chimeric minispidroin. Nat. Chem. Biol. 2017, 13, 262–264. [Google Scholar] [CrossRef]

- Cui, Y.; Gong, H.; Wang, Y.; Li, D.; Bai, H. A thermally insulating textile inspired by polar bear hair. Adv. Mater. 2018, 30, 1706807. [Google Scholar] [CrossRef]

- Yu, J.; Wei, W.; Danner, E.; Ashley, R.K.; Israelachvili, J.N.; Waite, J.H. Mussel protein adhesion depends on interprotein thiol-mediated redox modulation. Nat. Chem. Biol. 2011, 7, 588–590. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Jin, S.; Park, Y.; Jung, Y.M.; Cha, H.J. Coacervation of interfacial adhesive proteins for initial mussel adhesion to a wet surface. Small 2018, 14, 1803377. [Google Scholar] [CrossRef] [PubMed]

- Kono, N.; Nakamura, H.; Ohtoshi, R.; Tomita, M.; Numata, K.; Arakawa, K. The bagworm genome reveals a unique fibroin gene that provides high tensile strength. Commun. Biol. 2019, 2, 148. [Google Scholar] [CrossRef] [PubMed]

- Yoshioka, T.; Tsubota, T.; Tashiro, K.; Jouraku, A.; Kameda, T. A study of the extraordinarily strong and tough silk produced by bagworms. Nat. Commun. 2019, 10, 1469. [Google Scholar] [CrossRef] [PubMed]

- Shao, H.; Bachus, K.N.; Stewart, R.J. A water-borne adhesive modeled after the sandcastle glue of P. californica. Macromol. Biosci. 2009, 9, 464–471. [Google Scholar] [CrossRef] [PubMed]

- Pena-Francesch, A.; Demirel, M.C. Squid-inspired tandem repeat proteins: Functional fibers and films. Front. Chem. 2019, 7, 69. [Google Scholar] [CrossRef] [PubMed]

- Tomko, J.A.; Pena-Francesch, A.; Jung, H.; Tyagi, M.; Allen, B.D.; Demirel, M.C.; Hopkins, P.E. Tunable thermal transport and reversible thermal conductivity switching in topologically networked bio-inspired materials. Nat. Nanotechnol. 2018, 13, 959–964. [Google Scholar] [CrossRef] [PubMed]

- Sponner, A.; Vater, W.; Monajembashi, S.; Unger, E.; Grosse, F.; Weisshart, K. Composition and hierarchical organisation of a spider silk. PLoS ONE 2007, 2, e998. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Sponner, A.; Porter, D.; Vollrath, F. Proline and processing of spider silks. Biomacromolecules 2008, 9, 116–121. [Google Scholar] [CrossRef]

- Nguyen, T.P.; Nguyen, Q.; Nguyen, V.-H.; Le, T.-H.; Huynh, V.; Vo, D.-V.; Trinh, Q.T.; Kim, S.Y.; Le, Q. Silk Fibroin-Based Biomaterials for Biomedical Applications: A Review. Polymers 2019, 11, 1933. [Google Scholar] [CrossRef]

- Shao, Z.; Vollrath, F. Surprising strength of silkworm silk. Nature 2002, 418, 741. [Google Scholar] [CrossRef] [PubMed]

- Kaplan, D.; Adams, W.W.; Farmer, B.; Viney, C. Silk: Biology, Structure, Properties, and Genetics; ACS Publications: Washington, DC. USA, 1994. [Google Scholar]

- Vollrath, F.; Knight, D.P. Liquid crystalline spinning of spider silk. Nature 2001, 410, 541–548. [Google Scholar] [CrossRef] [PubMed]

- Winkler, S.; Kaplan, D.L. Molecular biology of spider silk. Rev. Mol. Biotechnol. 2000, 74, 85–93. [Google Scholar] [CrossRef] [PubMed]

- Foo, C.W.P.; Kaplan, D.L. Genetic engineering of fibrous proteins: Spider dragline silk and collagen. Adv. Drug Deliv. Rev. 2002, 54, 1131–1143. [Google Scholar]

- Altman, G.H.; Diaz, F.; Jakuba, C.; Calabro, T.; Horan, R.L.; Chen, J.; Lu, H.; Richmond, J.; Kaplan, D.L. Silk-based biomaterials. Biomaterials 2003, 24, 401–416. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.Z.; Confalonieri, F.; Jacquet, M.; Perasso, R.; Li, Z.G.; Janin, J. Silk fibroin: Structural implications of a remarkable amino acid sequence. Proteins Struct. Funct. Bioinform. 2001, 44, 119–122. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.-Z.; Confalonieri, F.; Medina, N.; Zivanovic, Y.; Esnault, C.; Yang, T.; Jacquet, M.; Janin, J.; Duguet, M.; Perasso, R. Fine organization of Bombyx mori fibroin heavy chain gene. Nucleic Acids Res. 2000, 28, 2413–2419. [Google Scholar] [CrossRef] [PubMed]

- Yamaguchi, K.; Kikuchi, Y.; Takagi, T.; Kikuchi, A.; Oyama, F.; Shimura, K.; Mizuno, S. Primary structure of the silk fibroin light chain determined by cDNA sequencing and peptide analysis. J. Mol. Biol. 1989, 210, 127–139. [Google Scholar] [CrossRef] [PubMed]

- Inoue, S.; Tanaka, K.; Arisaka, F.; Kimura, S.; Ohtomo, K.; Mizuno, S. Silk fibroin of Bombyx mori is secreted, assembling a high molecular mass elementary unit consisting of H-chain, L-chain, and P25, with a 6: 6: 1 molar ratio. J. Biol. Chem. 2000, 275, 40517–40528. [Google Scholar] [CrossRef]

- Vasconcelos, A.; Freddi, G.; Cavaco-Paulo, A. Biodegradable materials based on silk fibroin and keratin. Biomacromolecules 2008, 9, 1299–1305. [Google Scholar] [CrossRef]

- Bowen, C.H.; Dai, B.; Sargent, C.J.; Bai, W.; Ladiwala, P.; Feng, H.; Huang, W.; Kaplan, D.L.; Galazka, J.M.; Zhang, F. Recombinant Spidroins Fully Replicate Primary Mechanical Properties of Natural Spider Silk. Biomacromolecules 2018, 19, 3853–3860. [Google Scholar] [CrossRef] [PubMed]

- Bitar, L.; Isella, B.; Bertella, F.; Bettker Vasconcelos, C.; Harings, J.; Kopp, A.; van der Meer, Y.; Vaughan, T.J.; Bortesi, L. Sustainable Bombyx mori’s silk fibroin for biomedical applications as a molecular biotechnology challenge: A review. Int. J. Biol. Macromol. 2024, 264, 130374. [Google Scholar] [CrossRef] [PubMed]

- Bostan, F.; Surmeli, N.B. Cloning, expression, and characterization of a novel sericin-like protein. Biotechnol. Appl. Biochem. 2022, 69, 136–144. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Y.; Wang, Y.; Li, Q.; Liang, X.; Wang, G.; Li, J.; Peng, R.; Sima, Y.; Xu, S. Ectopic expression of sericin enables efficient production of ancient silk with structural changes in silkworm. Nat. Commun. 2022, 13, 6295. [Google Scholar] [CrossRef]

- Jin, H.-J.; Kaplan, D.L. Mechanism of silk processing in insects and spiders. Nature 2003, 424, 1057–1061. [Google Scholar] [CrossRef] [PubMed]

- Motta, A.; Fambri, L.; Migliaresi, C. Regenerated silk fibroin films: Thermal and dynamic mechanical analysis. Macromol. Chem. Phys. 2002, 203, 1658–1665. [Google Scholar] [CrossRef]

- Hümmerich, D.; Slotta, U.; Scheibel, T. Processing and modification of films made from recombinant spider silk proteins. Appl. Phys. A 2006, 82, 219–222. [Google Scholar] [CrossRef]

- Zhang, Y.-Q. Applications of natural silk protein sericin in biomaterials. Biotechnol. Adv. 2002, 20, 91–100. [Google Scholar] [CrossRef] [PubMed]

- Murphy, A.R.; Kaplan, D.L. Biomedical applications of chemically-modified silk fibroin. J. Mater. Chem. 2009, 19, 6443–6450. [Google Scholar] [CrossRef]

- Matsumoto, A.; Chen, J.; Collette, A.L.; Kim, U.-J.; Altman, G.H.; Cebe, P.; Kaplan, D.L. Mechanisms of silk fibroin sol−gel transitions. J. Phys. Chem. B 2006, 110, 21630–21638. [Google Scholar] [CrossRef]

- Rockwood, D.N.; Preda, R.C.; Yücel, T.; Wang, X.; Lovett, M.L.; Kaplan, D.L. Materials fabrication from Bombyx mori silk fibroin. Nat. Protoc. 2011, 6, 1612–1631. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Wang, X.; Rnjak, J.; Weiss, A.S.; Kaplan, D.L. Biomaterials derived from silk–tropoelastin protein systems. Biomaterials 2010, 31, 8121–8131. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.-C.; Wang, S.-S.; Chou, N.-K.; Chi, N.-H.; Huang, Y.-Y.; Chang, Y.-L.; Shieh, M.-J.; Chung, T.-W. The cardiomyogenic differentiation of rat mesenchymal stem cells on silk fibroin–polysaccharide cardiac patches in vitro. Biomaterials 2009, 30, 3757–3765. [Google Scholar] [CrossRef] [PubMed]

- Unger, R.E.; Wolf, M.; Peters, K.; Motta, A.; Migliaresi, C.; Kirkpatrick, C.J. Growth of human cells on a non-woven silk fibroin net: A potential for use in tissue engineering. Biomaterials 2004, 25, 1069–1075. [Google Scholar] [CrossRef] [PubMed]

- Niamsa, N.; Srisuwan, Y.; Baimark, Y.; Phinyocheep, P.; Kittipoom, S. Preparation of nanocomposite chitosan/silk fibroin blend films containing nanopore structures. Carbohydr. Polym. 2009, 78, 60–65. [Google Scholar] [CrossRef]

- Um, I.C.; Kweon, H.; Park, Y.H.; Hudson, S. Structural characteristics and properties of the regenerated silk fibroin prepared from formic acid. Int. J. Biol. Macromol. 2001, 29, 91–97. [Google Scholar] [CrossRef] [PubMed]

- Um, I.C.; Kweon, H.Y.; Lee, K.G.; Park, Y.H. The role of formic acid in solution stability and crystallization of silk protein polymer. Int. J. Biol. Macromol. 2003, 33, 203–213. [Google Scholar] [CrossRef] [PubMed]

- Min, B.-M.; Jeong, L.; Nam, Y.S.; Kim, J.-M.; Kim, J.Y.; Park, W.H. Formation of silk fibroin matrices with different texture and its cellular response to normal human keratinocytes. Int. J. Biol. Macromol. 2004, 34, 223–230. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Kim, H.-J.; Vunjak-Novakovic, G.; Kaplan, D.L. Stem cell-based tissue engineering with silk biomaterials. Biomaterials 2006, 27, 6064–6082. [Google Scholar] [CrossRef]

- Kundu, B.; Rajkhowa, R.; Kundu, S.C.; Wang, X. Silk fibroin biomaterials for tissue regenerations. Adv. Drug Deliv. Rev. 2013, 65, 457–470. [Google Scholar] [CrossRef]

- Chen, X.; Li, W.; Zhong, W.; Lu, Y.; Yu, T. pH sensitivity and ion sensitivity of hydrogels based on complex-forming chitosan/silk fibroin interpenetrating polymer network. J. Appl. Polym. Sci. 1997, 65, 2257–2262. [Google Scholar] [CrossRef]

- Haider, Z.A.; Arai, M.; Hirabayashi, K. Mechanism of the gelation of fibroin solution. Biosci. Biotechnol. Biochem. 1993, 57, 1910–1912. [Google Scholar]

- Hanawa, T.; Watanabe, A.; Tsuchiya, T.; Ikoma, R.; Hidaka, M.; Sugihara, M. New oral dosage form for elderly patients: Preparation and characterization of silk fibroin gel. Chem. Pharm. Bull. 1995, 43, 284–288. [Google Scholar] [CrossRef] [PubMed]

- Kim, U.-J.; Park, J.; Li, C.; Jin, H.-J.; Valluzzi, R.; Kaplan, D.L. Structure and properties of silk hydrogels. Biomacromolecules 2004, 5, 786–792. [Google Scholar] [CrossRef] [PubMed]

- Kim, I.; Yoo, M.; Seo, J.; Park, S.; Na, H.; Lee, H.; Kim, S.; Cho, C. Evaluation of semi-interpenetrating polymer networks composed of chitosan and poloxamer for wound dressing application. Int. J. Pharm. 2007, 341, 35–43. [Google Scholar] [CrossRef] [PubMed]

- Brinckmann, J.; Hunzelmann, N.; Kahle, B.; Rohwedel, J.; Kramer, J.; Gibson, M.A.; Hubmacher, D.; Reinhardt, D.P. Enhanced fibrillin-2 expression is a general feature of wound healing and sclerosis: Potential alteration of cell attachment and storage of TGF-β. Lab. Investig. 2010, 90, 739–752. [Google Scholar] [CrossRef] [PubMed]

- Mariencheck, M.C.; Davis, E.C.; Zhang, H.; Ramirez, F.; Rosenbloom, J.; Gibson, M.A.; Parks, W.C.; Mecham, R.P. Fibrillin-1 and Fibrillin-2 Show Temporal and Tissue-Specific Regulation of Expression in Developing Elastic Tissues. Connect. Tissue Res. 1995, 31, 87–97. [Google Scholar] [CrossRef] [PubMed]

- Handford, P.; Downing, A.K.; Rao, Z.; Hewett, D.R.; Sykes, B.C.; Kielty, C.M. The calcium binding properties and molecular organization of epidermal growth factor-like domains in human fibrillin-1. J. Biol. Chem. 1995, 270, 6751–6756. [Google Scholar] [CrossRef] [PubMed]

- Bragulla, H.H.; Homberger, D.G. Structure and functions of keratin proteins in simple, stratified, keratinized and cornified epithelia. J. Anat. 2009, 214, 516–559. [Google Scholar] [CrossRef]

- Wang, L.; Shang, Y.; Zhang, J.; Yuan, J.; Shen, J. Recent advances in keratin for biomedical applications. Adv. Colloid. Interface Sci. 2023, 321, 103012. [Google Scholar] [CrossRef]

- Schweizer, J.; Bowden, P.E.; Coulombe, P.A.; Langbein, L.; Lane, E.B.; Magin, T.M.; Maltais, L.; Omary, M.B.; Parry, D.A.; Rogers, M.A.; et al. New consensus nomenclature for mammalian keratins. J. Cell Biol. 2006, 174, 169–174. [Google Scholar] [CrossRef] [PubMed]

- Hardy, M.H. The secret life of the hair follicle. Trends Genet. 1992, 8, 55–61. [Google Scholar] [CrossRef] [PubMed]

- Panteleyev, A.A.; Jahoda, C.A.; Christiano, A.M. Hair follicle predetermination. J. Cell Sci. 2001, 114, 3419–3431. [Google Scholar] [CrossRef] [PubMed]

- Popescu, C.; Höcker, H. Hair—The most sophisticated biological composite material. Chem. Soc. Rev. 2007, 36, 1282–1291. [Google Scholar] [CrossRef] [PubMed]

- Parry, D.A.; Steinert, P.M. Intermediate filament structure. Curr. Opin. Cell Biol. 1992, 4, 94–98. [Google Scholar] [CrossRef] [PubMed]

- Hill, P.; Brantley, H.; Van Dyke, M. Some properties of keratin biomaterials: Kerateines. Biomaterials 2010, 31, 585–593. [Google Scholar] [CrossRef] [PubMed]

- Plowman, J.E. Proteomic database of wool components. J. Chromatogr. B 2003, 787, 63–76. [Google Scholar] [CrossRef] [PubMed]

- Vasconcelos, A.; Cavaco-Paulo, A. Wound dressings for a proteolytic-rich environment. Appl. Microbiol. Biotechnol. 2011, 90, 445–460. [Google Scholar] [CrossRef] [PubMed]

- Smack, D.P.; Korge, B.P.; James, W.D. Keratin and keratinization. J. Am. Acad. Dermatol. 1994, 30, 85–102. [Google Scholar] [CrossRef]

- Maclaren, J. The extent of reduction of wool proteins by thiols. Aust. J. Chem. 1962, 15, 824–831. [Google Scholar] [CrossRef]

- O’donnell, I.; Thompson, E. Studies on reduced wool. Aust. J. Biol. Sci. 1964, 17, 973–978. [Google Scholar] [CrossRef]

- Zahn, H. Progress report on hair keratin research. Int. J. Cosmet. Sci. 2002, 24, 163. [Google Scholar] [CrossRef] [PubMed]

- Tonin, C.; Aluigi, A.; Vineis, C.; Varesano, A.; Montarsolo, A.; Ferrero, F. Thermal and structural characterization of poly (ethylene-oxide)/keratin blend films. J. Therm. Anal. Calorim. 2007, 89, 601–608. [Google Scholar] [CrossRef]

- Coulombe, P.A.; Chan, Y.; Albers, K.; Fuchs, E. Deletions in epidermal keratins leading to alterations in filament organization in vivo and in intermediate filament assembly in vitro. J. Cell Biol. 1990, 111, 3049–3064. [Google Scholar] [CrossRef] [PubMed]

- Thomas, H.; Conrads, A.; Phan, K.-H.; van de Löcht, M.; Zahn, H. In vitro reconstitution of wool intermediate filaments. Int. J. Biol. Macromol. 1986, 8, 258–264. [Google Scholar] [CrossRef]

- Ikkai, F.; Naito, S. Dynamic light scattering and circular dichroism studies on heat-induced gelation of hard-keratin protein aqueous solutions. Biomacromolecules 2002, 3, 482–487. [Google Scholar] [CrossRef]

- Rouse, J.G.; Van Dyke, M.E. A review of keratin-based biomaterials for biomedical applications. Materials 2010, 3, 999–1014. [Google Scholar] [CrossRef]

- Kawano, Y.; Okamoto, S. Film and gel of keratins. Kagaku Seibutsu 1975, 13, 291–292. [Google Scholar]

- Yeo, J.; Jung, G.; Tarakanova, A.; Martín-Martínez, F.J.; Qin, Z.; Cheng, Y.; Zhang, Y.-W.; Buehler, M.J. Multiscale modeling of keratin, collagen, elastin and related human diseases: Perspectives from atomistic to coarse-grained molecular dynamics simulations. Extrem. Mech. Lett. 2018, 20, 112–124. [Google Scholar] [CrossRef]

- Costa, F.; Silva, R.; Boccaccini, A. Fibrous protein-based biomaterials (silk, keratin, elastin, and resilin proteins) for tissue regeneration and repair. In Peptides and Proteins as Biomaterials for Tissue Regeneration and Repair; Woodhead Publishing: Cambridge, UK, 2018; pp. 175–204. [Google Scholar]

- Zhou, Z.; Zhang, S.; Cao, Y.; Marelli, B.; Xia, X.; Tao, T.H. Engineering the future of silk materials through advanced manufacturing. Adv. Mater. 2018, 30, 1706983. [Google Scholar] [CrossRef]

- Zhu, B.; Wang, H.; Leow, W.R.; Cai, Y.; Loh, X.J.; Han, M.Y.; Chen, X. Silk fibroin for flexible electronic devices. Adv. Mater. 2016, 28, 4250–4265. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Ling, S.; Li, C.; Omenetto, F.G.; Kaplan, D.L. Silkworm silk-based materials and devices generated using bio-nanotechnology. Chem. Soc. Rev. 2018, 47, 6486–6504. [Google Scholar] [CrossRef] [PubMed]

- Koh, L.-D.; Yeo, J.; Lee, Y.Y.; Ong, Q.; Han, M.; Tee, B.C. Advancing the frontiers of silk fibroin protein-based materials for futuristic electronics and clinical wound-healing (Invited review). Mater. Sci. Eng. C 2018, 86, 151–172. [Google Scholar] [CrossRef] [PubMed]

- DeFrates, K.G.; Moore, R.; Borgesi, J.; Lin, G.; Mulderig, T.; Beachley, V.; Hu, X. Protein-Based Fiber Materials in Medicine: A Review. Nanomaterials 2018, 8, 457. [Google Scholar] [CrossRef] [PubMed]

- Grewell, D.; Schrader, J.; Srinivasan, G. Protein-based Plastics. In Bioplastics and Biocomposites: A Practical Introduction; Grewell, D., Ed.; Royal Society of Chemistry: Cambridge, UK, 2023; Volume 79. [Google Scholar]

- Kenneth, B.; Torkel, W.-F. Amino acid composition of a new rubber-like protein, resilin. Biochim. Biophys. Acta 1961, 48, 452–459. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.-C.; Fan, R.-X.; Tian, K.-K.; Xia, X.-X.; Qian, Z.-G. Controllable fibrillization reinforces genetically engineered rubberlike protein hydrogels. Biomacromolecules 2021, 22, 961–970. [Google Scholar] [CrossRef]

- Balu, R.; Dutta, N.K.; Dutta, A.K.; Choudhury, N.R. Resilin-mimetics as a smart biomaterial platform for biomedical applications. Nat. Commun. 2021, 12, 149. [Google Scholar] [CrossRef] [PubMed]

- Sage, E.; Gray, W. Evolution of elastin structure. In Elastin and Elastic Tissue; Springer: Berlin/Heidelberg, Germany, 1977; pp. 291–312. [Google Scholar]

- Mithieux, S.M.; Rasko, J.E.; Weiss, A.S. Synthetic elastin hydrogels derived from massive elastic assemblies of self-organized human protein monomers. Biomaterials 2004, 25, 4921–4927. [Google Scholar] [CrossRef] [PubMed]

- Lillie, M.; Gosline, J. The viscoelastic basis for the tensile strength of elastin. Int. J. Biol. Macromol. 2002, 30, 119–127. [Google Scholar] [CrossRef]

- Rauscher, S.; Pomès, R. Structural disorder and protein elasticity. In Fuzziness. Advances in Experimental Medicine and Biology; Springer: Berlin/Heidelberg, Germany, 2012; pp. 159–183. [Google Scholar]

- Muiznieks, L.D.; Weiss, A.S.; Keeley, F.W. Structural disorder and dynamics of elastin. Biochem. Cell Biol. 2010, 88, 239–250. [Google Scholar] [CrossRef]

- Muiznieks, L.D.; Weiss, A.S. Flexibility in the solution structure of human tropoelastin. Biochemistry 2007, 46, 8196–8205. [Google Scholar] [CrossRef] [PubMed]

- Toonkool, P.; Regan, D.G.; Kuchel, P.W.; Morris, M.B.; Weiss, A.S. Thermodynamic and hydrodynamic properties of human tropoelastin: Analytical ultracentrifuge and pulsed field-gradient spin-echo NMR studies. J. Biol. Chem. 2001, 276, 28042–28050. [Google Scholar] [CrossRef] [PubMed]

- Baldock, C.; Oberhauser, A.F.; Ma, L.; Lammie, D.; Siegler, V.; Mithieux, S.M.; Tu, Y.; Chow, J.Y.H.; Suleman, F.; Malfois, M. Shape of tropoelastin, the highly extensible protein that controls human tissue elasticity. Proc. Natl. Acad. Sci. USA 2011, 108, 4322–4327. [Google Scholar] [CrossRef] [PubMed]

- Pometun, M.S.; Chekmenev, E.Y.; Wittebort, R.J. Quantitative observation of backbone disorder in native elastin. J. Biol. Chem. 2004, 279, 7982–7987. [Google Scholar] [CrossRef]

- Kozel, B.A.; Rongish, B.J.; Czirok, A.; Zach, J.; Little, C.D.; Davis, E.C.; Knutsen, R.H.; Wagenseil, J.E.; Levy, M.A.; Mecham, R.P. Elastic fiber formation: A dynamic view of extracellular matrix assembly using timer reporters. J. Cell. Physiol. 2006, 207, 87–96. [Google Scholar] [CrossRef] [PubMed]

- Tamburro, A.M.; Pepe, A.; Bochicchio, B.; Quaglino, D.; Ronchetti, I.P. Supramolecular amyloid-like assembly of the polypeptide sequence coded by exon 30 of human tropoelastin. J. Biol. Chem. 2005, 280, 2682–2690. [Google Scholar] [CrossRef]

- Miao, M.; Bellingham, C.M.; Stahl, R.J.; Sitarz, E.E.; Lane, C.J.; Keeley, F.W. Sequence and structure determinants for the self-aggregation of recombinant polypeptides modeled after human elastin. J. Biol. Chem. 2003, 278, 48553–48562. [Google Scholar] [CrossRef]

- Hoeve, C.; Flory, P. The elastic properties of elastin. Biopolym. Orig. Res. Biomol. 1974, 13, 677–686. [Google Scholar] [CrossRef]

- Burrows, M.; Shaw, S.R.; Sutton, G.P. Resilin and chitinous cuticle form a composite structure for energy storage in jumping by froghopper insects. BMC Biol. 2008, 6, 41. [Google Scholar] [CrossRef]

- Bennet-Clark, H.; Lucey, E. The jump of the flea: A study of the energetics and a model of the mechanism. J. Exp. Biol. 1967, 47, 59–76. [Google Scholar] [CrossRef]

- Weis-Fogh, T. A rubber-like protein in insect cuticle. J. Exp. Biol. 1960, 37, 889–907. [Google Scholar] [CrossRef]

- Tamburro, A.M.; Panariello, S.; Santopietro, V.; Bracalello, A.; Bochicchio, B.; Pepe, A. Molecular and Supramolecular Structural Studies on Significant Repetitive Sequences of Resilin. ChemBioChem 2010, 11, 83–93. [Google Scholar] [CrossRef] [PubMed]

- Song, J.H.; Murphy, R.J.; Narayan, R.; Davies, G.B. Biodegradable and compostable alternatives to conventional plastics. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2009, 364, 2127–2139. [Google Scholar] [CrossRef] [PubMed]

- Grewell, D.; Schrader, J.; Srinivasan, G. Developing Protein-Based Plastics. In Soy-Based Chemicals and Materials, 1st ed.; Brentin, R.P., Ed.; American Chemical Society: Washington, DC, USA, 2014; Volume 1178. [Google Scholar]

- Sugiyama, T.; Rafalski, A.; Peterson, D.; Söll, D. A wheat HMW glutenin subunit gene reveals a highly repeated structure. Nucleic Acids Res. 1985, 13, 8729–8737. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Halfmann, C.; Gu, L.; Zhou, R. Engineering cyanobacteria for the production of a cyclic hydrocarbon fuel from CO2 and H2O. Green. Chem. 2014, 16, 3175–3185. [Google Scholar] [CrossRef]

- Elhai, J.; Wolk, C.P. Conjugal transfer of DNA to cyanobacteria. Methods Enzymol. 1988, 167, 747–754. [Google Scholar] [PubMed]

- Kubiak, A.; Pajewska-Szmyt, M.; Kotula, M.; Leśniewski, B.; Voronkina, A.; Rahimi, P.; Falahi, S.; Heimler, K.; Rogoll, A.; Vogt, C.; et al. Spongin as a Unique 3D Template for the Development of Functional Iron-Based Composites Using Biomimetic Approach In Vitro. Mar. Drugs 2023, 21, 460. [Google Scholar] [CrossRef]

- Ehrlich, H. Biological Materials of Marine Origin; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Petrenko, I.; Summers, A.P.; Simon, P.; Żółtowska-Aksamitowska, S.; Motylenko, M.; Schimpf, C.; Rafaja, D.; Roth, F.; Kummer, K.; Brendler, E.; et al. Extreme biomimetics: Preservation of molecular detail in centimeter-scale samples of biological meshes laid down by sponges. Sci. Adv. 2019, 5, eaax2805. [Google Scholar] [CrossRef]

- Ashouri, V.; Rahimi-Nasrabadi, M.; Attaran, G.; Adib, K.; Zahedi, M.; Ganjali, M.; Marzi, E. Extraction and pre-concentration of ketamine by using a three-dimensional spongin-based scaffold of the Haliclona sp. marine demosponge origin. Appl. Phys. A 2020, 126, 421. [Google Scholar] [CrossRef]

- Yang, S.; Wang, Z.; Hu, Y.; Zong, K.; Zhang, X.; Ke, H.; Wang, P.; Go, Y.; Chan, X.H.F.; Wu, J.; et al. Hydrolyzed Conchiolin Protein (HCP) Extracted from Pearls Antagonizes both ET-1 and α-MSH for Skin Whitening. Int. J. Mol. Sci. 2023, 24, 7471. [Google Scholar] [CrossRef]

- Chen, S.; Huang, S.; Li, Y.; Zhou, C. Recent Advances in Epsilon-Poly-L-Lysine and L-Lysine-Based Dendrimer Synthesis, Modification, and Biomedical Applications. Front. Chem. 2021, 9, 659304. [Google Scholar] [CrossRef] [PubMed]

- Björn, W.; Karl, F. Cyanophycin: A Nitrogen-Rich Reserve Polymer; IntechOpen: Winchester, UK, 2018. [Google Scholar] [CrossRef]

- Ziegler, K.; Diener, A.; Herpin, C.; Richter, R.; Deutzmann, R.; Lockau, W. Molecular characterization of cyanophycin synthetase, the enzyme catalyzing the biosynthesis of the cyanobacterial reserve material multi-L-arginyl-poly-L-aspartate (cyanophycin). Eur. J. Biochem. 1998, 254, 154–159. [Google Scholar] [CrossRef]

- Sharon, I.; Haque, A.S.; Grogg, M.; Lahiri, I.; Seebach, D.; Leschziner, A.E.; Hilvert, D.; Schmeing, T.M. Structures and function of the amino acid polymerase cyanophycin synthetase. Nat. Chem. Biol. 2021, 17, 1101–1110. [Google Scholar] [CrossRef] [PubMed]

- Steinle, A.; Steinbüchel, A. Establishment of a simple and effective isolation method for cyanophycin from recombinant Saccharomyces cerevisiae. Appl. Microbiol. Biotechnol. 2010, 85, 1393–1399. [Google Scholar] [CrossRef]

- Abd-El-Karem, Y.; Elbers, T.; Reichelt, R.; Steinbüchel, A. Heterologous expression of Anabaena sp. PCC7120 cyanophycin metabolism genes cphA1 and cphB1 in Sinorhizobium (Ensifer) meliloti 1021. Appl. Microbiol. Biotechnol. 2011, 89, 1177–1192. [Google Scholar] [CrossRef]

- Fokina, O.; Chellamuthu, V.R.; Zeth, K.; Forchhammer, K. A Novel Signal Transduction Protein P-II Variant from Synechococcus elongatus PCC 7942 Indicates a Two-Step Process for NAGK-P-II Complex Formation. J. Mol. Biol. 2010, 399, 410–421. [Google Scholar] [CrossRef] [PubMed]

- Watzer, B.; Engelbrecht, A.; Hauf, W.; Stahl, M.; Maldener, I.; Forchhammer, K. Metabolic pathway engineering using the central signal processor P-II. Microb. Cell Fact. 2015, 14, 192. [Google Scholar] [CrossRef] [PubMed]

- Trautmann, A.; Watzer, B.; Wilde, A.; Forchhammer, K.; Posten, C. Effect of phosphate availability on cyanophycin accumulation in Synechocystis sp PCC 6803 and the production strain BW86. Algal. Res. 2016, 20, 189–196. [Google Scholar] [CrossRef]

- Khlystov, N.A.; Chan, W.Y.; Kunjapur, A.M.; Shi, W.C.; Prather, K.U.; Olsen, B.D. Material properties of the cyanobacterial reserve polymer multi-L- arginyl-poly-L-aspartate (cyanophycin). Polymer 2017, 109, 238–245. [Google Scholar] [CrossRef]

- Kwiatos, N.; Steinbüchel, A. Cyanophycin Modifications—Widening the Application Potential. Front. Bioeng. Biotechnol. 2021, 9, 763804. [Google Scholar] [CrossRef]

- Frey, K.M.; Oppermann-Sanio, F.B.; Schmidt, H.; Steinbüchel, A. Technical-scale production of cyanophycin with recombinant strains of Escherichia coli. Appl. Environ. Microbiol. 2002, 68, 3377–3384. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Koch, M.; Forchhammer, K. Cyanobacterial Biopolymers. In Cyanobacteria Biotechnology; John Wiley & Sons: Hoboken, NJ, USA, 2021; pp. 301–330. [Google Scholar] [CrossRef]

- Halfmann, C.; Gu, L.; Gibbons, W.; Zhou, R. Genetically engineering cyanobacteria to convert CO2, water, and light into the long-chain hydrocarbon farnesene. Appl. Microbiol. Biotechnol. 2014, 98, 9869–9877. [Google Scholar] [CrossRef] [PubMed]

- Halfmann, C.T. The Synthetic Biology of N 2-Fixing Cyanobacteria for Photosynthetic Terpenoid Production. Ph.D. Dissertation, South Dakota State University, Brookings, SD, USA, 2017. [Google Scholar]

- Gu, L.; Xiang, X.; Raynie, D.; Gibbons, W.; Zhou, R. Biosolar Conversion of CO2 and H2O into Long-chain alcohol. In Proceedings of the Sun Grant National Conference, Science for Biomass Feedstock Production and Utilization, New Orleans, LA, USA, 2–5 October 2012. [Google Scholar]

- Chen, K.; Zhu, H.; Gu, L.; Tian, S.; Zhou, R. Target Gene Inactivation in Cyanobacterium Anabaena sp. PCC 7120. Bio-Protocol 2016, 6, e1890. [Google Scholar] [CrossRef]

- Xu, X.; Gu, L.; He, P.; Zhou, R. Characterization of five putative aspartate aminotransferase genes in the N2-fixing heterocystous cyanobacterium Anabaena sp. strain PCC 7120. Microbiology 2015, 161, 1219–1230. [Google Scholar] [CrossRef]

- Zhou, R.B.; Wolk, C.P. A two-component system mediates developmental regulation of biosynthesis of a heterocyst polysaccharide. J. Biol. Chem. 2003, 278, 19939–19946. [Google Scholar] [CrossRef]

- Chen, K.; Xu, X.; Gu, L.; Hildreth, M.; Zhou, R. Simultaneous gene inactivation and promoter reporting in cyanobacteria. Appl. Microbiol. Biotechnol. 2015, 99, 1779–1793. [Google Scholar] [CrossRef] [PubMed]

- Oppermann-Sanio, F.B.; Steinbüchel, A. Occurrence, functions and biosynthesis of polyamides in microorganisms and biotechnological production. Naturwissenschaften 2002, 89, 11–22. [Google Scholar] [CrossRef]

- Obst, M.; Sallam, A.; Luftmann, H.; Steinbüchel, A. Isolation and Characterization of Gram-Positive Cyanophycin-Degrading Bacteria Kinetic Studies on Cyanophycin Depolymerase Activity in Aerobic Bacteria. Biomacromolecules 2004, 5, 153–161. [Google Scholar] [CrossRef]

- Sallam, A.; Kast, A.; Przybilla, S.; Meiswinkel, T.; Steinbüchel, A. Biotechnological process for production of β-dipeptides from cyanophycin on a technical scale and its optimization. Appl. Environ. Microbiol. 2009, 75, 29–38. [Google Scholar] [CrossRef]

- Olechnovič, K.; Venclovas, Č. VoroMQA web server for assessing three-dimensional structures of proteins and protein complexes. Nucleic Acids Res. 2019, 47, W437–W442. [Google Scholar] [CrossRef]

- Pickel, B.; Schaller, A. Dirigent proteins: Molecular characteristics and potential biotechnological applications. Appl. Microbiol. Biotechnol. 2013, 97, 8427–8438. [Google Scholar] [CrossRef]

- Satarker, S.; Nampoothiri, M. Structural proteins in severe acute respiratory syndrome coronavirus-2. Arch. Med. Res. 2020, 51, 482–491. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.Z.; Jeon, J.; Jiang, B.; Subramani, S.V.; Li, J.; Zhang, F. Protein-Based Hydrogels and Their Biomedical Applications. Molecules 2023, 28, 4988. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Qi, X.; Chen, Y.; Wu, Z. Thermo-sensitive hydrogels for delivering biotherapeutic molecules: A review. Saudi Pharm. J. 2019, 27, 990–999. [Google Scholar] [CrossRef] [PubMed]

- Yan, W.; Jia, X.; Zhang, Q.; Chen, H.; Zhu, Q.; Yin, L. Interpenetrating polymer network hydrogels of soy protein isolate and sugar beet pectin as a potential carrier for probiotics. Food Hydrocoll. 2021, 113, 106453. [Google Scholar] [CrossRef]

- Joseph, C.A.; McCarthy, C.W.; Tyo, A.G.; Hubbard, K.R.; Fisher, H.C.; Altscheffel, J.A.; He, W.; Pinnaratip, R.; Liu, Y.; Lee, B.P. Development of an injectable nitric oxide releasing poly (ethylene) glycol-Fibrin adhesive hydrogel. ACS Biomater. Sci. Eng. 2018, 5, 959–969. [Google Scholar] [CrossRef] [PubMed]

- Yan, W.; Zhang, B.; Yadav, M.P.; Feng, L.; Yan, J.; Jia, X.; Yin, L. Corn fiber gum-soybean protein isolate double network hydrogel as oral delivery vehicles for thermosensitive bioactive compounds. Food Hydrocoll. 2020, 107, 105865. [Google Scholar] [CrossRef]

- Li, Z.; Xu, W.; Wang, X.; Jiang, W.; Ma, X.; Wang, F.; Zhang, C.; Ren, C. Fabrication of PVA/PAAm IPN hydrogel with high adhesion and enhanced mechanical properties for body sensors and antibacterial activity. Eur. Polym. J. 2021, 146, 110253. [Google Scholar] [CrossRef]

- Li, Z.; Meng, X.; Xu, W.; Zhang, S.; Ouyang, J.; Zhang, Z.; Liu, Y.; Niu, Y.; Ma, S.; Xue, Z. Single network double cross-linker (SNDCL) hydrogels with excellent stretchability, self-recovery, adhesion strength, and conductivity for human motion monitoring. Soft Matter 2020, 16, 7323–7331. [Google Scholar] [CrossRef]

- Huang, S.; Kong, X.; Xiong, Y.; Zhang, X.; Chen, H.; Jiang, W.; Niu, Y.; Xu, W.; Ren, C. An overview of dynamic covalent bonds in polymer material and their applications. Eur. Polym. J. 2020, 141, 110094. [Google Scholar] [CrossRef]

- Lim, S.; Jung, G.A.; Muckom, R.J.; Glover, D.J.; Clark, D.S. Engineering bioorthogonal protein–polymer hybrid hydrogel as a functional protein immobilization platform. Chem. Commun. 2019, 55, 806–809. [Google Scholar] [CrossRef] [PubMed]

- Najmi, L.; Hu, Z. Review on Molecular Dynamics Simulations of Effects of Carbon Nanotubes (CNTs) on Electrical and Thermal Conductivities of CNT-Modified Polymeric Composites. J. Compos. Sci. 2023, 7, 165. [Google Scholar] [CrossRef]

- Hu, Z.; Hong, H. Review on Material Performance of Carbon Nanotube-Modified Polymeric Nanocomposites. Recent. Prog. Mater. 2023, 5, 1–20. [Google Scholar] [CrossRef]

- Berger, J.; Reist, M.; Mayer, J.; Felt, O.; Peppas, N.; Gurny, R. Structure and interactions in covalently and ionically crosslinked chitosan hydrogels for biomedical applications. Eur. J. Pharm. Biopharm. 2004, 57, 19–34. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Xia, X.-X.; Huang, S.-C.; Qian, Z.-G. Development of adhesive and conductive resilin-based hydrogels for wearable sensors. Biomacromolecules 2019, 20, 3283–3293. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Han, G.; Wang, Q.; Zhang, S.; You, R.; Luo, Z.; Xu, A.; Li, X.; Li, M.; Zhang, Q. Directed assembly of robust and biocompatible silk fibroin/hyaluronic acid composite hydrogels. Compos. Part. B Eng. 2019, 176, 107204. [Google Scholar] [CrossRef]

- Hu, X.; Lu, Q.; Sun, L.; Cebe, P.; Wang, X.; Zhang, X.; Kaplan, D.L. Biomaterials from ultrasonication-induced silk fibroin− hyaluronic acid hydrogels. Biomacromolecules 2010, 11, 3178–3188. [Google Scholar] [CrossRef]

- Tang, Z.; Chen, Q.; Chen, F.; Zhu, L.; Lu, S.; Ren, B.; Zhang, Y.; Yang, J.; Zheng, J. General principle for fabricating natural globular protein-based double-network hydrogels with integrated highly mechanical properties and surface adhesion on solid surfaces. Chem. Mater. 2018, 31, 179–189. [Google Scholar] [CrossRef]

- Xu, R.; Ma, S.; Lin, P.; Yu, B.; Zhou, F.; Liu, W. High strength astringent hydrogels using protein as the building block for physically cross-linked multi-network. ACS Appl. Mater. Interfaces 2017, 10, 7593–7601. [Google Scholar] [CrossRef]

- Dai, X.; Zhang, Y.; Gao, L.; Bai, T.; Wang, W.; Cui, Y.; Liu, W. A Mechanically Strong, Highly Stable, Thermoplastic, and self-healable supramolecular polymer hydrogel. Adv. Mater. 2015, 27, 3566–3571. [Google Scholar] [CrossRef]

- Hoff, S.E.; Liu, J.; Heinz, H. Binding mechanism and binding free energy of amino acids and citrate to hydroxyapatite surfaces as a function of crystallographic facet, pH, and electrolytes. J. Colloid. Interface Sci. 2022, 605, 685–700. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Wu, T.; Wang, M.; Shi, S.; Yuan, G.; Li, X.; Chong, H.; Wu, B.; Zheng, P. Enzymatic biosynthesis and immobilization of polyprotein verified at the single-molecule level. Nat. Commun. 2019, 10, 2775. [Google Scholar] [CrossRef] [PubMed]

- Fisher, S.A.; Baker, A.E.; Shoichet, M.S. Designing peptide and protein modified hydrogels: Selecting the optimal conjugation strategy. J. Am. Chem. Soc. 2017, 139, 7416–7427. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Gao, W. Precision conjugation: An emerging tool for generating protein–polymer conjugates. Angew. Chem. Int. Ed. 2021, 60, 11024–11035. [Google Scholar] [CrossRef] [PubMed]

- Sun, F.; Zhang, W.-B.; Mahdavi, A.; Arnold, F.H.; Tirrell, D.A. Synthesis of bioactive protein hydrogels by genetically encoded SpyTag-SpyCatcher chemistry. Proc. Natl. Acad. Sci. USA 2014, 111, 11269–11274. [Google Scholar] [CrossRef] [PubMed]

- Lyu, S.; Fang, J.; Duan, T.; Fu, L.; Liu, J.; Li, H. Optically controlled reversible protein hydrogels based on photoswitchable fluorescent protein Dronpa. Chem. Commun. 2017, 53, 13375–13378. [Google Scholar] [CrossRef] [PubMed]

- Fierer, J.O.; Veggiani, G.; Howarth, M. SpyLigase peptide–peptide ligation polymerizes affibodies to enhance magnetic cancer cell capture. Proc. Natl. Acad. Sci. USA 2014, 111, E1176–E1181. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Wang, Z.; Xiao, Y.; Zhang, S.; Wang, J. Advances in crosslinking strategies of biomedical hydrogels. Biomater. Sci.-UK 2019, 7, 843–855. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Yang, L.; He, Y.; Xiao, H.; Lin, W. Microsphere-structured hydrogel crosslinked by polymerizable protein-based nanospheres. Polymer 2020, 211, 123114. [Google Scholar] [CrossRef]

- Su, J.; Lu, S.; Jiang, S.; Li, B.; Liu, B.; Sun, Q.; Li, J.; Wang, F.; Wei, Y. Engineered protein photo-thermal hydrogels for outstanding in situ tongue cancer therapy. Adv. Mater. 2021, 33, 2100619. [Google Scholar] [CrossRef]

- Wang, Y.; Xia, Y.; Xiang, P.; Dai, Y.; Gao, Y.; Xu, H.; Yu, J.; Gao, G.; Chen, K. Protein-assisted freeze-tolerant hydrogel with switchable performance toward customizable flexible sensor. Chem. Eng. J. 2022, 428, 131171. [Google Scholar] [CrossRef]

- Boonpavanitchakul, K.; Bast, L.K.; Bruns, N.; Magaraphan, R. Silk sericin-polylactide protein–polymer conjugates as biodegradable amphiphilic materials and their application in drug release systems. Bioconjugate Chem. 2020, 31, 2312–2324. [Google Scholar] [CrossRef]

- Lei, H.; Dong, L.; Li, Y.; Zhang, J.; Chen, H.; Wu, J.; Zhang, Y.; Fan, Q.; Xue, B.; Qin, M. Stretchable hydrogels with low hysteresis and anti-fatigue fracture based on polyprotein cross-linkers. Nat. Commun. 2020, 11, 4032. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Topuz, F.; Hahn, K.; Albrecht, K.; Groll, J. Embedding of Active Proteins and Living Cells in Redox-Sensitive Hydrogels and Nanogels through Enzymatic Cross-Linking. Angew. Chem. Int. Ed. 2013, 52, 3000–3003. [Google Scholar] [CrossRef] [PubMed]

- Le Thi, P.; Lee, Y.; Nguyen, D.H.; Park, K.D. In situ forming gelatin hydrogels by dual-enzymatic cross-linking for enhanced tissue adhesiveness. J. Mater. Chem. B 2017, 5, 757–764. [Google Scholar] [CrossRef]

- Chirila, T.V.; Suzuki, S.; Papolla, C. A comparative investigation of Bombyx mori silk fibroin hydrogels generated by chemical and enzymatic cross-linking. Biotechnol. Appl. Biochem. 2017, 64, 771–781. [Google Scholar] [CrossRef] [PubMed]

- Hou, S.; Lake, R.; Park, S.; Edwards, S.; Jones, C.; Jeong, K.J. Injectable macroporous hydrogel formed by enzymatic cross-linking of gelatin microgels. ACS Appl. Bio Mater. 2018, 1, 1430–1439. [Google Scholar] [CrossRef]

- Mezghani, K.; Spruiell, J. High speed melt spinning of poly (L-lactic acid) filaments. J. Polym. Sci. Part B Polym. Phys. 1998, 36, 1005–1012. [Google Scholar] [CrossRef]

- Matabola, K.; De Vries, A.; Moolman, F.; Luyt, A. Single polymer composites: A review. J. Mater. Sci. 2009, 44, 6213–6222. [Google Scholar] [CrossRef]

- Berry, S.M.; Harfenist, S.A.; Cohn, R.W.; Keynton, R.S. Characterization of micromanipulator-controlled dry spinning of micro-and sub-microscale polymer fibers. J. Micromechanics Microengineering 2006, 16, 1825. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, Y.; Zhao, Y.; Luo, J.; Shao, H.; Hu, X. Bio-inspired capillary dry spinning of regenerated silk fibroin aqueous solution. Mater. Sci. Eng. C 2011, 31, 1602–1608. [Google Scholar] [CrossRef]

- Phillips, D.M.; Drummy, L.F.; Naik, R.R.; Hugh, C.; Fox, D.M.; Trulove, P.C.; Mantz, R.A. Regenerated silk fiber wet spinning from an ionic liquid solution. J. Mater. Chem. 2005, 15, 4206–4208. [Google Scholar] [CrossRef]

- Nelson, K.D.; Romero, A.; Waggoner, P.; Crow, B.; Borneman, A.; Smith, G.M. Technique paper for wet-spinning poly (L-lactic acid) and poly (DL-lactide-co-glycolide) monofilament fibers. Tissue Eng. 2003, 9, 1323–1330. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.-M.; Zhang, Y.-Z.; Kotaki, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Pham, Q.P.; Sharma, U.; Mikos, A.G. Electrospinning of polymeric nanofibers for tissue engineering applications: A review. Tissue Eng. 2006, 12, 1197–1211. [Google Scholar] [CrossRef] [PubMed]

- Luo, C.; Stoyanov, S.D.; Stride, E.; Pelan, E.; Edirisinghe, M. Electrospinning versus fibre production methods: From specifics to technological convergence. Chem. Soc. Rev. 2012, 41, 4708–4735. [Google Scholar] [CrossRef] [PubMed]

- Reneker, D.H.; Yarin, A.L. Electrospinning jets and polymer nanofibers. Polymer 2008, 49, 2387–2425. [Google Scholar] [CrossRef]

- Badrossamay, M.R.; McIlwee, H.A.; Goss, J.A.; Parker, K.K. Nanofiber assembly by rotary jet-spinning. Nano Lett. 2010, 10, 2257–2261. [Google Scholar] [CrossRef]

- Plowman, J.E.; Deb-Choudhury, S.; Clerens, S.; Thomas, A.; Cornellison, C.D.; Dyer, J.M. Unravelling the proteome of wool: Towards markers of wool quality traits. J. Proteom. 2012, 75, 4315–4324. [Google Scholar] [CrossRef]

- Service Robert, F. Hunt for renewable plastics clears a hurdle. Science 2021, 371, 873. [Google Scholar] [CrossRef]

- Nanda, S.; Patra, B.R.; Patel, R.; Bakos, J.; Dalai, A.K. Innovations in applications and prospects of bioplastics and biopolymers: A review. Environ. Chem. Lett. 2021, 20, 379–395. [Google Scholar] [CrossRef] [PubMed]

- Springstein, B.L.; Woehle, C.; Weissenbach, J.; Helbig, A.O.; Dagan, T.; Stucken, K. Identification and characterization of novel filament-forming proteins in cyanobacteria. Sci. Rep. 2020, 10, 1894. [Google Scholar] [CrossRef] [PubMed]

- Lopez, C.V.; Garcia Mdel, C.; Fernandez, F.G.; Bustos, C.S.; Chisti, Y.; Sevilla, J.M. Protein measurements of microalgal and cyanobacterial biomass. Bioresour. Technol. 2010, 101, 7587–7591. [Google Scholar] [CrossRef]

- Menetrez, M.Y. An overview of algae biofuel production and potential environmental impact. Environ. Sci. Technol. 2012, 46, 7073–7085. [Google Scholar] [CrossRef] [PubMed]

- Lupatini, A.L.; Colla, L.M.; Canan, C.; Colla, E. Potential application of microalga Spirulina platensis as a protein source. J. Sci. Food Agric. 2017, 97, 724–732. [Google Scholar] [CrossRef] [PubMed]

- Betterle, N.; Hidalgo Martinez, D.; Melis, A. Cyanobacterial Production of Biopharmaceutical and Biotherapeutic Proteins. Front. Plant Sci. 2020, 11, 237. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Zhang, H.; Meng, H.; Zhu, Y.; Bao, G.; Zhang, Y.; Li, Y.; Ma, Y. Discovery of a super-strong promoter enables efficient production of heterologous proteins in cyanobacteria. Sci. Rep. 2014, 4, 4500. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Betterle, N.; Hidalgo Martinez, D.; Melis, A. Recombinant Protein Stability in Cyanobacteria. ACS Synth. Biol. 2021, 10, 810–825. [Google Scholar] [CrossRef] [PubMed]

- Kouba, P.; Kohout, P.; Haddadi, F.; Bushuiev, A.; Samusevich, R.; Sedlar, J.; Damborsky, J.; Pluskal, T.; Sivic, J.; Mazurenko, S. Machine Learning-Guided Protein Engineering. ACS Catal. 2023, 13, 13863–13895. [Google Scholar] [CrossRef]

- Singh, N.; Malik, S.; Gupta, A.; Srivastava, K.R. Revolutionizing enzyme engineering through artificial intelligence and machine learning. Emerg. Top. Life Sci. 2021, 5, 113–125. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nawaz, T.; Gu, L.; Gibbons, J.; Hu, Z.; Zhou, R. Bridging Nature and Engineering: Protein-Derived Materials for Bio-Inspired Applications. Biomimetics 2024, 9, 373. https://doi.org/10.3390/biomimetics9060373

Nawaz T, Gu L, Gibbons J, Hu Z, Zhou R. Bridging Nature and Engineering: Protein-Derived Materials for Bio-Inspired Applications. Biomimetics. 2024; 9(6):373. https://doi.org/10.3390/biomimetics9060373

Chicago/Turabian StyleNawaz, Taufiq, Liping Gu, Jaimie Gibbons, Zhong Hu, and Ruanbao Zhou. 2024. "Bridging Nature and Engineering: Protein-Derived Materials for Bio-Inspired Applications" Biomimetics 9, no. 6: 373. https://doi.org/10.3390/biomimetics9060373

APA StyleNawaz, T., Gu, L., Gibbons, J., Hu, Z., & Zhou, R. (2024). Bridging Nature and Engineering: Protein-Derived Materials for Bio-Inspired Applications. Biomimetics, 9(6), 373. https://doi.org/10.3390/biomimetics9060373