1. Introduction

In recent years, continuum robots have increasingly been used to perform operations in confined spaces due to their inherent dexterity, compact structure, and ability to adapt to complex environments [

1,

2]. Generally, the length-to-diameter ratio of continuum robots is very high, enabling the delivery of end effectors deep into tight spaces with limited access [

3,

4]. Additionally, given the availability of compatible specialty end effectors (for instance, NDT [

5] and other sensors [

6]), the number of applications that can be automated has been extended [

7,

8]. However, in some scenarios, a single continuum manipulator is insufficient to complete a complicated task [

9]. Take, for example, the need to cut and retrieve a solid sample from a confined space for decommissioning planning [

8]. At least two continuum arms working collaboratively are needed to perform the task (i.e., one to hold and one to remove the sample). However, correctly operating a continuum manipulator-based robot, which is likely to have many DoF’s, involves calculating the inverse kinematics and/or dynamics [

10], which is complicated for a single continuum arm conducting a straightforward task, let alone for multiple continuum arms [

11].

Significant effort has been expended recently in developing continuum robots to cope with the demands of specific challenging environments. For example, a particularly long and slender continuum arm (length: 1.5 m; diameter: 12.5 mm) was developed for aeroengine maintenance [

7]. Further, a 3 m long, dual segment (a dexterous section supported by a rigid section) continuum robot with 60 joints was designed to facilitate the maintenance of a nuclear power plant [

12]. Most of these robots are single manipulators designed to operate alone. However, there have been several attempts to develop continuum robots that either work together with other robots or have multiple manipulators that operate collaboratively. For instance, two identical robotic systems with different end effectors (one with a camera and flame ignitor, another with a thermal spray nozzle), developed at Nottingham University in collaboration with Rolls Royce plc [

13], were deployed to repair the coatings on the inside of a very cramped aeroengine collaboratively from two opposite inspection holes [

12]. Dual-arm continuum robots have been considered for telesurgery to perform ‘two-handed’ tasks, including suture passing and knot tying, such as the system developed by Columbia University and Vanderbilt University, where two or more concentric tube continuum arms extend from a rigid base [

13,

14]. As the shape of the arms here is dictated by complex anatomical features, the necessarily high-accuracy control relies on a complicated kinetostatic model [

15]. A hybrid dual-arm robotic system, developed by a consortium of universities in China, consists of a combination of a rigid manipulator and a continuum manipulator, which have been designed with the intent to operate collaboratively [

16]. However, to the best knowledge of the authors to date, the proposed design has been simulated but not yet validated experimentally.

As these robots have been largely used in challenging environments that humans cannot access (e.g., in dangerous conditions [

17] and/or in confined spaces [

18]) to perform tasks that often mimic or extend human performance, that is, multiple arms with complex end effectors working together, different collaboration strategies (e.g., robot–robot [

19,

20] and human–robot [

21,

22]) have been developed. For example, six commercial robots have been deployed to work collaboratively in a large-scale additive manufacturing process to reduce manufacturing time and improve flexibility [

23]. The activities of these robots are coordinated by a central control system that uses process sequencing to ensure that robot–robot interference is avoided. In many scenarios, especially in manufacturing and assembly, humans have also been regarded as part of the robotic system. This is called human–robot collaboration, where humans and robots carry out coordinated activities to achieve common goals, for example, the assembly of a pump in a hybrid production cell [

24] wherein tasks are allocated between humans and robots depending on complexity and operation time. This often requires interactions between human and robot so that intent is understood and safety is assured. That was achieved through the monitoring of body gestures in that were interpreted as commands to the robot. Capturing intent by monitoring the motion of both humans and robots and incorporating it into an adaptive impedance control to enable close collaboration was also considered in [

25].

Even though a lot of effort has been spent on the control of multiple collaboratively operating robots, a number of challenges and solution gaps exist, especially for continuum robots. These include: (1) a lack of an analytical solution for continuum robots comprising multiple sections, causing difficulty for real-time control; (2) continuum robots with many redundant actuators, having multiple solutions (i.e., configurations or shape) for the desired tip orientation; (3) the continuous adaption of the shape of the continuum robot for a given toolpath being important to avoid vibration and collision.

To address these challenges for cable-driven collaborative continuum robots, this paper focuses on the following aspects: First, the modelling of a dual 6-DoF continuum arm robot to establish the relationship between the length of the driving cables and the pose of the end effectors, as well as determining and analysing the collaboration workspace, as shown in

Section 3; an optimization-based path planning algorithm to obtain the continuous shape of the continuum arms using the developed inverse kinematic model, which is evaluated using case studies in

Section 4; and an experimental demonstration of the algorithm for collaborative operation in

Section 5 using the robot prototype shown in the next section. Finally, the conclusions are presented in

Section 6.

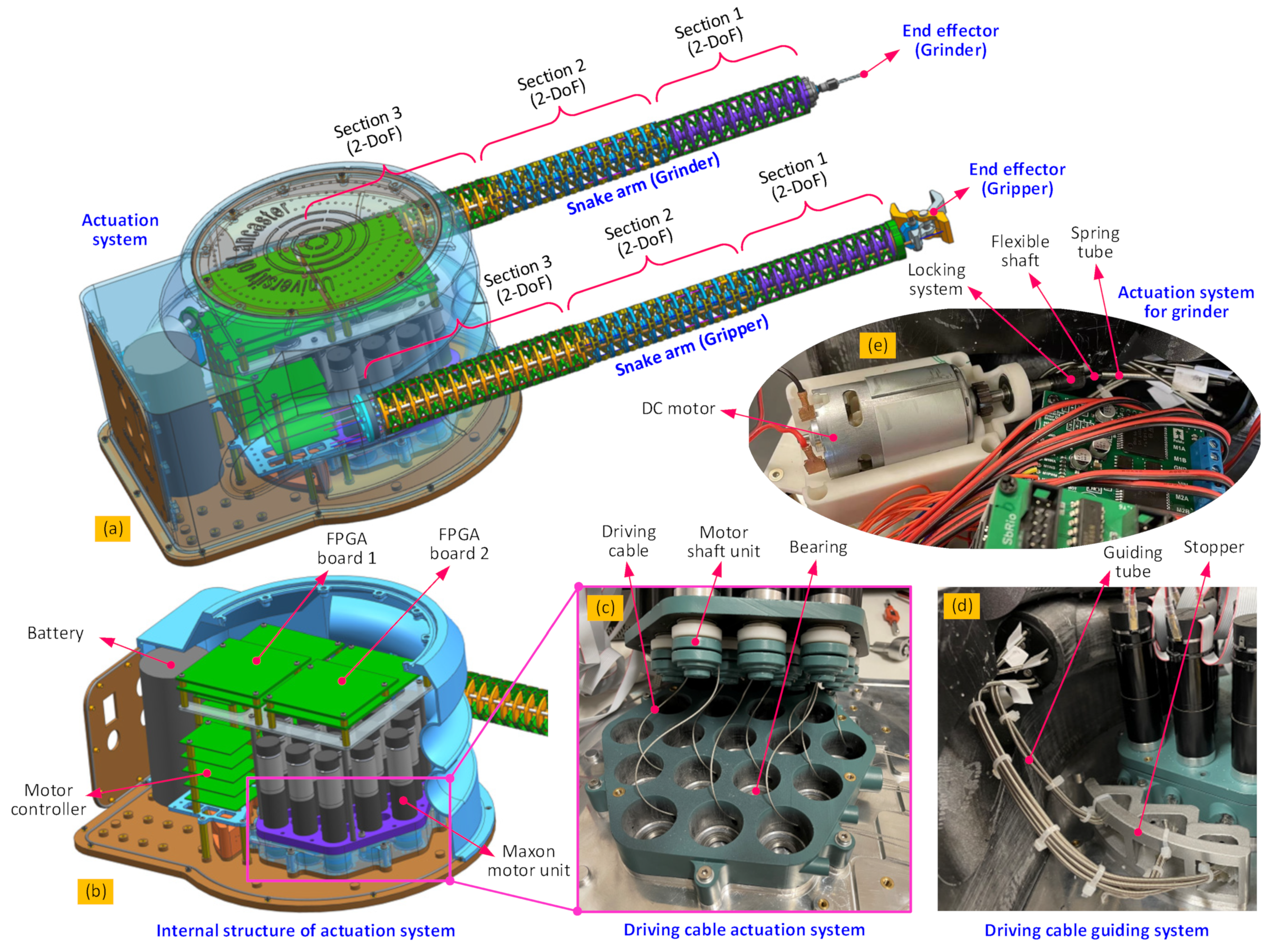

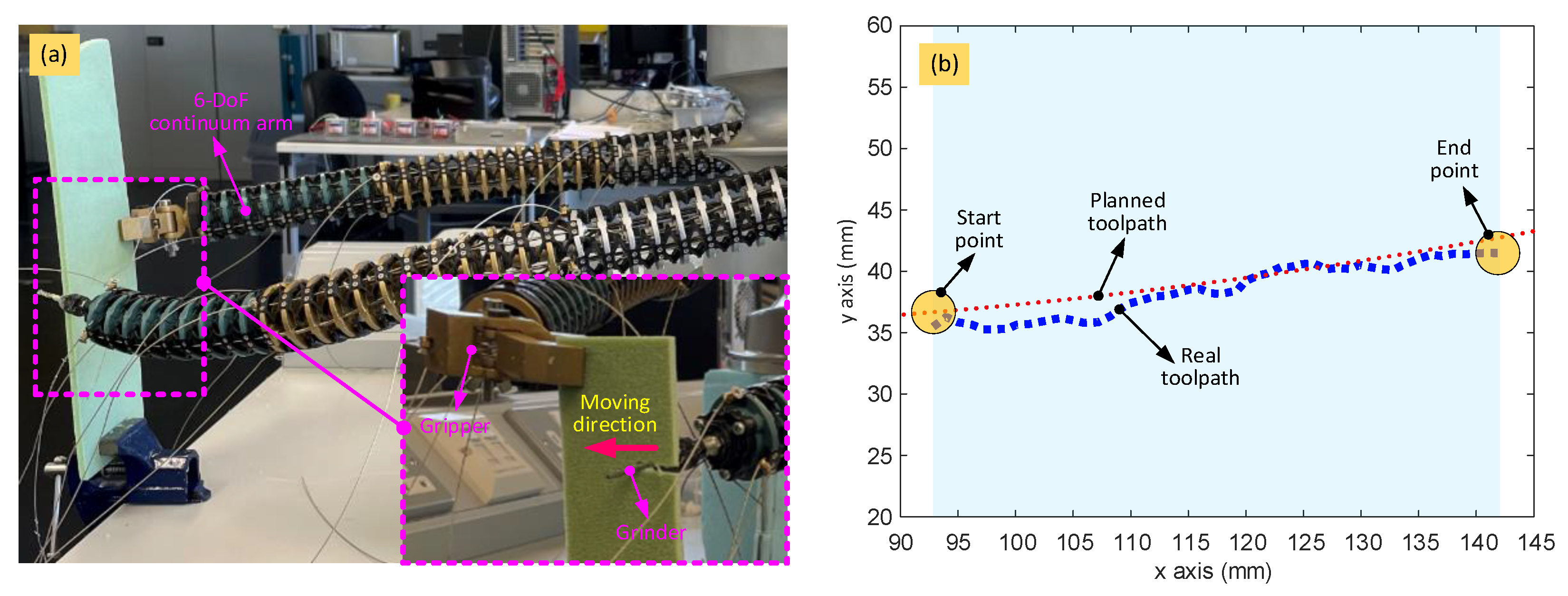

2. Design of a Dual-Arm Continuum Robot

In this paper, a novel dual-arm robotic system is proposed, wherein two 6-DoF continuum, or snake, arms have been incorporated to perform cooperative tasks using specialized end effectors (i.e., as an example here, a rotary grinder is used on the end of the left arm, with a gripper on the right).

The concept of dual-arm operation and structure of the arm originates from the biomimetic structures (e.g., dual-arm from human beings, arm from snakes). Each arm has 6-DoF to enable the dexterity operation capability. When the two arms work collaboratively with their end effectors (e.g., gripper and grinder), it resembles with human beings in using a fork and knife by the arms. To obtain the dexterity compatibility of the arm, the modular 2-DoF sections were serially connected and actuated by the cables, which is inspired by the working principle of snakes and arms of human beings. For each 2-DoF section, the modular disks were connected by ball joints (spine structure) and flexible hinges (muscles around the spine), which are mimicked by the body structure of snakes, enabling the system to have good mechanical performance. With the aforementioned bio-inspired structure, a new kind of dual-arm robotic system was developed for coping with the task in remote challenging environments.

This setup has been configured to operate as a solid sample removal and retrieval system mounted on an underwater remotely operated vehicle (ROV) in a decommissioning scenario as an example. However, it is easily envisioned how it could be adapted for a range of remote engineering and manufacturing applications. In the scenario mentioned, the gripper can hold the structure from which a sample is required, while the grinder on the other arm can be controlled to follow the planned cutting path to remove the sample from the structure. Then the ROV can take the obtained sample, as well as the continuum robot system back to a collection point. The system setup is shown in

Figure 1.

Each biomimetic snake arm is composed of three 2-DoF sections, each providing 6-DoF for each arm. This allows for the control of the position and orientation of the end effectors. These arms are designed to work together collaboratively and have the same length (540 mm) and a small diameter (40 mm), giving a slenderness ratio of 0.074.

To improve the stiffness characteristics of the continuum arms and increase the permissible payload and accuracy, each section is composed of an array of 2-DoF segments connected in series, each formed of three parallel flexure hinges between two rigid disks guided by a central ball joint [

8]. In each section, the diameter of the disks and the width of the flexure hinges are used to optimize the stiffness, with Section 3 being stiffer than Section 2 (as Section 3 has to support the most load), which in turn is stiffer than Section 1 (as Section 1 is ideally the most dexterous section). Cable-driven actuation (shown in detail in

Figure 2) is used to provide position and force control of the arms and, in turn, the end effectors. Each 2-DoF section is actuated by three cables, and therefore, 18 cables and their associated motor units are needed to actuate the dual arms [

8,

26,

27]. The gripper end effector is also cable-actuated, and so another motor unit is required, bringing the number of motor units to be controlled to 19. The grinder end effector is motorized but has its own direct drive system that transmits torque to the cutting tool by way of a long flexible drive shaft.

3. Modelling of the Continuum Robot

Unlike conventional rigid robots, controlling this kind of continuum robots requires adjusting the length of the driving cables. However, as there are normally more than two driving cables required to control each 2-DoF section, the redundancy in actuation will cause challenges in kinematic modelling and control. Further, as each 6-DoF continuum arm is formed by connecting three 2-DoF sections in series, the analytical solution for the inverse kinematics (i.e., given the position and orientation of the end effector, solving the shape parameters of the continuum arm) is difficult.

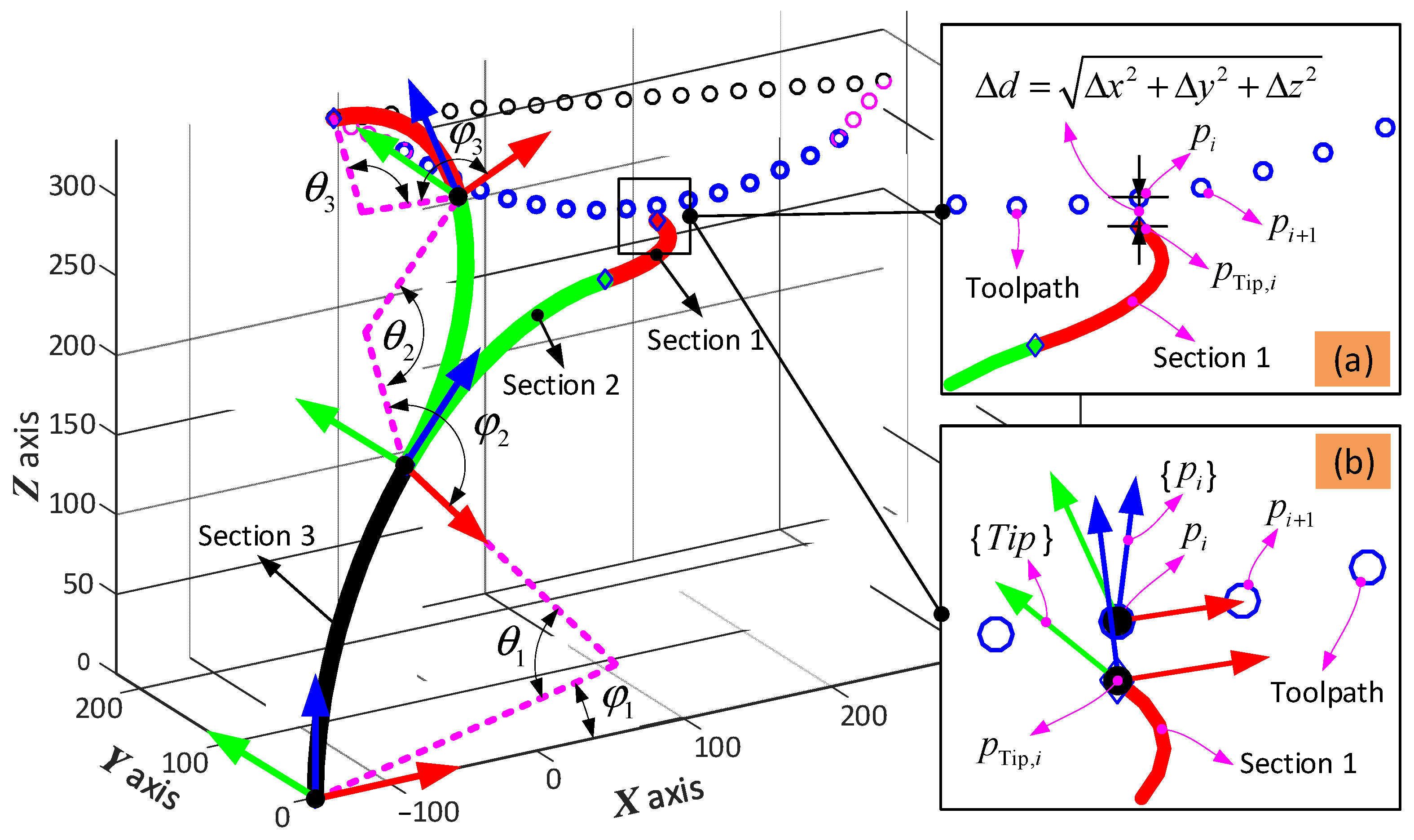

3.1. Kinematic Model

To describe the spatial configuration of the 6-DoF continuum arm, the piecewise constant-curvature theory (PCCT) is used in this paper [

28,

29]. Based on this assumption, the curvature of each 2-DoF section is regarded as part of a circle with a specific radius. For the forward kinematics, the position and orientation of the tip of the 6-DoF continuum arm can be determined given the bending and phase angles of the three sections. Then, given the shape of the 6-DoF continuum arm, the change in length of the driving cables can be determined as well. For the inverse kinematics, it is necessary to determine the bending and phase angles (θ and φ, respectively, in

Figure 3a) of the three sections to satisfy the required position and orientation of the end effector. As the equations are transcendental in nature, there is no analytical solution for the inverse kinematics, and so a novel optimization-based method has been developed to solve this problem.

The coordinate systems for the three sections that make up each 6-DoF arm are shown in

Figure 3. A local coordinate system ({

},

i = 1,2,3) is attached to the base of each 2-DoF continuum section to define the bending and phase angles to parameterize the 2-DoF of each section. One coordinate system {

} is attached to the base of the end effector to define its position and orientation during operation.

Consider a single 2-DoF continuum section, which consists of a series of identical structured segments, as an example. Based on the PCCT, the bending along its axis is assumed to cause a constant curvature, which means that the bending angle for the

j-th segment in the

i-th section,

, can be given as:

where

is the bending angle, and

is the number of segments in the

i-th section.

The transformation matrix from {

} to {

} can be defined as follows: first, {

} moves from its origin

to

along the

axis; then {

} rotates around the

axis by angle

. Thus, the homogeneous transformation matrix can be expressed as:

where

is the rotation matrix generated by rotating about the

axis by angle

of {

};

is the relative position vector from

to

in the {

} frame.

By postmultiplying the transformation matrices of the three sections, the entire kinematic model of the continuum robot can be established:

where

,

, and

are the number of segments in the three continuum sections, respectively;

is the initial transformation matrix of the continuum arm, which can be written as:

where

and

are the initial rotation matrix and position vector, which defines the initial orientation and position of the continuum arm.

The shape of the 6-DoF continuum arm depends on the length of the driving cables. Taking an arbitrary segment as an example, the closed-loop vector can be expressed as:

where

is the relative position vector of the ends of the

i-th driving cable in the

j-th segment;

is the position vector of the centre of the ball joint in {

};

is the position vector of the centre of the upper platform in {

};

is the position vector from the upper platform centre,

, to the cable attaching point in the upper platform,

;

is the position vector of the cable attaching point in the lower platform,

; and

is the rotation matrix of the upper platform. Please refer to [

8] for details.

The change in length of the

i-th driving cable in the

j-th segment can be expressed by taking the norm of the vector

:

Due to the PCCT assumption, wherein the curvature and, hence, the change in length of the

i-th driving cable are the same for all segments within a section, the total change in length of the

i-th driving cable for the whole section (total of all segments) can be expressed as:

where

is the number of 2-DoF segments in each section.

These calculations form the forward kinematic equations for the 6-DoF continuum arm. For the inverse kinematic calculations, the shape parameters (i.e., bending and phase angles) of the three sections need to be calculated for a given position and orientation of the end effector. Then, by using the kinematic model developed in this section, the calculated change in length of the driving cables can be used to control the actuation system.

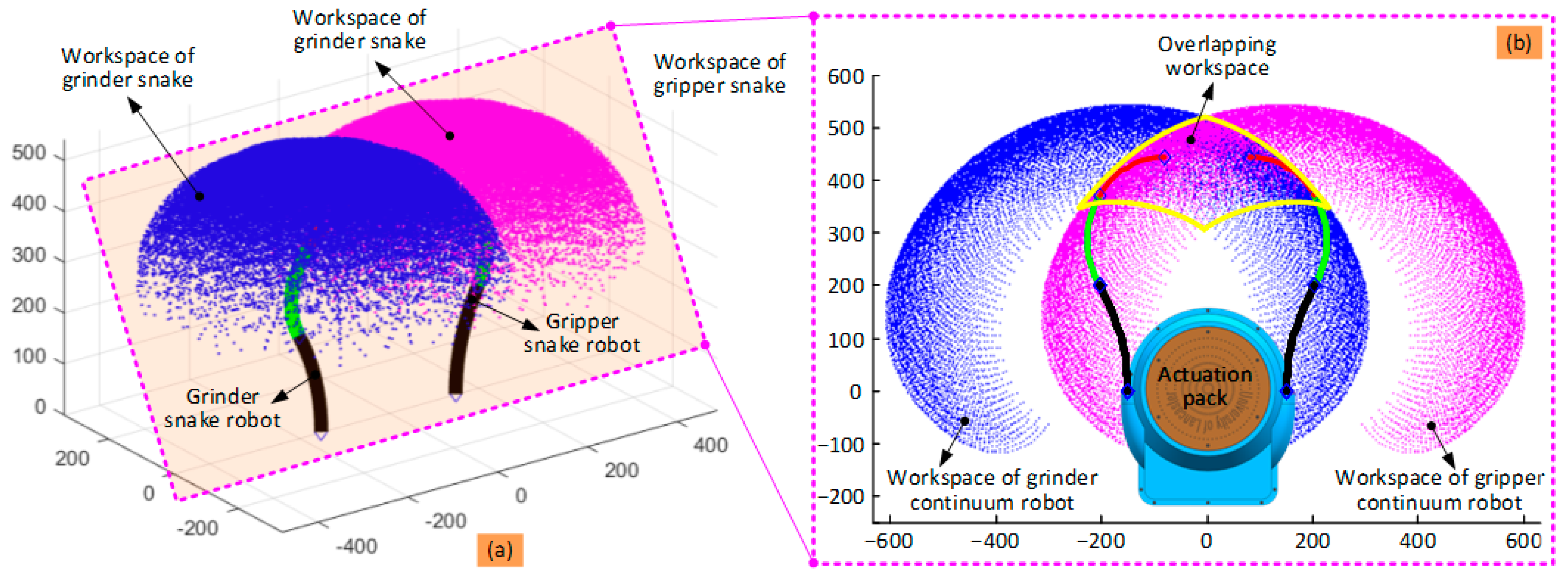

3.2. Cooperative Workspace

Here, the robot consists of two 6-DoF continuum arms, comparable to a human with two dexterous arms working together to complete complicated tasks. The calculation of the workspace for a single 6-DoF continuum robot can be conducted using the kinematic models developed in the last section. However, for the workspace of the dual-arm continuum robot working collaboratively on a task, it is more complicated as the workspace not only depends on the permissible configurations (e.g., bending stroke and length of each 2-DoF segment) of each 6-DoF continuum arm, but also will be dependent on the dimensions and shape of any workpiece that the arms are both working on.

Following the biomimetic design of the continuum arms, the structural dimensions (e.g., diameter of the continuum arm and width of the flexure hinge) in Section 3 are designed to be larger than Section 2 and, in turn, Section 1 to improve the stiffness of the arm. The details of the structural parameters for a 6-DoF continuum arm can be seen in

Table 1.

Based on the kinematic model developed in

Section 3.1, the workspace of the dual-arm continuum robot can be calculated by plotting the tip position of the two 6-DoF continuum arms when changing the bending and phase angles within their strokes (see

Figure 4).

It can be seen from

Figure 4a that the workspace of each 6-DoF continuum arm alone is a segment of a sphere owing to symmetry. For the cooperation workspace, it will be much dependent on the task and size of the object. For the collaborative task of carrying a large-sized object, the collaborative workspace will be larger than the overlapping workspace. Meanwhile, for the collaborative task of sample removal, the collaborative workspace will be much similar to the overlapping workspace. For the overlapping workspace, the tip of both 6-DoF continuum arms can occupy any point within this area, enabling the completion of the designed task (i.e., sample retrieval).

Figure 4b shows a section view of the workspace of the dual-arm continuum robot (defined by the yellow curve in the shape of a cownose ray) and can be used to plan the path of the two continuum arms working collaboratively.

4. Modelling of the Continuum Robot

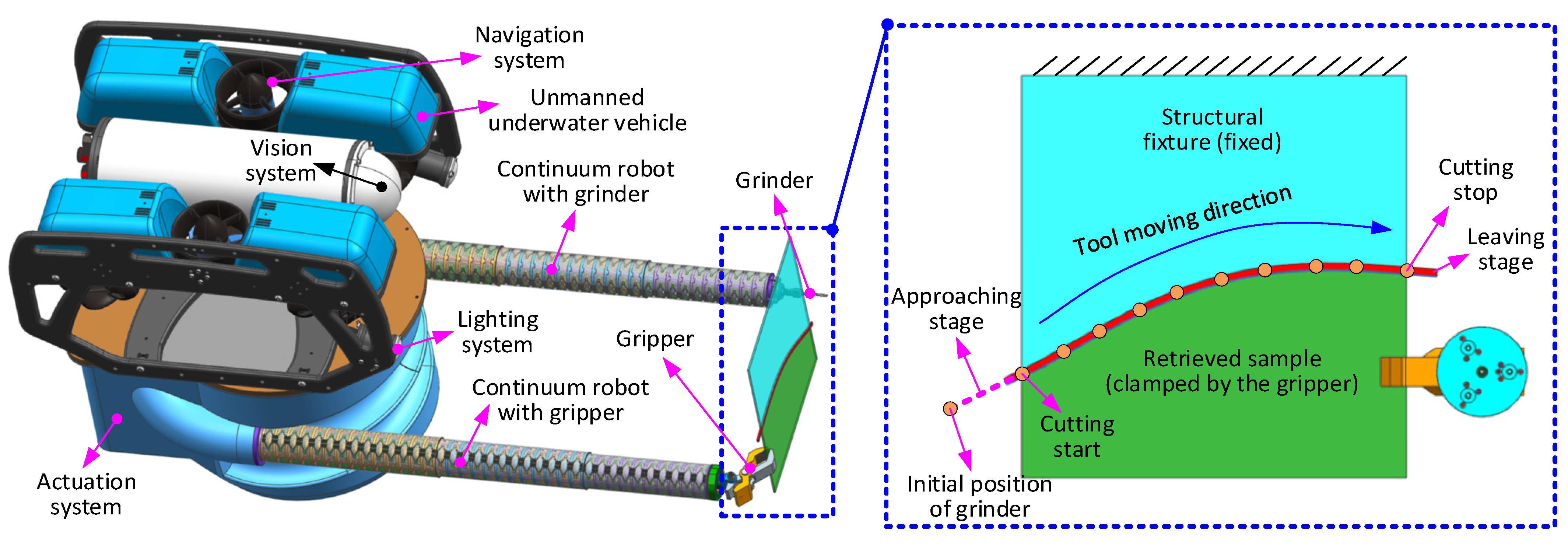

To complete a task collaboratively, the paths of the two 6-DoF continuum arms, and specifically the end effectors, need to be planned based on their specific functions. However, as there is no analytical solution for the inverse kinematics, the shape parameters (i.e., bending and phase angles) of each of the 2-DoF segments in each arm cannot be obtained directly, requiring a new optimization-based strategy.

4.1. Formulation of the Objective Function

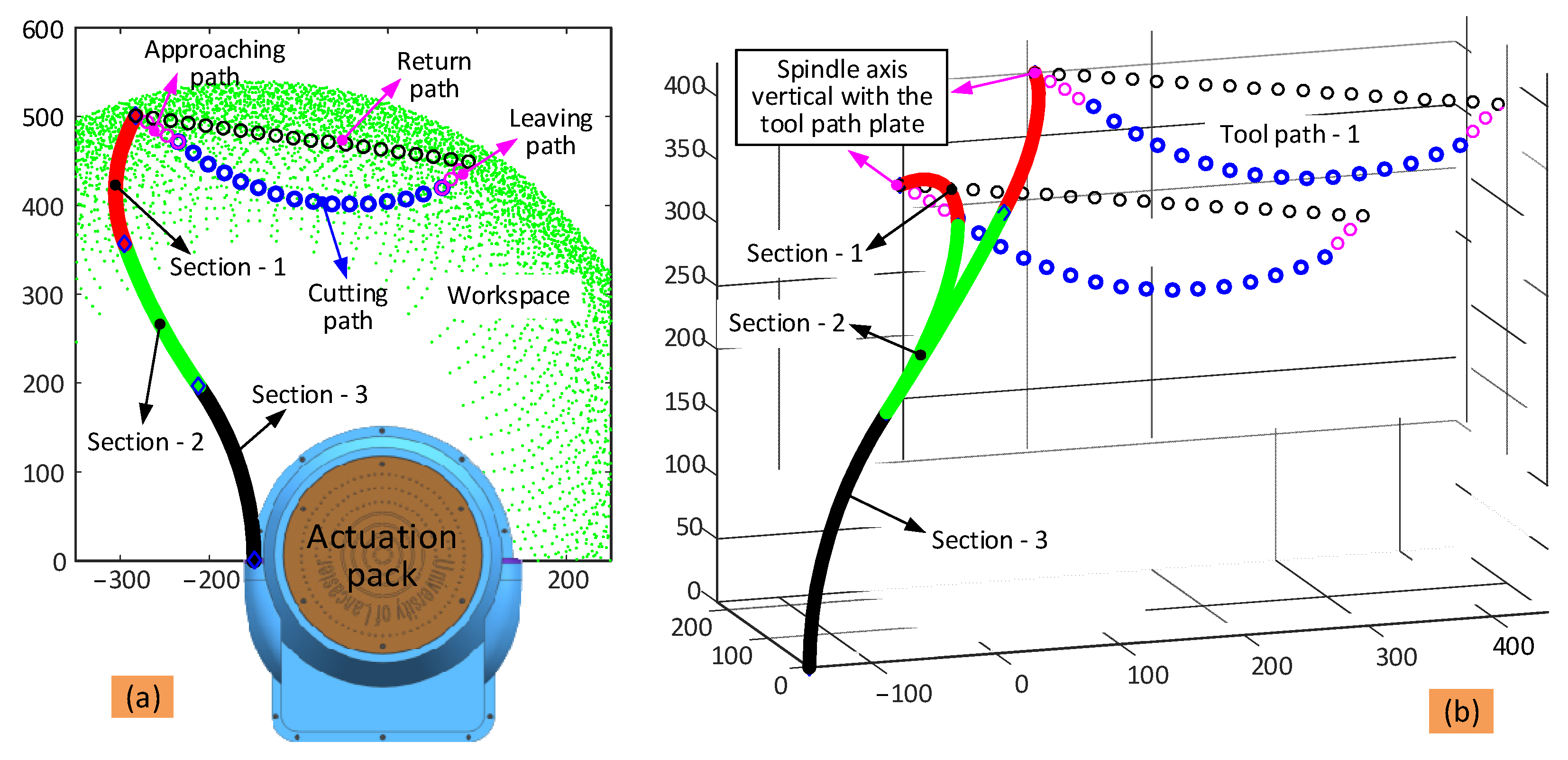

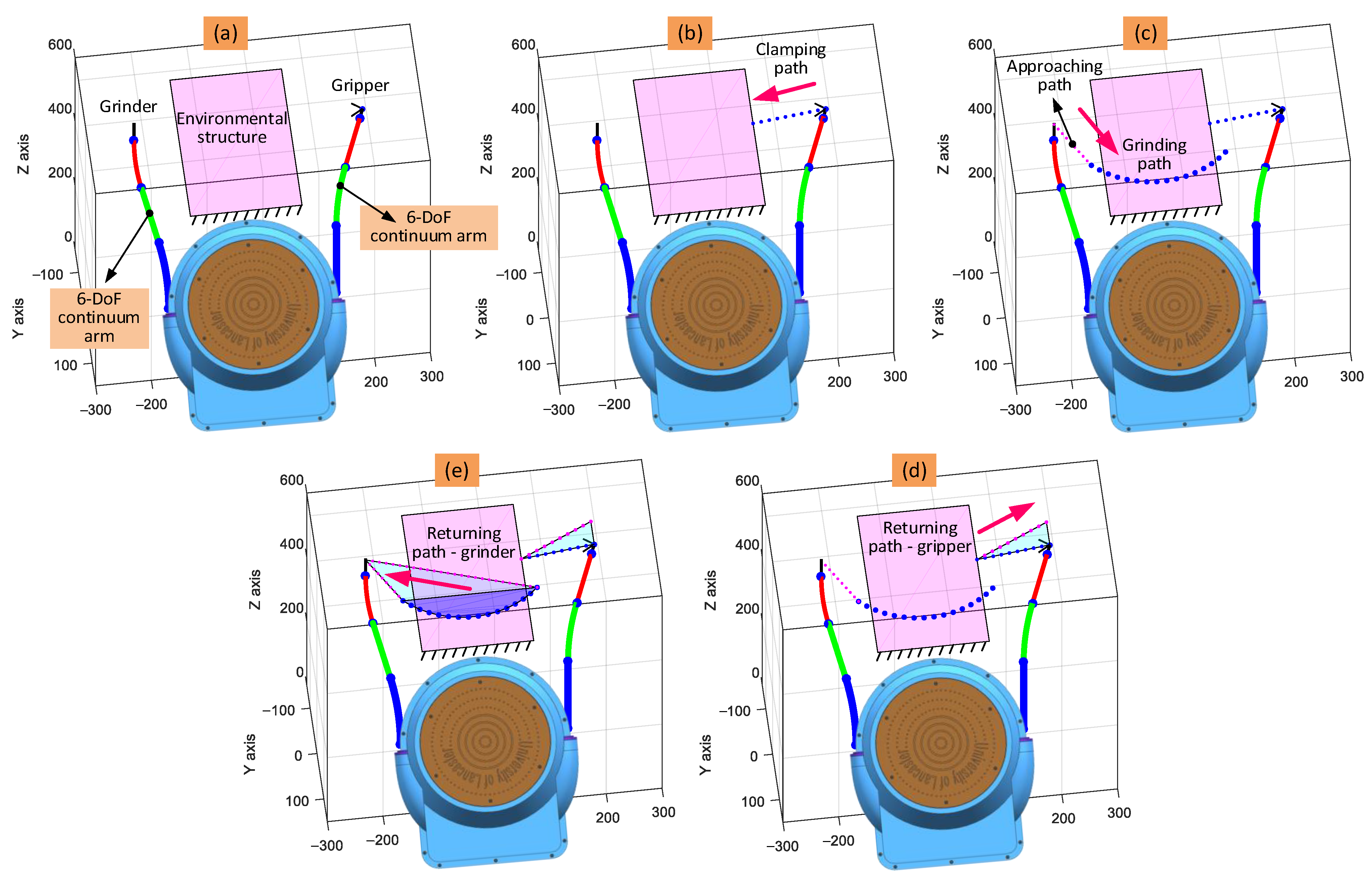

In the remote sample removal case study, the two continuum arms need to work collaboratively. To conduct the operation, the continuum arm with the gripper as an end effector holds the structure at a convenient location to secure the robot and the sample (such as the corner, as this can simplify the cutting path of the grinder), while the other arm with the grinder at the end moves along the specified cutting path to remove the sample from the structure. As the dual-arm robotic system will be attached to a commercial ROV, the initial positioning of the gripper can be aided by the operation of the ROV (see

Figure 5). However, the path of the other arm needs to be carefully planned to complete the task.

To successfully remove the sample from the structure, the following challenges need to be considered during path planning: (1) the path should fit entirely within the workspace of the arm; (2) the arm should not collide with other features (e.g., the other arm); and (3) the approach of the high-speed cutting tool, or grinder, towards the structure needs to be taken with care to enable effective cutting (see enlarged view of

Figure 5).

As the analytical solution for the inverse kinematics is hard to obtain, a new optimization-based approach is proposed to obtain the shape parameters (e.g., bending and phase angles) for each of the three 2-DoF sections of each arm under the specified position and orientation constraints. Taking a single arm as an example, the optimization procedure can be described thus:

- (1)

Generate the path of the end effector, which should fit entirely within the workspace.

- (2)

Parameterize the path at discrete points.

- (3)

Define the optimization objective function based on the position and orientation constraints of the end effector at each point along the path.

- (4)

Run the optimization function to find the shape parameters of the continuum arm to meet the given constraints.

- (5)

Repeat the optimization procedure to all the points to obtain the shape parameters of the continuum arm.

The optimization objective function of the arm can be written as:

where

,

, and

are specified increments of the bending angle, phase angle, and tip advancing distance, respectively;

is the maximization function;

and

are the position and orientation errors (i.e., between the actual and planned values) of the tip; and

and

are the coefficients to assign the weights to the position and orientation subobjectives for the overall objective function.

Specially, the position and orientation errors of the tip can be expressed as:

where

is the norm length of the vector;

is the matrix natural logarithm,

is the operator that maps change in orientation from so(3) to R3,

is the tip position at the new point,

is the planned position of the

i-th point,

is the orientation of the tip at the new point, and

is the planned orientation of the

i-th point.

An example path for the arm with the grinder end effector in the remote sample removal case study is shown in

Figure 6. The full path composed of the approaching and leaving stages (in pink) and operating stage (in blue) fits within the workspace of the 6-DoF continuum arm. The configuration of the 6-DoF continuum arm (configuration: bending and phase angles for the three sections are

and

,

and

, respectively) at two representative points along the path are shown (Section 1: black, Section 2: green, and Section 3: red) in

Figure 6a.

The definitions of the tip position and orientation error used in the subobjective functions are shown in

Figure 6a,b. The position error is defined to be the shortest distance between the actual position and the planned position, which can be expressed as

(see

Figure 6a). Similarly, the orientation error is defined to be the difference in orientation of the three axes, which can be calculated by using Equation (10) (see in

Figure 6b).

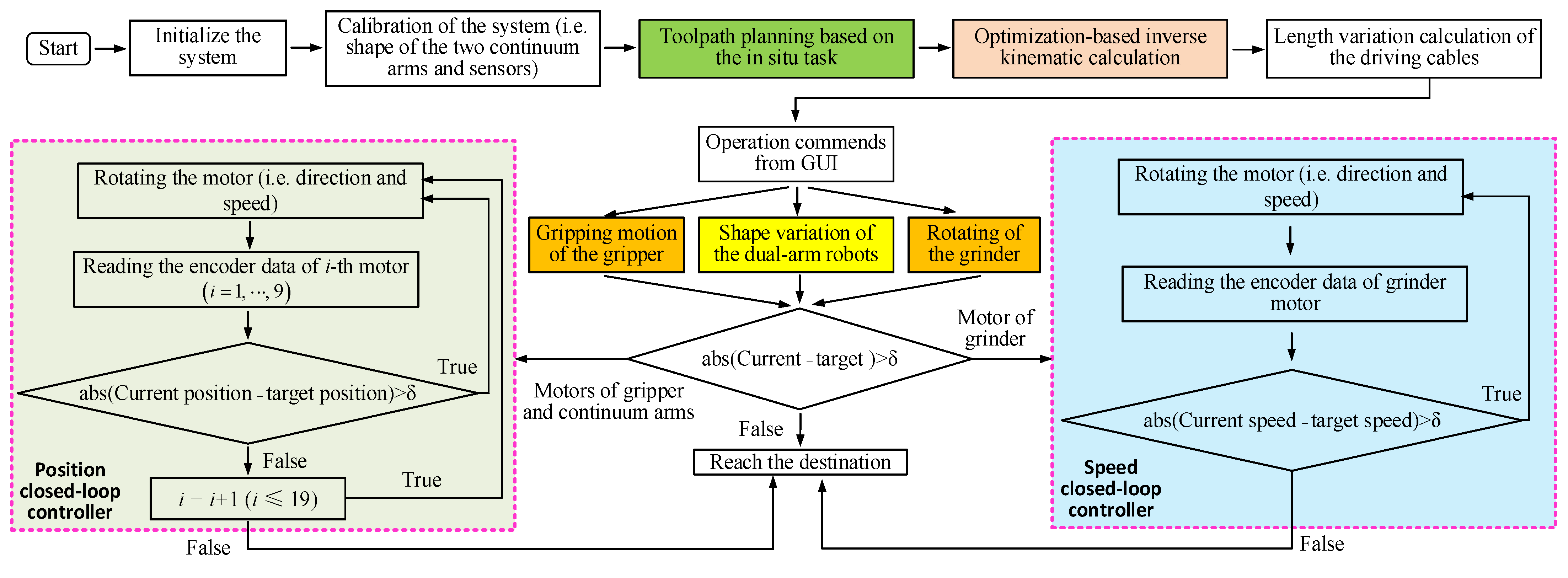

4.2. Toolpath Generation Algorithm

As optimization is a time-consuming procedure, it is unrealistic to infinitely discretize the planned path, even though this could improve the cutting efficacy of the system. To solve this problem, it is proposed that the planned path is discretized into a relatively small number of points whereat the optimization algorithm is used to calculate the configuration of the arms, and then interpolation is used to obtain the results at intermediate locations.

Taking the cutting operation as an example, the full process includes the following steps: (1) the end effector approaches the structure from its initial position at a high speed; (2) the end effector moves along the planned cutting path to remove the sample from the structure at a slow speed; (3) the end effector leaves the structure along the leaving path at a high speed; and finally, (4) the end effector returns to the initial position along the return path at a high speed (see

Figure 7a).

In order to maintain cutting efficiency, the position and orientation of the cutting tool have additional constraints. The spindle axis should be kept normal to the structure surface, and the axis should be coincident with the planned point, with the location of the tip consistent with the required cutting depth. Thus, the following equations should be satisfied:

where,

and

are the position and orientation errors of the end effector, and

and

are the specified position vector and orientation matrix of the end effector.

Given this procedure, the bending angle (

) and phase angle (

) of the

j-th section of each arm at the

i-th point along the toolpath can be determined. Similarly, the bending angle (

) and phase angle (

) at the adjacent (

i + 1-th) point can be obtained in the same way. The bending angle (

) and phase angle (

) at intermediate points can be calculated via interpolation by:

where

is the number of intermediate points between the adjacent toolpath points (i.e.,

i-th and

i + 1-th, respectively). This is an efficient way for calculating the shape parameters of the 6-DoF continuum arms.

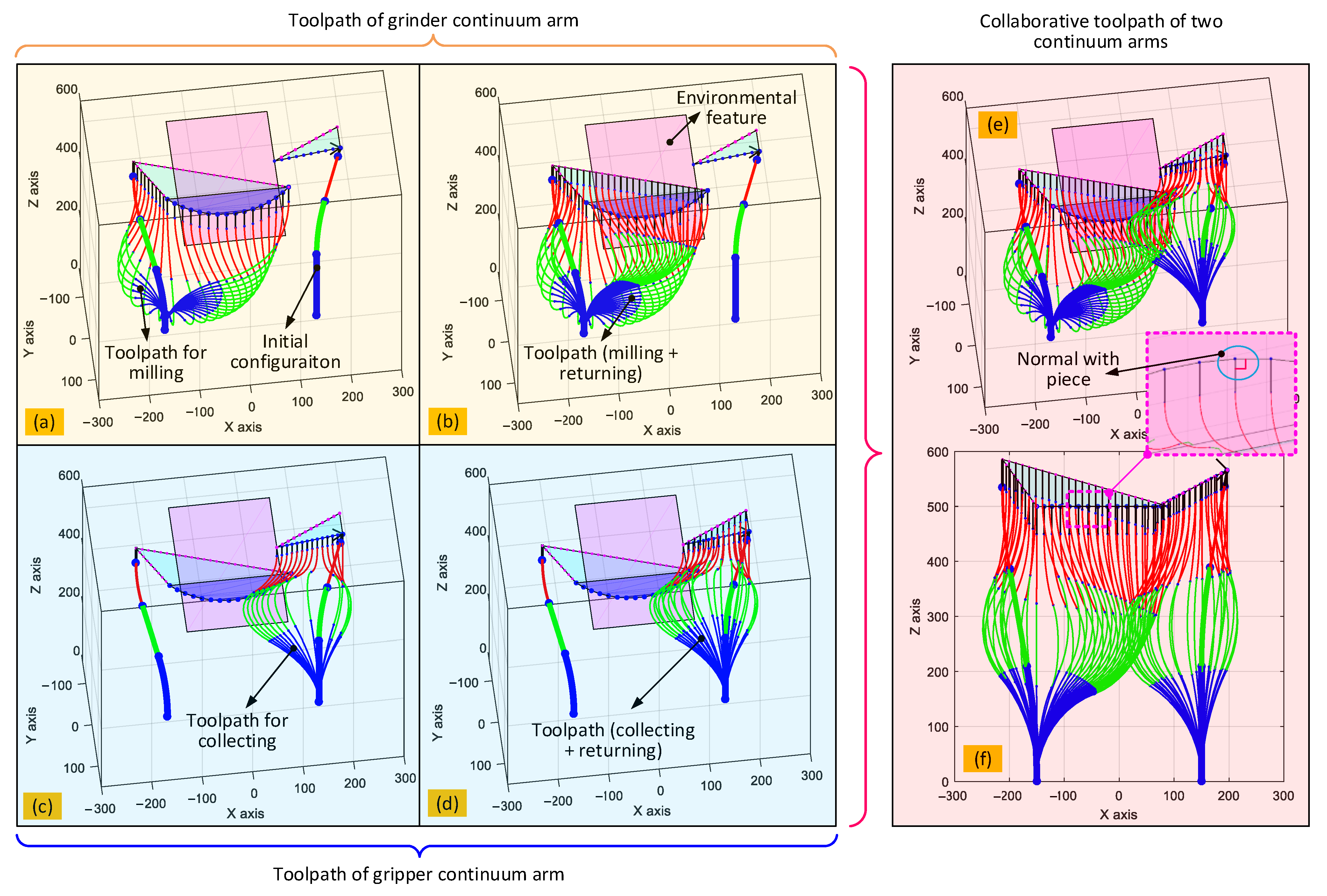

4.3. Simulation-Based Evaluation

This optimization-based inverse kinematics algorithm allows the shape parameters of the dual-arm continuum robot to be calculated for a given toolpath for any application. As the two 6-DoF continuum arms are similar, only one is used to demonstrate the proposed algorithm.

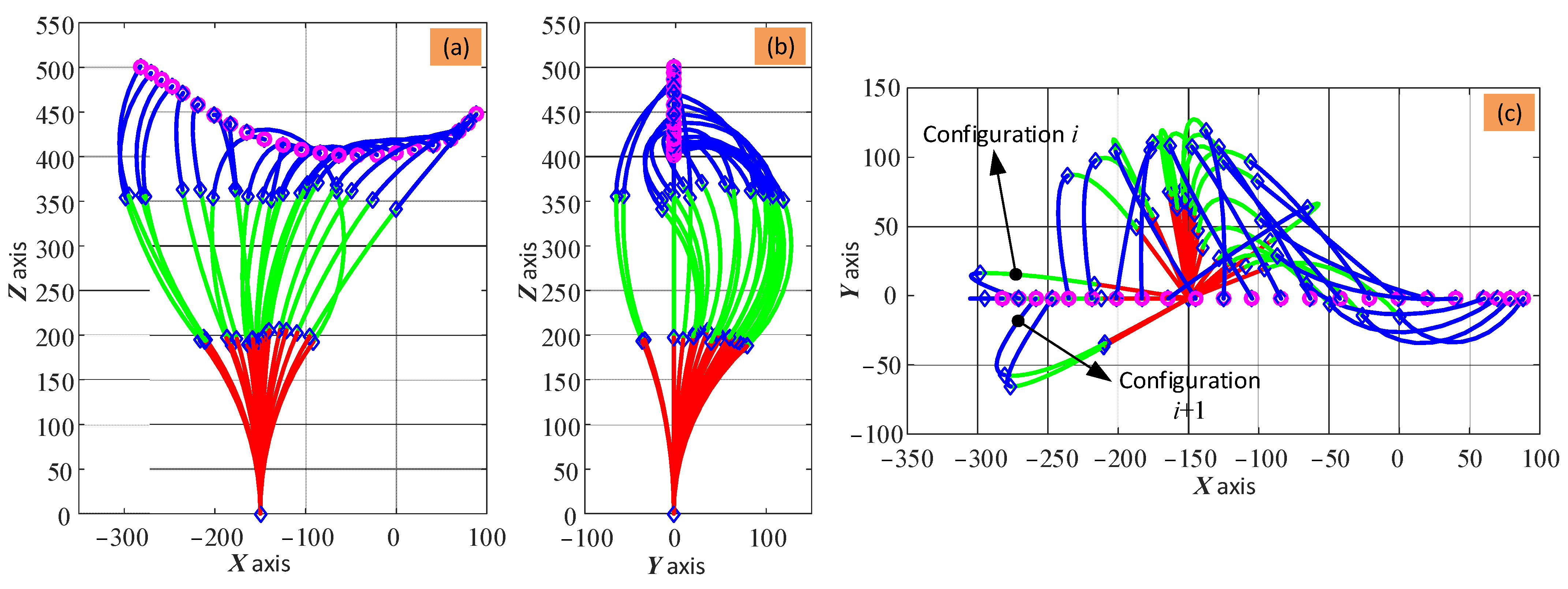

The scenario is as defined in

Figure 7, where the toolpath is located between the two continuum arms and c.a. 450 mm distance away from the actuation system. So that the end effector follows the desired toolpath while maintaining the position of the tip, the shape of the three sections of the arm needs to be adjusted dynamically. As such, the toolpath is parameterized into discrete points, and the algorithm run at each point to find the suitable set of bending and phase angles that fulfil the convergence conditions of the algorithm.

The change in shape of the arm for the given toolpath is shown in

Figure 8. In the case studies of this paper, the constraint for the optimization is the maximum bending angle of the three sections, which is set based on the physical structure design of the 2-DoF sections. By running the developed algorithm of this paper and using the commercial build-in optimization algorithm of the MATLAB software (i.e., fmincon nonlinear optimization), the shape variation of the continuum arm can be obtained.

It can be seen in

Figure 8 that the shape of the three sections (defined by the bending angle,

, and phase angle,

) can vary significantly while trying to keep the tip of the arm at the intended position. As there are no constraints on the shape, the change in shape at adjacent steps is not continuous, which means that there are large changes. Taking

Figure 8c as an example, even though adjacent points (e.g.,

and

) are close, the two configurations may be in different quadrants. To solve this problem, the change in angle should be limited, as demonstrated below.

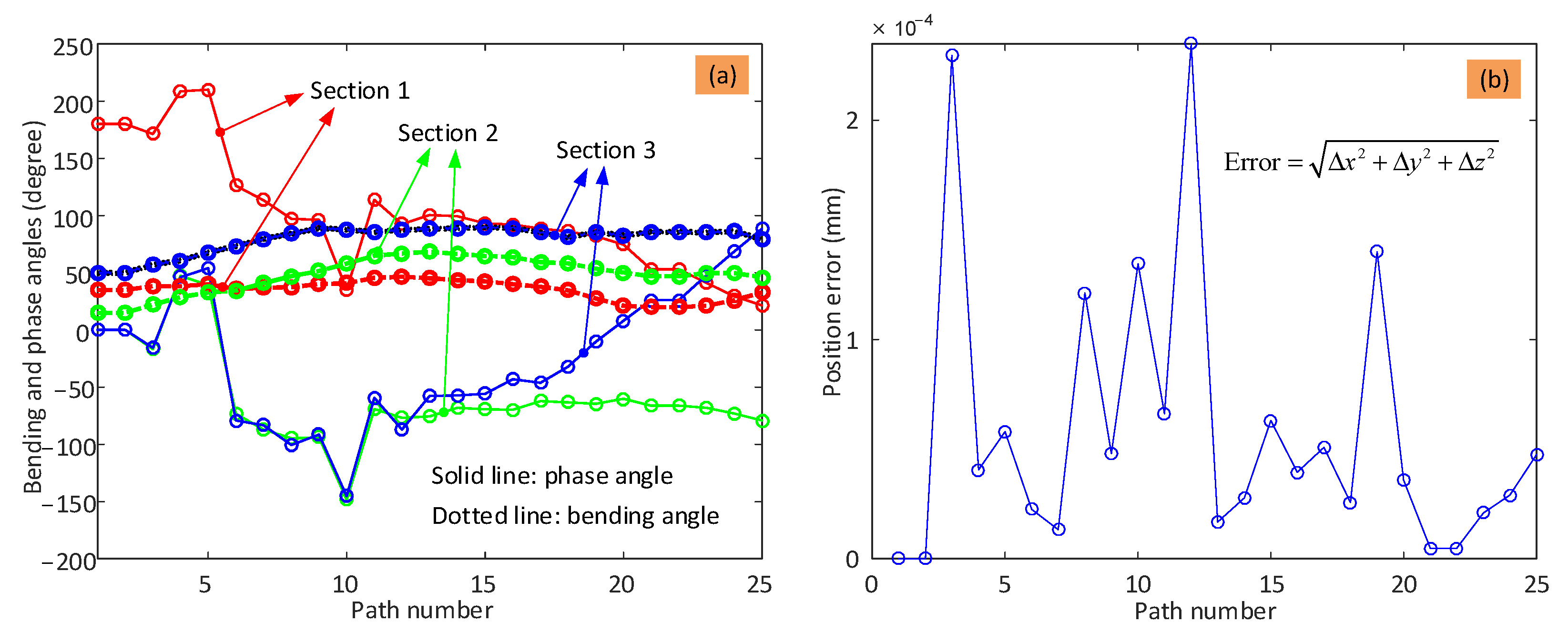

To provide the kinematic parameters for controlling the 6-DoF continuum arm, the shape parameters (i.e., bending angle and phase angle) of the three sections, as well as the error between the calculated path and the desired path, were obtained and are displayed in

Figure 9.

It can be seen from

Figure 9a that the bending angle and phase angle of the three sections change to control the end effector position. The bending angle is limited in the optimization algorithm to stay in the range [0°, 90°], which is observed for each section. The phase angles are not constrained, and while they stay within the same quadrant most of the time as the end effector moves from point to point, occasionally, the phase angle jumps to another quadrant. This is bad for the performance of the system. Taking the phase angle of Section 2 as an example (green dotted line), the angle jumps into a different quadrant at step 4 and returns to the initial quadrant at step 6. The main reason is that there are multiple solutions for the shape configuration of the continuum arm for any given tip position due to the symmetrical structure of the arm. It can be seen from

Figure 9b that high accuracy is still achieved; that is, the position errors between the planned toolpath and desired toolpath are within 0.3 μm, despite of these jumps in shape.

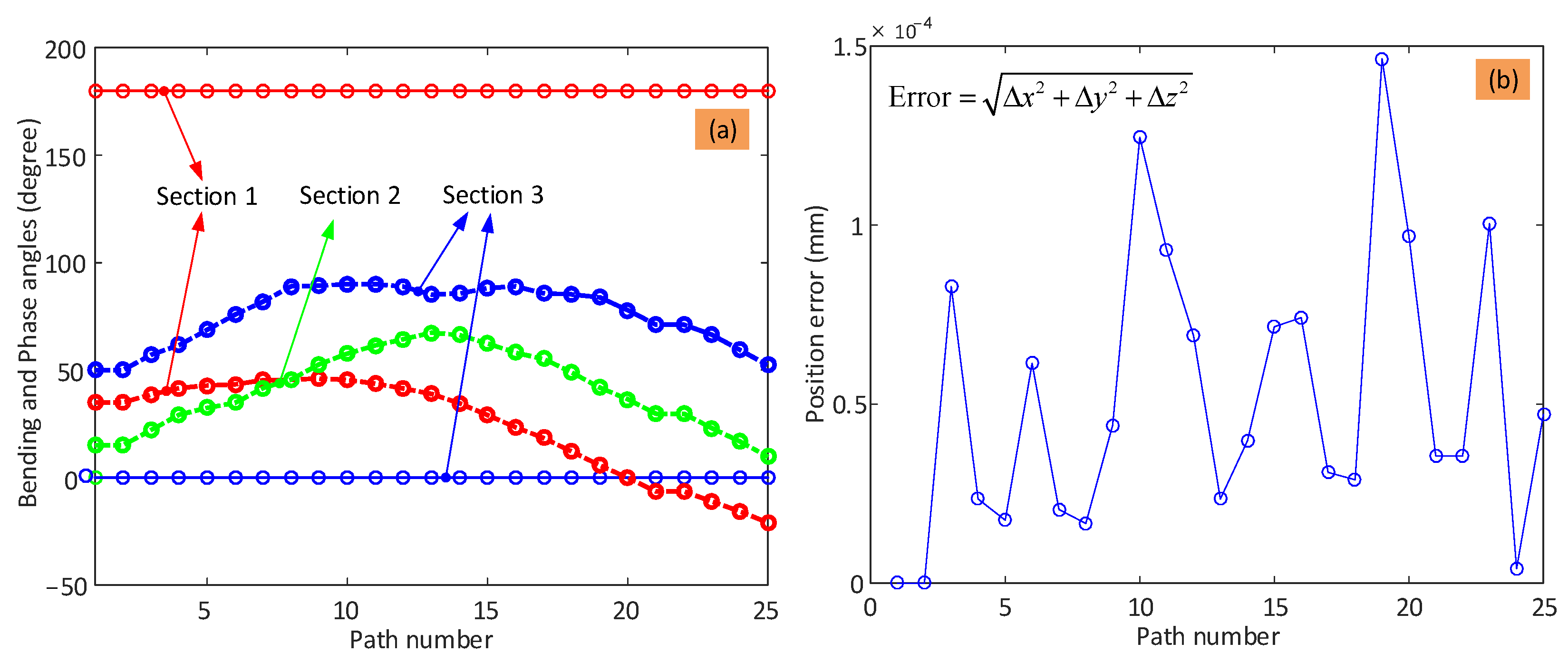

As having multiple solutions for the shape configuration of the arm has implications for the control and stability of the system, this was investigated further. Taking the scenario shown in

Figure 8 as an example, additional constraints were applied to the phase angles of the three sections in the optimization algorithm. Here, the phase angles of the three sections were kept constant at 0° or 180°, which means that the continuum arm can only bend within the

plane.

Figure 10 shows the change in shape of the 6-DoF continuum arm while tracking the desired toolpath with the additional constraints of the phase angles. It can be seen that the configuration of the arm gradually and smoothly changes as the end effector moves along the given path, which demonstrates the possibility of regulating the phase angle to improve the performance of the system.

Under the given constraints on the phase angles of the 6-DoF continuum arm, the bending angles changed gradually while the end effector moved along the path, as seen in

Figure 11a. As can be seen, the phase angles of the three sections are either 0° or 180°, and this keeps the continuum arm within a plane. The bending varies within the range [0° 90°], as before.

Figure 11b shows the error between the calculated end effector position and the desired location at each point. It can be seen that the additional constraints resulted in a higher accuracy (within 0.15 μm) than without the constraints (within 0.3 μm).