Recent Advances in Biomimetic Porous Materials for Real-World Applications

Abstract

1. Introduction

- i.

- Providing the first unified framework comparing five key fabrication techniques (biological templating, microbial templating, biomimetic mineralization, 3D printing, self-assembly) through the lens of pore engineering fundamentals and industrial scalability.

- ii.

- Establishing quantitative structure–function correlations using 100+ case studies to reveal how hierarchical porosity governs performance in target applications.

- iii.

- Delivering a translational roadmap from laboratory innovation to commercial deployment, with emphasis on overcoming barriers in mass production, stability, and cost-effectiveness.

2. Preparation Methods of Biomimetic Porous Materials

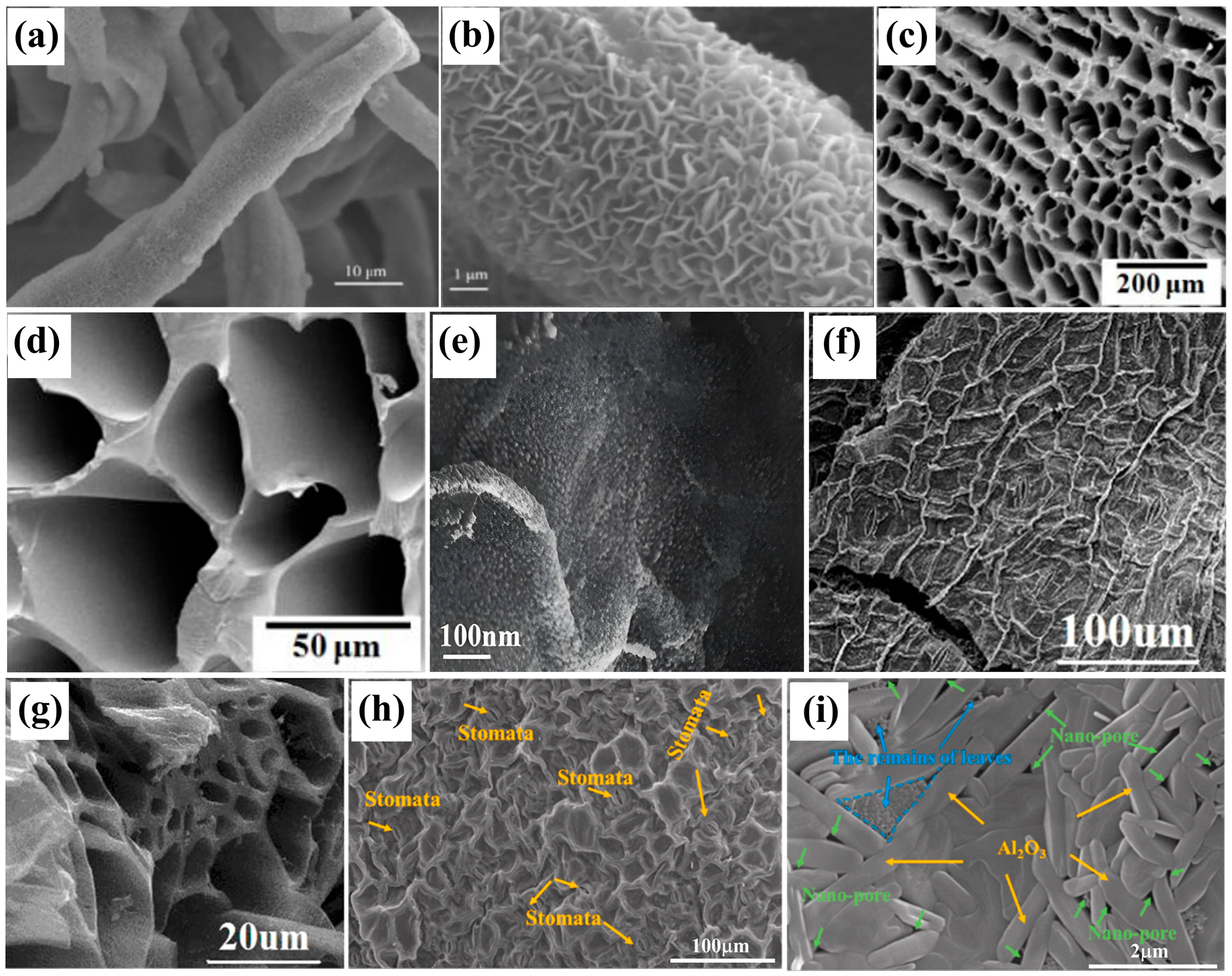

2.1. Biological Tissue Template Technique

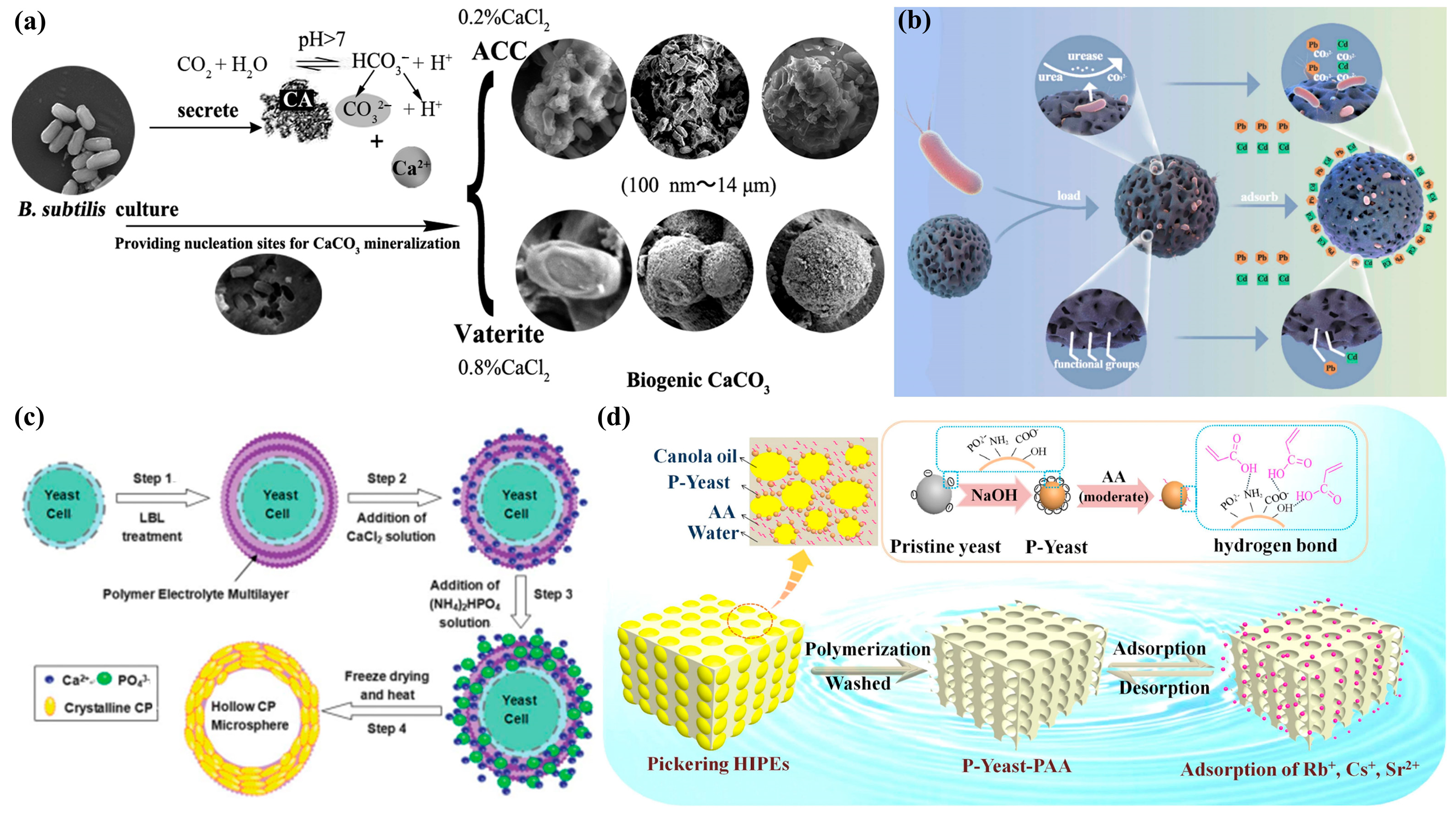

2.2. Microbial Template Technique

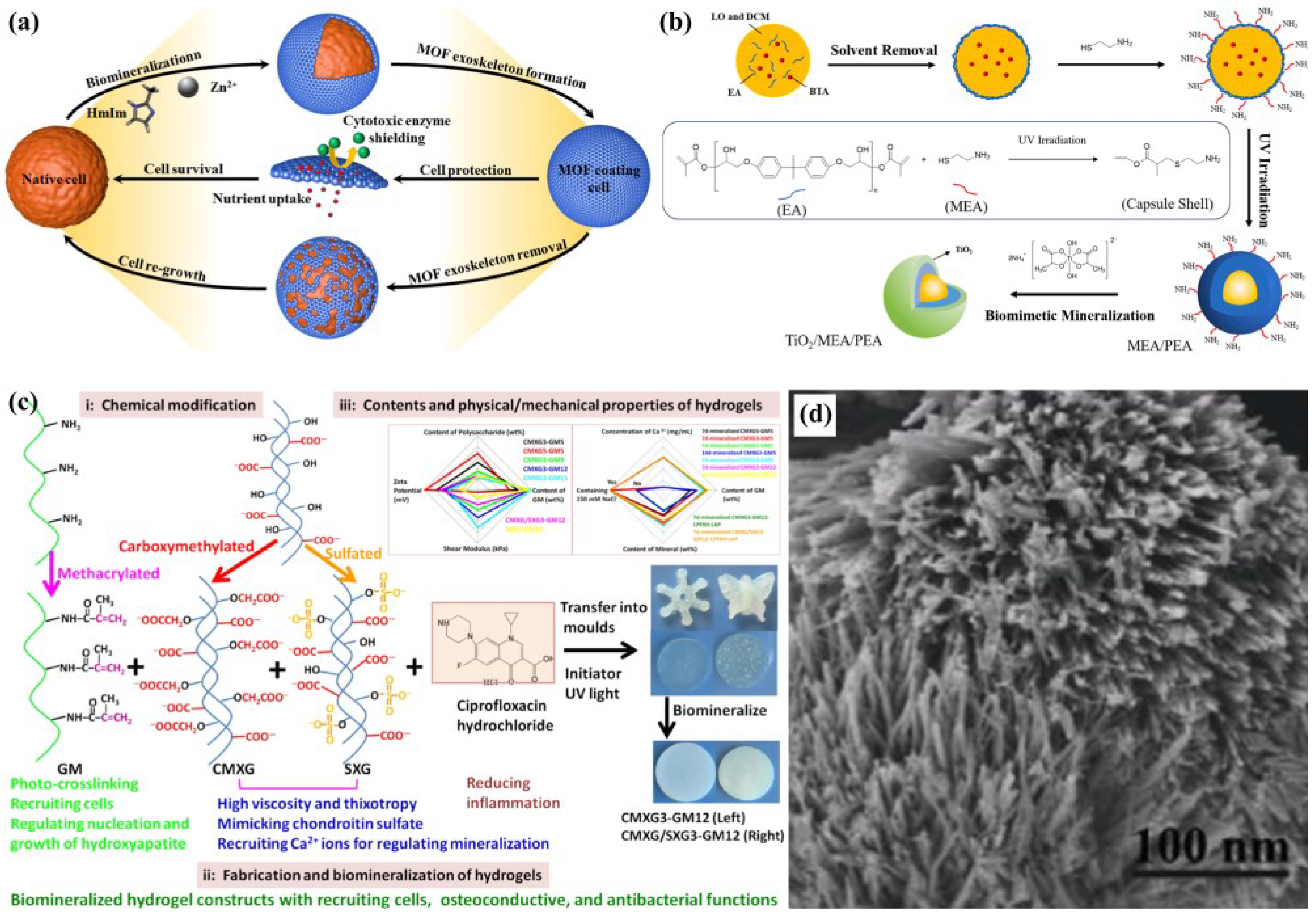

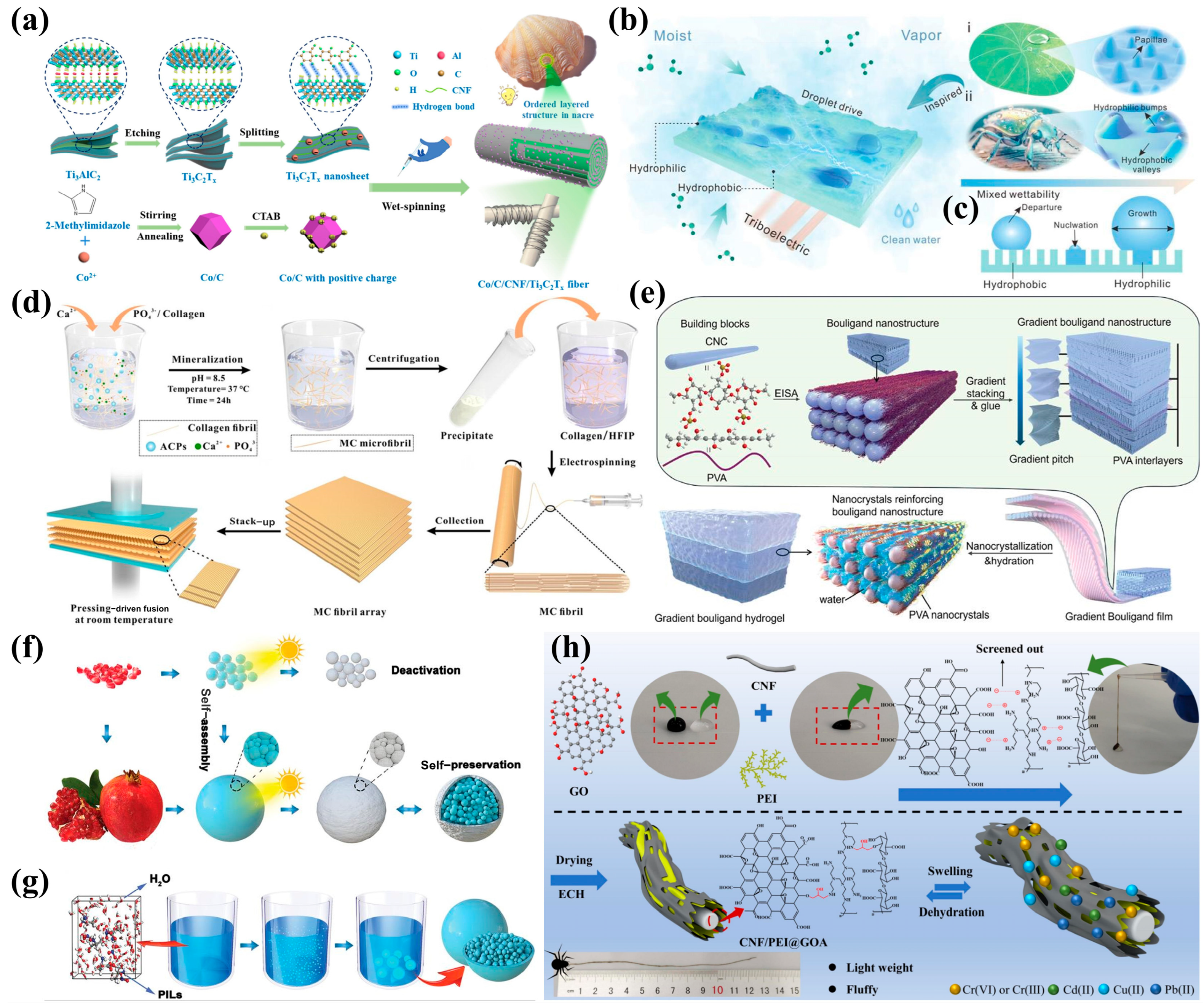

2.3. Biomimetic Mineralization Technique

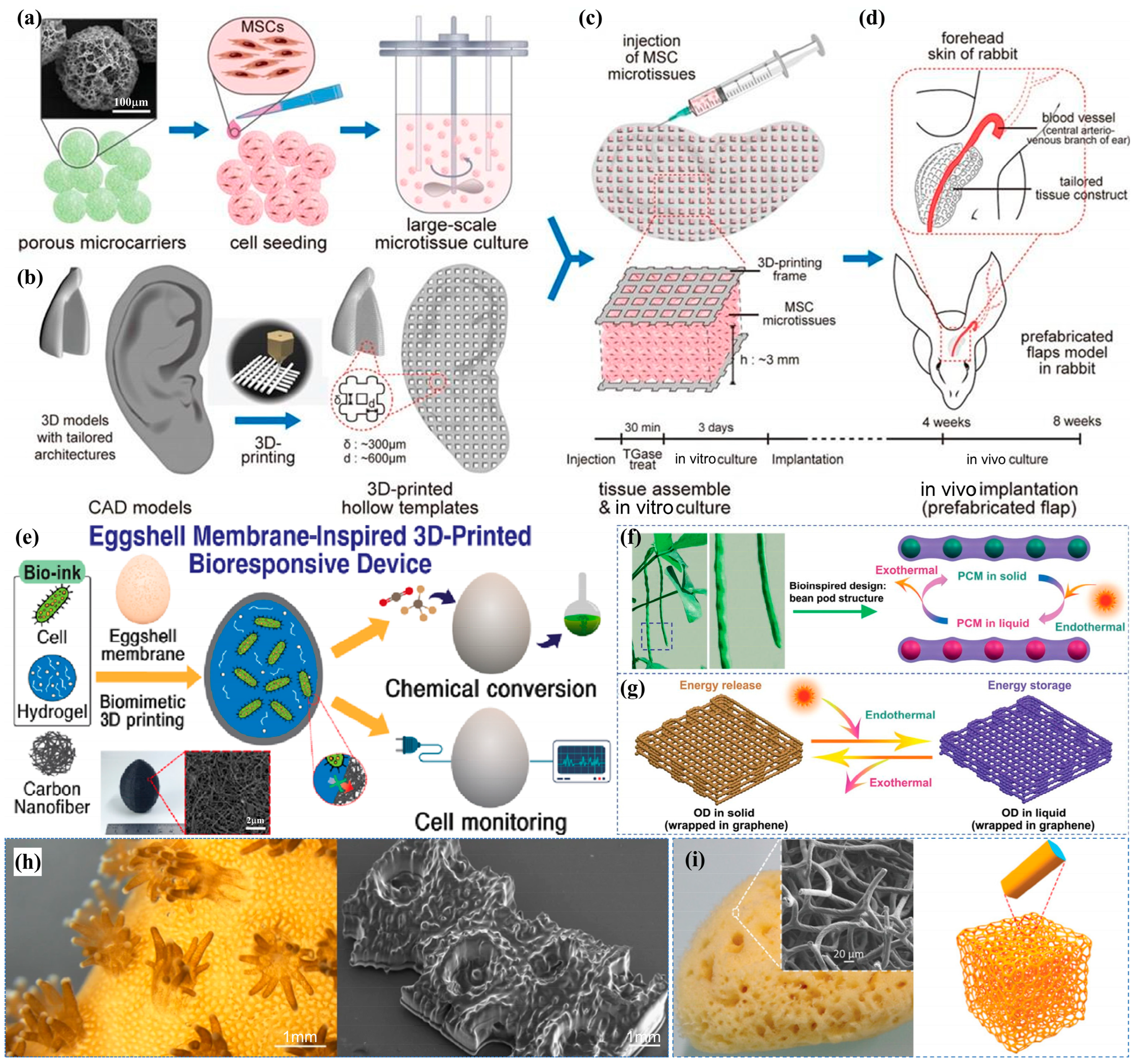

2.4. Three-Dimensional Printing Technique

2.5. Self-Assembly Technique

2.6. Other Techniques

3. Applications of Biomimetic Porous Materials

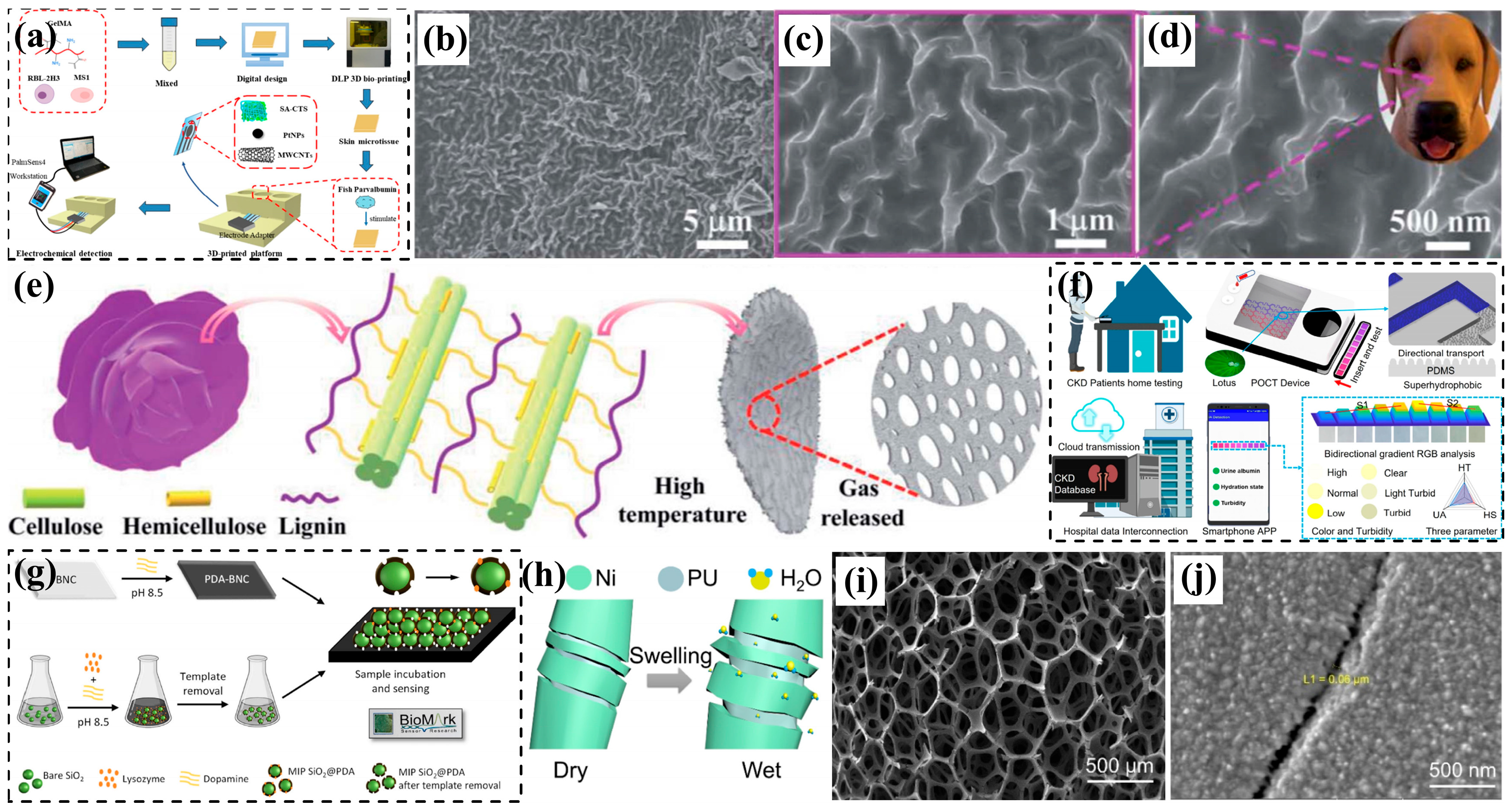

3.1. Biomedical Applications

3.1.1. Biomimetic Bone

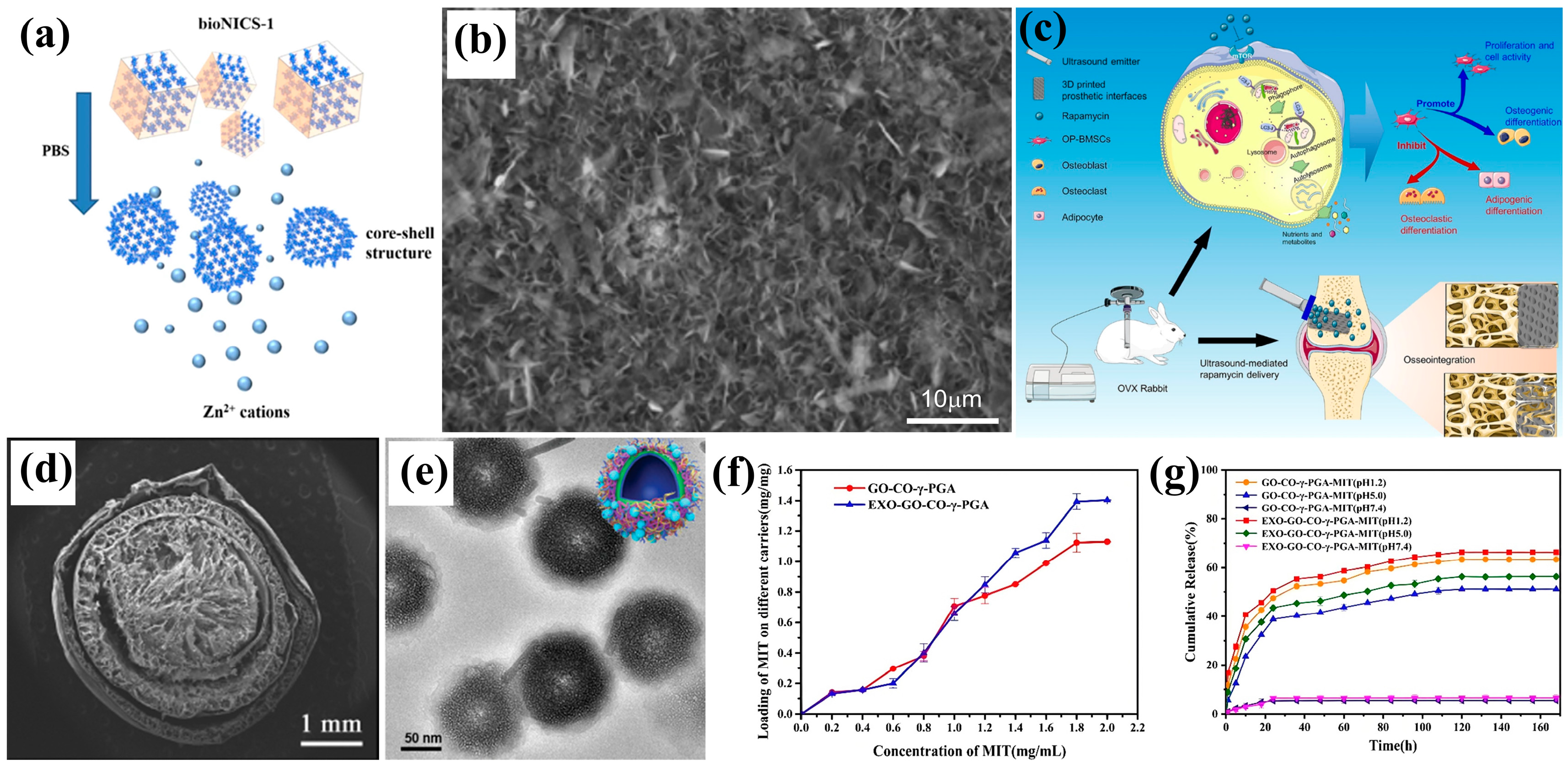

3.1.2. Drug Delivery and Release

3.1.3. Biosensors

3.1.4. Other Applications

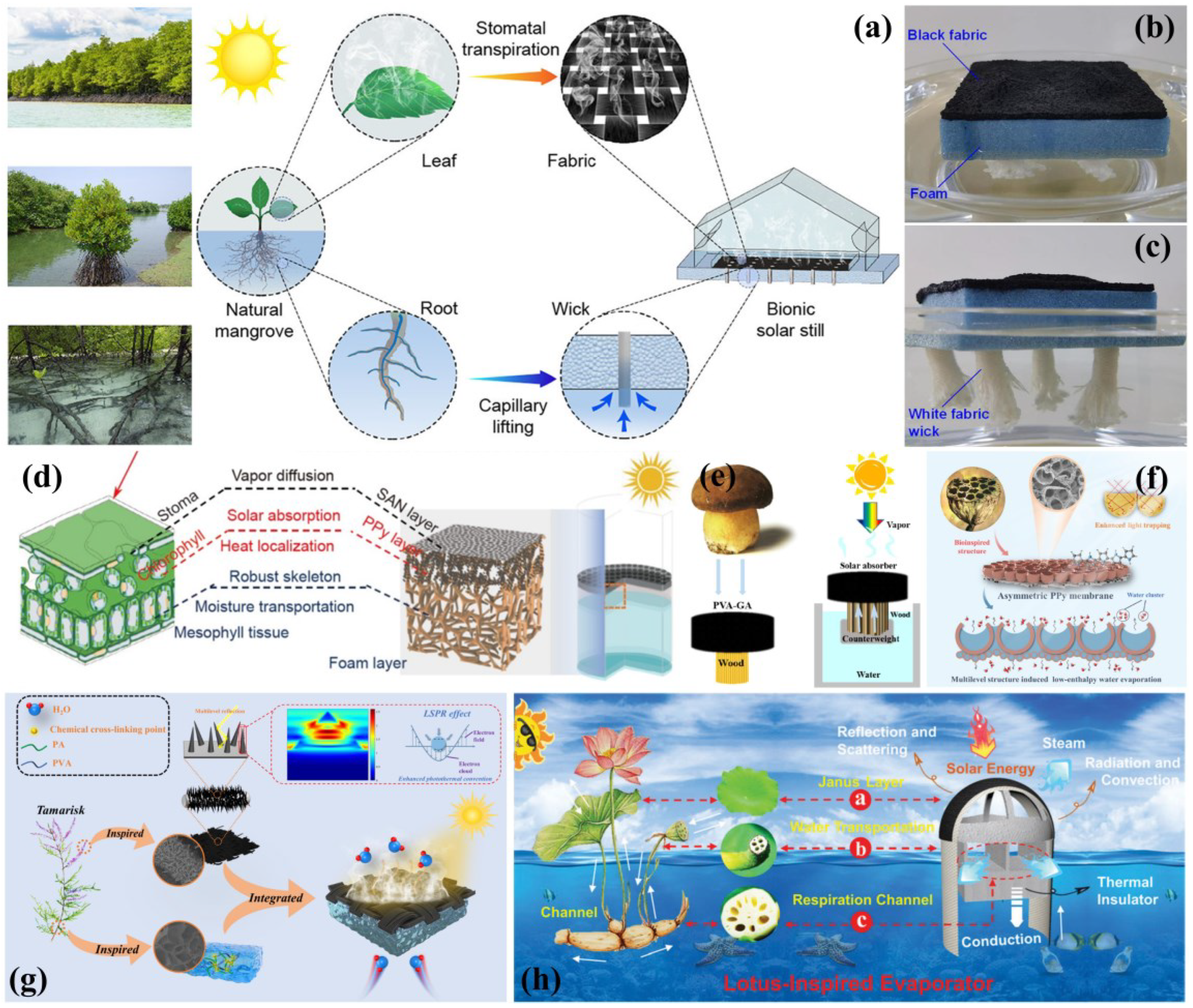

3.2. Environmental Applications

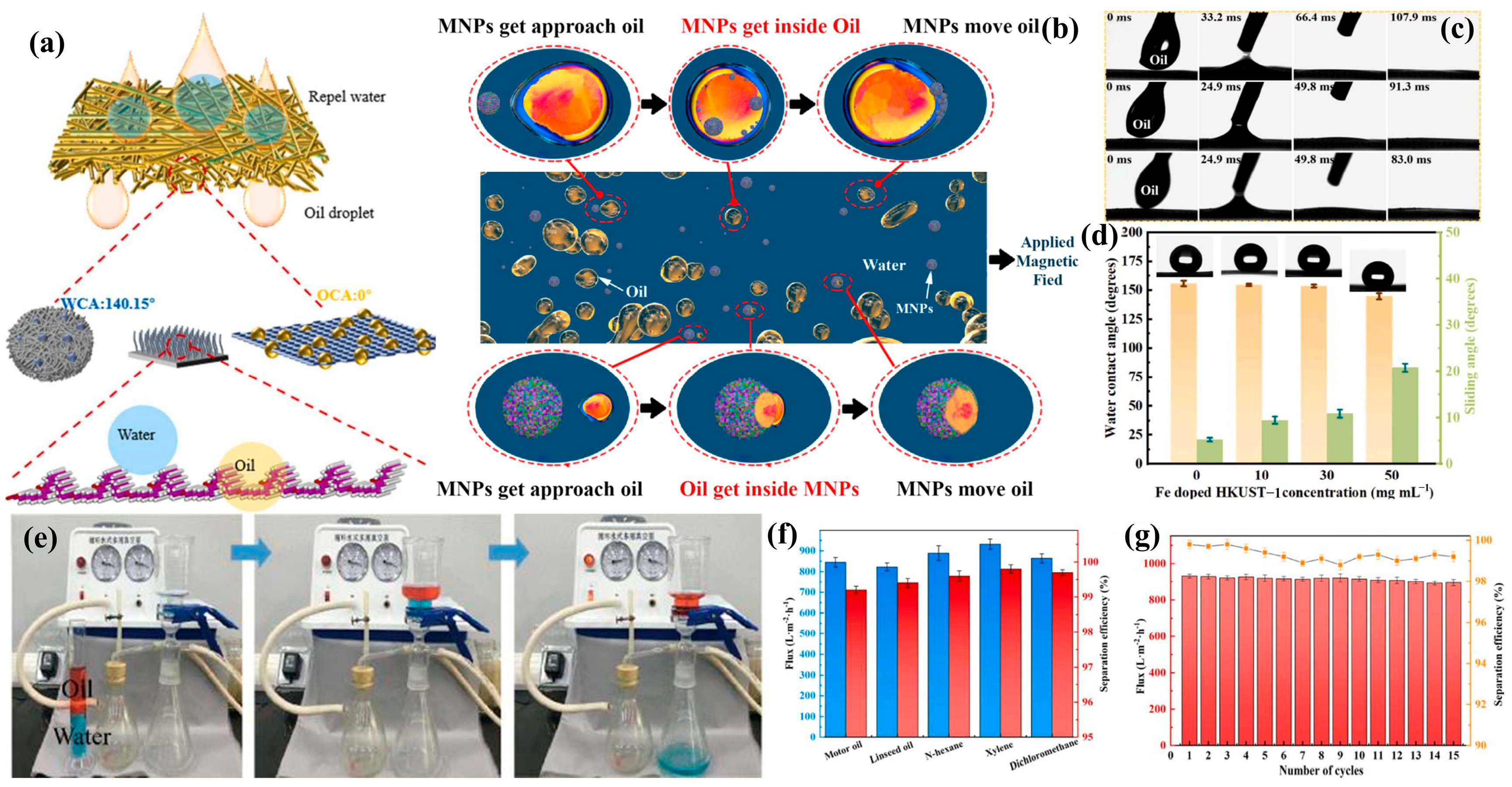

3.2.1. Oil–Water Separation

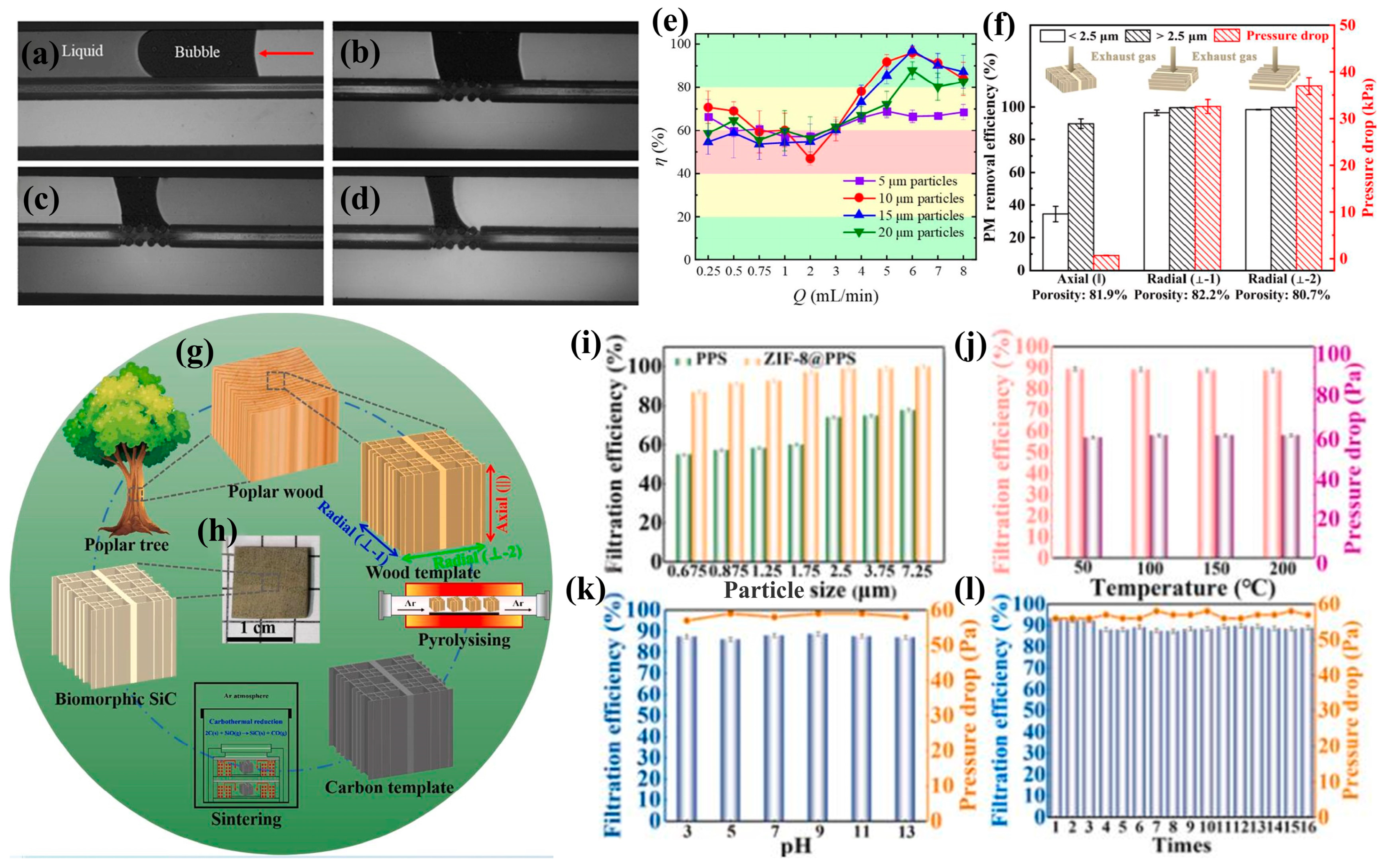

3.2.2. Filtration

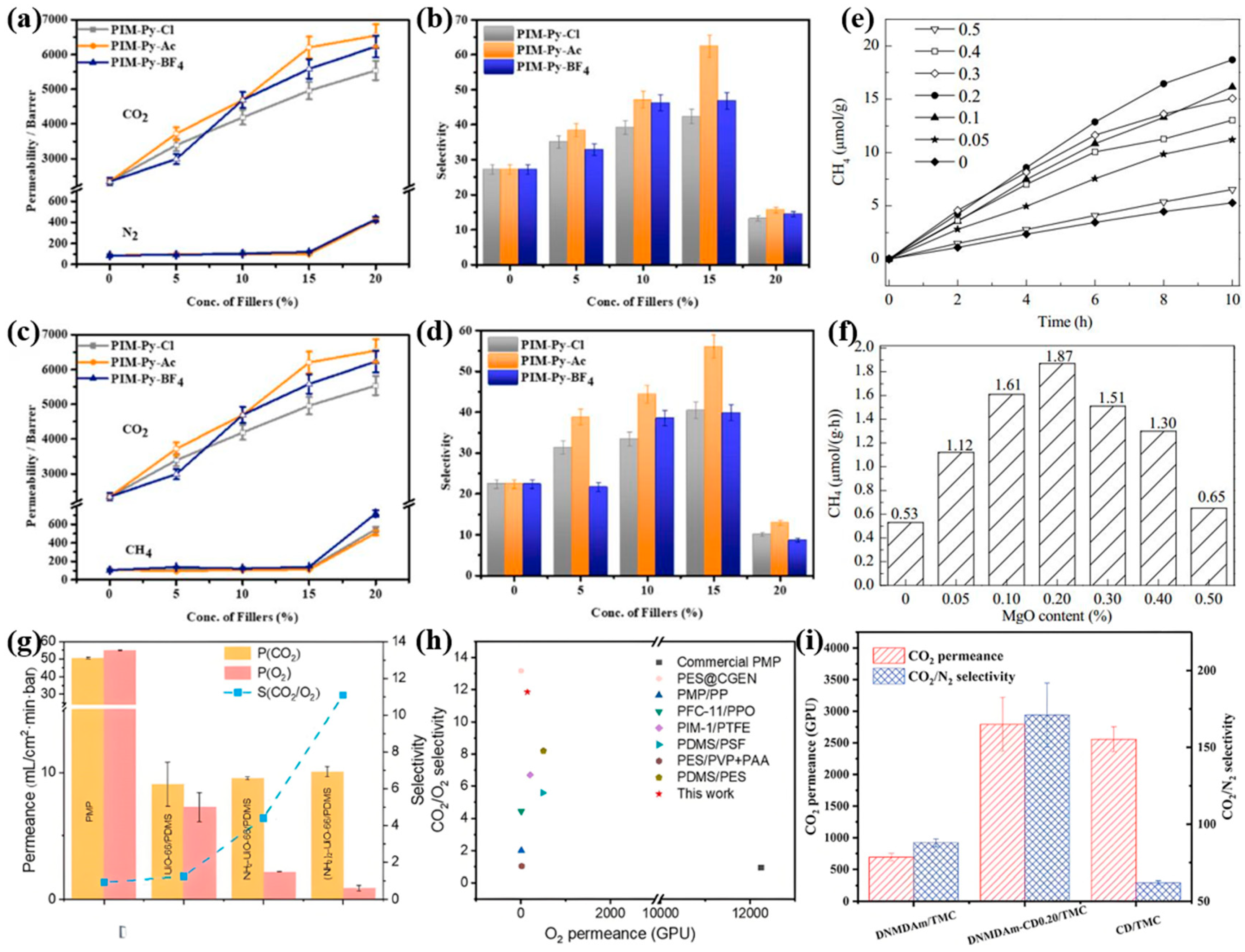

3.2.3. Gas Adsorption and Separation

3.2.4. Sound Absorption Materials

3.2.5. Other Applications

3.3. Energy Field

3.3.1. Energy Storage

3.3.2. Thermal Insulation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xie, Z.; Peng, Y.-P.; Yu, L.; Xing, C.; Qiu, M.; Hu, J.; Zhang, H. Solar-inspired water purification based on emerging 2D materials: Status and challenges. Solar RRL 2020, 4, 1900400. [Google Scholar] [CrossRef]

- Galeano-Caro, D.; Rios, A.A.; Chejne, F.; Moreno-Castilla, C.; Perez-Cadenas, A.; Carrasco-Marin, F.; Maya, J.C.; Gomez, C.A.; Franco, C.A.; Cortes, F.B. Freshwater production from air dehumidification using novel SiO2-based supported material and solar energy: Colombia case study. Energy Rep. 2022, 8, 3115–3126. [Google Scholar] [CrossRef]

- Charitar, D.; Madhlopa, A. Integration of waste heat in thermal desalination technologies: A review. J. Energy S. Afr. 2022, 33, 68–84. [Google Scholar] [CrossRef]

- Cortez, F.; Monicelli, F.; Cavalcante, H.; Becker, V. Effects of prolonged drought on water quality after drying of a semiarid tropical reservoir, Brazil. Limnologica 2022, 93, 125959. [Google Scholar] [CrossRef]

- Podgorski, J.; Berg, M. Global threat of arsenic in groundwater. Science 2020, 368, 845–850. [Google Scholar] [CrossRef]

- Zamora-Ledezma, C.; Negrete-Bolagay, D.; Figueroa, F.; Zamora-Ledezma, E.; Ni, M.; Alexis, F.; Guerrero, V.H. Heavy metal water pollution: A fresh look about hazards, novel and conventional remediation methods. Environ. Technol. Innov. 2021, 22, 101504. [Google Scholar] [CrossRef]

- Sullivan, T.; O’Callaghan, I. Recent developments in biomimetic antifouling materials: A review. Biomimetics 2020, 5, 58. [Google Scholar] [CrossRef]

- Wan, K.; Gou, X.; Guo, Z. Bio-inspired Fog Harvesting Materials: Basic Research and Bionic Potential Applications. J. Bionic Eng. 2021, 18, 501–533. [Google Scholar] [CrossRef]

- Ge, M.; Cao, C.; Liang, F.; Liu, R.; Zhang, Y.; Zhang, W.; Zhu, T.; Yi, B.; Tang, Y.; Lai, Y. A “PDMS-in-water” emulsion enables mechanochemically robust superhydrophobic surfaces with self-healing nature. Nanoscale Horiz. 2020, 5, 65–73. [Google Scholar] [CrossRef]

- Chen, Z.G.; Liu, C.B.; Qian, J.C.; Chen, F.; Gu, C.; Ma, J.N.; Li, P. Preparation of bionic TiO2 structure using aquatic plants as template. Mater. Sci. Forum 2013, 743–744, 660–664. [Google Scholar]

- Pouget, E.; Dujardin, E.; Cavalier, A.; Moreac, A.; Valery, C.; Marchi-Artzner, V.; Weiss, T.; Renault, A.; Paternostre, M.; Artzner, F. Hierarchical architectures by synergy between dynamical template self-assembly and biomineralization. Nat. Mater. 2007, 6, 434–439. [Google Scholar] [CrossRef]

- Liang, F.; Dong, H.; Dai, J.; He, H.; Zhang, W.; Chen, S.; Lv, D.; Liu, H.; Kim, I.S.; Lai, Y.; et al. Fast energy storage of SnS2 anode nanoconfined in hollow porous carbon nanofibers for lithium-ion batteries. Adv. Sci. 2023, 11, 2306711. [Google Scholar] [CrossRef]

- Green, D.W.; Goto, T.K.; Kim, K.S.; Jung, H.S. Calcifying tissue regeneration via biomimetic materials chemistry. J. R. Soc. Interface 2014, 11, 20140537. [Google Scholar] [CrossRef]

- Huang, Z.; Qi, Y.; Zhang, K.; Gu, L.; Guo, J.; Wang, R.; Mai, S. Use of experimental-resin-based materials doped with carboxymethyl chitosan and calcium phosphate microfillers to induce biomimetic remineralization of caries-affected dentin. J. Mech. Behav. Biomed. 2019, 89, 81–88. [Google Scholar] [CrossRef]

- Yang, G.; Liu, Y.; Jin, S.; Zhao, C.X. Development of core-shell nanoparticle drug delivery systems based on biomimetic mineralization. Chembiochem 2020, 21, 2871–2879. [Google Scholar] [CrossRef]

- Xie, F.; Long, J.; Yang, J.; Qin, H.; Lin, X.; Chen, W. Effect of a new modified polyamidoamine dendrimer biomimetic system on the mineralization of type I collagen fibrils: An in vitro study. J. Biomater. Sci. Polym. Ed. 2022, 33, 212–228. [Google Scholar] [CrossRef]

- Gao, P.; Wu, M.; Li, B.; Liu, Y. Structure characterization and oxidation mechanism study of porous biomorphic carbon template derived from basswood. Mater. Res. Bull. 2009, 44, 644–648. [Google Scholar] [CrossRef]

- Huang, R.; Yan, Q.; Xia, X.; Yang, H.; Qian, J.; Chen, Z.; Chen, F. Synthesis of environmentally friendly carbon/iron oxide with leaf and stem morphology and enhanced photocatalytic performance for hydrogen production from water. Fresen Environ. Bull. 2020, 29, 6922–6928. [Google Scholar]

- Thomas, A. Much ado about nothing—A decade of porous materials research. Nat. Commun. 2020, 11, 4985. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Liu, G. Porous organic materials offer vast future opportunities. Nat. Commun. 2020, 11, 4984. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Ge, X.; Tang, H.; Yang, X. Research advancement of porous fiber metals. Adv. Eng. Mater. 2013, 750–752, 569–573. [Google Scholar]

- Gao, X.; Yang, Y.; Gou, Y.; Lu, N.; Yan, P.; Liu, H.; Yi, M.; Cai, W.; Huang, J.; Lai, Y. Ultrafine nanofiber-based membrane with rational hierarchical networks for efficient and high-flux air and water purification. Adv. Fiber Mater. 2025, 7, 1220–1231. [Google Scholar] [CrossRef]

- Novak, M.T.; Bryers, J.D.; Reichert, W.M. Biomimetic strategies based on viruses and bacteria for the development of immune evasive biomaterials. Biomaterials 2009, 30, 1989–2005. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, Y.; Bu, X.; Xue, J.; Hu, J.; Wang, Y.; Zhang, M. Bio-inspired fabrication of hierarchically porous Mg–Al composites for enhanced BSA adsorption properties. Microporous Mesoporous Mater. 2014, 188, 37–45. [Google Scholar] [CrossRef]

- Guo, F.; Wang, Y.; Chen, M.; Wang, C.; Kuang, S.; Pan, Q.; Ren, D.; Chen, Z. Lotus-root-like supermacroporous cryogels with superphilicity for rapid separation of oil-in-water emulsions. ACS Appl. Polym. Mater. 2019, 1, 2273–2281. [Google Scholar] [CrossRef]

- Wu, R.; Zhang, H.; Liu, W.; Bai, R.; Zheng, D.; Tian, X.; Lin, W.; Li, L.; Ke, Q. In-situ biomimetic synthesis of Ru-TiO2/PC composite for photocatalytic dye degradation of wastewater under simulated sunlight. J. Alloys Compd. 2025, 1011, 178418. [Google Scholar] [CrossRef]

- Gu, X.; Wu, L.; Li, Z.; Chen, F.; Chen, Z.; Qian, J.; Zhou, X. Bionic titania coating carbon multi-layer material derived from natural leaf and its superior photocatalytic performance. Prog. Nat. Sci. Mater. 2017, 27, 561–565. [Google Scholar] [CrossRef]

- Sun, M.; He, X.; Wang, B.; Liang, J.; Yi, H.; Zhang, T. Preparation of bionic porous Al2O3 from green leaf of epipremnum aureum as a biotemplate. Ceram. Int. 2022, 48, 7309–7315. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Z.; Li, C.; Liu, L.; Xiao, Y.; Wang, Z.; Li, S.; Soo, S. Steering the adsorption modes and oxidation state of Co oxyhydroxide active sites to unlock selective glucose oxidation to formate for efficient solar reforming of biomass to green hydrogen. eScience 2025, 5, 100431. [Google Scholar] [CrossRef]

- Zou, Y.; Fu, J.; Chen, Z.; Ren, L. The effect of microstructure on mechanical properties of corn cob. Micron 2021, 146, 103070. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Yang, R.; Zhu, R. Leaf-inspired structural design of artificial leaf BiVO4/InVO4 heterojunction with enhanced photocatalytic activity for pollutant degradation. Colloids Surfaces A 2020, 589, 124448. [Google Scholar] [CrossRef]

- Majumdar, A.; Kar, R.K. Chloroplast avoidance movement: A novel paradigm of ROS signalling. Photosynth. Res. 2020, 144, 109–121. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Yadav, A.N.; Mondal, R.; Kour, D.; Subrahmanyam, G.; Shabnam, A.A.; Khan, S.A.; Yadav, K.K.; Sharma, G.K.; Cabral-Pinto, M.; et al. Myco-remediation: A mechanistic understanding of contaminants alleviation from natural environment and future prospect. Chemosphere 2021, 284, 131325. [Google Scholar] [CrossRef]

- Cao, C.; Su, H.; Ai, L.; Lv, D.; Gu, J.; Li, R.; Li, D.; Zhang, W.; Ge, M.; Yao, X. Highly stable liquid metal-based electronic textiles by adaptive interfacial interactions. Adv. Funct. Mater. 2024, 34, 2409586. [Google Scholar] [CrossRef]

- Harish, R.; Samuel, J.; Mishra, R.; Chandrasekaran, N.; Mukherjee, A. Bio-reduction of Cr(VI) by exopolysaccharides (EPS) from indigenous bacterial species of Sukinda chromite mine, India. Biodegradation 2012, 23, 487–496. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; Shi, X.; Ullah, M.W.; Li, S.; Revin, V.V.; Yang, G. Fabrication of nanocomposites and hybrid materials using microbial biotemplates. Adv. Compos. Hybrid Mater. 2018, 1, 79–93. [Google Scholar] [CrossRef]

- Blaker, J.J.; Lee, K.Y.; Mantalaris, A.; Bismarck, A. Ice-microsphere templating to produce highly porous nanocomposite PLA matrix scaffolds with pores selectively lined by bacterial cellulose nano-whiskers. Compos. Sci. Technol. 2010, 70, 1879–1888. [Google Scholar] [CrossRef]

- Liu, R.; Huang, S.; Zhang, X.; Song, Y.; He, G.; Wang, Z.; Lian, B. Bio-mineralisation, characterization, and stability of calcium carbonate containing organic matter. RSC Adv. 2021, 11, 14415–14425. [Google Scholar] [CrossRef]

- Song, H.; Wang, C.; Kumar, A.; Ding, Y.; Li, S.; Bai, X.; Liu, T.; Wang, J.; Zhang, Y. Removal of Pb2+ and Cd2+ from contaminated water using novel microbial material (Scoria@UF1). J. Environ. Chem. Eng. 2021, 9, 106495. [Google Scholar] [CrossRef]

- Huang, M.; Wang, Y. Synthesis of calcium phosphate microcapsules using yeast-based biotemplate. J. Mater. Chem. 2012, 22, 626–630. [Google Scholar] [CrossRef]

- Lu, T.; Zhu, Y.; Wang, W.; Qi, Y.; Wang, A. Interconnected superporous adsorbent prepared via yeast-based Pickering HIPEs for high-efficiency adsorption of Rb+ Cs+ and Sr2+. Chem. Eng. J. 2019, 361, 1411–1422. [Google Scholar] [CrossRef]

- He, W.; Li, Z.; Wang, Y.; Chen, X.; Zhang, X.; Zhao, H.; Yan, S.; Zhou, W. Synthesis of mesoporous structured hydroxyapatite particles using yeast cells as the template. J. Mater. Sci. Mater. Med. 2010, 21, 155–159. [Google Scholar] [CrossRef] [PubMed]

- Kitamoto, D.; Isoda, H.; Nakahara, T. Functions and potential applications of glycolipid biosurfactants--from energy-saving materials to gene delivery carriers. J. Biosci. Bioeng. 2002, 94, 187–201. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Zhao, L.; Ala, M.; Zhao, K.; Liu, H.; Zhang, W.; Dai, J.; Ge, J.; Yan, T.; Cheng, Y.; et al. Dynamic covalent bonds enabled robust and self-healing superhydrophobic coatings with multifunctions. Sep. Purif. Technol. 2025, 359, 130824. [Google Scholar] [CrossRef]

- Long, G.Y.; Zhu, P.T.; Shen, Y.; Tong, M.P. Influence of extracellular polymeric substances (EPS) on deposition kinetics of bacteria. Environ. Sci. Technol. 2009, 43, 2308–2314. [Google Scholar] [CrossRef]

- Shi, F.; Yu, T.; Hu, S.C.; Liu, J.X.; Yu, L.; Liu, S.H. Synthesis of highly porous SiO2-(WO3)x·TiO2 composite aerogels using bacterial cellulose as template with solvothermal assisted crystallization. Chem. Eng. J. 2016, 292, 105–112. [Google Scholar] [CrossRef]

- Al-dujaili, M.A.A.; Saud, A.N.; Aswad, M.A. Synthesis of meso-macro alumina using yeast cells as a bio-template and optimization using a genetic algorithm. Int. J. Appl. Ceram. Technol. 2020, 17, 392–402. [Google Scholar] [CrossRef]

- Xu, G.; Li, J.; Cui, H.; He, Q.; Zhang, Z.; Zhan, X. Biotemplated fabrication of porous alumina ceramics with controllable pore size using bioactive yeast as pore-forming agent. Ceram. Int. 2015, 41, 7042–7047. [Google Scholar] [CrossRef]

- Xu, G.; Ma, Y.; Cui, H.; Ruan, G.; Zhang, Z.; Zhao, H. Preparation of porous mullite-corundum ceramics with controlled pore size using bioactive yeast as pore-forming agent. Mater. Lett. 2014, 116, 349–352. [Google Scholar] [CrossRef]

- Wang, S.; Cai, Q.; Du, M.; Cao, M.; Xu, H. Biomimetic Mineralization of Silica. Prog. Chem. 2015, 27, 229–241. [Google Scholar]

- He, H.; Wang, L.; Al-Abbasi, M.; Cao, C.; Li, H.; Xu, Z.; Chen, S.; Zhang, W.; Li, R.; Lai, Y.; et al. Interface engineering on constructing physical and chemical stable solid-state electrolyte towards practical lithium batteries. Energy Environ. Mater. 2024, 7, e12699. [Google Scholar] [CrossRef]

- Salado, M. Advanced and sustainable functional materials for potassium-ion batteries. Energy Mater. 2023, 3, 300037. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Q.; Guo, Z.; Pan, H.; Liu, Z.; Tang, R. Progress on biomimetic mineralization and materials for hard tissue regeneration. ACS Biomater. Sci. Eng. 2021, 9, 1757–1773. [Google Scholar] [CrossRef]

- Jin, Y.L.; Pan, H.-H.; Tang, R.K. Biomimetic mineralization and hard tissue repair. Chin. J. Inorg. Chem. 2020, 36, 1049–1062. [Google Scholar]

- Wang, M.; Deng, H.; Jiang, T.; Wang, Y. Biomimetic remineralization of human dentine via a “bottom-up” approach inspired by nacre formation. Biomater. Adv. 2022, 135, 112670. [Google Scholar] [CrossRef]

- Liu, B.Y.; Li, X.; Wang, T.S.; Wang, T. Advances in researches on enamel biomimetic mineralization. Zhonghua Kou Qiang Yi Xue Za Zhi Chin. J. Stomatol. 2022, 57, 307–313. [Google Scholar]

- Chang, R.; Liu, Y.J.; Zhang, Y.L.; Zhang, S.Y.; Han, B.B.; Chen, F.; Chen, Y.X. P Phosphorylated and phosphonated low-complexity protein segments for biomimetic mineralization and repair of tooth enamel. Adv. Sci. 2022, 9, 2103829. [Google Scholar] [CrossRef] [PubMed]

- Xu, A.W.; Ma, Y.; Cölfen, H. Biomimetic mineralization. J. Mater. Chem. 2007, 17, 415–449. [Google Scholar] [CrossRef]

- Shao, H.; Cheng, J.; Kang, D.; Qin, S. Superhydrophilic membranes produced by biomimetic mineralization for water treatment. J. Mater. Sci. 2021, 56, 1347–1358. [Google Scholar] [CrossRef]

- Cromme, P.; Zollfrank, C.; Mueller, L.; Mueller, F.A.; Greil, P. Biomimetic mineralisation of apatites on Ca2+ activated cellulose templates. Mater. Sci. Eng. C Biomim. Supramol. Syst. 2007, 27, 1–7. [Google Scholar] [CrossRef]

- Petrauskaite, O.; Gomes, P.d.S.; Fernandes, M.H.; Juodzbalys, G.; Stumbras, A.; Maminskas, J.; Liesiene, J.; Cicciu, M. Biomimetic mineralization on a macroporous cellulose-based matrix for bone regeneration. Biomed. Res. Int. 2013, 2013, 452750. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Zheng, R.; He, H.; Du, H.; Lin, Y. Application of biomimetic mineralization: A prophylactic therapy for cracked teeth? Med. Hypotheses 2009, 73, 493–494. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Shu, J.; Huang, X.; Yue, X. The hollow porous octet phosphate superstructure regulated by polyallylammonium chloride and its adsorption characteristics for Pb(II). J. Environ. Sci. 2021, 41, 2147–2155. [Google Scholar]

- Li, M.; Li, L.; Wang, S.; Sun, Y.; Zhang, H.; Li, F. Development of MOF exoskeleton with robust cytoprotection on bacterial cells enables enhanced bioremediation of pesticide pollution in soil. Pestic. Biochem. Phys. 2025, 213, 106534. [Google Scholar] [CrossRef]

- Ji, J.; Chen, G.; Li, L. Preparation and performance research of biomimetic mineralized keratin porous materials. J. Biol. 2022, 39, 57. [Google Scholar]

- Zhu, Z.; Zhang, X.; Guo, K.; Wang, M.; Wang, X.; Zhu, G. Biomimetic mineralization in double-walled microcapsules making for self-healing anticorrosive coatings. Colloids Surfaces A 2025, 709, 136046. [Google Scholar] [CrossRef]

- Liu, S.; Han, F.; Chen, P.; Zhang, R.; Tao, Y. Injectable and drug-loaded gelatin methacrylate and carboxymethylated-sulfated xanthan gum hydrogels as biomimetic mineralization constructs. Carbohydr. Polym. 2025, 355, 123354. [Google Scholar] [CrossRef]

- Liu, P.; Fan, G.; Wang, J.; Zhou, G.; Cao, Y.; Han, X.; Xu, X. Biomimetic mineralization of montmorillonite-based nanomaterials for efficient capture of copper ions. Appl. Clay Sci. 2020, 195, 105720. [Google Scholar] [CrossRef]

- Kong, S. Research on modeling of extruded 3D printing materials and preparation of complex structures; Nanjing University: Nanjing, China, 2019. [Google Scholar]

- Wang, Z.; Yang, Y. Application of 3D Printing in Implantable Medical Devices. Biomed. Res. Int. 2021, 2021, 6653967. [Google Scholar] [CrossRef]

- Wilhite, R.; Woelfel, I. 3D Printing for veterinary anatomy: An overview. Anat. Histol. Embryol. 2019, 48, 609–620. [Google Scholar] [CrossRef]

- Yu, H.; You, Z.; Yan, X.; Liu, W.; Nan, Z.; Xing, D.; Huang, C.; Du, Y. TGase-enhanced microtissue assembly in 3D-printed-template-scaffold (3D-MAPS) for large tissue defect reparation. Adv. Healthc. Mater. 2020, 9, 2000531. [Google Scholar] [CrossRef]

- Huang, D.; Li, Z.; Li, G.; Zhou, F.; Wang, G.; Ren, X.; Su, J. Biomimetic structural design in 3D-printed scaffolds for bone tissue engineering. Mater. Today Bio 2025, 32, 101664. [Google Scholar] [CrossRef]

- Sun, L.; Hua, G.; Cheng, T.C.E.; Wang, Y. How to price 3D-printed products? Pricing strategy for 3D printing platforms. Int. J. Prod. Econ. 2020, 226, 107600. [Google Scholar] [CrossRef]

- Jeon, Y.; Jeon, M.S.; Shin, J.; Jin, S.; Yi, J.; Kang, S.; Kim, S.C.; Cho, B.K.; Lee, J.K.; Kim, D.R. 3D printed bioresponsive devices with selective permeability inspired by eggshell membrane for effective biochemical conversion. ACS Appl. Mater. Interfaces 2020, 12, 30112–30119. [Google Scholar] [CrossRef]

- Xie, M.; Duan, H.; Cheng, P.; Chen, Y.; Dong, Z.; Wang, Z. Underwater unidirectional cellular fluidics. ACS Appl. Mater. Interfaces 2022, 14, 9891–9898. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Jia, S.; Niu, Y.; Lv, X.; Fu, H.; Zhang, Y.; Liu, D.; Wang, B.; Li, Q. Bean-pod-inspired 3D-printed phase change microlattices for solar-thermal energy harvesting and storage. Small 2021, 17, 2101093. [Google Scholar] [CrossRef]

- Zhou, G.; Wang, K.P.; Liu, H.W.; Wang, L.; Xiao, X.F.; Dou, D.D.; Fan, Y.B. Three-dimensional polylactic acid@graphene oxide/chitosan sponge bionic filter: Highly efficient adsorption of crystal violet dye. Int. J. Biol. Macromol. 2018, 113, 792–803. [Google Scholar] [CrossRef] [PubMed]

- Wangpraseurt, D.; You, S.; Azam, F.; Jacucci, G.; Gaidarenko, O.; Hildebrand, M.; Kuhl, M.; Smith, A.G.; Davey, M.P.; Smith, A.; et al. Bionic 3D printed corals. Nat. Commun. 2020, 11, 1748. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Song, J.; Lin, S.; Wen, J.; Ma, C.; Yuan, Y.; Lei, M.; Wang, X.; Wang, N.; Wu, H. A marine-inspired hybrid sponge for highly efficient uranium extraction from seawater. Adv. Funct. Mater. 2019, 29, 1901009. [Google Scholar] [CrossRef]

- Liu, C.; Yan, C.; Zhou, S.; Ge, W. Fabrication of sponge biomass adsorbent through UV-induced surface-initiated polymerization for the adsorption of Ce(III) from wastewater. Water Sci. Technol. 2017, 75, 2755–2764. [Google Scholar] [CrossRef]

- Zhan, S.; Guo, A.X.Y.; Cao, S.C.; Liu, N. 3D Printing soft matters and applications: A review. Int. J. Mol. Sci. 2022, 23, 3790. [Google Scholar] [CrossRef]

- Borah, B.M.; Bhuyan, B.J.; Das, G. Low-molecular-weight poly-carboxylate as crystal growth modifier in biomineralization. J. Chem. Sci. 2006, 118, 519–524. [Google Scholar] [CrossRef]

- Yu, Z.; Zhu, T.; Zhang, J.; Ge, M.; Fu, S.; Lai, Y. Fog harvesting devices inspired from single to multiple creatures: Current progress and future perspective. Adv. Funct. Mater. 2022, 32, 2200359. [Google Scholar] [CrossRef]

- Fernandes, F.M.; Coradin, T.; Aime, C. Self-Assembly in Biosilicification and Biotemplated Silica Materials. Nanomaterials 2014, 4, 792–812. [Google Scholar] [CrossRef]

- Wang, L.; Bai, W.; Feng, H.; Jia, X. In vitro biomineralization of self-assembly oligopeptide T2. Sheng Wu Yi Xue Gong Cheng Xue Za Zhi 2007, 24, 798–801. [Google Scholar]

- Groeger, C.; Lutz, K.; Brunner, E. Biomolecular self-assembly and its relevance in silica biomineralization. Cell Biochem. Biophys. 2008, 50, 23–39. [Google Scholar] [CrossRef] [PubMed]

- Atwood, J.L.; Barbour, L.J.; Jerga, A. Organization of the interior of molecular capsules by hydrogen bonding. Proc. Natl. Acad. Sci. USA 2002, 99, 4837–4841. [Google Scholar] [CrossRef]

- He, M.; Lv, X.; Peng, H.; Zhou, Y.; Li, H.; Li, Z.; Wang, Y.; Bu, X. Biomimetic artificial nacre-like microfiber of Co/C modified cellulose nanofiber/Ti3C2Tx/MXene with efficient microwave absorption. Chem. Eng. J. 2024, 491, 151726. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, S.; Li, X.; Liu, T.; Zhao, T.; Wang, J.; Luo, B.; Cai, C.; Liu, Y.; Shao, Y.; et al. Biomimetic superhydrophobic triboelectric surface prepared by interfacial self-assembly for water harvesting. Adv. Funct. Mater. 2025, 35, 2413201. [Google Scholar] [CrossRef]

- Zhao, Y.; Zheng, J.; Xiong, Y.; Wang, H.; Yang, S.; Sun, X.; Zhao, L.; Mikos, A.G.; Wang, X. Hierarchically engineered artificial lamellar bone with high strength and toughness. Small Struct. 2023, 4, 2200256. [Google Scholar] [CrossRef]

- Tang, Y.; Wu, B.; Li, J.; Lu, C.; Wu, J.; Xiong, R. Biomimetic structural hydrogels reinforced by gradient twisted plywood architectures. Adv. Mater. 2024, 37, 2411372. [Google Scholar] [CrossRef]

- Zhang, L.; Tao, G.H.; Xu, C.M.; Zhang, G.H.; He, L. Self-assembled biomimetic capsules for self-preservation. Small 2020, 16, e2000930. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Zhu, H.; Shi, X.; Wang, L.; He, H.; Wang, S. Design of amphoteric bionic fibers by imitating spider silk for rapid and complete removal of low-level multiple heavy metal ions. Chem. Eng. J. 2021, 412, 128670. [Google Scholar] [CrossRef]

- Cao, L.; Li, Y.F.; Tong, Y.; Yang, R.; Sun, L.; Cao, Q.; Chen, R. A novel Bi12TiO20/g-C3N4 hybrid catalyst with a bionic granum configuration for enhanced photocatalytic degradation of organic pollutants. J. Hazard. Mater. 2019, 379, 120808. [Google Scholar] [CrossRef]

- Liu, C.; Wang, C.; Guo, Y.; Zhang, J.; Cao, Y.; Liu, H.; Hu, Z.; Zhang, C. High-performance polyamide membrane with tailored water channel prepared via bionic neural networks for textile wastewater treatment. J. Mater. Chem. A 2019, 7, 6695–6707. [Google Scholar] [CrossRef]

- Das, S.; Heasman, P.; Ben, T.; Qiu, S. Porous organic materials: Strategic design and structure-function correlation. Chem. Rev. 2017, 117, 1515–1563. [Google Scholar] [CrossRef]

- Ge, M.; Cao, C.; Huang, J.; Zhang, X.; Tang, Y.; Zhou, X.; Zhang, K.; Chen, Z.; Lai, Y. Rational design of materials interface at nanoscale towards intelligent oil–water separation. Nanoscale Horiz. 2018, 3, 235–260. [Google Scholar] [CrossRef]

- Li, H.; Yang, J.Y.; Su, P.C.; Wang, W.S. Computer aided modeling and pore distribution of bionic porous bone structure. J. Cent. South Univ. 2012, 19, 3492–3499. [Google Scholar] [CrossRef]

- Xiong, J.; Mines, R.; Ghosh, R.; Vaziri, A.; Ma, L.; Ohrndorf, A.; Christ, H.J.; Wu, L.Z. Advanced micro-lattice materials. Adv. Eng. Mater. 2015, 17, 1253–1264. [Google Scholar] [CrossRef]

- Nugroho, A.W.; Leadbeater, G.; Davies, I.J. Processing of a porous titanium alloy from elemental powders using a solid state isothermal foaming technique. J. Mater. Sci. Mater. Med. 2010, 21, 3103–3107. [Google Scholar] [CrossRef] [PubMed]

- de Vasconcellos, L.M.R.; Leite, D.D.; Nascimento, F.O.; de Vasconcellos, L.G.O.; Graca, M.L.D.; Carvalho, Y.R.; Cairo, C.A.A. Porous titanium for biomedical applications: An experimental study on rabbits. Med. Oral Patol. Oral 2010, 15, E407–E412. [Google Scholar] [CrossRef]

- de Vasconcellos, L.M.R.; Oliveira, F.N.; Leite, D.D.; de Vasconcellos, L.G.O.; do Prado, R.F.; Ramos, C.J.; Graca, M.L.D.; Cairo, C.A.A.; Carvalho, Y.R. Novel production method of porous surface Ti samples for biomedical application. J. Mater. Sci. Mater. Med. 2012, 23, 357–364. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Le Coz-Botrel, R.; Beddoes, C.; Sjostrom, T.; Su, B. Gelatin freeze casting of biomimetic titanium alloy with anisotropic and gradient pore structure. Biomed. Mater. 2017, 12, 015014. [Google Scholar] [CrossRef]

- Wang, X.J.; Xu, S.Q.; Zhou, S.W.; Xu, W.; Leary, M.; Choong, P.; Qian, M.; Brandt, M.; Xie, Y.M. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review. Biomaterials 2016, 83, 127–141. [Google Scholar] [CrossRef]

- Wang, G.h.; Fu, H.; Zhou, K.C.; Zhao, Y.Z.; Zhu, S.H. Nanospike surface-modified bionic porous titanium implant and in vitro osteogenic performance. Trans. Nonferrous Met. Soc. China 2017, 27, 1815–1821. [Google Scholar] [CrossRef]

- Ryan, G.E.; Pandit, A.S.; Apatsidis, D.P. Porous titanium scaffolds fabricated using a rapid prototyping and powder metallurgy technique. Biomaterials 2008, 29, 3625–3635. [Google Scholar] [CrossRef]

- Wu, Y.C.; Kuo, C.N.; Wu, T.H.; Liu, T.Y.; Chen, Y.W.; Guo, X.H.; Huang, J.C. Empirical rule for predicting mechanical properties of Ti-6Al-4V bone implants with radial-gradient porosity bionic structures. Mater. Today Commun. 2021, 27, 102346. [Google Scholar] [CrossRef]

- Zhang, J.H.; Feng, Y.H.; Zhou, X.; Shi, Y.B.; Wang, L. Research status of artificial bone materials. Int. J. Polym. Mater. Polym. Biomater. 2021, 70, 37–53. [Google Scholar] [CrossRef]

- Wegst, U.G.K.; Schecter, M.; Donius, A.E.; Hunger, P.M. Biomaterials by freeze casting. Philos. Trans. R. Soc. A 2010, 368, 2099–2121. [Google Scholar] [CrossRef] [PubMed]

- Porter, M.M.; Mckittrick, J.; Meyers, M.A. Biomimetic Materials by Freeze Casting. Jom-Us 2013, 65, 720–727. [Google Scholar] [CrossRef]

- Wang, C.; Xu, D.L.; Li, S.J.; Yi, C.; Zhang, X.L.; He, Y.; Yu, D.S. Effect of pore size on the physicochemical properties and osteogenesis of Ti6Al4V porous scaffolds with bionic structure. ACS Omega 2020, 5, 28684–28692. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.Z.; Nie, J.Y.; Zhang, Q.R.; Li, Y.L.; Wang, Z.K.; Hu, Q.L. Preparation and characterization of bionic bone structure chitosan/hydroxyapatite scaffold for bone tissue engineering. J. Biomater. Sci. Polym. Ed. 2014, 25, 61–74. [Google Scholar] [CrossRef]

- Yang, Y.R.; Gao, B.B.; Hu, Y.N.; Wei, H.; Zhang, C.; Chai, R.J.; Gu, Z.Z. Ordered inverse-opal scaffold based on bionic transpiration to create a biomimetic spine. Nanoscale 2021, 13, 8614–8622. [Google Scholar] [CrossRef]

- Montazerian, H.; Davoodi, E.; Asadi-Eydivand, M.; Kadkhodapour, J.; Solati-Hashjin, M. Porous scaffold internal architecture design based on minimal surfaces: A compromise between permeability and elastic properties. Mater. Des. 2017, 126, 98–114. [Google Scholar] [CrossRef]

- Zhao, L.; Pei, X.; Jiang, L.H.; Hu, C.; Sun, J.X.; Xing, F.; Zhou, C.C.; Fan, Y.J.; Zhang, X.D. Bionic design and 3D printing of porous titanium alloy scaffolds for bone tissue repair. Compos. Part B-Eng. 2019, 162, 154–161. [Google Scholar] [CrossRef]

- Zhu, Y.; Joralmon, D.; Shan, W.; Chen, Y.; Rong, J.; Zhao, H.; Xiao, S.; Li, X. 3D printing biomimetic materials and structures for biomedical applications. Bio-des. Manuf. 2021, 4, 405–428. [Google Scholar] [CrossRef]

- Libonati, F.; Buehler, M.J. Advanced structural materials by bioinspiration. Adv. Eng. Mater. 2017, 19, 160787. [Google Scholar] [CrossRef]

- Kurzydlowsiki, T.W.J.S.L.M.K.J. Modeling structures of cellular materials for application at various length-scales. Comput. Methods Mater. Sci. 2013, 13, 493–500. [Google Scholar] [CrossRef]

- Pei, X.; Zhang, B.Q.; Fan, Y.J.; Zhu, X.D.; Sun, Y.; Wang, Q.G.; Zhang, X.D.; Zhou, C.C. Bionic mechanical design of titanium bone tissue implants and 3D printing manufacture. Mater. Lett. 2017, 208, 133–137. [Google Scholar] [CrossRef]

- Shi, J.P.; Zhu, L.Y.; Li, L.; Li, Z.A.; Yang, J.Q.; Wang, X.S. A TPMS-based method for modeling porous scaffolds for bionic bone tissue engineering. Sci. Rep. 2018, 8, 7395. [Google Scholar] [CrossRef]

- Xue, B.; Liang, B.; Yuan, G.; Zhu, L.; Wang, H.; Lu, Z.; Xu, Z. A pilot study of a novel biodegradable magnesium alloy airway stent in a rabbit model. Int. J. Pediatr. Otorhinolaryngol. 2019, 117, 88–95. [Google Scholar] [CrossRef] [PubMed]

- Echeverry-Rendon, M.; Allain, J.P.; Robledo, S.M.; Echeverria, F.; Harmsen, M.C. Coatings for biodegradable magnesium-based supports for therapy of vascular disease: A general view. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 102, 150–163. [Google Scholar] [CrossRef]

- Cun, Y.W.; Dou, C.H.; Tian, S.Y.; Li, M.; Zhu, Y.B.; Cheng, X.D.; Chen, W. Traditional and bionic dynamic hip screw fixation for the treatment of intertrochanteric fracture: A finite element analysis. Int. Orthop. 2020, 44, 551–559. [Google Scholar] [CrossRef]

- Bao, L.L.; Park, J.; Bonfante, G.; Kim, B. Recent advances in porous microneedles: Materials, fabrication, and transdermal applications. Drug Deliv. Transl. Res. 2022, 12, 395–414. [Google Scholar] [CrossRef]

- Zhang, D.X.; Esser, L.; Vasani, R.B.; Thissen, H.; Voelcker, N.H. Porous silicon nanomaterials: Recent advances in surface engineering for controlled drug-delivery applications. Nanomedicine 2019, 14, 3213–3230. [Google Scholar] [CrossRef]

- Mao, X.; Wang, M.; Jin, S.H.; Rao, J.Y.; Deng, R.H.; Zhu, J.T. Monodispersed polymer particles with tunable surface structures: Droplet microfluidic-assisted fabrication and biomedical applications. J. Polym. Sci. 2022, 60, 1653–1669. [Google Scholar] [CrossRef]

- Tao, J.; Su, X.D.; Li, J.; Shi, W.H.; Teng, Z.G.; Wang, L.H. Intricately structured mesoporous organosilica nanoparticles: Synthesis strategies and biomedical applications. Biomater. Sci. 2021, 9, 1609–1626. [Google Scholar] [CrossRef] [PubMed]

- Jain, K.K. An Overview of drug delivery systems. Methods Mol. Biol. 2020, 2059, 1–54. [Google Scholar]

- Zhang, Y.W.; Shi, J.J.; Li, Y.J.; Wei, L. Cardiomyocyte death in doxorubicin-induced cardiotoxicity. Arch. Immunol. Ther. Ex. 2009, 57, 435–445. [Google Scholar] [CrossRef]

- Huang, X.; Brazel, C.S. On the importance and mechanisms of burst release in matrix-controlled drug delivery systems. J. Control Release 2001, 73, 121–136. [Google Scholar] [CrossRef]

- Tajnsek, T.K.; Grape, E.S.; Willhammar, T.; Jelic, T.A.; Javornik, U.; Drazic, G.; Logar, N.Z.; Mazaj, M. Design and degradation of permanently porous vitamin C and zinc-based metal-organic framework. Commun. Chem. 2022, 5, 24. [Google Scholar] [CrossRef] [PubMed]

- Xie, C.L.; Tang, H.Z.; Xiao, X.F. The Influence of biomimetic deposition Ca-P coatings on the release of simvastatin from TiO2 nanotube Array. MATEC Web Conf. 2016, 67, 01005. [Google Scholar] [CrossRef]

- Lin, L.L.; Zhou, L.P.; Wang, Z.K.; Hu, Q.X.; Fang, M.L. Freeze Drying Technology Forming Drug Release Bionic Scaffolds with Gradient Structure. Appl. Mech. Mater. 2012, 121–126, 3935–3939. [Google Scholar]

- Li, Z.H.; Bai, H.T.; Wang, Z.H.; Liu, Y.Z.; Ren, M.; Wang, X.G.; Gao, W.N.; Li, Q.J.; Wu, M.F.; Liu, H.; et al. Ultrasound-mediated rapamycin delivery for promoting osseointegration of 3D printed prosthetic interfaces via autophagy regulation in osteoporosis. Mater. Des. 2022, 216, 110586. [Google Scholar] [CrossRef]

- Zhang, W.; Jin, X.; Li, H.; Wei, C.X.; Wu, C.W. Onion-structure bionic hydrogel capsules based on chitosan for regulating doxorubicin release. Carbohydr. Polym. 2019, 209, 152–160. [Google Scholar] [CrossRef]

- Zhao, Y.F.; Shi, C.X.; Cao, J. Biomimetic phototherapy in cancer treatment: From synthesis to application. Drug Deliv. 2021, 28, 2085–2099. [Google Scholar] [CrossRef] [PubMed]

- Deng, H.Z.; Lin, L.S.; Wang, S.; Yu, G.C.; Zhou, Z.J.; Liu, Y.J.; Niu, G.; Song, J.B.; Chen, X.Y. X-ray-controlled bilayer permeability of bionic nanocapsules stabilized by nucleobase pairing interactions for pulsatile drug delivery. Adv. Mater. 2019, 31, 1903443. [Google Scholar] [CrossRef]

- Chen, Q.; Che, C.C.; Liu, J.F.; Gong, Z.J.; Si, M.R.; Yang, S.S.; Yang, G. Construction of an exosome-functionalized graphene oxide based composite bionic smart drug delivery system and its anticancer activity. Nanotechnology 2022, 33, 175101. [Google Scholar] [CrossRef]

- Shivaramakrishnan, K.; Namasivayam, K.R.; Aswin, L.N.; GorgeRobin, A.T. Synthesis and characterisation of optically active and water soluble carbon nano particles by chemical reduction method. In Proceedings of the 2013 International Conference on Advanced Nanomaterials and Emerging Engineering Technologies (Icanmeet), Chennai, India, 24–26 July 2013; pp. 18–20. [Google Scholar]

- Liu, H.; Wang, L.; Lin, G.; Feng, Y. Recent progress in the fabrication of flexible materials for wearable sensors. Biomater. Sci. 2022, 10, 614–632. [Google Scholar] [CrossRef]

- Qian, X.; Su, M.; Li, F.; Song, Y. Research progress in flexible wearable electronic sensors. Acta Chim. Sin. 2016, 74, 565–575. [Google Scholar] [CrossRef]

- Wang, L.; Xu, T.; Zhang, X. Multifunctional conductive hydrogel-based flexible wearable sensors. Trac-Trend Anal. Chem. 2021, 134, 116130. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, B.; Hua, Z.; Zhang, J.; Guo, P.; Hao, D.; Gao, Y.; Huang, J. Recent advancements in flexible and wearable sensors for biomedical and healthcare applications. J. Phys. D Appl. Phys. 2022, 55, 134001. [Google Scholar] [CrossRef]

- Xu, F.; Li, X.; Shi, Y.; Li, L.; Wang, W.; He, L.; Liu, R. Recent developments for flexible pressure sensors: A review. Micromachines 2018, 9, 580. [Google Scholar] [CrossRef] [PubMed]

- Chang, Q.; Darabi, M.A.; Liu, Y.; He, Y.; Zhong, W.; Mequanint, K.; Li, B.; Lu, F.; Xing, M.M.Q. Hydrogels from natural egg white with extraordinary stretchability, direct-writing 3D printability and self-healing for fabrication of electronic sensors and actuators. J. Mater. Chem. A 2019, 7, 24626–24640. [Google Scholar] [CrossRef]

- Jiang, D.; Xu, Y.; Jiang, H.; Xiang, X.; Wang, L. A biomimetic skin microtissue biosensor for the detection of fish parvalbumin. Bioelectrochemistry 2025, 161, 108805. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.; Wu, Z.; Qin, Z.; Chen, X.; Zhang, C.; Cao, B.; Duan, H.; Zhang, J. A dog nose-inspired high-performance NH3 gas sensor of biomass carbon materials with a pleated structure derived from rose tea. J. Mater. Chem. A 2022, 10, 14326–14335. [Google Scholar] [CrossRef]

- Miao, F.; Lu, N.; Zhang, P.; Zhang, Z.; Shao, G. Multidimension-controllable synthesis of ant nest-sructural electrode materials with unique 3D hierarchical porous features toward electrochemical applications. Adv. Funct. Mater. 2020, 30, 1808994. [Google Scholar] [CrossRef]

- Yang, C.; He, G.; Liu, Y.; Ma, Y.; Jiang, T.; Gao, X.; Zhao, S.; Chen, L.; Zhang, X.; Yi, K.; et al. Accurate point-of-care lotus biomimetic microfluidic urine testing platform for patients with chronic kidney disease. Chem. Eng. J. 2024, 497, 154736. [Google Scholar] [CrossRef]

- Suleimenova, A.; Frasco, M.F.; Soares da Silva, F.A.G.; Gama, M.; Fortunato, E.; Sales, M.G.F. Bacterial nanocellulose membrane as novel substrate for biomimetic structural color materials: Application to lysozyme sensing. Biosens. Bioelectron. X 2023, 13, 100130. [Google Scholar] [CrossRef]

- Batool, R.; Soler, M.; Singh, R.; Lechuga, L.M. A novel biomimetic nanoplasmonic sensor for rapid and accurate evaluation of checkpoint inhibitor immunotherapy. Anal. Bioanal. Chem. 2024, 416, 7295–7304. [Google Scholar] [CrossRef]

- Wang, Q.; Tong, J.; Wang, N.; Chen, S.; Sheng, B. Humidity sensor of tunnel-cracked nickel@polyurethane sponge for respiratory and perspiration sensing. Sens. Actuators B-Chem. 2021, 330, 129322. [Google Scholar] [CrossRef]

- Zhou, C.; Zang, J.; Xue, C.; Ma, Y.; Hua, X.; Gao, R.; Zhang, Z.; Li, B.; Zhang, Z. Design of a novel medical acoustic sensor based on MEMS bionic fish ear structure. Micromachines 2022, 13, 163. [Google Scholar] [CrossRef]

- Jian, M.; Xia, K.; Wang, Q.; Yin, Z.; Wang, H.; Wang, C.; Xie, H.; Zhang, M.; Zhang, Y. Flexible and highly sensitive pressure sensors based on bionic hierarchical structures. Adv. Funct. Mater. 2017, 27, 1606066. [Google Scholar] [CrossRef]

- Cao, Y.; Ge, J. Hybrid enzyme catalysts synthesized by a de novo approach for expanding biocatalysis. Chin. J. Catal. 2021, 42, 1625–1633. [Google Scholar] [CrossRef]

- Gao, X.; Zhai, Q.; Hu, M.; Li, S.; Jiang, Y. Hierarchically porous magnetic Fe3O4/Fe-MOF used as an effective platform for enzyme immobilization: A kinetic and thermodynamic study of structure-activity. Catal. Sci. Technol. 2021, 11, 2446–2455. [Google Scholar] [CrossRef]

- Gao, X.; Pan, H.; He, Z.; Yang, K.; Qiao, C.; Liu, Y.; Zhou, C. Construction and structure-activity relationship of immobilized enzyme reactor based on Al-MOF-derived Al2O3 with hierarchical structure. Acta Chim. Sin. 2021, 79, 1502–1510. [Google Scholar] [CrossRef]

- Wang, B.; Lei, B.H.; Tang, Y.H.; Xiang, D.; Li, H.; Ma, Q.; Zhao, C.X.; Li, Y.T. Facile fabrication of robust superhydrophobic cotton fabrics modified by polysiloxane nanowires for oil/water separation. J. Coat. Technol. Res. 2018, 15, 611–621. [Google Scholar] [CrossRef]

- Liu, Z.A.; Wang, X.Y.; Gao, M.Q.; Song, J.L.; Huang, L.; Liu, J.Y.; Liu, X.; Xu, W.; Zhao, D.Y. Unpowered oil absorption by a wettability sponge based oil skimmer. RSC Adv. 2016, 6, 88001–88009. [Google Scholar] [CrossRef]

- Sun, H.D.; Liu, Z.M.; Liu, K.Y.; Gibril, M.E.; Kong, F.G.; Wang, S.J. Lignin-based superhydrophobic melamine resin sponges and their application in oil/water separation. Ind. Crops Prod. 2021, 170, 113798. [Google Scholar] [CrossRef]

- Li, B.; Qi, B.; Han, J.; Yang, C.; Qian, X.; Jiao, T. Preparation and separation performance of biomimetic polycaprolactone/ graphene oxide composite membrane. Colloids Surface A 2024, 693, 134088. [Google Scholar] [CrossRef]

- Yu, M.; Ma, C.; Liao, C.; Wang, Y.; Wang, D. Preparation and oil-water separation performance of lignin-based durable superhydrophobic petaloid structure inspired from springtail cuticle surface. Prog. Org. Coat. 2025, 198, 108907. [Google Scholar] [CrossRef]

- He, H.; Wen, S.; Tan, Y.; Chen, L.; Liu, Y.; Liu, X.; Yuan, S. A desert beetle-like mesh membrane by decorating superhydrophilic Fe-doped Cu-MOFs onto superhydrophobic CuC2O4 bowknot-like arrays for boosting water-in-oil emulsion separation. J. Environ. Chem. Eng. 2024, 12, 114673. [Google Scholar] [CrossRef]

- Sun, F.; Ren, H.T.; Li, T.T.; Huang, S.Y.; Zhang, Y.; Lou, C.W.; Lin, J.H. Bioinspired design of underwater superoleophobic Poly(N-isopropylacrylamide)/polyacrylonitrile/TiO2 nanofibrous membranes for highly efficient oil/water separation and photocatalysis. Environ. Res. 2020, 186, 109499. [Google Scholar] [CrossRef]

- Newton, M.A.A.; Gao, D.; Xin, B.; Zheng, Y.; Gong, H. Development of a biomimetic polyvinylidene fluoride membrane with a lotus leaf-inspired structure for enhanced oil-water separation. Colloids Surface A 2025, 706, 135773. [Google Scholar] [CrossRef]

- Chai, L.Y.; Li, Q.Z.; Wang, Q.W.; Yan, X. Solid-liquid separation: An emerging issue in heavy metal wastewater treatment. Environ. Sci. Pollut. Res. 2018, 25, 17250–17267. [Google Scholar] [CrossRef]

- Razafimanantsoa, V.A.; Adyasari, D.; Sahu, A.K.; Rusten, B.; Bilstad, T.; Ydstebo, L. Pilot-scale study to investigate the impact of rotating belt filter upstream of a MBR for nitrogen removal. Water Sci. Technol. 2019, 79, 458–465. [Google Scholar] [CrossRef]

- Pan, J.K.; Shen, Q.S.; Cui, X.; Wu, J.W.; Ma, L.; Tian, C.C.; Fu, P.B.; Wang, H.L. Cyclones of different sizes and underflow leakage for aerosol particles separation enhancement. J. Clean. Prod. 2021, 280, 124379. [Google Scholar] [CrossRef]

- Divi, R.V.; Strother, J.A.; Paig-Tran, E.W.M. Manta rays feed using ricochet separation, a novel nonclogging filtration mechanism. Sci. Adv. 2018, 4, eaat9533. [Google Scholar] [CrossRef]

- Sibanda, V.; Greenwood, R.W.; Seville, J.P.K.; Ding, Y.; Iyuke, S. Predicting particle segregation in cross-flow gas filtration. Powder Technol. 2010, 203, 419–427. [Google Scholar] [CrossRef]

- Regula, C.; Carretier, E.; Wyart, Y.; Gesan-Guiziou, G.; Vincent, A.; Boudot, D.; Moulin, P. Chemical cleaning/disinfection and ageing of organic UF membranes: A review. Water Res. 2014, 56, 325–365. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.W.; Hu, D.A.; Li, C.R.; Zhuang, C.; Yang, G. CFD-DEM simulation of the hydrodynamic filtration performance in balaenid whale filter feeding. Sci. Total Environ. 2021, 787, 147696. [Google Scholar] [CrossRef]

- Yin, W.; Ran, P.; Yang, L.; Peng, Z.; Jin, C.; Chen, L.; Liu, C.; Li, J. A biomimetic microfluidic chip based on the bubble filtration mechanism of stomatal pore membranes. New J. Chem. 2024, 48, 14605–14615. [Google Scholar] [CrossRef]

- Hu, X.; Yu, L.; Zhu, Z.; Bao, F.; Lin, J.; Tu, C.; Lin, P. A self-cleaning micro-fluidic chip biospired by the filtering system of manta rays. Lab Chip 2024, 24, 3064–3079. [Google Scholar] [CrossRef]

- Zhou, X.N.; Hao, X.; Xu, J.Q.; Ren, Y.; Zhi, Q.; Zhang, N.L.; Wei, Z.L.; Yang, J.-F.; Wang, B.; Ishizaki, K. Light-weight, wood-derived, biomorphic SiC ceramics by carbothermal reduction. Ceram. Int. 2024, 50, 23135–23149. [Google Scholar] [CrossRef]

- Wang, W.; Hou, Z.; Zhang, H.; Ma, X.; Wang, G.; Miao, J.; Fan, T. Harsh environmental-tolerant ZIF-8@polyphenylene sulfide membrane for efficient oil/water separation and air filtration under extreme conditions. J. Membrane Sci. 2023, 685, 121885. [Google Scholar] [CrossRef]

- Olajire, A.A. CO2 capture and separation technologies for end-of-pipe applications—A review. Energy 2010, 35, 2610–2628. [Google Scholar] [CrossRef]

- Wang, C.; Guo, F.; Li, H.; Xu, J.; Hu, J.; Liu, H.; Wang, M. A porous ionic polymer bionic carrier in a mixed matrix membrane for facilitating selective CO2 permeability. J. Membrane Sci. 2020, 598, 117677. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, Y.; Li, P.; Kuai, L.; Zou, Z. Synthesis of bionic-macro/microporous MgO-modified TiO2 for enhanced CO2 photoreduction into hydrocarbon fuels. Chin. J. Catal. 2016, 37, 863–868. [Google Scholar] [CrossRef]

- He, T.; Yao, S.; Chen, D.; Sun, Z.; Wang, X.; Wang, K.; Chen, J.; Li, Q.; Chen, R.; Wang, Y.; et al. Biomimetic gas channel constructed for efficient CO2 removal based on computational simulations. J. Membrane Sci. 2025, 716, 123469. [Google Scholar] [CrossRef]

- Li, N.; Wang, Z.; Wang, J. Biomimetic hydroxypropyl-β-cyclodextrin (Hβ-CD)/polyamide (PA) membranes for CO2 separation. J. Membrane Sci. 2023, 668, 121211. [Google Scholar] [CrossRef]

- Huang, H.; Wang, J.; Dong, R. Noise pollution and control measures in construction site of shallow warehouse in port. J. Coast. Res. 2020, 103, 586–589. [Google Scholar] [CrossRef]

- Al-Abbasi, M.; Zhao, Y.; He, H.; Liu, H.; Xia, H.; Zhu, T.; Wang, K.; Xu, Z.; Wang, H.; Zhang, W.; et al. Challenges and protective strategies on zinc anode towards practical aqueous zinc-ion batteries. Carbon Neutralization 2024, 3, 108–141. [Google Scholar] [CrossRef]

- Yorzinski, J.L.; Hermann, F.S. Noise pollution has limited effects on nocturnal vigilance in peahens. Peerj 2016, 4, e2525. [Google Scholar] [CrossRef]

- Borlea, S.I.; Tiuc, A.-E.; Nemes, O.; Vermesan, H.; Vasile, O. Innovative use of sheep wool for obtaining materials with improved sound-absorbing properties. Materials 2020, 13, 694. [Google Scholar] [CrossRef]

- Malawade, U.A.; Malgaonkar, V.V.; Badadhe, A.M.; Jadhav, M.G. Utilization and study of raw groundnut shell as a source of sound absorbing material. J. Nat. Fibers 2021, 19, 6335–6347. [Google Scholar] [CrossRef]

- Sagar, P.; Teotia, P.; Sahlot, A.D.; Thakur, H.C. An analysis of silent flight of owl. Mater. Today 2017, 4, 8571–8575. [Google Scholar] [CrossRef]

- Ji, G.; Cui, J.; Fang, Y.; Yao, S.; Zhou, J.; Kim, J.K. Nano-fibrous composite sound absorbers inspired by owl feather surfaces. Appl. Acoust. 2019, 156, 151–157. [Google Scholar] [CrossRef]

- Wang, Y.H.; Zhang, C.C.; Ren, L.Q.; Ichchou, M.; Galland, M.A.; Bareille, O. Acoustic performance analysis of bionic coupling multi-layer structure. Appl. Mech. Mater. 2013, 461, 22–30. [Google Scholar]

- Korde, J.M.; Shaikh, M.; Kandasubramanian, B. Bionic Prototyping of honeycomb patterned polymer composite and its engineering application. Polym. Plast. Technol. 2018, 57, 1828–1844. [Google Scholar] [CrossRef]

- Ma, Y.; Ye, W. Biomimetic coupling structure increases the noise friction and sound absorption effect. Materials 2023, 16, 7148. [Google Scholar] [CrossRef]

- Xie, S.; Yang, S.; Yan, H.; Li, Z. Sound absorption performance of a conch-imitating cavity structure. Sci. Prog. 2022, 105, 00368504221075167. [Google Scholar] [CrossRef]

- Farahani, M.D.; Dastjerdi, R. Bio-waste-based sequin fabrics to control interior noise pollution. Int. J. Environ. Sci. Technol. 2024, 21, 9447–9458. [Google Scholar] [CrossRef]

- Zou, L.; Zhang, A.; Liu, Z.; Du, P.; Guo, Y. The sound absorption performance of laser-sintered composite biomimetic wood porous structures. Polymers 2024, 16, 3290. [Google Scholar] [CrossRef]

- Feng, J.; Qiao, J.; Xu, Q.; Wu, Y.; Zhang, G.; Li, L. Broadband sound absorption and high damage resistance in a turtle shell-inspired multifunctional lattice: Neural network-diven design and optimization. Small 2024, 20, 2403254. [Google Scholar] [CrossRef]

- Elimelech, M.; Phillip, W.A. The future of seawater desalination: Energy, technology, and the environment. Science 2011, 333, 712–717. [Google Scholar] [CrossRef]

- Ge, M.; Cao, C.; Biesold, G.M.; Sewell, C.D.; Hao, S.M.; Huang, J.; Zhang, W.; Lai, Y.; Lin, Z. Recent advances in silicon-based electrodes: From fundamental research toward practical applications. Adv. Mater. 2021, 33, 2004577. [Google Scholar] [CrossRef]

- Yan, T.; Xie, G.; Sun, L.; Du, M.; Liu, H. Experimental investigation on a two-effect tubular solar still operating under vacuum conditions. Desalination 2019, 468, 114057. [Google Scholar] [CrossRef]

- Zhu, L.; Gao, M.; Peh, C.K.N.; Wang, X.; Ho, G.W. Self-contained monolithic carbon sponges for solar-driven interfacial water evaporation distillation and electricity generation. Adv. Energy Mater. 2018, 8, 1702149. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, P.; Xie, G.; Wei, Y.; Lyu, Y.; Zhang, Y.; Yan, T.; Zhang, T. A floating solar still inspired by continuous root water intake. Desalination 2021, 512, 115133. [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, Z.; Wu, G.; Zhang, X.; Zheng, H. Energy analysis and experimental verification of a solar freshwater self- produced ecological film floating on the sea. Appl. Energy 2018, 224, 510–526. [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, Z.; Zheng, H. Investigation of a floating solar desalination film. Desalination 2018, 447, 43–54. [Google Scholar] [CrossRef]

- Li, Y.; Jin, X.; Li, W.; Niu, J.; Han, X.; Yang, X.; Wang, W.; Lin, T.; Zhu, Z. Biomimetic hydrophilic foam with micro/nano-scale porous hydrophobic surface for highly efficient solar-driven vapor generation. Sci. China-Mater. 2022, 65, 1057–1067. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Y.; Guan, W.; Wang, P.; Feng, J.; Song, N.; Dong, H.; Yu, L.; Sui, L.; Gan, Z.; et al. A self-floating and integrated bionic mushroom for highly efficient solar steam generation. J. Colloids Interface Sci. 2022, 612, 88–96. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Hang, C.; Li, K.; Yao, J.; Shi, H.; Ge, R.; Gong, X.; Quan, F.; Zhang, L.; Zhang, K.; et al. Highly efficient solar seawater evaporation by aerogel with vertical channels and hierarchical pores structure based on high-absorbent alginate fibers. Chem. Eng. J. 2024, 501, 157562. [Google Scholar] [CrossRef]

- Gao, C.; Li, Y.; Lan, L.; Wang, Q.; Zhou, B.; Chen, Y.; Li, J.; Guo, J.; Mao, J. Bioinspired asymmetric polypyrrole membranes with enhanced photothermal conversion for highly efficient solar evaporation. Adv. Sci. 2024, 11, 2306833. [Google Scholar] [CrossRef]

- Zou, L.; Zhang, H.; Chen, Q.; Zheng, S.; Chen, N.; Wu, X.; Li, X. Achieving highly interfacial evaporation rate and continuous salt resistance simultaneously via multi-dimensional composite biomimetic evaporator. Chem. Eng. J. 2024, 498, 155762. [Google Scholar] [CrossRef]

- Zhang, R.; Xiang, B.; Wang, Y.; Tang, S.; Meng, X. A lotus-inspired 3D biomimetic design toward an advanced solar steam evaporator with ultrahigh efficiency and remarkable stability. Mater. Horiz. 2022, 9, 1232–1242. [Google Scholar] [CrossRef]

- Wang, Y.C.; Chu, F.L.; Zeng, J.; Wang, Q.J.; Naren, T.Y.; Li, Y.Y.; Cheng, Y.; Lei, Y.P.; Wu, F.X. Single atom catalysts for fuel cells and rechargeable batteries: Principles, advances, and opportunities. ACS Nano 2021, 15, 210–239. [Google Scholar] [CrossRef]

- Tong, Z.M.; Huang, L.; Lei, W.; Zhang, H.J.; Zhang, S.W. Carbon-containing electrospun nanofibers for lithium-sulfur battery: Current status and future directions. J. Energy Chem. 2021, 54, 254–273. [Google Scholar] [CrossRef]

- Ghalambaz, M.; Zadeh, S.M.H.; Mehryan, S.A.M.; Pop, I.; Wen, D.S. Analysis of melting behavior of PCMs in a cavity subject to a non-uniform magnetic field using a moving grid technique. Appl. Math. Model. 2020, 77, 1936–1953. [Google Scholar] [CrossRef]

- Mofijur, M.; Mahlia, T.M.I.; Silitonga, A.S.; Ong, H.C.; Silakhori, M.; Hasan, M.H.; Putra, N.; Rahman, S.M.A. Phase change materials (PCM) for solar energy usages and storage: An overview. Energies 2019, 12, 3167. [Google Scholar] [CrossRef]

- Xiao, X.; Jia, H.W.; Wen, D.S.; Zhao, X.D. Thermal performance analysis of a solar energy storage unit encapsulated with HITEC salt/copper foam/nanoparticles composite. Energy 2020, 192, 116593. [Google Scholar] [CrossRef]

- Wang, H.F.; Wang, X.X.; Li, M.L.; Zheng, L.J.; Guan, D.H.; Huang, X.L.; Xu, J.J.; Yu, J.H. Porous materials applied in nonaqueous Li-O2 batteries: Status and perspectives. Adv. Mater. 2020, 32, 2002559. [Google Scholar] [CrossRef]

- Fu, A.; Wang, C.Z.; Pei, F.; Cui, J.Q.; Fang, X.L.; Zheng, N.F. Recent Advances in Hollow Porous Carbon Materials for Lithium-Sulfur Batteries. Small 2019, 15, 1804786. [Google Scholar] [CrossRef]

- Gao, M.; Pan, S.Y.; Chen, W.C.; Chiang, P.C. A cross-disciplinary overview of naturally derived materials for electrochemical energy storage. Mater. Today Energy 2018, 7, 58–79. [Google Scholar] [CrossRef]

- Wei, Q.; Xiong, F.; Tan, S.; Huang, L.; Lan, E.H.; Dunn, B.; Mai, L. Porous one-dimensional nanomaterials: Design, fabrication and applications in electrochemical energy storage. Adv. Mater. 2017, 29, 1602300. [Google Scholar] [CrossRef]

- Sarı, A.; Biçer, A.; Hekimoğlu, G. Effects of carbon nanotubes additive on thermal conductivity and thermal energy storage properties of a novel composite phase change material. J. Compos. Mater. 2018, 53, 2967–2980. [Google Scholar] [CrossRef]

- Lachheb, M.; Karkri, M.; Albouchi, F.; Ben Nasrallah, S.; Fois, M.; Sobolciak, P. Thermal properties measurement and heat storage analysis of paraffin/graphite composite phase change material. Compos. Part B-Eng. 2014, 66, 518–525. [Google Scholar] [CrossRef]

- Li, R.; Xu, X.; Zeng, J.; Zhang, X.; Wan, X.; Guo, S.; Wang, X.; Xie, S.; Cao, Z.; Zhang, Y.; et al. Revealing crucial influences of boron support on regulating geometric and electronic structures of 3D catalyst for hydrogen evolution and oxygen reduction reactions. Nano Lett. 2025, 25, 1272–1280. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhu, Z.; Arshad, A.; Zhang, S.; Shi, L.; Yan, Y. Magnetic field-induced enhancement of phase change heat transfer via biomimetic porous structure for solar-thermal energy storage. J. Bionic Eng. 2021, 18, 1215–1224. [Google Scholar] [CrossRef]

- Tao, J.L.; Luan, J.D.; Liu, Y.; Qu, D.Y.; Yan, Z.; Ke, X. Technology development and application prospects of organic-based phase change materials: An overview. Renew. Sustain. Energy Rev. 2022, 159, 115923. [Google Scholar] [CrossRef]

- Chen, D.; Chen, Y.; Guo, X.W.; Tao, W.W.; Wang, J.B.; Gao, S.F.; Gao, J.K. Mesoporous silica nanoparticles with wrinkled structure as the matrix of myristic acid for the preparation of a promising new shape-stabilized phase change material via simple method. RSC Adv. 2018, 8, 34224–34231. [Google Scholar] [CrossRef]

- Qiu, L.; Yan, K.; Feng, Y.; Liu, X.; Zhang, X. Bionic hierarchical porous aluminum nitride ceramic composite phase change material with excellent heat transfer and storage performance. Compos. Commun. 2021, 27, 100892. [Google Scholar] [CrossRef]

- Shi, T.; Xu, H.; Qi, C.; Lei, B.; Wu, Y.; Zhao, C. Multi-physics modeling of thermochemical heat storage with enhance heat transfer. Appl. Therm. Eng. 2021, 198, 117508. [Google Scholar] [CrossRef]

- Wang, F.Q.; Zhang, G.L.; Shi, X.H.; Dong, Y.; Xun, Y.M.; Zhang, A.Y. Biomimetically calabash-inspired phase change material capsule: Experimental and numerical analysis on thermal performance and flow characteristics. J. Energy Storage 2022, 52, 104859. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, F.Q.; Zhang, Y.Q.; Shi, X.H.; Zhang, A.Y.; Shuai, Y. Experimental and numerical study on flow characteristic and thermal performance of macro-capsules phase change material with biomimetic oval structure. Energy 2022, 238, 121830. [Google Scholar] [CrossRef]

- Yang, X.H.; Yu, J.B.; Xiao, T.; Hu, Z.H.; He, Y.L. Design and operating evaluation of a finned shell-and-tube thermal energy storage unit filled with metal foam. Appl. Energy 2020, 261, 114385. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Tao, W.Q.; Shah, R.K. The field synergy (coordination) principle and its applications in enhancing single phase convective heat transfer. Int. J. Heat Mass Transf. 2005, 48, 1797–1807. [Google Scholar] [CrossRef]

- Tian, Y.; Liu, X.; Xu, Q.; Luo, Q.; Zheng, H.; Song, C.; Zhu, Z.; Gao, K.; Dang, C.; Wang, H.; et al. Bionic topology optimization of fins for rapid latent heat thermal energy storage. Appl. Therm. Eng. 2021, 194, 117104. [Google Scholar] [CrossRef]

- He, Z.Y.; Wang, X.H.; Du, X.Z.; Xu, C.; Yang, L.J. Cyclic characteristics of water thermocline storage tank with encapsulated PCM packed bed. Int. J. Heat Mass Transf. 2019, 139, 1077–1086. [Google Scholar] [CrossRef]

- Mao, Q.J.; Chen, H.Z.; Yang, Y.Z. Energy storage performance of a PCM in the solar storage tank. J. Therm. Sci. 2019, 28, 195–203. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, F.Q.; Yang, L.W.; Shi, X.H.; Zhang, G.L.; Shuai, Y. Thermal performance analysis of PCM capsules packed-bed system with biomimetic leaf hierarchical porous structure. J. Therm. Sci. 2021, 30, 1559–1571. [Google Scholar] [CrossRef]

- Kang, K.S.; Meng, Y.S.; Breger, J.; Grey, C.P.; Ceder, G. Electrodes with high power and high capacity for rechargeable lithium batteries. Science 2006, 311, 977–980. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Qiu, J.; Wang, W.; Hou, Y.; Shuai, Y. Efficient-thermal conductivity, storage and application of bionic tree-ring composite phase change materials based on freeze casting. Sol. Energy Mater. Sol. Cells 2024, 264, 112628. [Google Scholar] [CrossRef]

- Grabowska, B.; Kasperski, J. The thermal conductivity of 3D printed plastic insulation materials-the effect of optimizing the regular structure of closures. Materials 2020, 13, 4400. [Google Scholar] [CrossRef]

- Zhong, M.T.; Zhou, W.; Xi, H.F.; Liang, Y.J.; Wu, Z.G. Double-Level Energy Absorption of 3D Printed TPMS Cellular Structures via Wall Thickness Gradient Design. Materials 2021, 14, 6262. [Google Scholar] [CrossRef] [PubMed]

- Jia, H.; Zhu, J.J.; Li, Z.L.; Cheng, X.M.; Guo, J.S. Design and optimization of a photo-thermal energy conversion model based on polar bear hair. Sol. Energy Mater. Sol. Cells 2017, 159, 345–351. [Google Scholar] [CrossRef]

- Zhou, X.Y.; Jin, Y.; Du, J.K. Functionally graded scaffolds with programmable pore size distribution based on triply periodic minimal surface fabricated by selective laser melting. Materials 2020, 13, 5046. [Google Scholar] [CrossRef]

- Stegmaier, T.; Linke, M.; Planck, H. Bionics in textiles: Flexible and translucent thermal insulations for solar thermal applications. Philos. Trans. R. Soc. A 2009, 367, 1749–1758. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Shi, Y.; Gu, X.; Wang, S.; Yang, R.; Cao, L.; Zhang, X. Additive manufacturing of biomimetic lightweight silicon oxycarbide ceramics with high mechanical strength and low thermal conductivity. Mater. Today Adv. 2024, 21, 100466. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Wu, J.; Zhou, J.; Wang, W.; Liu, S.; Pan, Y.; Sang, M.; Liu, B.; Gong, X. STF-filled biomimetic variable stiffness hierarchic porous material with impact resistance, thermal insulation, and sensing. Chem. Eng. J. 2023, 477, 146939. [Google Scholar] [CrossRef]

- Zheng, L.; Zuo, Y.; Li, X.; Wu, Y. Biomimetic swallow nest structure: A lightweight and high-strength thermal insulation material. ACS Nano 2022, 16, 8116–8127. [Google Scholar] [CrossRef] [PubMed]

- Zhuo, H.; Li, Q.; Mei, X.; Chen, Y.; Liu, Y.; Xie, H.; Li, Y.; Dong, F.; Dai, L. Leaf-Inspired biomimetic aerogels for thermal insulation in extreme environments. Small 2025, 21, 2501682. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Li, K.; Zhao, S.; Zhang, Z.; Song, Y.; Gan, Z.; Yang, Z. Bionic composite nanofibrous aerogel inspired by blind shrimp for broad temperature range thermal insulation and broad frequency range noise reduction. Mater. Lett. 2025, 389, 138381. [Google Scholar] [CrossRef]

| Biomimetic Sources | Pore Size | Specific Surface Area (m2/g) | Main Components | Preparation Method | Ref. |

|---|---|---|---|---|---|

| Cotton fiber | 0–100 nm | 292.51 | Crystalline alumina | Biological template method, hydrothermal method | [24] |

| Lotus root | 1~100 μm | 1462.81 | Polyethylene glycol diacrylate | Freeze polymerization followed by crosslinking | [25] |

| Banana leaf | — | — | Titanium dioxide layer | Calcination in pure nitrogen | [27] |

| Golden grape leaf | — | — | Aluminum oxide nanostructures | — | [28] |

| Urease bacteria | — | — | Urease bacteria slag | Adsorption method, microbial mineralization method | [39] |

| Yeast cell capsule | — | — | Calcium phosphate | Biological template method, calcination method | [40] |

| Yeast cell | 20.75–76.17 μm | — | Caustic soda pre-treated yeast, acrylic acid | High internal phase emulsion template method | [41] |

| Keratin porous material | — | — | Modified keratin, sodium alginate | Freeze-drying method, alternate soaking method | [65] |

| Bone tissue | Gelatin and xanthan gum derivatives | Photo-crosslinked | [67] | ||

| Coral | — | 80 | Montmorillonite, humic acid graphene | — | [68] |

| Eggshell membrane | Micrometer | — | Carbon nanofibers | — | [68] |

| Cow ear plant stomata | 400 μm | — | Cured resin, TiO2 nanoparticles | Projection micro stereolithography 3D printing technology | [68] |

| Natural leguminous plant | — | — | Octadecane/graphene | Extrusion-based core–shell 3D printing | [77] |

| Fish mouth | — | — | Polylactide | — | [78] |

| Sponge | Several hundred micrometers | — | Inert melamine sponge skeleton | — | [80] |

| Pearl | — | — | Cellulose nanofibers and titanium carbide | Wet-spinning | [89] |

| Nanocloth desert beetles and lotus leaves | — | — | Microcrystalline cellulose | Interfacial self-assembly | [90] |

| Bone | — | — | Collagen and calcium phosphate nanocrystals | Molecular self-assembly, electrostatic spinning, and pressure-driven fusion process | [91] |

| Crustacean | — | — | Cellulose nanocrystals | Cholesteric-phase liquid crystal self-assembly and nanocrystal engineering | [92] |

| Pomegranate seed encapsulation | — | — | Silver chloride | Bottom-up method for in situ formation | [93] |

| Spider silk | — | — | Cellulose nanofibers/graphene oxide/polyethyleneimine | Electrostatic assembly | [94] |

| Chloroplast stacking structure | — | — | C3N4, Bi12TiO20 | Hydrothermal method, calcination method | [95] |

| Biomimetic neural network | — | — | Polyimide, hydrophilic polyolefin | — | [96] |

| Application | Material | Structure | Performance | Ref. |

|---|---|---|---|---|

| Titanium implant | Titanium powder/camphene | Nanospike surface-modified structure | Porosity: (58.32 ± 1.08)%, compressive strength: (58.51 ± 20.38) MPa | [106] |

| Scaffold in bone tissue engineering | Chitosan(CS)/hydroxyapatite | Three-dimensional (3D)-oriented | Superior to pure CS scaffolds | [113] |

| Spinal cord scaffold | SiO2 | Inter-surface ordered microstructures | Neural regeneration and the formation of neural networks | [114] |

| The dynamic hip screw | Biodegradable magnesium alloy | — | Eliminate the need for implant removal | [124] |

| Drug release | Vitamin C /Zn/EtOH | 3D chiral framework | Biocompatible permanent porosity | [132] |

| Drug release | TiO2/octacalcium phosphate | — | Increase the drug loading | [133] |

| Drug release | Beta-tricalcium phosphate | Gradient structure | The two layers had gradient porosity and pores size | [134] |

| Drug delivery | Rapamycin | — | Promote prosthetic interfaces osseointegration | [135] |

| Drug delivery and release | Chitosan, hyaluronic acid/sodium tripolyphosphate | Multilayer hydrogel capsules | Inhibit the explosive release of doxorubicin | [136] |

| Drug delivery | Polythymine, photoisomerized polyazobenzene/adenine-modified ZnS nanoparticles | Nanocapsules | Remotely controlled drug release, effective antitumor effects | [138] |

| Drug delivery | Chito oligosaccharides/γ-polyglutamic acid/Mitoanthraquinone | — | Increase the local drug concentration of tumor and enhance the pro-apoptotic ability of MIT | [139] |

| Electronic sensors | Egg white | Hydrogel | Superstretchable, self-healing, injectable | [146] |

| Biosensor | Pt nanoparticles/multiwalled carbon nanotube/self-assembly chitosan–sodium alginate | 3D bioprinting | Determine fish parvalbumin | [147] |

| As sensor | Rose petals | Pleated structure | High selectivity for NH3, good stability and good repeatability | [148] |

| Electrode material | CuO/NiO/TiO2/SiO2 | NestStructural | Maximum energy density of 10 Wh kg−1, maximum power density of 10 kW kg−1 | [149] |

| Urine monitoring | Biomimetic optofluidic chip | Lotus leaf bionic structure | Accurate, fast, and easy to operate | [150] |

| Biosensor | Bacterial nanocellulose/polydopamine | — | To be selective against cystatin C | [151] |

| Nanoplasmonic sensor | Gold nanodisks | Lipid bilayer | Limit of detection of 6.7 ng/mL | [152] |

| Humidity sensor | Polyurethane sponges/nickel target | Porous structure | Ultrahigh sensitivity, long-term stability of 90 days | [153] |

| Oil–water separation | Polycaprolactone/GO | Membrane | Separation efficiency of 99.94% for hexane–water mixtures | [162] |

| Oil–water separation | SiO2/kraft lignin/FeCl3⋅6H2O/FeCl2⋅4H2O | Petaloid structure | Oil–water separation efficiency of 97%, with a permeation flux of 850 Lm−2h−1 | [163] |

| Separation of water-in-oil emulsions | Copper mesh/FeCl3·H2O | Bowknot-like arrays | Oil permeation flux of approximately 1200 L·m−2·h−1, with a water content in the oil phase below 57.0 mg·L−1 | [164] |

| Oil–water separation | Poly(N-isopropylacrylamide)/polyacrylonitrile/TiO2 | Bionic fish scale structure | Separation efficiency between 98% and 99% | [165] |

| Oil–water separation | Polyvinylidene fluoride/polyvinylpyrrolidone/SiO2 nanoparticles/dopamine hydrochloride | Lotus leaf-inspired structure | Separation efficiency of various oil–water mixtures exceeds 99.9%, and the flux loss in 15 cycles is only 2.1% | [166] |

| Adsorption of CV dye | Polylactic acid/chitosan/GO | 3D bionic | Removal efficiency (97.8 ± 0.5% for crystal violet (CV)) | [78] |

| Bubble filtration | Cellulose/PVA | — | — | [174] |

| Filter monodisperse suspensions, didisperse suspensions, and yeast cells | Fluorescent polystyrene particles | — | Maximum filtration efficiencies of 96.08% and 97.14% for 10 and 15 μm particles | [175] |

| Filtration | Poplar wood/SiO micron particles | — | Filtration efficiency of 89.81% for PM > 2.5 μm (PM2.5) under an extremely low pressure drop (0.69 kPa) | [176] |

| Air filtration | Polyphenylene sulfide/ZIF-8 | Hierarchically lotus leaf papillary structure | Air filtration performance to PM2.5 with a high efficiency of 99.5% | [177] |

| Gas separation | Triptycene/paraformaldehyde | Membrane | CO2 permeability of 6205 barrer | [179] |

| Gas adsorption | The stem of water convolvulus/MgO/TiO2 | 3D hierarchical architecture | Efficient photo-conversion of CO2 into CH4 | [180] |

| CO2 separation | Polydimethylsiloxane/zirconium (IV) chloride | Membrane | CO2 permeance of 7.39 mL cm−2 min−1 bar−1, selectivity of CO2/O2 of 11.19 | [181] |

| CO2 separation | Hydroxypropyl-β-cyclodextrin/polyamide/3,3′-Diamino-N-methyldipropylamine | Membrane | CO2 permeance and CO2/N2 selectivity could reach 2792 GPU and 171 | [182] |

| Sound absorbers | Poly (vinylidene fluoride-co-hexafluoropropylene) | Layered microstructure | — | [189] |

| Sound absorption | Acrylonitrile butadiene styrene plastic filament | Biomimetic coupling structure | Up to a 25–35% increase in the average absorption, 95% broader working bandwidth | [192] |

| Sound absorption | Wenext 8100 resins | Conch-imitating cavity structure | Realize the broadband absorption of over 68.7% at frequencies below 3000 Hz; the first sound absorption peak at around 920 Hz exceeds 0.99 | [193] |

| Sound absorption | Pine/phenolic resin | Composite biomimetic wood porous structures | Minimum absorption coefficient of 0.234 across the entire frequency spectrum | [195] |

| Sound absorption | Turtle shell-inspired multifunctional lattice | Multifunctional lattice | Average sound absorption coefficients reaching 0.88 and 0.93 within the frequency ranges of 300–600 Hz and 500–1000 Hz | [196] |

| Desalination | Cellulose, lightweight material | Bionic tree roots | Daily freshwater yield reached 1.5 kg/m2/d | [201] |

| Saline/seawater treatment | Polyvinyl alcohol (PVA), photothermal polypyrrole(ppy) | Leaf-inspired 3D material structure | Solar vapor generation rate of 3.09 kg m−2 h−1 with a solar–thermal conversion efficiency of up to 98% | [204] |

| Desalination | Graphene oxide (GO)/PVA | Bionic mushroom | Evaporation rate of 1.67 kg m−2h−1 | [205] |

| Desalination | Alginate fibers/ppy | — | Maximum evaporation rate of 4.27 kg m−2h−1 with an energy efficiency of more than 99% | [206] |

| Desalination | Ppy | Macro/micro bubbles and nanotube asymmetric structures | Full-spectrum light absorption of 96.3% and high evaporation rate of 2.03 kg m−2 h−1 under 1 sun | [207] |

| Desalination | Carbon cloth/PVA-phytic acid | — | Evaporation rate of 3.190 kg m−2h−1 and an efficiency of 94.1% in pure water | [208] |

| Desalination | Carbon nanofibers/zeolitic imidazolate framework (ZIF-8) | 3D biomimetic architectures | Evaporation rate of 3.23 kg m−2 h−1, energy conversion efficiency of 153.20% | [209] |

| Energy storage | Fe3O4/liquid paraffin wax | Biomimetic porous structure | Maximum storage efficiency of the biomimetic phase-change materials increased by 56.3% compared to that of the based materials | [222] |

| Energy storage | Aluminum nitride/polyethylene glycol 2000 | Bionic hierarchical porous | The thermal conductivity of 17.16 m−1·K−1 | [225] |

| Thermal energy storage | N-octadecane | Biomimetically calabash-inspired | — | [227] |

| Thermal energy storage | Phase-change material | Biomimetic leaf hierarchical porous structure | — | [234] |

| Phase-change thermal storage | α-SiC powders/Al2O3/Y2O3 | Vertical tree-ring porous structure | Thermal conductivity of 12.54 W·m−1·K−1, photo-thermal storage efficiency of 91.8% | [236] |

| Thermal insulation | Siloxane resins | Imitate the hierarchical structure of cuttlebones | Low thermal conductivity of 0.12 W/(m·K) at room temperature. After being exposed to a preset temperature of 800 °C for 1200 s, the back surface temperature was 179.5 °C | [242] |

| Thermal insulation | Polyurethane foam/silicone tube/shear thickening fluid/carbon nanotubes | Bionic hierarchical porous | Thermal conductivity is less than 0.1 W/m·K | [243] |

| Thermal insulation | MgO/MgCl2·6H2O/vinyl acetate/ethylene | Biomimetic swallow nest structure | Thermal conductivity lower than 0.12 W/m·K | [244] |

| Thermal insulation | SiO2 nanofibrous nonwoven fabric/silica sol/SiC whiskers/agr powder | Silica sol | Thermal conductivity of 0.0232–0.0643 W·m−1·k−1 between −50 and 800 °C | [245] |

| Thermal insulation | Silica/chitosan/zirconia | Leaf-inspired biomimetic aerogels | Ultralow thermal conductivity of 0.030 W m−1 K−1 | [246] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, Q.; Yang, Y.; Liang, F.; Wang, G.; Han, X.; Zang, C.; Ge, M. Recent Advances in Biomimetic Porous Materials for Real-World Applications. Biomimetics 2025, 10, 521. https://doi.org/10.3390/biomimetics10080521

Qiu Q, Yang Y, Liang F, Wang G, Han X, Zang C, Ge M. Recent Advances in Biomimetic Porous Materials for Real-World Applications. Biomimetics. 2025; 10(8):521. https://doi.org/10.3390/biomimetics10080521

Chicago/Turabian StyleQiu, Qunren, Yi Yang, Fanghua Liang, Gang Wang, Xuelong Han, Chuanfeng Zang, and Mingzheng Ge. 2025. "Recent Advances in Biomimetic Porous Materials for Real-World Applications" Biomimetics 10, no. 8: 521. https://doi.org/10.3390/biomimetics10080521

APA StyleQiu, Q., Yang, Y., Liang, F., Wang, G., Han, X., Zang, C., & Ge, M. (2025). Recent Advances in Biomimetic Porous Materials for Real-World Applications. Biomimetics, 10(8), 521. https://doi.org/10.3390/biomimetics10080521