Development of a Variable-Configuration Bionic Robotic Fish

Abstract

:1. Introduction

2. Structural Design of Variable-Configuration Robotic Fish

2.1. Structural Design of the Main Configuration of the Cownose Ray

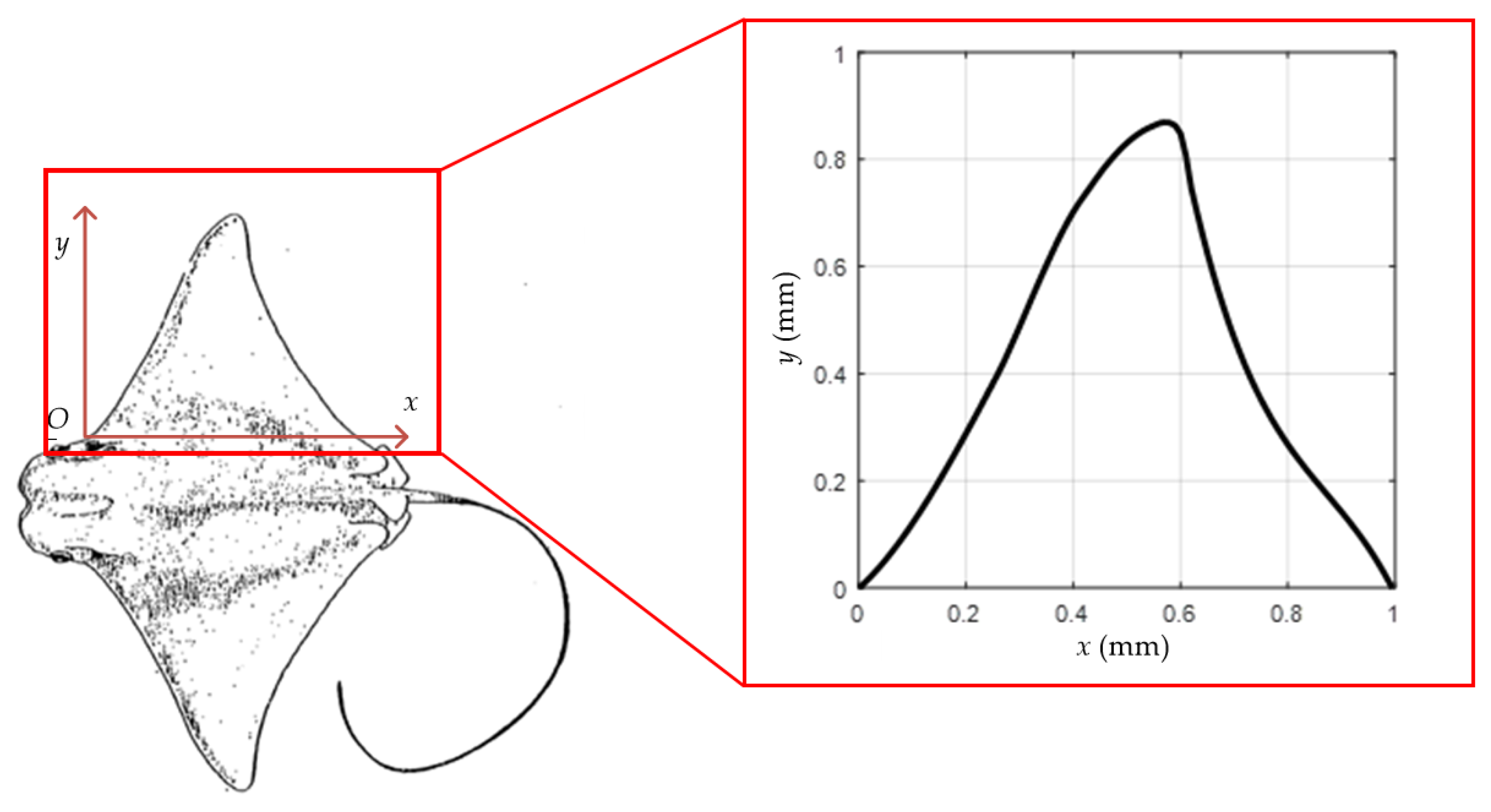

2.1.1. Biological Characteristics of the Cownose Ray

2.1.2. Physical Model and Motion Analysis of the Cownose Ray

2.2. Structural Design of the Secondary Configuration of the Caranx melampygus

2.2.1. Biological Characteristics of the Caranx melampygus

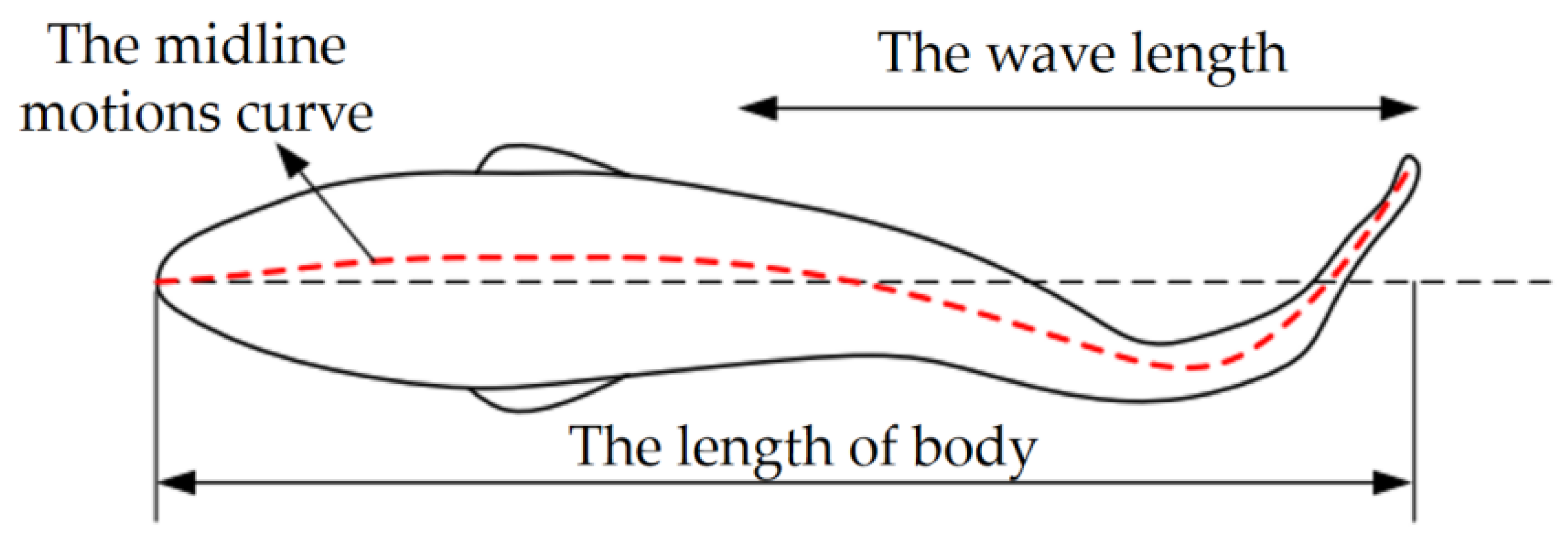

2.2.2. Physical Model and Motion Analysis of the Caranx melampygus

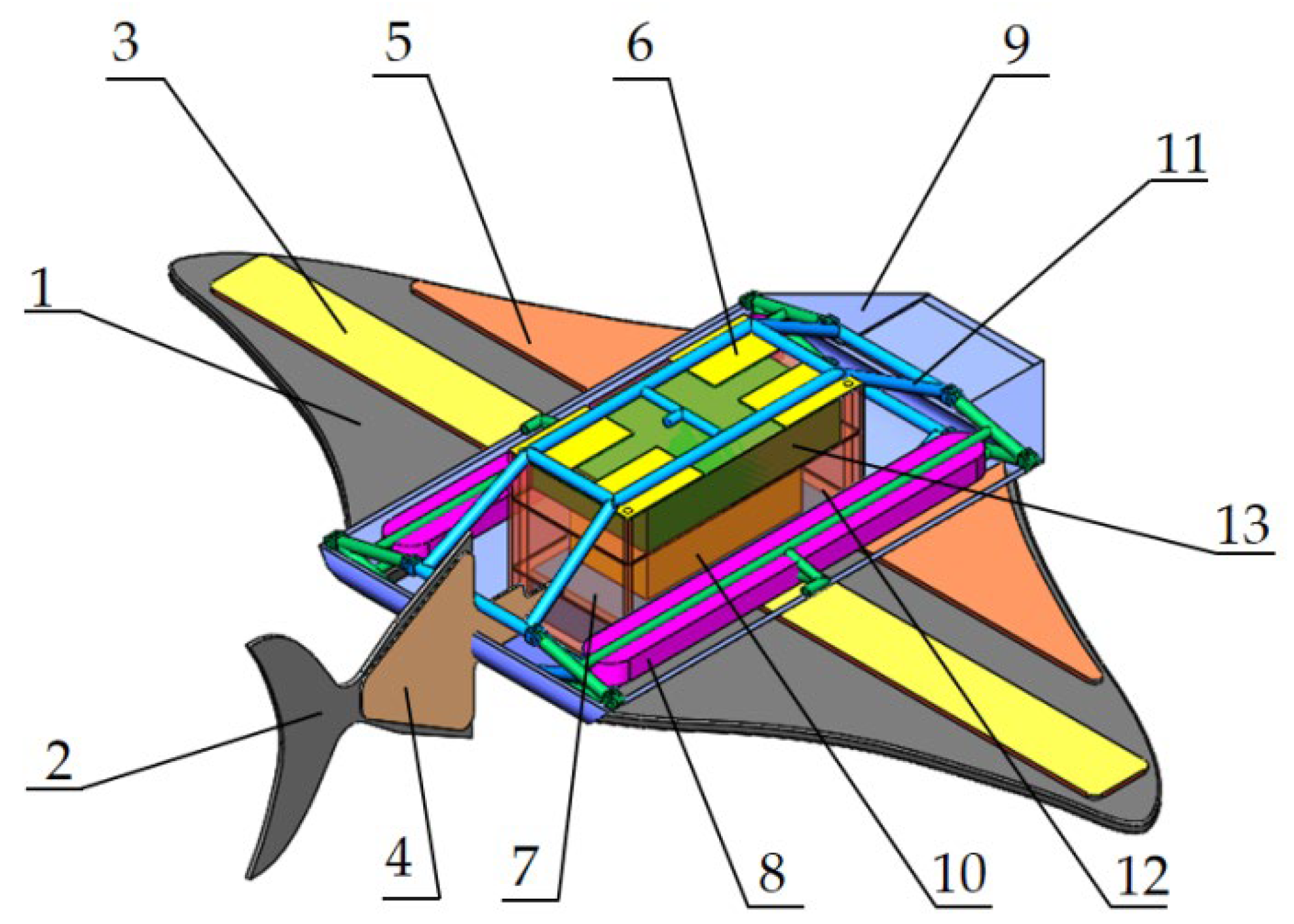

2.3. Overall Design of Variable-Configuration Bionic Robotic Fish

2.3.1. Overall Design of the Structure

2.3.2. Overall Design of the Structure

2.3.3. Design of the Drive Module

3. Design of Motion Control System for Variable-Configuration Robotic Fish

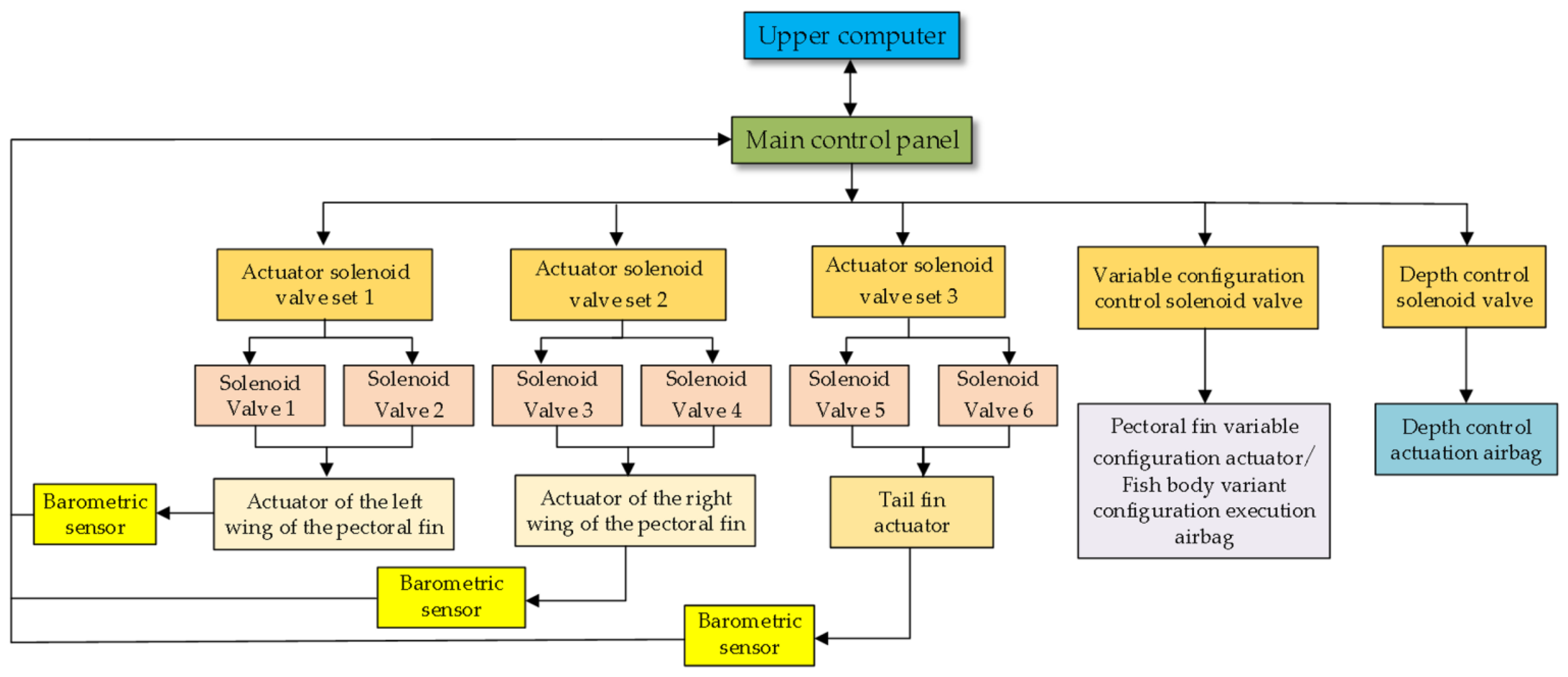

3.1. Overall Solution and Design of the Control System

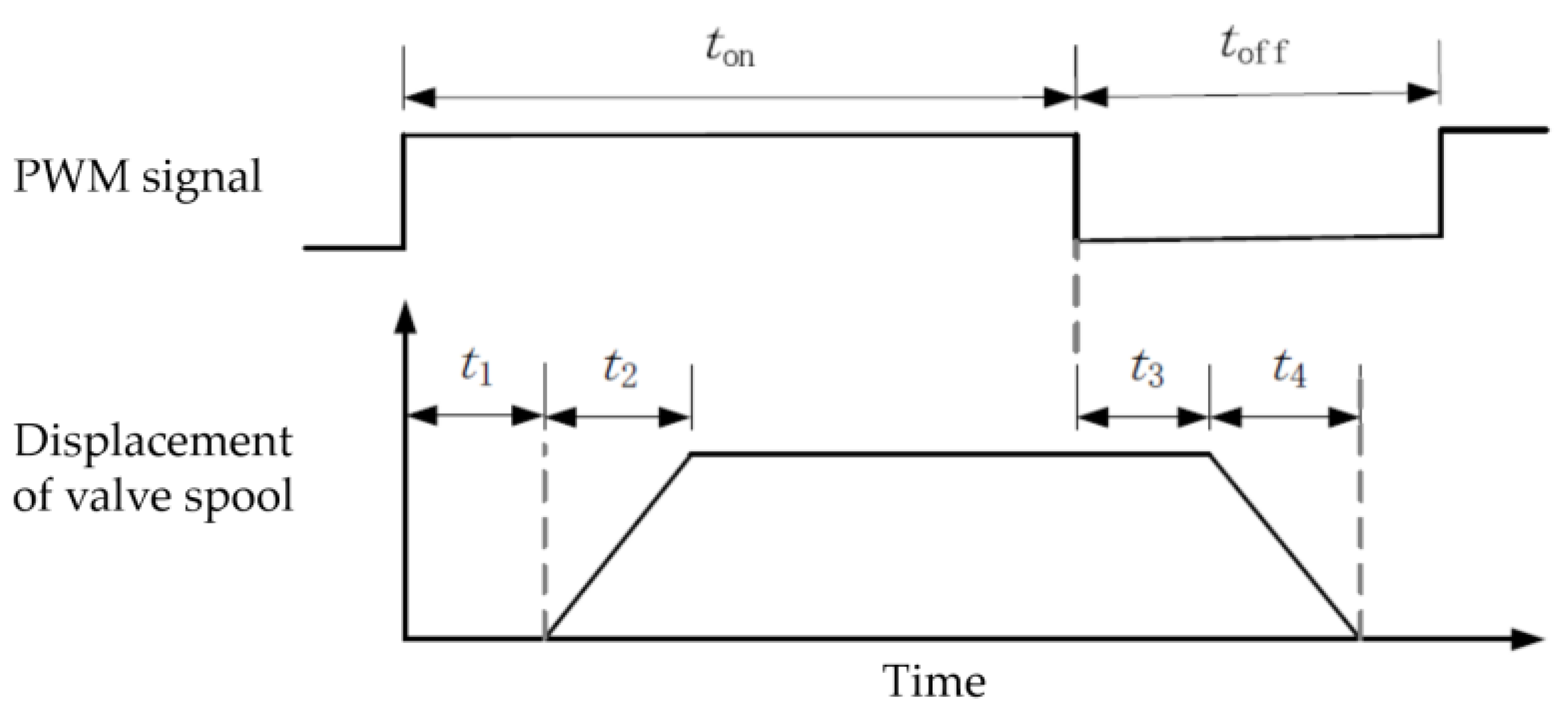

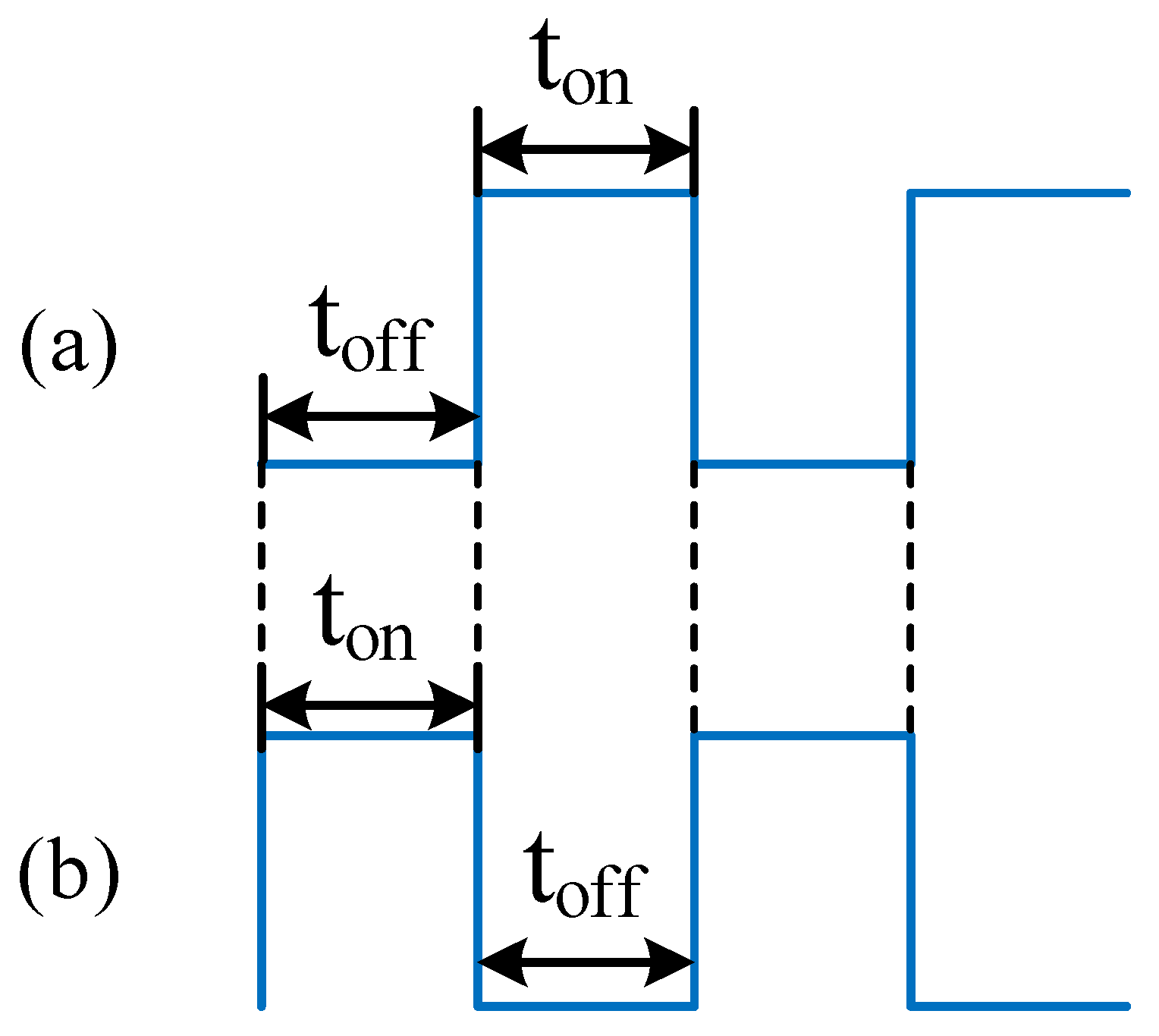

3.2. Motion Control of Variable-Configuration Robotic Fish

4. Underwater Experiments and Discussion of Variable-Configuration Robotic Fish

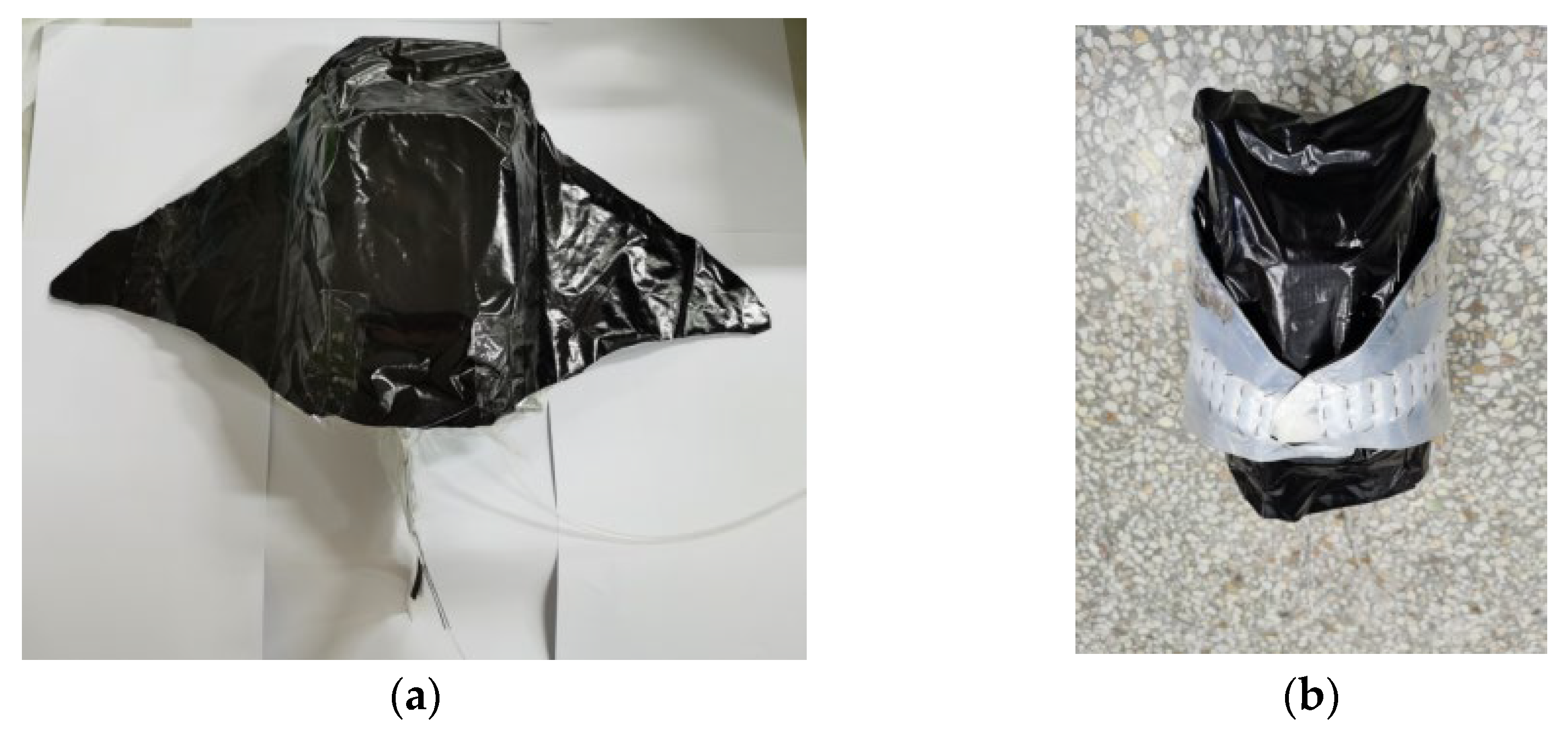

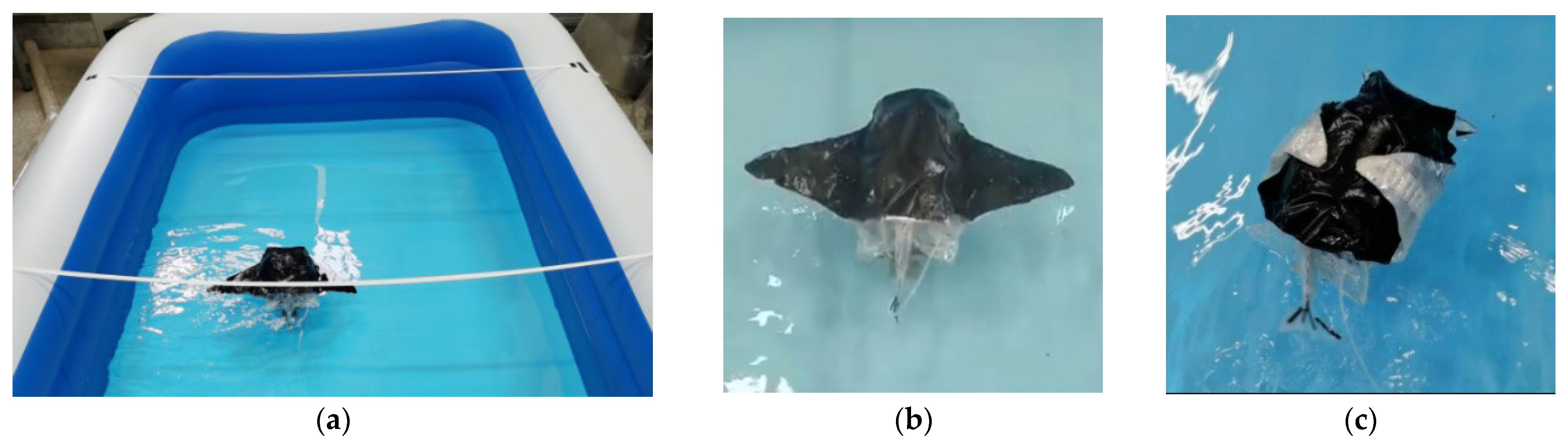

4.1. Construction of the Underwater Test Platform

4.2. Underwater Performance Test of the Main Configuration of the Cownose Ray

4.2.1. Straight Line Propulsion Test

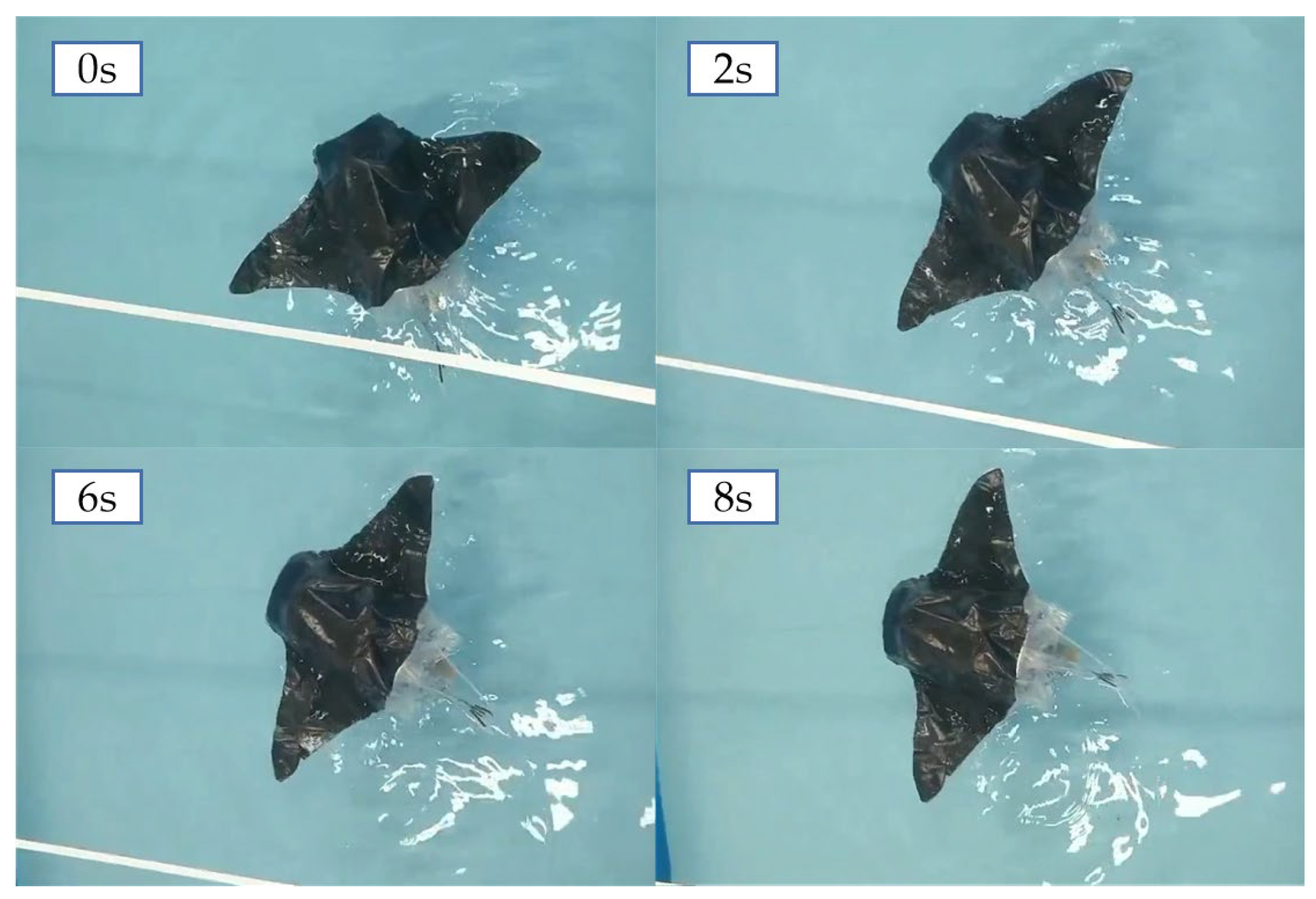

4.2.2. Turning Performance Test

4.3. Underwater Performance Tests of the Secondary Configuration of the Caranx melampygus

4.3.1. Straight Line Propulsion Test

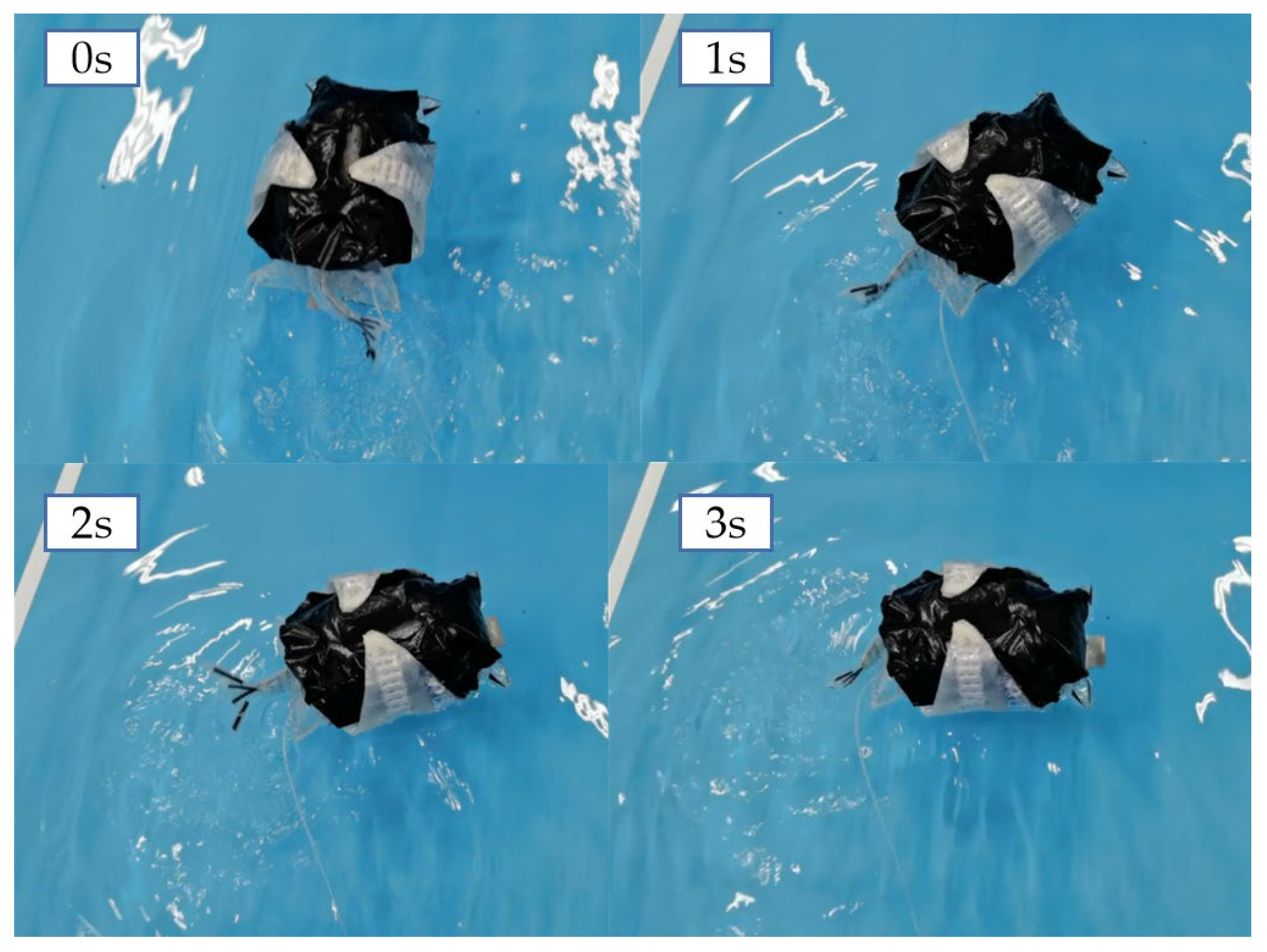

4.3.2. Turning Performance Test

4.4. Experiment Summary and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, S.; Zhao, Q.; Ding, M.; Zhang, M.; Zhao, L.; Huang, C.; Zhang, J.; Liang, X.; Yuan, J.; Wang, X.; et al. A Review of Robotic Fish Based on Smart Materials. Biomimetics 2023, 8, 227. [Google Scholar] [CrossRef] [PubMed]

- Duraisamy, P.; Kumar Sidharthan, R.; Nagarajan Santhanakrishnan, M. Design, modeling, and control of biomimetic fish robot: A review. J. Bionic Eng. 2019, 16, 967–993. [Google Scholar] [CrossRef]

- Yan, Z.; Yang, H.; Zhang, W.; Lin, F.; Gong, Q.; Zhang, Y. Bionic Fish Tail Design and Trajectory Tracking Control. Ocean Eng. 2022, 257, 111659. [Google Scholar] [CrossRef]

- Katzschmann, R.K.; DelPreto, J.; MacCurdy, R.; Rus, D. Exploration of underwater life with an acoustically controlled soft robotic fish. Sci. Robot. 2018, 3, eaar3449. [Google Scholar] [CrossRef] [PubMed]

- Marchese, A.D.; Katzschmann, R.K.; Rus, D. A recipe for soft fluidic elastomer robots. Soft Robot. 2015, 2, 7–25. [Google Scholar] [CrossRef]

- Xia, Q.; Li, H.; Song, N.; Wu, Z.; Wang, X.; Sun, X.; Zhang, S.; Yang, C. Research on Flexible Collapsible Fluid-Driven Bionic Robotic Fish. Ocean Eng. 2023, 276, 114203. [Google Scholar] [CrossRef]

- Chen, Z.; Hou, P.; Ye, Z. Robotic fish propelled by a servo motor and ionic polymer-metal composite hybrid tail. J. Dyn. Syst. Meas. Control 2019, 141, 071001. [Google Scholar] [CrossRef]

- Cai, Y.; Bi, S.; Li, G.; Hildre, H.P.; Zhang, H. From natural complexity to biomimetic simplification: The realization of bionic fish inspired by the cownose ray. IEEE Robot. Autom. Mag. 2018, 26, 27–38. [Google Scholar] [CrossRef]

- Cai, Y.; Chen, L.; Bi, S.; Li, G.; Zhang, H. Bionic flapping pectoral fin with controllable spatial deformation. J. Bionic Eng. 2019, 16, 916–930. [Google Scholar] [CrossRef]

- Zhang, C.W.; Zou, W.; Yu, H.C.; Hao, X.P.; Li, G.; Li, T.; Yang, W.; Wu, Z.L.; Zheng, Q. Manta Ray Inspired Soft Robot Fish with Tough Hydrogels as Structural Elements. ACS Appl. Mater. Interfaces 2022, 14, 52430–52439. [Google Scholar] [CrossRef]

- Bianchi, G.; Maffi, L.; Tealdi, M.; Cinquemani, S. A Bioinspired Cownose Ray Robot for Seabed Exploration. Biomimetics 2023, 8, 30. [Google Scholar] [CrossRef]

- Yu, J.Z.; Chen, E.K.; Wang, S.; Tan, M. Research evolution and analysis of biomimetic robot fish. Control. Theory Appl. Accept. Chin. 2003, 20, 485–491. [Google Scholar]

- Lindsey, C.C. Fish Physiology Vol. VII Locomotion. In Form, Function and Locomotory Habits; Academic Press: Cambridge, MA, USA, 1978; pp. 12–17. [Google Scholar]

- Gao, S. Structure Design and Experimental Research of Biomimetic Rays. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2014. [Google Scholar]

- Wang, A.; Liu, G.; Wang, X.; Fu, B. Development and Analysis of Body and/or Caudal Fin Biomimetic Robot Fish. J. Mech. Eng. 2016, 52, 137–146. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, K.; Yan, Y. Research Status and Development Trend of Bionic Robot Fish with BCF Propulsion Model. Small Spec. Electr. Mach. 2016, 44, 75–80. [Google Scholar]

- Fan, Z.; Wang, Y.; Liu, K.; Zhao, D. Modeling and Experimental Research of Integrating Propulsion Mechanism of Pectoral Fin’s Fluctuation and Swing for the Biomimetic Robotic Fish. J. Unmanned Undersea Syst. 2019, 27, 166–173. [Google Scholar]

- Tan, J.; Wang, Y.; Gu, B.; Zhao, D. Research Advances and Analysis of Biomimetic Robot Fish Propelled by Undulating Pectoral Fin. Small Spec. Electr. Mach. 2014, 42, 6. [Google Scholar] [CrossRef]

- Rosenberger, L.J. Pectoral fin locomotion in batoid fishes: Undulation versus oscillation. J. Exp. Biol. 2001, 204, 379–394. [Google Scholar] [CrossRef]

- Heine, C.E. Mechanics of Flapping Fin Locomotion in the Cownose Ray, Rhinoptera bonasus (Elasmobranchii: Myliobatidae); Duke University: Durham, NC, USA, 1992; ISBN 9798207621203. [Google Scholar]

- Yang, S. Hydrodynamic Analysis of Cownose Ray’s Swimming and Research of Bionic Robotic Fish. Ph.D. Thesis, National University of Defense Technology, Changsha, China, 2010. [Google Scholar]

- Zhu, J. Research on the Tail Driving System of a Bionic Carangiform Fish Based on Linear Hypocycloid. Master’s Thesis, Jiangsu University of Science and Technology, Zhenjiang, China, 2010. [Google Scholar]

- Chen, W.; Xia, D.; Liu, J.; Shi, S. Comparison of Swimming Mechanism of Carangiform and Thunniform Fishlike Robot during Self-propulsion. J. Mech. Eng. 2010, 46, 1–7+15. [Google Scholar] [CrossRef]

- Westneat, M.W.; Hoese, W.; Pell, C.A.; Wainwright, S.A. The horizontal septum: Mechanisms of force transfer in locomotion of scombrid fishes (Scombridae, Perciformes). J. Morphol. 1993, 217, 183–204. [Google Scholar] [CrossRef]

- Cui, Z. Research on the Composite Undulation Pattern and Propulsive Performance of Swimming Fish Propelled by Body/Caudal Fin. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2017. [Google Scholar]

- Zhong, Y.; Li, Z.; Du, R. A Novel Robot Fish with Wire-Driven Active Body and Compliant Tail. IEEE/ASME Trans. Mechatron. 2017, 22, 1633–1643. [Google Scholar] [CrossRef]

- Wang, Q.; Hong, Z.; Zhong, Y. Learn to Swim: Online Motion Control of an Underactuated Robotic Eel Based on Deep Reinforcement Learning. Biomim. Intell. Robot. 2022, 2, 100066. [Google Scholar] [CrossRef]

- Wan, S. Design of the Power System of Wearable and Flexible Lower-Limb Exoskeleton. Master’s Thesis, Southeastern University, Lakeland, FL, USA, 2017. [Google Scholar]

- Suebsaiprom, P.; Lin, C.; Engkaninan, A. Undulatory locomotion and effective propulsion for fish-inspired robot. Control. Eng. Pract. 2017, 58, 66–77. [Google Scholar] [CrossRef]

- Verma, S.; Xu, J. Analytic modeling for precise speed tracking of multilink robotic fish. IEEE Trans. Ind. Electron. 2017, 65, 5665–5672. [Google Scholar] [CrossRef]

- Xia, D.; Chen, W.; Wu, Z.; Xu, F.; Li, L. Research on Hydrodynamics of Carangiform Mode Robotic Fish Swimming under Self-propulsion. J. Mech. Eng. 2013, 49, 54–61. [Google Scholar] [CrossRef]

- Suzuki, H.; Kato, N.; Suzumori, K. Load characteristics of mechanical pectoral fin. Exp. Fluids 2008, 44, 759–771. [Google Scholar] [CrossRef]

| Parameters | Main Configuration | Secondary Configuration |

|---|---|---|

| Width of the body plate | 50 cm | 12 cm |

| Height of the body plate | 9 cm | 16 cm |

| Maximum propulsion speed | 38.42 mm/s | 43.05 mm/s |

| Turning angle speed | 5.6°/s | 30°/s |

| Turning radius | 36 cm | 15 cm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, D.; Li, Y.; Li, Z.; Tian, M.; Wang, X. Development of a Variable-Configuration Bionic Robotic Fish. Biomimetics 2023, 8, 407. https://doi.org/10.3390/biomimetics8050407

Xia D, Li Y, Li Z, Tian M, Wang X. Development of a Variable-Configuration Bionic Robotic Fish. Biomimetics. 2023; 8(5):407. https://doi.org/10.3390/biomimetics8050407

Chicago/Turabian StyleXia, Dan, Yuyao Li, Zhihan Li, Mengqian Tian, and Xingsong Wang. 2023. "Development of a Variable-Configuration Bionic Robotic Fish" Biomimetics 8, no. 5: 407. https://doi.org/10.3390/biomimetics8050407

APA StyleXia, D., Li, Y., Li, Z., Tian, M., & Wang, X. (2023). Development of a Variable-Configuration Bionic Robotic Fish. Biomimetics, 8(5), 407. https://doi.org/10.3390/biomimetics8050407