Exploiting Arch-like Foot Structure for Knee-Extended Walking in Bipedal Robots

Abstract

1. Introduction

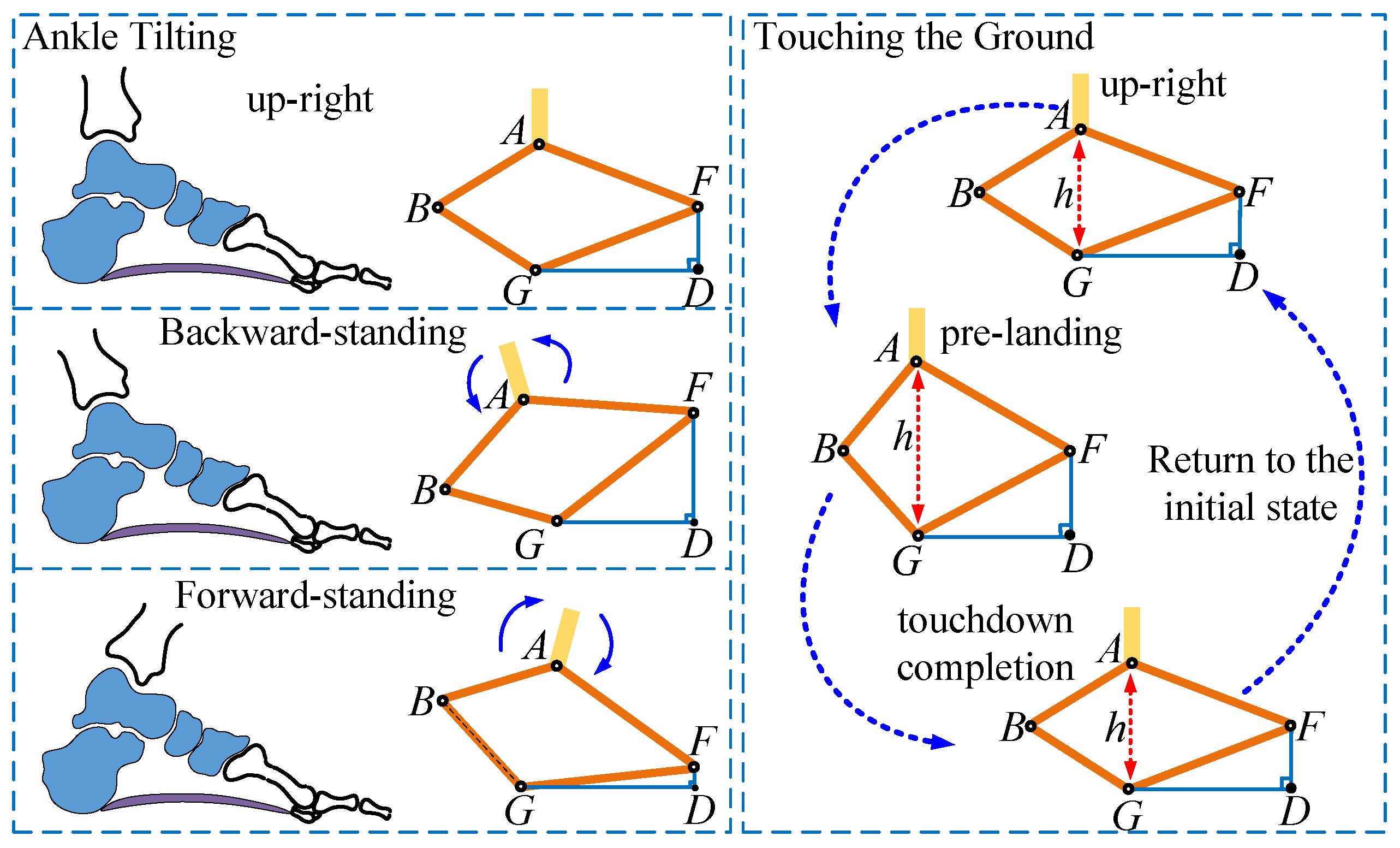

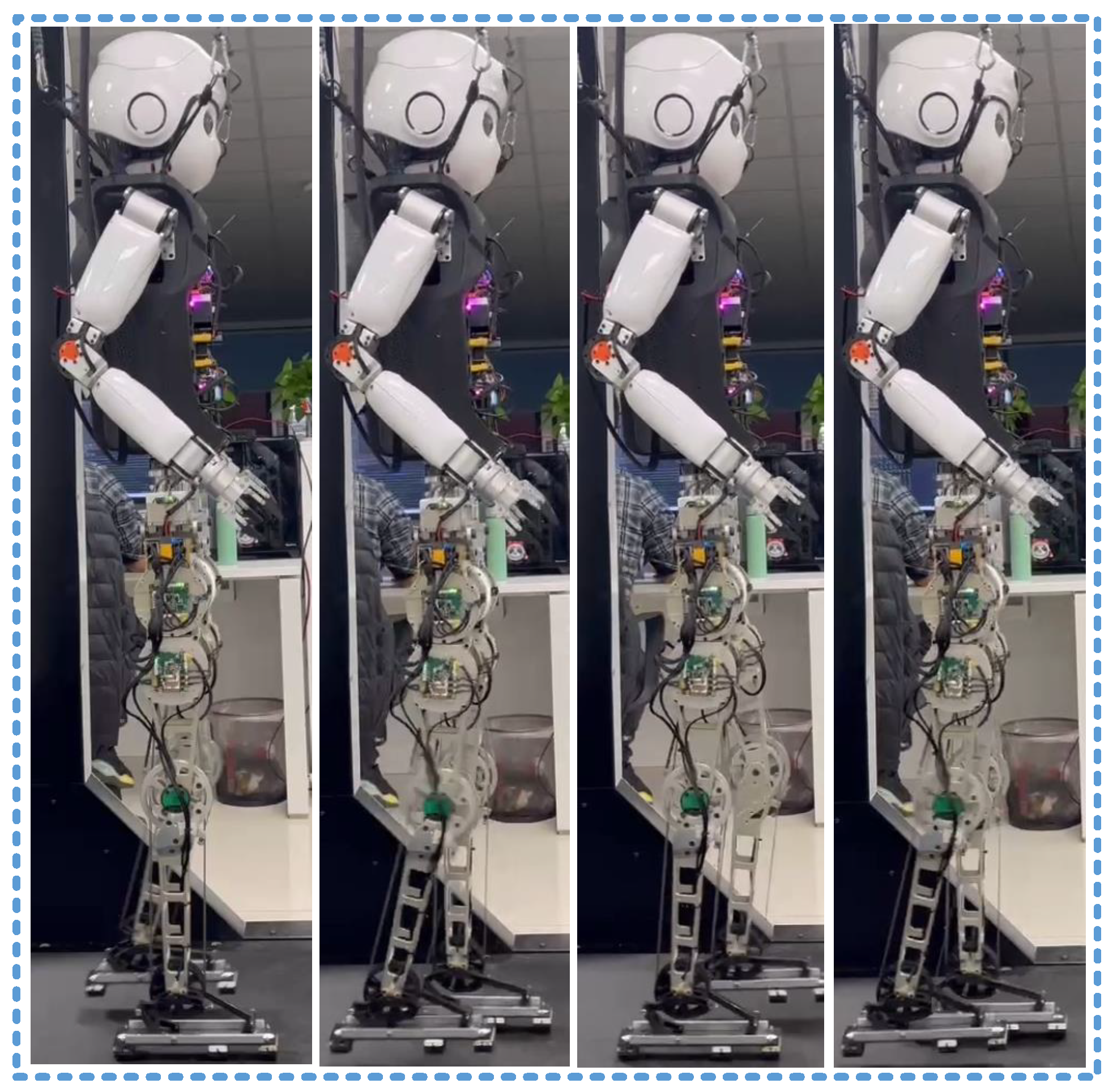

2. Novel Cable-Driven Mechanism for Bipedal Robots

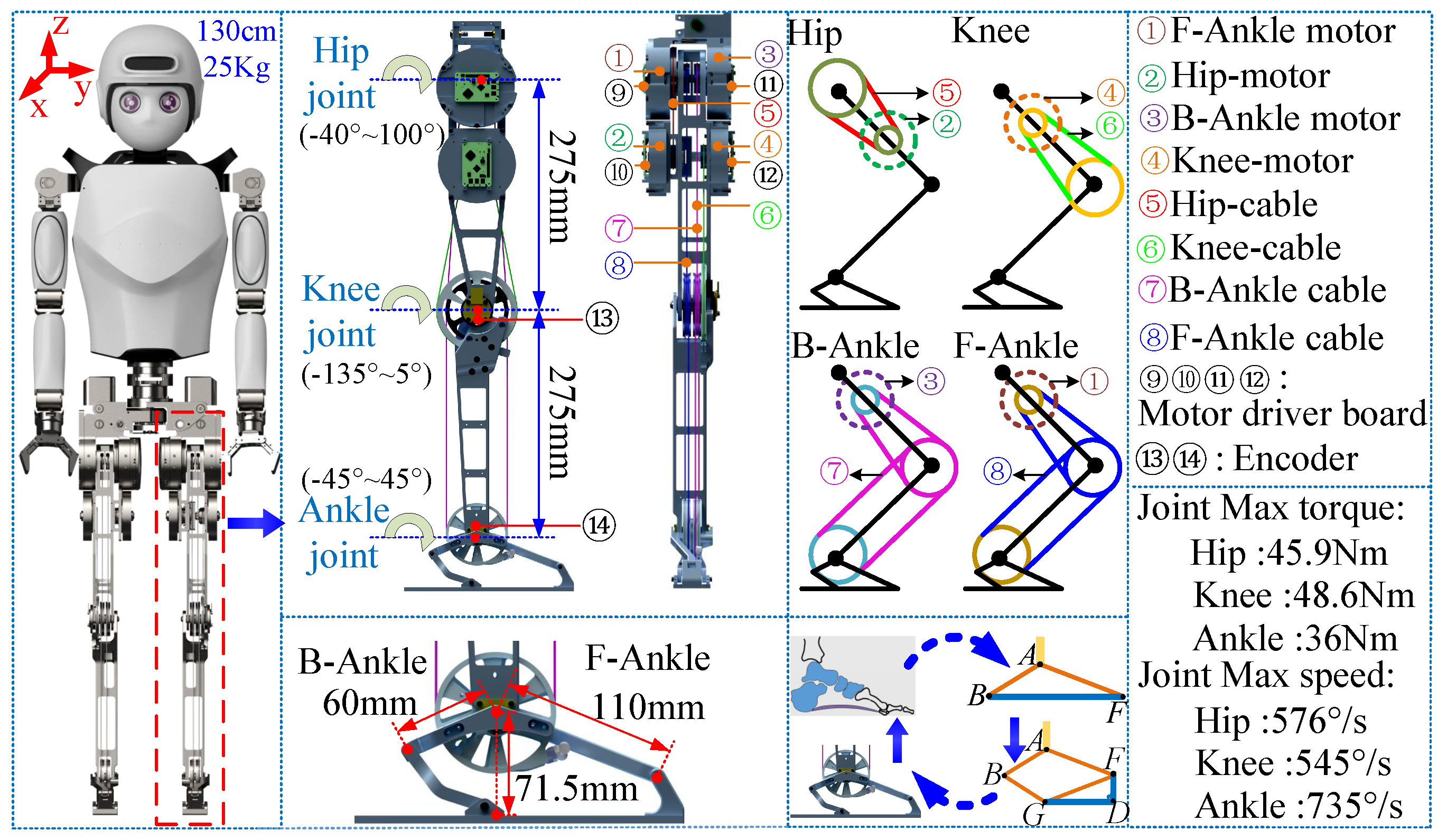

2.1. Mechanism Description for Robot

2.2. Hardware Description

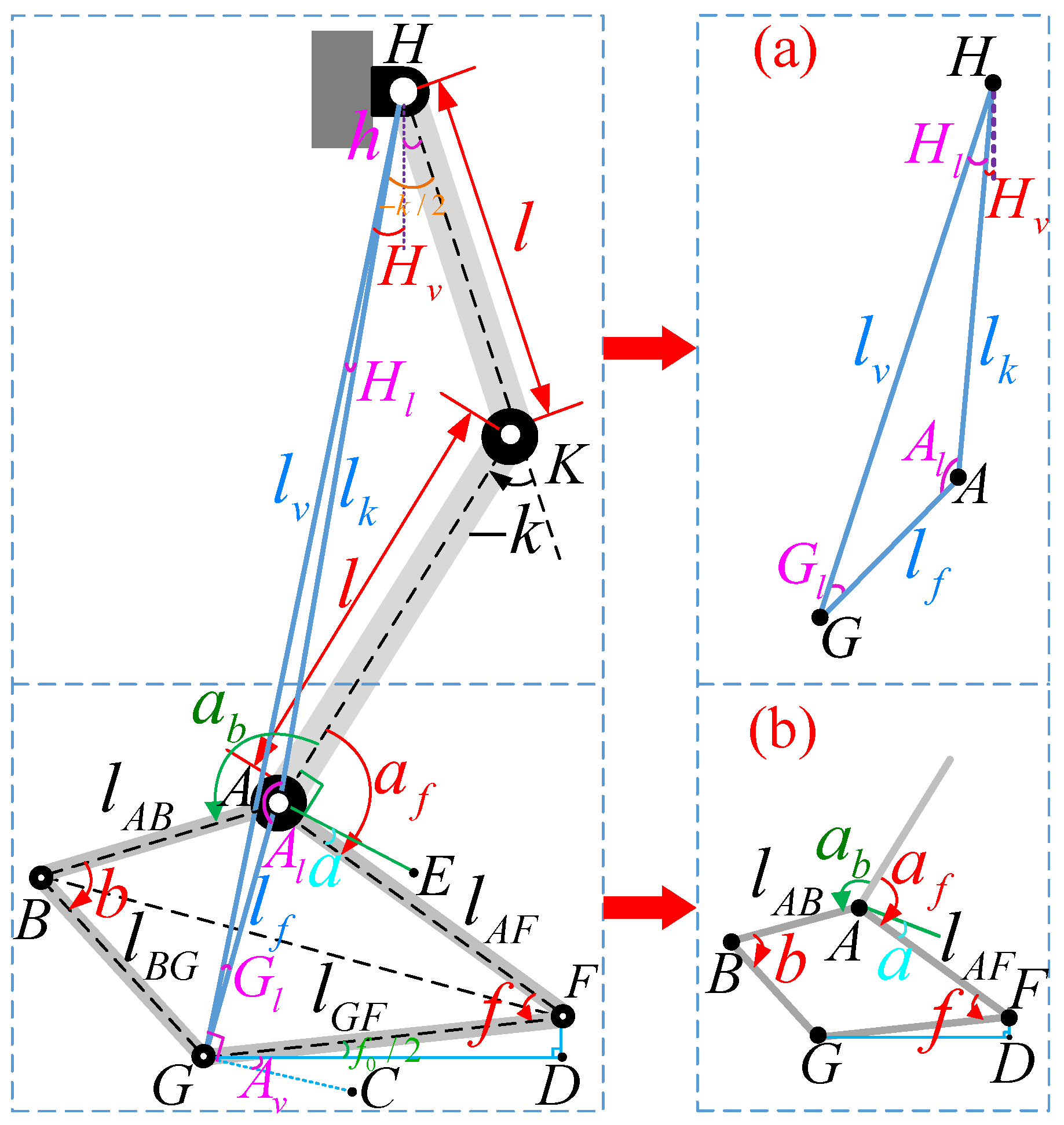

2.3. Kinematics Analysis

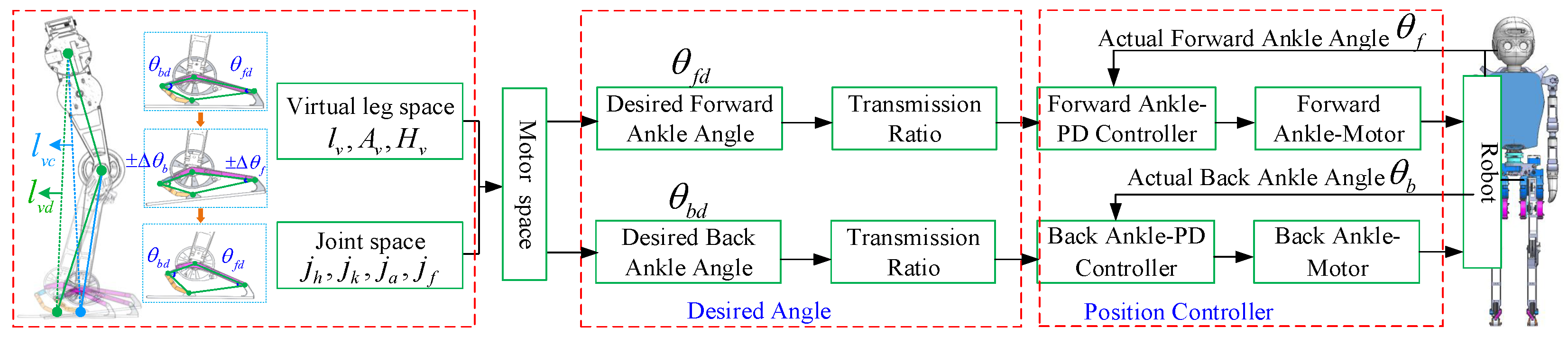

3. Compliance Control Strategy Based on the Biomechanics of Arch Structure

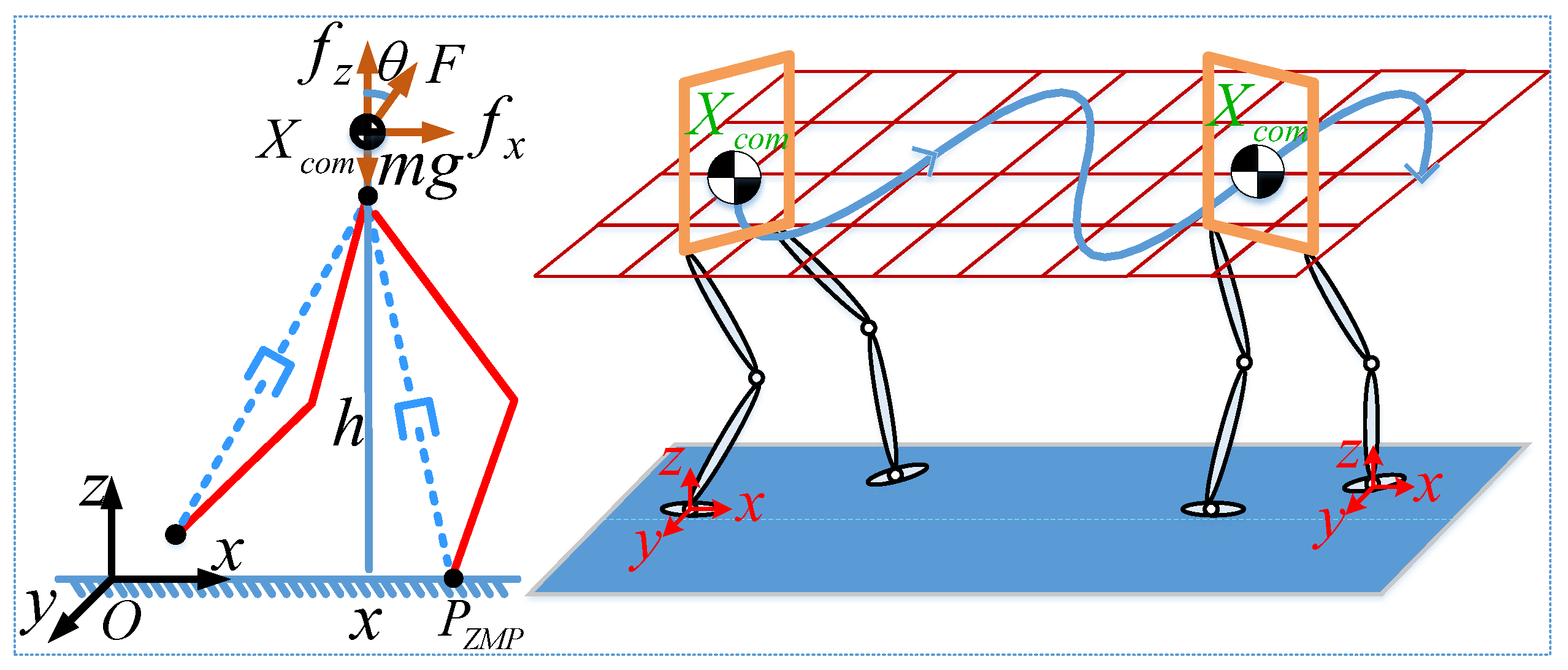

4. Pattern Generation Based on ILIPM

4.1. Steady-State Control Model of COM

4.2. Error Correction for DCM

5. Results

5.1. Virtual Leg Compliance Control

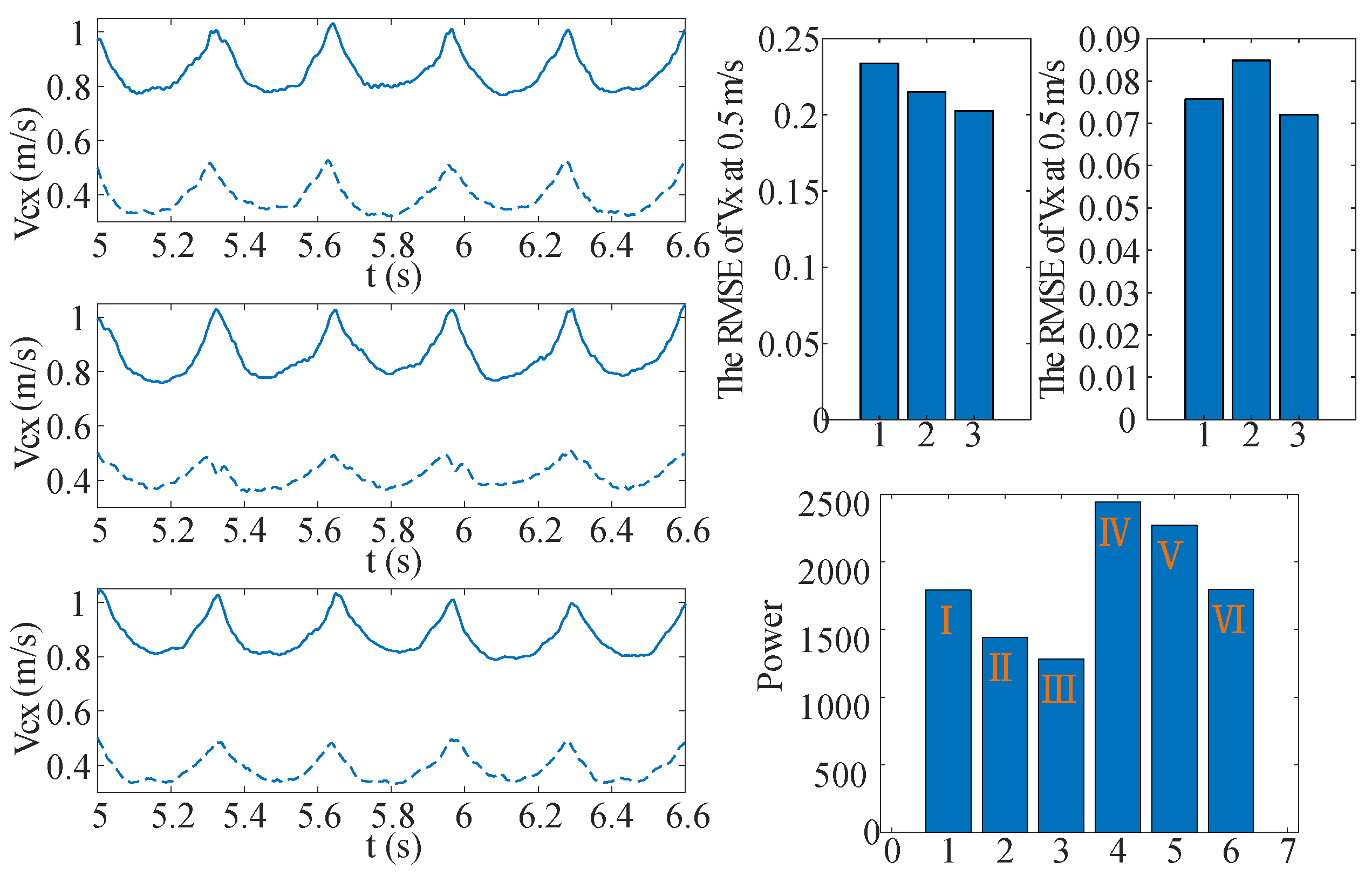

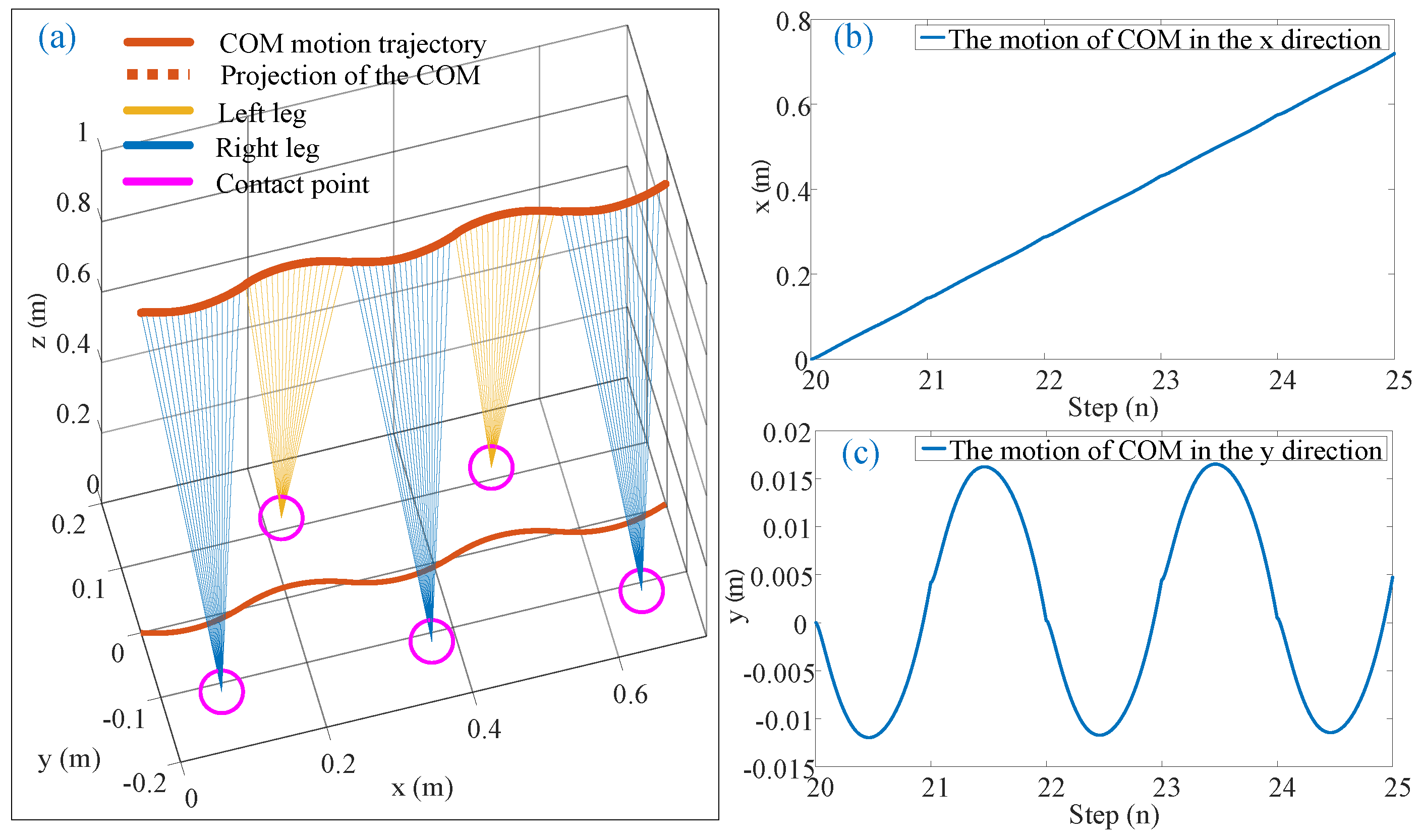

5.2. Walking Experiment of ILIPM

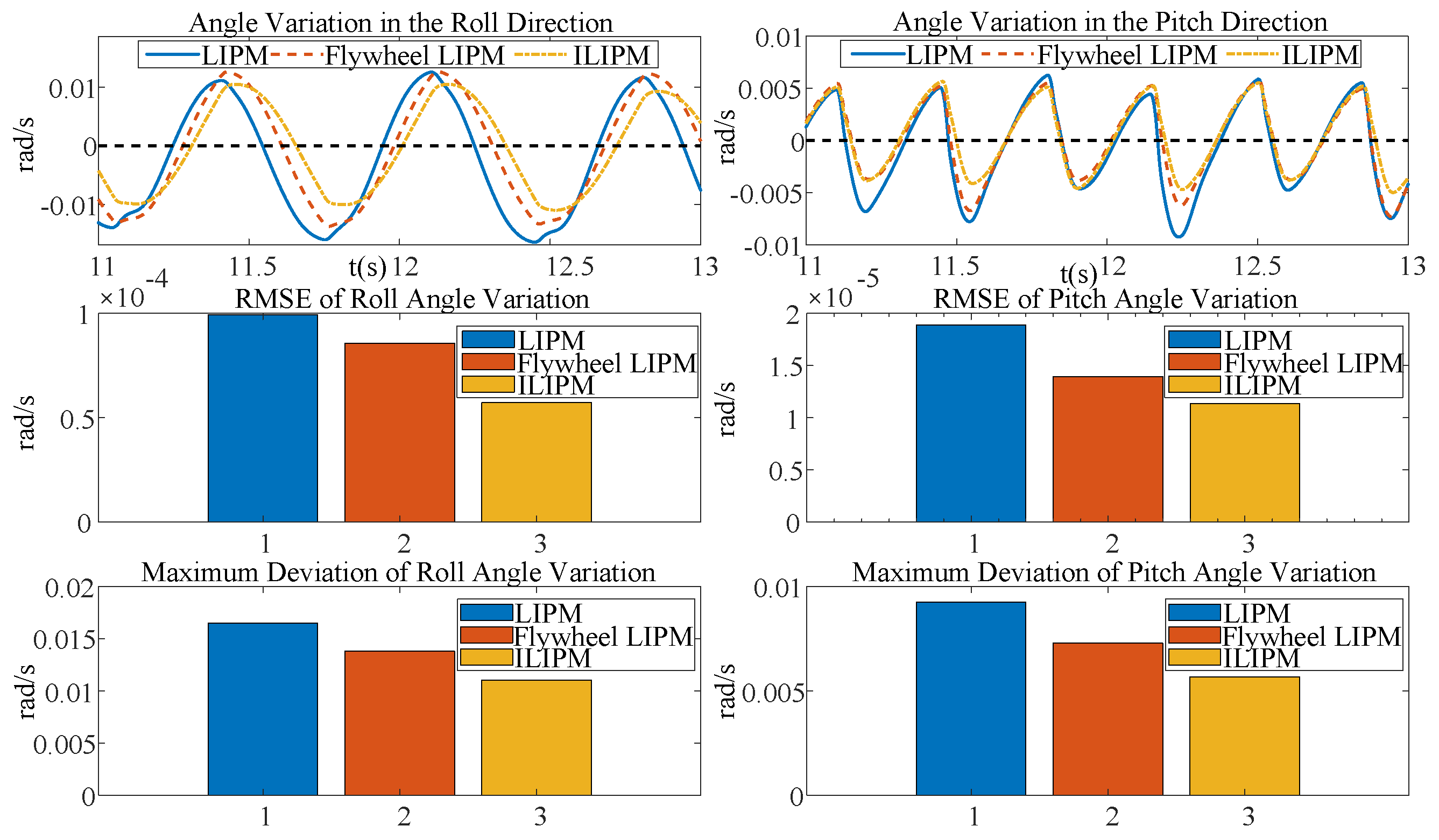

5.3. Comparison of LIPM, Flywheel LIPM, and ILIPM

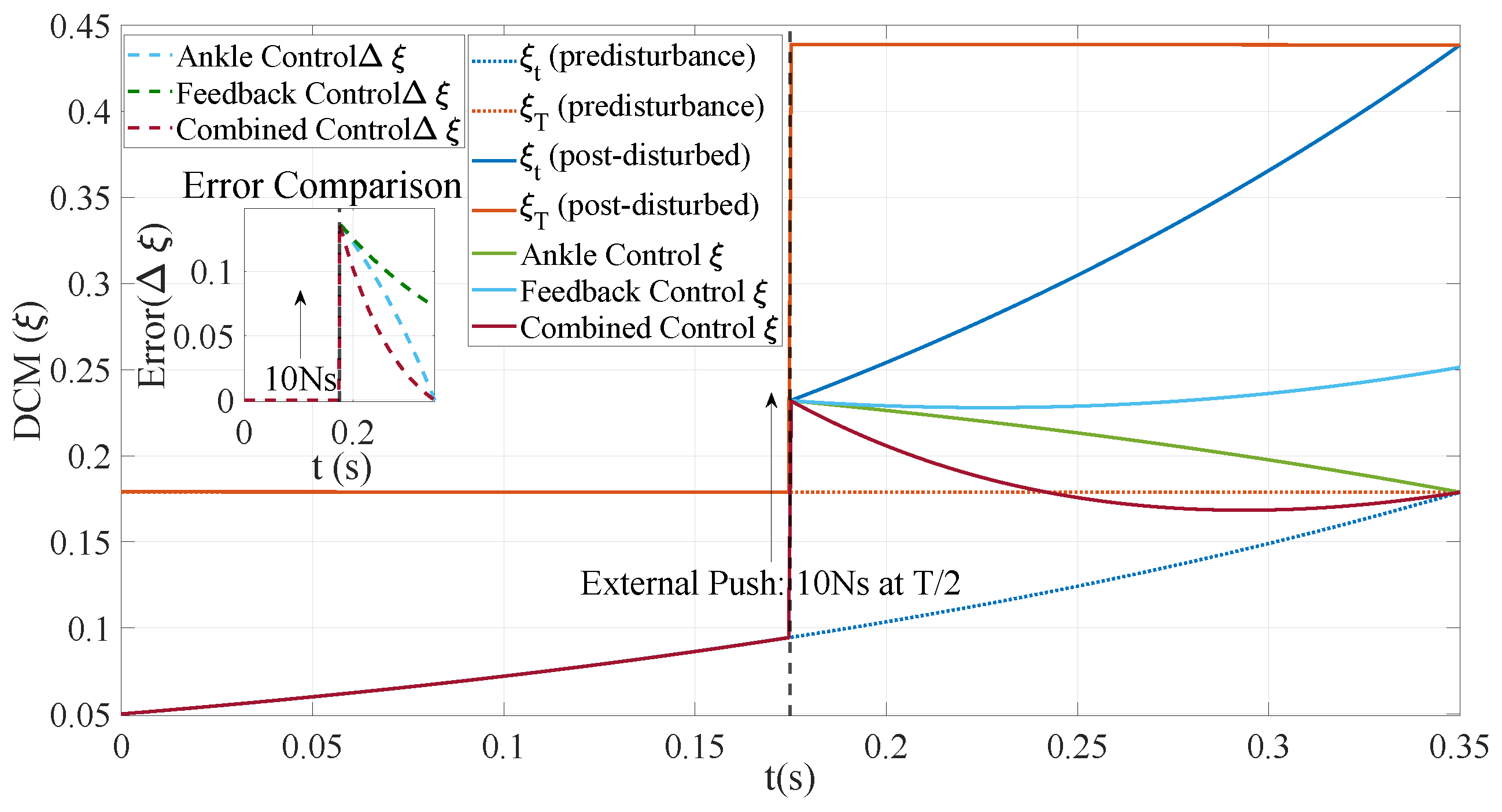

5.4. Ankle Joint Control: Assessing Disturbance Resistance

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, H.; Thomas, U. An Enhanced Walking Pattern Generator with Variable Height for Robot Locomotion. In Proceedings of the 2023 IEEE 19th International Conference on Automation Science and Engineering (CASE), Auckland, New Zealand, 26–30 August 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–7. [Google Scholar]

- Ezati, M.; Khadiv, M.; Moosavian, S.A.A. Effects of toe-off and heel-off motions on gait performance of biped robots. In Proceedings of the 2015 3rd RSI international conference on robotics and mechatronics (ICROM), Tehran, Iran, 7–9 October 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 7–12. [Google Scholar]

- Miura, K.; Morisawa, M.; Kanehiro, F.; Kajita, S.; Kaneko, K.; Yokoi, K. Human-like walking with toe supporting for humanoids. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 4428–4435. [Google Scholar]

- Ogura, Y.; Shimomura, K.; Kondo, H.; Morishima, A.; Okubo, T.; Momoki, S.; Lim, H.o.; Takanishi, A. Human-like walking with knee stretched, heel-contact and toe-off motion by a humanoid robot. In Proceedings of the 2006 IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, China, 9–13 October 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 3976–3981. [Google Scholar]

- Park, B.; Park, J. Heel-strike and toe-off walking of humanoid robot using quadratic programming considering the foot contact states. Robot. Auton. Syst. 2023, 163, 104396. [Google Scholar] [CrossRef]

- Kiss, B.; Gonen, E.C.; Mo, A.; Badri-Spröwitz, A.; Buchmann, A.; Renjewski, D. Gastrocnemius and power amplifier soleus spring-tendons achieve fast human-like walking in a bipedal robot. In Proceedings of the 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 23–27 October 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 5202–5209. [Google Scholar]

- Yoon, J.; Kim, G.; Handharu, N.; Özer, A. A Bio-Robotic Toe & Foot & Heel Model of a Biped Robot for More Natural Walking: Foot Mechanism & Gait Pattern; InTechOpen: Houston, TX, USA, 2011; pp. 237–260. [Google Scholar]

- Huang, Z.; Yu, Z.; Chen, X.; Li, Q.; Meng, L.; Dong, C.; Meng, X.; Liao, W.; Huang, Q. Knee-stretched walking with toe-off and heel-strike for a position-controlled humanoid robot based on model predictive control. Int. J. Adv. Robot. Syst. 2021, 18, 17298814211036282. [Google Scholar] [CrossRef]

- Geyer, H.; Seyfarth, A.; Blickhan, R. Compliant leg behaviour explains basic dynamics of walking and running. Proc. R. Soc. Biol. Sci. 2006, 273, 2861–2867. [Google Scholar] [CrossRef]

- Pratt, J.; Chee-Meng, C.; Ann, T.; Peter, D.; Gill, P. Virtual Model Control: An Intuitive Approach for Bipedal Locomotion. Int. J. Robot. Res. 2001, 20, 129–143. [Google Scholar] [CrossRef]

- Minami, Y.; Kryczka, P.; Hashimoto, K.; Lim, H.O.; Takanishi, A. Heel-contact toe-off walking model based on the linear inverted pendulum. In Proceedings of the 5th IEEE RAS/EMBS International Conference on Biomedical Robotics and Biomechatronics, Sao Paulo, Brazil, 12–15 August 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 221–226. [Google Scholar]

- Yi, S.J.; Lee, D.D. Dynamic heel-strike toe-off walking controller for full-size modular humanoid robots. In Proceedings of the 2016 IEEE-RAS 16th International Conference on Humanoid Robots (Humanoids), Cancun, Mexico, 15–17 November 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 395–400. [Google Scholar]

- Wu, Y.; Pan, Y.; Leng, X.; He, Z. Kid-size robot humanoid walking with heel-contact and toe-off motion. PeerJ Comput. Sci. 2022, 7, e797. [Google Scholar] [CrossRef]

- Oda, N.; Yanada, O. Motion controller design of biped robot for human-like walking with stretched knee. In Proceedings of the IECON 2012-38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 5434–5439. [Google Scholar]

- Catalano, M.G.; Frizza, I.; Morandi, C.; Grioli, G.; Ayusawa, K.; Ito, T.; Venture, G. HRP-4 Walks on Soft Feet. IEEE Robot. Autom. Lett. 2021, 6, 470–477. [Google Scholar] [CrossRef]

- Li, T.; Shangguan, W.B.; Yin, Z. Error analysis of inertia parameters measurement for irregular-shaped rigid bodies using suspended trifilar pendulum. Measurement 2021, 174, 108956. [Google Scholar] [CrossRef]

- Lee, J.; Joe, H.M. Design of Humanoid Robot Foot to Absorb Ground Reaction Force by Mimicking Longitudinal Arch and Transverse Arch of Human Foot. Int. J. Control. Autom. Syst. 2023, 21, 3519–3527. [Google Scholar] [CrossRef]

- Aboufazeli, M.; Samare Filsoofi, A.; Gurney, J.; Meek, S.G.; Mathews, V.J. An online learning algorithm for adapting leg stiffness and stride angle for efficient quadruped robot trotting. Front. Robot. AI 2023, 10, 1127898. [Google Scholar] [CrossRef]

- Choi, J.; Chun, Y.; Min, I.; Ahn, M.S.; Han, J. The Study on the Energy Efficiency of the Bipedal-Walking Pattern of a Humanoid Robot Using Four-Bar-Linkage Toe Joints. In Proceedings of the 2023 20th International Conference on Ubiquitous Robots (UR), Honolulu, HI, USA, 25–28 June 2023; pp. 108–114. [Google Scholar]

- Collins, S.; Ruina, A. A Bipedal Walking Robot with Efficient and Human-Like Gait. In Proceedings of the 2005 IEEE International Conference on Robotics and Automation, Barcelona, Spain, 18–22 April 2005; pp. 1983–1988. [Google Scholar]

- Gan, W.; Liu, J.; Tang, J.; Xu, W.; Zhu, Y.; Li, Q. Walking Control of Telescopic Leg Bipedal Robot Based on Angular Momentum Predictive Foothold. In Proceedings of the 2023 IEEE International Conference on Robotics and Biomimetics (ROBIO), Koh Samui, Thailand, 4–9 December 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- Kajita, S.; Tani, K. Study of dynamic biped locomotion on rugged terrain-derivation and application of the linear inverted pendulum mode. In Proceedings of the 1991 IEEE International Conference on Robotics and Automation, Sacramento, CA, USA, 9–11 April 1991; IEEE Computer Society: Washington, DC, USA, 1991; pp. 1405–1406. [Google Scholar]

- Marion, J.B. Classical Dynamics of Particles and Systems; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Townsend, M.A. Dynamics and coordination of torso motions in human locomotion. J. Biomech. 1981, 14, 727–738. [Google Scholar] [CrossRef] [PubMed]

- Englsberger, J.; Ott, C.; Albu-Schäffer, A. Three-Dimensional Bipedal Walking Control Based on Divergent Component of Motion. IEEE Trans. Robot. 2015, 31, 355–368. [Google Scholar] [CrossRef]

- Pratt, J.; Carff, J.; Drakunov, S.; Goswami, A. Capture Point: A Step toward Humanoid Push Recovery. In Proceedings of the 2006 6th IEEE-RAS International Conference on Humanoid Robots, Genova, Italy, 4–6 December 2006; pp. 200–207. [Google Scholar]

- Mesesan, G.; Englsberger, J.; Ott, C.; Albu-Schäffer, A. Convex properties of center-of-mass trajectories for locomotion based on divergent component of motion. IEEE Robot. Autom. Lett. 2018, 3, 3449–3456. [Google Scholar] [CrossRef]

- Shafiee-Ashtiani, M.; Yousefi-Koma, A.; Shariat-Panahi, M. Robust bipedal locomotion control based on model predictive control and divergent component of motion. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 3505–3510. [Google Scholar]

- Jeong, H.; Lee, I.; Oh, J.; Lee, K.K.; Oh, J.H. A Robust Walking Controller Based on Online Optimization of Ankle, Hip, and Stepping Strategies. IEEE Trans. Robot. 2019, 35, 1367–1386. [Google Scholar] [CrossRef]

- Caron, S. Biped Stabilization by Linear Feedback of the Variable-Height Inverted Pendulum Model. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 9782–9788. [Google Scholar]

- Tang, J.; Zhu, Y.; Gan, W.; Mou, H.; Leng, J.; Li, Q.; Yu, Z.; Zhang, J. Design, Control, and Validation of a Symmetrical Hip and Straight-Legged Vertically-Compliant Bipedal Robot. Biomimetics 2023, 8, 340. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Zhang, Y.; Zuo, G.; Ruan, X.; Wu, P. Humanoid Robot Gait Imitation Based on ZMP Criterion. J. Beijing Univ. Technol. 2018, 44, 1187–1192. [Google Scholar]

- Masoumeh, S.; Morteza, D.; Hamidreza, M.D. Gait cycles of passive walking biped robot model with flexible legs. Mech. Mach. Theory 2021, 159, 104292. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Liang, Z.; Tang, J.; Hou, Y.; Li, Q.; Zhang, J. Exploiting Arch-like Foot Structure for Knee-Extended Walking in Bipedal Robots. Biomimetics 2025, 10, 96. https://doi.org/10.3390/biomimetics10020096

Zhu Y, Liang Z, Tang J, Hou Y, Li Q, Zhang J. Exploiting Arch-like Foot Structure for Knee-Extended Walking in Bipedal Robots. Biomimetics. 2025; 10(2):96. https://doi.org/10.3390/biomimetics10020096

Chicago/Turabian StyleZhu, Yudi, Zhiyuan Liang, Jun Tang, Yunfeng Hou, Qingdu Li, and Jianwei Zhang. 2025. "Exploiting Arch-like Foot Structure for Knee-Extended Walking in Bipedal Robots" Biomimetics 10, no. 2: 96. https://doi.org/10.3390/biomimetics10020096

APA StyleZhu, Y., Liang, Z., Tang, J., Hou, Y., Li, Q., & Zhang, J. (2025). Exploiting Arch-like Foot Structure for Knee-Extended Walking in Bipedal Robots. Biomimetics, 10(2), 96. https://doi.org/10.3390/biomimetics10020096