Crystallization Behavior and Morphology of Biodegradable Poly(ε-caprolactone)/Reduced Graphene Oxide Scaffolds

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Scaffold Preparation

2.2. Characterizations

3. Results and Discussion

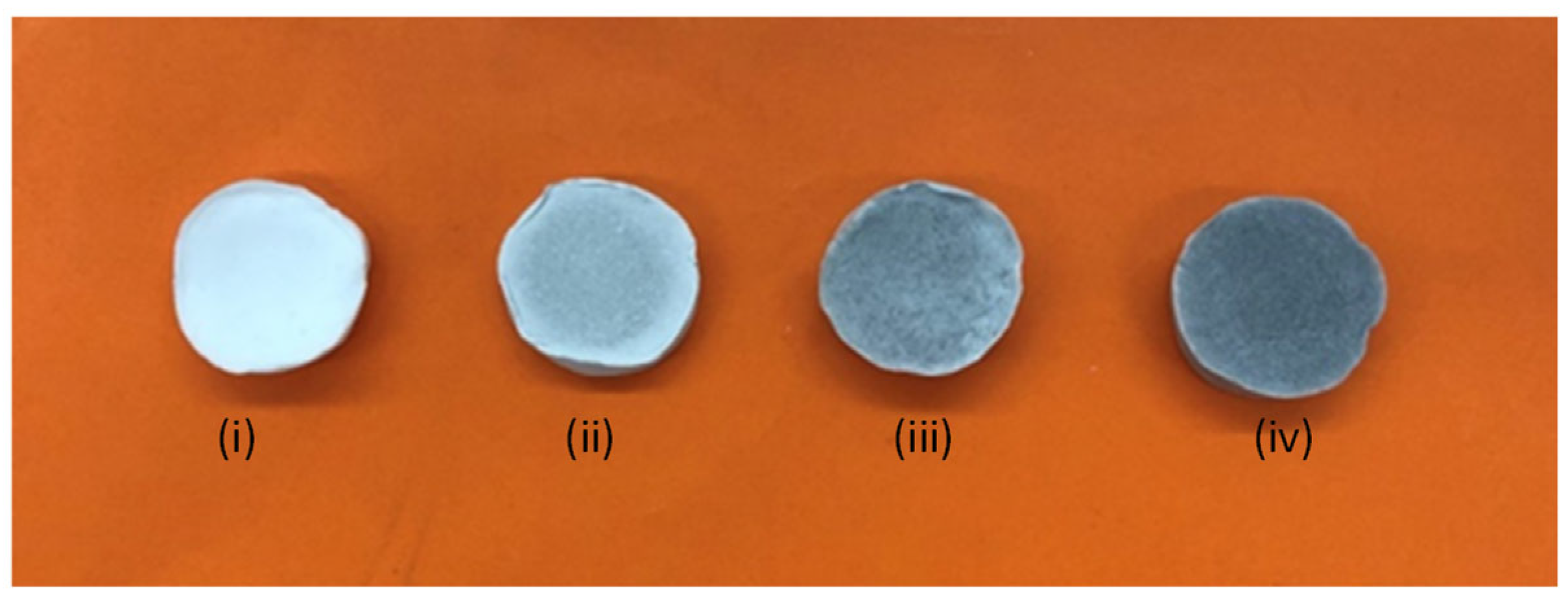

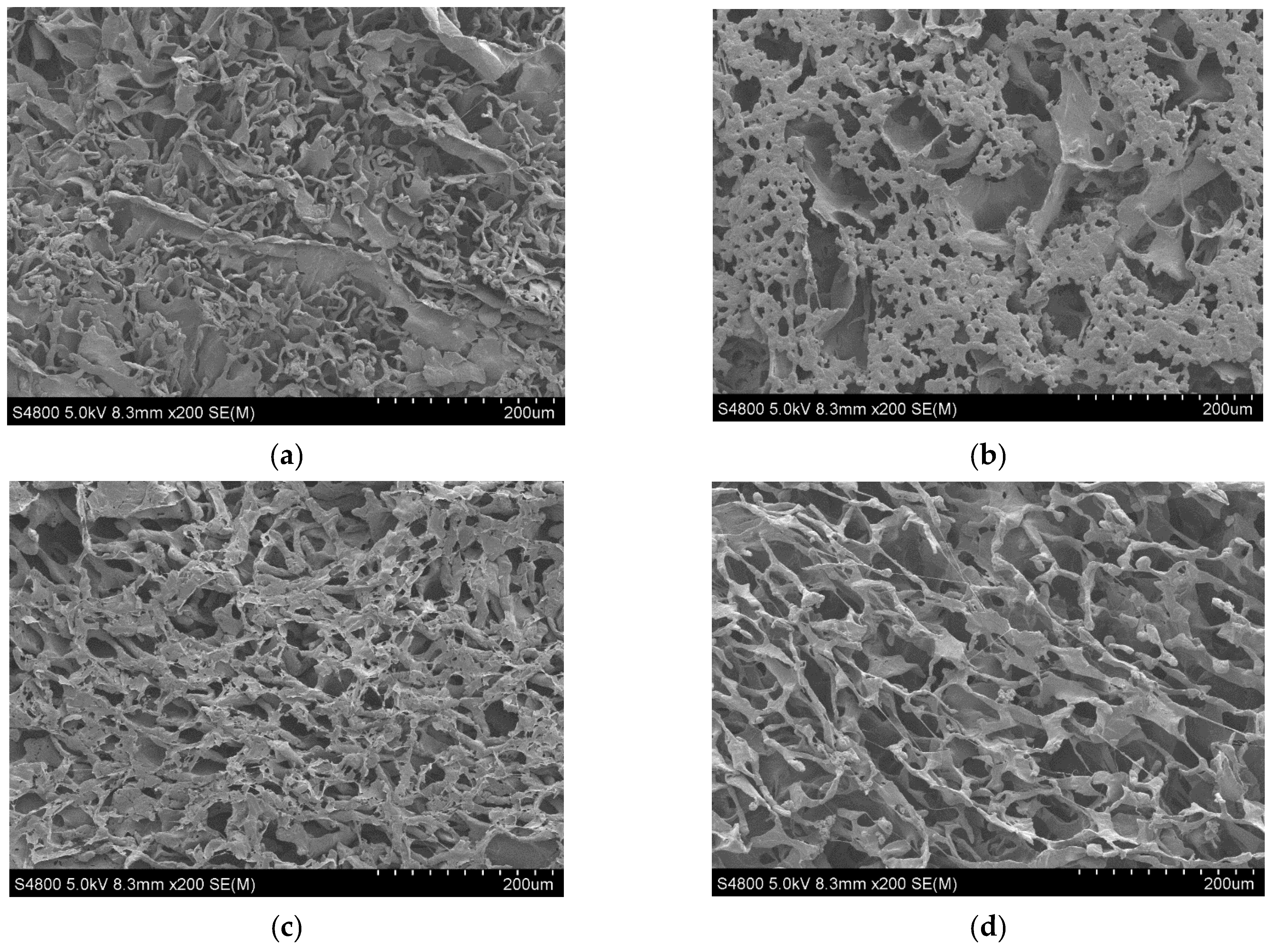

3.1. Morphology

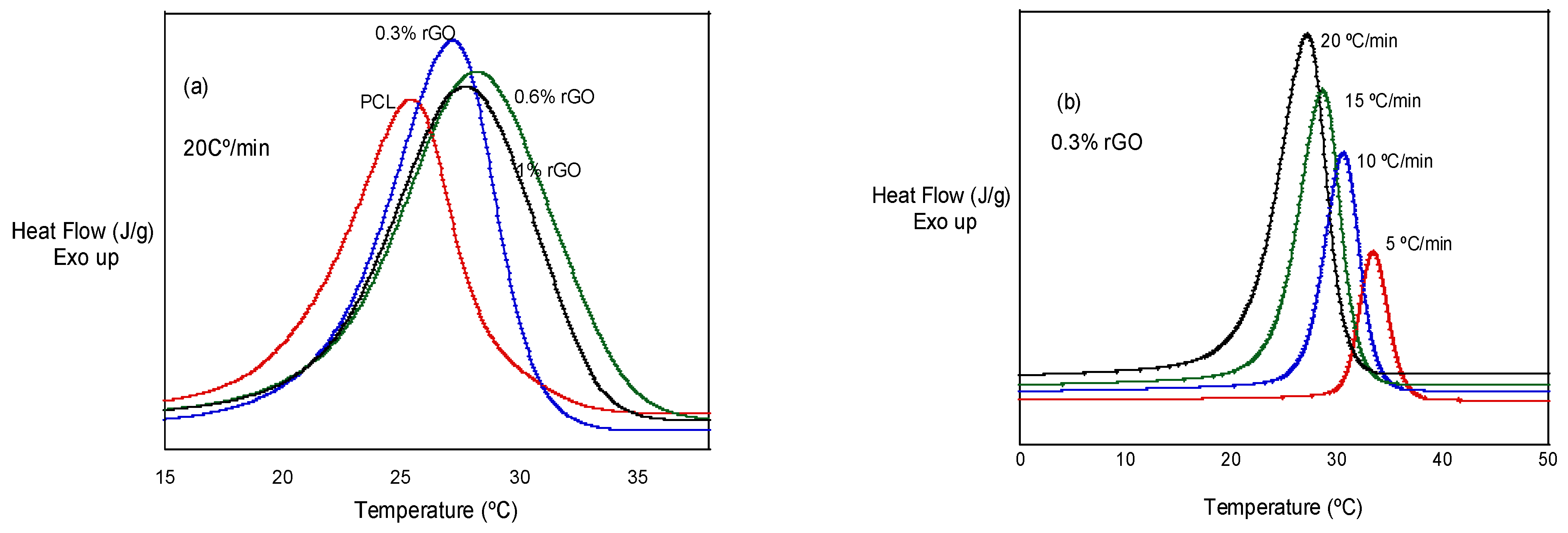

3.2. Crystallization Behavior

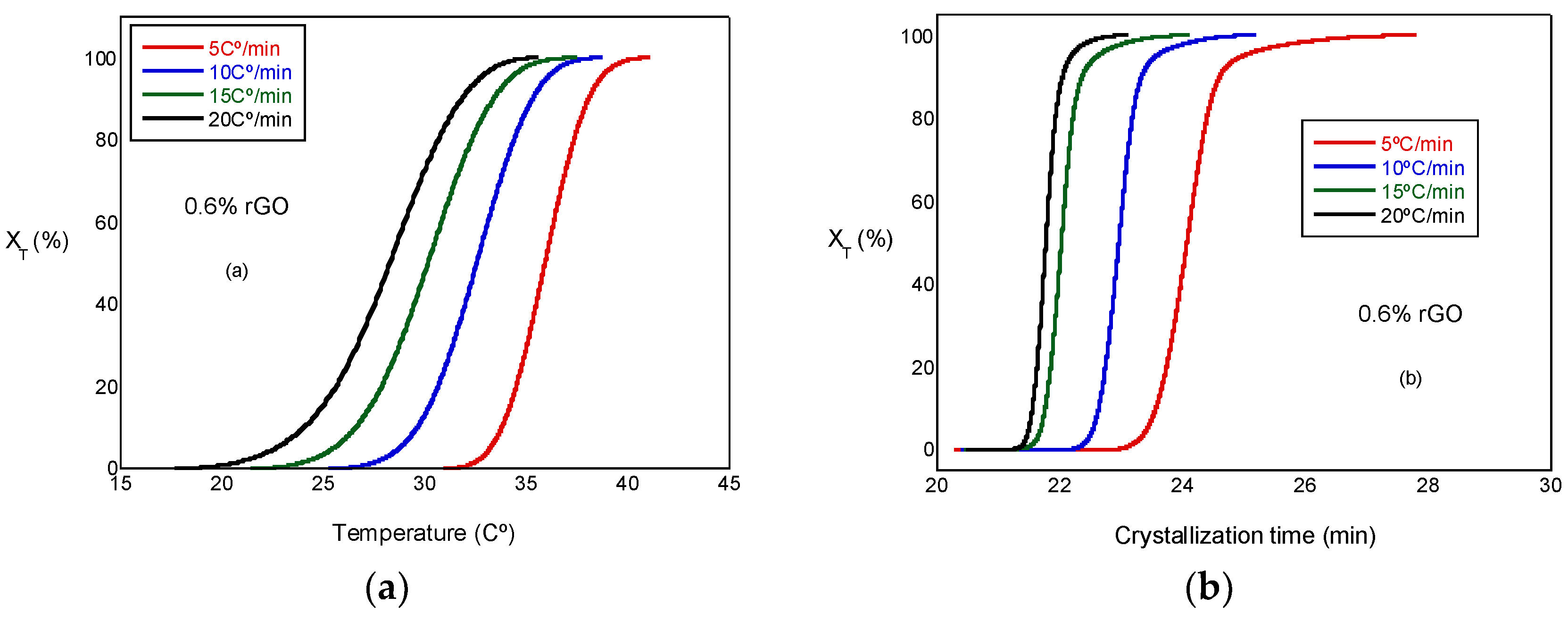

3.3. Non-Isothermal Melt Crystallization and Kinetics Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bezwada, R.S.; Jamiolkowski, D.D.; Lee, I.-Y.; Agarwal, V.; Persivale, J.; Trenka-Benthin, S.; Erneta, M.; Suryadevara, J.; Yang, A.; Liu, S. Monocryl® suture, a new ultra-pliable absorbable monofilament suture. Biomaterials 1995, 16, 1141–1148. [Google Scholar] [CrossRef]

- Anderson, J.M.; Shive, M.S. Biodegradation and biocompatibility of PLA and PLGA microspheres. Adv. Drug Deliv. Rev. 1997, 28, 5–24. [Google Scholar] [CrossRef]

- Engelberg, I.; Kohn, J. Physico-mechanical properties of degradable polymers used in medical applications: A comparative study. Biomaterials 1991, 12, 292–304. [Google Scholar] [CrossRef]

- You, Y.; Min, B.-M.; Lee, S.J.; Lee, T.S.; Park, W.H. In vitro degradation behavior of electrospun polyglycolide, polylactide, and poly(lactide-co-glycolide). J. Appl. Polym. Sci. 2004, 95, 193–200. [Google Scholar] [CrossRef]

- Abedalwafa, M.; Wang, F.; Wang, L.; Li, C. Biodegradable poly-epsilon-caprolactone (PCL) for tissue engineering applications: A review. Rev. Adv. Mater. Sci. 2013, 34, 123–140. [Google Scholar]

- Díaz, E.; Sandonis, I.; Valle, M.B. In Vitro Degradation of Poly(caprolactone)/nHA Composites. J. Nanomater. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Díaz, E.; Martín, J.; León, J. Carbon nanotube reinforced poly(l-lactide) scaffolds: In vitro degradation, conductivity, mechanical and thermal properties. Compos. Interfaces 2021, 28, 511–525. [Google Scholar] [CrossRef]

- Díaz, E.; Aresti, J.; León, J. Evaluation of physicochemical and mechanical properties with the in vitro degradation of PCL/nHA/MWCNT composite scaffolds. J. Reinf. Plast. Compos. 2021, 40, 134–142. [Google Scholar] [CrossRef]

- Ha, H.; Ellison, C.J. Polymer/graphene oxide (GO) thermoset composites with GO as a crosslinker. Korean J. Chem. Eng. 2018, 35, 303–317. [Google Scholar] [CrossRef]

- Díaz, E.; Iglesias, N.; Ribeiro, S.; Lanceros-Méndez, S. Cytocompatible scaffolds of poly(L-lactide)/reduced graphene oxide for tissue engineering. J. Biomater. Sci. Polym. Ed. 2021, 32, 1406–1419. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H.-M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Cooper, D.R.; D’Anjou, B.; Ghattamaneni, N.; Harack, B.; Hilke, M.; Horth, A.; Yu, V. Experimental review of graphene. Int. Sch. Res. Not. 2012, 2012, 501686. [Google Scholar] [CrossRef] [Green Version]

- Guex, L.G.; Sacchi, B.; Peuvot, K.F.; Andersson, R.L.; Pourrahimi, A.M.; Ström, V.; Farris, S.; Olsson, R.T. Experimental review: Chemical reduction of graphene oxide (GO) to reduced graphene oxide (rGO) by aqueous chemistry. Nanoscale 2017, 9, 9562–9571. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qiu, Z.; Ikehara, T.; Nishi, T. Crystallization behaviour of biodegradable poly(ethylene succinate) from the amorphous state. Polymer 2003, 44, 5429–5437. [Google Scholar] [CrossRef]

- Zhao, Y.; Qiu, Z.; Yan, S.; Yang, W. Crystallization behavior of biodegradable poly(L-lactide)/multiwalled carbon nanotubes nanocomposites from the amorphous state. Polym. Eng. Sci. 2011, 51, 1564–1573. [Google Scholar] [CrossRef]

- Zhou, W.Y.; Duan, B.; Wang, M.; Cheung, W.L. Crystallization kinetics of poly(L-lactide)/carbonated hydroxyapatite nanocomposite microspheres. J. Appl. Polym. Sci. 2009, 113, 4100–4115. [Google Scholar] [CrossRef]

- Nejati, E.; Firouzdor, V.; Eslaminejad, M.; Bagheri, F. Needle-like nano hydroxyapatite/poly(l-lactide acid) composite scaffold for bone tissue engineering application. Mater. Sci. Eng. C 2009, 29, 942–949. [Google Scholar] [CrossRef]

- Pluta, M.; Jeszka, J.; Boiteux, G. Polylactide/montmorillonite nanocomposites: Structure, dielectric, viscoelastic and thermal properties. Eur. Polym. J. 2007, 43, 2819–2835. [Google Scholar] [CrossRef]

- Wang, H.; Qiu, Z. Crystallization behaviors of biodegradable poly(l-lactic acid)/graphene oxide nanocomposites from the amorphous state. Thermochim. Acta 2011, 526, 229–236. [Google Scholar] [CrossRef]

- Amestoy, H.; Diego, P.; Meaurio, E.; Muñoz, J.; Sarasua, J.-R. Crystallization Behavior and Mechanical Properties of Poly(ε-caprolactone) Reinforced with Barium Sulfate Submicron Particles. Materials 2021, 14, 2368. [Google Scholar] [CrossRef]

- Pitt, C.G.; Chasalow, F.I.; Hibionada, Y.M.; Klimas, D.M.; Schindler, A. Aliphatic polyesters. I. The degradation of poly(ϵ-caprolactone) in vivo. J. Appl. Polym. Sci. 1981, 26, 3779–3787. [Google Scholar] [CrossRef]

- Díaz, E.; León, J.; Murillo-Marrodán, A.; University of the Basque Country (UPV/EHU), Portugalete, Spain. 2022; (submitted to Polymer).

- Khanna, Y.P. A barometer of crystallization rates of polymeric materials. Polym. Eng. Sci. 1990, 30, 1615–1619. [Google Scholar] [CrossRef]

- Bruna, P.; Crespo, D.; González-Cinca, R.; Pineda, E. On the validity of Avrami formalism in primary crystallization. J. Appl. Phys. 2006, 100, 054907. [Google Scholar] [CrossRef] [Green Version]

- Wu, T.-M.; Chen, E.-C. Crystallization behavior of poly(ɛ-caprolactone)/multiwalled carbon nanotube composites. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 598–606. [Google Scholar] [CrossRef]

| Samples | Tm (°C) | ΔHm (J/g) | ΔHc (J/g) | Xc (%) |

|---|---|---|---|---|

| PCL | 32.0 | 49.5 | 50.9 | 35.6 |

| PCL/0.3% rGO | 33.5 | 63.7 | 61.2 | 45.9 |

| PCL/0.6% rGO | 37.3 | 77.3 | 61.0 | 55.9 |

| PCL/1% rGO | 36.2 | 55.7 | 52.8 | 40.5 |

| Samples | Φ (°C/min) | Tp (°C) | Tm (°C) | ΔHc (J/g) | t1/2 (min) |

|---|---|---|---|---|---|

| PCL | 5 | 30.76 | 35.60 | 51.20 | 45.92 |

| 10 | 28.20 | 32.04 | 50.89 | 23.36 | |

| 15 | 26.55 | 30.38 | 51.03 | 15.74 | |

| 20 | 25.43 | 28.95 | 50.58 | 11.92 | |

| PLC/0.3% rGO | 5 | 33.45 | 36.17 | 61.61 | 45.54 |

| 10 | 30.57 | 33.55 | 61.16 | 23.15 | |

| 15 | 28.63 | 31.87 | 59.38 | 15.63 | |

| 20 | 27.18 | 30.62 | 59.46 | 11.84 | |

| PLC/0.6% rGO | 5 | 35.71 | 39.46 | 63.52 | 45.07 |

| 10 | 32.30 | 37.31 | 61.06 | 22.96 | |

| 15 | 29.86 | 35.71 | 58.21 | 15.52 | |

| 20 | 28.14 | 34.54 | 56.92 | 11.77 | |

| PLCL/1% rGO | 5 | 35.31 | 38.42 | 55.40 | 45.19 |

| 10 | 32.17 | 36.20 | 52.78 | 22.99 | |

| 15 | 29.68 | 34.68 | 52.26 | 15.51 | |

| 20 | 27.70 | 33.44 | 51.83 | 11.81 |

| Sample | CRC |

|---|---|

| PCL | 0.89 |

| PCL/0.3% rGO | 0.99 |

| PCL/0.6% rGO | 0.98 |

| PCL/1% rGO | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díaz, E.; Mendivil, A.; León, J. Crystallization Behavior and Morphology of Biodegradable Poly(ε-caprolactone)/Reduced Graphene Oxide Scaffolds. Biomimetics 2022, 7, 116. https://doi.org/10.3390/biomimetics7030116

Díaz E, Mendivil A, León J. Crystallization Behavior and Morphology of Biodegradable Poly(ε-caprolactone)/Reduced Graphene Oxide Scaffolds. Biomimetics. 2022; 7(3):116. https://doi.org/10.3390/biomimetics7030116

Chicago/Turabian StyleDíaz, Esperanza, Ainhoa Mendivil, and Joseba León. 2022. "Crystallization Behavior and Morphology of Biodegradable Poly(ε-caprolactone)/Reduced Graphene Oxide Scaffolds" Biomimetics 7, no. 3: 116. https://doi.org/10.3390/biomimetics7030116

APA StyleDíaz, E., Mendivil, A., & León, J. (2022). Crystallization Behavior and Morphology of Biodegradable Poly(ε-caprolactone)/Reduced Graphene Oxide Scaffolds. Biomimetics, 7(3), 116. https://doi.org/10.3390/biomimetics7030116