Effective Microorganism Solution and High Volume of Fly Ash Blended Sustainable Bio-Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Mix Design

2.2. Test Procedure

3. Results and Discussion

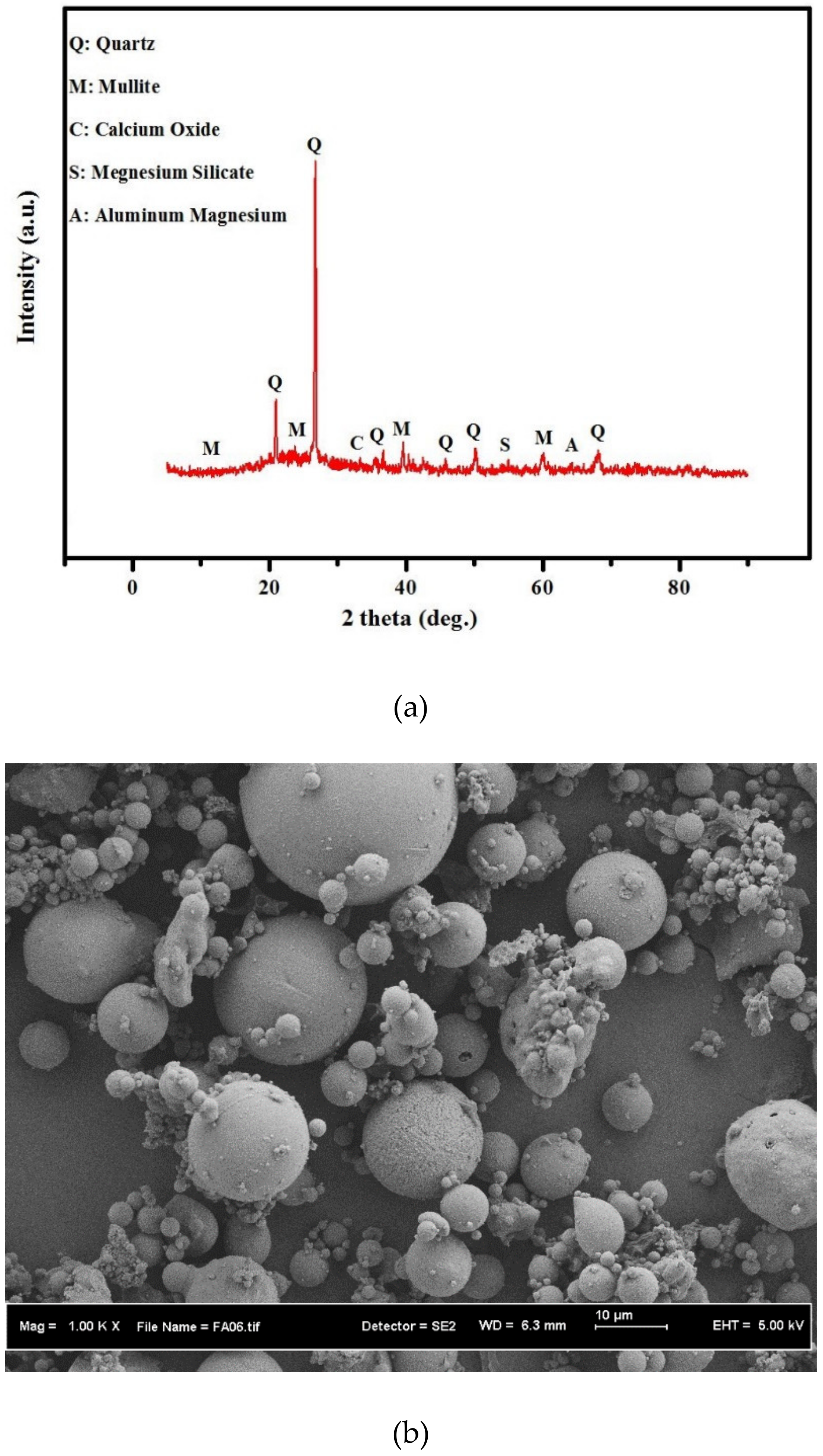

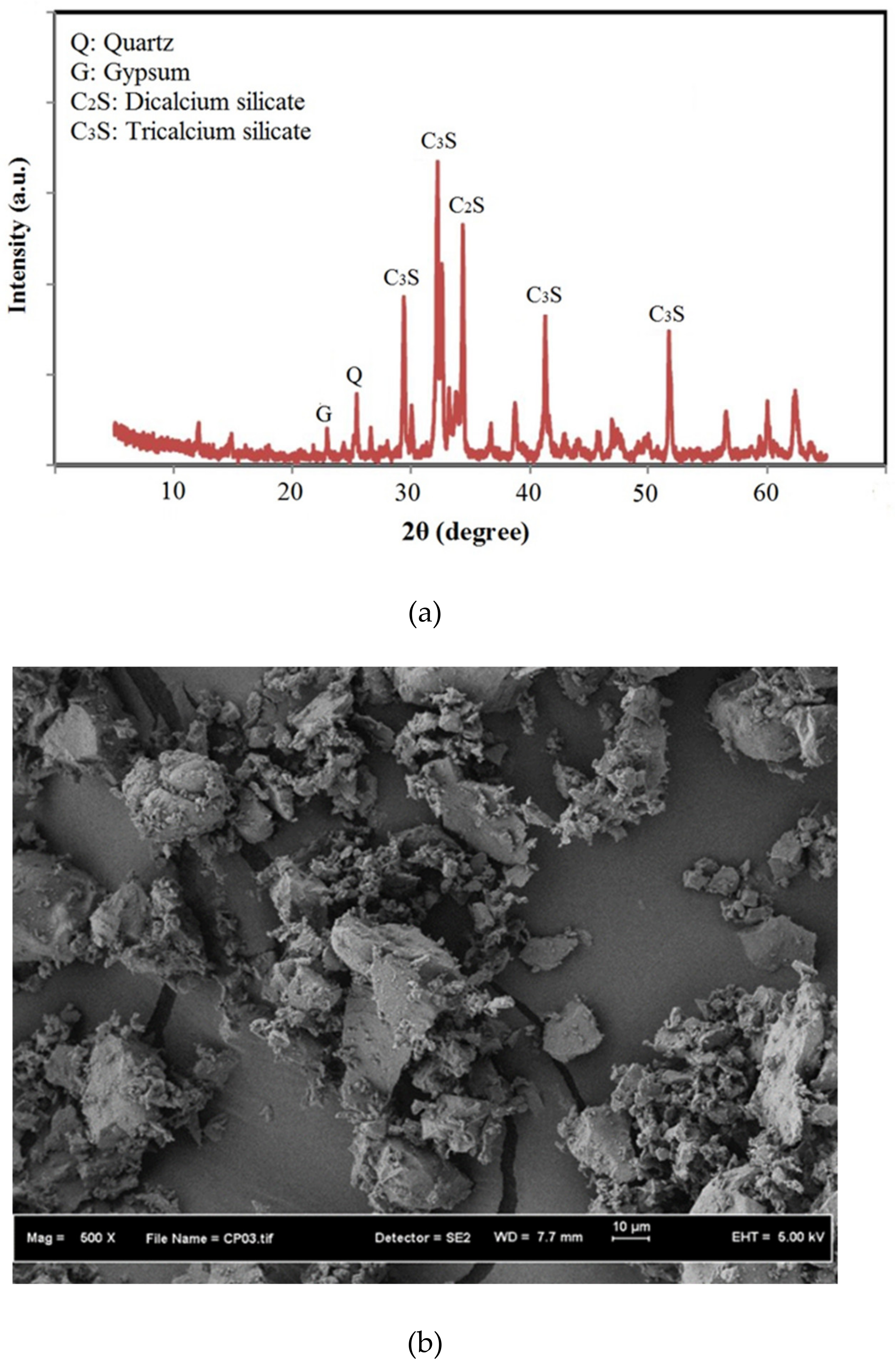

3.1. Microstructure Properties of FA and OPC

3.2. Surface Tension, pH and Viscosity of EM Solution

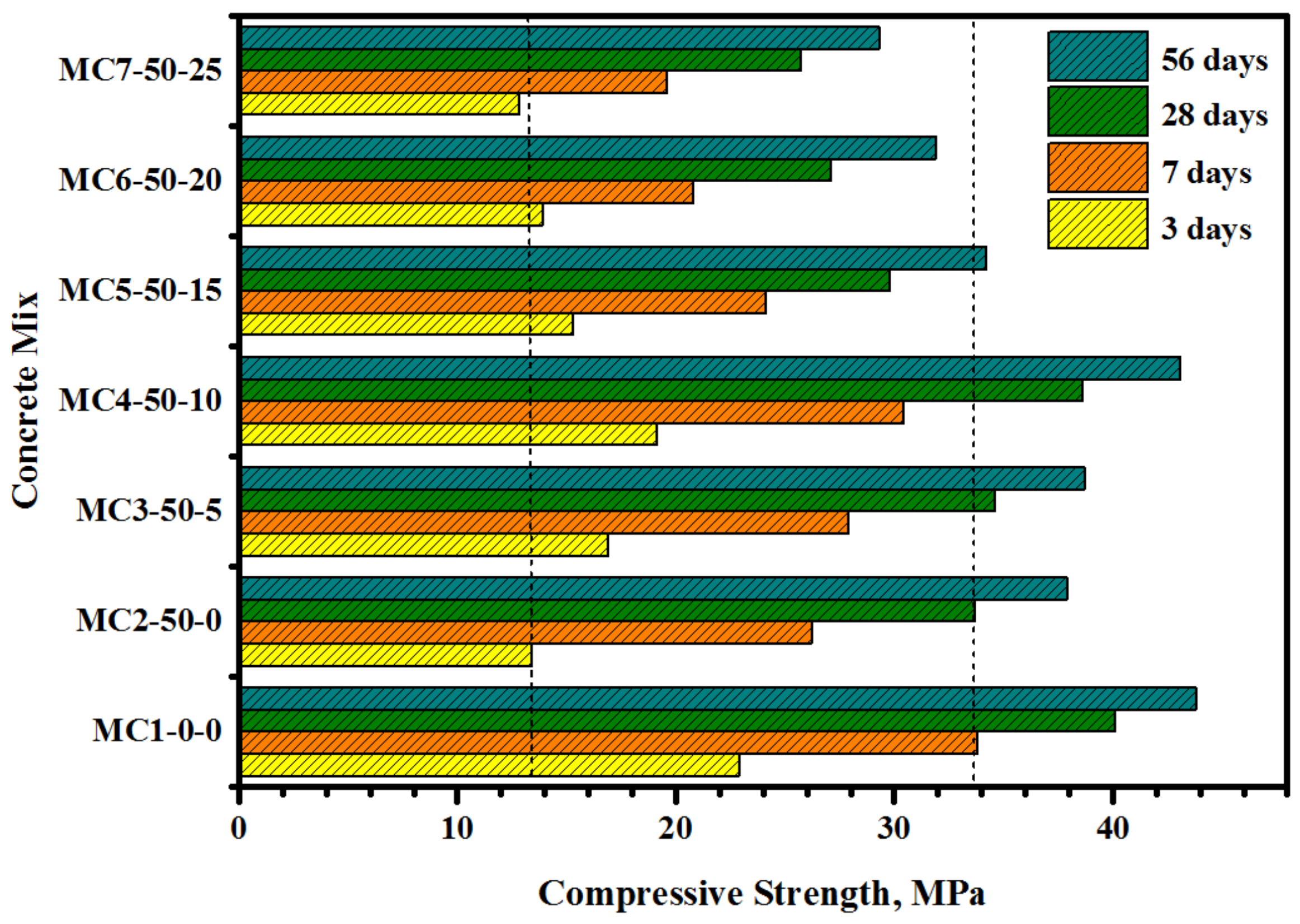

3.3. Compressive Strength

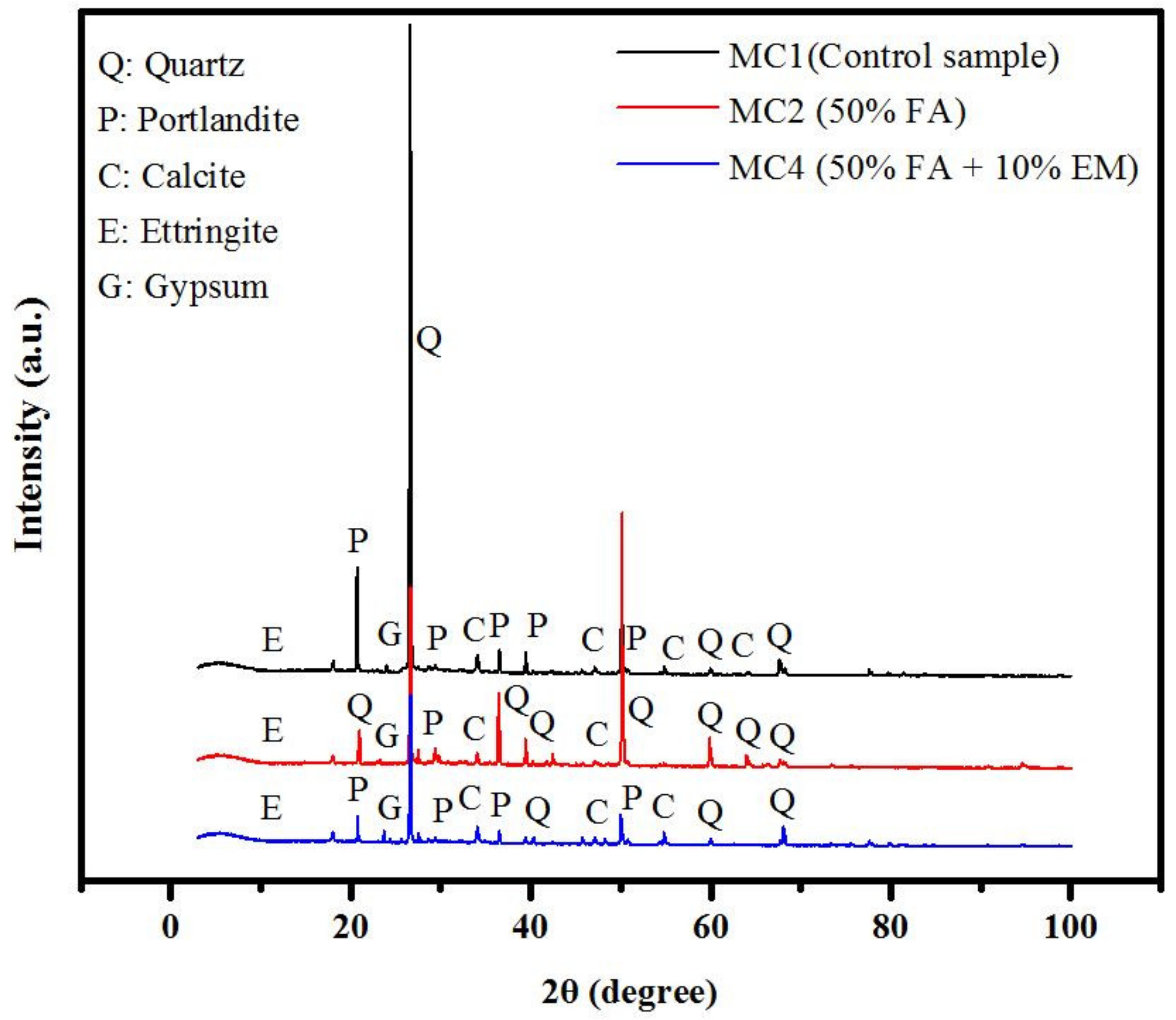

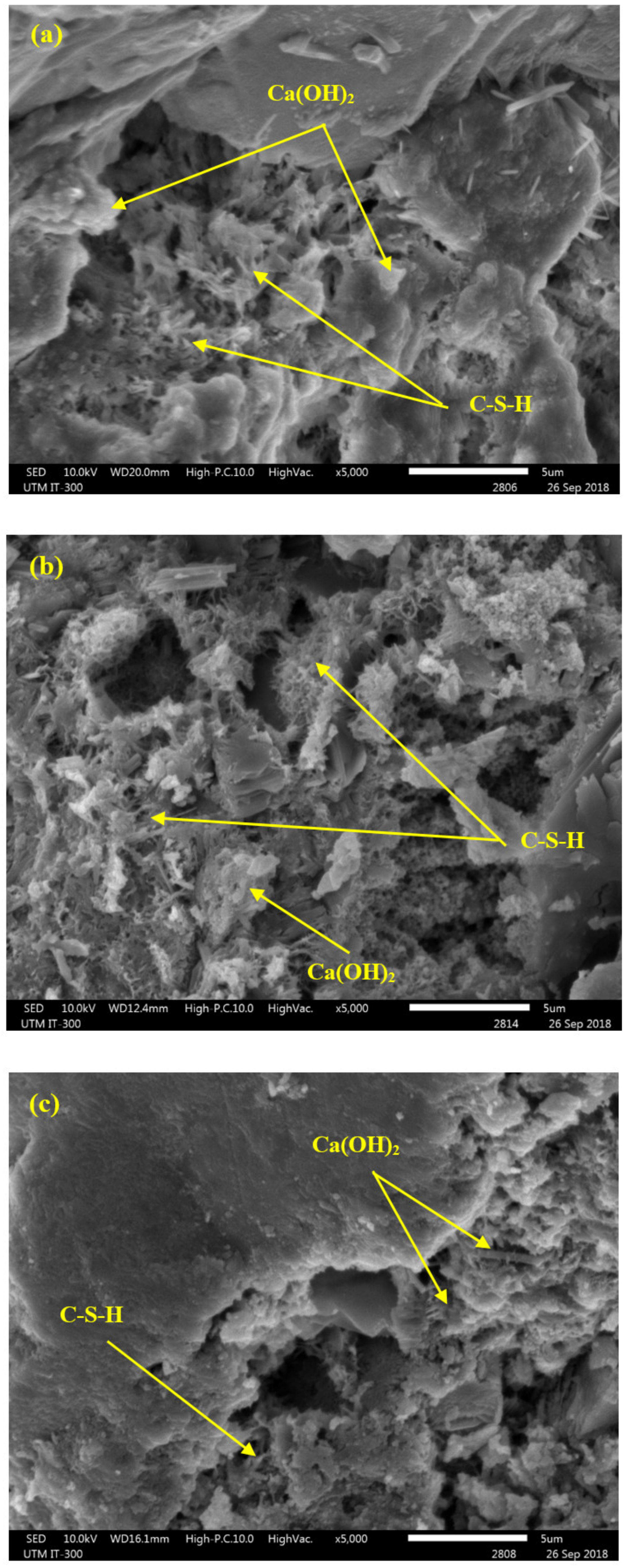

3.4. Microstructure Properties

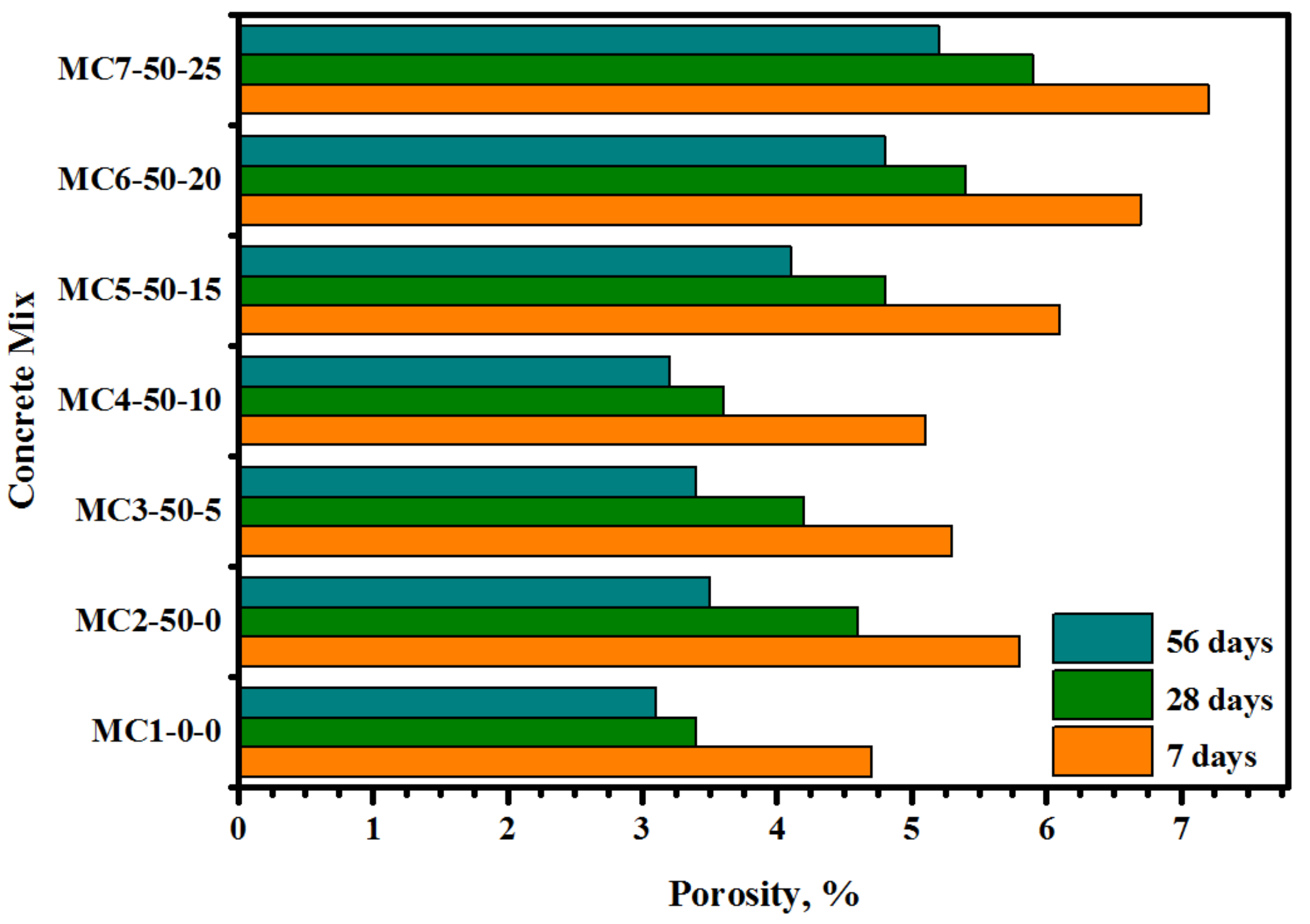

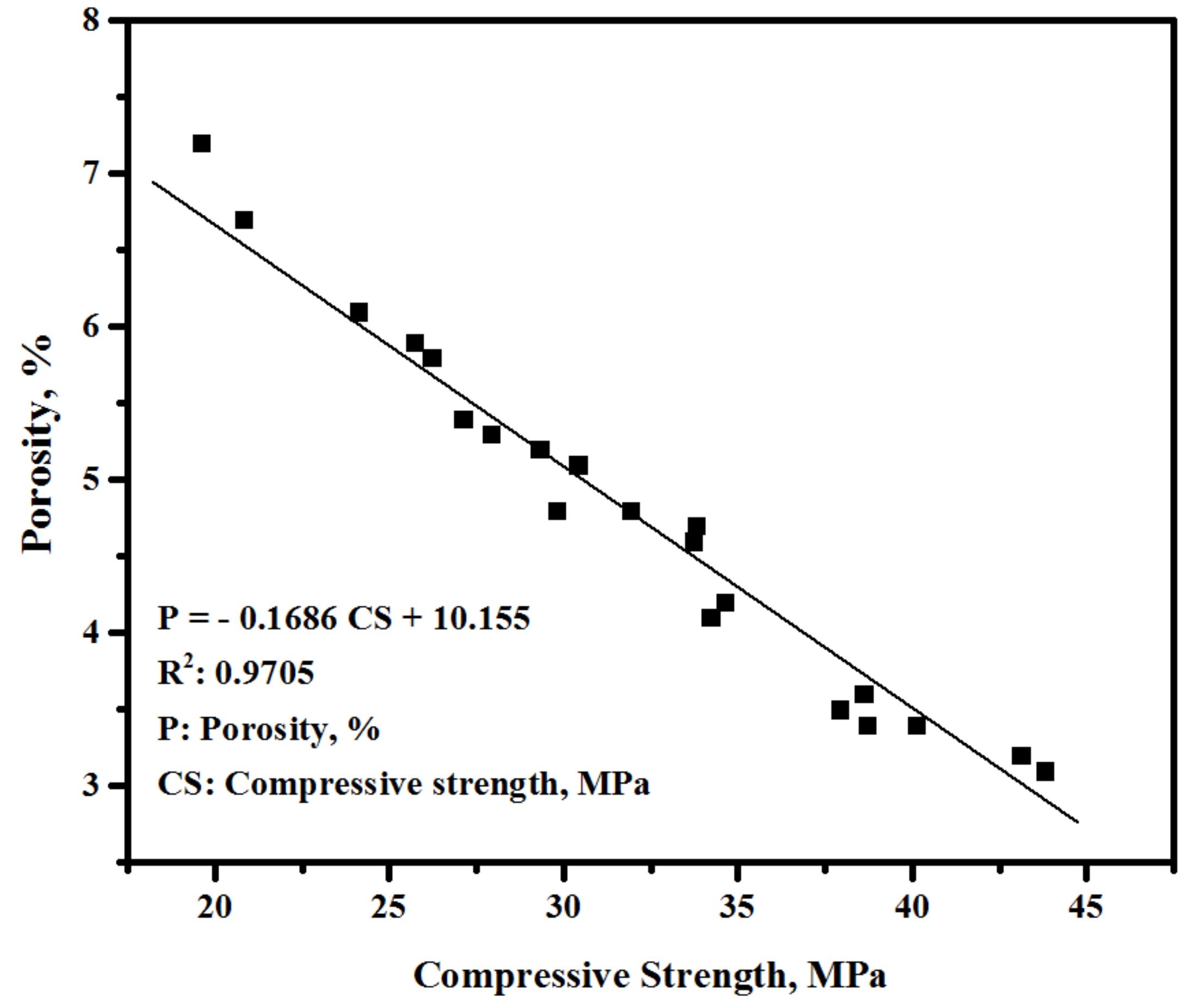

3.5. Porosity

3.6. Carbonation Depth

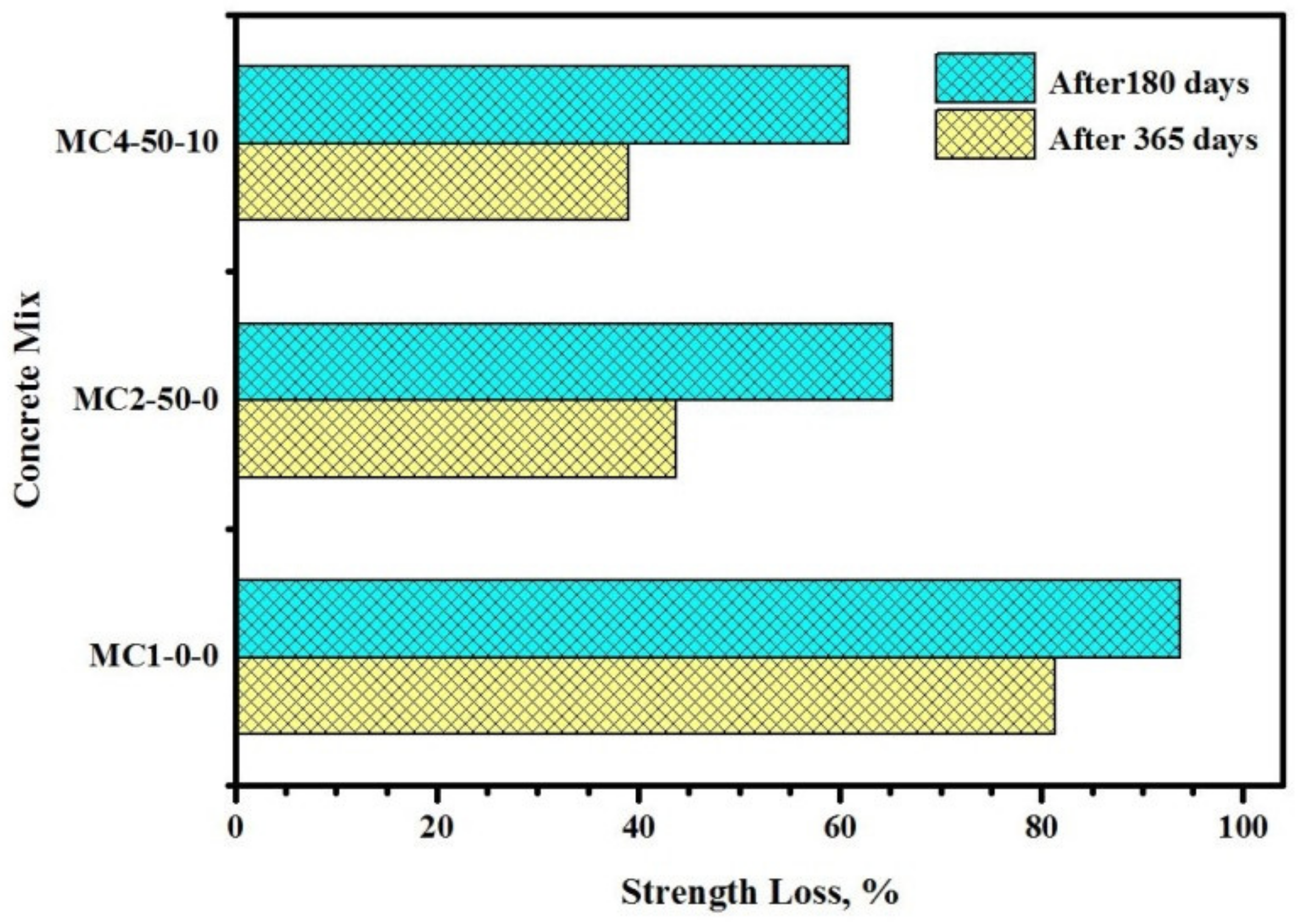

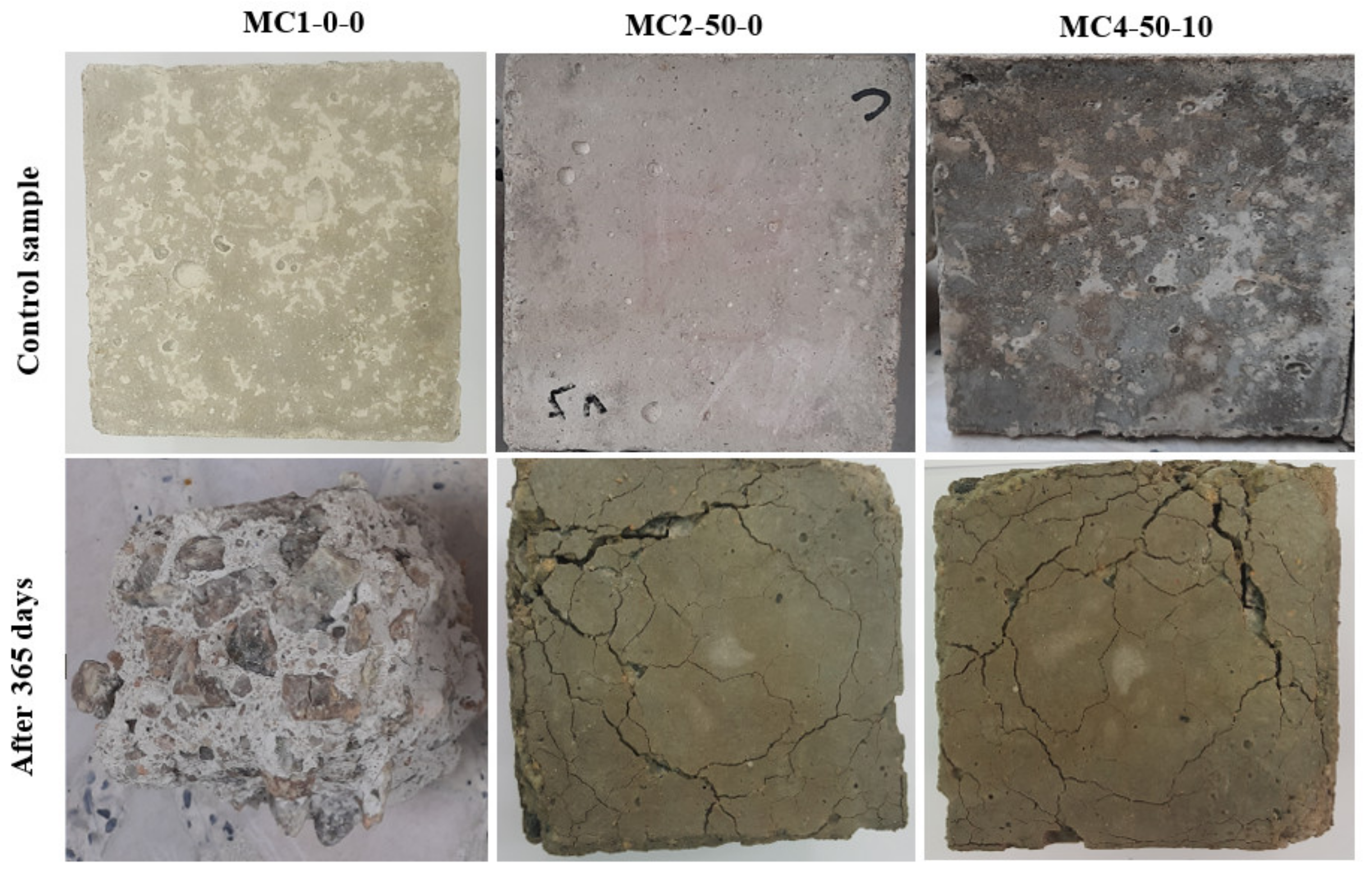

3.7. Sulphuric Acid Resistance

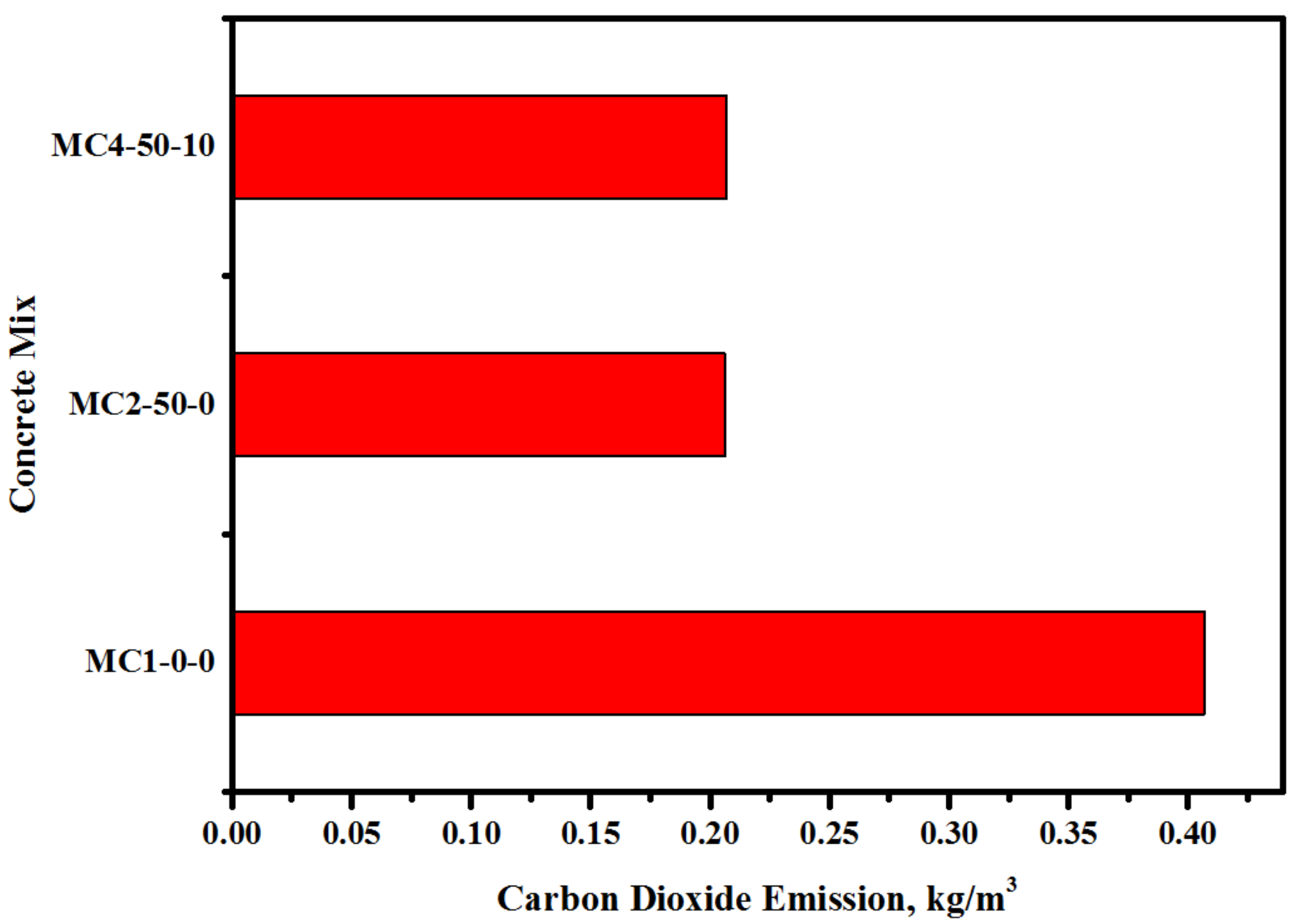

3.8. Reduction of Carbon Dioxide Emission

4. Conclusions

- i.

- The replacement of tap water with the EM solution led to a reduced pH and surface tension. However, the viscosity of EM solution was increased with the increase in the EM level. The fresh and hardened properties of bio-concrete were significantly influenced by the inclusion of the EM solution.

- ii.

- The inclusion of 50% FA as an OPC replacement could directly affect the early and late strength development of the proposed bio-concrete.

- iii.

- The inclusion of 5% and 10% EM in the cement-FA matrix improved the CS at early and late ages.

- iv.

- The highest CS was achieved for the bio-concrete prepared with 10% EM. The EM solution improved the hydration process and led to the formulation of denser gels, thus yielding a better performance compared to other dosages of EMs.

- v.

- The SEM results showed that the replacement of tap water with 10% EM solution could improve the surface morphology of the bio-concrete and reduce the number of pores. This, in turn, increased the strength and reduced the porosity of the bio-concrete. An inverse relationship was observed between strength and porosity of modified concretes.

- vi.

- The reduction in the porosity and total number of pores in the modified concrete prepared with 10% EM could contribute to the improvement of their durability by reducing the carbonation depth.

- vii.

- The inclusion of FA and EM in the cement matrix led to an increase in the concrete resistance during sulphuric acid attack in terms of the reduced strength loss, weight loss, internal cracks, and deterioration of both the surface and edges.

- viii.

- Overall, the FA and EM solution-incorporated concrete showed a great potential for construction applications. It is asserted that such bio-concretes may offer a possible solution to reduce the reliance on standard OPC-based concretes that contribute appreciably to pollution, promoting the development of materials of greater sustainability and thus minimizing the negative effect on the environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Talaiekhozan, A.; Majid, M.Z.A. A review of self-healing concrete research development. J. Environ. Treat. Tech. 2014, 2, 1–11. [Google Scholar]

- Huseien, G.F.; Joudah, Z.H.; Memon, R.P.; Sam, A.R.M. Compressive strength and microstructure properties of modified concrete incorporated effective microorganism and fly ash. Mater. Today Proc. 2021, 46, 2036–2044. [Google Scholar] [CrossRef]

- Huseien, G.F.; Sam, A.R.M.; Algaifi, H.A.; Alyousef, R. Development of a sustainable concrete incorporated with effective microorganism and fly Ash: Characteristics and modeling studies. Constr. Build. Mater. 2021, 285, 122899. [Google Scholar] [CrossRef]

- Wu, M.; Johannesson, B.; Geiker, M. A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Jonkers, H.M. Self healing concrete: A biological approach. In Self Healing Materials; Springer: Berlin/Heidelberg, Germany, 2007; pp. 195–204. [Google Scholar]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N.; De Muynck, W.; Verstraete, W. Use of bacteria to repair cracks in concrete. Cem. Concr. Res. 2010, 40, 157–166. [Google Scholar] [CrossRef]

- Nathaniel, O.; Sam, A.R.M.; Lim, N.H.A.S.; Adebisi, O.; Abdulkareem, M. Biogenic approach for concrete durability and sustainability using effective microorganisms: A review. Constr. Build. Mater. 2020, 261, 119664. [Google Scholar] [CrossRef]

- Hamzah, N.; Saman, H.M.; Baghban, M.H.; Sam, A.R.M.; Faridmehr, I.; Sidek, M.N.M.; Benjeddou, O.; Huseien, G.F. A Review on the Use of Self-Curing Agents and Its Mechanism in High-Performance Cementitious Materials. Buildings 2022, 12, 152. [Google Scholar] [CrossRef]

- Hemsley, R.A.; Griffiths, P.C. Architecture in the microcosm: Biocolloids, self-assembly and pattern formation. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 2000, 358, 547–564. [Google Scholar] [CrossRef]

- Huseien, G.F.; Shah, K.W.; Sam, A.R.M. Sustainability of nanomaterials based self-healing concrete: An all-inclusive insight. J. Build. Eng. 2019, 23, 155–171. [Google Scholar] [CrossRef]

- Isa, M.N.; Garba, M.M.; Kawu, A.L. Influence of locally made effective microorganisms on the compressive strength of concrete. J. Multidiscip. Eng. Sci.Technol. 2016, 3, 4425–4429. [Google Scholar]

- Rong, H.; Qian, C.-X.; Li, L.-Z. Study on microstructure and properties of sandstone cemented by microbe cement. Constr. Build. Mater. 2012, 36, 687–694. [Google Scholar] [CrossRef]

- Ghosh, S.; Biswas, M.; Chattopadhyay, B.; Mandal, S. Microbial activity on the microstructure of bacteria modified mortar. Cem. Concr. Compos. 2009, 31, 93–98. [Google Scholar] [CrossRef]

- Sato, N.; Higa, T.; Sugita, S.; Shuya., M. Some properties of concrete mixed with effective microorganisms and the on-site investigation of the completed structures. In Proceedings of the 28th International Conference, Our World in Concrete and Structures, Singapore, 28–29 August 2003. [Google Scholar]

- Andrew, T.C.S.; Syahrizal, I.I.; Jamaluddin, M.Y. Effective microorganisms for concrete (EMC) admixture–its effects to the mechanical properties of concrete. In Proceedings of the Awam International Conference on Civil Engineering (AICCE’12) Geohazard Information Zonation (GIZ’12), Penang, Malaysia, 28–30 August 2012; pp. 419–426. [Google Scholar]

- Rizwan, S.A.; Khan, H.; Bier, T.A.; Adnan, F. Use of Effective Micro-organisms (EM) technology and self-compacting concrete (SCC) technology improved the response of cementitious systems. Constr. Build. Mater. 2017, 152, 642–650. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, J.; Zhao, X.; Zhao, X.; Duan, J.; Song, X. Effects of microorganism on corrosion performance of zinc in natural seawater. Int. J. Electrochem. Sci. 2014, 9, 7587–7595. [Google Scholar]

- Zhai, X.; Ren, Y.; Wang, N.; Guan, F.; Agievich, M.; Duan, J.; Hou, B. Microbial Corrosion Resistance and Antibacterial Property of Electrodeposited Zn–Ni–Chitosan Coatings. Molecules 2019, 24, 1974. [Google Scholar] [CrossRef] [Green Version]

- Nelson, V.V.; Maria, O.T.; Mamiè, S.V.; Maritza, P.C. Microbiologically influenced corrosion in aluminium alloys 7075 and 2024, in Aluminium Alloys-Recent Trends in Processing, Characterization, Mechanical Behavior and Applications. IntechOpen 2017, 12, 225–242. [Google Scholar]

- Huseien, G.F.; Nehdi, M.L.; Faridmehr, I.; Ghoshal, S.K.; Hamzah, H.K.; Benjeddou, O.; Alrshoudi, F. Smart Bio-Agents-Activated Sustainable Self-Healing Cementitious Materials: An All-Inclusive Overview on Progress, Benefits and Challenges. Sustainability 2022, 14, 1980. [Google Scholar] [CrossRef]

- Memon, R.P.; Mohd, A.R.B.; Awang, A.Z.; Huseien, G.F.; Memon, U. A review: Mechanism, materials and properties of self-curing concrete. ARPN J. Eng. Appl.Sci. 2018, 13, 9397–9409. [Google Scholar]

- Huseien, G.F.; Joudah, Z.H.; Khalid, N.H.A.; Sam, A.R.M.; Tahir, M.M.; Lim, N.H.A.S.; Alyousef, R.; Mirza, J. Durability performance of modified concrete incorporating fly ash and effective microorganism. Constr. Build. Mater. 2021, 267, 120947. [Google Scholar] [CrossRef]

- Iriti, M.; Scarafoni, A.; Pierce, S.; Castorina, G.; Vitalini, S. Soil application of effective microorganisms (EM) Maintains leaf photosynthetic efficiency, increases seed yield and quality traits of bean (Phaseolus vulgaris L.) plants grown on different substrates. Int. J. Mol.Sci. 2019, 20, 2327. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cabrera, M.; Galvín, A.; Agrela, F. Leaching issues in recycled aggregate concrete. In New Trends in Eco-Efficient and Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2019; pp. 329–356. [Google Scholar]

- Wang, H.; Li, Q. Prediction of elastic modulus and Poisson’s ratio for unsaturated concrete. Int. J. Solids Struct. 2007, 44, 1370–1379. [Google Scholar] [CrossRef] [Green Version]

- Rashad, A.M.; Ezzat, M. A Preliminary study on the use of magnetic, Zamzam, and sea water as mixing water for alkali-activated slag pastes. Constr. Build. Mater. 2019, 207, 672–678. [Google Scholar] [CrossRef]

- Zhang, J.; Dong, B.; Hong, S.; Teng, X.; Li, G.; Li, W.; Tang, L.; Xing, F. Investigating the influence of fly ash on the hydration behavior of cement using an electrochemical method. Constr. Build. Mater. 2019, 222, 41–48. [Google Scholar] [CrossRef]

- Liu, J.; Qiu, Q.; Xing, F.; Pan, D. Permeation properties and pore structure of surface layer of fly ash concrete. Materials 2014, 7, 4282–4296. [Google Scholar] [CrossRef] [Green Version]

- Yu, Z.; Ye, G. The pore structure of cement paste blended with fly ash. Constr. Build. Mater. 2013, 45, 30–35. [Google Scholar] [CrossRef]

- Shaikh, F.U.; Supit, S.W. Compressive strength and durability properties of high volume fly ash (HVFA) concretes containing ultrafine fly ash (UFFA). Constr. Build. Mater. 2015, 82, 192–205. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Liang, X.; Zhou, H.; Xie, N.; Dai, Z. Investigation on the mechanical properties and environmental impacts of pervious concrete containing fly ash based on the cement-aggregate ratio. Constr. Build. Mater. 2019, 202, 387–395. [Google Scholar] [CrossRef]

- Cho, Y.K.; Jung, S.H.; Choi, Y.C. Effects of chemical composition of fly ash on compressive strength of fly ash cement mortar. Constr. Build. Mater. 2019, 204, 255–264. [Google Scholar] [CrossRef]

- Sathyan, D.; Anand, K.B. Influence of superplasticizer family on the durability characteristics of fly ash incorporated cement concrete. Constr. Build. Mater. 2019, 204, 864–874. [Google Scholar] [CrossRef]

- Gulbandilar, E.; Kocak, Y. Prediction of the effects of fly ash and silica fume on the setting time of Portland cement with fuzzy logic. Neural Comput. Appl. 2013, 22, 1485–1491. [Google Scholar]

- Mhaya, A.M.; Baghban, M.H.; Faridmehr, I.; Huseien, G.F.; Abidin, A.R.Z.; Ismail, M. Performance evaluation of modified rubberized concrete exposed to aggressive environments. Materials 2021, 14, 1900. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Shi, N.; Huang, D. Influence of initial curing temperature on the long-term strength of concrete. Mag. Concr. Res. 2013, 65, 358–364. [Google Scholar]

- Lothenbach, B.; Scrivener, K.; Hooton, R. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar]

- Al-Fasih, M.Y.M.; Huseien, F.G.; bin Ibrahim, S.I.; Sam, M.A.R.; Algaifi, A.H.; Alyousef, R. Synthesis of rubberized alkali-activated concrete: Experimental and numerical evaluation. Constr. Build. Mater. 2021, 303, 124526. [Google Scholar] [CrossRef]

- Nedunuri, S.S.S.A.; Sertse, S.G.; Muhammad, S. Microstructural study of Portland cement partially replaced with fly ash, ground granulated blast furnace slag and silica fume as determined by pozzolanic activity. Constr. Build. Mater. 2020, 238, 117561. [Google Scholar] [CrossRef]

- Zuo, W.; Feng, P.; Zhong, P.; Tian, Q.; Gao, N.; Wang, Y.; Yu, C.; Miao, C. Effects of novel polymer-type shrinkage-reducing admixture on early age autogenous deformation of cement pastes. Cem. Concr. Res. 2017, 100, 413–422. [Google Scholar]

- Huseien, G.; Ismail, M.; Tahir, M.; Mirza, J.; Hussein, A.; Khalid, N.; Sarbini, N. Performance of sustainable alkali activated mortars containing solid waste ceramic powder. Chem. Eng. Trans. 2018, 63, 673–678. [Google Scholar]

- Sun, Y.; Yu, R.; Shui, Z.; Wang, X.; Qian, D.; Rao, B.; Huang, J.; He, Y. Understanding the porous aggregates carrier effect on reducing autogenous shrinkage of Ultra-High Performance Concrete (UHPC) based on response surface method. Constr. Build. Mater. 2019, 222, 130–141. [Google Scholar] [CrossRef]

- Wehbe, Y.; Ghahremaninezhad, A. Combined effect of shrinkage reducing admixtures (SRA) and superabsorbent polymers (SAP) on the autogenous shrinkage, hydration and properties of cementitious materials. Constr. Build. Mater. 2017, 138, 151–162. [Google Scholar]

- Zhan, P.-M.; He, Z.-H. Application of shrinkage reducing admixture in concrete: A review. Constr. Build. Mater. 2019, 201, 676–690. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Baig, H.S.; Malik, S.; Din, M.; Aslam, H.M.U. Effect of molasses and water–cement ratio on properties of recycled aggregate concrete. Arab. J. Sci. Eng. 2020, 45, 3455–3467. [Google Scholar] [CrossRef]

- Qin, R.; Hao, H.; Rousakis, T.; Lau, D. Effect of shrinkage reducing admixture on new-to-old concrete interface. Compos. Part B: Eng. 2019, 167, 346–355. [Google Scholar] [CrossRef]

- Dang, Y.; Qian, J.; Qu, Y.; Zhang, L.; Wang, Z.; Qiao, D.; Jia, X. Curing cement concrete by using shrinkage reducing admixture and curing compound. Constr. Build. Mater. 2013, 48, 992–997. [Google Scholar] [CrossRef]

- Ngene, B.U.; Olofinnade, O.M.; Agomo, C.E. Effect of magnetized water on the mechanical properties of concrete containing recycled waste glass aggregate. In International Journal of Engineering Research in Africa; Trans Tech Publications Ltd.: Freinbach, Switzerland, 2019; Volume 41, pp. 103–114. [Google Scholar]

- Souza, M.T.; Onghero, L.; Correa, B.N.; Selhorst, M.A.; Dias, A.M.; Repette, W.L.; Pereira, F.R.; de Oliveira, A.P.N. Novel low-cost shrinkage-compensating admixture for ordinary Portland cement. Constr. Build. Mater. 2020, 230, 117024. [Google Scholar] [CrossRef]

- Akar, C.; Canbaz, M. Effect of molasses as an admixture on concrete durability. J. Clean. Prod. 2016, 112, 2374–2380. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Lim, N.H.A.S.; Tahir, M.M.; Alyousef, R.; Alabduljabbar, H.; Samadi, M. Enhanced performance of green mortar comprising high volume of ceramic waste in aggressive environments. Constr. Build. Mater. 2019, 212, 607–617. [Google Scholar] [CrossRef]

- Liew, K.; Sojobi, A.; Zhang, L. Green concrete: Prospects and challenges. Constr. Build. Mater. 2017, 156, 1063–1095. [Google Scholar] [CrossRef]

- Ahmed, M.A.B.; Hussin, M.W.; Muthusamy, K.; Ismail, M.A. Performance of high strength POFA concrete in acidic environment. Concr. Res. Lett. 2010, 1, 14–18. [Google Scholar]

- Ariffin, M.; Bhutta, M.; Hussin, M.; Tahir, M.M.; Aziah, N. Sulfuric acid resistance of blended ash geopolymer concrete. Constr. Build. Mater. 2013, 43, 80–86. [Google Scholar] [CrossRef]

- Bamaga, S.; Ismail, M.A.; Majid, Z.A.; Ismail, M.; Hussin, M.W. Evaluation of sulfate resistance of mortar containing palm oil fuel ash from different sources. Arab. J. Sci. Eng. 2013, 38, 2293–2301. [Google Scholar] [CrossRef]

- Noruzman, A.; Ismail, M.; Bhutta, M.A.R.; Yusuf, T.O.; Shehu, I.A.; Hassan, I.O. Strength and durability characteristics of polymer modified concrete incorporating Vinyl acetate effluent. In Advanced Materials Research; Trans Tech Publications Ltd.: Freinbach, Switzerland, 2013; Volume 693, pp. 1054–1056. [Google Scholar]

- Huseien, G.F.; Shah, K.W. Durability and life cycle evaluation of self-compacting concrete containing fly ash as GBFS replacement with alkali activation. Constr. Build. Mater. 2020, 235, 117458. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Yatim, J.M.; Sam, A.R.M.; Awal, A.A. Durability performance of green concrete composites containing waste carpet fibers and palm oil fuel ash. J. Clean. Prod. 2017, 144, 448–458. [Google Scholar] [CrossRef]

- Vafaei, M.; Allahverdi, A.; Dong, P.; Bassim, N. Acid attack on geopolymer cement mortar based on waste-glass powder and calcium aluminate cement at mild concentration. Constr. Build. Mater. 2018, 193, 363–372. [Google Scholar] [CrossRef]

- Slaty, F.; Khoury, H.; Rahier, H.; Wastiels, J. Durability of alkali activated cement produced from kaolinitic clay. Appl. Clay Sci. 2015, 104, 229–237. [Google Scholar] [CrossRef]

| Raw Materials | Elements (Weight%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | SO3 | LOT | |

| OPC | 20.4 | 5.2 | 4.2 | 62.4 | 1.6 | 0.01 | 0.2 | 2.1 | 2.4 |

| FA | 57.2 | 28.8 | 3.7 | 5.2 | 1.5 | 0.9 | 0.1 | 0.1 | 0.1 |

| Properties | FA | OPC | Permissible Limits | Relevant Standard |

|---|---|---|---|---|

| Specific gravity | 2.20 | 3.15 | 3.10–3.25 | ASTM C33 |

| Color | Grey | Dark Grey | - | - |

| %Passing through 45 μm wet sieve | 100 | 90 | ≥ 34 | ASTM C430 |

| Mix | Binder, kg/m3 | Solution, kg/m3 | Aggregates, kg/m3 | ||||

|---|---|---|---|---|---|---|---|

| OPC | FA | CaO:SiO2 | Water | EM | Sand | Gravel | |

| MC1-0-0 | 450 | 0 | 3.06 | 250 | 0 | 875 | 815 |

| MC2-50-0 | 225 | 225 | 0.92 | 250 | 0 | 875 | 815 |

| MC3-50-5 | 225 | 225 | 0.92 | 237.5 | 12.5 | 875 | 815 |

| MC4-50-10 | 225 | 225 | 0.92 | 225 | 25 | 875 | 815 |

| MC5-50-15 | 225 | 225 | 0.92 | 212.5 | 37.5 | 875 | 815 |

| MC6-50-20 | 225 | 225 | 0.92 | 200 | 50 | 875 | 815 |

| MC7-50-25 | 225 | 225 | 0.92 | 225 | 62.5 | 875 | 815 |

| Properties | EM Solution | Water Replacement by EM Solution (%) | |||||

|---|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 15 | 20 | 25 | ||

| pH | 3.45 | 6.7 | 6.4 | 6.3 | 5.7 | 5.2 | 4.0 |

| Viscosity, mPas | 1.44 | 0.95 | 1.0 | 1.05 | 1.1 | 1.2 | 1.25 |

| Surface tension, mN/m | 66 | 66 | 58.3 | 54.5 | 51.7 | 44.8 | 39.9 |

| Index | MC1-0-0 | MC2-50-0 | MC4-50-10 |

|---|---|---|---|

| Ca(OH)2 | 13.9 | 8.4 | 18.4 |

| SiO2 | 68.6 | 76.3 | 67.5 |

| CaCO3 | 8.8 | 6.1 | 9.2 |

| Ca6Al2(SO4)3(OH)12·26H2O | 7.1 | 1.3 | 2.1 |

| Transportation Cost Parameters | |||

|---|---|---|---|

| Speed, km/h | Diesel consumption, liter/km | Truck volume, m3 | CO2 emission for 1 L diesel, ton |

| 80 | 0.09 | 12 | 0.0027 |

| Materials CO2 emission, energy consumption and cost. | |||

| Materials | Manufacturing (CO2, t/t) | Transportation (CO2, t/t) | Total (CO2, t/t) |

| OPC | 0.9023 | 0.0017 | 0.904 |

| FA | 0 | 0.012 | 0.012 |

| EM | 0 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huseien, G.F.; Saleh, A.T.; Ghoshal, S.K. Effective Microorganism Solution and High Volume of Fly Ash Blended Sustainable Bio-Concrete. Biomimetics 2022, 7, 65. https://doi.org/10.3390/biomimetics7020065

Huseien GF, Saleh AT, Ghoshal SK. Effective Microorganism Solution and High Volume of Fly Ash Blended Sustainable Bio-Concrete. Biomimetics. 2022; 7(2):65. https://doi.org/10.3390/biomimetics7020065

Chicago/Turabian StyleHuseien, Ghasan Fahim, Ali Taha Saleh, and Sib K. Ghoshal. 2022. "Effective Microorganism Solution and High Volume of Fly Ash Blended Sustainable Bio-Concrete" Biomimetics 7, no. 2: 65. https://doi.org/10.3390/biomimetics7020065

APA StyleHuseien, G. F., Saleh, A. T., & Ghoshal, S. K. (2022). Effective Microorganism Solution and High Volume of Fly Ash Blended Sustainable Bio-Concrete. Biomimetics, 7(2), 65. https://doi.org/10.3390/biomimetics7020065