Field Traction Performance Test Analysis of Bionic Paddy Wheel and Vaned Wheel

Abstract

1. Introduction

2. Materials and Methods

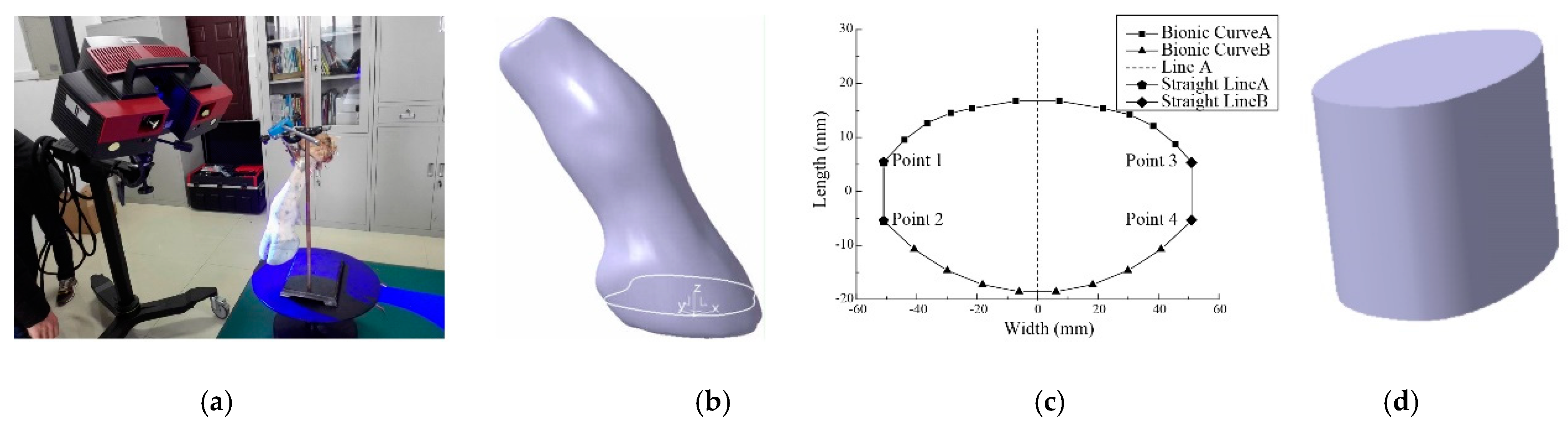

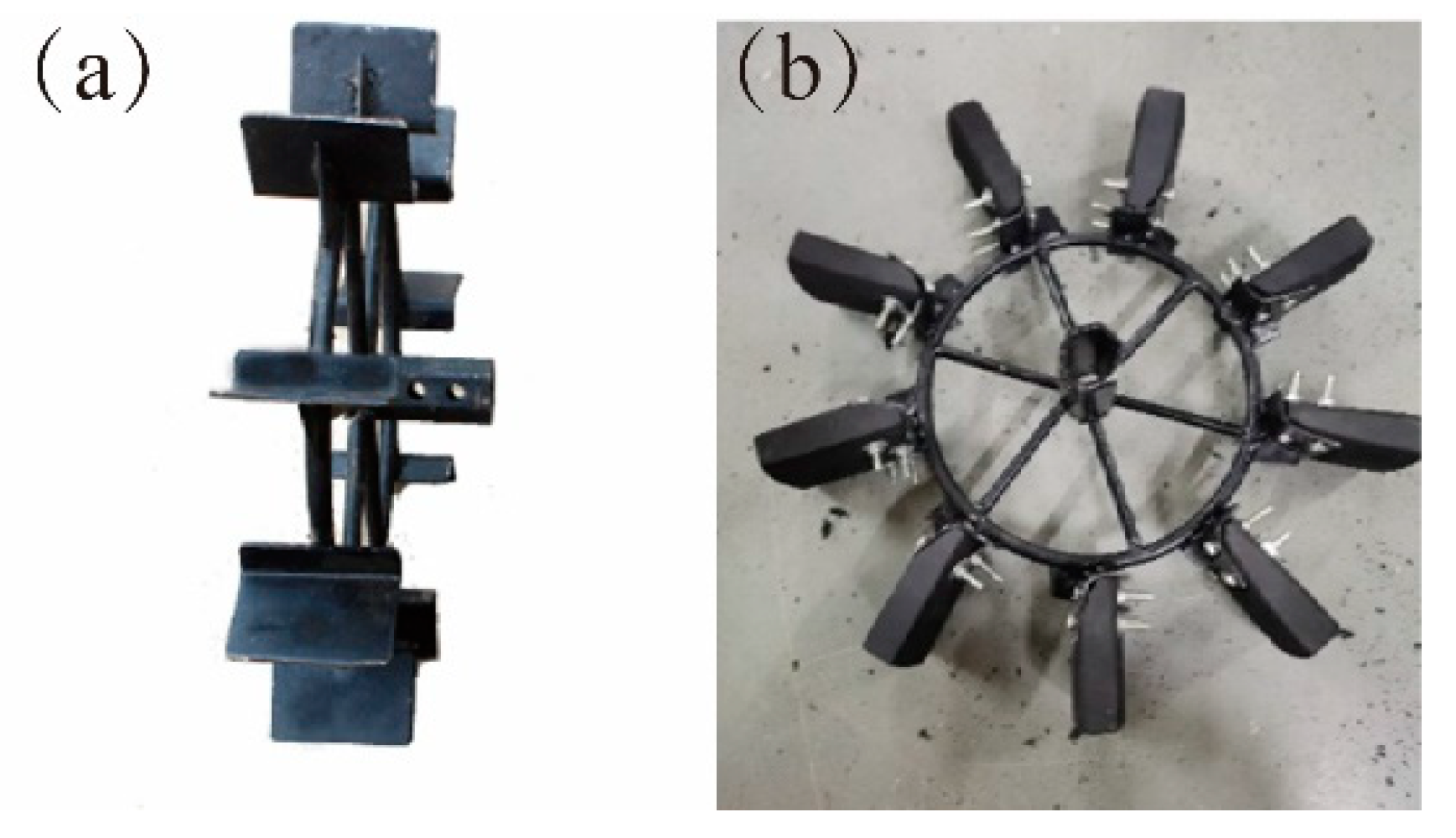

2.1. Preparation of Bionic Structure

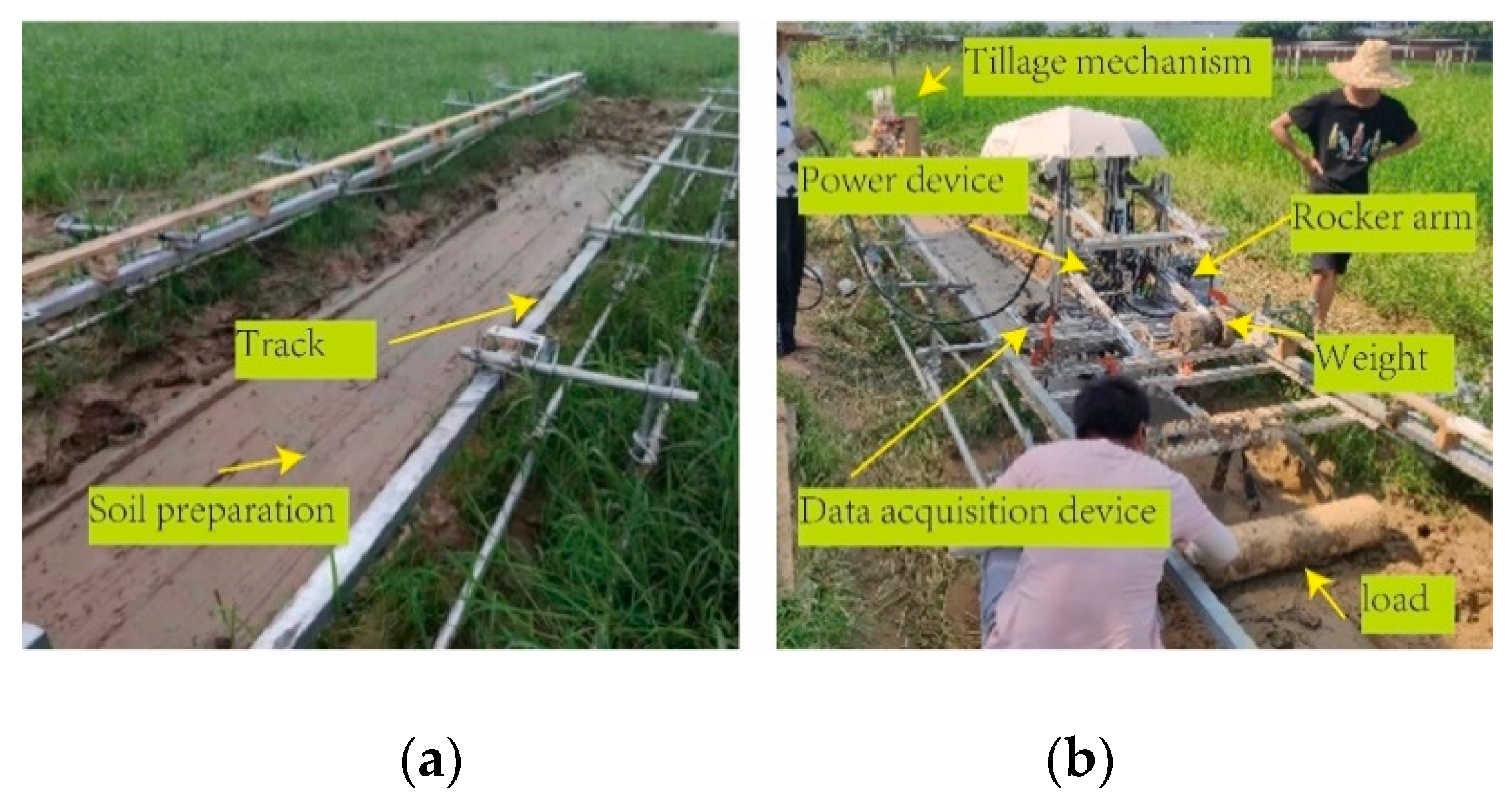

2.2. Test Rig Construction

2.3. Experimental Design

3. Results and Discussion

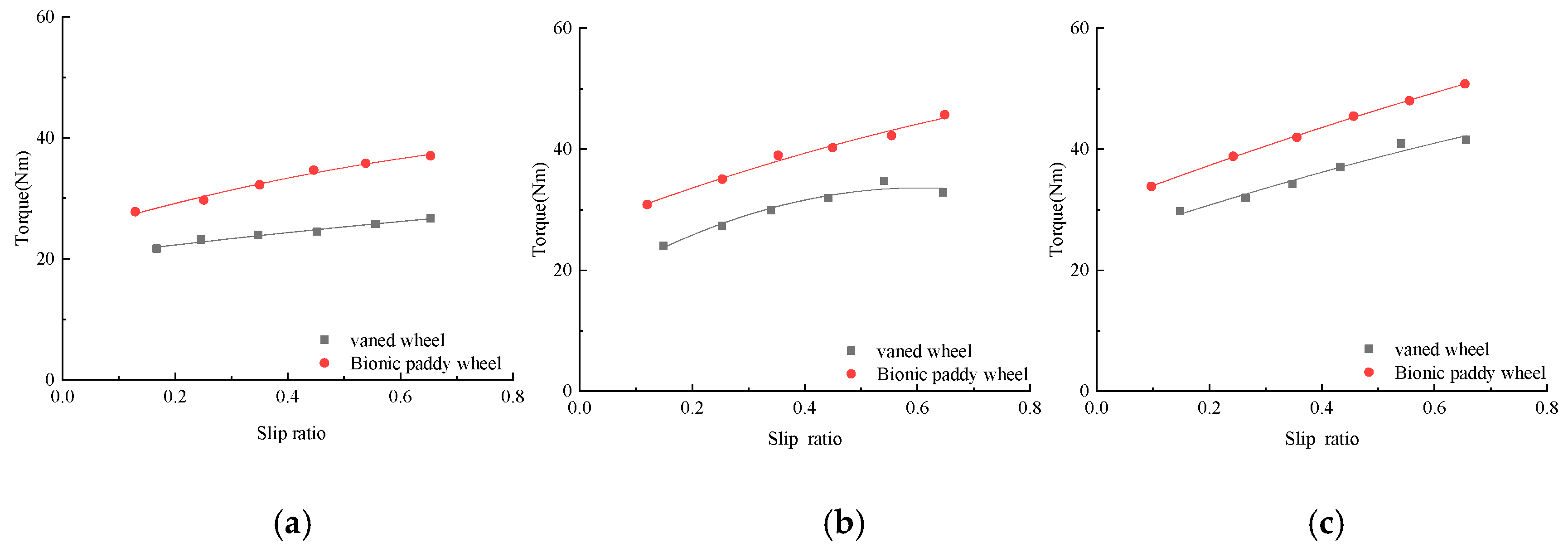

3.1. Relationship between Torque and Slip Ratio

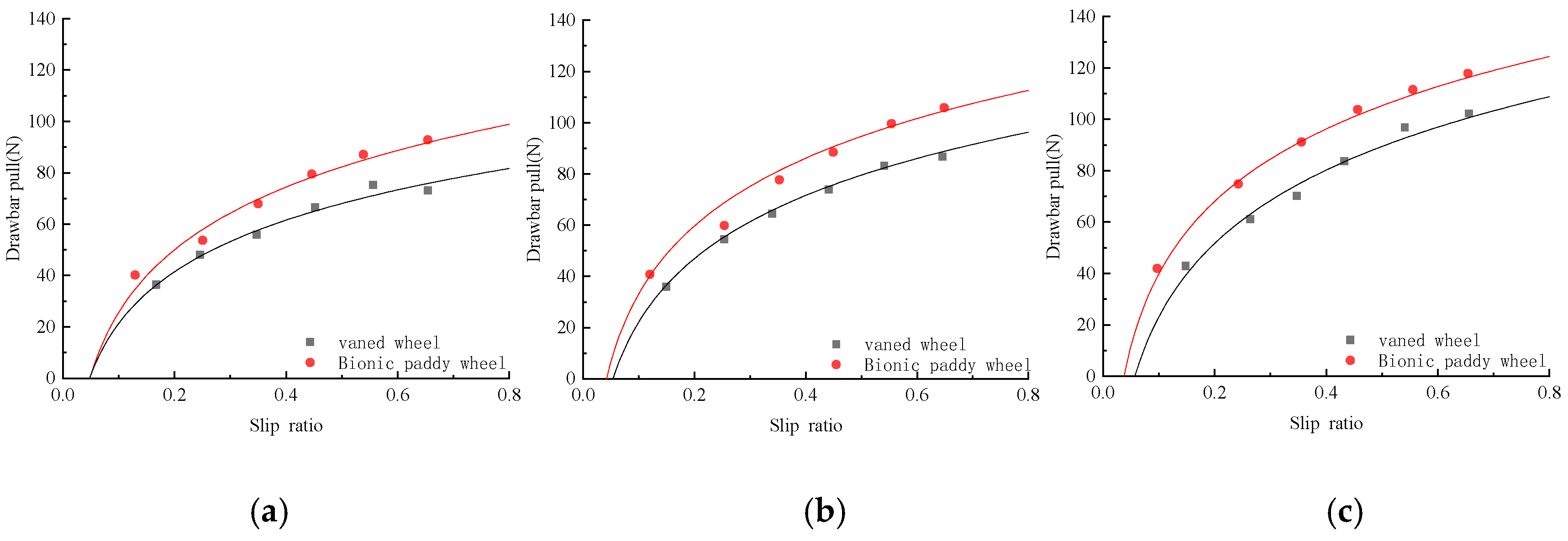

3.2. Hook Traction and Slip Ratio

3.3. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, C.; Zhang, T.; Goldman, D.I. A Terradynamics of Legged Locomotion on Granular Media. Science 2013, 339, 1408–1412. [Google Scholar] [CrossRef]

- Comin, F.J.; Lewinger, W.A.; Saaj, C.M.; Matthews, M.C. Trafficability Assessment of Deformable Terrain through Hybrid Wheel-Leg Sinkage Detection. J. Field Robot. 2017, 34, 451–476. [Google Scholar] [CrossRef]

- Allen, T.J.; Quinn, R.D.; Bachmann, R.J.; Ritzmann, R.E. Abstracted biological principles applied with reduced actuation improve mobility of legged vehicles. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2003) (Cat. No.03CH37453), Las Vegas, NV, USA, 27–31 October 2003; Volume 1372, pp. 1370–1375. [Google Scholar]

- Eich, M.; Grimminger, F.; Kirchner, F. A Versatile Stair-Climbing Robot for Search and Rescue Applications. In Proceedings of the 2008 IEEE International Workshop on Safety, Security and Rescue Robotics, Sendai, Japan, 21–24 October 2008; pp. 35–40. [Google Scholar]

- Belter, D.; Łabęcki, P.; Skrzypczyński, P. Adaptive Motion Planning for Autonomous Rough Terrain Traversal with a Walking Robot. J. Field Robot. 2016, 33, 337–370. [Google Scholar] [CrossRef]

- Kolvenbach, H.; Wisth, D.; Buchanan, R.; Valsecchi, G.; Grandia, R.; Fallon, M.; Hutter, M. Towards autonomous inspection of concrete deterioration in sewers with legged robots. J. Field Robot. 2020, 37, 1314–1327. [Google Scholar] [CrossRef]

- Ren, L.; Tong, J.; Li, J.; Chen, B. Biomimetics of Machinery for Soft Terrain. Trans. Chin. Soc. Agric. Mach. 2000, 31, 5–9. [Google Scholar]

- Xie, X.; Gao, F. Tractive Performance Analysis of Transformable Wheel on Soft Terrain. Trans. Chin. Soc. Agric. Mach. 2016, 47, 457–463. [Google Scholar]

- Ding, L.; Gao, H.; Deng, Z.; Song, J.; Liu, Y.; Liu, G.; Iagnemma, K. Foot–terrain interaction mechanics for legged robots: Modeling and experimental validation. Int. J. Robot. Res. 2013, 32, 1585–1606. [Google Scholar] [CrossRef]

- Zhang, R.; Yang, M.; Liu, H.; Zeng, G.; Pang, R.; Li, J. Numerical simulation of sand flow fixation characteristics of plantar surface of ostric. J. Jilin Univ. (Eng. Technol. Ed.) 2015, 45, 508–515. [Google Scholar] [CrossRef]

- Zhang, R.; Ji, Q.; Zhang, S.; Li, J. Bionic design and dynamics performance simulation of walking wheel to travel on sand. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2016, 32, 26–31. [Google Scholar]

- Chen, Y. Motion of the Yellow Cattle Bostaurus Walking on Soft Ground and Its Bionic Application. Bachelor’s Thesis, Jinlin University, Changchun, China, 2008. [Google Scholar]

- Cai, K. Imitation Cow Gait of Quadruped Robot Leg Hoof and Flexible Joints. Master’s Thesis, Southwest University of Science and Technology, Mianyang, China, 2016. [Google Scholar]

- Lu, Z. On Gaits of a Buffalo. J. Nanjing Agric. Univ. 1995, 18, 123–126. [Google Scholar]

| Coefficient | Bionic Curve A | Bionic Curve B |

|---|---|---|

| a | −9.9 × 10−7 | 2.85 × 10−7 |

| b | −1.45 × 10−7 | 1.25 × 10−10 |

| c | −1.73 × 10−3 | 4.33 × 10−3 |

| d | 2.76 × 10−4 | −5.11 × 10−7 |

| e | 16.69 | −18.72 |

| R-square | 0.998 | 0.999 |

| RMSE | 0.174 | 2.51 × 10−3 |

|

Cohesive Defor-mation Modulus of Soil

|

Soil Friction Defor-mation Modulus

| Internal Friction Angle

(deg) | ||

|---|---|---|---|---|

| 0.61 | 5.27 | 90.24 | 2346.2 | 23.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, L.; Xie, B.; Lin, F.; Cheng, S.; Li, L.; Liu, M.; Li, J. Field Traction Performance Test Analysis of Bionic Paddy Wheel and Vaned Wheel. Biomimetics 2022, 7, 185. https://doi.org/10.3390/biomimetics7040185

Xue L, Xie B, Lin F, Cheng S, Li L, Liu M, Li J. Field Traction Performance Test Analysis of Bionic Paddy Wheel and Vaned Wheel. Biomimetics. 2022; 7(4):185. https://doi.org/10.3390/biomimetics7040185

Chicago/Turabian StyleXue, Long, Baofeng Xie, Fei Lin, Song Cheng, Lan Li, Muhua Liu, and Jing Li. 2022. "Field Traction Performance Test Analysis of Bionic Paddy Wheel and Vaned Wheel" Biomimetics 7, no. 4: 185. https://doi.org/10.3390/biomimetics7040185

APA StyleXue, L., Xie, B., Lin, F., Cheng, S., Li, L., Liu, M., & Li, J. (2022). Field Traction Performance Test Analysis of Bionic Paddy Wheel and Vaned Wheel. Biomimetics, 7(4), 185. https://doi.org/10.3390/biomimetics7040185