Abstract

The aim of this article is to propose a bio-inspired morphological classification for soft robots based on an extended review process. The morphology of living beings that inspire soft robotics was analyzed; we found coincidences between animal kingdom morphological structures and soft robot structures. A classification is proposed and depicted through experiments. Additionally, many soft robot platforms present in the literature are classified using it. This classification allows for order and coherence in the area of soft robotics and provides enough freedom to expand soft robotics research.

1. Introduction

Since the inception of the robotics discipline, it has drawn massive inspiration from biology, imitating animal capabilities to provide robotic systems with new forms of actuation and sensing, as well as new modeling and control techniques [1].

The amazing animal kingdom, through evolution, has endowed animals with interesting and special capacities for survival. Their continuous adaptation to a changing environment gives them advantages in locomotion, cognition, control, and information processing. For example, a mouse or an octopus can pass through a small hole by squeezing its deformable body through it; it is capable of maneuvering through confined spaces without suffering pressure or stress concentration damage. Another remarkable example of extreme capabilities involves froghoppers, which are able to jump up to 70 vertically, accelerating at 4.000 m/s2 and experiencing over 400 g—unit of acceleration, without damage and with low energy consumption.

All living beings, including humans, are mainly composed of soft and flexible materials, such as muscles, skin, and even bones. In contrast, traditional robots have been developed with hard actuators and rigid structures, which are effective mainly in industrial environments and applications. However, in unstructured environments where robots need to interact with humans or animals, they pose risks and limitations due to differences in structural softness and actuator elasticity [2].

Soft robotics is based on mimicking the structures, sensors, and actuators that are present in animals, such as worms, snakes, jellyfish, octopuses, and many others [3]. Soft structures, sensing, and the movement strategies of these animals in complex environments represent desirable advantages [4,5]. As an example, earthworms and inchworms use peristaltic movements to move in a single axis, which may be beneficial for the exploration of human intestines and gastroesophageal cavities [6].

Soft robotics is an emerging field with a wide range of materials, platforms, actuators, sensors, and control strategies. As such, it can be challenging to navigate and organize the diverse advancements made in the field, resulting in fragmented and disorganized landscapes. However, the authors of this work propose a solution to this problem in Section 4. We suggest that a bio-inspired classification could be used to structure the study area of soft robotics, which would help to systematize the various advances in the field and generate a better understanding of the science behind the technology.

The proposed bio-inspired classification scheme has the potential to bring order to the field of soft robotics and facilitate the development of new and innovative soft robotic technologies. By grouping advances into structures and actuation categories based on their morphology, researchers can more easily identify areas of opportunity for further exploration and development. This classification scheme may also allow for a more straightforward comparison of different soft robotic technologies, enabling researchers to assess their relative strengths and weaknesses in a more meaningful way.

This paper is organized as follows: Section 2 expands on soft robot definitions, Section 3 describes biological beings from a structural and actuation viewpoint, and in Section 4, the proposed classification is described and depicted using several experimental platforms. They are also shown other authors’ soft robots classified using the proposed bio-inspired classification. Lastly, Section 5 presents the advantages of the classification, reflections on the topic of soft robotics, and conclusions.

2. Soft Robots

Soft robots are constructed using soft and deformable materials, and their softness is typically defined in terms of elasticity or Young’s modulus [7,8,9]. Although this may not be a perfect way to describe softness [8], it highlights the reason for the existence of soft robots. Conventional robots are typically made of metals and plastics with moduli in the order of 10 to 10 , whereas natural organisms are composed of skin and muscles with moduli in the order of to 10 . This large difference in elasticity between materials can lead to safety concerns when in contact, with uneven force distribution and stress concentration potentially causing damage to the softer material, which is typically biological tissue [7].

As different authors have proposed their own definitions of soft robotics, it is important for this work to consider the definition proposed by Wang and Iida [9], “We define soft-matter robotics as robotics that studies how deformation of soft matter can be exploited or controlled to achieve robotic functions”.

Lashi and Cianchetti [10] propose a definition of soft robotics that goes beyond a matter-based approach. They describe soft robotics using two approaches, “control of the actuator stiffness of robot with rigid links” and “softness intrinsically due to the passive characteristics of the robot bodyware”.

Another definition of robot softness and soft robotics is given by Chen and his colleagues [11]: “Softness of a robot is thus defined as: the stress and other damage quantities created in a robot’s environment as well as receiver given a particular material deformation in a particular structural configuration of the robot”, and “Soft robotics is the subject to study how to make use of the softness of an object or a piece of materials or a system for building a robot by satisfying a required softness to both its environment and its receiver”.

In 2016, the RoboSoft community defined soft robots as “soft robots/devices that can actively interact with the environment and can undergo “large” deformations relying on inherent or structural compliance.” For more definitions of soft structures, soft control, and other types of soft robot compliance, we recommend reading the article by Wang, Nurzaman, and Iida [12].

Soft robots have a great diversity of structures, materials, and actuation [13,14,15]. However, soft robot structural characteristics, actuators, and materials share design coincidences. For example, platforms and actuators created with silicone, such as ecoflex or dragonskin, and actuated by means of pressurized air, have common structural elements, including solid silicone walls for support and inflatable cavities for actuation. Soft robots take inspiration from nature, where there are also coincidences in structural design, materials, and actuators among groups of animals. The next section provides an analysis of animal morphology.

3. Morphology Analysis

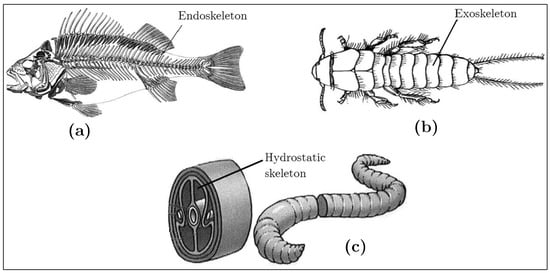

Multi-cellular animals can be divided into two groups: invertebrates and vertebrates. The spine is the component that characterizes a vertebrate animal. Mammals, reptiles, birds, and fish have spines and, therefore, belong to the vertebrate group. On the other hand, worms, sponges, insects, spiders, starfish, and other similar organisms do not have a spine, and belong to the invertebrate group. Examples of invertebrates and vertebrates can be seen in Figure 1 [16].

Figure 1.

Skeletal animal structures. Vertebrate: (a) fish; invertebrates: (b) insects and (c) earthworms.

3.1. Animal Support Structures

Both invertebrates and vertebrates require a skeleton for support, movement, and protection. A skeleton is a solid or fluid system that allows muscles to return to their original length after contraction [17].

For vertebrates, the most common skeletal system is the endoskeleton, while for invertebrates, the exoskeleton and the hydrostatic skeleton prevail. Many animals have more than one type of skeleton. For example, a tortoise has both an endoskeleton and an exoskeleton [18].

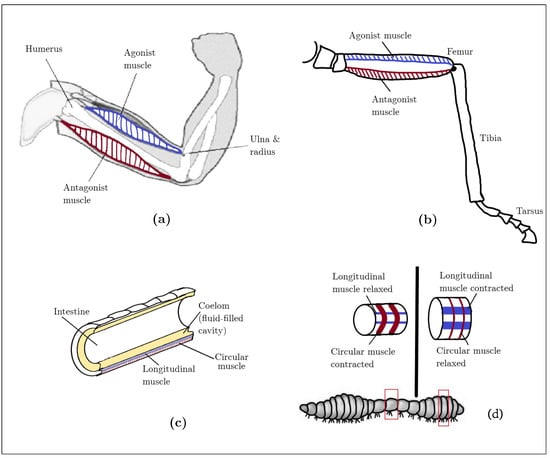

The endoskeleton forms deep within the body; it includes fibrous connective tissue, bone, and cartilage. It is actuated using agonist and antagonist skeletal muscles attached to bones by tendons, as depicted in Figure 2a.

Figure 2.

Types of animal actuation. (a) Agonist/antagonist muscle actuation with endoskeleton; (b) agonist/antagonist muscle actuation with exoskeleton; (c) hydrostatic skeleton actuation; (d) earthworm radial and longitudinal muscle actuation.

The exoskeleton is formed from within the dermis and epidermis. It varies in thickness and is not uniformly hardened over the entire body, which makes many regions thin and flexible, forming joints. Appropriate agonist and antagonist muscles allow a jointed exoskeleton to move, as shown in Figure 2b.

The hydrostatic skeleton includes a fluid-filled cavity enclosed within a membrane, usually encased with a muscular layer, as shown in Figure 2c. At its simplest, the muscular layer is composed of circular and longitudinal bands of muscle. Contractions of the circular muscles lengthen the organism’s body, while contractions of the longitudinal muscles shorten the body, as depicted in Figure 2d. The fluid, mainly water, must be incompressible for the hydrostatic skeleton to function properly [19].

3.2. Animal Actuation

Muscles provide animals with their main source of actuation. There are two general classes of muscle named for the characteristic appearance of individual cells: striated and smooth. The muscles that move and support the skeletal framework are made of striated muscle cells, as shown in Figure 2. Smooth muscle is found in the gut, blood vessels, the uterus, and other locations where contractions are usually slow. The cells that make up the muscle of the heart are also striated like skeletal muscles, but they are electrically different and are usually regarded as a distinct class of muscle [20].

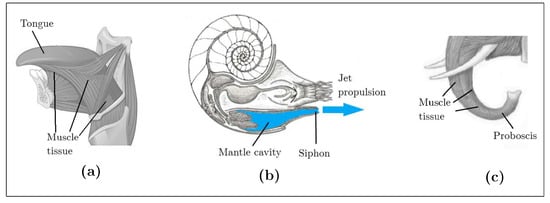

Animal inflation is a noteworthy actuation mechanism. For defensive purposes, some animals, such as the pufferfish, can inflate their bodies up to triple their volume by pumping water into their stomach [21]. The pufferfish and other animals exhibit striking structural and functional specializations for inflation, including large and extensible cavities, the absence of bones, highly stretchable skin, and specialized musculature. Another aspect of inflation is seen through the mantle cavity present in all mollusks, which allows locomotion through jet propulsion [22]. Nautiluses, squids, and octopuses move rapidly by expelling water from the mantle cavity through a tube called a siphon using quick muscle contractions. For the mantle cavity to act as a jet propulsion actuator, it needs to be attached to a shell or be thick and replete with muscles.

3.3. Support Structure with Actuation

The organ known as the muscular hydrostat serves as both a support structure and an actuator. It mainly consists of muscles with no skeletal support and has a composition similar to the hydrostatic skeleton in the sense that both use water (muscle tissue itself is mainly made of water), which is incompressible at physiological pressures, to function. However, the water cavity surrounded by muscles in the hydrostatic skeleton can provide support to other structures, while the muscle hydrostat cannot [23]. Examples of muscular hydrostats include elephant trunks, mammal tongues, and cephalopod arms, which are mainly composed of muscle tissue, as shown in Figure 3a,b.

Figure 3.

Animal support structures with actuation. Muscular hydrostat: (a) human tongue and (b) elephant trunk; animal inflation: (c) nautilus jet propulsion.

4. Soft Robot Classification

One of the main justifications for a soft robot classification is the analogy with other well-studied and heavily researched robots. For example, robotic arms are classified by the type, number, and arrangement of rotational and prismatic joints [24], while parallel robots are classified using similar parameters [25]. Wheeled mobile robots are classified based on the number and type of wheels and their degree of mobility [26], and legged robots are classified by the number of legs and degrees of freedom of the legs [27]. These classifications provide general methodologies for modeling and control, such as the Denavit–Hartenberg [24] or the Canudas de Wit [26] kinematic modeling.

The variety of soft robots demonstrates the difficulty of modeling and control [28,29]. Therefore, a classification could pave the way for modeling and control methodologies. Soft robots are usually classified by their parts, actuation, structure, materials, and sensors [2,30]. While separating a soft robot into its parts or subsystems is an intuitive way of studying its behavior, the biological inspiration that motivated the creation of soft robots shows us that mixed materials and interconnected systems generate exceptional performance and coordination of the systems.

4.1. Bio-Inspired Classification

Biological inspiration has been a major driving force in soft robot research. Therefore, we propose using animal morphology as a guide to classify soft robots. As detailed in Section 3, three skeletal systems and three animal actuation mechanisms serve as sources of inspiration for soft robots: endoskeleton, exoskeleton, hydrostatic skeleton, skeletal muscles, muscular hydrostats, and inflation. Table 1 presents the proposed classification, which uses two defining characteristics for soft robots: support structure and actuator type.

Table 1.

Bio-inspired classification.

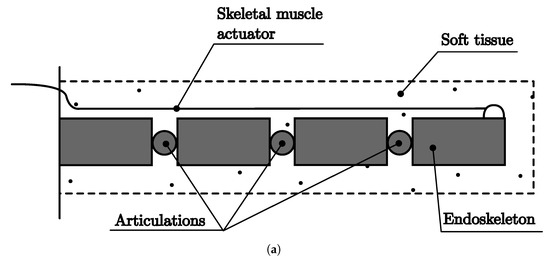

As the support structure, we consider the endoskeleton, which must be composed of a hard structure surrounded by a soft material; the exoskeleton, which must have a hard structure outside with soft material inside or a hard structure with weaker sections acting as joints; the hydrostatic skeleton, which uses a fluid (or soft fluid-like material) as the support structure; and the muscular hydrostat, a structure composed of soft actuators.

For actuators, we consider skeletal muscle actuators that provide linear agonist–antagonist movements and inflatable actuators that use a work fluid to transmit power or deformations. This type of classification has the capacity to integrate different actuators. For example, cable-driven, shape memory alloy, magnetic-based, spring, and other related actuators could be classified as muscular actuators. On the other hand, pneumatic, hydraulic, chemical, and other related actuators could be classified as inflatable actuators.

4.2. Prototypes

To better exemplify the possible combinations for the proposed classification, we developed eight soft robots as shown in Table 2. Each prototype was developed to detail the type of classification and is associated with a table detailing various classified soft robots from the literature.

Table 2.

Soft robot prototypes based on the proposed classification.

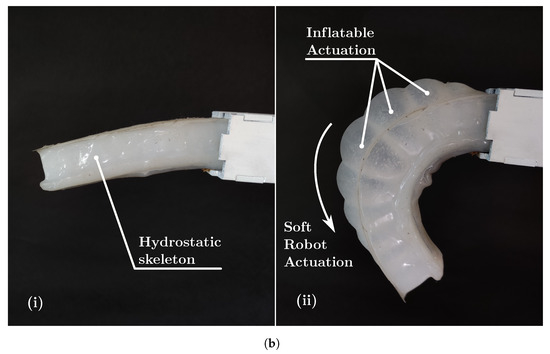

4.2.1. Endoskeleton Soft Robots

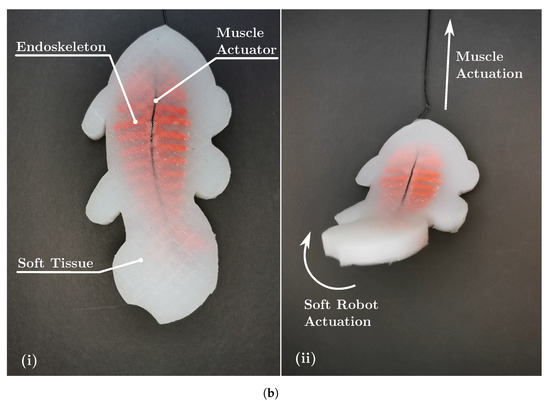

Figure 4 and Figure 5 show soft robots from the classes EndMu and EndIn, where the endoskeleton is covered with soft tissue. The EndMu prototype is represented by the schematic diagram in Figure 4a and the prototype in Figure 4b, which uses a PLA 3D-printed articulated fish as the endoskeleton covered by Ecoflex 35 and is actuated by a nylon-coated wire. The prototype moves its tail by pulling the cable as an agonist movement, and the antagonist movement is provided by the Ecoflex returning to its original form.

Figure 4.

Soft robot EndMu Class. (a) Soft robot schematic diagram EndMu. (b) Soft robot prototype EndMu.

Figure 5.

Soft robot EndIn Class. (a) Soft robot schematic diagram EndIn. (b) Soft robot prototype EndIn.

The prototype EndIn is represented by the schematic diagram in Figure 5a and the prototype in Figure 5b. It uses a PLA 3D-printed articulated section as an endoskeleton covered by Ecoflex 35 and actuated by pneumatic chambers within the Ecoflex. The prototype moves using pneumatic inflation, some examples are shown in the Figure 6.

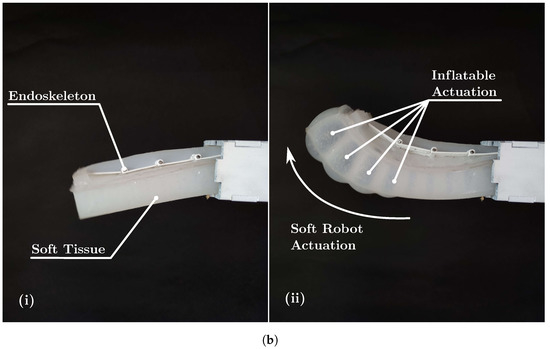

Figure 6.

Examples of endoskeletons: (a) elephant’s trunk manipulator [31]; (b) soft humanoid robotic hand [32]; (c) spherical rolling robots [33], adapted with permission.

Table 3 lists literature examples of EndMu and EndIn classes, such as the robot elephant’s trunk manipulator by [31], the soft humanoid robotic hand by [32], the spherical rolling robots [33], and the peristaltic crawling robot [34].

Table 3.

Classified soft robots with denomination endoskeleton.

4.2.2. Exoskeleton Soft Robots

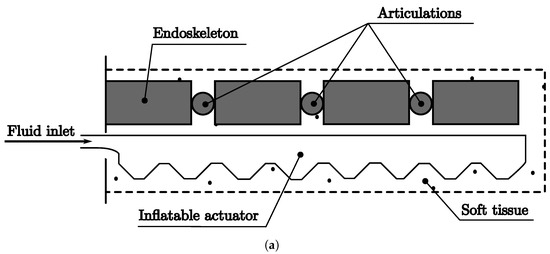

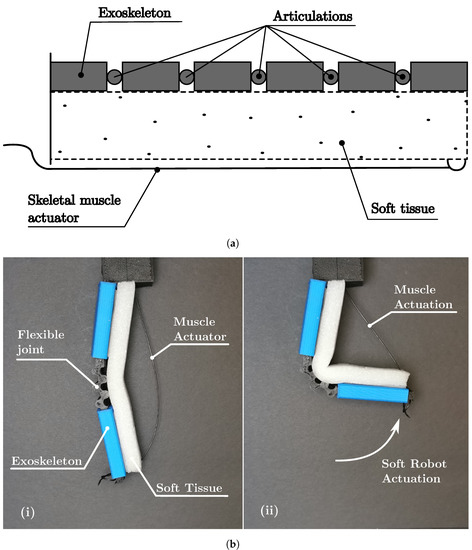

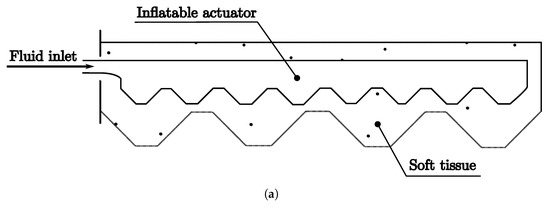

Figure 7 and Figure 8 display soft robots of classes ExoMu and ExoIn, where the exoskeleton protects a soft tissue and weaker sections act as articulations. The ExoMu prototype is represented by the schematic diagram in Figure 7a, and the prototype is shown in Figure 7b. It is built with a 3D-printed TPU (black) core, protected by 3D-printed PLA (blue) sections acting as the exoskeleton, and the inner part is made of soft polyurethane foam (white). The prototype is actuated by pulling a nylon-coated wire as an agonist movement, while the TPU and the polyurethane foam provide the antagonist movement by returning to their original form.

Figure 7.

Soft robot ExoMu class. (a) Soft robot schematic diagram ExoMu. (b) Soft robot prototype ExoMu.

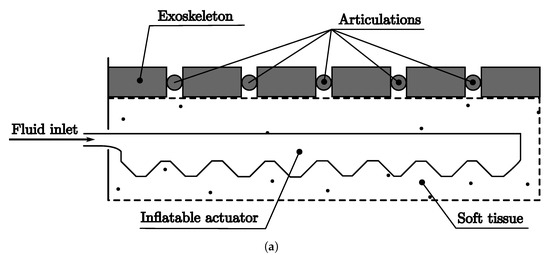

Figure 8.

Soft robot ExoIn Class. (a) Soft robot schematic diagram ExoIn. (b) Soft robot prototype ExoIn.

The prototype ExoIn, represented by the schematic diagram in Figure 8a, and the prototype in Figure 8b, are similarly built to the prototype ExoMu, but without the polyurethane foam-filling. A pneumatic fluidic actuator (twisting balloon) is used to expand the articulation.

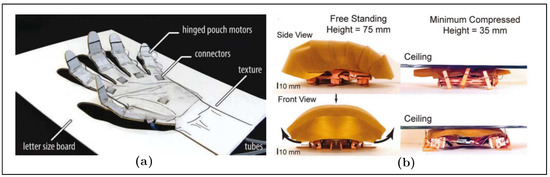

The exoskeleton soft robot configurations classified in group 2, shown in Table 4, mainly consist of origami robots and compliant robots with soft actuators. Although origami robots obtain their name from the Japanese art of paper folding, their structural similarity to insects is striking: the act of folding paper (or other materials) creates a weaker, softer joint at the crease or pleat, similar to an insect’s exoskeleton. Some of the features observed in these robots include the ability to fold and unfold from external signals [48] as well as the ability to adapt to small spaces and resist external loads [49]. Some examples are shown in the Figure 9.

Table 4.

Classified soft robots with denomination 2, exoskeleton.

Figure 9.

Examples of exoskeleton configurations: (a) origami robot with soft actuator [48]; (b) cockroach-inspired robot in a reduced space [49], adapted with permission.

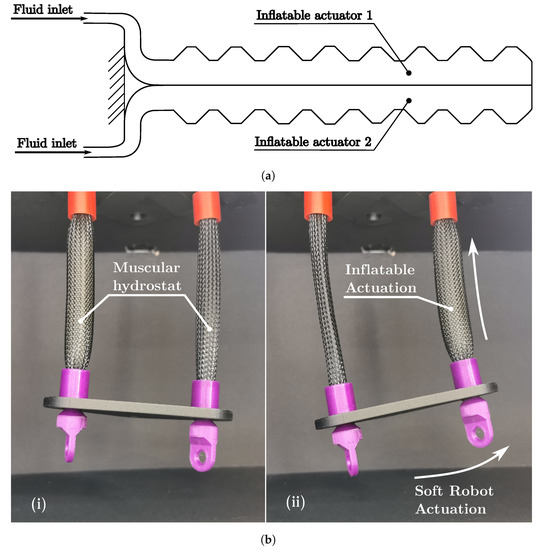

4.2.3. Hydrostatic Skeleton Soft Robots

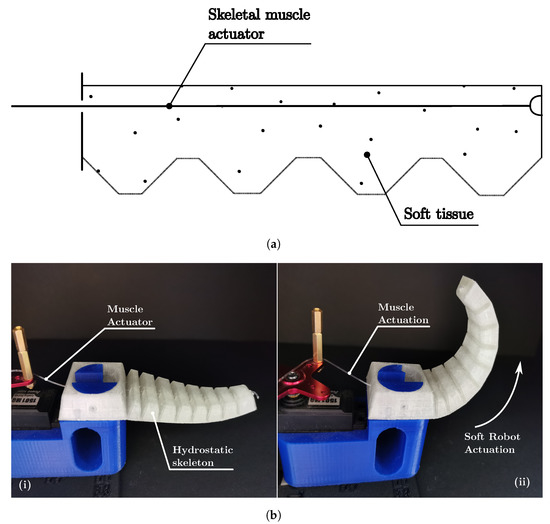

Figure 10 and Figure 11 depict soft robot classes HySMu and HySIn. The HySMu class is shown in the schematic diagram in Figure 10a and the prototype in Figure 10b shows a prototype 3D-printed entirely of TPU, actuated by a monofilament nylon fishing line. Being built of just one soft material, with no exoskeleton or endoskeleton, the bottom continuous part acts as a hydrostatic skeleton, where the cable creates the agonist movement, and the antagonist movement is provided by the TPU hydrostatic skeleton returning to its original form.

Figure 10.

Soft robot, HysMu class. (a) Soft robot schematic diagram, HySMu. (b) Soft robot prototype, HySMu.

Figure 11.

Soft robot, HySIn Class. (a) Soft robot schematic diagram, HySIn. (b) Soft robot prototype, HySIn.

Secondly, the HysIn class is represented by the schematic diagram in Figure 11a and the prototype in Figure 11b. It uses Ecoflex 35 to create a hydrostatic skeleton and a series of pneumatic chambers on top of it. The inflated chambers generate bending motions, while the continuous bottom part acts as a hydrostatic skeleton providing support to the pneumatic chambers.

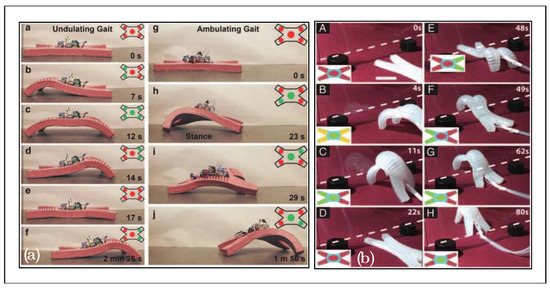

The largest classification, shown in Table 5, may be due to the biological influence on soft robots, as well as the basic and well-studied examples such as octopuses, worms, and other invertebrates. In this classification, we can find many robots with pneumatic actuators, as shown in the Figure 12, classified as HySIn, such as those in [76] or [77]. Another interesting and unusual example is the Jellyfish 2D muscle architecture robot [78], which simulates a jellyfish actuated by rat cardiomyocytes.

Table 5.

Classified soft robots with denomination 3, hydrostatic skeleton.

Figure 12.

Examples of hydrostatic skeletons: (a) quadruped soft robot [76]; (b) quadruped soft robot [77], adapted with permission.

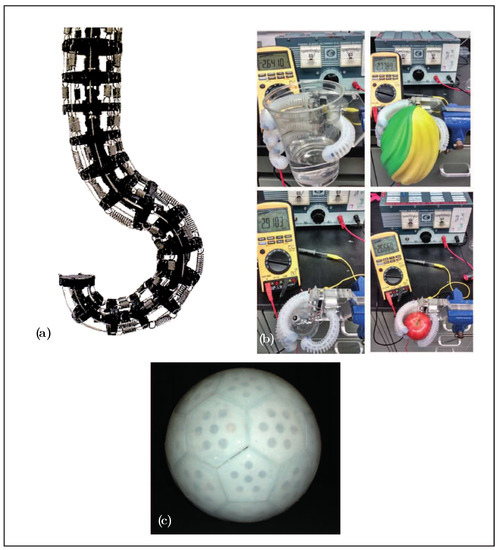

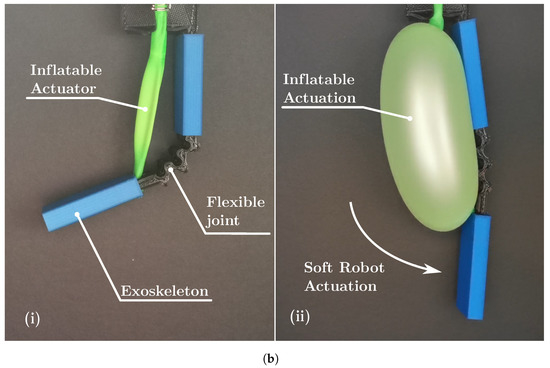

4.2.4. Muscular Hydrostat Soft Robots

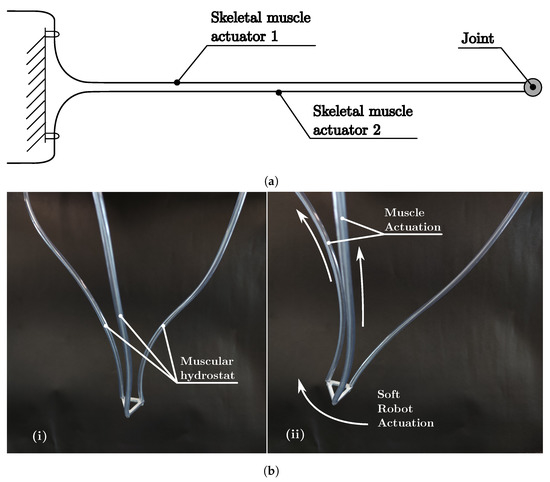

Soft robot classes MuHMu and MuHIn are presented in Figure 13 and Figure 14. The cable-driven muscular hydrostat is represented by the schematic diagram in Figure 13a and the prototype in Figure 13b. It is built using three cables inside a cable housing (such as those used in bicycle V brakes), attached to a PLA triangular end part, and is actuated by pulling the cables in a differential manner. This configuration is unique because no structural elements are used; the actuator functions as the structure, as in mammal tongues or elephant trunks.

Figure 13.

Soft robot MuHMu class. (a) Soft robot schematic diagram MuHMu. (b) Soft robot prototype MuHMu.

Figure 14.

Soft robot MuHIn Class. (a) Soft robot schematic diagram MuHIn. (b) Soft robot prototype MuHIn.

The fluidic muscular hydrostat is presented by the schematic diagram in Figure 14a and the prototype in Figure 14b, where two McKibben artificial muscles provide support and actuation to the PLA 3D printed base. Differential pneumatic actuation of the muscles provides movement for the robot.

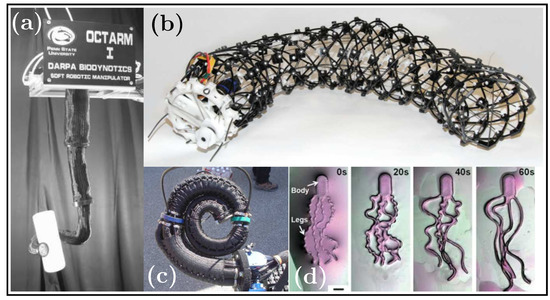

Examples of muscle hydrostat soft robots from the literature are presented in Table 6, including octopus-inspired arm prototypes [150,151], a peristaltic robot made of cables inside a housing [152], and miniature aquabots [153]. These examples are shown in the Figure 15.

Table 6.

Classified soft robots with denomination 4, muscular hydrostat.

Figure 15.

Examples of muscular hydrostats: (a) OctArm I [150]; (b) robot with peristalsis [152]; (c) OctArm V [151]; (d) Mini soft aquabots [153], adapted with permission.

4.3. Classification Analysis

The proposed classification scheme offers an overview of the development of soft robots, providing a clear and concise way to define the requirements and characteristics of different types of soft robots. In engineering design processes, properly defining the requirements and characteristics is essential, as without it, the range of possibilities can become overwhelming. By establishing four types of soft robots with distinct characteristics, our classification scheme facilitates the design and manufacture of prototypes.

The classification scheme also enables decision-making regarding the morphology inherent to each classification and the location of the necessary components for actuation. For instance, robots with endoskeletons (End) benefit from the distribution of actuation systems due to the presence of internal rigid components. In contrast, hydrostatic skeleton robots (HyS) lack rigid structures where components can be distributed and protected, necessitating the search for alternative methods compatible with the hydrostatic structure.

Furthermore, the classification scheme is helpful in defining the materials and procedures required for manufacturing soft robots. For example, a robot consisting of a muscular hydrostat and cable actuation (MuHMu) would require channels within a soft material for the passage of actuator cables, whereas a structure with an exoskeleton (Exo) can be correlated with additive manufacturing processes or even origami.

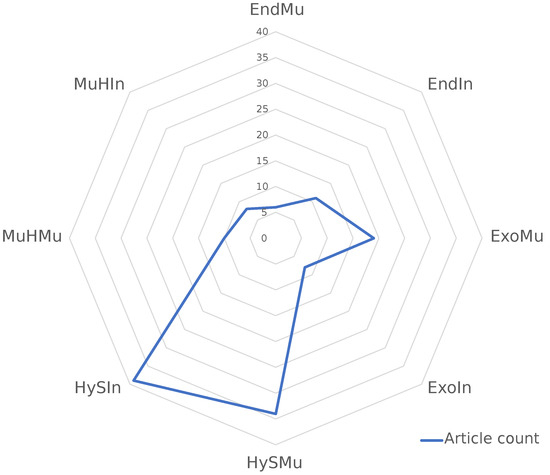

Figure 16 reveals that the majority of the 135 reviewed articles pertain to hydrostatic skeletons with inflatable or muscular actuation. This observation is not surprising given that hydrostatic skeletons, particularly those in the octopus, serve as a strong source of bioinspiration in soft robotics. This analysis further identifies areas of opportunity for soft robotics research. Specifically, the less common classifications include endoskeletons with muscular actuation, exoskeletons with inflatable actuation, and muscular hydrostats with inflatable actuation. By recognizing these less explored areas, researchers can concentrate on advancing soft robotics in novel directions.

Figure 16.

Classification graph of the 135 reviewed articles.

5. Discussion and Conclusions

The advantage of this classification is discussed in Section 1 and Section 4. The proposed classification allows for an analytical analogy with other types of robots that are widely studied. For example, while a robot arm can be classified as RRR due to its three rotational joints, a soft muscle origami robot will be classified as ExoMu. In the same way that the kinematic model of a rotational joint in a robot arm is modeled using angular quantities, the rotational joints of an origami robot could also be modeled using angles. Similarly, the classification of HySIn soft robots, which are hydrostatic skeletons with inflatable actuation, could have kinematic and dynamic models based on fluid pressure. Dynamic models for MuHIn robots, which are muscular hydrostats with pneumatic actuators, could be based on fluid pressure and curve bending profiles, and so forth with all other classes.

The vast majority of animals on the planet use a support structure with adequate characteristics to live on land, sea, or air. Few organisms, such as octopuses and squids, have this apparent lack of support structure. As shown in Section 3, these invertebrates have a skeletal system that directly depends on the aqueous environment where they live. If these animals are taken to a different environment, they cannot move in the same way as in water. Therefore, soft robots that are designed to work in environments similar to those of humans, should probably have a morphology similar to that of other animals on the surface.

Ideally, all components of a soft robot should be soft, including power sources, sensors, and electronics. However, as of now, this is not yet possible. It is essential to note that the proposed classification scheme does not require a robot to be completely soft. The classification allows for the presence of rigid internal or external parts as long as the structural and actuation elements are soft. Robots that are rigid and covered with soft materials are excluded.

The muscular and inflatable actuator classes are designed to be very general. However, other types of muscles exist, as discussed in Section 3.2. Hence, the term “muscle” provides room for expansion and allows for more dimensions to be added to the classification. The same applies to inflatable actuation, which can be subdivided into different types of movements caused by the fluid, depending on cavity geometry, characteristics, or the work fluid. We believe that the flexibility of the classification will be advantageous for future expansions and subdivisions.

Using this bio-inspired classification, many hybrid options for classification are possible. For example, a hypothetical tortoise robot could be considered a soft robot type EndExoMu, which refers to a soft robot with an endoskeleton and exoskeleton that uses muscles for actuation. Another example is Disney’s Baymax from the movie Big Hero 6 [168], which is a soft robot-type EndIn until Hiro Hamada adds an exoskeleton, making it an EndExoIn soft robot. Jamming robots are another example of hybrid robots. They have soft structures until a vacuum is applied, turning their structure into a hydrostatic skeleton. Then, when actuated, they transform into an endoskeleton, as seen in [41] or the soft robot platform in [169] that uses jamming and rotational actuators. Some robots have two types of actuators that allow them to perform combined movements and actions, such as [170]. The use of different types of actuators and structures in soft robots creates interesting skills that increase capabilities and provide versatility in their actuation and movement.

This article can begin a discussion about the possible features of a classification method. Our hope is that the scientific community takes this proposal and improves it, remakes it, or discards it to make way for a better version that can guide the field of soft robotics toward the bright future of human–machine interaction.

Author Contributions

Conceptualization, methodology, analysis of results and writing—original draft preparation, J.C.T. and A.L.-G.; conceptualization, methodology, J.L.-R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Universidad Iberoamericana (Ibero DCI-002847 and Convocatoria 17 DINV) and Universidad EIA (CO12021002).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, A. López-Gonzalez (alexandro.lopez@ibero.mx), upon reasonable request.

Acknowledgments

The authors thanks to Universidad Iberoamericana (Ibero DCI-002847 and Convocatoria 14 DINV, Universidad EIA (CO12021002) and CONACYT.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gao, Z.; Shi, Q.; Fukuda, T.; Li, C.; Huang, Q. An overview of biomimetic robots with animal behaviors. Neurocomputing 2019, 332, 339–350. [Google Scholar] [CrossRef]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef]

- Laschi, C.; Mazzolai, B.; Cianchetti, M. Soft robotics: Technologies and systems pushing the boundaries of robot abilities. Sci. Robot. 2016, 1. [Google Scholar] [CrossRef]

- Rossiter, J.; Hauser, H. Soft Robotics—The Next Industrial Revolution? [Industrial Activities]. IEEE Robot. Autom. Mag. 2016, 23, 17–20. [Google Scholar] [CrossRef]

- Tolley, M.T.; Rus, D. Design, fabrication and control of soft robots. Nature 2015, 521, 467. [Google Scholar]

- Bernth, J.E.; Arezzo, A.; Liu, H. A novel robotic meshworm with segment-bending anchoring for colonoscopy. IEEE Robot. Autom. Lett. 2017, 2, 1718–1724. [Google Scholar] [CrossRef]

- Kim, J. Microscale Soft Robotics; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Majidi, C. Soft robotics: A perspective—Current trends and prospects for the future. Soft Robot. 2014, 1, 5–11. [Google Scholar] [CrossRef]

- Wang, L.; Iida, F. Deformation in soft-matter robotics: A categorization and quantitative characterization. IEEE Robot. Autom. Mag. 2015, 22, 125–139. [Google Scholar] [CrossRef]

- Laschi, C.; Cianchetti, M. Soft Robotics: New Perspectives for Robot Bodyware and Control; Frontiers Media SA: Lausanne, Switzerland, 2016. [Google Scholar]

- Chen, A.; Yin, R.; Cao, L.; Yuan, C.; Ding, H.; Zhang, W. Soft robotics: Definition and research issues. In Proceedings of the 2017 24th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Auckland, New Zealand, 21–23 November 2017. [Google Scholar] [CrossRef]

- Wang, L.; Nurzaman, S.G.; Iida, F. Soft-Material Robotics. Found. Trends Robot. 2017, 5, 191–259. [Google Scholar] [CrossRef]

- Schmitt, F.; Piccin, O.; Barbé, L.; Bayle, B. Soft robots manufacturing: A review. Front. Robot. AI 2018, 5, 84. [Google Scholar] [CrossRef]

- Coyle, S.; Majidi, C.; LeDuc, P.; Hsia, K.J. Bio-inspired soft robotics: Material selection, actuation, and design. Extrem. Mech. Lett. 2018, 22, 51–59. [Google Scholar] [CrossRef]

- Lipson, H. Challenges and opportunities for design, simulation, and fabrication of soft robots. Soft Robot. 2014, 1, 21–27. [Google Scholar] [CrossRef]

- Minelli, A. The Development of Animal Form; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Pechenik, J. Biology of the Invertebrates; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Kardong, K. Vertebrates: Comparative Anatomy, Function, Evolution; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

- Brusca, R.C. Invertebrates; Sinauer Associates is an imprint of Oxford University Press: Oxford, UK, 2016. [Google Scholar]

- Matthews, G.G. Cellular Physiology of Nerve and Muscle; Blackwell Pub: New York, NY, USA, 2003. [Google Scholar]

- Brainerd, E.L. Pufferfish inflation: Functional morphology of postcranial structures in diodon holocanthus (tetraodontiformes). J. Morphol. 1994, 220, 243–261. [Google Scholar] [CrossRef]

- Chamberlain, J.A., Jr. Jet propulsion of Nautilus: A surviving example of early Paleozoic cephalopod locomotor design. Can. J. Zool. 1990, 68, 806–814. [Google Scholar] [CrossRef]

- Kier, W.M.; Smith, K.K. Tongues, tentacles and trunks: The biomechanics of movement in muscular-hydrostats. Zool. J. Linn. Soc. 2008, 83, 307–324. [Google Scholar] [CrossRef]

- Spong, M. Robot Modeling and Control; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2020. [Google Scholar]

- Taghirad, H. Parallel Robots: Mechanics and Control; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2013. [Google Scholar]

- Wit, C. Theory of Robot Control; Springer: London, UK, 1996. [Google Scholar]

- Santos, P. Quadrupedal Locomotion: An Introduction to the Control of Four-Legged Robots; Springer: London, UK, 2006. [Google Scholar]

- Das, A.; Nabi, M. A review on soft robotics: Modeling, control and applications in human-robot interaction. In Proceedings of the 2019 International Conference on Computing, Communication, and Intelligent Systems (ICCCIS), Greater Noida, India, 18–19 October 2019. [Google Scholar]

- Rus, D.; Tolley, M.T. Design, fabrication and control of origami robots. Nat. Rev. Mater. 2018, 3, 101–112. [Google Scholar] [CrossRef]

- Lee, C.; Kim, M.; Kim, Y.J.; Hong, N.; Ryu, S.; Kim, H.J.; Kim, S. Soft robot review. Int. J. Control. Autom. Syst. 2017, 15, 3–15. [Google Scholar] [CrossRef]

- Hannan, M.W.; Walker, I.D. Kinematics and the implementation of an elephants trunk manipulator and other continuum style robots. J. Robot. Syst. 2003, 20, 45–63. [Google Scholar] [CrossRef]

- She, Y.; Li, C.; Cleary, J.; Su, H.J. Design and fabrication of a soft robotic hand with embedded actuators and sensors. J. Mech. Robot. 2015, 7, 2. [Google Scholar] [CrossRef]

- Wait, K.W.; Jackson, P.J.; Smoot, L.S. Self locomotion of a spherical rolling robot using a novel deformable pneumatic method. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 3757–3762. [Google Scholar]

- Nakamura, T.; Hidaka, Y.; Yokojima, M.; Adachi, K. Development of peristaltic crawling robot with artificial rubber muscles attached to large intestine endoscope. Adv. Robot. 2012, 26, 1161–1182. [Google Scholar] [CrossRef]

- Kim, S.; Clark, J.E.; Cutkosky, M.R. isprawl: Design and tuning for high-speed autonomous open-loop running. Int. J. Robot. Res. 2006, 25, 903–912. [Google Scholar] [CrossRef]

- Kaufhold, T.; Bohm, V.; Zimmermann, K. Design of a miniaturized locomotion system with variable mechanical compliance based on amoeboid movement. In Proceedings of the 2012 4th IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics (BioRob), Rome, Italy, 24–27 June 2012. [Google Scholar]

- Zhao, L.; Wu, Y.; Blanchet, J.; Perroni-Scharf, M.; Huang, X.; Booth, J.; Kramer-Bottiglio, R.; Balkcom, D. Soft Lattice Modules That Behave Independently and Collectively. IEEE Robot. Autom. Lett. 2022, 7, 5942–5949. [Google Scholar] [CrossRef]

- Ramadoss, V.; Sagar, K.; Ikbal, M.S.; Calles, J.H.L.; Siddaraboina, R.; Zoppi, M. HEDRA: A Bio-Inspired Modular Tensegrity Robot with Polyhedral Parallel Modules. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, UK, 4–8 April 2022. [Google Scholar] [CrossRef]

- Ranzani, T.; Gerboni, G.; Cianchetti, M.; Menciassi, A. A bioinspired soft manipulator for minimally invasive surgery. Bioinspiration Biomimetics 2015, 10, 3. [Google Scholar] [CrossRef]

- Amend, J.R.; Brown, E.; Rodenberg, N.; Jaeger, H.M.; Lipson, H. A positive pressure universal gripper based on the jamming of granular material. IEEE Trans. Robot. 2012, 28, 341–350. [Google Scholar] [CrossRef]

- Steltz, E.; Mozeika, A.; Rodenberg, N.; Brown, E.; Jaeger, H.M. JSEL: Jamming skin enabled locomotion. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 11–15 October 2009. [Google Scholar]

- Cianchetti, M.; Ranzani, T.; Gerboni, G.; Falco, I.D.; Laschi, C.; Menciassi, A. STIFF-FLOP surgical manipulator: Mechanical design and experimental characterization of the single module. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013. [Google Scholar]

- Li, S.; Vogt, D.M.; Rus, D.; Wood, R.J. Fluid-driven origami-inspired artificial muscles. Proc. Natl. Acad. Sci. USA 2017, 114, 13132–13137. [Google Scholar] [CrossRef]

- Gollob, S.D.; Poss, J.; Memoli, G.; Roche, E.T. A Multi-Material, Anthropomorphic Metacarpophalangeal Joint with Abduction and Adduction Actuated by Soft Artificial Muscles. IEEE Robot. Autom. Lett. 2022, 7, 5882–5887. [Google Scholar] [CrossRef]

- Nilles, A.; Ceron, S.; Napp, N.; Petersen, K. Strain-Based Consensus in Soft, Inflatable Robots. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, UK, 4–8 April 2022. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Kan, Z.; Zeng, J.; Wang, M.Y. Hybrid Jamming for Bioinspired Soft Robotic Fingers. Soft Robot. 2020, 7, 292–308. [Google Scholar] [CrossRef]

- der Maur, P.A.; Djambazi, B.; Haberthur, Y.; Hormann, P.; Kubler, A.; Lustenberger, M.; Sigrist, S.; Vigen, O.; Forster, J.; Achermann, F.; et al. RoBoa: Construction and Evaluation of a Steerable Vine Robot for Search and Rescue Applications. In Proceedings of the 2021 IEEE 4th International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 12–16 April 2021. [Google Scholar] [CrossRef]

- Niiyama, R.; Sun, X.; Sung, C.; An, B.; Rus, D.; Kim, S. Pouch motors: Printable soft actuators integrated with computational design. Soft Robot. 2015, 2, 59–70. [Google Scholar] [CrossRef]

- Jayaram, K.; Full, R.J. Cockroaches traverse crevices, crawl rapidly in confined spaces, and inspire a soft, legged robot. Proc. Natl. Acad. Sci. 2016, 113, E950–E957. [Google Scholar] [CrossRef]

- Kim, S.R.; Lee, D.Y.; Koh, J.S.; Cho, K.J. Fast, compact, and lightweight shape-shifting system composed of distributed self-folding origami modules. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016. [Google Scholar]

- Cham, J.G.; Bailey, S.A.; Clark, J.E.; Full, R.J.; Cutkosky, M.R. Fast and robust: Hexapedal robots via shape deposition manufacturing. Int. J. Robot. Res. 2002, 21, 869–882. [Google Scholar] [CrossRef]

- Lee, D.Y.; Kim, S.R.; Kim, J.S.; Park, J.J.; Cho, K.J. Origami wheel transformer: A variable-diameter wheel drive robot using an origami structure. Soft Robot. 2017, 4, 163–180. [Google Scholar] [CrossRef]

- Suzuki, K.; Shimoyama, I.; Miura, H. Insect-model based microrobot with elastic hinges. J. Microelectromech. Syst. 1994, 3, 4–9. [Google Scholar] [CrossRef]

- Ge, Q.; Dunn, C.K.; Qi, H.J.; Dunn, M.L. Active origami by 4d printing. Smart Mater. Struct. 2014, 23, 9. [Google Scholar] [CrossRef]

- Liu, B.; Hammond, F.L. Modular platform for the exploration of form-function relationships in soft swimming robots. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Pagano, A.; Yan, T.; Chien, B.; Wissa, A.; Tawfick, S. A crawling robot driven by multi-stable origami. Smart Mater. Struct. 2017, 26, 9. [Google Scholar] [CrossRef]

- Faal, S.G.; Chen, F.; Tao, W.; Agheli, M.; Tasdighikalat, S.; Onal, C.D. Hierarchical kinematic design of foldable hexapedal locomotion platforms. J. Mech. Robot. 2016, 8, 1. [Google Scholar] [CrossRef]

- Felton, S.; Tolley, M.; Demaine, E.; Rus, D.; Wood, R. A method for building self-folding machines. Science 2014, 345, 644–646. [Google Scholar] [CrossRef]

- Firouzeh, A.; Paik, J. Robogami: A fully integrated low-profile robotic origami. J. Mech. Robot. 2015, 7, 2. [Google Scholar] [CrossRef]

- Onal, C.D.; Wood, R.J.; Rus, D. An origami-inspired approach to worm robots. Ieee/Asme Trans. Mechatronics 2012, 18, 430–438. [Google Scholar] [CrossRef]

- Koh, J.S.; Cho, K.J. Omega-shaped inchworm-inspired crawling robot with large-index-and-pitch (LIP) SMA spring actuators. IEEE/ASME Trans. Mechatron. 2012, 18, 419–429. [Google Scholar] [CrossRef]

- Felton, S.M.; Tolley, M.T.; Shin, B.; Onal, C.D.; Demaine, E.D.; Rus, D.; Wood, R.J. Self-folding with shape memory composites. Soft Matter 2013, 9, 7688–7694. [Google Scholar] [CrossRef]

- Bowen, L.; Springsteen, K.; Feldstein, H.; Frecker, M.; Simpson, T.W.; von Lockette, P. Development and validation of a dynamic model of magneto-active elastomer actuation of the origami waterbomb base. J. Mech. Robot. 2015, 7, 1. [Google Scholar] [CrossRef]

- Zhang, K.; Qiu, C.; Dai, J.S. Helical kirigami-enabled centimeter-scale worm robot with shape-memory-alloy linear actuators. J. Mech. Robot. 2015, 7, 2. [Google Scholar] [CrossRef]

- Jeong, D.; Lee, K. Design and analysis of an origami-based three-finger manipulator. Robotica 2018, 36, 261–274. [Google Scholar] [CrossRef]

- Gafer, A.; Heymans, D.; Prattichizzo, D.; Salvietti, G. The quad-spatula gripper: A novel soft-rigid gripper for food handling. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Bern, J.M.; Yanez, L.Z.; Sologuren, E.; Rus, D. Contact-Rich Soft-Rigid Robots Inspired by Push Puppets. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, UK, 4–8 April 2022. [Google Scholar] [CrossRef]

- Sun, Y.; Jiang, Y.; Yang, H.; Walter, L.C.; Santoso, J.; Skorina, E.H.; Onal, C. Salamanderbot: A soft-rigid composite continuum mobile robot to traverse complex environments. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020. [Google Scholar] [CrossRef]

- Bartlett, N.W.; Tolley, M.T.; Overvelde, J.T.B.; Weaver, J.C.; Mosadegh, B.; Bertoldi, K.; Whitesides, G.M.; Wood, R.J. A 3d-printed, functionally graded soft robot powered by combustion. Science 2015, 349, 161–165. [Google Scholar] [CrossRef]

- Zhou, X.; Teng, Y.; Li, X. Development of a new pneumatic-driven earthworm-like soft robot. In Proceedings of the 2016 23rd International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Nanjing, China, 28–30 November 2016. [Google Scholar]

- Fras, J.; Althoefer, K. Soft biomimetic prosthetic hand: Design. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018. [Google Scholar]

- Aston, J.P.; Benko, N.; Truong, T.; Zaki, A.; Olsen, N.; Eshete, E.; Luttmer, N.G.; Coats, B.; Minor, M.A. Optimization of a soft robotic bladder array for dissipating high impact loads: An initial study in designing a smart helmet. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Liu, S.; Zhu, Y.; Zhang, Z.; Fang, Z.; Tan, J.; Peng, J.; Song, C.; Asada, H.H.; Wang, Z. Otariidae-Inspired Soft-Robotic Supernumerary Flippers by Fabric Kirigami and Origami. IEEE/ASME Trans. Mechatronics 2021, 26, 2747–2757. [Google Scholar] [CrossRef]

- Zhang, Z.; Fan, W.; Chen, G.; Luo, J.; Lu, Q.; Wang, H. A 3D Printable Origami Vacuum Pneumatic Artificial Muscle with Fast and Powerful Motion. In Proceedings of the 2021 IEEE 4th International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 12–16 April 2021. [Google Scholar] [CrossRef]

- Arachchige, D.D.K.; Godage, I.S. Hybrid Soft Robots Incorporating Soft and Stiff Elements. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, UK, 4–8 April 2022. [Google Scholar] [CrossRef]

- Tolley, M.T.; Shepherd, R.F.; Mosadegh, B.; Galloway, K.C.; Wehner, M.; Karpelson, M.; Wood, R.J.; Whitesides, G.M. A resilient, untethered soft robot. Soft Robot. 2014, 1, 213–223. [Google Scholar] [CrossRef]

- Shepherd, R.F.; Ilievski, F.; Choi, W.; Morin, S.A.; Stokes, A.A.; Mazzeo, A.D.; Chen, X.; Wang, M.; Whitesides, G.M. Multigait soft robot. Proc. Natl. Acad. Sci. 2011, 108, 20400–20403. [Google Scholar] [CrossRef]

- Nawroth, J.C.; Lee, H.; Feinberg, A.W.; Ripplinger, C.M.; McCain, M.L.; Grosberg, A.; Dabiri, J.O.; Parker, K.K. A tissue-engineered jellyfish with biomimetic propulsion. Nat. Biotechnol. 2012, 30, 792–797. [Google Scholar] [CrossRef]

- Seok, S.; Onal, C.D.; Cho, K.J.; Wood, R.J.; Rus, D.; Kim, S. Meshworm: A peristaltic soft robot with antagonistic nickel titanium coil actuators. IEEE/ASME Trans. Mechatron. 2013, 18, 1485–1497. [Google Scholar] [CrossRef]

- Cianchetti, M.; Calisti, M.; Margheri, L.; Kuba, M.; Laschi, C. Bioinspired locomotion and grasping in water: The soft eight-arm OCTOPUS robot. Bioinspiration Biomimetics 2015, 10, 3. [Google Scholar] [CrossRef]

- Cheng, N.G.; Lobovsky, M.B.; Keating, S.J.; Setapen, A.M.; Gero, K.I.; Hosoi, A.E.; Iagnemma, K.D. Design and analysis of a robust, low-cost, highly articulated manipulator enabled by jamming of granular media. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012. [Google Scholar]

- Lin, H.T.; Leisk, G.G.; Trimmer, B. GoQBot: A caterpillar-inspired soft-bodied rolling robot. Bioinspiration Biomimetics 2011, 6, 2. [Google Scholar] [CrossRef] [PubMed]

- Laschi, C.; Cianchetti, M.; Mazzolai, B.; Margheri, L.; Follador, M.; Dario, P. Soft robot arm inspired by the octopus. Adv. Robot. 2012, 26, 709–727. [Google Scholar] [CrossRef]

- Kim, S.; Spenko, M.; Trujillo, S.; Heyneman, B.; Santos, D.; Cutkosky, M.R. Smooth vertical surface climbing with directional adhesion. IEEE Trans. Robot. 2008, 24, 65–74. [Google Scholar]

- Follador, M.; Cianchetti, M.; Laschi, C. Development of the functional unit of a completely soft octopus-like robotic arm. In Proceedings of the 2012 4th IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics (BioRob), Rome, Italy, 24–27 June 2012. [Google Scholar]

- Arienti, A.; Calisti, M.; Giorgio-Serchi, F.; Laschi, C. PoseiDRONE: Design of a soft-bodied ROV with crawling, swimming and manipulation ability. In Proceedings of the 2013 OCEANS, San Diego, CA, USA, 23–27 September 2013; pp. 1–7. [Google Scholar]

- Umedachi, T.; Vikas, V.; Trimmer, B.A. Softworms: The design and control of non-pneumatic, 3d-printed, deformable robots. Bioinspiration Biomimetics 2016, 11, 2. [Google Scholar] [CrossRef] [PubMed]

- Low, K.; Yang, J.; Pattathil, A.; Zhang, Y. Initial prototype design and investigation of an undulating body by SMA. In Proceedings of the 2006 IEEE International Conference on Automation Science and Engineering, Shanghai, China, 8–10 October 2006. [Google Scholar]

- Umedachi, T.; Vikas, V.; Trimmer, B.A. Highly deformable 3-D printed soft robot generating inching and crawling locomotions with variable friction legs. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013. [Google Scholar] [CrossRef]

- Sugiyama, Y.; Hirai, S. Crawling and jumping by a deformable robot. Int. J. Robot. Res. 2006, 25, 603–620. [Google Scholar] [CrossRef]

- Deng, T.; Wang, H.; Chen, W.; Wang, X.; Pfeifer, R. Development of a new cable-driven soft robot for cardiac ablation. In Proceedings of the 2013 IEEE International Conference on Robotics and Biomimetics (ROBIO), Shenzhen, China, 12–14 December 2013. [Google Scholar]

- Guo, S.; Fukuda, T.; Asaka, K. A new type of fish-like underwater microrobot. IEEE/ASME Trans. Mechatron. 2003, 8, 136–141. [Google Scholar]

- Chen, Z.; Um, T.I.; Zhu, J.; Bart-Smith, H. Bio-inspired robotic cownose ray propelled by electroactive polymer pectoral fin. Biomed. Biotechnol. Eng. Nanoeng. Med. Biol. 2011, 54884, 817–824. [Google Scholar]

- Rogóż, M.; Zeng, H.; Xuan, C.; Wiersma, D.S.; Wasylczyk, P. Light-driven soft robot mimics caterpillar locomotion in natural scale. Adv. Opt. Mater. 2016, 4, 1689–1694. [Google Scholar] [CrossRef]

- Dollar, A.M.; Jentoft, L.P.; Gao, J.H.; Howe, R.D. Contact sensing and grasping performance of compliant hands. Auton. Robot. 2010, 28, 1. [Google Scholar] [CrossRef]

- Kofod, G.; Wirges, W.; Paajanen, M.; Bauer, S. Energy minimization for self-organized structure formation and actuation. Appl. Phys. Lett. 2007, 90, 8. [Google Scholar] [CrossRef]

- Su, K.Y.; Gul, J.Z.; Choi, K.H. A biomimetic jumping locomotion of functionally graded frog soft robot. In Proceedings of the 2017 14th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Jeju, Republic of Korea, 28 June–1 July 2017. [Google Scholar]

- Chang, M.H.; Chae, S.H.; Yoo, H.J.; Kim, S.H.; Kim, W.; Cho, K.J. Loco-sheet: Morphing inchworm robot across rough-terrain. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Republic of Korea, 14–18 April 2019. [Google Scholar]

- Munadi, M.; Ariyanto, M.; Setiawan, J.D.; Ayubi, M.F.A. Development of a low-cost quadrupedal starfish soft robot. In Proceedings of the 2018 5th International Conference on Information Technology, Computer, and Electrical Engineering (ICITACEE), Semarang, Indonesia, 27–28 September 2018. [Google Scholar]

- Tawk, C.; Sariyildiz, E.; Zhou, H.; Marc in het Panhuis; Spinks, G.M.; Alici, G. Position control of a 3D printed soft finger with integrated soft pneumatic sensing chambers. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Teeple, C.B.; Koutros, T.N.; Graule, M.A.; Wood, R.J. Multi-segment soft robotic fingers enable robust precision grasping. Int. J. Robot. Res. 2020, 39, 1647–1667. [Google Scholar] [CrossRef]

- Honji, S.; Tahara, K. Dynamic modeling and joint design of a cable driven soft gripper. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Gatto, V.L.; Rossiter, J.M.; Hauser, H. Robotic jellyfish actuated by soft FinRay effect structured tentacles. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Patterson, Z.J.; Sabelhaus, A.P.; Majidi, C. Robust Control of a Multi-Axis Shape Memory Alloy-Driven Soft Manipulator. IEEE Robot. Autom. Lett. 2022, 7, 2210–2217. [Google Scholar] [CrossRef]

- Zheng, Z.; Kumar, P.; Chen, Y.; Cheng, H.; Wagner, S.; Chen, M.; Verma, N.; Sturm, J.C. Model-Based Control of Planar Piezoelectric Inchworm Soft Robot for Crawling in Constrained Environments. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, UK, 4–8 April 2022. [Google Scholar] [CrossRef]

- Bhattacharjee, A.; Rogowski, L.W.; Zhang, X.; Kim, M.J. Untethered Soft Millirobot with Magnetic Actuation. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020. [Google Scholar] [CrossRef]

- Meder, F.; Babu, S.P.M.; Mazzolai, B. A Plant Tendril-Like Soft Robot That Grasps and Anchors by Exploiting its Material Arrangement. IEEE Robot. Autom. Lett. 2022, 7, 5191–5197. [Google Scholar] [CrossRef]

- Sakuhara, Y.; Shimizu, H.; Ito, K. Climbing Soft Robot Inspired by Octopus. In Proceedings of the 2020 IEEE 10th International Conference on Intelligent Systems (IS), Varna, Bulgaria, 28–30 August 2020. [Google Scholar] [CrossRef]

- Alizadehyazdi, V.; Bonthron, M.; Spenko, M. An Electrostatic/Gecko-Inspired Adhesives Soft Robotic Gripper. IEEE Robot. Autom. Lett. 2020, 5, 4679–4686. [Google Scholar] [CrossRef]

- Oh, B.; Park, Y.G.; Jung, H.; Ji, S.; Cheong, W.H.; Cheon, J.; Lee, W.; Park, J.U. Untethered Soft Robotics with Fully Integrated Wireless Sensing and Actuating Systems for Somatosensory and Respiratory Functions. Soft Robot. 2020, 7, 564–573. [Google Scholar] [CrossRef] [PubMed]

- Karipoth, P.; Christou, A.; Pullanchiyodan, A.; Dahiya, R. Bioinspired Inchworm- and Earthworm-like Soft Robots with Intrinsic Strain Sensing. Adv. Intell. Syst. 2021, 4, 2100092. [Google Scholar] [CrossRef]

- Sun, W.; Li, B.; Zhang, F.; Fang, C.; Lu, Y.; Gao, X.; Cao, C.; Chen, G.; Zhang, C.; Wang, Z.L. TENG-Bot: Triboelectric nanogenerator powered soft robot made of uni-directional dielectric elastomer. Nano Energy 2021, 85, 106012. [Google Scholar] [CrossRef]

- Morin, S.A.; Shepherd, R.F.; Kwok, S.W.; Stokes, A.A.; Nemiroski, A.; Whitesides, G.M. Camouflage and display for soft machines. Science 2012, 337, 828–832. [Google Scholar] [CrossRef]

- Marchese, A.D.; Onal, C.D.; Rus, D. Autonomous soft robotic fish capable of escape maneuvers using fluidic elastomer actuators. Soft Robot. 2014, 1, 75–87. [Google Scholar] [CrossRef]

- Shepherd, R.F.; Stokes, A.A.; Freake, J.; Barber, J.; Snyder, P.W.; Mazzeo, A.D.; Cademartiri, L.; Morin, S.A.; Whitesides, G.M. Using explosions to power a soft robot. Angew. Chem. Int. Ed. 2013, 52, 2892–2896. [Google Scholar] [CrossRef]

- Mosadegh, B.; Polygerinos, P.; Keplinger, C.; Wennstedt, S.; Shepherd, R.F.; Gupta, U.; Shim, J.; Bertoldi, K.; Walsh, C.J.; Whitesides, G.M. Pneumatic networks for soft robotics that actuate rapidly. Adv. Funct. Mater. 2014, 24, 2163–2170. [Google Scholar] [CrossRef]

- Onal, C.D.; Rus, D. Autonomous undulatory serpentine locomotion utilizing body dynamics of a fluidic soft robot. Bioinspiration Biomimetics 2013, 8, 2. [Google Scholar] [CrossRef] [PubMed]

- Onal, C.D.; Chen, X.; Whitesides, G.M.; Rus, D. Soft mobile robots with on-board chemrical pressure geneation. In Tracts in Advanced Robotics; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; pp. 525–540. [Google Scholar]

- Tolley, M.T.; Shepherd, R.F.; Karpelson, M.; Bartlett, N.W.; Galloway, K.C.; Wehner, M.; Nunes, R.; Whitesides, G.M.; Wood, R.J. An untethered jumping soft robot. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14–18 September 2014. [Google Scholar]

- Stokes, A.A.; Shepherd, R.F.; Morin, S.A.; Ilievski, F.; Whitesides, G.M. A hybrid combining hard and soft robots. Soft Robot. 2014, 1, 70–74. [Google Scholar] [CrossRef]

- Suzumori, K.; Endo, S.; Kanda, T.; Kato, N.; Suzuki, H. A bending pneumatic rubber actuator realizing soft-bodied manta swimming robot. In Proceedings of the Proceedings 2007 IEEE International Conference on Robotics and Automation, Roma, Italy, 10–14 April 2007. [Google Scholar]

- Maeder-York, P.; Clites, T.; Boggs, E.; Neff, R.; Polygerinos, P.; Holland, D.; Stirling, L.; Galloway, K.; Wee, C.; Walsh, C. Biologically inspired soft robot for thumb rehabilitation1. J. Med Devices 2014, 8, 2. [Google Scholar] [CrossRef]

- Follador, M.; Tramacere, F.; Mazzolai, B. Dielectric elastomer actuators for octopus inspired suction cups. Bioinspiration Biomimetics 2014, 9, 4. [Google Scholar] [CrossRef] [PubMed]

- Goldfield, E.C.; Park, Y.L.; Chen, B.R.; Hsu, W.H.; Young, D.; Wehner, M.; Kelty-Stephen, D.G.; Stirling, L.; Weinberg, M.; Newman, D.; et al. Bio-inspired design of soft robotic assistive devices: The interface of physics, biology, and behavior. Ecol. Psychol. 2012, 24, 300–327. [Google Scholar] [CrossRef]

- Deimel, R.; Brock, O. A novel type of compliant and underactuated robotic hand for dexterous grasping. Int. J. Robot. Res. 2015, 35, 161–185. [Google Scholar] [CrossRef]

- Suzumori, I.A. Tanaka. Applying a flexible microactuator to robotic mechanisms. IEEE Control. Syst. 1992, 12, 21–27. [Google Scholar]

- Marchese, A.D.; Komorowski, K.; Onal, C.D.; Rus, D. Design and control of a soft and continuously deformable 2d robotic manipulation system. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014. [Google Scholar]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Walsh, C.J. Soft robotic glove for combined assistance and at-home rehabilitation. Robot. Auton. Syst. 2015, 73, 135–143. [Google Scholar] [CrossRef]

- Martinez, R.V.; Branch, J.L.; Fish, C.R.; Jin, L.; Shepherd, R.F.; Nunes, R.M.D.; Suo, Z.; Whitesides, G.M. Robotic tentacles with three-dimensional mobility based on flexible elastomers. Adv. Mater. 2012, 25, 205–212. [Google Scholar] [CrossRef]

- Park, Y.L.; Rong Chen, B.; Pérez-Arancibia, N.O.; Young, D.; Stirling, L.; Wood, R.J.; Goldfield, E.C.; Nagpal, R. Design and control of a bio-inspired soft wearable robotic device for ankle–foot rehabilitation. Bioinspiration Biomimetics 2014, 9, 016007. [Google Scholar] [CrossRef] [PubMed]

- Sanan, S.; Lynn, P.S.; Griffith, S.T. Pneumatic torsional actuators for inflatable robots. J. Mech. Robot. 2014, 6, 3. [Google Scholar] [CrossRef]

- Roche, E.T.; Wohlfarth, R.; Overvelde, J.T.B.; Vasilyev, N.V.; Pigula, F.A.; Mooney, D.J.; Bertoldi, K.; Walsh, C.J. A bioinspired soft actuated material. Adv. Mater. 2013, 26, 1200–1206. [Google Scholar] [CrossRef] [PubMed]

- Devi, M.A.; Udupa, G.; Sreedharan, P. A novel underactuated multi-fingered soft robotic hand for prosthetic application. Robot. Auton. Syst. 2018, 100, 267–277. [Google Scholar]

- Chen, L.; Yang, C.; Wang, H.; Branson, D.T.; Dai, J.S.; Kang, R. Design and modeling of a soft robotic surface with hyperelastic material. Mech. Mach. Theory 2018, 130, 109–122. [Google Scholar] [CrossRef]

- Qi, Q.; Teng, Y.; Li, X. Design and characteristic study of a pneumatically actuated earthworm-like soft robot. In Proceedings of the 2015 International Conference on Fluid Power and Mechatronics (FPM), Harbin, China, 5–7 August 2015. [Google Scholar]

- Vergara, A.; Lau, Y.-s.; Mendoza-Garcia, R.F.; Zagal, J.C. Soft Modular Robotic Cubes: Toward Replicating Morphogenetic Movements of the Embryo. PLoS ONE 2017, 12, e0169179. [Google Scholar] [CrossRef]

- Ortiz, D.; Gravish, N.; Tolley, M.T. Soft robot actuation strategies for locomotion in granular substrates. IEEE Robot. Autom. Lett. 2019, 4, 2630–2636. [Google Scholar] [CrossRef]

- Truby, R.L.; Katzschmann, R.K.; Lewis, J.A.; Rus, D. Soft robotic fingers with embedded ionogel sensors and discrete actuation modes for somatosensitive manipulation. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft) COEX, Seoul, Republic of Korea, 14–18 April 2019; pp. 14–18. [Google Scholar]

- Gamus, B.; Salem, L.; Gat, A.D.; Or, Y. Understanding inchworm crawling for soft-robotics. IEEE Robot. Autom. Lett. 2020, 5, 1397–1404. [Google Scholar] [CrossRef]

- Das, R.; Babu, S.P.M.; Palagi, S.; Mazzolai, B. Soft Robotic Locomotion by Peristaltic Waves in Granular Media. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar] [CrossRef]

- Milana, E.; Raemdonck, B.V.; Cornelis, K.; Dehaerne, E.; Clerck, J.D.; Groof, Y.D.; Vil, T.D.; Gorissen, B.; Reynaerts, D. EELWORM: A bioinspired multimodal amphibious soft robot. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Tse, Y.A.; Liu, S.; Yang, Y.; Wang, M.Y. A flexible connector for soft modular robots based on micropatterned intersurface jamming. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Partridge, A.J.; Conn, A.T. Passive, reflex response units for reactive soft robotic systems. IEEE Robot. Autom. Lett. 2020, 5, 4014–4020. [Google Scholar] [CrossRef]

- Yao, Y.; He, L.; Maiolino, P. A Simulation-Based Toolbox to Expedite the Digital Design of Bellow Soft Pneumatic Actuators. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, UK, 4–8 April 2022. [Google Scholar] [CrossRef]

- Yang, H.D.; Cooper, M.; Akbas, T.; Schumm, L.; Orzel, D.; Walsh, C.J. A Soft Inflatable Wearable Robot for Hip Abductor Assistance: Design and Preliminary Assessment. In Proceedings of the 2020 8th IEEE RAS/EMBS International Conference for Biomedical Robotics and Biomechatronics (BioRob), New York, NY, USA, 29 November–1 December 2020. [Google Scholar] [CrossRef]

- Hao, Y.; Biswas, S.; Hawkes, E.W.; Wang, T.; Zhu, M.; Wen, L.; Visell, Y. A Multimodal, Enveloping Soft Gripper: Shape Conformation, Bioinspired Adhesion, and Expansion-Driven Suction. IEEE Trans. Robot. 2021, 37, 350–362. [Google Scholar] [CrossRef]

- Ma, J.; Chen, D.; Liu, Z.; Wang, M. A Soft Wearable Exoskeleton with Pneumatic Actuator for Assisting Upper Limb. In Proceedings of the 2020 IEEE International Conference on Real-time Computing and Robotics (RCAR), Asahikawa, Japan, 28–29 September 2020. [Google Scholar] [CrossRef]

- Zou, J.; Yang, M.; Jin, G. A five-way directional soft valve with a case study: A starfish like soft robot. In Proceedings of the 2020 5th International Conference on Automation, Control and Robotics Engineering (CACRE), Dalian, China, 19–20 September 2020. [Google Scholar] [CrossRef]

- Abondance, S.; Teeple, C.B.; Wood, R.J. A Dexterous Soft Robotic Hand for Delicate In-Hand Manipulation. IEEE Robot. Autom. Lett. 2020, 5, 5502–5509. [Google Scholar] [CrossRef]

- Walker, I.D.; Dawson, D.M.; Flash, T.; Grasso, F.W.; Hanlon, R.T.; Hochner, B.; Kier, W.M.; Pagano, C.C.; Rahn, C.D.; Zhang, Q.M. Continuum robot arms inspired by cephalopods. In Unmanned Ground Vehicle Technology VII; Gerhart, G.R., Shoemaker, C.M., Gage, D.W., Eds.; SPIE: Orlando, FL, USA, 2005. [Google Scholar]

- McMahan, W.; Chitrakaran, V.; Csencsits, M.; Dawson, D.; Walker, I.D.; Jones, B.A.; Pritts, M.; Dienno, D.; Grissom, M.; Rahn, C.D. Field trials and testing of the OctArm continuum manipulator. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, Orlando, FL, USA, 15–19 May 2006. [Google Scholar]

- Boxerbaum, A.S.; Shaw, K.M.; Chiel, H.J.; Quinn, R.D. Continuous wave peristaltic motion in a robot. Int. J. Robot. Res. 2012, 31, 302–318. [Google Scholar] [CrossRef]

- Kwon, G.H.; Park, J.Y.; Kim, J.Y.; Frisk, M.L.; Beebe, D.J.; Lee, S.H. Biomimetic soft multifunctional miniature aquabots. Small 2008, 4, 2148–2153. [Google Scholar] [CrossRef] [PubMed]

- Galloway, K.C.; Clark, J.E.; Yim, M.; Koditschek, D.E. Experimental investigations into the role of passive variable compliant legs for dynamic robotic locomotion. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 1243–1249. [Google Scholar]

- Nakabo, Y.; Mukai, T.; Asaka, K. Biomimetic soft robots with artificial muscles. In Smart Materials III; Wilson, A.R., Ed.; SPIE: Sydney, Australia, 2004. [Google Scholar]

- Otake, M.; Kagami, Y.; Inaba, M.; Inoue, H. Motion design of a starfish-shaped gel robot made of electro-active polymer gel. Robot. Auton. Syst. 2002, 40, 185–191. [Google Scholar] [CrossRef]

- Morales, D.; Palleau, E.; Dickey, M.D.; Velev, O.D. Electro-actuated hydrogel walkers with dual responsive legs. Soft Matter 2014, 10, 1337–1348. [Google Scholar] [CrossRef] [PubMed]

- Yu, B.; Natarajan, S. An easy use auxiliary arm: Design and control of a portable continuum manipulator for enhanced dexterity by soft rigid arms collaboration. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Deutschmann, B.; Reinecke, J.; Dietrich, A. Open Source Tendon-driven Continuum Mechanism: A Platform for Research in Soft Robotics. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, UK, 4–8 April 2022. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, B.; Li, W.; Zu, L.; Tang, W.; Wang, Z.L. Bioinspired Triboelectric Soft Robot Driven by Mechanical Energy. Adv. Funct. Mater. 2021, 31, 2104770. [Google Scholar] [CrossRef]

- Li, D.; Wang, S.; He, J.; Zeng, H.; Yao, K.; Gao, Z.; Wu, M.; Liu, Y.; Wang, L.; Xie, Z.; et al. Bioinspired Ultrathin Piecewise Controllable Soft Robots. Adv. Mater. Technol. 2021, 6, 2001095. [Google Scholar] [CrossRef]

- Marchese, A.D.; Rus, D. Design, kinematics, and control of a soft spatial fluidic elastomer manipulator. Int. J. Robot. Res. 2015, 35, 840–869. [Google Scholar] [CrossRef]

- Rafter, A.; Hollinger, G.A.; Menguc, Y.; Olson, G. Analyzing the effect of soft arm design on obstacle navigation through collision. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Bodily, D.M.; Allen, T.F.; Killpack, M.D. Multi-objective design optimization of a soft, pneumatic robot. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017. [Google Scholar]

- Wakamatsu, K.; Inoue, K.; Hagiwara, D.; Adachi, H.; Matsui, D.; Kurumaya, S.; Nishihama, R.; Okui, M.; Nakajima, K.; Kuniyoshi, Y.; et al. Mixing state estimation of peristaltic continuous mixing conveyor with distributed sensing system based on soft intestine motion. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Nguyen, P.H.; Qiao, Z.; Seidel, S.; Amatya, S.; Mohd, I.I.B.; Zhang, W. Towards an untethered knit fabric soft continuum robotic module with embedded fabric sensing. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Lamping, F.; Muller, D.; de Payrebrune, K.M. A systematically derived design for a modular pneumatic soft bending actuator. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, UK, 4–8 April 2022. [Google Scholar] [CrossRef]

- Hall, D.; Williams, C. Big Hero 6; Walt Disney Animation Studios: Burbank, CA, USA, 2014. [Google Scholar]

- Karimi, M.A.; Alizadehyazdi, V.; Busque, B.P.; Jaeger, H.M.; Spenko, M. A boundary-constrained swarm robot with granular jamming. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

- Meng, J.; Gerez, L.; Chapman, J.; Liarokapis, M. A tendon-driven, pneumatically actuated, soft robotic gripper with a telescopic palm. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).