Mycelium-Based Composite Graded Materials: Assessing the Effects of Time and Substrate Mixture on Mechanical Properties

Abstract

:1. Introduction

2. Background

2.1. The Cultivation Process of MBC

2.2. Role of Cultivation Parameters on the Mechanical Behavior of MBC

3. Materials and Methods

3.1. Substrate Mixtures Preparation

3.2. Cultivation of Materials

3.3. Preparing Samples for Mechanical Test

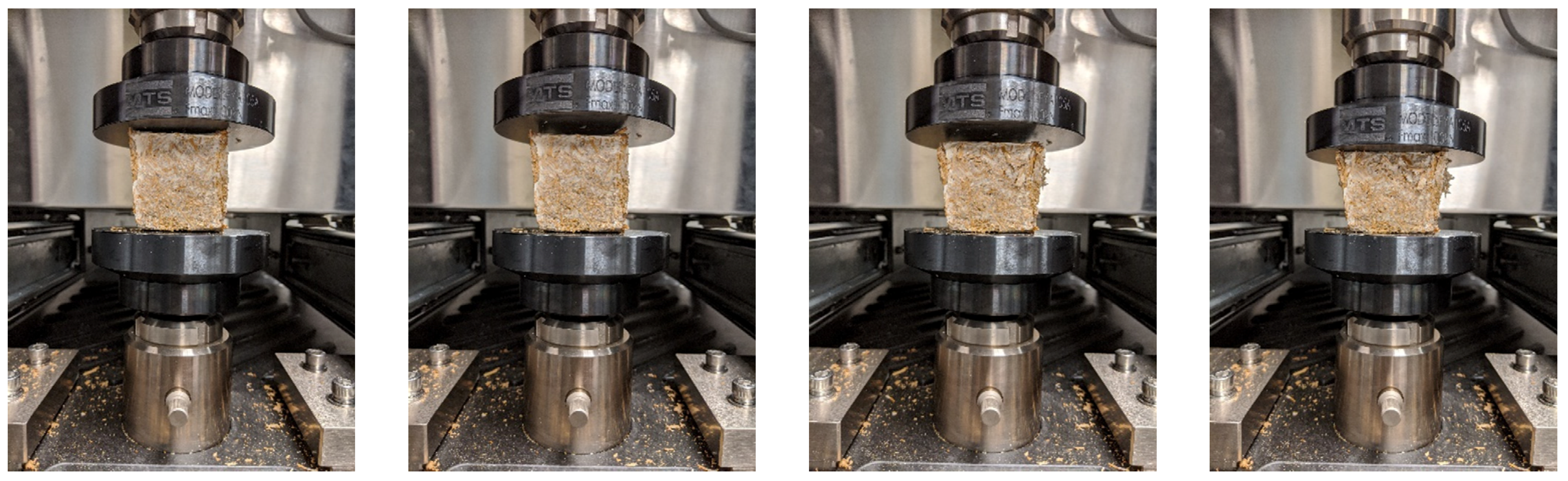

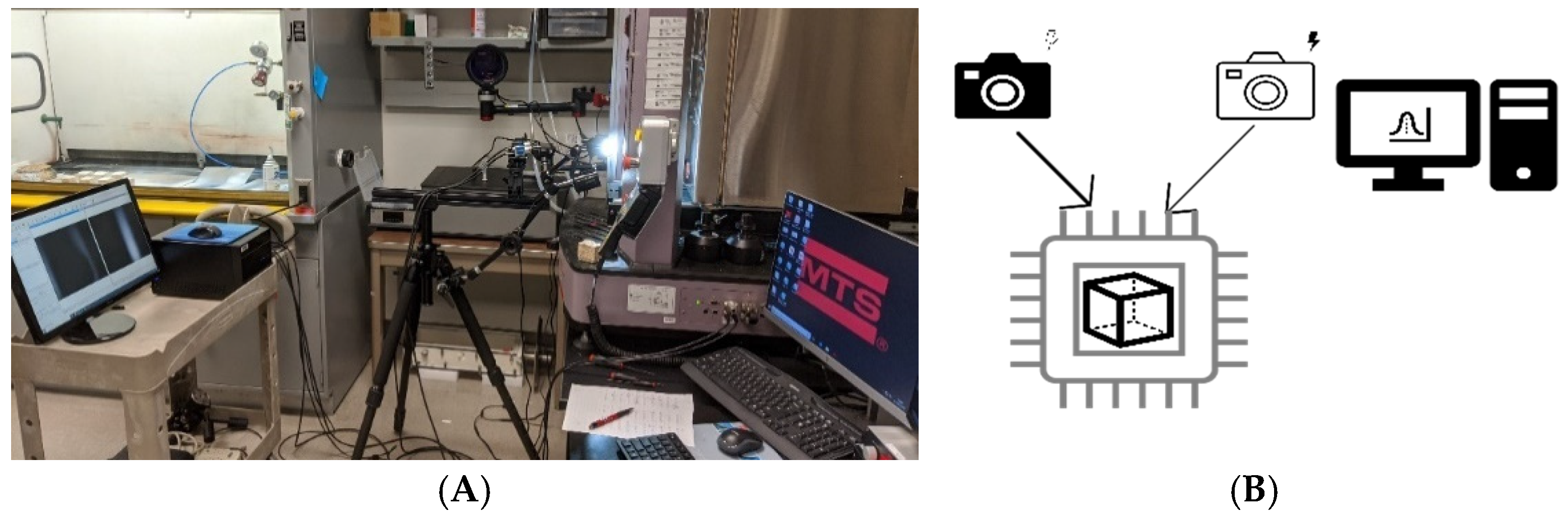

3.4. Mechanical Tests

4. Results and Discussion

4.1. The Effects of Sawdust to Straw Ratio in Substrate Mixtures on Compressive Strength

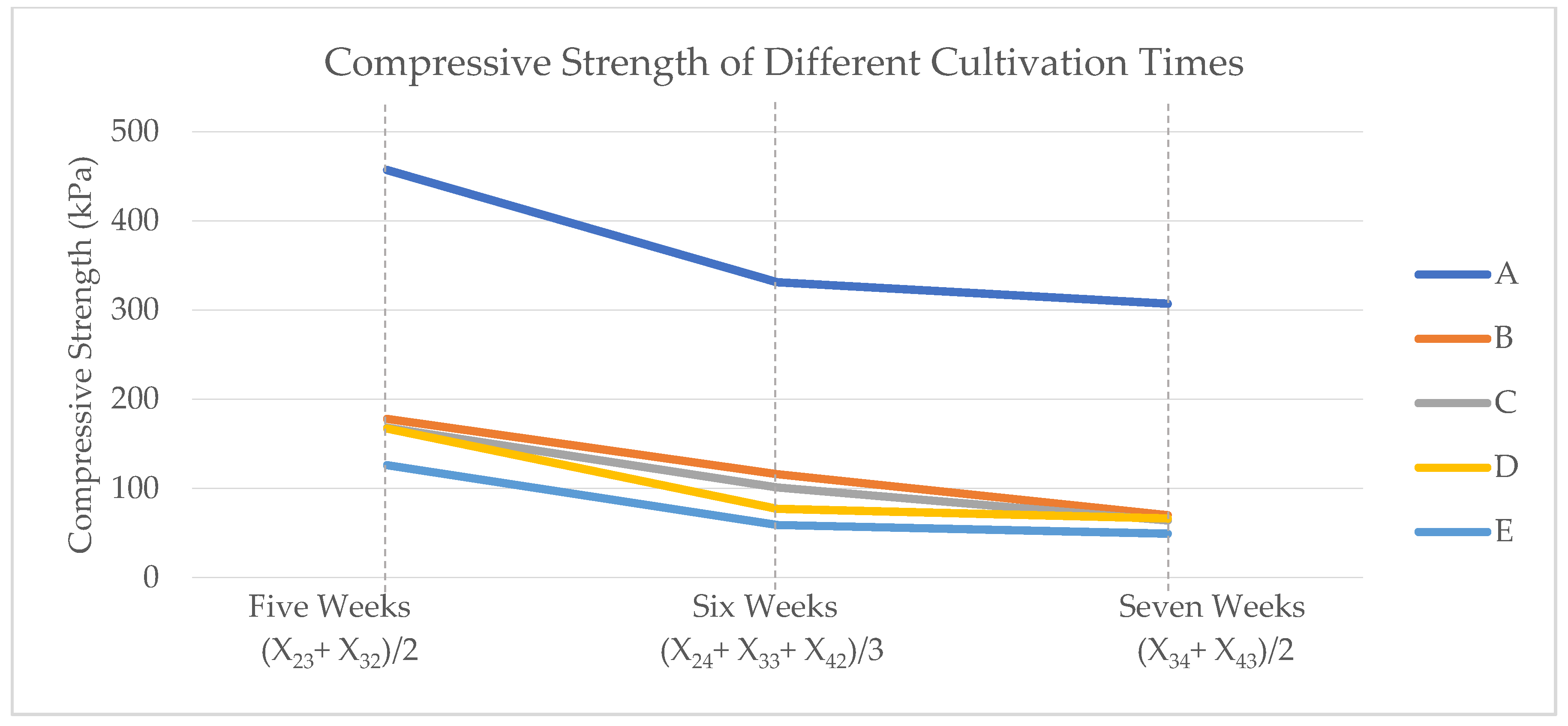

4.2. The Effects of Total Growth Time on Compressive Strength

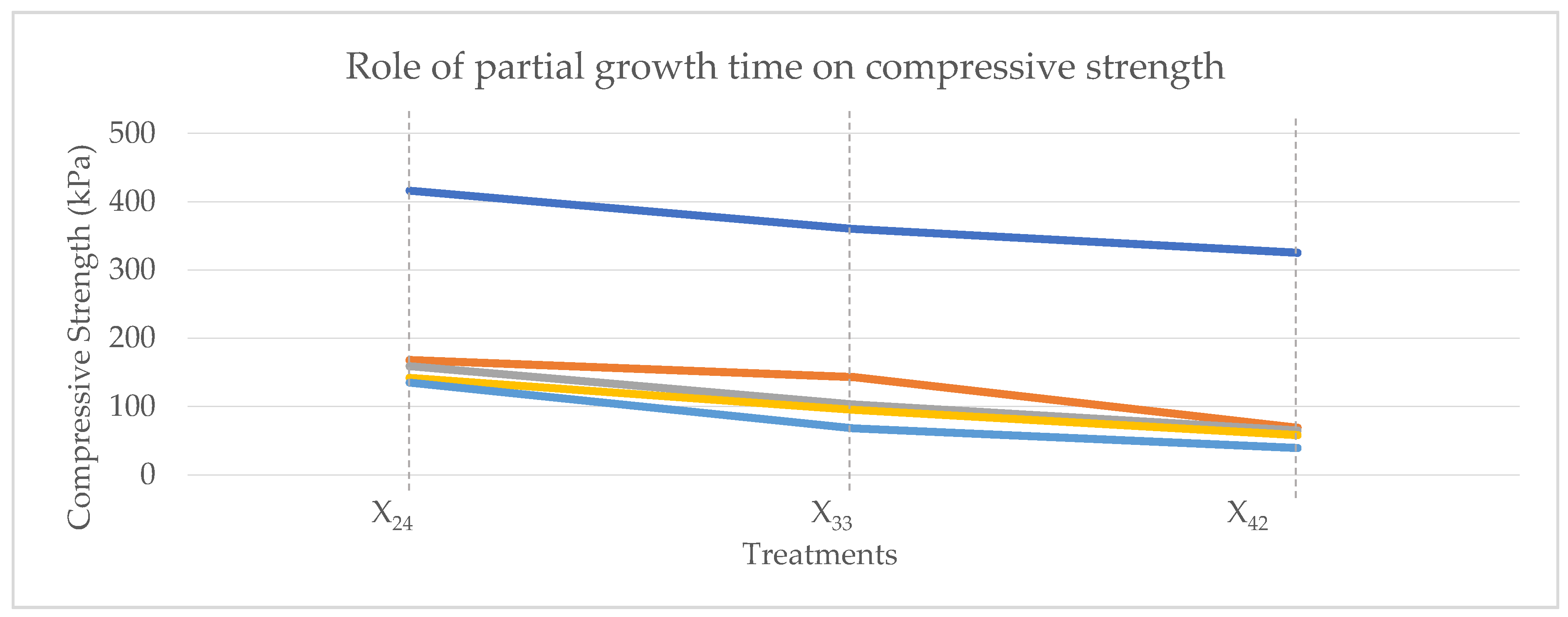

4.3. The Effects of Varied Bag/Formwork Growth Times on Compressive Strength

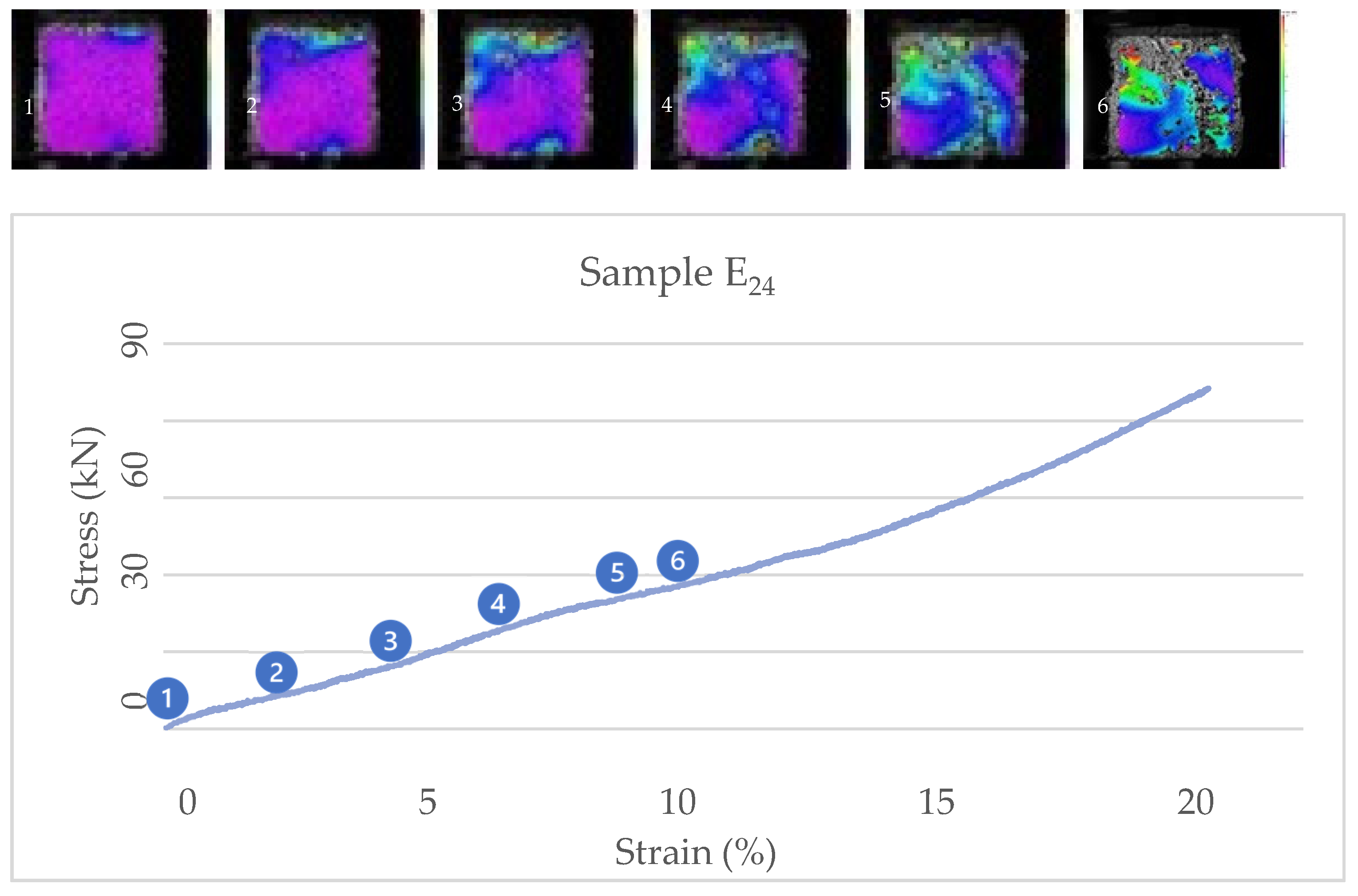

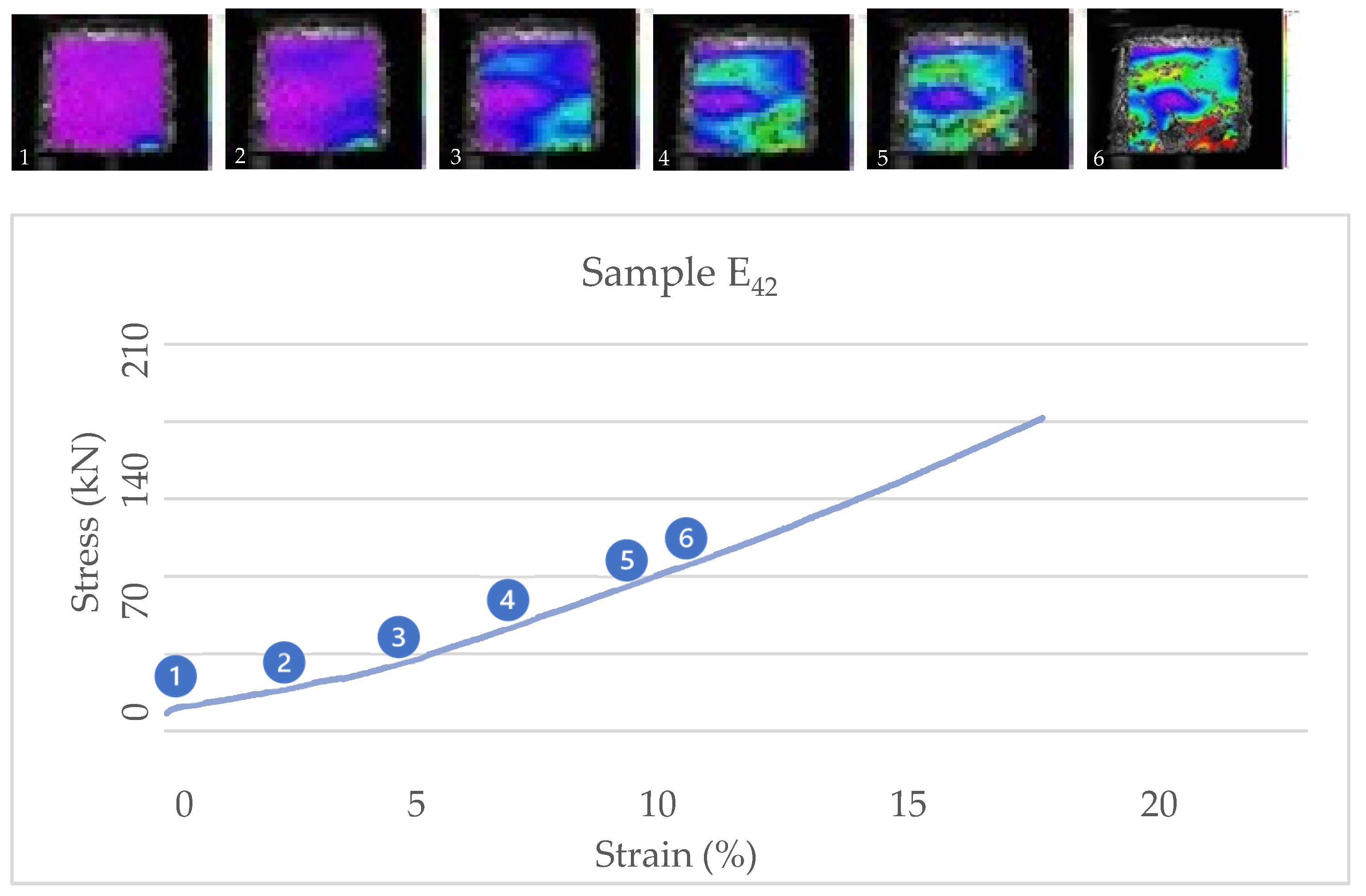

4.4. Digital Image Correlation (DIC)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Treatment | Substrate Mixture | Growth in Bags (Days) | Growth in Formwork (Days) | Total Growth Time (Days) | Mechanical Strength (kPa) | Elastic Moduli (MPa) |

|---|---|---|---|---|---|---|

| A23 | A: Sawdust only 65–70% Water Content 7% DW Wheat Flour 7% DW Fungal sp. | 14 | 21 | 35 | 491 | 6.1 |

| A24 | 14 | 28 | 42 | 418 | 3.4 | |

| A32 | 21 | 14 | 35 | 335 | 3.3 | |

| A33 | 21 | 21 | 42 | 355 | 3.5 | |

| A34 | 21 | 28 | 49 | 300 | 3.4 | |

| A42 | 28 | 14 | 42 | 321 | 3.4 | |

| A43 | 28 | 21 | 49 | 292 | 3.0 | |

| B23 | B: Straw to Sawdust = 7/1 65–70% Water Content 7% DW Wheat Flour 7% DW Fungal sp. | 14 | 21 | 35 | 190 | 1.8 |

| B24 | 14 | 28 | 42 | 170 | 1.6 | |

| B32 | 21 | 14 | 35 | 110 | 1.1 | |

| B33 | 21 | 21 | 42 | 140 | 0.9 | |

| B34 | 21 | 28 | 49 | 98 | 0.9 | |

| B42 | 28 | 14 | 42 | 70 | 0.8 | |

| B43 | 28 | 21 | 49 | 68 | 0.7 | |

| C23 | C: Straw to Sawdust = 3/1 65–70% Water Content 7% DW Wheat Flour 7% DW Fungal sp. | 14 | 21 | 35 | 181 | 1.6 |

| C24 | 14 | 28 | 42 | 161 | 1.4 | |

| C32 | 21 | 14 | 35 | 121 | 1.7 | |

| C33 | 21 | 21 | 42 | 101 | 0.9 | |

| C34 | 21 | 28 | 49 | 81 | 0.8 | |

| C42 | 28 | 14 | 42 | 66 | 0.8 | |

| C43 | 28 | 21 | 49 | 61 | 0.7 | |

| D23 | D: Straw to Sawdust = 2/1 65–70% Water Content 7% DW Wheat Flour 7% DW Fungal sp. | 14 | 21 | 35 | 193 | 0.6 |

| D24 | 14 | 28 | 42 | 142 | 2.0 | |

| D32 | 21 | 14 | 35 | 63 | 1.5 | |

| D33 | 21 | 21 | 42 | 96 | 0.5 | |

| D34 | 21 | 28 | 49 | 75 | 0.8 | |

| D42 | 28 | 14 | 42 | 59 | 0.7 | |

| D43 | 28 | 21 | 49 | 72 | 0.6 | |

| E23 | E: Straw to Sawdust = 1/1 65–70% Water Content 7% DW Wheat Flour 7% D.W. Fungal sp. | 14 | 21 | 35 | 120 | 0.6 |

| E24 | 14 | 28 | 42 | 130 | 1.3 | |

| E32 | 21 | 14 | 35 | 33 | 1.1 | |

| E33 | 21 | 21 | 42 | 69 | 0.5 | |

| E34 | 21 | 28 | 49 | 74 | 0.7 | |

| E42 | 28 | 14 | 42 | 40 | 0.7 | |

| E43 | 28 | 21 | 49 | 60 | 0.6 |

References

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Kadiri, K.O. Reducing waste to landfill: A need for cultural change in the UK construction industry. J. Build. Eng. 2015, 5, 185–193. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Xing, Y.; Jones, P.; Donnison, I. Characterisation of Nature-Based Solutions for the Built Environment. Sustainability 2017, 9, 149. [Google Scholar] [CrossRef] [Green Version]

- Karana, E.; Blauwhoff, D.; Hultink, E.J.; Camere, S. When the material grows: A case study on designing (with) mycelium-based materials. Int. J. Des. 2018, 12, 119–136. Available online: www.ijdesign.org (accessed on 15 January 2022).

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered mycelium composite construction materials from fungal biorefineries: A critical review. Mater. Des. 2019, 187, 108397. [Google Scholar] [CrossRef]

- Yevich, R.; Logan, J.A. An assessment of biofuel use and burning of agricultural waste in the developing world. Glob. Biogeochem. Cycles 2003, 17. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, F.; Still, B.; White, M.; Amstislavski, P. Physical and Mechanical Properties of Fungal Mycelium-Based Biofoam. J. Mater. Civ. Eng. 2017, 29, 04017030. [Google Scholar] [CrossRef]

- Haneef, M.; Ceseracciu, L.; Canale, C.; Bayer, I.S.; Heredia-Guerrero, J.A.; Athanassiou, A. Advanced Materials From Fungal Mycelium: Fabrication and Tuning of Physical Properties. Sci. Rep. 2017, 7, 41292. [Google Scholar] [CrossRef]

- Meyer, V.; Basenko, E.Y.; Benz, J.P.; Braus, G.H.; Caddick, M.X.; Csukai, M.; De Vries, R.P.; Endy, D.; Frisvad, J.C.; Gunde-Cimerman, N.; et al. Growing a circular economy with fungal biotechnology: A white paper. Fungal Biol. Biotechnol. 2020, 7, 5. [Google Scholar] [CrossRef] [Green Version]

- Girometta, C.; Picco, A.M.; Baiguera, R.M.; Dondi, D.; Babbini, S.; Cartabia, M.; Pellegrini, M.; Savino, E. Physico-Mechanical and Thermodynamic Properties of Mycelium-Based Biocomposites: A Review. Sustainability 2019, 11, 281. [Google Scholar] [CrossRef] [Green Version]

- Elsacker, E.; Vandelook, S.; Van Wylick, A.; Ruytinx, J.; De Laet, L.; Peeters, E. A comprehensive framework for the production of mycelium-based lignocellulosic composites. Sci. Total Environ. 2020, 725, 138431. [Google Scholar] [CrossRef] [PubMed]

- Pelletier, M.; Holt, G.; Wanjura, J.; Bayer, E.; McIntyre, G. An evaluation study of mycelium based acoustic absorbers grown on agricultural by-product substrates. Ind. Crop. Prod. 2013, 51, 480–485. [Google Scholar] [CrossRef]

- Pelletier, M.; Holt, G.; Wanjura, J.; Lara, A.; Tapia-Carillo, A.; McIntyre, G.; Bayer, E. An evaluation study of pressure-compressed acoustic absorbers grown on agricultural by-products. Ind. Crop. Prod. 2017, 95, 342–347. [Google Scholar] [CrossRef]

- Wimmers, G.; Klick, J.; Tackaberry, L.; Zwiesigk, C.; Egger, K.; Massicotte, H. Fundamental studies for designing insulation panels from wood shavings and filamentous fungi. BioResources 2019, 14, 5506–5520. [Google Scholar] [CrossRef]

- Dias, P.P.; Jayasinghe, L.B.; Waldmann, D. Investigation of Mycelium-Miscanthus composites as building insulation material. Results Mater. 2021, 10, 100189. [Google Scholar] [CrossRef]

- Schritt, H.; Vidi, S.; Pleissner, D. Spent mushroom substrate and sawdust to produce mycelium-based thermal insulation composites. J. Clean. Prod. 2021, 313, 127910. [Google Scholar] [CrossRef]

- Gauvin, F.; Tsao, V.; Vette, J.; Brouwers, H.J.H. Physical Properties and Hygrothermal Behavior of Mycelium-Based Composites as Foam-Like Wall Insulation Material. Constr. Technol. Archit. 2022, 1, 643–651. [Google Scholar] [CrossRef]

- Abhijith, R.; Ashok, A.; Rejeesh, C. Sustainable packaging applications from mycelium to substitute polystyrene: A review. Mater. Today Proc. 2018, 5, 2139–2145. [Google Scholar] [CrossRef]

- Sivaprasad, S.; Byju, S.K.; Prajith, C.; Shaju, J.; Rejeesh, C. Development of a novel mycelium bio-composite material to substitute for polystyrene in packaging applications. Mater. Today Proc. 2021, 47, 5038–5044. [Google Scholar] [CrossRef]

- Holt, G.A.; McIntyre, G.; Flagg, D.; Bayer, E.; Wanjura, J.D.; Pelletier, M.G. Fungal Mycelium and Cotton Plant Materials in the Manufacture of Biodegradable Molded Packaging Material: Evaluation Study of Select Blends of Cotton Byproducts. J. Biobased Mater. Bioenergy 2012, 6, 431–439. [Google Scholar] [CrossRef]

- Jose, J.; Uvais, K.N.; Sreenadh, T.S.; Deepak, A.V.; Rejeesh, C.R. Investigations into the Development of a Mycelium Biocomposite to Substitute Polystyrene in Packaging Applications. Arab. J. Sci. Eng. 2021, 46, 2975–2984. [Google Scholar] [CrossRef]

- Jones, M.; Bhat, T.; Huynh, T.; Kandare, E.; Yuen, K.K.R.; Wang, C.-H.; John, S. Waste-derived low-cost mycelium composite construction materials with improved fire safety. Fire Mater. 2018, 42, 816–825. [Google Scholar] [CrossRef]

- Jones, M.; Bhat, T.; Kandare, E.; Thomas, A.; Joseph, P.; Dekiwadia, C.; Yuen, K.K.R.; John, S.; Ma, J.; Wang, C.-H. Thermal Degradation and Fire Properties of Fungal Mycelium and Mycelium—Biomass Composite Materials. Sci. Rep. 2018, 8, 17583. [Google Scholar] [CrossRef] [PubMed]

- Jones, M.; Bhat, T.; Wang, C.H.; Moinuddin, K.; John, S. Thermal degradation and fire reaction properties of mycelium composites. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017; Available online: https://www.researchgate.net/publication/319065199 (accessed on 15 January 2022).

- Attias, N.; Danai, O.; Abitbol, T.; Tarazi, E.; Ezov, N.; Pereman, I.; Grobman, Y.J. Mycelium bio-composites in industrial design and architecture: Comparative review and experimental analysis. J. Clean. Prod. 2019, 246, 119037. [Google Scholar] [CrossRef]

- Javadian, A.; le Ferrand, H.; Hebel, D.E.; Saeidi, N. Application of Mycelium-Bound Composite Materials in Construction Industry: A Short Review. SOJ Mater. Sci. Eng. 2020, 7, 1–9. Available online: www.symbiosisonlinepublishing.com (accessed on 15 January 2022).

- Zimele, Z.; Irbe, I.; Grinins, J.; Bikovens, O.; Verovkins, A.; Bajare, D. Novel Mycelium-Based Biocomposites (MBB) as Building Materials. J. Renew. Mater. 2020, 8, 1067–1076. [Google Scholar] [CrossRef]

- Ghazvinian, A.; Farrokhsiar, P.; Vieira, F.; Pecchia, J.; Gursoy, B. Mycelium-Based Bio-Composites for Architecture: Assessing the Effects of Cultivation Factors on Compressive Strength. In Proceedings of the 37th eCAADe/23rd SIGraDi Conference, Porto, Portugal, 11–13 September 2019; pp. 505–514. [Google Scholar]

- Escaleira, R.M.; Campos, M.J.; Alves, M.L. Mycelium-Based Composites: A New Approach to Sustainable Materials. In Sustainability and Automation in Smart Constructions; Springer: Cham, Switzerland, 2020; pp. 261–266. [Google Scholar] [CrossRef]

- Yang, L.; Park, D.; Qin, Z. Material Function of Mycelium-Based Bio-Composite: A Review. Front. Mater. 2021, 8, 737377. [Google Scholar] [CrossRef]

- Manan, S.; Ullah, M.W.; Ul-Islam, M.; Atta, O.M.; Yang, G. Synthesis and applications of fungal mycelium-based advanced functional materials. J. Bioresour. Bioprod. 2021, 6, 1–10. [Google Scholar] [CrossRef]

- Ghazvinian, A. A Sustainable Alternative to Architectural Materials: Mycelium-Based Bio-Composites. In Proceedings of the Divergence in Architectural Research, Atlanta, GA, USA, 15 February 2021; Georgia Institute of Technology: Atlanta, GA, USA, 2021; pp. 159–167. [Google Scholar]

- Ongpeng, J.M.C.; Inciong, E.; Sendo, V.; Soliman, C.; Siggaoat, A. Using Waste in Producing Bio-Composite Mycelium Bricks. Appl. Sci. 2020, 10, 5303. [Google Scholar] [CrossRef]

- Gou, L.; Li, S.; Yin, J.; Li, T.; Liu, X. Morphological and physico-mechanical properties of mycelium biocomposites with natural reinforcement particles. Constr. Build. Mater. 2021, 304, 124656. [Google Scholar] [CrossRef]

- Ghazvinian, A.; Gursoy, B. Basics of Building with Mycelium-Based Bio-Composites: A Review of Built Projects and Related Material Research. J. Green Build. 2022, 17, 37–69. [Google Scholar] [CrossRef]

- Jones, M.; Huynh, T.; Dekiwadia, C.; Daver, F.; John, S. Mycelium Composites: A Review of Engineering Characteristics and Growth Kinetics. J. Bionanosci. 2017, 11, 241–257. [Google Scholar] [CrossRef]

- Nashiruddin, N.I.; Chua, K.S.; Mansor, A.F.; Rahman, R.A.; Lai, J.C.; Azelee, N.I.W.; El Enshasy, H. Effect of growth factors on the production of mycelium-based biofoam. Clean Technol. Environ. Policy 2021, 24, 351–361. [Google Scholar] [CrossRef]

- Heisel, F.; Lee, J.; Schlesier, K.; Rippmann, M.; Saeidi, N.; Javadian, A.; Nugroho, A.R.; Van Mele, T.; Block, P.; Hebel, D.E. Design, Cultivation and Application of Load-Bearing Mycelium Components: The MycoTree at the 2017 Seoul Biennale of Architecture and Urbanism. Int. J. Sustain. Energy Dev. 2017, 6, 296–303. [Google Scholar] [CrossRef]

- Dessi-Olive, J. Monolithic Mycelium: Growing Vault Structures. In Proceedings of the 18th International Conference on Non-Conventional Materials and Technologies (NOCMAT), Nairobi, Kenya, 24–26 July 2019; Available online: https://www.academia.edu/39909593/Monolithic_Mycelium_Growing_Vault_Structures?auto=download&campaign=weekly_digest (accessed on 15 January 2022).

- Bhardwaj, A.; Rahman, A.M.; Wei, X.; Pei, Z.; Truong, D.; Lucht, M.; Zou, N. 3D Printing of Biomass–Fungi Composite Material: Effects of Mixture Composition on Print Quality. J. Manuf. Mater. Process. 2021, 5, 112. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Vasselli, J.; Lucht, M.; Pei, Z.; Shaw, B.; Grasley, Z.; Wei, X.; Zou, N. 3D Printing of Biomass-Fungi Composite Material: A Preliminary Study. Manuf. Lett. 2020, 24, 96–99. [Google Scholar] [CrossRef]

- Modanloo, B.; Ghazvinian, A.; Matini, M.; Andaroodi, E. Tilted Arch; Implementation of Additive Manufacturing and Bio-Welding of Mycelium-Based Composites. Biomimetics 2021, 6, 68. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Abdullayev, A.; Bekheet, M.F.; Schmidt, B.; Regler, I.; Pohl, C.; Vakifahmetoglu, C.; Czasny, M.; Kamm, P.H.; Meyer, V.; et al. Extrusion-based additive manufacturing of fungal-based composite materials using the tinder fungus Fomes fomentarius. Fungal Biol. Biotechnol. 2021, 8, 21. [Google Scholar] [CrossRef]

- Soh, E.; Chew, Z.Y.; Saeidi, N.; Javadian, A.; Hebel, D.; Le Ferrand, H. Development of an extrudable paste to build mycelium-bound composites. Mater. Des. 2020, 195, 109058. [Google Scholar] [CrossRef]

- Goidea, A.; Floudas, D.; Andréen, D. Pulp Faction: 3d printed material assemblies through microbial biotransformation. Fabricate 2020, 2020, 42–49. [Google Scholar]

- Alima, N.; Snooks, R.; McCormack, J. Bio Scaffolds: The orchestration of biological growth through robotic intervention. Int. J. Intell. Robot. Appl. 2022, 1–8. [Google Scholar] [CrossRef]

- Cheng, A.; Lim, S.; Thomsen, M.R. Multi-Material Fabrication for Biodegradable Structures—Enabling the printing of porous mycelium composite structures. In Proceedings of the 39th eCAADe Conference, Novi Sad, Serbia, 8–10 September 2021; pp. 85–94. [Google Scholar]

- Goidea, A.; Floudas, D.; Andréen, D. Transcalar Design: An Approach to Biodesign in the Built Environment. Infrastructures 2022, 7, 50. [Google Scholar] [CrossRef]

- Appels, F.V.W.; Dijksterhuis, J.; Lukasiewicz, C.E.; Jansen, K.; Wösten, H.A.B.; Krijgsheld, P. Hydrophobin gene deletion and environmental growth conditions impact mechanical properties of mycelium by affecting the density of the material. Sci. Rep. 2018, 8, 4703. [Google Scholar] [CrossRef]

- Appels, F.V.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.; Dijksterhuis, J.; Krijgsheld, P.; Wösten, H.A. Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites. Mater. Des. 2018, 161, 64–71. [Google Scholar] [CrossRef]

- Liu, R.; Long, L.; Sheng, Y.; Xu, J.; Qiu, H.; Li, X.; Wang, Y.; Wu, H. Preparation of a kind of novel sustainable mycelium/cotton stalk composites and effects of pressing temperature on the properties. Ind. Crop. Prod. 2019, 141, 111732. [Google Scholar] [CrossRef]

- Islam, M.R.; Tudryn, G.; Bucinell, R.; Schadler, L.; Picu, R.C. Mechanical behavior of mycelium-based particulate composites. J. Mater. Sci. 2018, 53, 16371–16382. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; De Laet, L. Mechanical, physical and chemical characterisation of mycelium-based composites with different types of lignocellulosic substrates. PLoS ONE 2019, 14, e0213954. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Attias, N.; Danai, O.; Tarazi, E.; Pereman, I.; Grobman, Y.J. Implementing bio-design tools to develop mycelium-based products. Des. J. 2019, 22, 1647–1657. [Google Scholar] [CrossRef] [Green Version]

- Bruscato, C.; Malvessi, E.; Brandalise, R.N.; Camassola, M. High performance of macrofungi in the production of mycelium-based biofoams using sawdust—Sustainable technology for waste reduction. J. Clean. Prod. 2019, 234, 225–232. [Google Scholar] [CrossRef]

- Stelzer, L.; Hoberg, F.; Bach, V.; Schmidt, B.; Pfeiffer, S.; Meyer, V.; Finkbeiner, M. Life Cycle Assessment of Fungal-Based Composite Bricks. Sustainability 2021, 13, 11573. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Damsin, B.; Van Wylick, A.; Peeters, E.; De Laet, L. Mechanical characteristics of bacterial cellulose-reinforced mycelium composite materials. Fungal Biol. Biotechnol. 2021, 8, 18. [Google Scholar] [CrossRef] [PubMed]

| Mixture | Sawdust Ratio | Straw Ratio | Water Content | Wheat Flour Content | Fungal sp. Content |

|---|---|---|---|---|---|

| A | 1 | 0 | 65–70% | 7% DW | 7% DW |

| B | 1 | 7 | 65–70% | 7% DW | 7% DW |

| C | 1 | 3 | 65–70% | 7% DW | 7% DW |

| D | 1 | 2 | 65–70% | 7% DW | 7% DW |

| E | 1 | 1 | 65–70% | 7% DW | 7% DW |

| Treatments | ||||||||

|---|---|---|---|---|---|---|---|---|

| Substrate Mixtures | X23 | X24 | X32 | X33 | X34 | X42 | X43 | |

| A | 498 | 416 | 330 | 360 | 303 | 325 | 288 | |

| B | 187 | 168 | 107 | 143 | 97 | 69 | 71 | |

| C | 177 | 159 | 118 | 103 | 82 | 65 | 62 | |

| D | 192 | 142 | 62 | 95 | 74 | 58 | 73 | |

| E | 116 | 135 | 34 | 68 | 75 | 39 | 58 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghazvinian, A.; Gürsoy, B. Mycelium-Based Composite Graded Materials: Assessing the Effects of Time and Substrate Mixture on Mechanical Properties. Biomimetics 2022, 7, 48. https://doi.org/10.3390/biomimetics7020048

Ghazvinian A, Gürsoy B. Mycelium-Based Composite Graded Materials: Assessing the Effects of Time and Substrate Mixture on Mechanical Properties. Biomimetics. 2022; 7(2):48. https://doi.org/10.3390/biomimetics7020048

Chicago/Turabian StyleGhazvinian, Ali, and Benay Gürsoy. 2022. "Mycelium-Based Composite Graded Materials: Assessing the Effects of Time and Substrate Mixture on Mechanical Properties" Biomimetics 7, no. 2: 48. https://doi.org/10.3390/biomimetics7020048

APA StyleGhazvinian, A., & Gürsoy, B. (2022). Mycelium-Based Composite Graded Materials: Assessing the Effects of Time and Substrate Mixture on Mechanical Properties. Biomimetics, 7(2), 48. https://doi.org/10.3390/biomimetics7020048