Composite Biomimetic Multi-Subsoiler for Drag Reduction and Wear Resistance Simulation and Experimental Validation

Abstract

1. Introduction

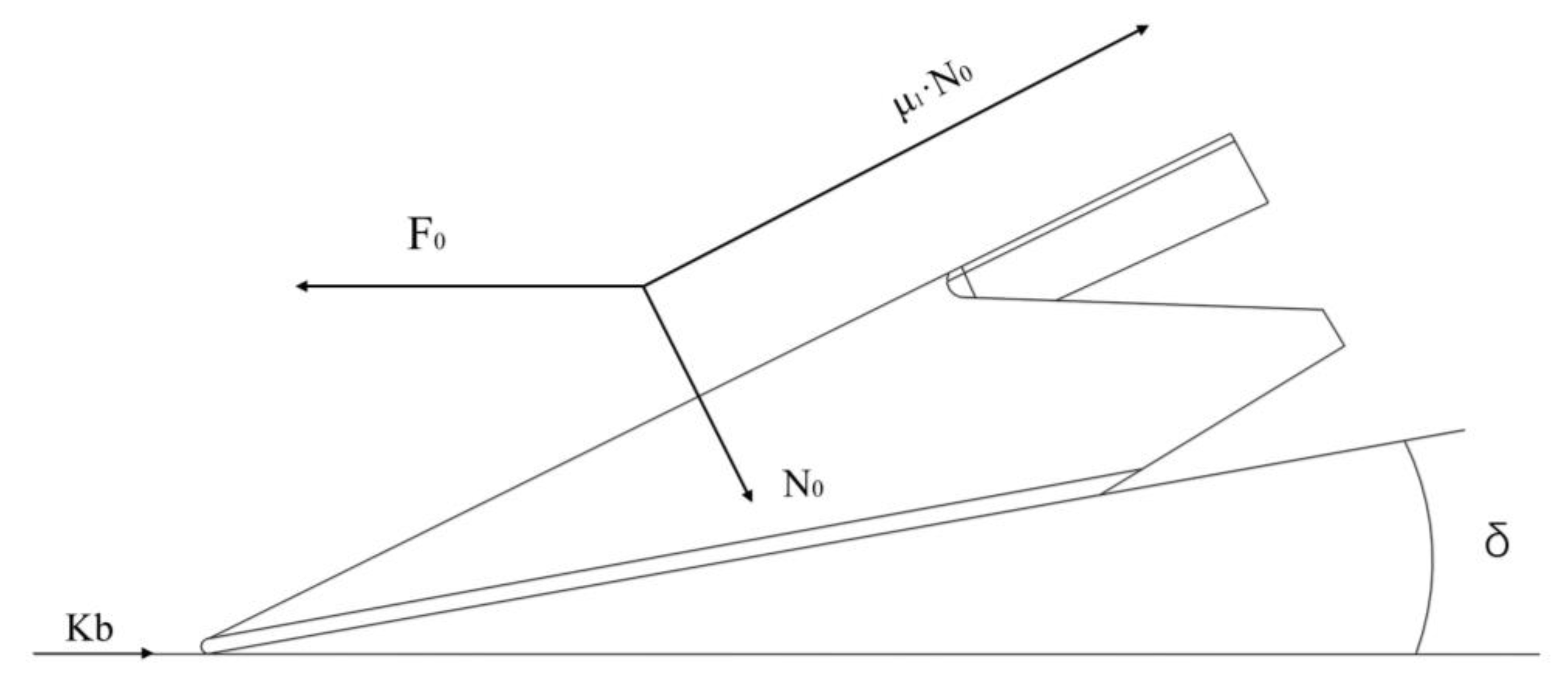

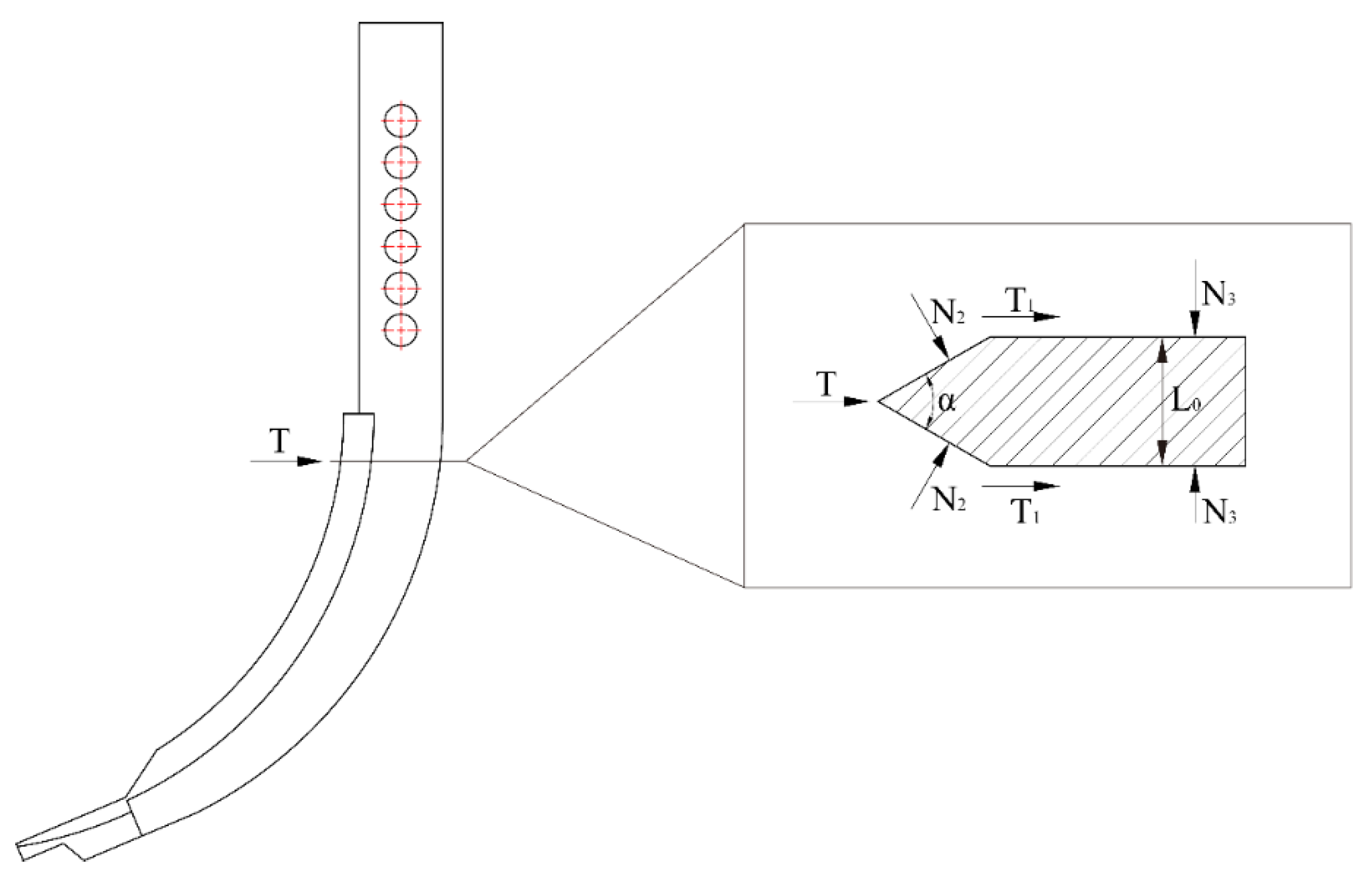

2. Design of the Bionic Geometric Structure Surface of the Subsoiler Tip

3. Modeling and Finite Element Analysis of the Bionic Subsoiler

4. Discrete Element Simulation of the Operation Process of the Bionic Multi-Subsoiler Implement

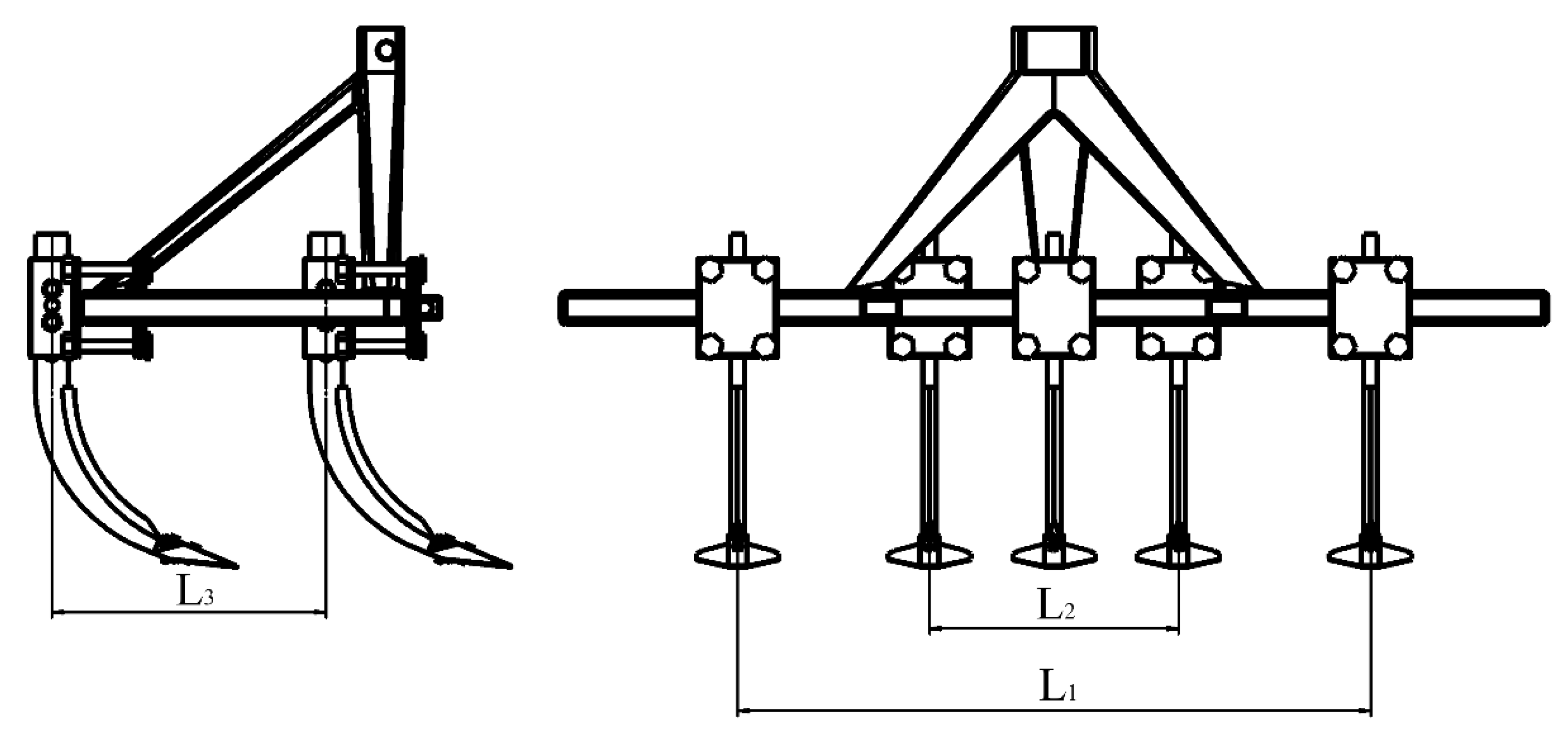

4.1. Establishment of a Subsoiling Implement Model

4.2. Establishment of a Soil Model

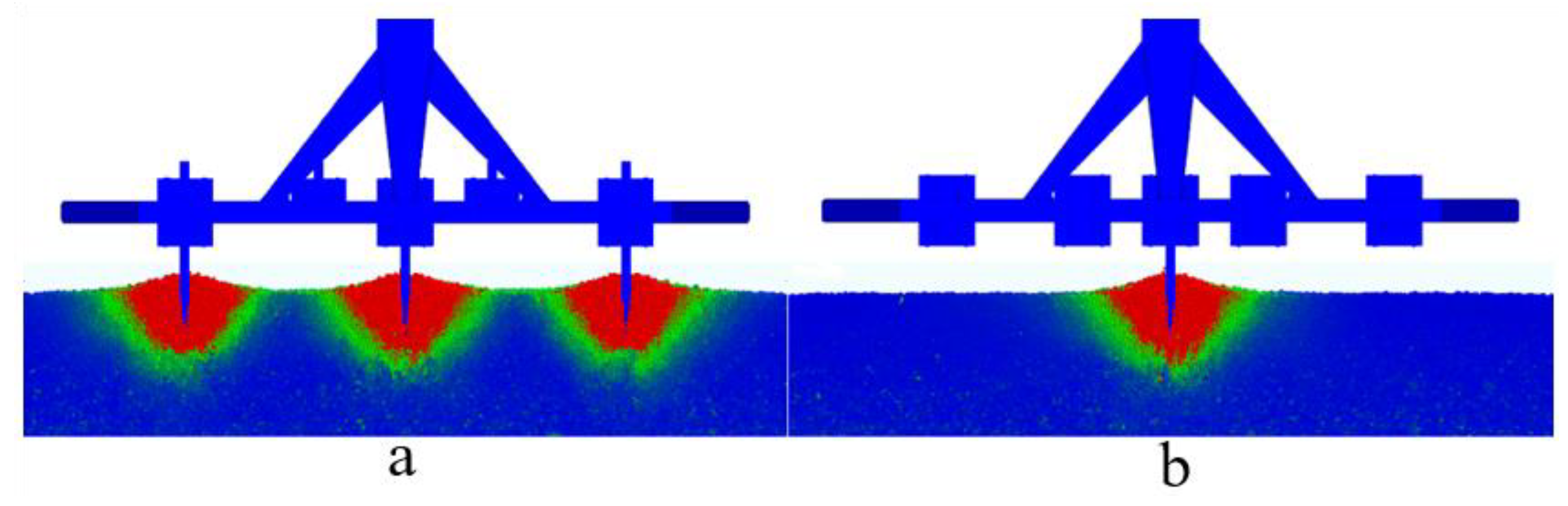

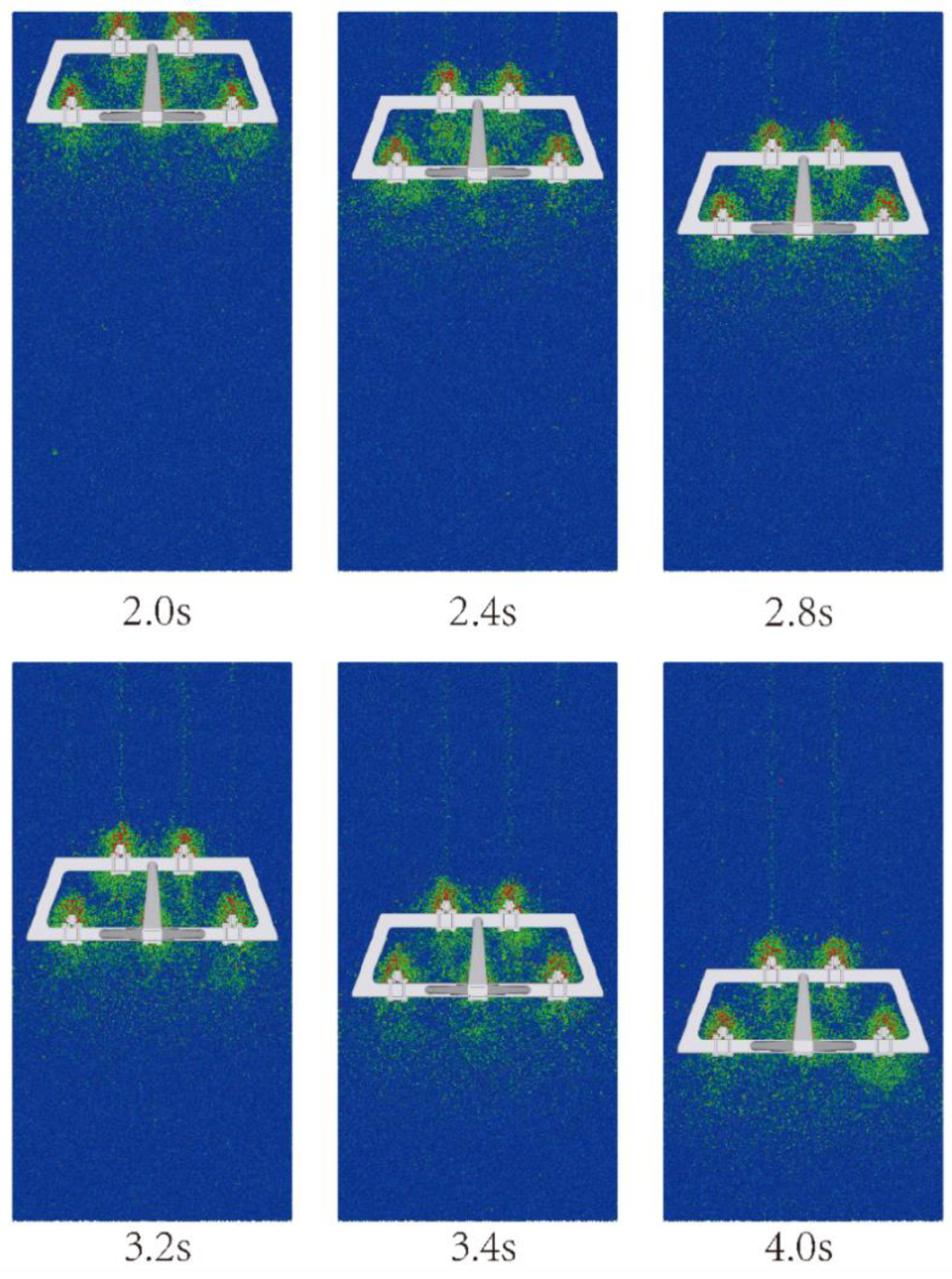

4.3. Establishment of the Discrete Element Models for the Interaction Between Single-Shovel and Multi-Subsoiler Implements and Soil

4.4. Discrete Element Simulation Experiment and Analysis

4.5. Performance and Wear Analysis of Various Subsoilers During Subsoiling Operations

4.6. Optimization of the Subsoiler Structure

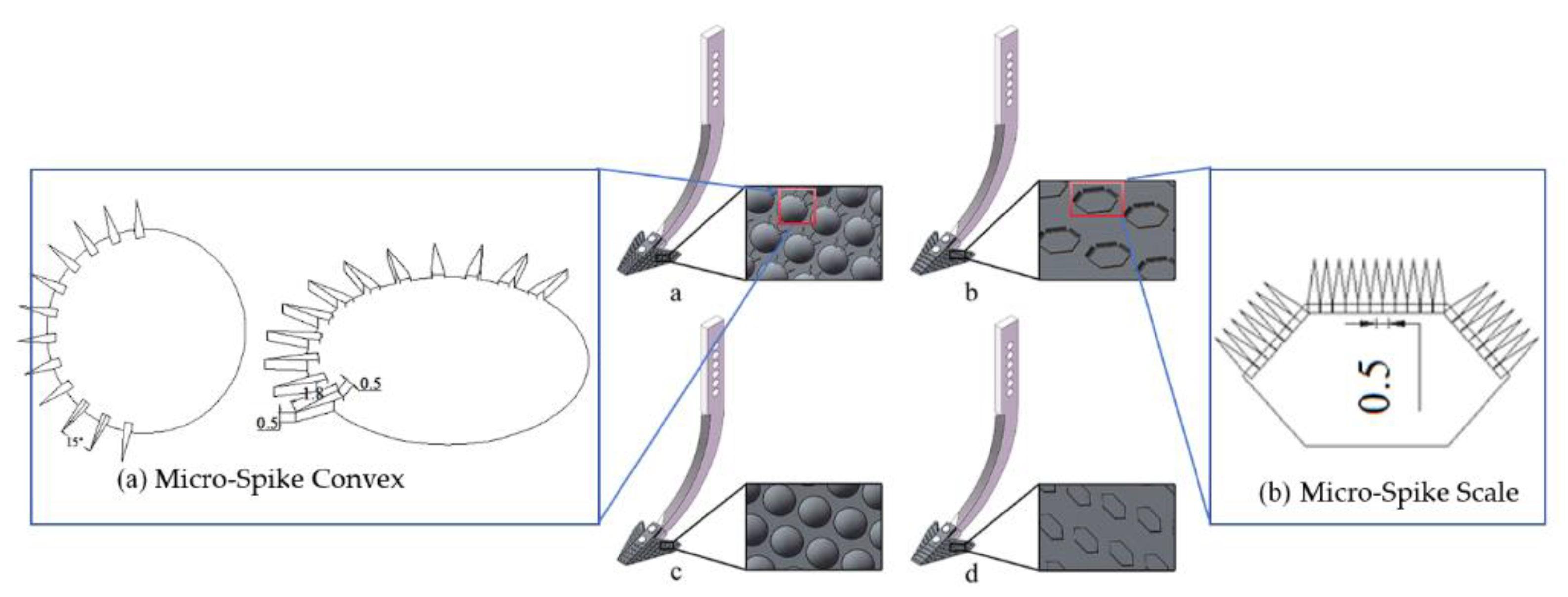

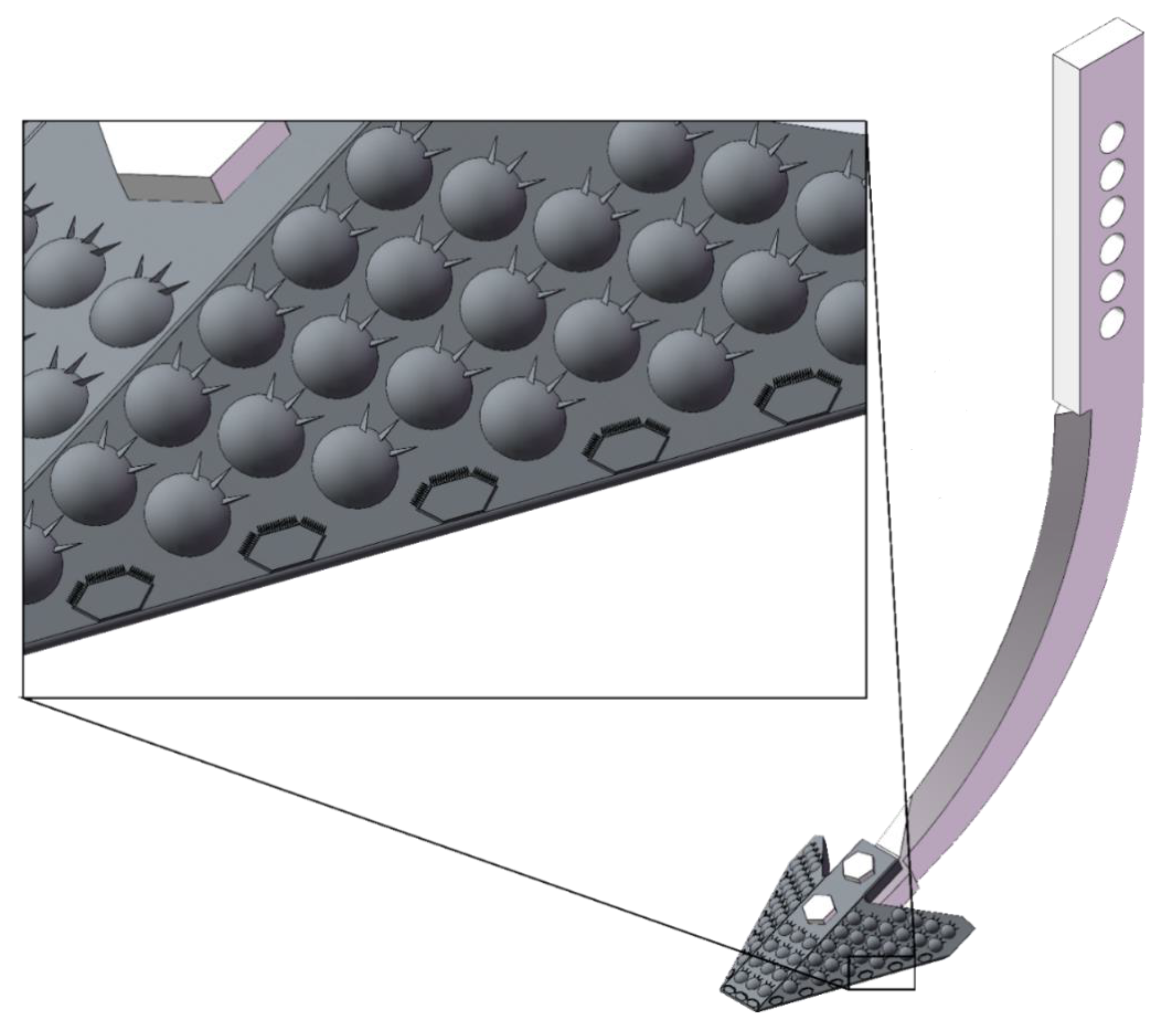

- For the establishment of the geometric model of the optimized subsoiler based on a detailed analysis of the wear conditions of various subsoilers during subsoiling operations, the original bionic micro-spike convex hull subsoiler was used as a foundation. By adjusting the arrangement of the micro-spike convex hulls and introducing a micro-spike scale structure, the new design features an equidistant arrangement on the edge corners of the shovel surface, with six on each side wing and three in the middle, as shown in Figure 11 and Figure 12. This adjustment aims to enhance the wear resistance performance of the subsoiler.

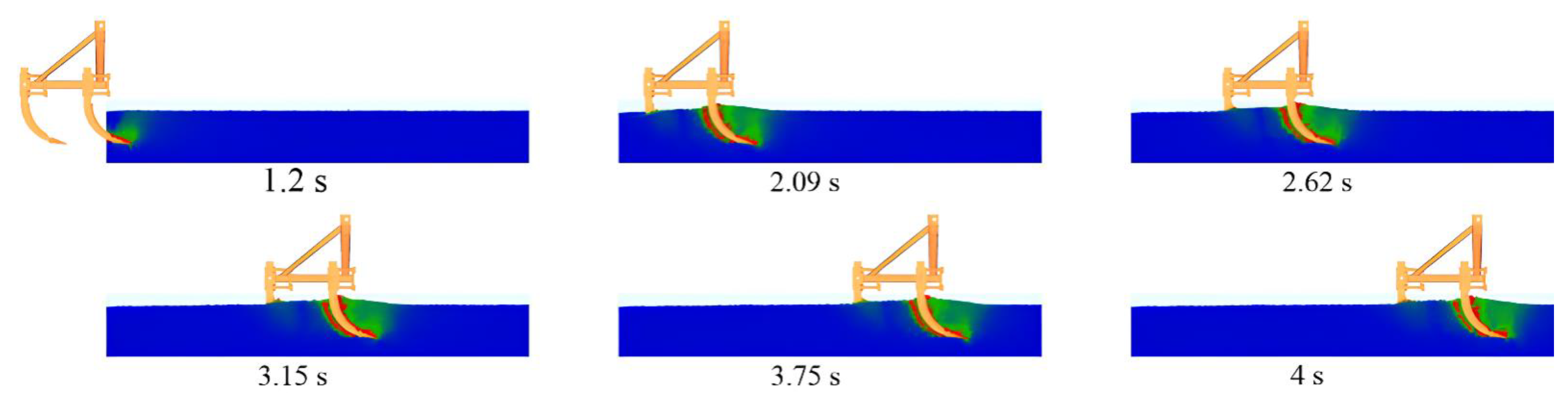

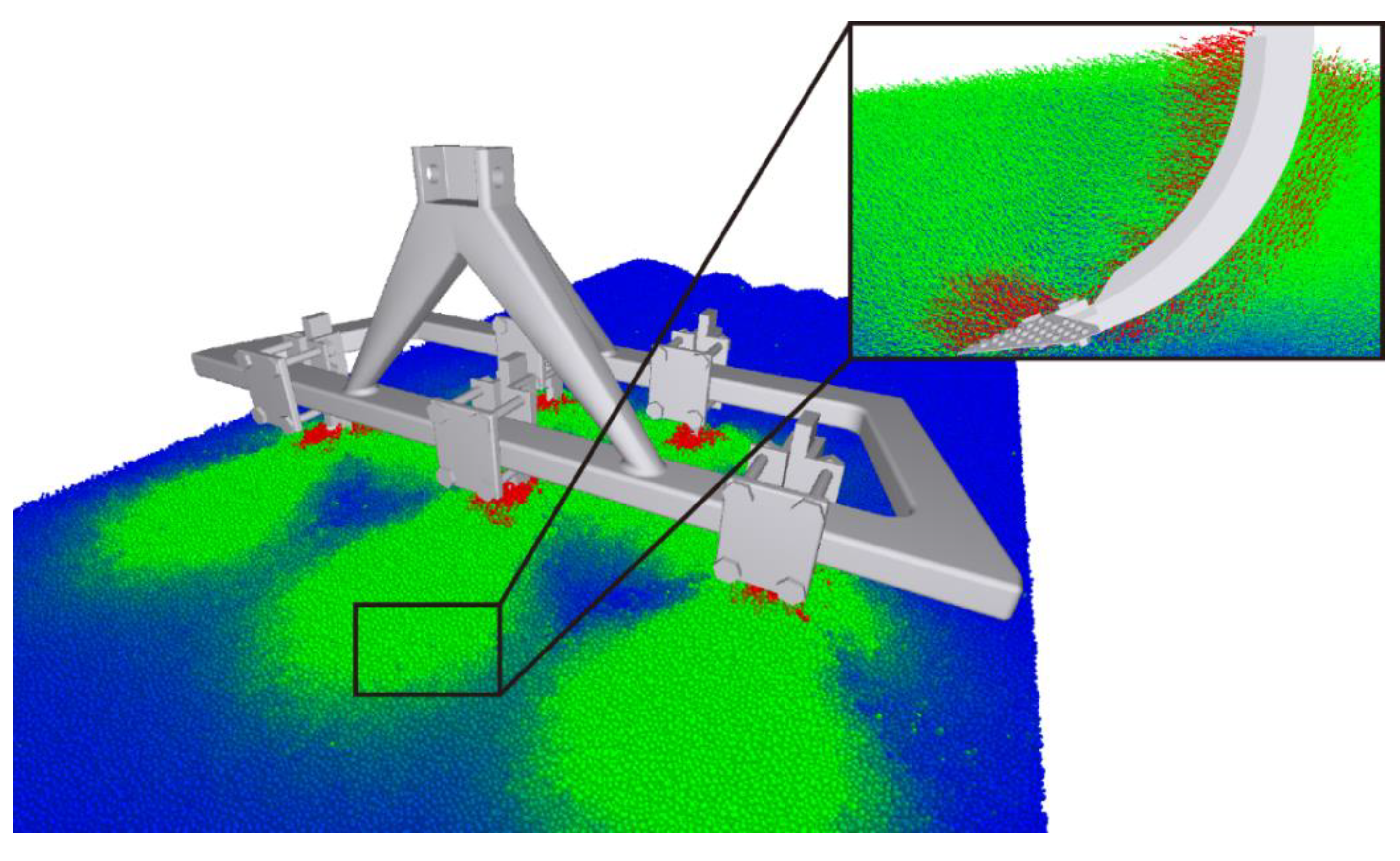

- 2.

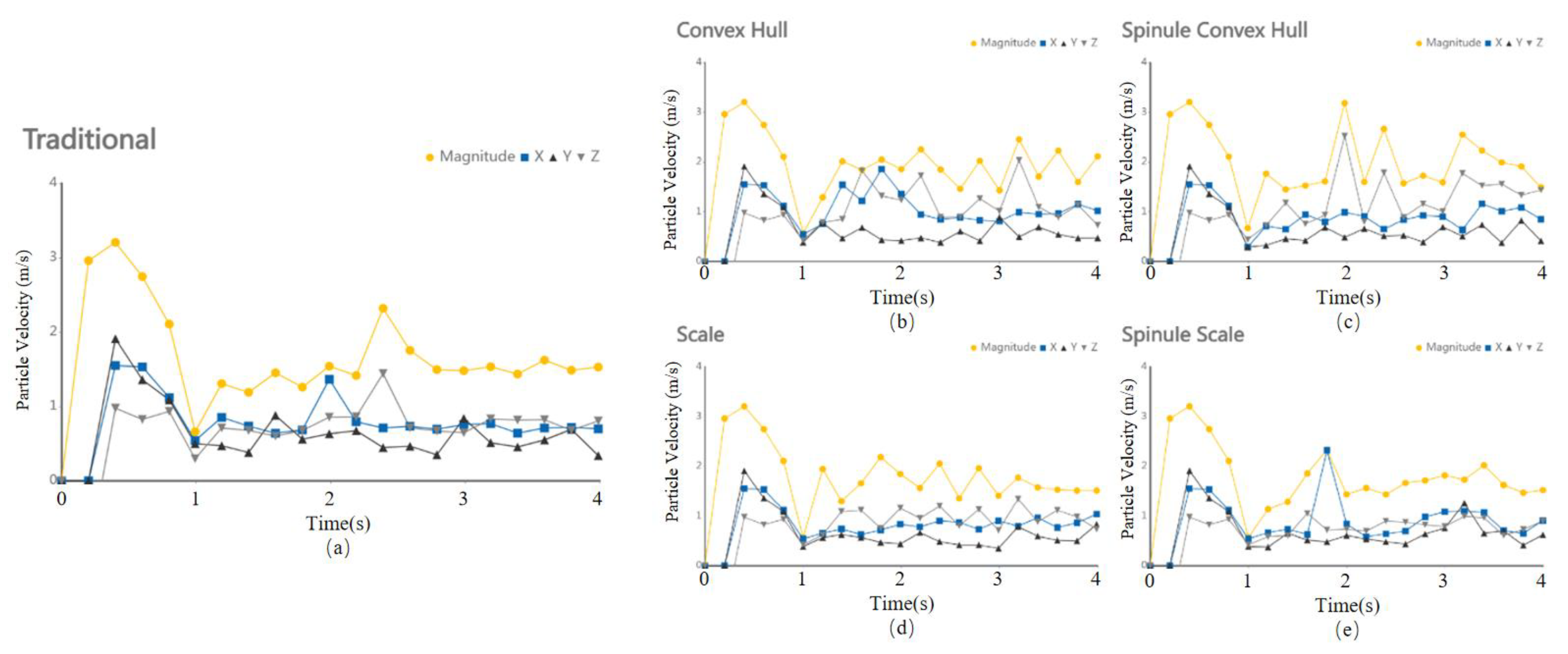

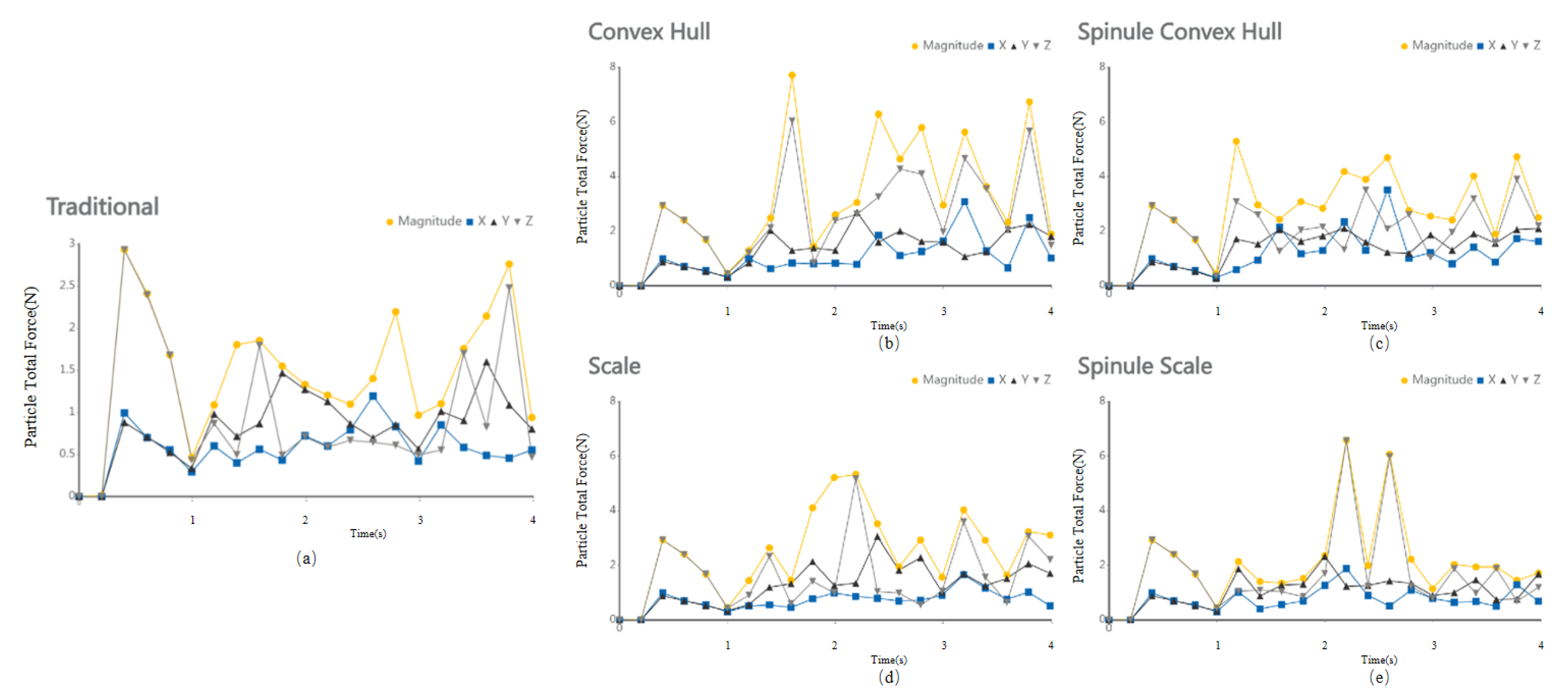

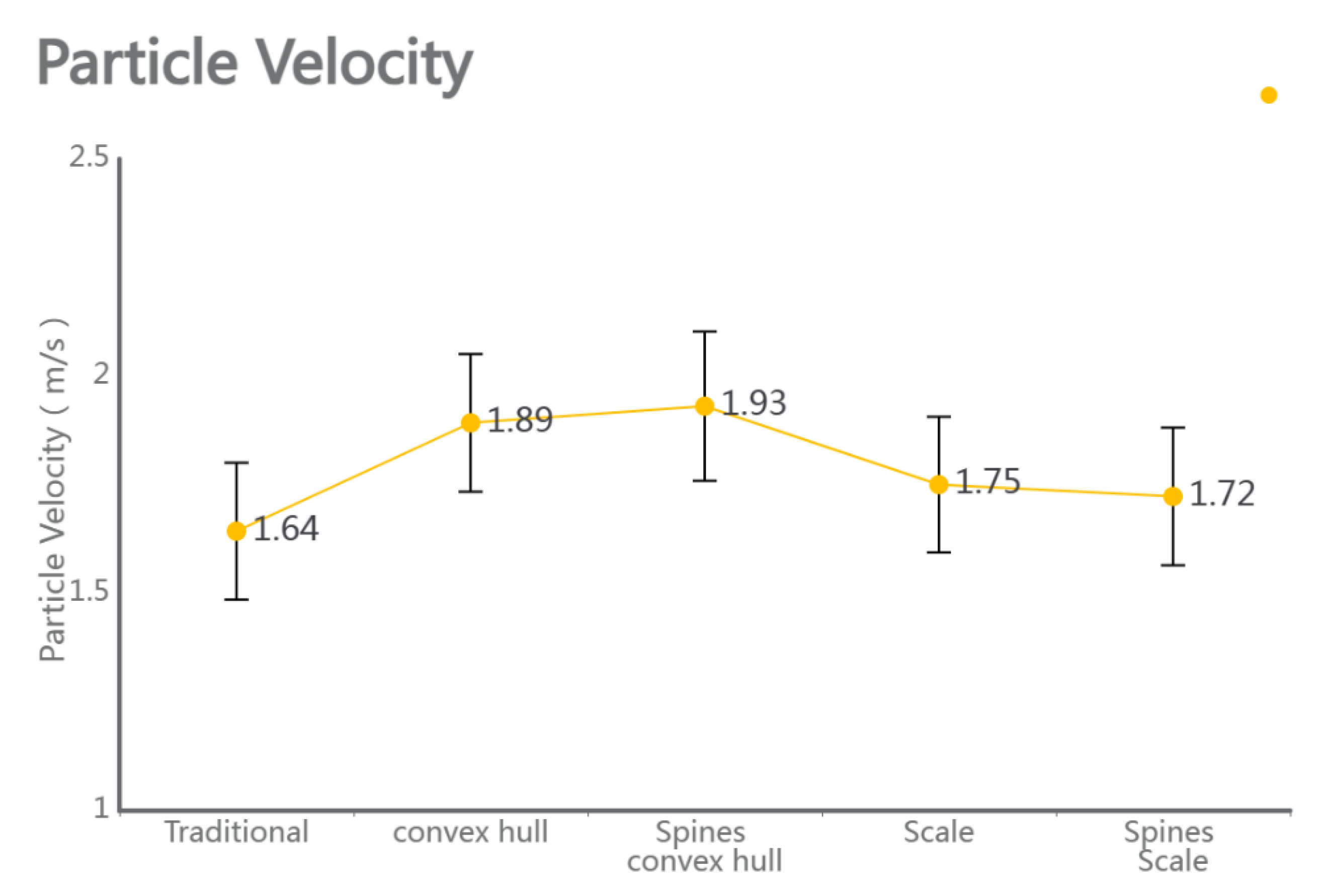

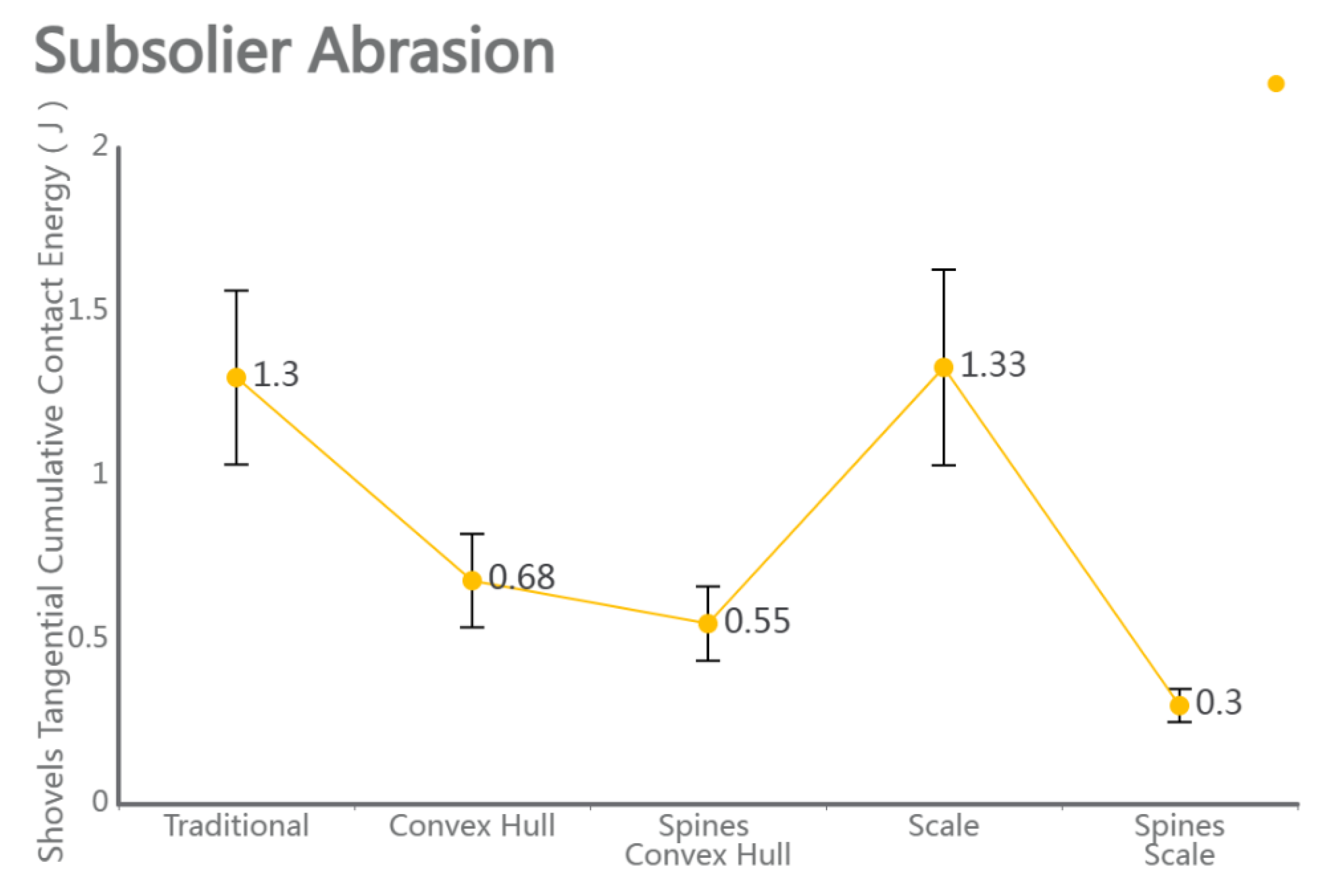

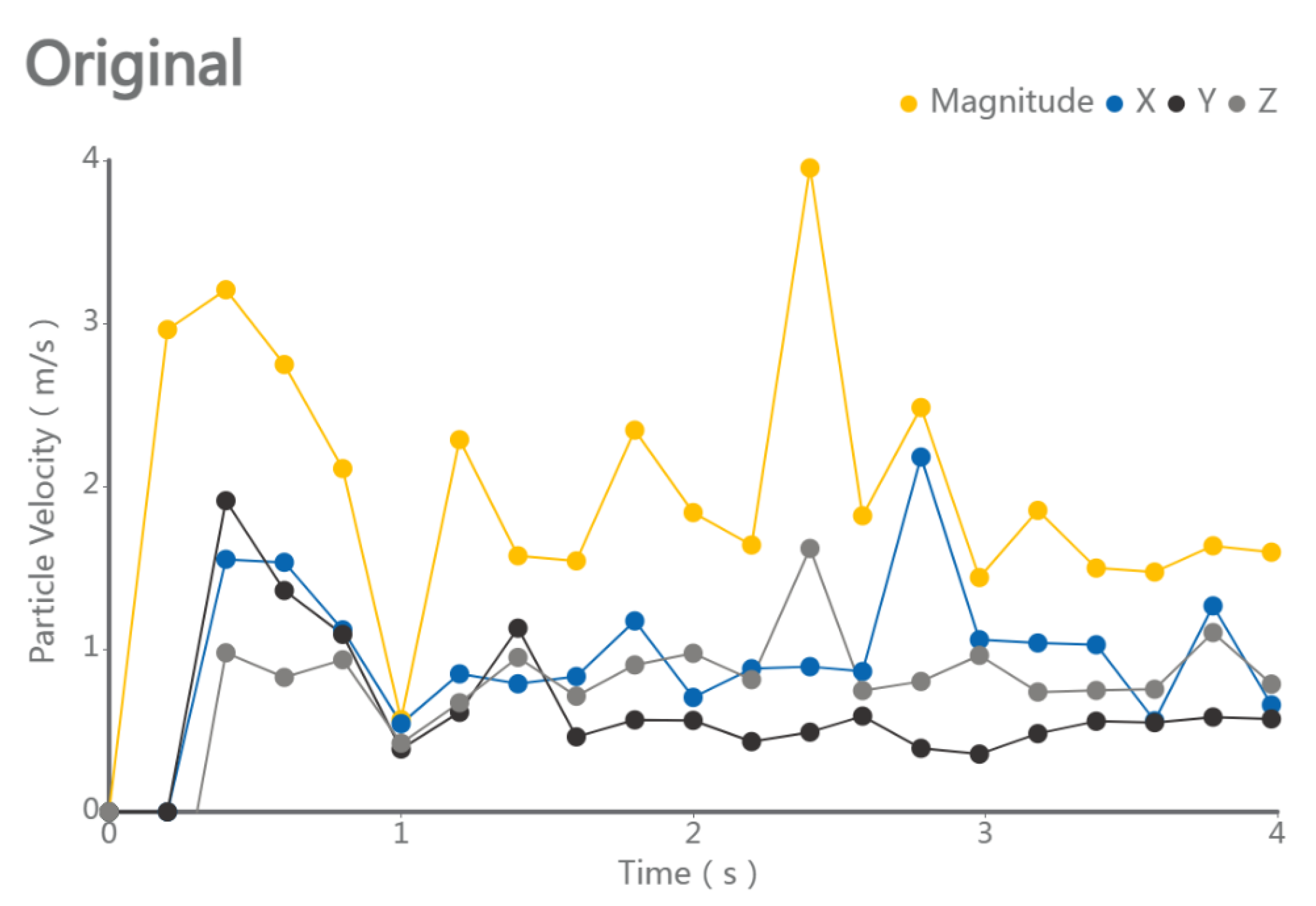

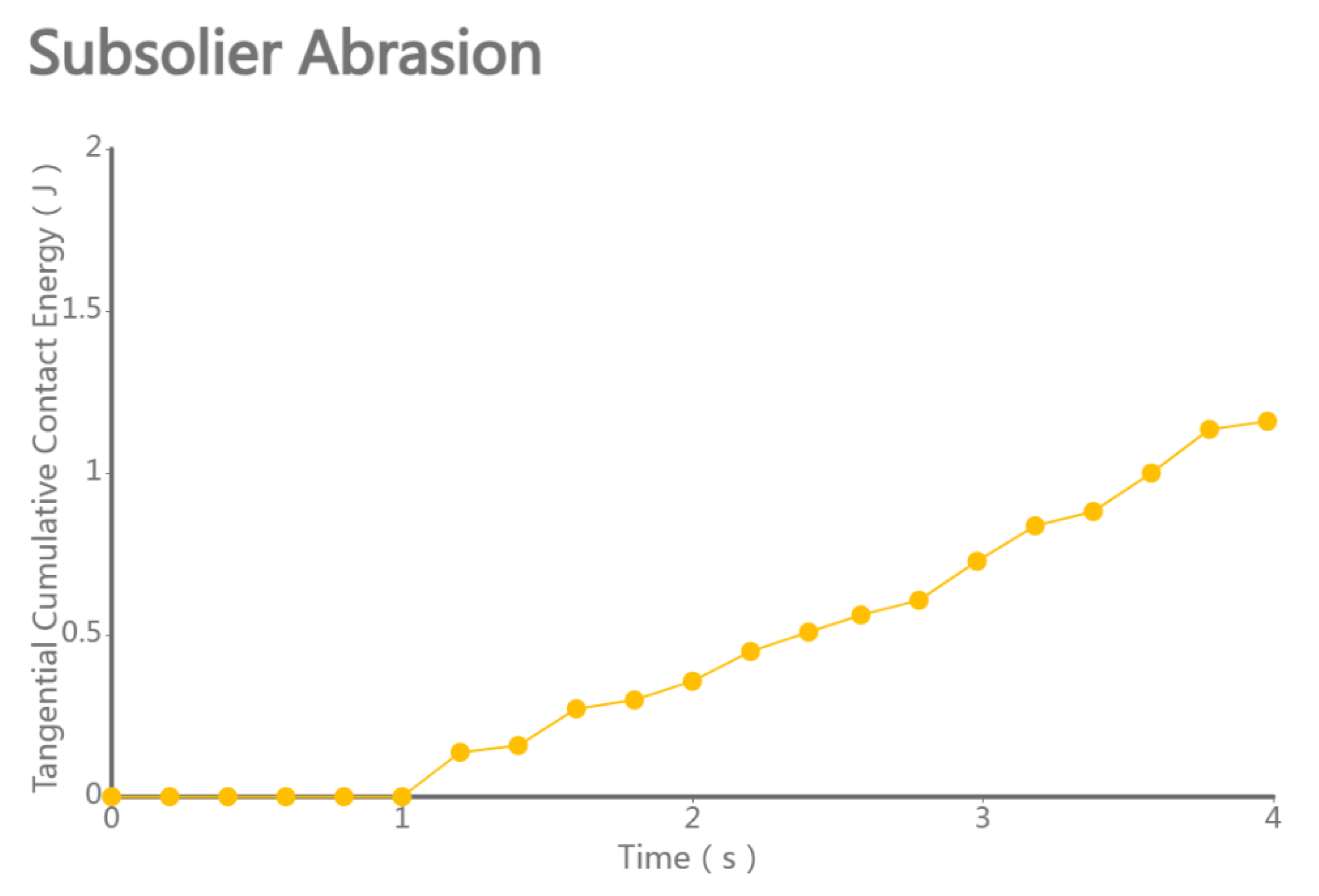

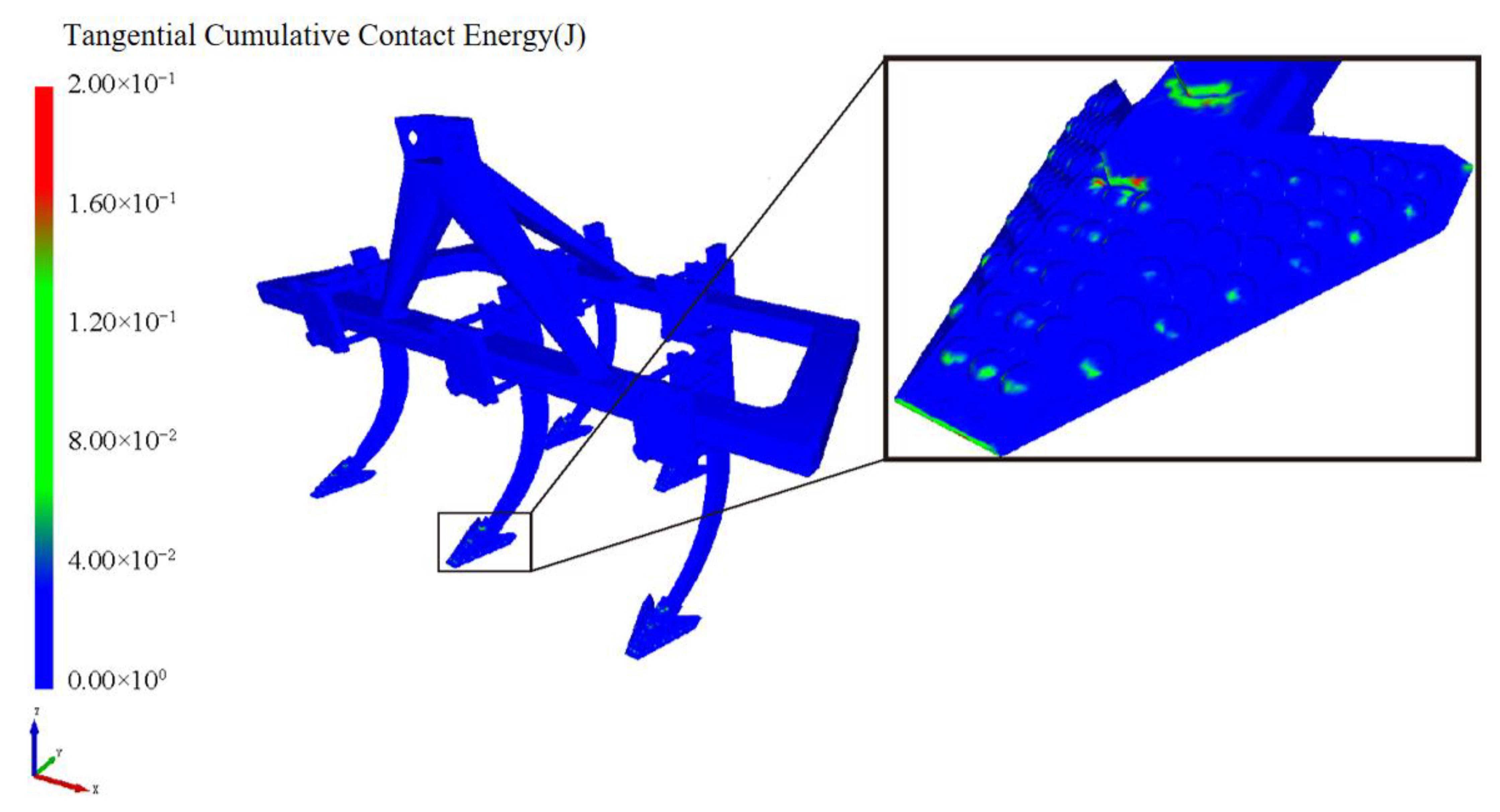

- Discrete Element Analysis of the Optimized Bionic Subsoiler: The optimized subsoiling device model was exported as a STEP file and subjected to discrete element simulation experiments in the EDEM soil model. Using the discrete element post-processing module, data on the changes in particle speed and force over time, resulting from the traditional shovel tip acting on soil particles, were analyzed and processed, as shown in the figures. The line chart indicates that, after 1 s, the shovel tip advanced in the soil bin at a speed of 1 m/s, and the particle movement speed stabilized. The average total particle speed was 2.399 m/s, with a maximum of 3.797 m/s and a minimum of 1.552 m/s, as shown in Figure 13 and Figure 14. The Relative Wear model was loaded, which records the cumulative tangential energy generated by the interaction between particles and the shovel body. This model can infer the wear location and condition of the shovel tip based on the magnitude and position of the generated energy, as shown in Figure 15 and Figure 16. Within 4 s, the cumulative tangential energy was 0.699 J, with the edge wear of the shovel wings being superior to that of the bionic micro-spike convex hull structure shovel tip.

5. Drag Reduction Performance Test of the Optimized Bionic Multi-Subsoiler Implement

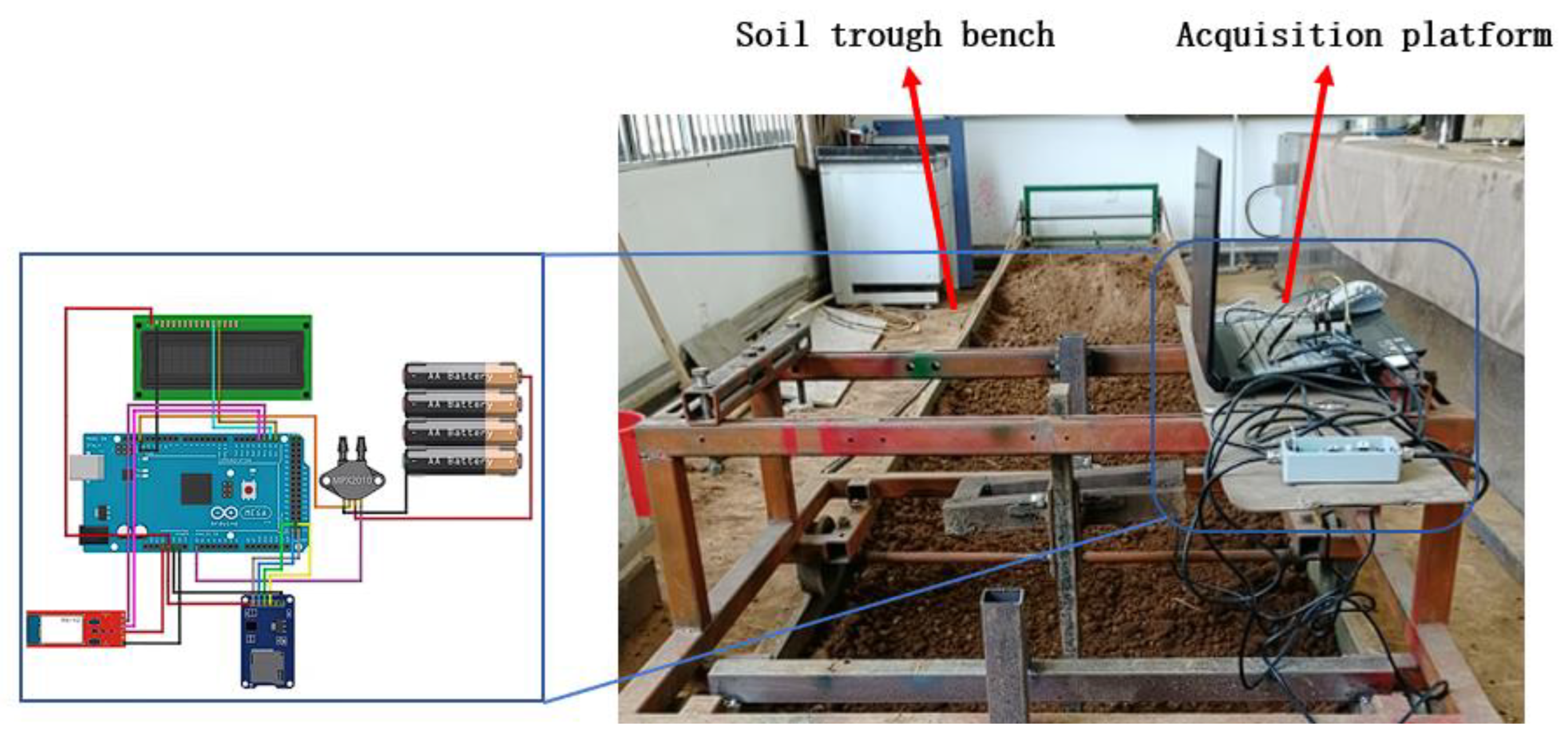

5.1. Discrete Element Simulation and Experiment

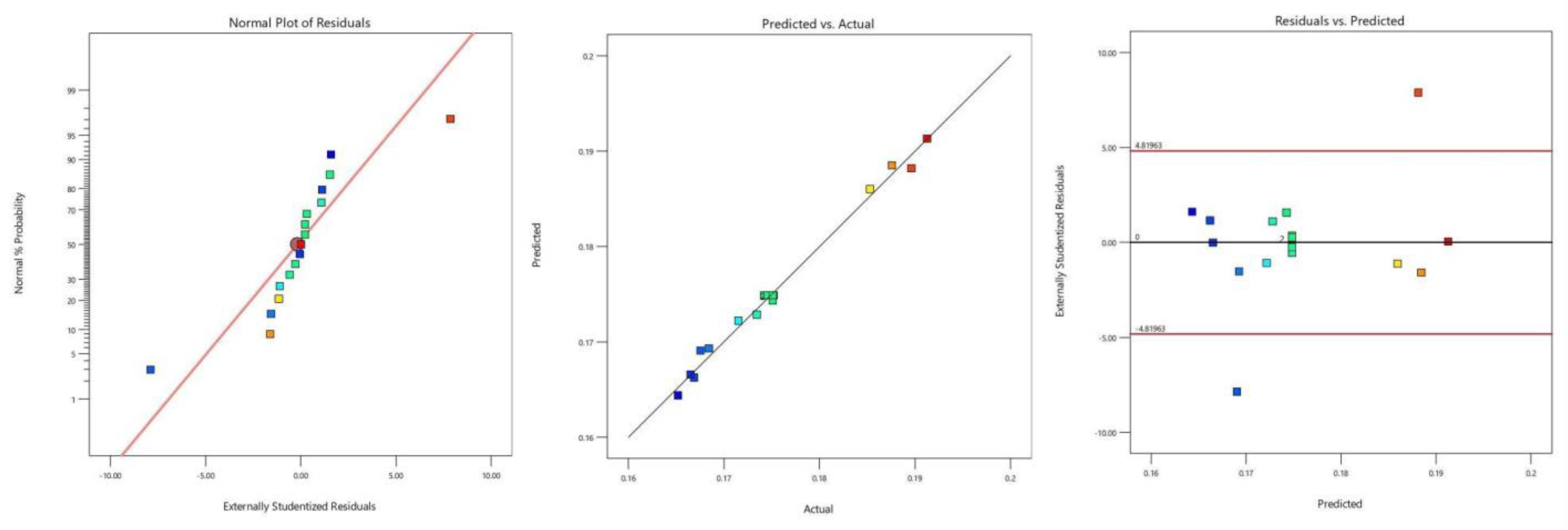

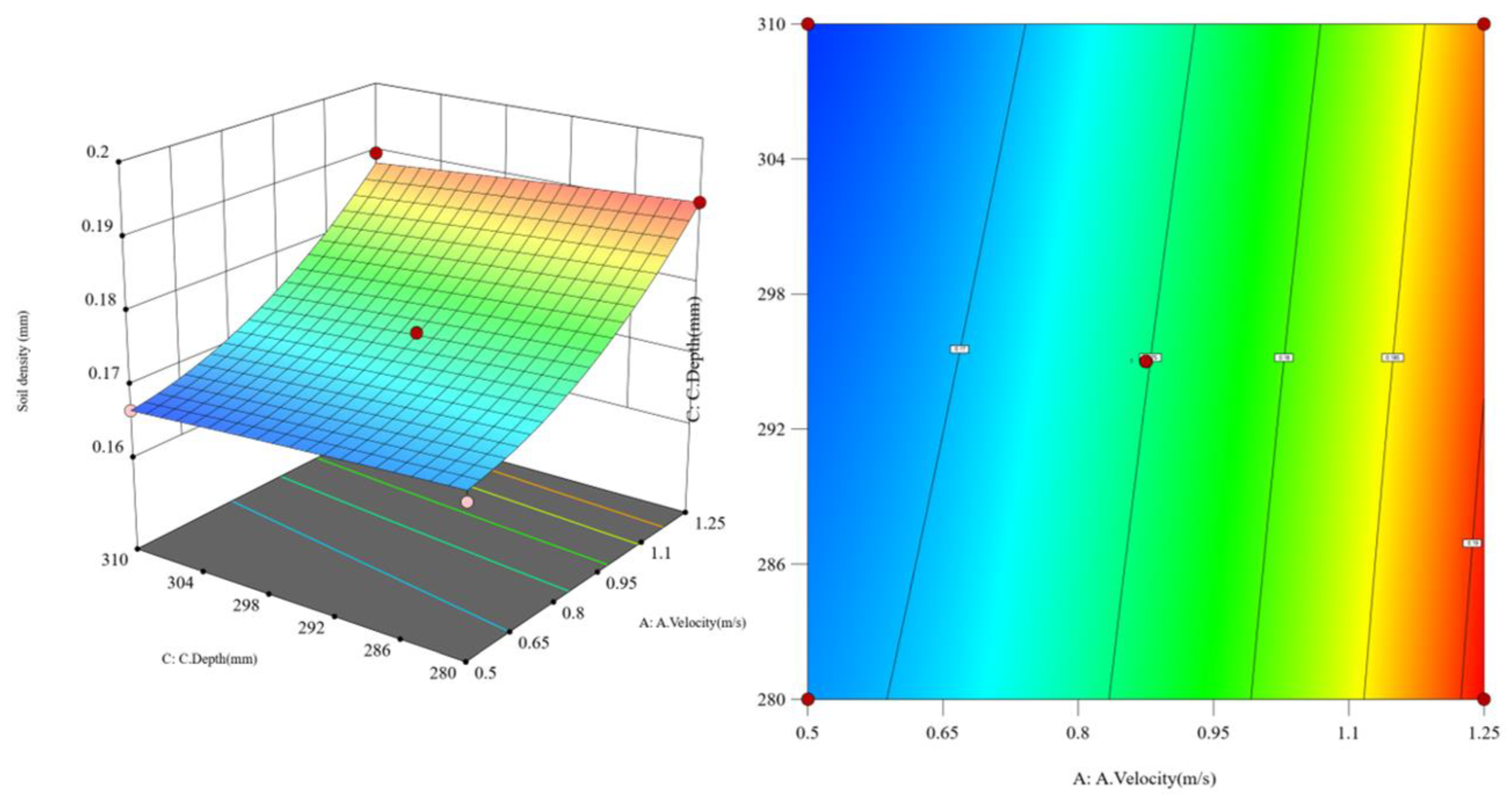

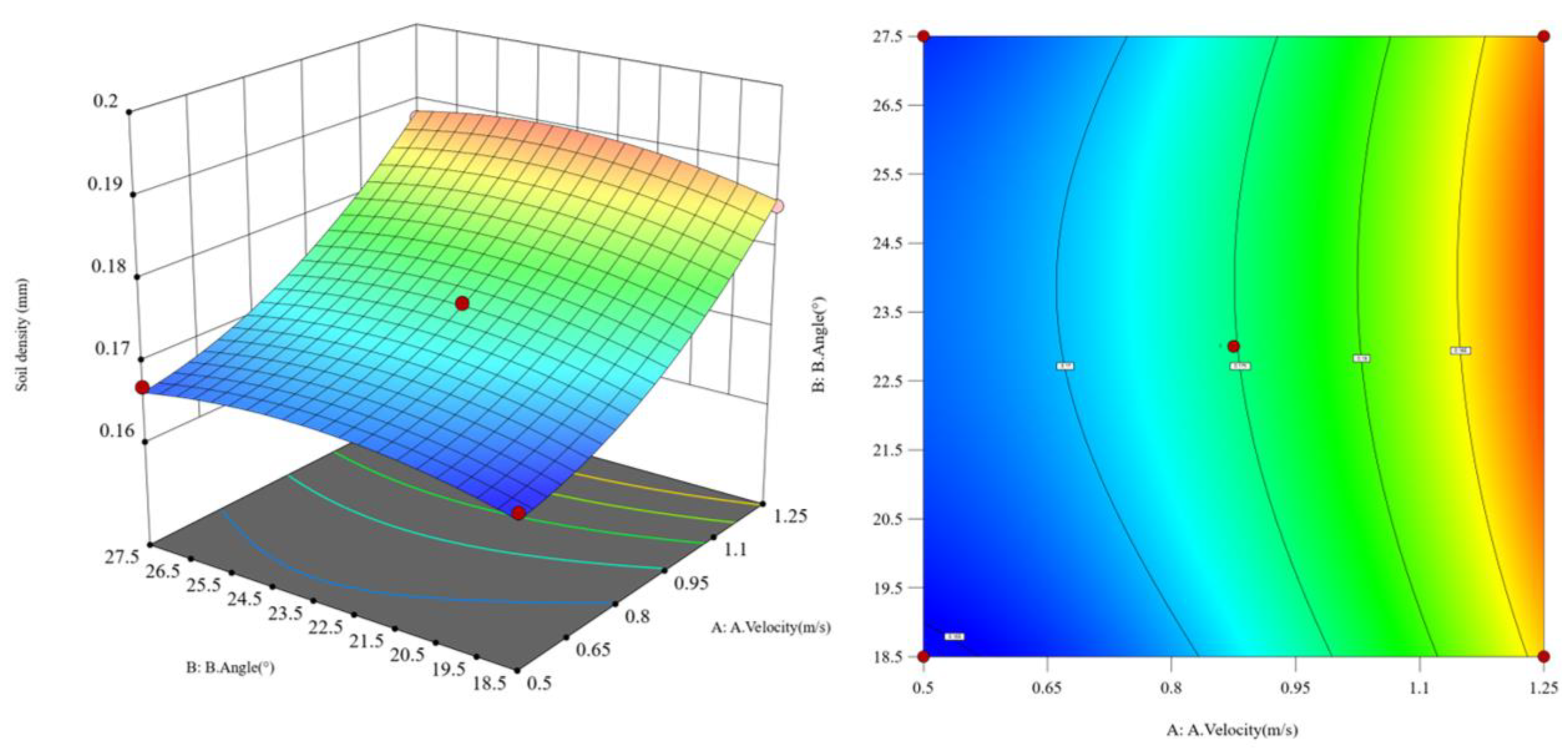

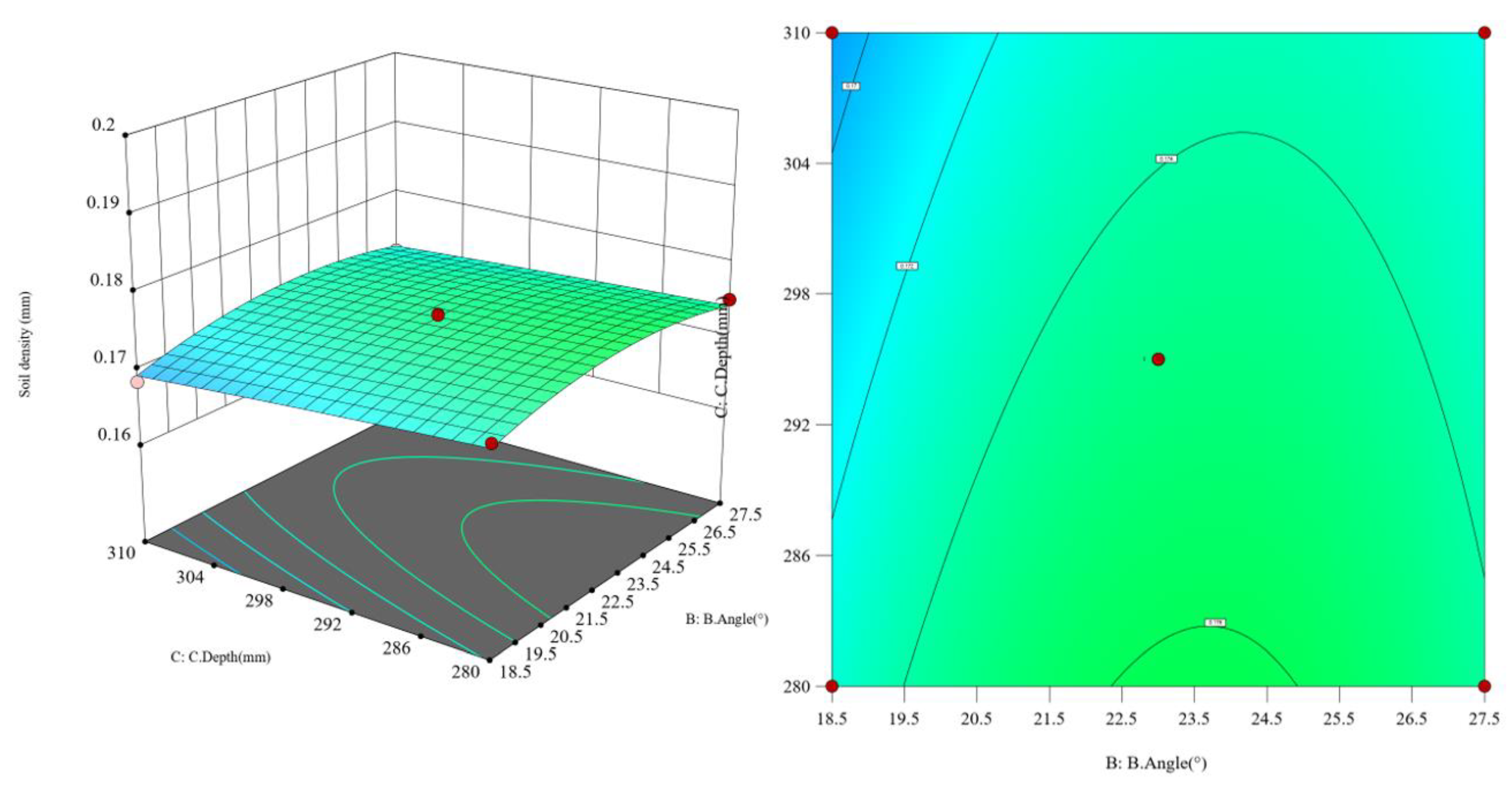

5.2. Parameter Optimization and Comparative Experiments

6. Conclusions

- 1.

- Mechanical benefits of bionic geometries: FEA demonstrates that the bionic surface geometries reduce the equivalent stress and total deformation compared with the baseline, lowering the risk of structural fracture and improving the bearing capacity—an advantage for operations in viscous red soil.

- 2.

- Trade-off between disturbance and wear: EDEM and wear analysis show that the micro-spike convex hull generates the strongest soil disturbance (mean particle speed ≈ 1.92 m/s), while the micro-spike scale generates the lowest cumulative tangential contact energy, indicating a better wear performance. The engineering implication is to adopt a hybrid design: micro-spike convex features for enhancing disturbance and localized micro-spike scales at edges for reducing wear.

- 3.

- Optimization and validation: The optimized multi-subsoiler arrangement (micro-spike convex hulls arranged equidistantly along edge corners—six per side wing, three centrally) and operating parameters (speed = 1.25 m/s; entry angle ≈ 23.92°; depth ≈ 280.17 mm) produced consistent results in EDEM and soil bin tests. The reported values are as follows: simulated soil looseness = 19.7%, experimental = 19.5%; simulated soil disturbance = 18.1%, experimental = 17.6%. Using the experimental values as reference, the recalculated relative errors are ≈ 1.03% (looseness) and ≈ 2.84% (disturbance), indicating a good agreement under the tested conditions.

- 4.

- Practical significance and scope: The study provides practical geometric and operational guidelines for resistance reduction and wear mitigation in sloping red soil environments. The proposed hybrid bionic surface design achieves a viable compromise between disturbance efficiency and tool longevity.

- 5.

- Limitations and future work: The findings are based on laboratory soil bin tests and EDEM simulations; DEM parameter calibration, field variability, and long-term wear/fatigue performance require field validation and extended durability testing. Future work should include field trials across different soil moistures and textures, long-term wear and fatigue studies, and production feasibility and cost–benefit analysis.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, S.; Liu, J.; Gao, L.; Yuan, Y.; Yang, Y. Design and Experiment of High Disturbance and Low Resistance Subsoiler for Corn Stalks. J. Agric. Mech. Res. 2024, 46, 49–57. [Google Scholar]

- Zou, L.; Liu, G.; Yuan, J.; Xin, Z.; Niu, Z. Design and Experiment of Active Lubrication and Drag Reduction Curved Subsoiler. Trans. Chin. Soc. Agric. Mach. 2022, 53, 34–43. [Google Scholar]

- Zhu, H.; Liu, Q.; Bai, L.; Guo, G.; Wang, M.; Li, R.; Lei, F. Design and Experiment of Layered Subsoiling and Fertilizing Machine Based on Bionics. Trans. Chin. Soc. Agric. Mach. 2024, 55, 41–52. [Google Scholar]

- Zhu, F.; Tong, J. Progress in Subsoiling Technology and Efficient Energy-saving Bionic Research. J. Jilin Univ. 2003, 4, 95–99. [Google Scholar]

- Garibaldi-Márquez, F.; Martínez-Reyes, E.; Morales-Morales, C.; Ramos-Cantú, L.; Castro-Bello, M.; González-Lorence, A. Subsoiler Tool with Bio-Inspired Attack Edge for Reducing Draft Force during Soil Tillage. AgriEngineering 2024, 6, 2678–2693. [Google Scholar] [CrossRef]

- Zhang, Z.; Gan, S.; Zuo, G.; Tong, J. Design and Discrete Element Simulation of Bionic Subsoiler Tip Based on the Head of Sandfish Lizard. Trans. Chin. Soc. Agric. Mach. 2021, 52, 33–42. [Google Scholar]

- Zhou, D.; Hou, P.; Xin, Y.; Wu, B.; Tong, J.; Yu, H.; Qi, J.; Zhang, J.; Zhang, Q. Resistance and Consumption Reduction Mechanism of Bionic Vibration and Verification of Field Subsoiling Experiment. Appl. Sci. 2021, 11, 10480. [Google Scholar] [CrossRef]

- Yu, Y.; Xu, W.; Song, S.; Yang, H.; Zhang, Y. Effects of Red Soil Particle Size, Fertilizer Concentration, and Irrigation Methods on Clogging of Different Irrigators. Trans. Chin. Soc. Agric. Eng. 2018, 34, 92–97. [Google Scholar]

- Sun, J.; Chen, H.; Wang, Z.; Ou, Z.; Yang, Z.; Liu, Z.; Duan, J. Study on plowing performance of EDEM low-resistance animal bionic device based on red soil. Soil Tillage Res. 2020, 196, 104336. [Google Scholar] [CrossRef]

- Zhang, J. Bionic Theory and Technology of Drag Reduction and Wear Resistance for Subsoiler. Ph.D. Thesis, Jilin University, Changchun, China, 2014. [Google Scholar]

- Sedara, A.M.; Abdeldayem, M.A.; de Freitas, F.P.G.; Mehari, T.Z. Optimization of subsoiler design using similitude-based DEM simulation and soil bin testing on cohesive-frictional artificial soil. J. Terramechanics 2025, 117, 101026. [Google Scholar] [CrossRef]

- Bilodeau, M. A Guide to Successful Subsoiling; CETAB+: Victoriaville, QC, Canada, 2015; 43p. [Google Scholar]

- Qiao, D.; Shi, Q.; Lv, P.; Guo, Y.; Fu, D.; Liu, M.; Jiang, L.; Wang, Y.; Wang, J.; Feng, W. Development of a Mathematical Model and Structural Optimization of the Specific Resistance of a Broken Line Subsoiler. Agriculture 2025, 15, 352. [Google Scholar] [CrossRef]

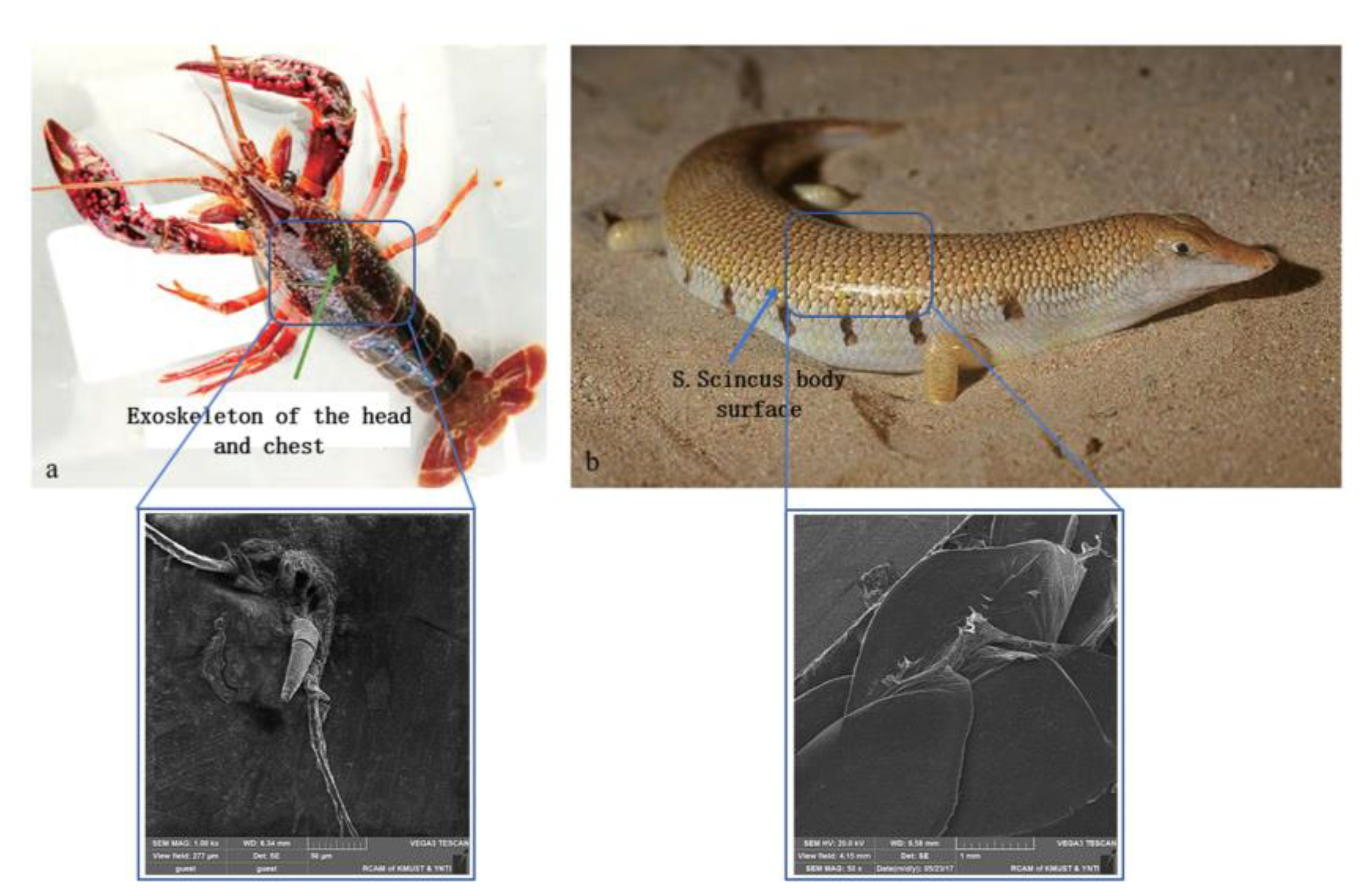

- Zhang, Z.; Zhang, G.; Tong, J.; Lai, Q.; Gao, X.; Tang, Y. Ultra-structure and mechanical properties of the Procambarus clarkii head and chest exoskeleton. J. Chin. Electron Microsc. Soc. 2018, 32, 171–177. [Google Scholar]

- Zhang, Z.; Li, Y.; Tong, J.; Lai, Q.; Gao, X.; Tang, Y. Scanning electron microscopic observation on ultrastructure of the sandfish skin. J. Chin. Electron Microsc. Soc. 2018, 37, 298–304. [Google Scholar]

- Raabe, D.; Sachs, C.; Romano, P. The crustacean exoskeleton as an example of a structurally and mechanically graded biological nanocomposite material. Acta Mater. 2005, 53, 4281–4292. [Google Scholar] [CrossRef]

- Raabe, D.; Romano, P.; Sachs, C.; Al-Sawalmih, A.; Brokmeier, H.-G.; Yi, S.-B.; Servos, G.; Hartwig, H. Discovery of a honeycomb structure in the twisted plywood patterns of fibrous biological nanocomposite tissue. J. Cryst. Growth 2005, 283, 1–7. [Google Scholar] [CrossRef]

- Raabe, D.; Al-Sawalmih, A.; Yi, S.; Fabritius, H. Preferred crystallographic texture of α-chitin as a microscopic and macroscopic design principle of the exoskeleton of the lobster Homarus americanus. Acta Biomater. 2007, 3, 882–895. [Google Scholar] [CrossRef]

- Sachs, C.; Fabritius, H.; Raabe, D. Experimental investigation of the elastic plastic deformation of mineralized lobster cuticle by digital image correlation. J. Struct. Biol. 2006, 155, 409–524. [Google Scholar] [CrossRef] [PubMed]

- Romano, P.; Fabritius, H.; Raabe, D. The exoskeleton of the lobster Homarus americanus as an example of a smart anisotropic biological material. Acta Biomater. 2007, 3, 301–309. [Google Scholar] [CrossRef] [PubMed]

- Staudt, K.; Saxe, F.; Schmied, H.; Böhme, W.; Baumgartner, W. Sandfish inspires engineering. In Bioinspiration, Biomimetics, and Bioreplication, Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 6–10 March 2011; SPIE: Bellingham, WA, USA, 2011; Volume 7975, pp. 299–307. [Google Scholar]

- Zhang, Z. Finite Element Analysis and Optimal Design of Key Components of Subsoiler. Master’s Thesis, Northwest A&F University, Xianyang, China, 2012. [Google Scholar]

- GB/T 24676-2021; Vibrating Subsoiler. Standardization Administration of the People’s Republic of China: Beijing, China, 2021.

- Wang, X.; Zhou, H.; Ji, J. Effect of Mounting Angle on Bending Subsoiling Tool–Soil Interactions Using DEM Simulations. Agriculture 2022, 12, 1830. [Google Scholar] [CrossRef]

- Wu, T.; Huang, W.F.; Chen, X.S.; Ma, X.; Han, Z.; Pan, T. Parameter calibration of discrete element model for cohesive soil considering interparticle bonding force. J. South China Agric. Univ. 2017, 38, 93–98. [Google Scholar]

- Zhang, Z.; Zhu, R. Finite Element Analysis and Improved Design of Double-wing Subsoiler Structure. J. Gansu Agric. Univ. 2012, 47, 140–144. [Google Scholar]

- Li, J.; Sun, K.; Zhang, Y.; Zhang, T. Simulation Analysis of Wear Behavior of Chisel-shaped Subsoiler Based on Discrete Element Method. J. Anyang Inst. Technol. 2023, 22, 34–40. [Google Scholar]

- Tong, Z.; Li, H.; He, J.; Wang, Q.; Lu, C.; Wang, C.; Zhong, G.; Cui, D.; Li, D. Design and Experiment of In Situ Soil-Lifting Shovel for Direct-Injection Straw Deep-Burial Machine. Agriculture 2023, 13, 1650. [Google Scholar] [CrossRef]

- Li, W. Application of Response Surface Methodology in Structural Optimization. Ship Sci. Technol. 2020, 42, 13–15. [Google Scholar]

| Parameter | Numerical Value |

|---|---|

| Poisson’s Ratio of Soil Particle | 0.4 |

| Shear Modulus of Soil Particles/Pa | 1.09 × 106 |

| Density of Soil Particles | 1350 |

| Poisson’s Ratio of 65 Mn | 0.3 |

| Shear Modulus of 65 Mn/Pa | 1.92 × 106 |

| Density of 65 Mn/ | 7800 |

| Correlation Coeffcient Between Particles | 0.2 |

| Rolling Friction Coefficient Between Particles | 0.3 |

| Static Friction Coefficient Between Particles | 0.4 |

| Correlation Coefficient Between Particles and Subsoiler | 0.3 |

| Rolling Friction Coefficient Between Particles and Subsoiler | 0.4 |

| Static Friction Coefficient Between Particles and Subsoiler | 0.5 |

| Particle Radius/mm | 4 |

| Particle Mass/ | 2400 |

| Gravitational Acceleration/ | 9.81 |

| Simulation Time Step/s | 4 |

| Code | Name | Organization | Min | Max |

|---|---|---|---|---|

| A | Speed | m/s | 0.5 | 1.25 |

| B | Angle | ° | 18.5 | 27.5 |

| C | Depth | mm | 280 | 310 |

| Std | Run | C/(mm) | Soil Looseness/(%) | ||

|---|---|---|---|---|---|

| 17 | 1 | 0.875 | 18.5 | 280 | 0.173456 |

| 9 | 2 | 1.25 | 23 | 310 | 0.189655 |

| 5 | 3 | 0.875 | 23 | 295 | 0.174231 |

| 1 | 4 | 0.5 | 23 | 295 | 0.167574 |

| 14 | 5 | 0.875 | 23 | 295 | 0.174514 |

| 3 | 6 | 0.875 | 27.5 | 310 | 0.171546 |

| 10 | 7 | 0.875 | 23 | 295 | 0.174555 |

| 7 | 8 | 1.25 | 18.5 | 295 | 0.185316 |

| 2 | 9 | 0.5 | 18.5 | 295 | 0.165214 |

| 13 | 10 | 0.875 | 23 | 295 | 0.175315 |

| 4 | 11 | 0.875 | 23 | 295 | 0.175239 |

| 12 | 12 | 0.875 | 18.5 | 310 | 0.168445 |

| 15 | 13 | 0.5 | 23 | 310 | 0.166516 |

| 8 | 14 | 0.875 | 27.5 | 280 | 0.175123 |

| 11 | 15 | 1.25 | 23 | 280 | 0.191302 |

| 16 | 16 | 0.5 | 27.5 | 295 | 0.166894 |

| 6 | 17 | 1.25 | 27.5 | 295 | 0.187615 |

| Source of Variance | Sum-of-Squares | Degrees of Freedom | Mean Square | F | p |

|---|---|---|---|---|---|

| Model | 0.0011 | 9 | 0.0001 | 285.13 | <0.0001 |

| A | 0.0007 | 1 | 0.0007 | 1747.37 | <0.0001 |

| B | 9.56 × 10−6 | 1 | 9.56 × 10−6 | 22.58 | 0.0021 |

| C | 0 | 1 | 0 | 54.13 | 0.0002 |

| AB | 9.58 × 10−8 | 1 | 9.58 × 10−8 | 0.2262 | 0.6489 |

| AC | 2.47 × 10−6 | 1 | 2.47 × 10−6 | 5.83 | 0.0464 |

| BC | 5.14 × 10−7 | 1 | 5.14 × 10−7 | 1.21 | 0.307 |

| A2 | 0.0001 | 1 | 0.0001 | 186.64 | <0.0001 |

| B2 | 0 | 1 | 0 | 82.79 | <0.0001 |

| C2 | 1.49 × 10−6 | 1 | 1.49 × 10−6 | 3.52 | 0.1028 |

| Residual | 2.97 × 10−6 | 7 | 4.24 × 10−7 | ||

| Lack-of-fit Term | 2.05 × 10−6 | 3 | 6.82 × 10−7 | 2.97 | 0.1604 |

| Pure Error | 9.19 × 10−7 | 4 | 2.30 × 10−7 | ||

| Sum | 0.0011 | 16 |

| Serial Number | Soil Looseness % | Simulation | Soil Disturbance Coefficient % | Simulation | ||

|---|---|---|---|---|---|---|

| Experimental | Simulation | Experimental | Simulation | |||

| 1 | 0 | 0 | 0 | 5 × 12.7 | 5 × 18.1 | 5 × 2.76 |

| 2 | 5.3 | 5.5 | 3.63 | |||

| 3 | 9.7 | 10.1 | 3.96 | |||

| 4 | 13.1 | 14.3 | 8.93 | |||

| 5 | 19.5 | 19.7 | 1.01 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Li, J.; Liu, J.; Yang, L.; Dai, F.; Long, C.; Zhao, L. Composite Biomimetic Multi-Subsoiler for Drag Reduction and Wear Resistance Simulation and Experimental Validation. Biomimetics 2025, 10, 793. https://doi.org/10.3390/biomimetics10120793

Wang X, Li J, Liu J, Yang L, Dai F, Long C, Zhao L. Composite Biomimetic Multi-Subsoiler for Drag Reduction and Wear Resistance Simulation and Experimental Validation. Biomimetics. 2025; 10(12):793. https://doi.org/10.3390/biomimetics10120793

Chicago/Turabian StyleWang, Xiaoyang, Jinguang Li, Junyan Liu, Le Yang, Fancheng Dai, Chanjuan Long, and Lijun Zhao. 2025. "Composite Biomimetic Multi-Subsoiler for Drag Reduction and Wear Resistance Simulation and Experimental Validation" Biomimetics 10, no. 12: 793. https://doi.org/10.3390/biomimetics10120793

APA StyleWang, X., Li, J., Liu, J., Yang, L., Dai, F., Long, C., & Zhao, L. (2025). Composite Biomimetic Multi-Subsoiler for Drag Reduction and Wear Resistance Simulation and Experimental Validation. Biomimetics, 10(12), 793. https://doi.org/10.3390/biomimetics10120793