Design, Optimization, and Modeling of a Hydraulic Soft Robot for Chronic Total Occlusions

Abstract

1. Introduction

1.1. Research Background

1.2. Related Works

1.3. Challenges and Contributions

2. Bionic Design of the Soft Hydraulic Robot Based on the Earthworm’s Locomotion

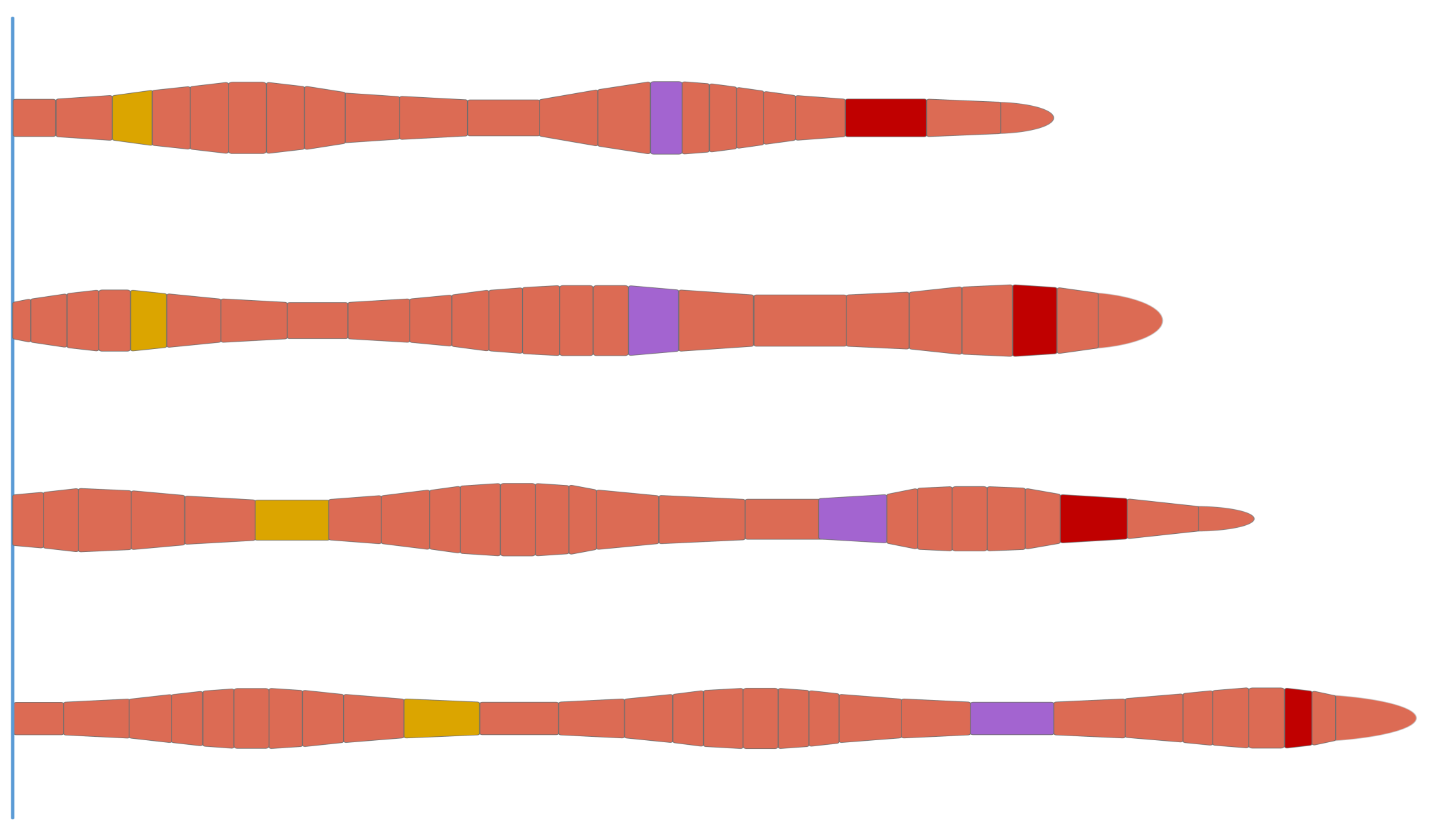

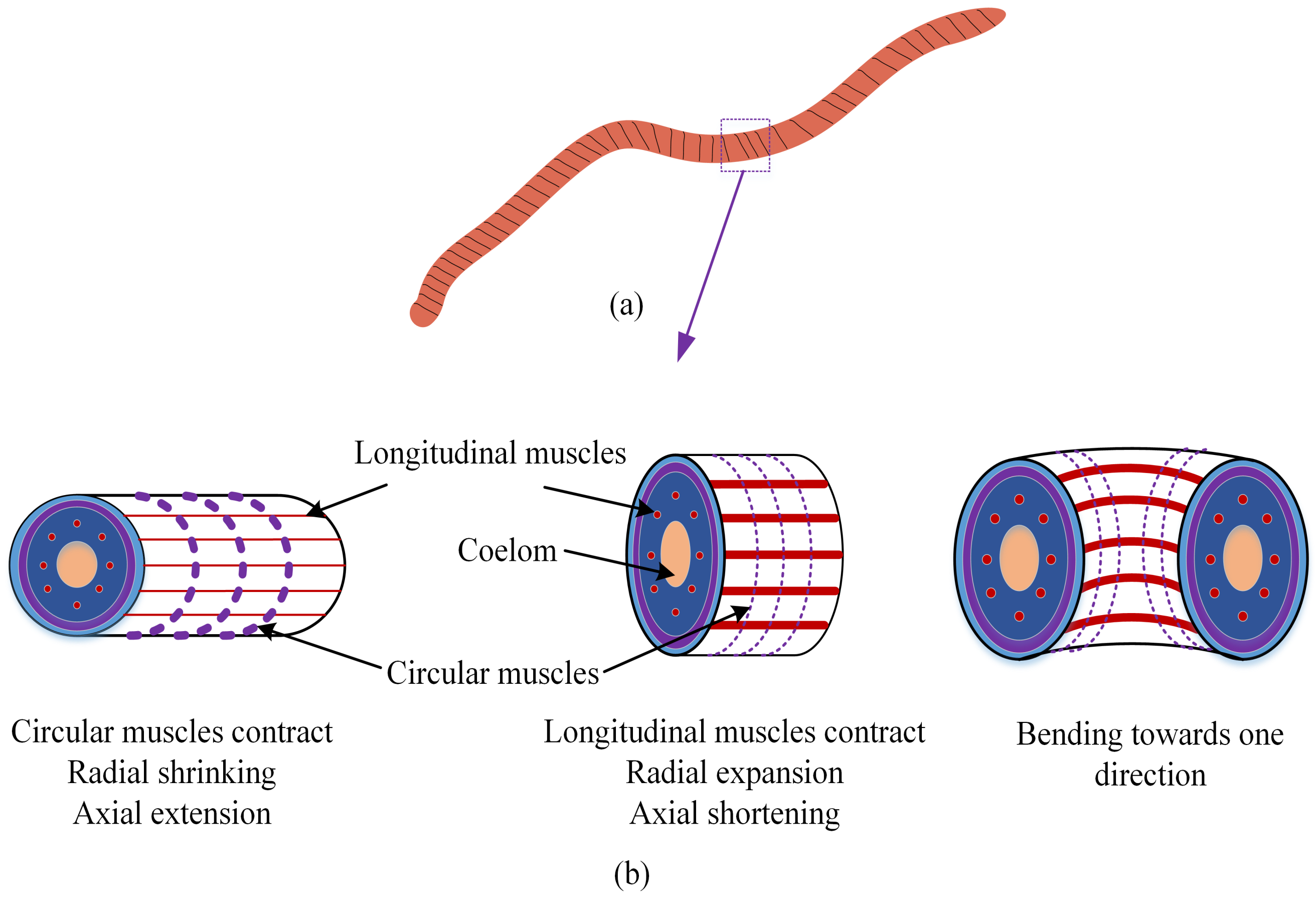

2.1. Locomotion Principles of the Earthworm

2.2. Bionic Design of the Soft Actuators

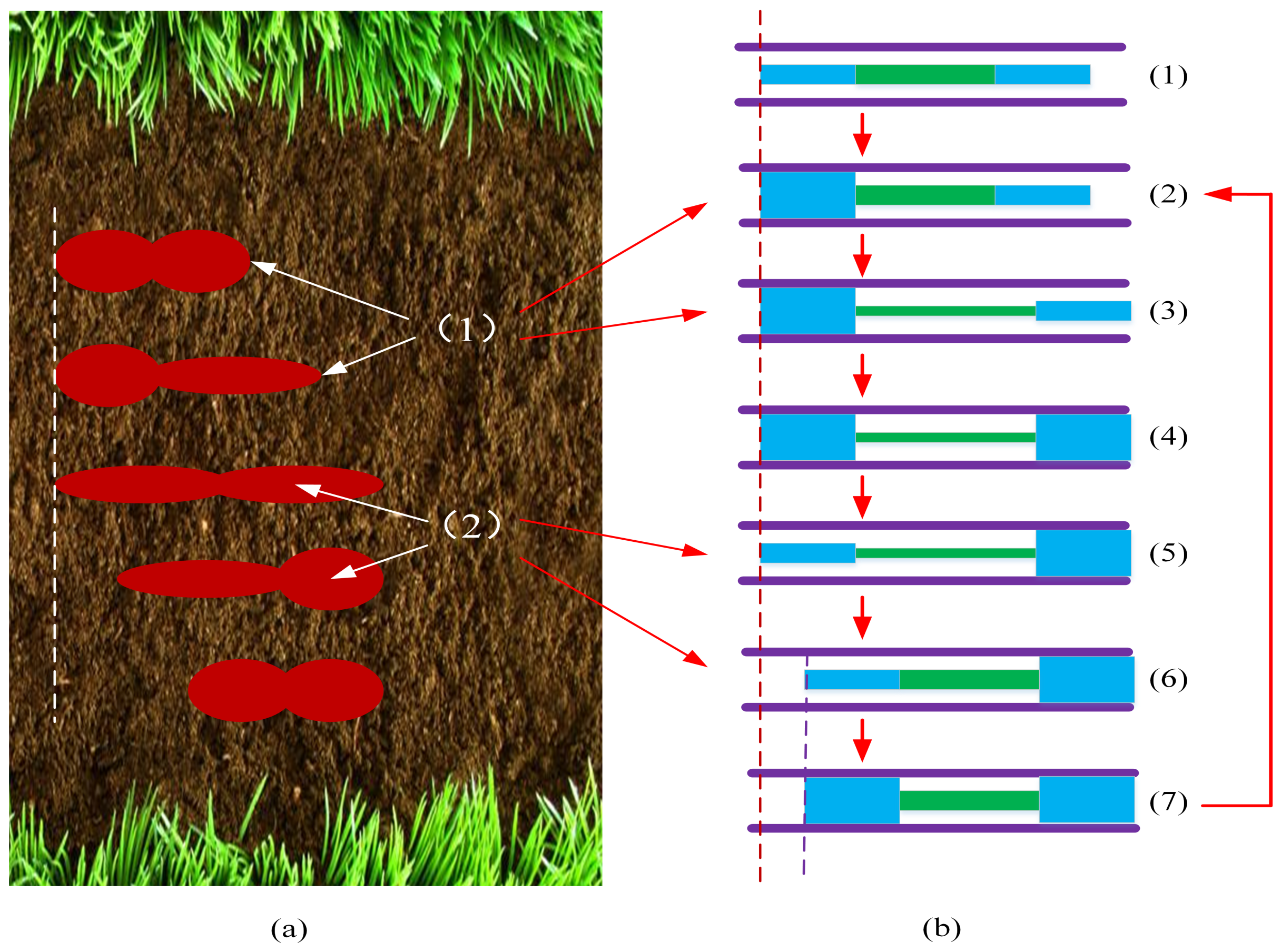

2.3. Locomotion Realization

2.4. Actuation Methods

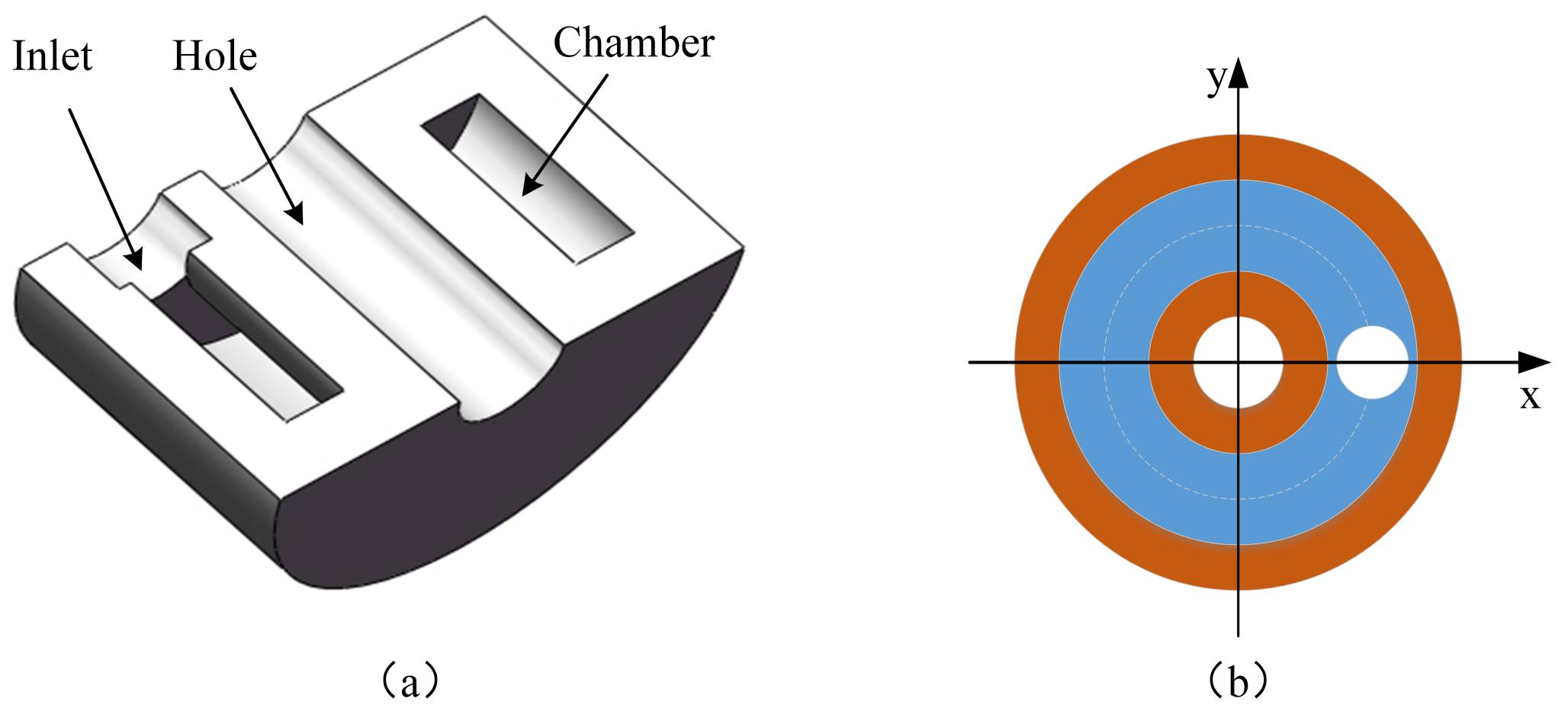

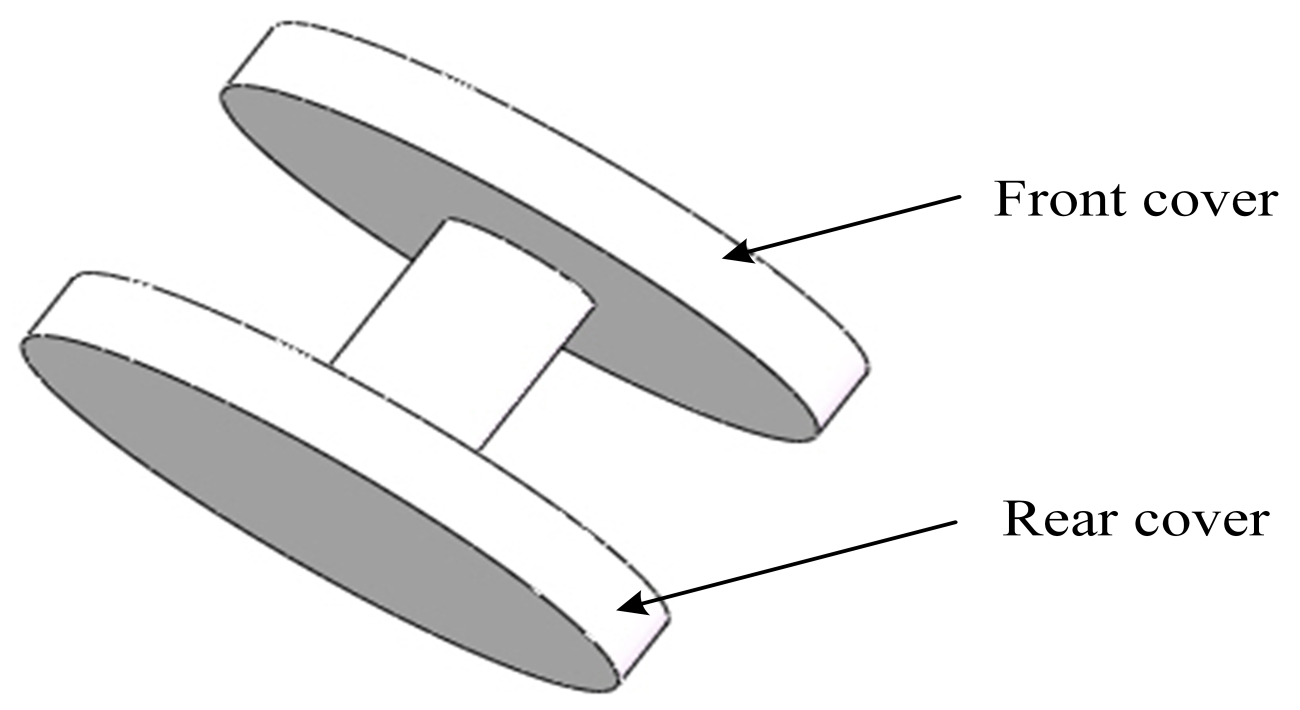

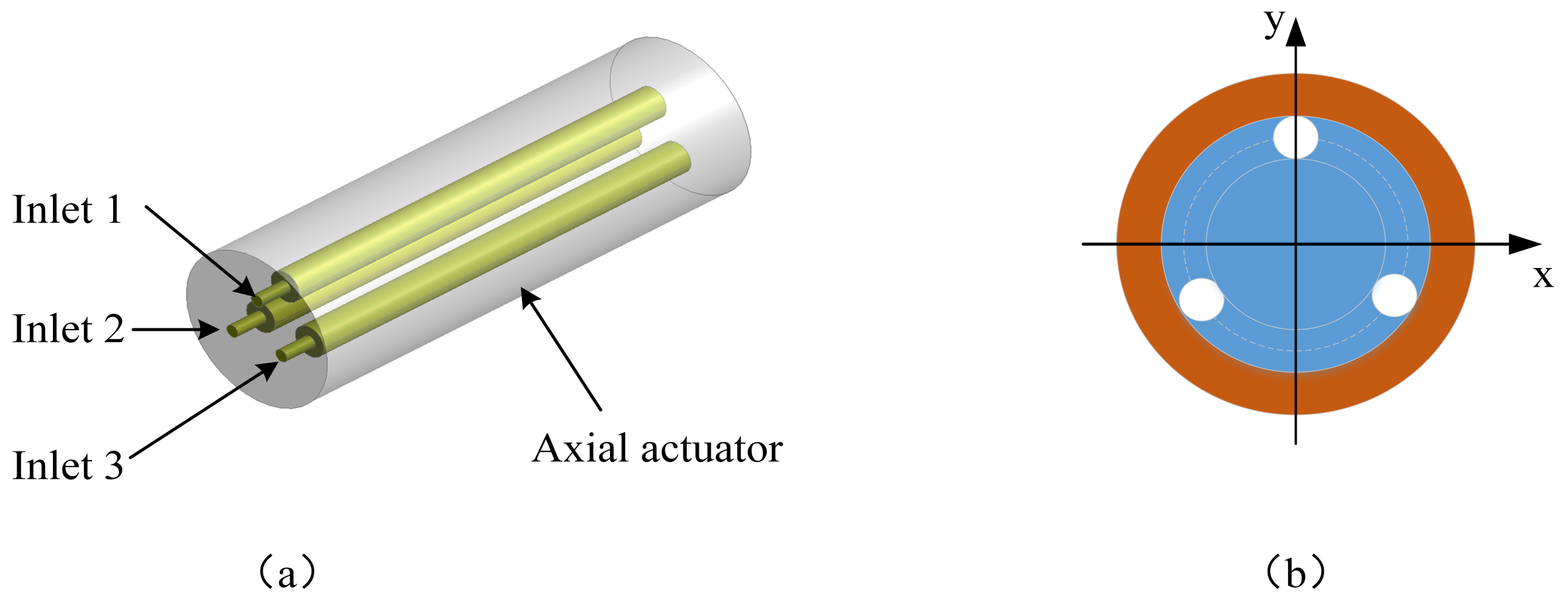

2.5. Structure Details of the Soft Actuators

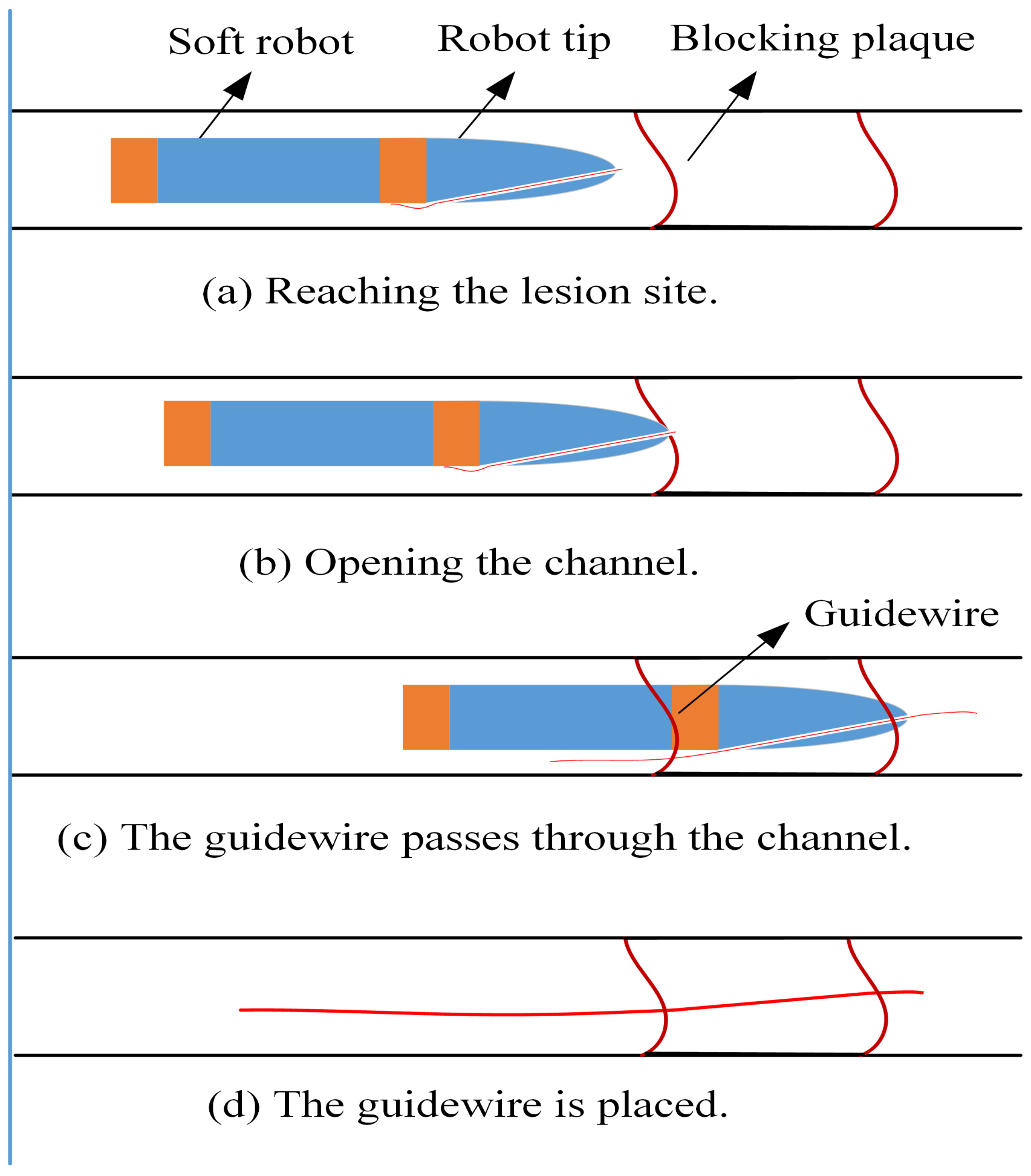

2.6. Opening Process

3. Structure Optimization

3.1. Constitutive Model of the Rubber

3.2. Structure Parameter Optimization of the Axial Actuator

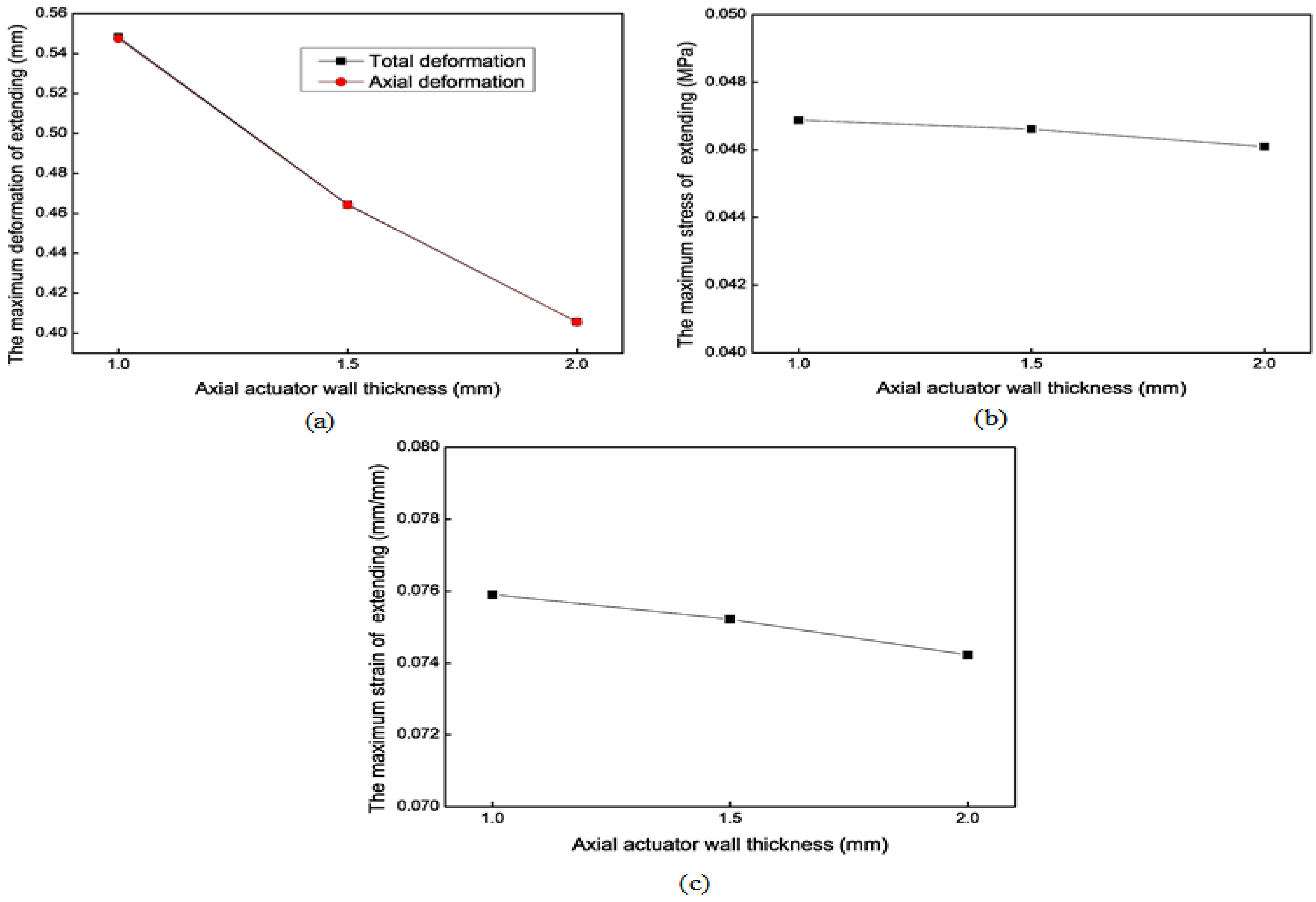

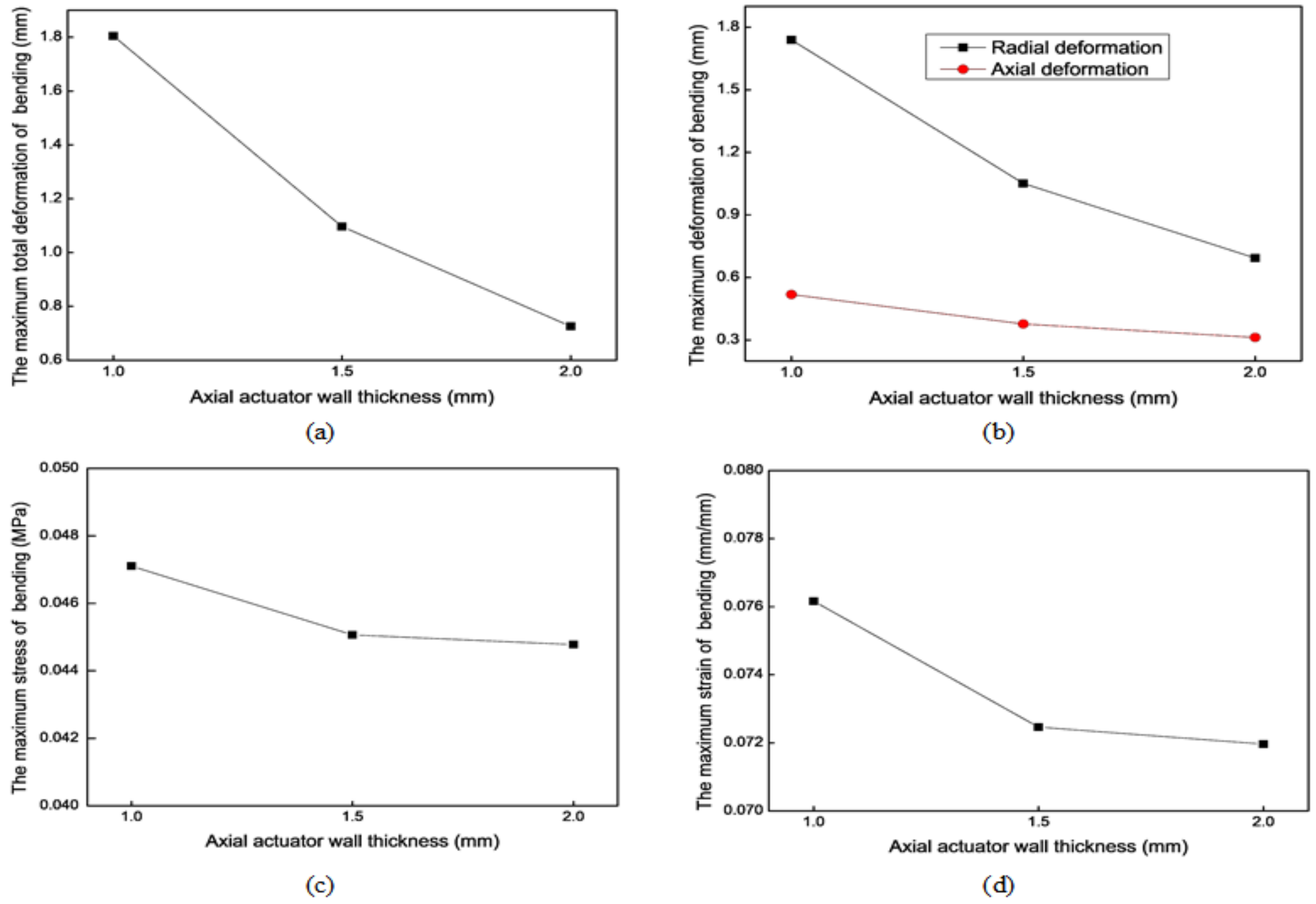

3.2.1. Wall Thickness (e)

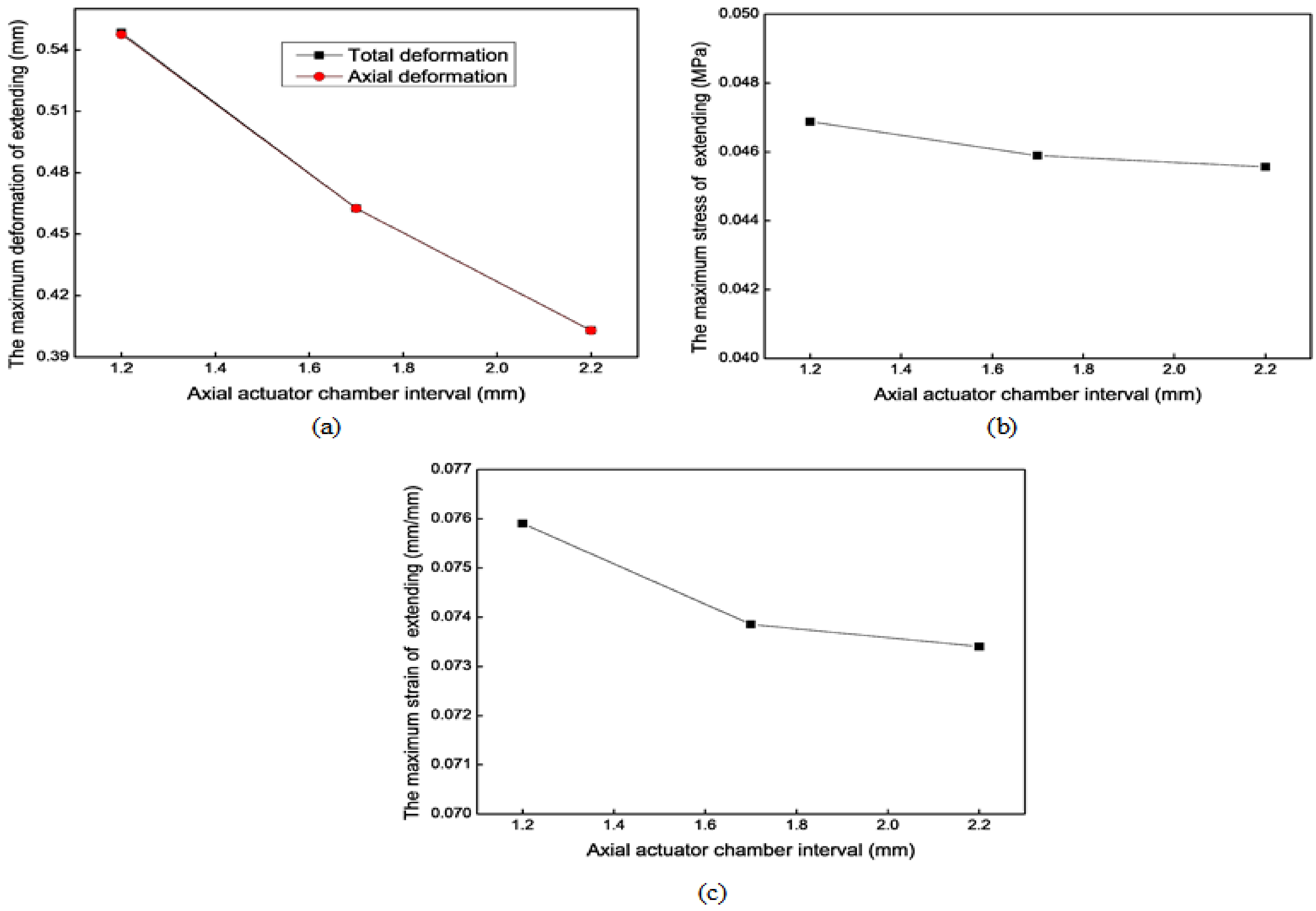

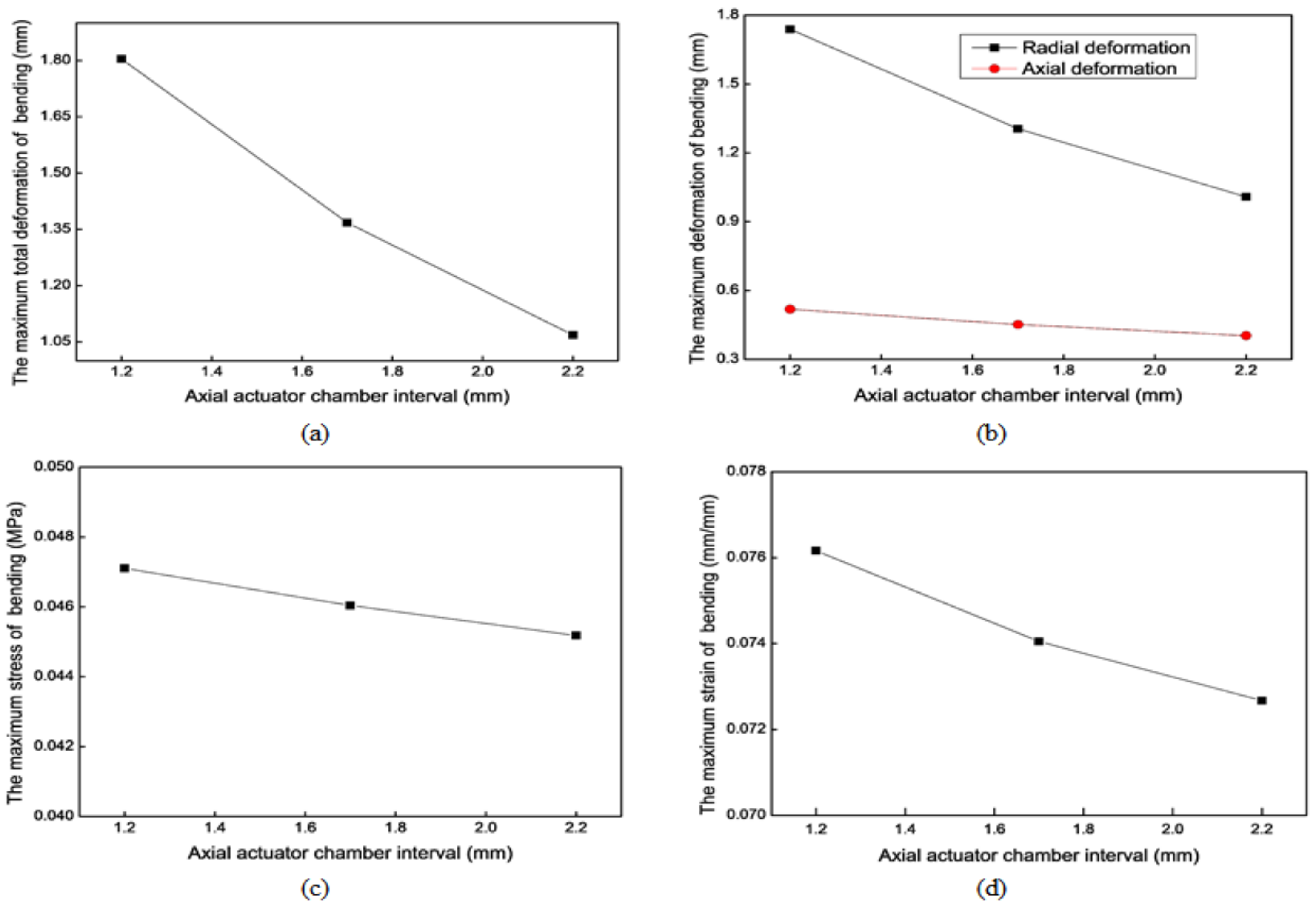

3.2.2. Chamber Interval (i)

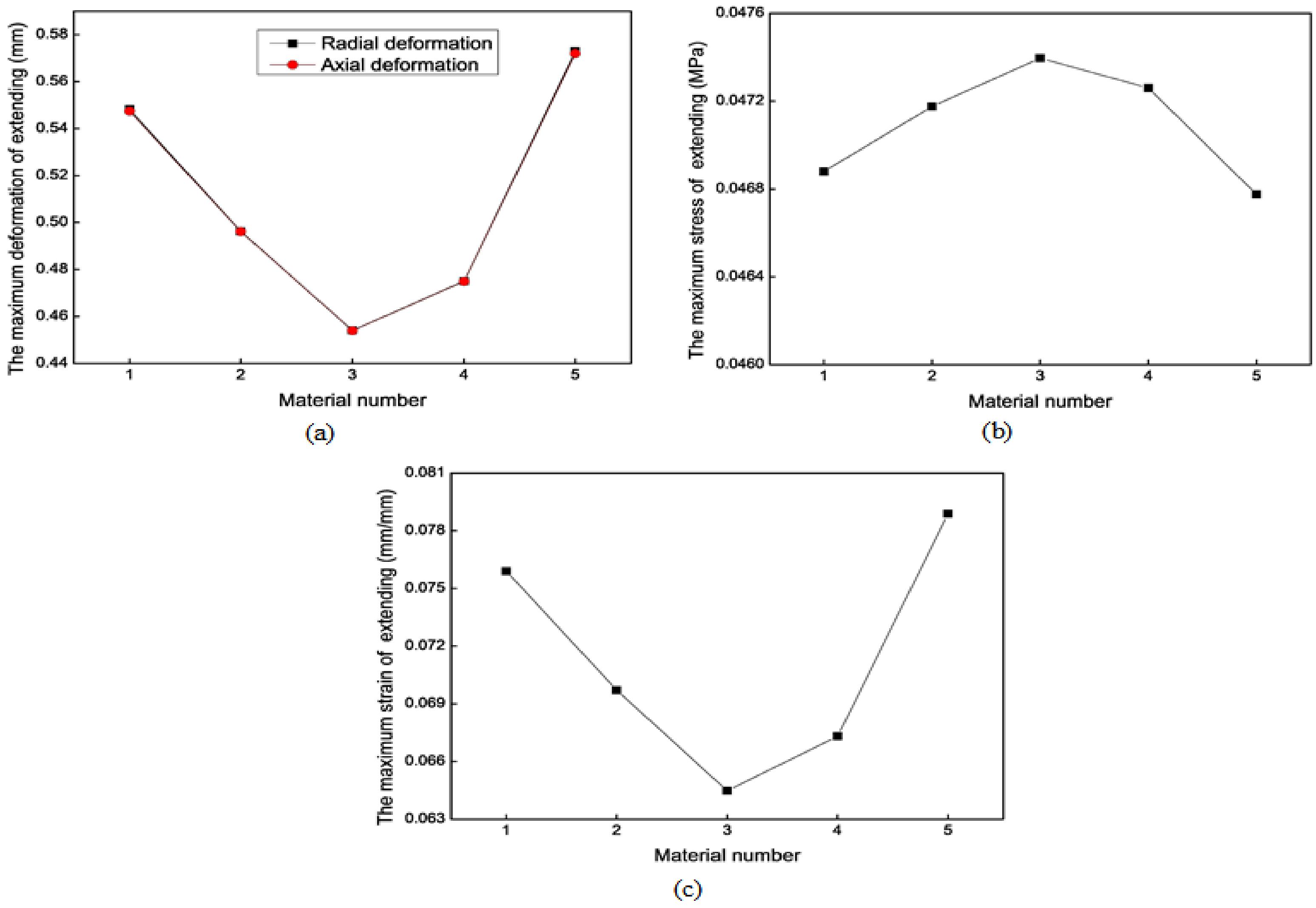

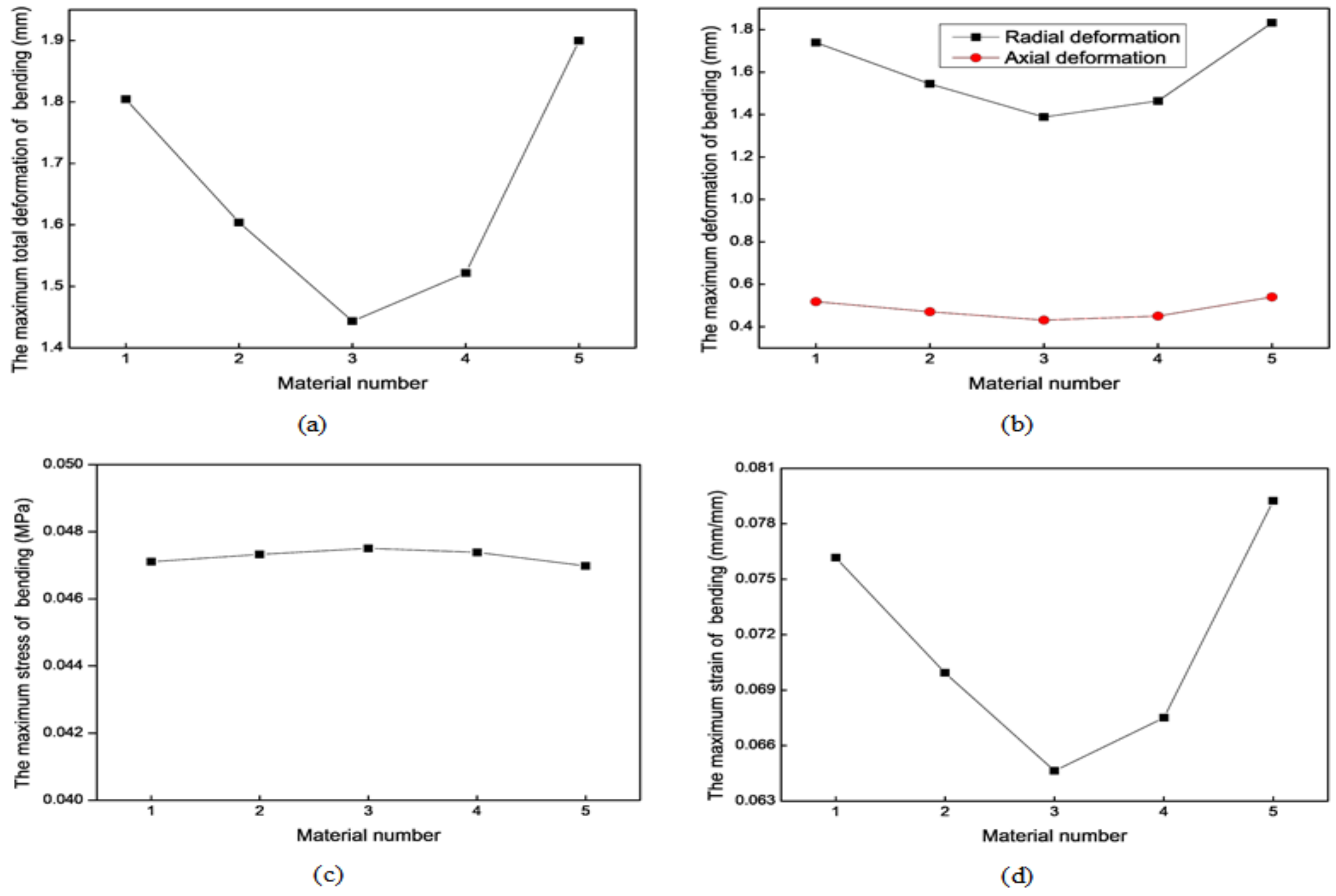

3.2.3. Material Properties

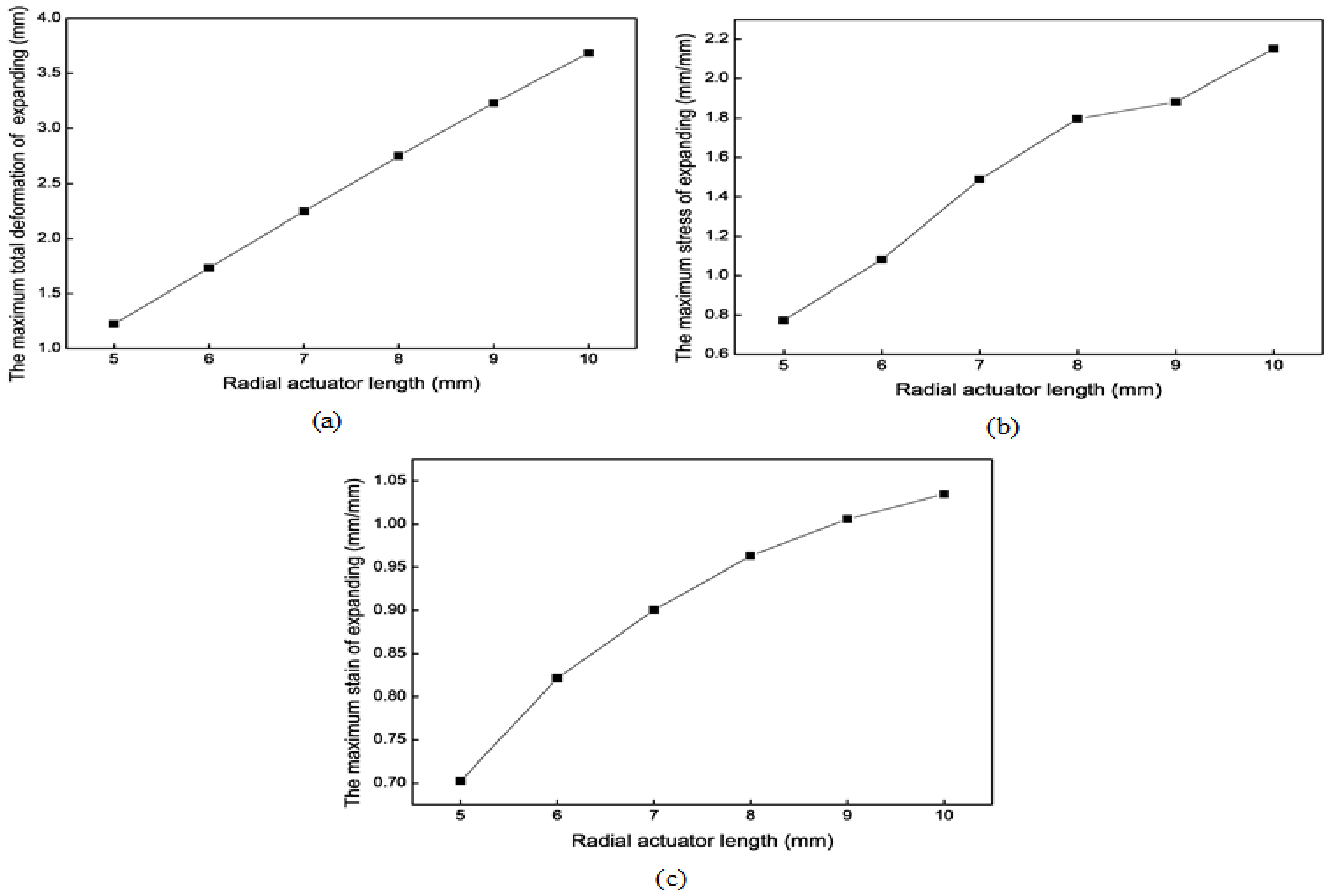

3.3. Structure Parameter Optimization for the Radial Actuator

4. Kinematic Models of the Soft Actuators

4.1. Selection of the Modeling Methods

4.2. FSI Simulation Settings

4.3. Simulation Results of the Axial Actuator

4.3.1. Flow Field

4.3.2. Axial Extension Results

4.3.3. Bending Results

4.4. Simulation Results of the Radial Actuator

4.4.1. Flow Field

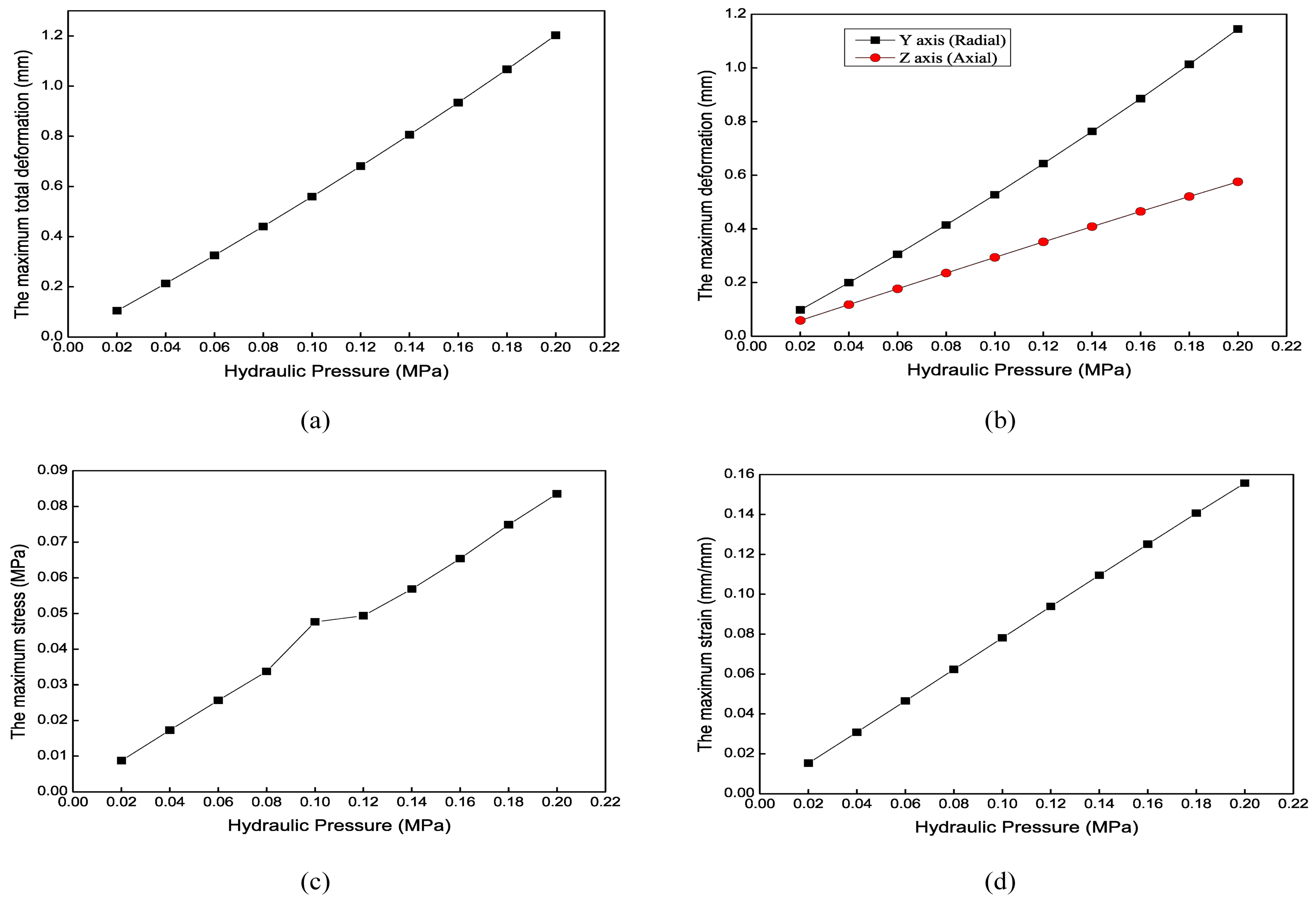

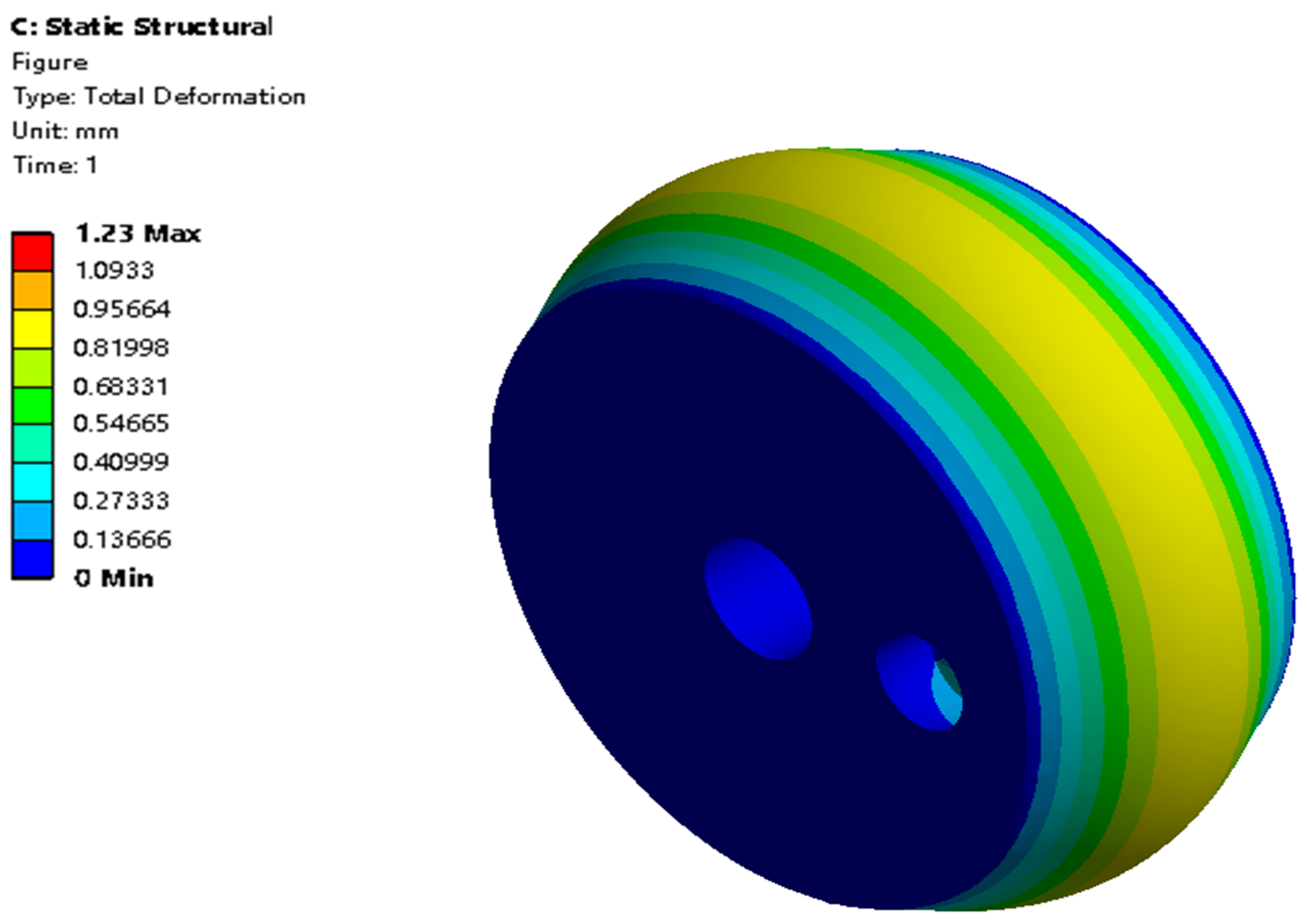

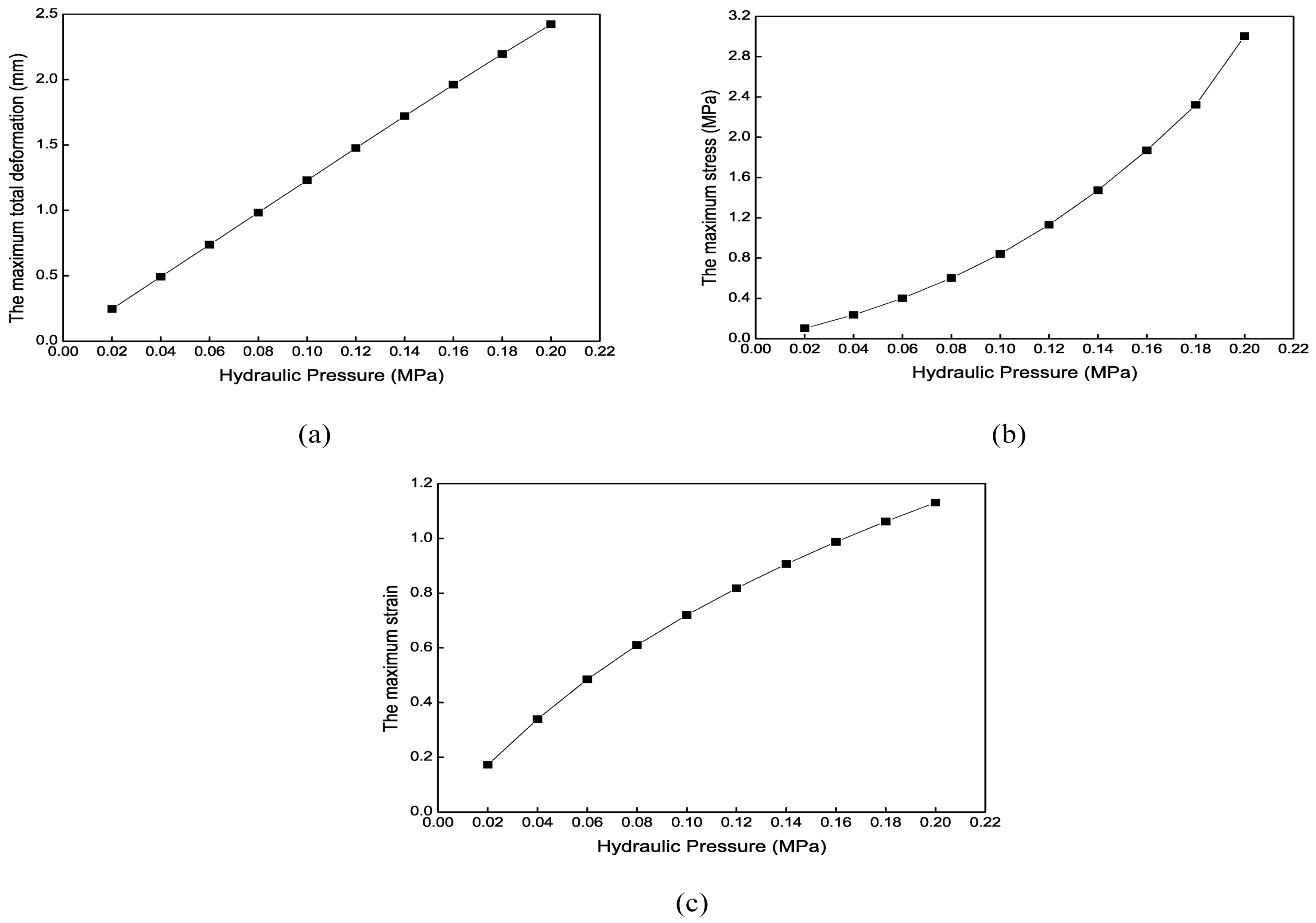

4.4.2. Radial Expansion Results

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CTO | chronic total occlusion |

| FSI | fluid–structure interaction |

| TIMI | thrombosis in myocardial infarction |

| PCI | percutaneous coronary intervention |

| CAD | coronary artery disease |

| PAD | peripheral artery disease |

| SFA | soft fluidic actuator |

| SMA | shape memory alloy |

| EAP | electroactive polymer |

| PCC | piecewise constant curvature |

References

- Dash, D.; Mody, R. Treatment of Chronic Total Occlusion; Academic Press: Cambridge, MA, USA, 2020; pp. 587–621. [Google Scholar]

- Fefer, P.; Knudtson, M.L.; Cheema, A.N.; Galbraith, P.D.; Osherov, A.B.; Yalonetsky, S.; Gannot, S.; Samuel, M.; Weisbrod, M.; Bierstone, D.; et al. Current perspectives on coronary chronic total occlusions: The Canadian Multicenter Chronic Total Occlusions Registry. J. Am. Coll. Cardiol. 2012, 59, 991–997. [Google Scholar] [CrossRef]

- Hamur, H.; Onk, O.A.; Vuruskan, E.; Duman, H.; Bakirci, E.M.; Kucuksu, Z.; Degirmenci, H.; Buyuklu, M.; Topal, E. Determinants of chronic total occlusion in patients with peripheral arterial occlusive disease. Angiology 2017, 68, 151–158. [Google Scholar] [CrossRef] [PubMed]

- Bhatt, H.; Janzer, S.; George, J.C. Crossing techniques and devices in femoropopliteal chronic total occlusion intervention. Cardiovasc. Revasc. Med. 2017, 18, 623–631. [Google Scholar] [CrossRef] [PubMed]

- Petrick, T.B.; Willard, S.N.; Keith, P.T.; Wahr, D.W. Devices and Methods for Crossing a Chronic Total Occlusion. U.S. Patent 7,763,012, 27 July 2010. [Google Scholar]

- Deckman, R.K.; Thai, E.; Aguilar, A.R.; Clark, B.J.; Salinas, S.; Francis, D.E.; Sparks, K.D. Catheter Systems and Methods for Crossing Vascular Occlusions. U.S. Patent 8,702,679, 22 April 2014. [Google Scholar]

- Selmon, M.; Milo, C.; Wynne, R.; Pai, S.; Dell, K.; Gresl, C.; Hansen, G.; Hill, E. Blunt Micro-Dissection Catheter. U.S. Patent App. 10/647,904, 22 April 2004. [Google Scholar]

- Banerjee, S.; Hadidi, O.; Mohammad, A.; Alsamarah, A.; Thomas, R.; Sarode, K.; Garg, P.; Baig, M.S.; Brilakis, E.S. Blunt microdissection for endovascular treatment of infrainguinal chronic total occlusions. J. Endovasc. Ther. 2014, 21, 71–78. [Google Scholar] [CrossRef] [PubMed]

- Hassan, A.E.; Nakao, M.; Katsumata, H.; Inagaki, Y.; Tanaka, K.; Otsuki, H.; Arashi, H.; Yamaguchi, J.; Hagiwara, N. Clinical outcomes after balloon angioplasty with crosser device for heavily calcified common femoral and popliteal artery disease. Heart Vessels 2021, 36, 1359–1365. [Google Scholar] [CrossRef] [PubMed]

- Vaquerizo, B.; Barros, A.; Pujadas, S.; Bajo, E.; Estrada, D.; Miranda-Guardiola, F.; Rigla, J.; Jiménez, M.; Cinca, J.; Serra, A. Bioresorbable everolimus-eluting vascular scaffold for the treatment of chronic total occlusions: CTO-ABSORB pilot study. Eurointerv. J. Eur. Collab. Work. Group Interv. Cardiol. Eur. Soc. Cardiol. 2015, 11, 555–563. [Google Scholar] [CrossRef] [PubMed]

- Pigott, J.P. Crossing CTOs with the Wildcat catheter. Endovasc. Today 2011, 1, 30–32. [Google Scholar]

- Wosik, J.; Shorrock, D.; Christopoulos, G.; Kotsia, A.; Rangan, B.V.; Roesle, M.; Maragkoydakis, S.; Abdullah, S.M.; Banerjee, S.; Brilakis, E.S. Systematic review of the BridgePoint system for crossing coronary and peripheral chronic total occlusions. J. Invasive Cardiol. 2015, 27, 269–276. [Google Scholar] [PubMed]

- Banerjee, S.; Sarode, K.; Das, T.; Hadidi, O.; Thomas, R.; Vinas, A.; Garg, P.; Mohammad, A.; Baig, M.S.; Shammas, N.W.; et al. Endovascular treatment of infrainguinal chronic total occlusions using the TruePath device: Features, handling, and 6-month outcomes. J. Endovasc. Ther. 2014, 21, 281–288. [Google Scholar] [CrossRef]

- Ai, X.; Gao, A.; Lin, Z.; He, C.; Chen, W. A multi-contact-aided continuum manipulator with anisotropic shapes. IEEE Robot. Autom. Lett. 2021, 6, 4560–4567. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Y.; Lueth, T.C. Optimization of stress distribution in tendon-driven continuum robots using fish-tail-inspired method. IEEE Robot. Autom. Lett. 2022, 7, 3380–3387. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Walsh, C.J. Soft robotic glove for combined assistance and at-home rehabilitation. Robot. Auton. Syst. 2015, 73, 135–143. [Google Scholar] [CrossRef]

- Justus, K.; Saurabh, S.; Bruchez, M.; Majidi, C.; LeDuc, P.; Tan, C. Integrating synthetic cells and flexible electronics for the control of bio-opto-fluidic materials. Biophys. J. 2014, 106, 617a–618a. [Google Scholar] [CrossRef]

- Wakimoto, S.; Suzumori, K. Fabrication and basic experiments of pneumatic multi-chamber rubber tube actuator for assisting colonoscope insertion. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 3260–3265. [Google Scholar]

- Heung, H.; Chiu, P.W.; Li, Z. Design and prototyping of a soft earthworm-like robot targeted for GI tract inspection. In Proceedings of the 2016 IEEE International Conference on Robotics and Biomimetics (ROBIO), Qingdao, China, 3–7 December 2016; pp. 497–502. [Google Scholar]

- Calderón, A.A.; Ugalde, J.C.; Zagal, J.C.; Pérez-Arancibia, N.O. Design, fabrication and control of a multi-material-multi-actuator soft robot inspired by burrowing worms. In Proceedings of the 2016 IEEE International Conference on Robotics and Biomimetics (ROBIO), Qingdao, China, 3–7 December 2016; pp. 31–38. [Google Scholar]

- Mark, A.G.; Palagi, S.; Qiu, T.; Fischer, P. Auxetic metamaterial simplifies soft robot design. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 4951–4956. [Google Scholar]

- Zhou, X.; Teng, Y.; Li, X. Development of a new pneumatic-driven earthworm-like soft robot. In Proceedings of the 2016 23rd International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Nanjing, China, 28–30 November 2016; pp. 1–5. [Google Scholar]

- Jung, K.; Koo, J.C.; Lee, Y.K.; Choi, H.R.; Nam, J.-d. Artificial annelid robot driven by soft actuators. Bioinspir. Biomimet. 2007, 2, S42. [Google Scholar] [CrossRef]

- Connolly, F.; Polygerinos, P.; Walsh, C.J.; Bertoldi, K. Mechanical programming of soft actuators by varying fiber angle. Soft Robot. 2015, 2, 26–32. [Google Scholar] [CrossRef]

- Shepherd, R.F.; Ilievski, F.; Choi, W.; Morin, S.A.; Stokes, A.A.; Mazzeo, A.D.; Chen, X.; Wang, M.; Whitesides, G.M. Multigait soft robot. Proc. Natl. Acad. Sci. USA 2011, 108, 20400–20403. [Google Scholar] [CrossRef]

- Renda, F.; Giorelli, M.; Calisti, M.; Cianchetti, M.; Laschi, C. Dynamic model of a multibending soft robot arm driven by cables. IEEE Trans. Robot. 2014, 30, 1109–1122. [Google Scholar] [CrossRef]

- Villoslada, A.; Flores, A.; Copaci, D.; Blanco, D.; Moreno, L. High-displacement flexible shape memory alloy actuator for soft wearable robots. Robot. Auton. Syst. 2015, 73, 91–101. [Google Scholar] [CrossRef]

- She, Y.; Chen, J.; Shi, H.; Su, H.J. Modeling and validation of a novel bending actuator for soft robotics applications. Soft Robot. 2016, 3, 71–81. [Google Scholar] [CrossRef]

- Amiri Moghadam, A.A.; Torabi, K.; Kaynak, A.; Zainal Alam, M.N.H.; Kouzani, A.; Mosadegh, B. Control-oriented modeling of a polymeric soft robot. Soft Robot. 2016, 3, 82–97. [Google Scholar] [CrossRef]

- Yeoh, O.H. Characterization of elastic properties of carbon-black-filled rubber vulcanizates. Rubber Chem. Technol. 1990, 63, 792–805. [Google Scholar] [CrossRef]

- Xavier, M.S.; Fleming, A.J.; Yong, Y.K. Finite element modeling of soft fluidic actuators: Overview and recent developments. Adv. Intell. Syst. 2021, 3, 2000187. [Google Scholar] [CrossRef]

- Jones, B.A.; Walker, I.D. Kinematics for multisection continuum robots. IEEE Trans. Robot. 2006, 22, 43–55. [Google Scholar] [CrossRef]

- Neppalli, S.; Csencsits, M.A.; Jones, B.A.; Walker, I.D. Closed-form inverse kinematics for continuum manipulators. Adv. Robot. 2009, 23, 2077–2091. [Google Scholar] [CrossRef]

- Webster, R.J., III; Jones, B.A. Design and kinematic modeling of constant curvature continuum robots: A review. Int. J. Robot. Res. 2010, 29, 1661–1683. [Google Scholar] [CrossRef]

- Chen, L.; Yang, C.; Hua, W.; Branson, D.T.; Dai, J.S.; Kang, R. Design and modeling of a soft robotic surface with hyperelastic material. Mech. Mach. Theory 2018, 130, 109–122. [Google Scholar] [CrossRef]

| Type | Action | Radial | Axial |

|---|---|---|---|

| Circular muscles | Contraction | Shrink | Extend |

| Circular muscles | Relaxation | Expand | Shorten |

| Longitudinal muscles | Contraction | Expand | Shorten |

| Longitudinal muscles | Relaxation | Shrink | Extend |

| Radial actuators | Pumping in | Expand | Invariant |

| Radial actuators | Pumping out | Shrink | Invariant |

| Axial actuators | Pumping in | Shrink | Extend |

| Axial actuators | Pumping out | Expand | Shorten |

| Material Number | (MPa) | (MPa) |

|---|---|---|

| 1 | 0.1 | 0.02 |

| 2 | 0.11 | 0.02 |

| 3 | 0.12 | 0.02 |

| 4 | 0.11488 | 0.001232 |

| 5 | 0.096 | 0.0095 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, L.-W.; Xie, X.-L.; Zhou, X.-H.; Liu, S.-Q.; Hou, Z.-G. Design, Optimization, and Modeling of a Hydraulic Soft Robot for Chronic Total Occlusions. Biomimetics 2024, 9, 163. https://doi.org/10.3390/biomimetics9030163

Meng L-W, Xie X-L, Zhou X-H, Liu S-Q, Hou Z-G. Design, Optimization, and Modeling of a Hydraulic Soft Robot for Chronic Total Occlusions. Biomimetics. 2024; 9(3):163. https://doi.org/10.3390/biomimetics9030163

Chicago/Turabian StyleMeng, Ling-Wu, Xiao-Liang Xie, Xiao-Hu Zhou, Shi-Qi Liu, and Zeng-Guang Hou. 2024. "Design, Optimization, and Modeling of a Hydraulic Soft Robot for Chronic Total Occlusions" Biomimetics 9, no. 3: 163. https://doi.org/10.3390/biomimetics9030163

APA StyleMeng, L.-W., Xie, X.-L., Zhou, X.-H., Liu, S.-Q., & Hou, Z.-G. (2024). Design, Optimization, and Modeling of a Hydraulic Soft Robot for Chronic Total Occlusions. Biomimetics, 9(3), 163. https://doi.org/10.3390/biomimetics9030163